Influence of Milling Time on the Homogeneity and Magnetism of a Fe70Zr30 Partially Amorphous Alloy: Distribution of Curie Temperatures

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

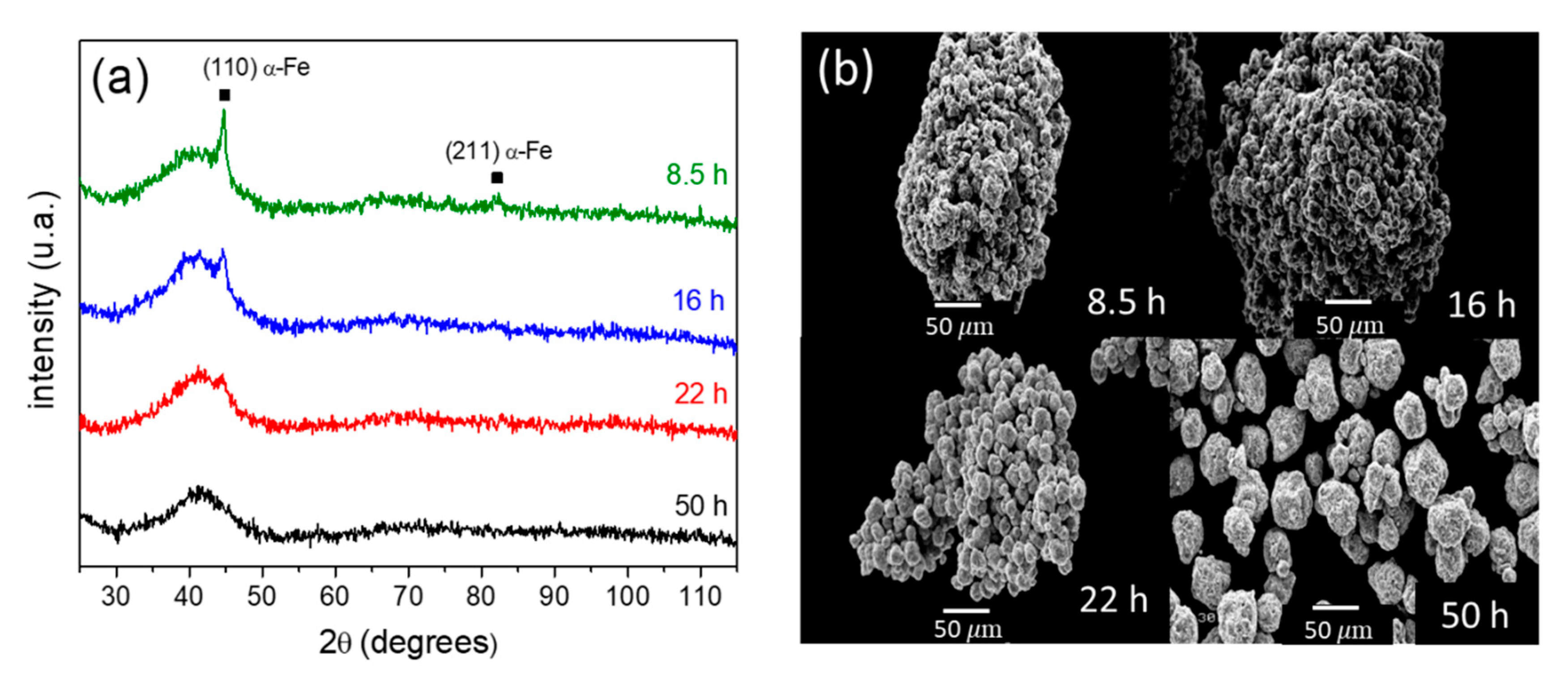

3.1. Microstructural Characterization

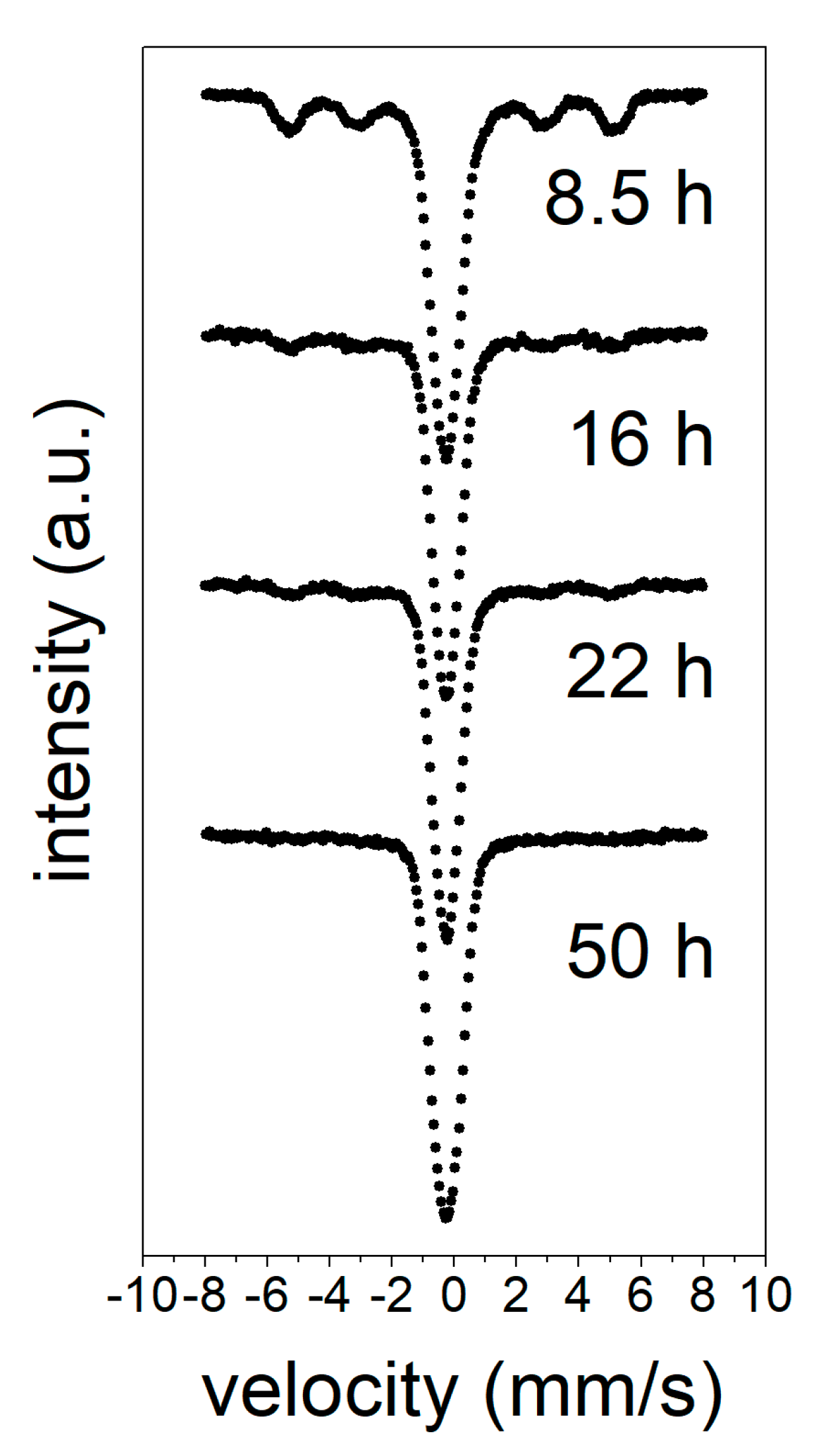

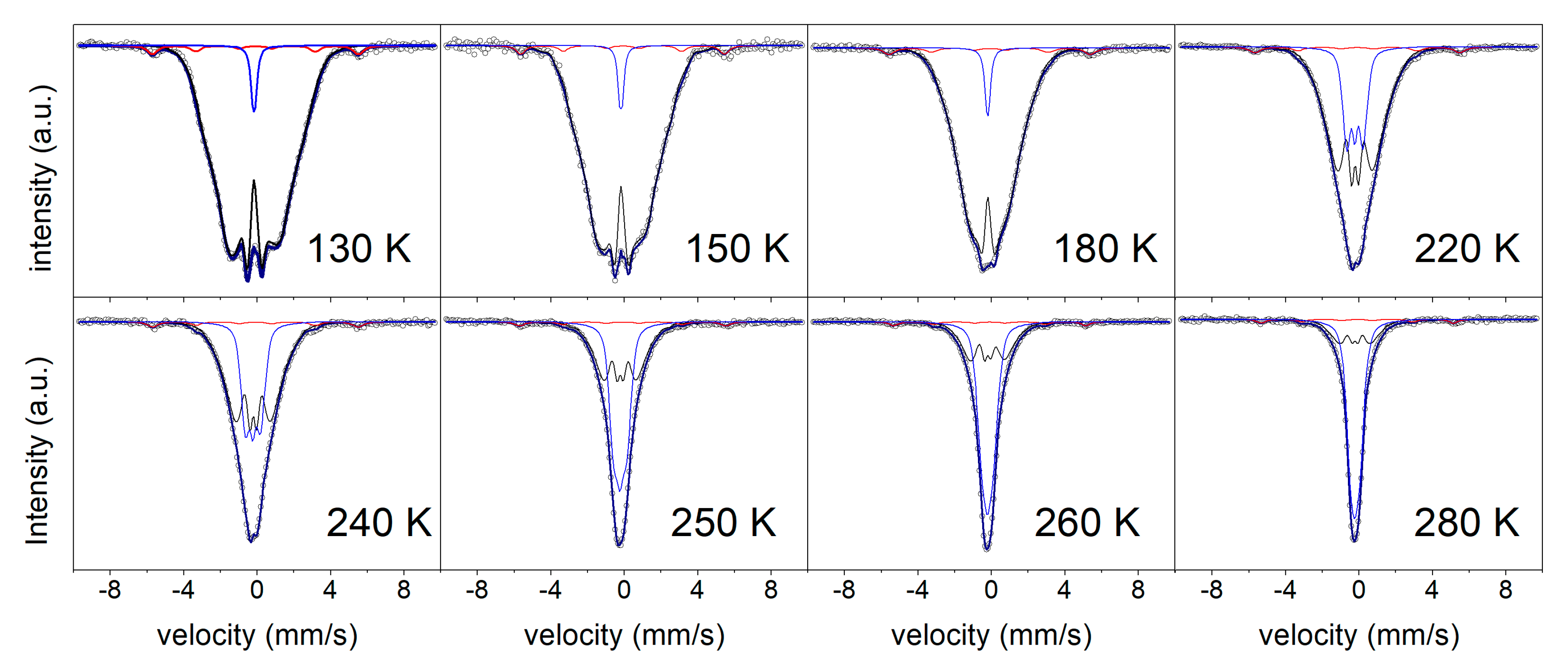

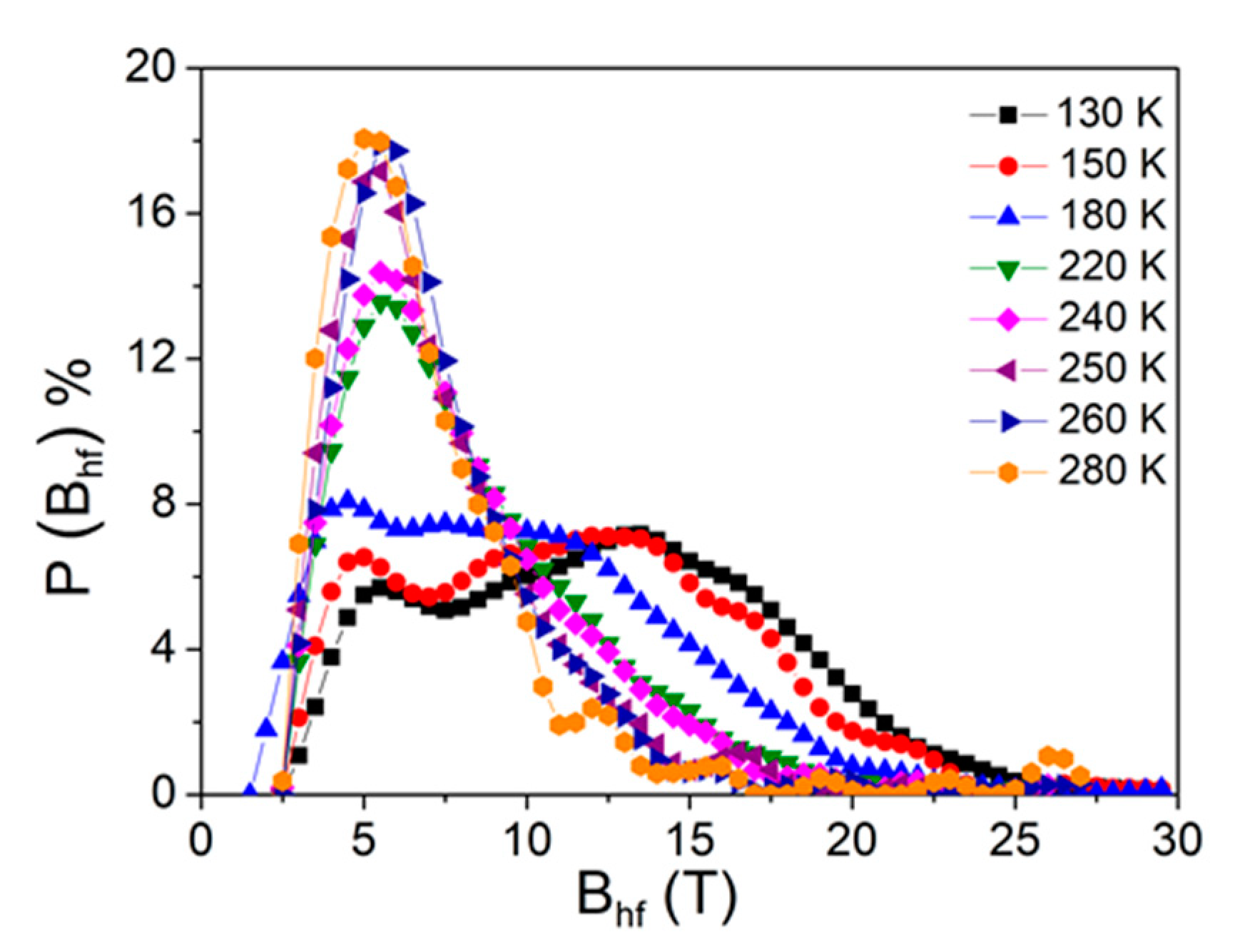

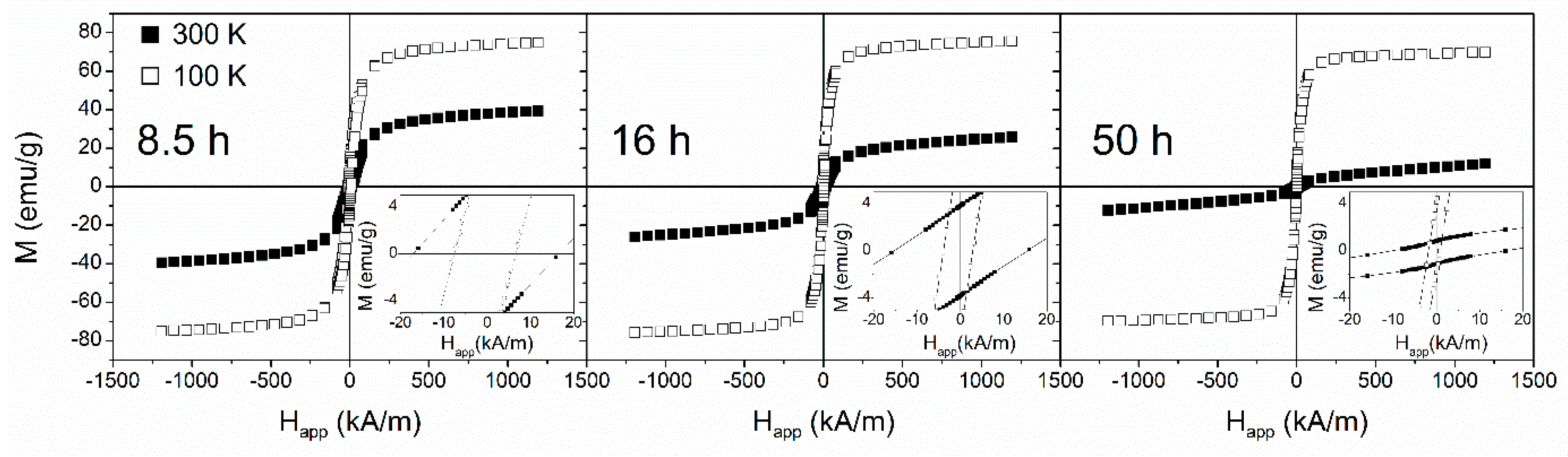

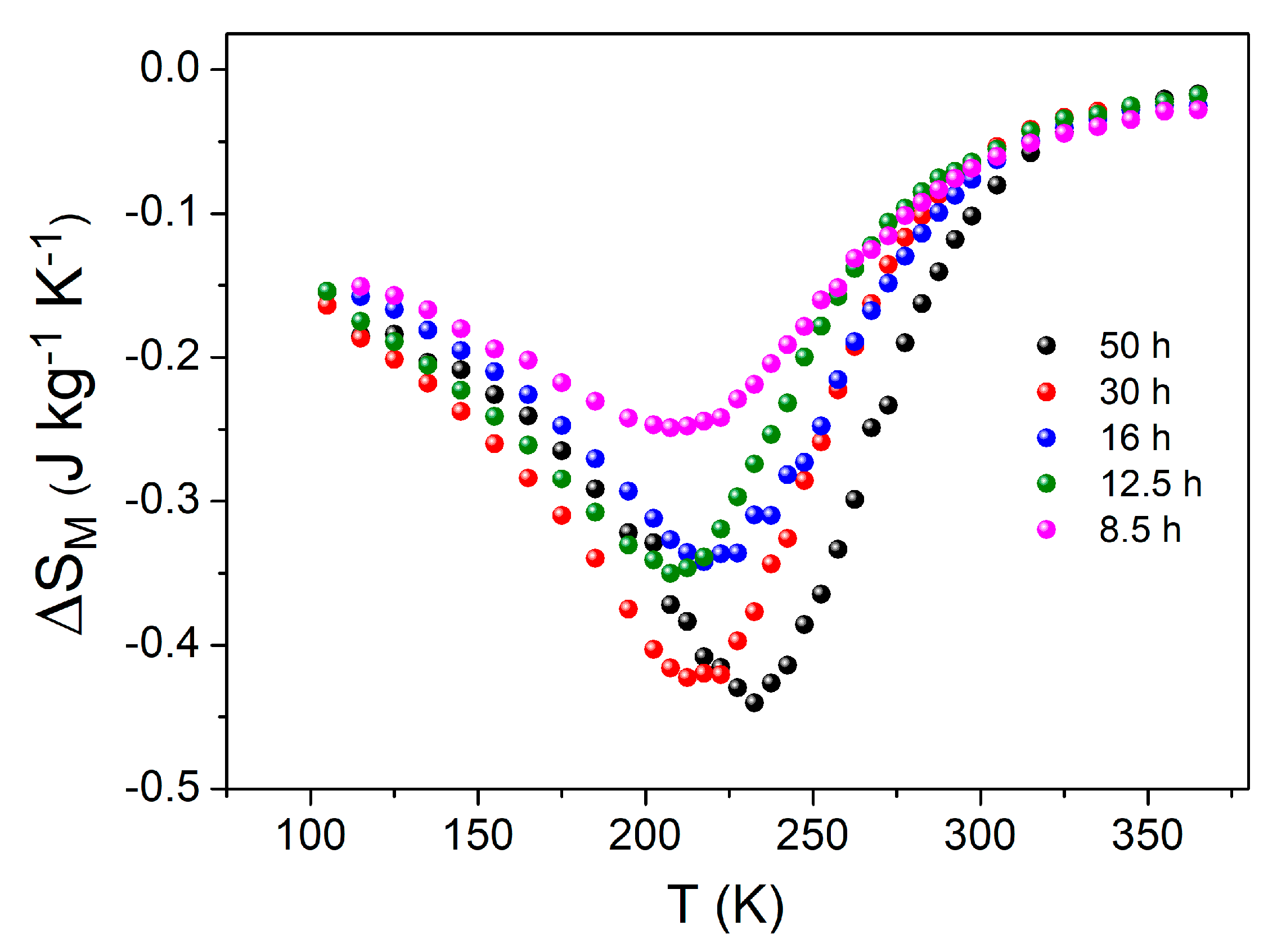

3.2. Magnetic Characterization

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Li, G.; Borisenko, K.B.; Chen, Y.X.; Nguyen-Manh, D.; Ma, E.; Cockayne, D.J.H. Local structure variations in Al89La6Ni5 metallic glass. Acta Mater. 2009, 57, 804–811. [Google Scholar] [CrossRef]

- Blazquez, J.S.; Ipus, J.J.; Lozano-Perez, S.; Conde, A. Metastable Soft Magnetic Materials Produced by Mechanical Alloying: Analysis Using an Equivalent Time Approach. JOM 2013, 65, 870–882. [Google Scholar] [CrossRef]

- McHenry, M.E.; Willard, M.A.; Laughlin, D.E. Amorphous and nanocrystalline materials for applications as soft magnets. Prog. Mater. Sci. 1999, 44, 291–433. [Google Scholar] [CrossRef]

- Coey, J.M.D.; Ryan, D.H.; Buder, R. Kohlrausch thermal relaxation in a random magnet. Phys. Rev. Lett. 1987, 58, 385–388. [Google Scholar] [CrossRef] [PubMed]

- Vincze, I.; Kaptas, D.; Kemény, T.; Kiss, L.; Balogh, J. Temperature and external magnetic field dependence of the spin freezing in amorphous Fe93Zr7. J. Magn. Magn. Mater. 1995, 140, 297–298. [Google Scholar] [CrossRef]

- Altounian, Z.; Stromolsen, J.O. Superconductivity and spin fluctuations in Cu-Zr, Ni-Zr, Co-Zr and Fe-Zr metallic glasses. Phys. Rev. B 1983, 27, 4149–4156. [Google Scholar] [CrossRef]

- Mishra, D.; Perumal, A.; Srinivasan, A. Magnetic properties of mechanically alloyed Fe100−xZrx (20 ≤ x ≤ 35) powder. J. Phys. D Appl. Phys. 2008, 41, 215003. [Google Scholar] [CrossRef]

- Concas, G.; Congiu, F.; Spanò, G.; Bionducci, M. Investigation of the ferromagnetic order in crystalline and amorphous Fe2Zr alloys. J. Magn. Magn. Mater. 2004, 279, 421–428. [Google Scholar] [CrossRef]

- Malakhova, T.O.; Alekseyeva, Z.M. The Zr-Fe phase-diagram in the range 20–40 at-percent Fe and the crystalline-structure of the intermetallic compound Zr3Fe. J. Less Common Met. 1981, 81, 293–300. [Google Scholar] [CrossRef]

- Granovsky, M.; Arias, D. Intermetallic phases in the iron-rich region of the Zr-Fe phase diagram. J. Nucl. Mater. 1996, 229, 29–35. [Google Scholar] [CrossRef]

- Burgio, N.; Iasonna, A.; Magini, M.; Martelli, S.; Padella, F. Mechanical alloying of the Fe-Zr system. Correlation between input energy and end products. IL Nuovo Cimento D 1991, 13, 459–476. [Google Scholar] [CrossRef]

- Buschow, K.; Smit, P. Magnetic and electrical transport properties of amorphous Zr-Fe alloys. J. Magn. Magn. Mater. 1981, 23, 85–91. [Google Scholar] [CrossRef]

- Unruh, K.M.; Chien, C.L. Magnetic properties and hyperfine interactions in amorphous Fe-Zr alloys. Phys. Rev. B 1984, 30, 4968–4974. [Google Scholar] [CrossRef]

- Chuang, C.Y.; Lee, J.W.; Li, C.L.; Chu, J.P. Mechanical properties study of a magnetron-sputtered Zr-based thin film metallic glass. Surf. Coat. Technol. 2013, 215, 312–321. [Google Scholar] [CrossRef]

- Schultz, L. Formation of amorphous metals by mechanical alloying. Mater. Sci. Eng. 1988, 97, 15–23. [Google Scholar] [CrossRef]

- Suryanarayana, C. Mechanical alloying and milling. Prog. Mater. Sci. 2001, 46, 1–184. [Google Scholar] [CrossRef]

- Gheiratmand, T.; Hosseini, H.M.; Davami, P.; Gjoka, M.; Song, M. The effect of mechanical milling on the soft magnetic properties of amorphous FINEMET alloy. J. Magn. Magn. Mater. 2015, 381, 322–327. [Google Scholar] [CrossRef]

- Xu, Y.B.; Zhou, S.F.; Liao, B.Q.; Zhao, S.Z.; Dai, X.Q.; Chen, D.C. Effect of milling time on the microstructure and magnetic properties of amorphous Ti50Fe50 alloys prepared by mechanical alloying. J. Mater. Res. Technol. 2019, 8, 3929–3935. [Google Scholar] [CrossRef]

- Guo, F.Q.; Lu, K. Ball-milling-induced crystallization and ball-milling effect on thermal crystallization kinetics in an amorphous FeMoSiB alloy. Met. Mater. Trans. A 1997, 28, 1123–1131. [Google Scholar] [CrossRef]

- Luo, X.T.; Li, C.J.; Yang, G.J. Correlations between milling conditions and iron contamination, microstructure and hardness of mechanically alloyed cubic BN particle reinforced NiCrAl matrix composite powders. J. Alloys Compd. 2013, 548, 180–187. [Google Scholar] [CrossRef]

- Manchón-Gordón, A.; Ipus, J.; Blázquez, J.; Conde, C.; Condé, A. Evolution of Fe environments and phase composition during mechanical amorphization of Fe70Zr30 and Fe70Nb30 alloys. J. Non Cryst. Solids 2018, 494, 78–85. [Google Scholar] [CrossRef]

- Lashgari, H.R.; Chu, D.; Xie, S.S.; Sun, H.D.; Ferry, M.; Li, S. Composition dependence of the microstructure and soft magnetic properties of Fe-based amorphous/nanocrystalline alloys: A review study. J. Non Cryst. Solids 2014, 391, 61–82. [Google Scholar] [CrossRef]

- Herzer, G. Modern soft magnets: Amorphous and nanocrystalline materials. Acta Mater. 2013, 61, 718–734. [Google Scholar] [CrossRef]

- Ipus, J.J.; Blázquez, J.S.; Franco, V.; Conde, C.F.; Conde, A. Two milling time regimes in the evolution of magnetic anisotropy of mechanically alloyed soft magnetic powders. J. Alloys Compd. 2011, 509, 1407–1410. [Google Scholar] [CrossRef]

- Schlorke, N.; Eckert, J.; Schultz, L. Thermal and magnetic properties of bulk glass forming Fe-Al-P-C-B-(Ga) alloys. J. Phys. D Appl. Phys. 1999, 32, 855–861. [Google Scholar] [CrossRef]

- Ipus, J.; Blázquez, J.S.; Franco, V.; Conde, A. Ball milling of Fe83Zr6B10Cu1 amorphous alloy containing quenched in crystals. Intermetallics 2007, 15, 1132–1138. [Google Scholar] [CrossRef]

- Moreno, L.M.; Blazquez, J.S.; Ipus, J.J.; Borrego, J.; Franco, V.; Conde, A. Magnetocaloric effect of Co62Nb6Zr2B30 amorphous alloys obtained by mechanical alloying or rapid quenching. J. Appl. Phys. 2014, 115, 17A302. [Google Scholar] [CrossRef]

- Manchón-Gordón, A.; Ipus, J.; Moreno-Ramírez, L.; Blázquez, J.; Conde, C.; Franco, V.; Condé, A. Correction of the shape effect on magnetic entropy change in ball milled Fe70Zr30 alloys. J. Alloys Compd. 2018, 765, 437–443. [Google Scholar] [CrossRef]

- Álvarez-Alonso, P.; Llamazares, J.L.S.; Sánchez-Valdés, C.F.; Cuello, G.J.; Franco, V.; Gorria, P.; Blanco, J.A. On the broadening of the magnetic entropy change due to Curie temperature distribution. J. Appl. Phys. 2014, 115, 17A929. [Google Scholar] [CrossRef]

- Blázquez, J.S.; Ipus, J.J.; Franco, V.; Conde, C.F.; Conde, A. Extracting the composition of nanocrystals of mechanically alloyed systems using Mössbauer spectroscopy. J. Alloys Compd. 2014, 610, 92–99. [Google Scholar] [CrossRef]

- Menil, F. Systematic trends of the 57Fe, Mossbauer isomer-shifts in (FeOn) and (FeFn) polyhedral—Evidence of a new correlation between the isomer-shift and the inductive effect of the competing bond T-X(→Fe) (where X is O or F and T any element with a formal positive charge). J. Phys. Chem. Solids 1985, 46, 763–789. [Google Scholar]

- Dambournet, D.; Duttine, M.; Chapman, K.W.; Wattiaux, A.; Borkiewicz, O.; Chupas, P.J.; Demourgues, A.; Groult, H. Resolving and Quantifying Nanoscaled Phases in Amorphous FeF3 by Pair Distribution Function and Mössbauer Spectroscopy. J. Phys. Chem. C 2014, 118, 14039–14043. [Google Scholar] [CrossRef]

- Manchon-Gordon, A.F.; Moreno-Ramirez, L.M.; Ipus, J.J.; Blazquez, J.S.; Conde, C.F.; Franco, V.; Conde, A. A procedure to obtain the parameters of Curie temperature distribution from thermomagnetic and magnetocaloric data. J. Non Cryst. Solids 2019, 520, 119460. [Google Scholar] [CrossRef]

- Coey, J.M.D. Magnetism and Magnetic Material, 1st ed.; Cambridge University Press: New York, NY, USA, 2010. [Google Scholar]

- Brand, R.A.; Lauer, J.; Herlach, D.M. The evaluation of hyperfine field distributions in overlapping and asymmetric Mossbauer spectra: A study of the amorphous alloy Pd77.5−xCu6Si16.5Fex. J. Phys. F Met. Phys. 1983, 13, 675–683. [Google Scholar] [CrossRef]

- Brown, W.F. Theory of the Approach to Magnetic Saturation. Phys. Rev. 1940, 58, 736–743. [Google Scholar] [CrossRef]

- Brown, W.F. The Effect of Dislocations on Magnetization Near Saturation. Phys. Rev. 1941, 60, 139–147. [Google Scholar] [CrossRef]

- Xiong, X.Y.; Finlayson, T.R.; Muddle, B.C. The approach to saturation magnetization of nanocrystalline Fe90Zr7B3 alloy. J. Phys. D Appl. Phys. 2001, 34, 2845. [Google Scholar] [CrossRef]

| Temperature (K) | Component | Area% | ||

|---|---|---|---|---|

| 130 | Hyperfine distribution | 94.0 | 12.4 | −0.17 |

| α-Fe site | 3.0 | - | - | |

| 150 | Hyperfine distribution | 94.0 | 11.5 | −0.18 |

| α-Fe site | 2.9 | |||

| 180 | Hyperfine distribution | 92.6 | 9.7 | −0.20 |

| α-Fe site | 3.3 | - | ||

| 220 | Hyperfine distribution | 77.5 | 8.3 | −0.22 |

| α-Fe site | 0.1 | - | - | |

| 240 | Hyperfine distribution | 69.5 | 8.0 | −0.22 |

| α-Fe site | 0.1 | - | - | |

| 250 | Hyperfine distribution | 47.7 | 7.3 | −0.23 |

| α-Fe site | 0.1 | - | - | |

| 260 | Hyperfine distribution | 37.5 | 7.3 | −0.23 |

| α-Fe site | 0.1 | - | - | |

| 280 | Hyperfine distribution | 26.5 | 7.1 | −0.23 |

| α-Fe site | 0.1 | - | - |

| Milling Time (h) | ||||

|---|---|---|---|---|

| 8.5 | 245 | 207.5 | 234 | 40 |

| 12.5 | 250 | 212.5 | 239 | 40 |

| 16 | 255 | 217.5 | 244 | 40 |

| 30 | 260 | 222.5 | 249 | 40 |

| 50 | 265 | 237.5 | 261 | 35 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manchón-Gordón, A.F.; Ipus, J.J.; Blázquez, J.S.; Conde, C.F.; Conde, A. Influence of Milling Time on the Homogeneity and Magnetism of a Fe70Zr30 Partially Amorphous Alloy: Distribution of Curie Temperatures. Materials 2020, 13, 490. https://doi.org/10.3390/ma13020490

Manchón-Gordón AF, Ipus JJ, Blázquez JS, Conde CF, Conde A. Influence of Milling Time on the Homogeneity and Magnetism of a Fe70Zr30 Partially Amorphous Alloy: Distribution of Curie Temperatures. Materials. 2020; 13(2):490. https://doi.org/10.3390/ma13020490

Chicago/Turabian StyleManchón-Gordón, Alejandro F., Jhon J. Ipus, Javier S. Blázquez, Clara F. Conde, and Alejandro Conde. 2020. "Influence of Milling Time on the Homogeneity and Magnetism of a Fe70Zr30 Partially Amorphous Alloy: Distribution of Curie Temperatures" Materials 13, no. 2: 490. https://doi.org/10.3390/ma13020490

APA StyleManchón-Gordón, A. F., Ipus, J. J., Blázquez, J. S., Conde, C. F., & Conde, A. (2020). Influence of Milling Time on the Homogeneity and Magnetism of a Fe70Zr30 Partially Amorphous Alloy: Distribution of Curie Temperatures. Materials, 13(2), 490. https://doi.org/10.3390/ma13020490