Solidification Crack Evolution in High-Strength Steel Welding Using the Extended Finite Element Method

Abstract

1. Introduction

2. Materials and Methods

2.1. Experiment

2.1.1. Material and Welding-Process Experiment

2.1.2. Uniaxial Tensile Test and Measurement

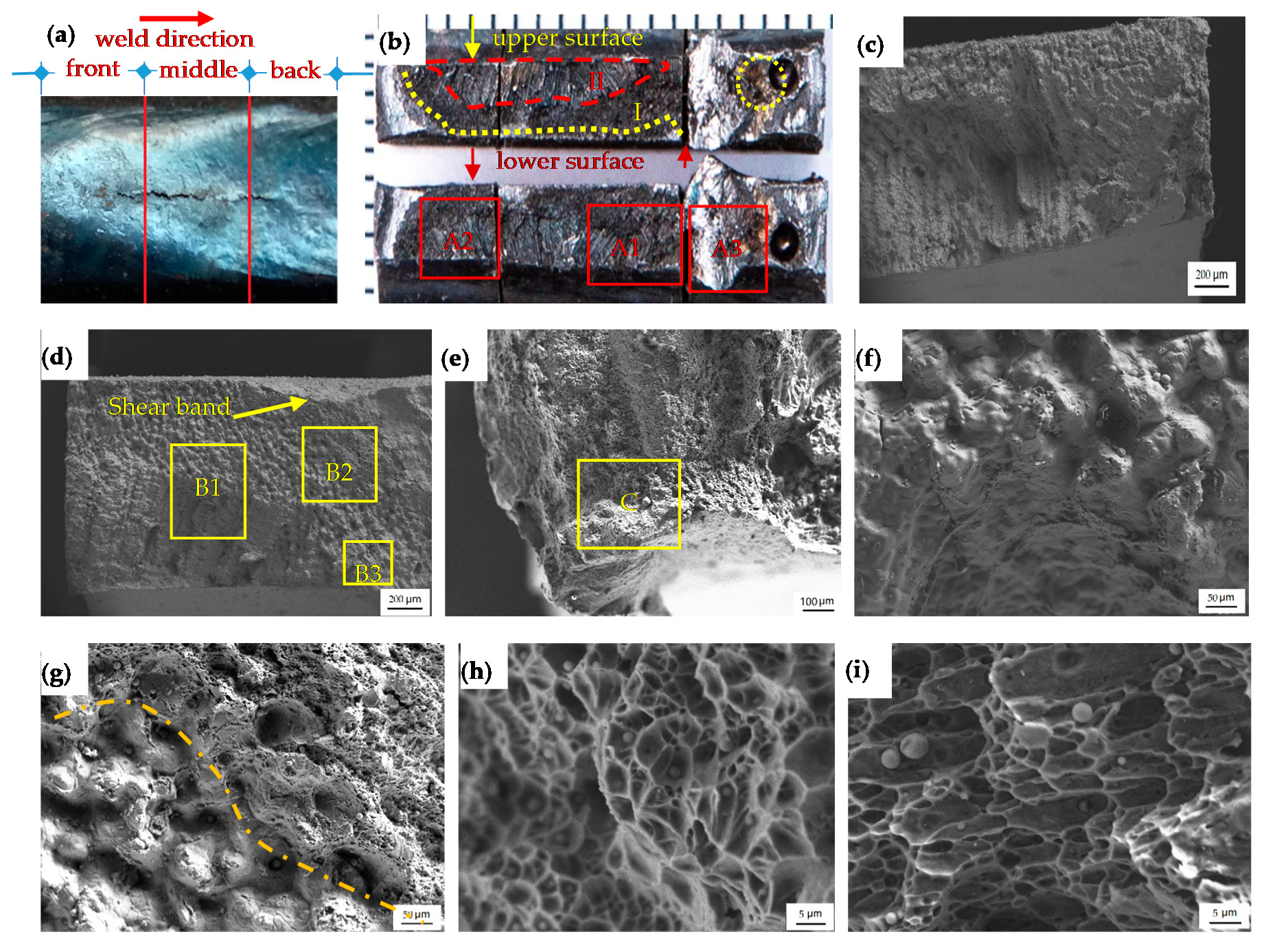

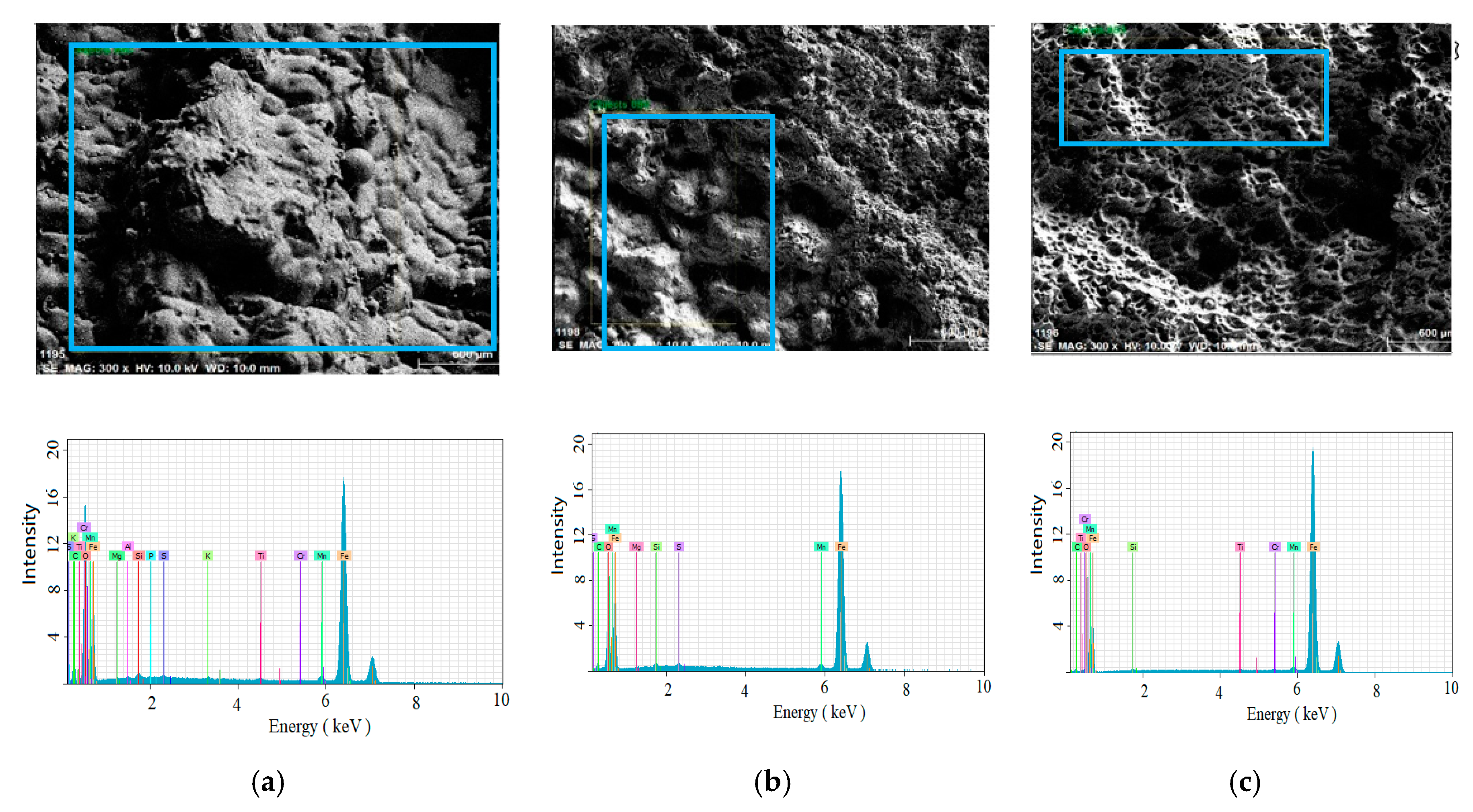

2.1.3. Failure Fractography

2.2. Numerical Prediction

2.2.1. Thermo-Mechanical Modeling

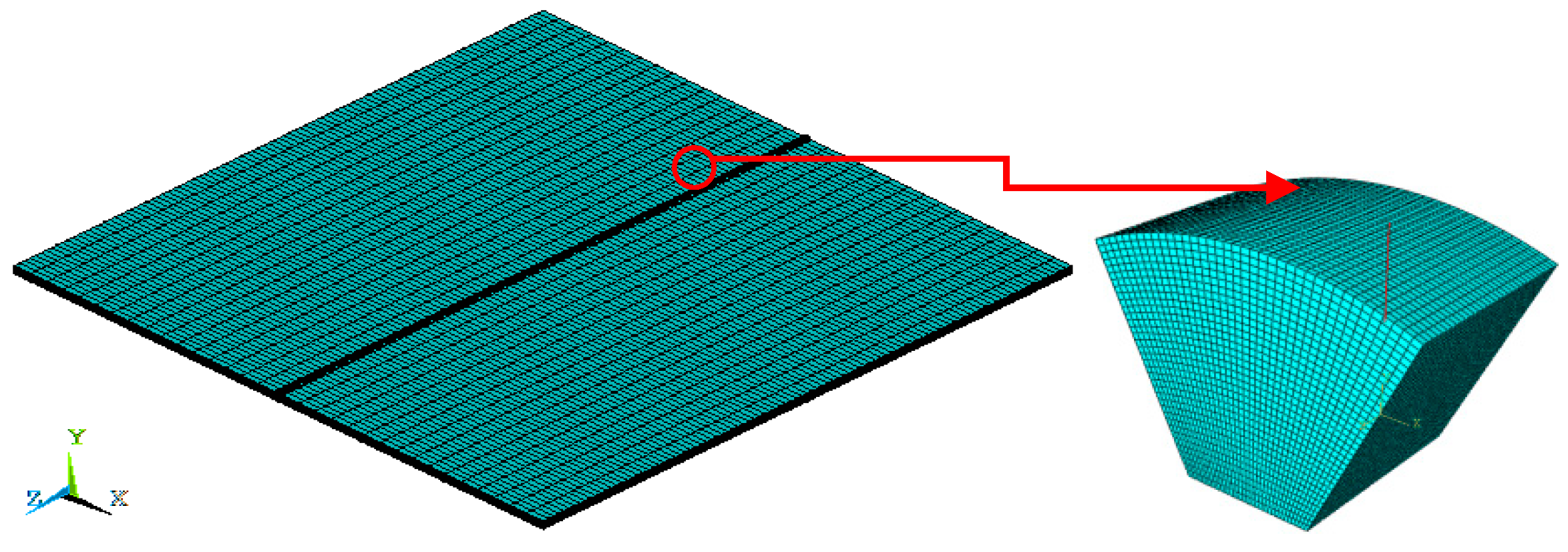

2.2.2. Submodeling Method

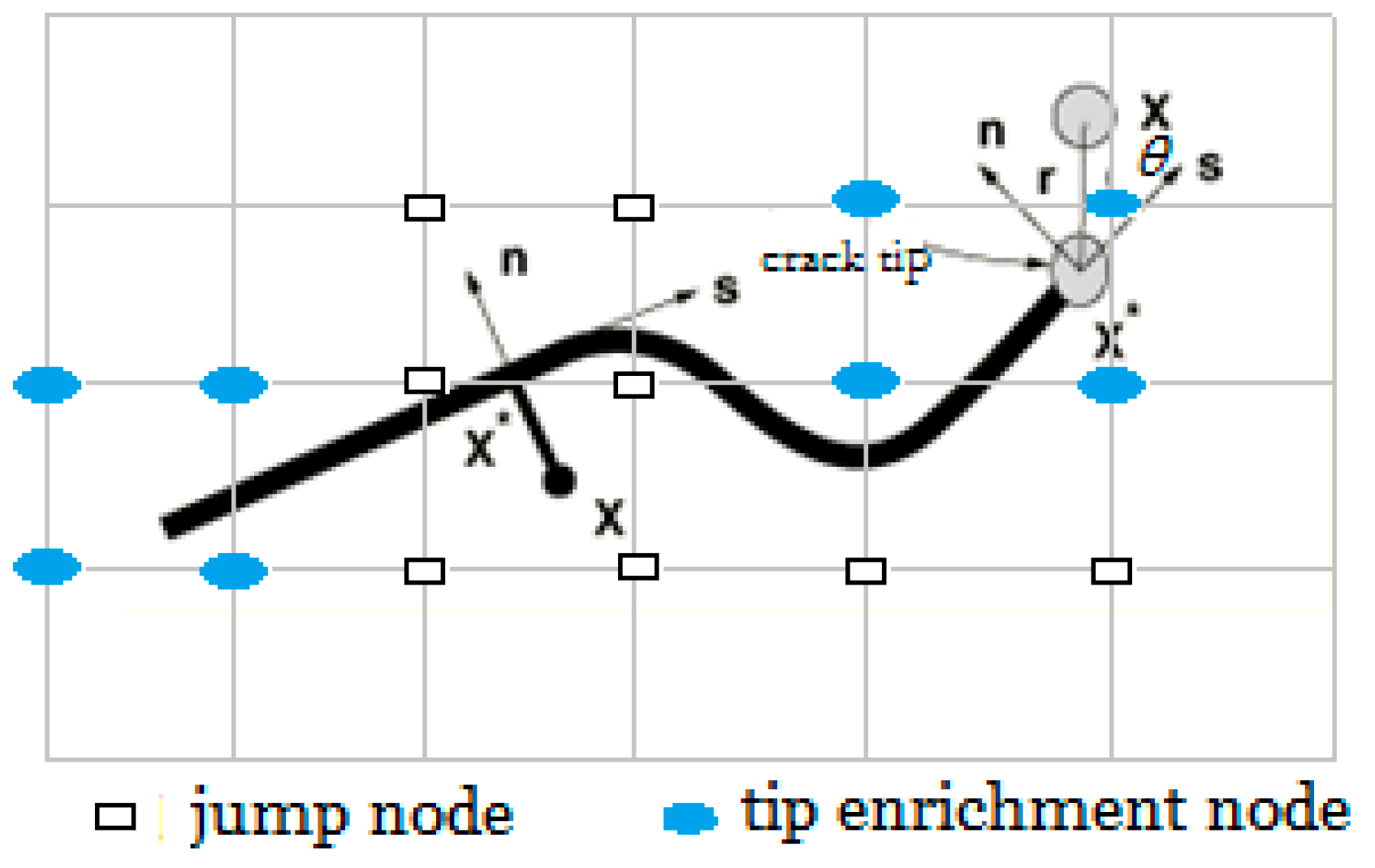

2.2.3. Extended Finite Element Method

2.2.4. Displacement–Extrapolation Method

3. Results

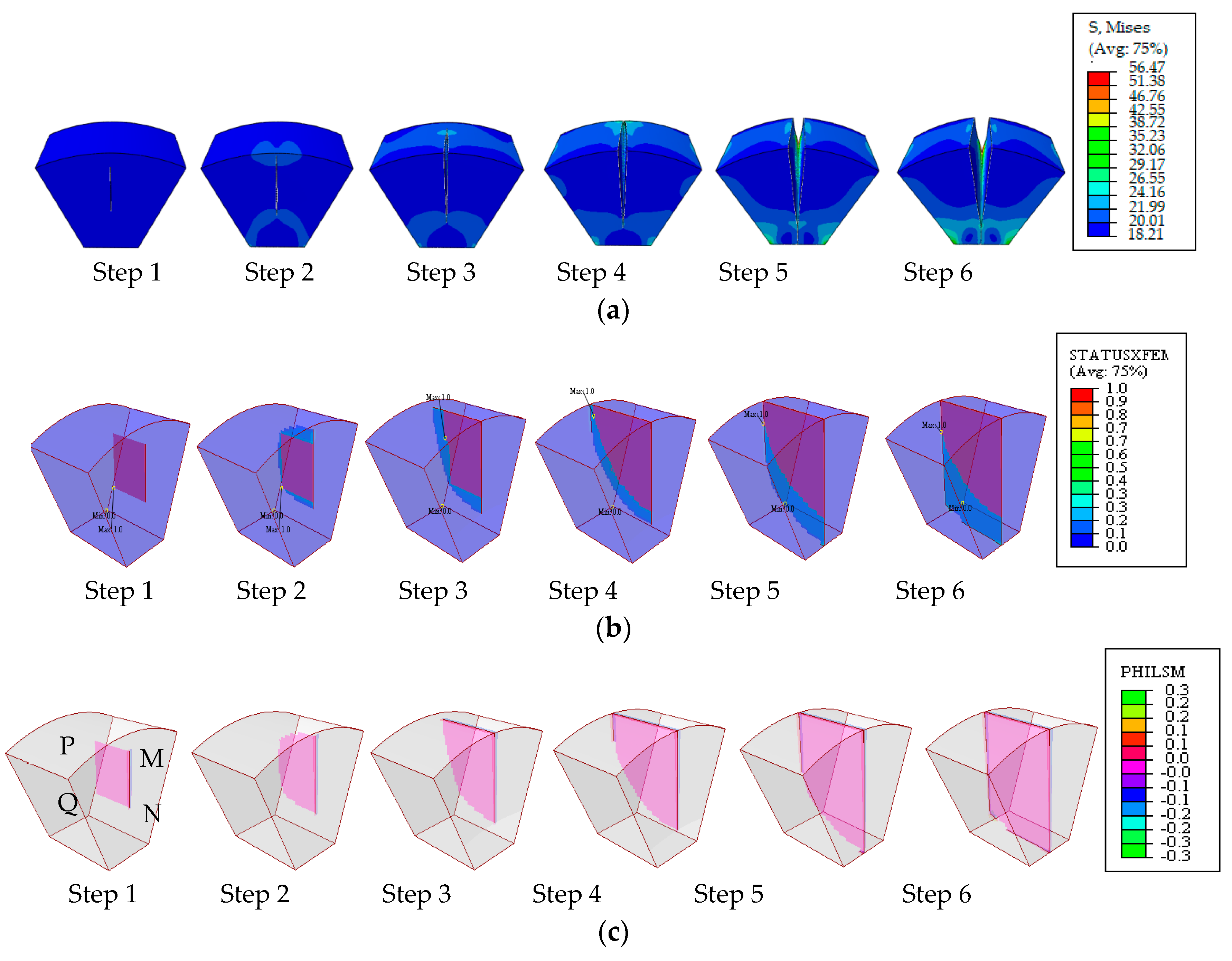

3.1. Modeling

3.2. Experiment

4. Discussion

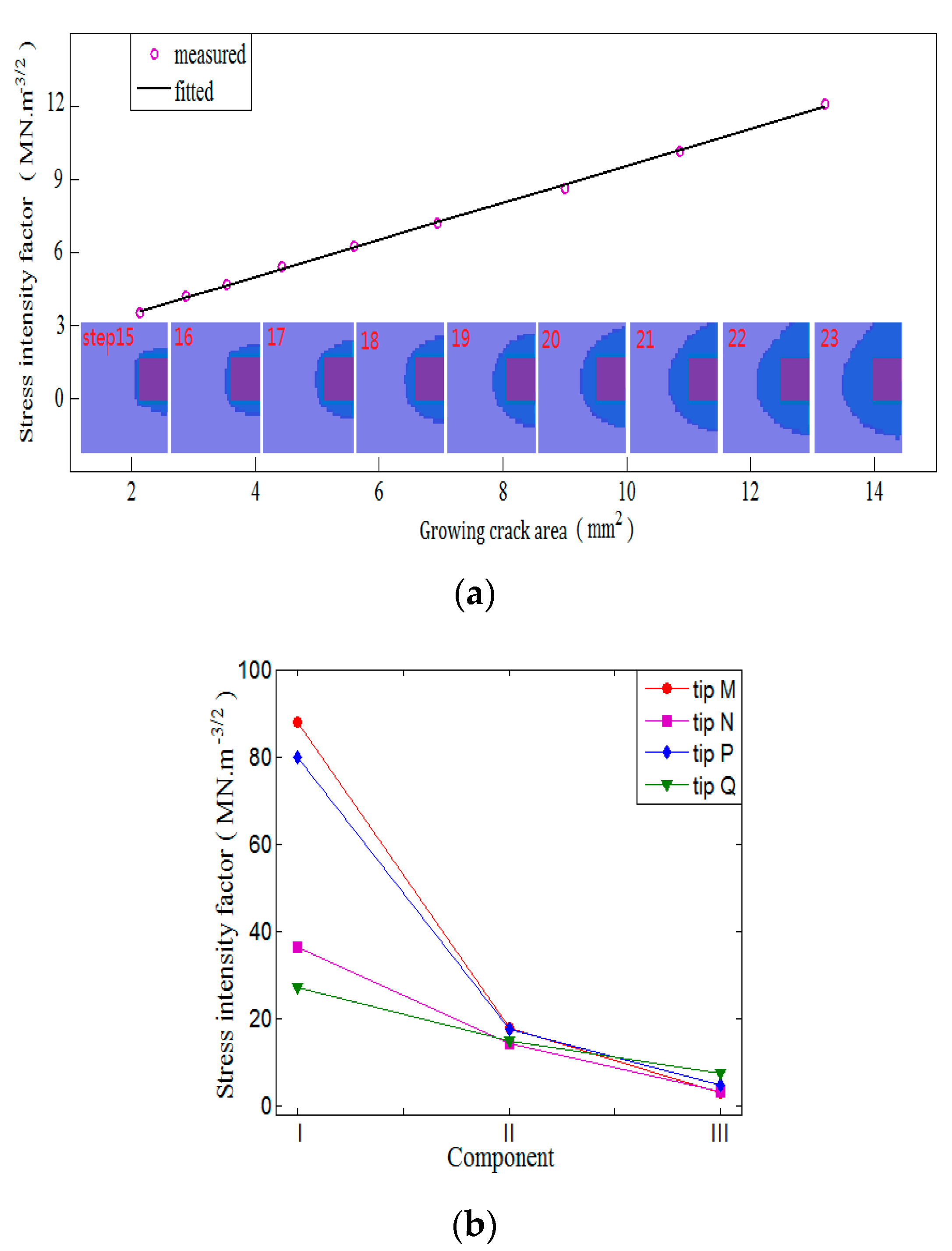

4.1. Driving Force

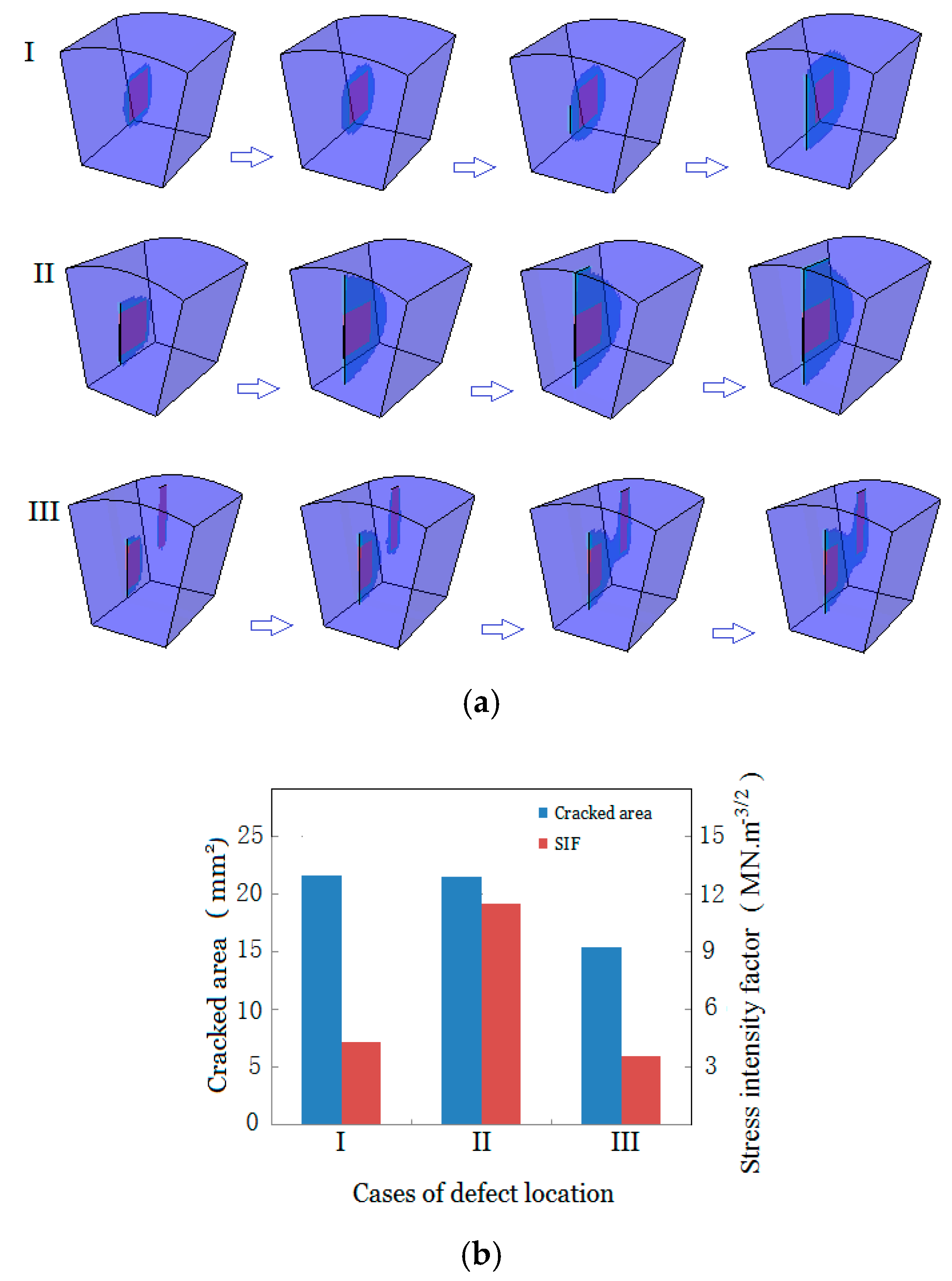

4.2. Propagation Paths

5. Conclusions

- The solidification crack profile test confirms that XFEM is an effective numerical method for reproducing weld solidification crack propagation. SIF is an effective fracture parameter to correlate with solidification cracking.

- Upon exposure to weld stress higher than the maximum tensile principal stress, the solidification crack initiates and inherently prefers to propagate upward towards the weld’s upper surface due to its higher weld stress.

- Among the three SIF components, the mode I is dominant. Initial defects open to current cross section and vertical to the weld plate plane are more susceptible to solidification cracking compared to the closed and tilted ones, respectively.

- The brittle nature of solidification cracking and the dominant role of the weld’s transverse stress component make the initial defect propagate vertically towards weld plate plane in spite of its initial tilting orientation. Lightly scattered initial defects show a lower total cracking susceptibility compared to highly concentrated initial defects with same area.

Author Contributions

Funding

Conflicts of Interest

References

- Weidinger, P.; Gunther, K.; Fitzel, M.; Logvinov, R.; Ilin, A.; Ploshikhin, V.; Hugger, F.; Mann, V.; Roth, S.; Schmidt, M. Testing of new materials and computer aided optimization of process parameters and clamping device during predevelopment of laser welding processes. Phys. Procedia 2014, 56, 487–496. [Google Scholar] [CrossRef]

- Hojo, T.; Kobayashi, J.; Sugimoto, K.I.; Nagasaka, A.; Akiyama, E. Effecs of alloying elements addition on delayed fracture properties of ultra high-strength trip-aided martensitic steels. Metals 2020, 10, 6. [Google Scholar] [CrossRef]

- Osuki, T.; Hirata, H.; Ogawa, K. Numerical analysis of solidification process of austenitic stainless steel weld metal with dependence of welding velocity-Study of solidification structure on austenitic stainless steel weld metal. Q. J. Jpn. Weld. Soc. 2007, 25, 140–148. [Google Scholar] [CrossRef][Green Version]

- Hosseini, S.A.; Abdollah-zadeh, A.; Naffakh-Moosavy, H.; Mehri, A. Elimination of hot cracking in the electron beam welding of AA2024-T351 by controlling the welding speed and heat input. J. Manuf. Process. 2019, 46, 147–158. [Google Scholar] [CrossRef]

- Azimzadegan, T.; Mousavi, S.A.A.A. Investigation of the occurrence of hot cracking in pulsed Nd-YAG laser welding of Hastelloy-X by numerical and microstructure studies. J. Manuf. Process. 2019, 44, 226–240. [Google Scholar] [CrossRef]

- Cao, J.; Li, F.G.; Ma, W.F.; Wang, K.; Ren, J.J.; Nie, H.L.; Dang, W. A strain rate dependent fracture model of 7050 Aluminum alloy. Metals 2020, 10, 3. [Google Scholar] [CrossRef]

- Rappaz, M.; Drezet, J.M.; Gremaud, M. A new hot-tearing criterion. Metall. Mater. Trans. A 1999, 30, 449–455. [Google Scholar] [CrossRef]

- Vernede, S.; Rappaz, M. A simple and efficient model for mesoscale solidification simulation of globular grain structures. Acta. Mater. 2007, 55, 1703–1710. [Google Scholar] [CrossRef]

- Niel, A.; Bordreuil, C.; Deschaux-beaume, F.; Fras, G. Modelling hot cracking in 6061 aluminum alloy weld metal with microstructure based on criterion. Sci. Technol. Weld. Join. 2013, 18, 154–160. [Google Scholar] [CrossRef]

- Kou, S. A criterion for cracking during solidification. Acta Mater. 2015, 88, 366–374. [Google Scholar] [CrossRef]

- Agarwal, G.; Kumar, A.; Richardon, I.M.; Hermans, M.J.M. Evaluation of solidification cracking susceptibility during laser welding in advanced high strength automotive steels. Mater. Des. 2019, 83, 108104. [Google Scholar] [CrossRef]

- Ma-Magdalena, P.A.; Francesc, R.F.; Xavier, A.G.; Jordi, B.B.; Elsa, P.G.; Irene, B.C. Elastic asymmetry of PLA material in FDM-printed parts: Considerations concerning experimental characterization for use in numerical simulations. Materials 2020, 13, 15. [Google Scholar]

- Chen, Z.L.; Xiong, Y.F.; Qiu, H.J.; Lin, G.Z.; Li, Z.M. Stress intensity factor-based prediction of solidification crack growth during welding of high strength steel. J. Mater. Process. Tech. 2018, 252, 270–278. [Google Scholar] [CrossRef]

- Tian, Q.; Zhuge, H.Q.; Xie, X. Prediction of the ultra-low-cycle fatigue damage of Q345C steel and its weld joint. Materials 2019, 12, 4014. [Google Scholar] [CrossRef] [PubMed]

- Kossakowski, P.G. Modelling the damage of structural components with macrostructure defects. Metals 2019, 9, 1238. [Google Scholar] [CrossRef]

- Belyschko, T.; Black, T. Elastic crack growth in finite element with minimal remeshing. Int. J. Numer. Meth. Eng. 1999, 45, 601–620. [Google Scholar] [CrossRef]

- Qian, Y.W.; Zhao, J.P. Fracture toughness calculation method amendment of the dissimilar steel welded joint based on 3D XFEM. Metals 2019, 9, 509. [Google Scholar] [CrossRef]

- Zhou, B.; Xue, S.F. Displacement extrapolation method for stress intensity factor based on extended finite element method. Mech. Eng. 2017, 39, 371–378. [Google Scholar]

- Kirthan, L.J.; Hegde, R.; Girisha, V.A. Evaluation of mode I stress intensity factor for edge crack using displacement extrapolation method. Int. J. Mater. Struct. Integr. 2016, 10, 11–22. [Google Scholar] [CrossRef]

- Fedorikova, A.; Kvackaj, T.; Kocisko, R.; Bidulsky, R.; Petrousek, P. Hot compression test of heat resistant steel. Acta Physica Polonica A 2017, 131, 1340–1343. [Google Scholar] [CrossRef]

- Gao, H.; Agarwal, G.; Amirthalingam, M.; Hermans, M.J.M. Hot cracking investigation during laser welding of high-strength steels with multi-scale modelling approach. Sci. Technol. Weld. Join. 2018, 23, 287–294. [Google Scholar] [CrossRef]

- Konovalov, S.V.; Kormyshev, V.E.; Gromov, V.E.; Ivanov, Y.F.; Kapralov, E.V.; Semin, A.P. Formation features of structure-phase states of Cr–Nb–C–V containing coatings on martensitic steel. J. Synch. Investig. 2016, 10, 1119–1124. [Google Scholar] [CrossRef]

- Ventura, G.; Moran, B.; Belytschko, T. Dislocations by partition of unity. Int. J. Numer. Meth. Eng. 2005, 62, 1463–1487. [Google Scholar] [CrossRef]

- Wen, P.; Shinozaki, K.; Yamamoto, M. Evaluation of solidification cracking susceptibility during laser welding by in-situ observation method. Chin. J. Lasers 2011, 6, 603005. [Google Scholar]

- Mohammad, S.; Amir, K.E.N.; Mohammad, J. On the hot cracking of HSLA steel welds: Role of epitaxial growth and HAZ grain size. J. Manuf. Process. 2019, 41, 242–251. [Google Scholar]

- Aucott, L.; Huang, D.; Dong, H.B.; Wen, S.W.; Marsden, J.A.; Rack, A.; Cocks, A.C.F. Initiation and growth kinetics of solidification cracking during welding of steel. Sci. Rep. 2017, 7, 40255. [Google Scholar] [CrossRef]

- Tagawa, T.; Kayamori, Y.; Ohata, M.; Handa, T.; Kawabata, T.; Yamashita, Y.; Tsutsumi, K.; Yoshinari, H.; Aihara, S.; Hagihara, Y. Comparison of CTOD standards: BS 7448-Part 1 and revised ASTM E1290. Eng. Fract. Mech. 2010, 77, 327–336. [Google Scholar] [CrossRef]

- Wilson, D.; Zheng, Z.B.; Dunne, F.P.E. A microstructure-sensitive driving force for crack growth. J. Mech. Phys. Solids 2018, 121, 147–174. [Google Scholar] [CrossRef]

- Wilson, D.; Dunne, F.P.E. A mechanistic modeling methodology for microstructure-sensitive fatigue crack growth. J. Mech. Phys. Solids 2019, 124, 827–848. [Google Scholar] [CrossRef]

- Khallaf, M.E.; Lbrahim, M.A.; El-Mahallawy, N.A.; Taha, M.A. On crack susceptibility in the submerged arc welding of medium-carbon steel plates. J. Mater. Process. Tech. 1997, 68, 43–49. [Google Scholar] [CrossRef]

- Mishnev, R.; Dudova, N.; Kaibyshev, R.; Belyakov, A. On the fracture behavior of a creep resistant 10% Cr steel with high boron and low nitrogen contents at low temperatures. Materials 2020, 13, 3. [Google Scholar] [CrossRef] [PubMed]

- Quintana, M.A.; Mclane, J.; Babu, S. Inclusion formation in self-shielded flux cored arc welds. Weld. J. 2001, 80, 98–105. [Google Scholar]

- Rong, P.; Wang, N.; Wang, L.; Yang, R.N.; Yao, W.J. The influence of grain boundary angle on the hot cracking of single crystal supperalloy DD6. J. Alloys Compd. 2016, 676, 181–186. [Google Scholar] [CrossRef]

- Phillion, A.B.; Hamilton, R.W.; Fuloria, D. In situ X-ray observation of semi-solid deformation and failure in Al-Cu alloys. Acta Mater. 2011, 59, 1436–1444. [Google Scholar] [CrossRef]

- Terzi, S.; Salvo, L.; Suery, M.; Limodin, N.; Adrien, J.; Maire, E.; Pannier, Y.; Bornert, M.; Bernard, D.; Felberbaum, M.; et al. In situ x-ray tomography observation of inhomogeneous deformation in semi-solid aluminium alloys. Scripta Mater. 2009, 61, 449–452. [Google Scholar] [CrossRef]

- Puncreobutr, C.; Lee, P.D.; Kareh, K.M. Influence on Fe-rich intermetallics on solidification defects in Al-Si-Cu alloys. Acta Mater. 2014, 68, 42–51. [Google Scholar] [CrossRef]

- Phillion, A.B.; Cockcroft, S.L.; Lee, P.D. A new methodology for measurement of semi-solid constitutive behavior and its application to examination of as-case porosity and hot tearing in aluminum alloys. Mater. Sci. Eng. A 2008, 491, 237–247. [Google Scholar] [CrossRef]

- Terzi, S.; Boller, E.; Salvo, L.; Suery, M. In situ X-ray microtomography study of the solidification and remelted microstructure Al-Cu alloys. Int. J. Cast Met. Res. 2009, 22, 275–278. [Google Scholar] [CrossRef]

- Chen, S.G.; Ye, X.X.; Tsang, D.K.L.; Jiang, L.; Yu, K.; Li, C.W.; Li, Z.J. Welding solidification cracking susceptibility and behavior of a Ni-28W-6Cr alloy. J. Mater. Sci. Tech. 2019, 35, 29–35. [Google Scholar] [CrossRef]

- Bakir, N.; Gumenyuk, A.; Rethmeier, M. Investigation of solidification cracking susceptibility during laser beam welding using an in-situ observation technique. Sci. Technol. Weld. Join. 2018, 23, 234–240. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | P | S | Cr | Al | Ti | Nb | Ni | Mo |

|---|---|---|---|---|---|---|---|---|---|---|---|

| wt. | 0.14 | 0.312 | 1.471 | 0.015 | 0.010 | 0.826 | 0.031 | 0.23 | 0.03 | 0.68 | 0.212 |

| Element | Fe | Mn | O | C | S | Mg | Ti | Cr |

|---|---|---|---|---|---|---|---|---|

| Liquid-film region | 94.08 | 1.11 | 3.13 | 1.01 | - | - | 0.27 | 0.35 |

| Boundary region | 97.75 | 1.06 | 0.80 | 0.39 | 0.01 | 0.0 | - | - |

| Dimple region | 98.05 | 0.84 | 0.03 | 0.25 | - | - | 0.28 | 0.55 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Liu, J.; Qiu, H. Solidification Crack Evolution in High-Strength Steel Welding Using the Extended Finite Element Method. Materials 2020, 13, 483. https://doi.org/10.3390/ma13020483

Chen Z, Liu J, Qiu H. Solidification Crack Evolution in High-Strength Steel Welding Using the Extended Finite Element Method. Materials. 2020; 13(2):483. https://doi.org/10.3390/ma13020483

Chicago/Turabian StyleChen, Zhanglan, Jianmin Liu, and Haijun Qiu. 2020. "Solidification Crack Evolution in High-Strength Steel Welding Using the Extended Finite Element Method" Materials 13, no. 2: 483. https://doi.org/10.3390/ma13020483

APA StyleChen, Z., Liu, J., & Qiu, H. (2020). Solidification Crack Evolution in High-Strength Steel Welding Using the Extended Finite Element Method. Materials, 13(2), 483. https://doi.org/10.3390/ma13020483