Influence of Annealing Atmosphere on the Characteristics of Ga2O3/4H-SiC n-n Heterojunction Diodes

Abstract

1. Introduction

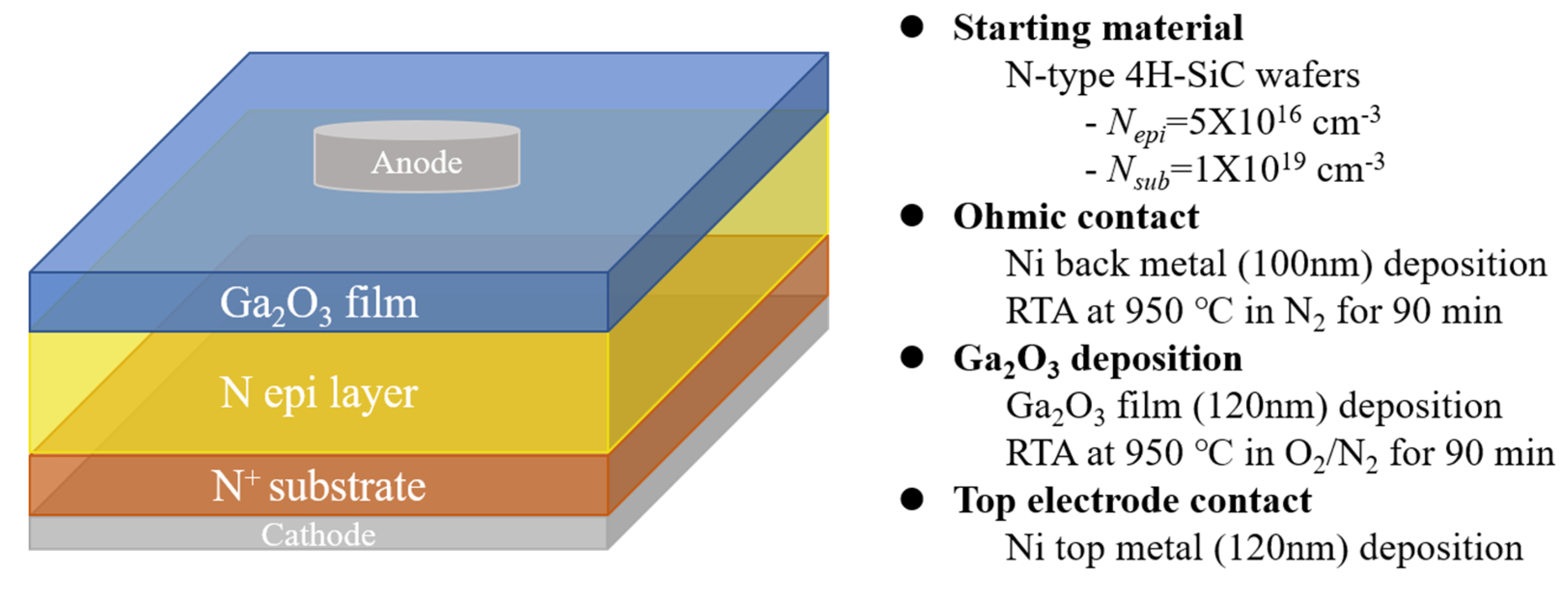

2. Materials and Methods

3. Results

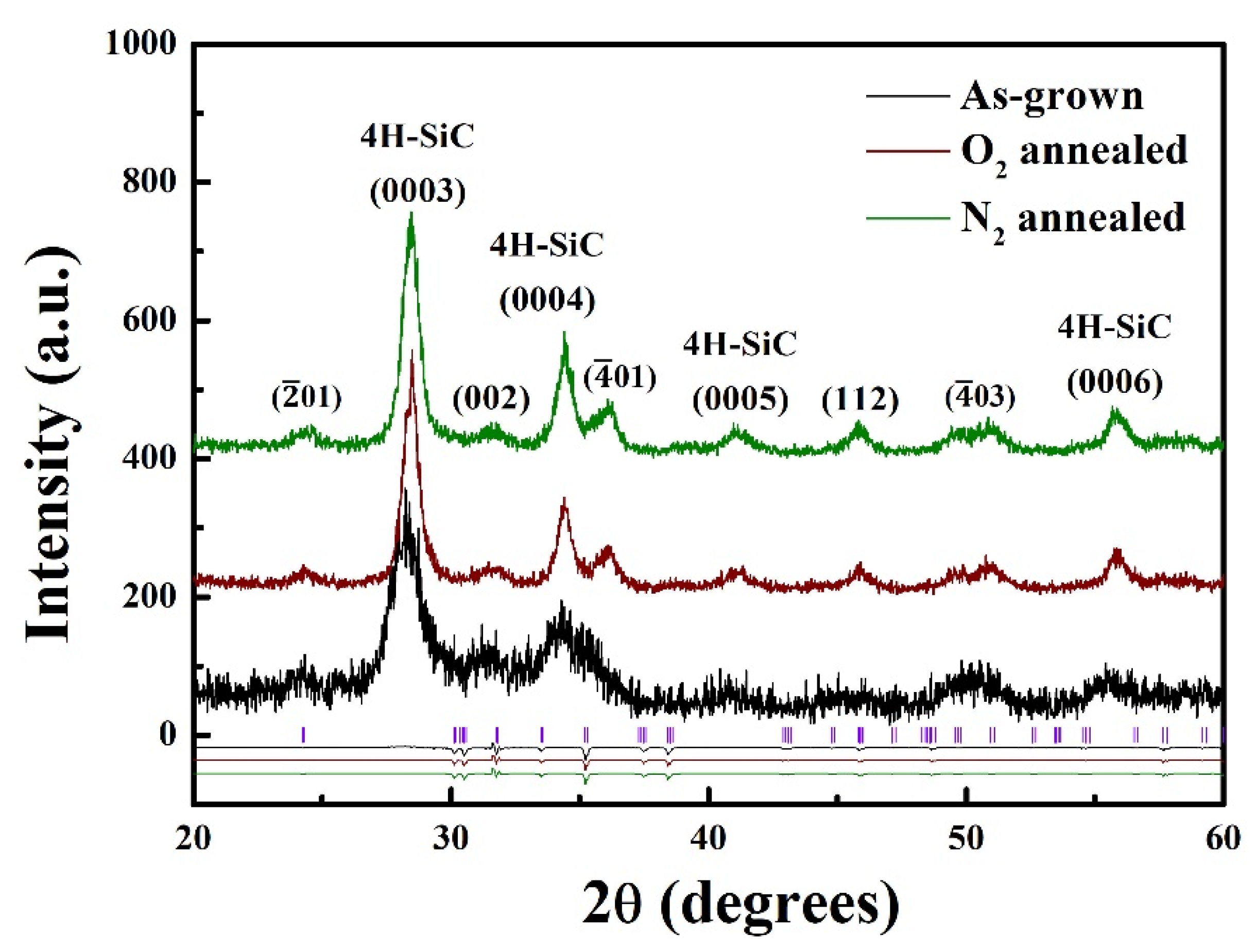

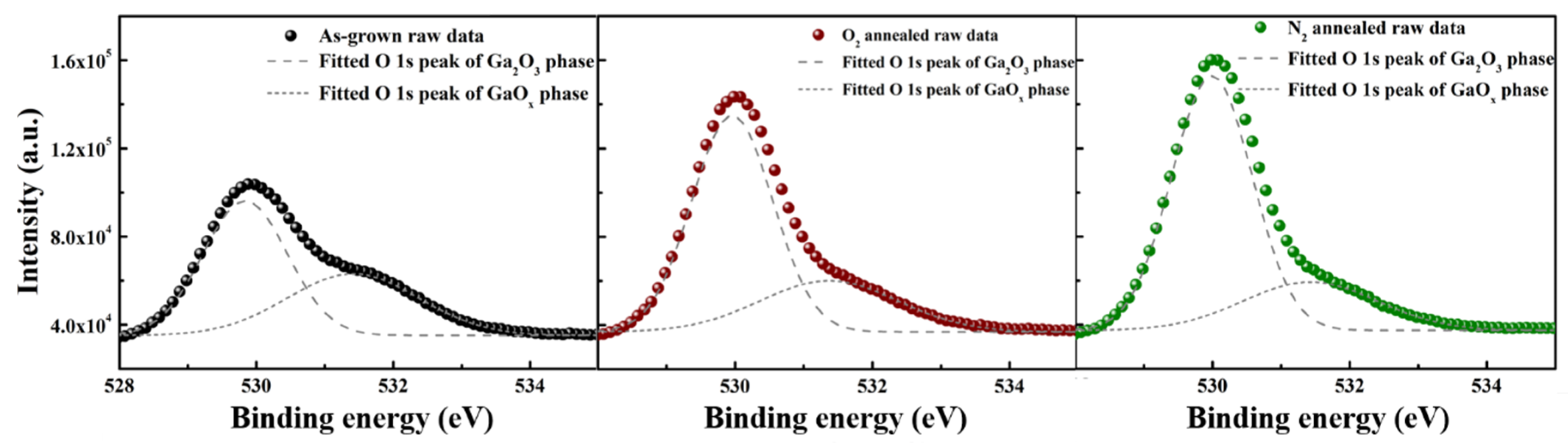

3.1. Material Properties

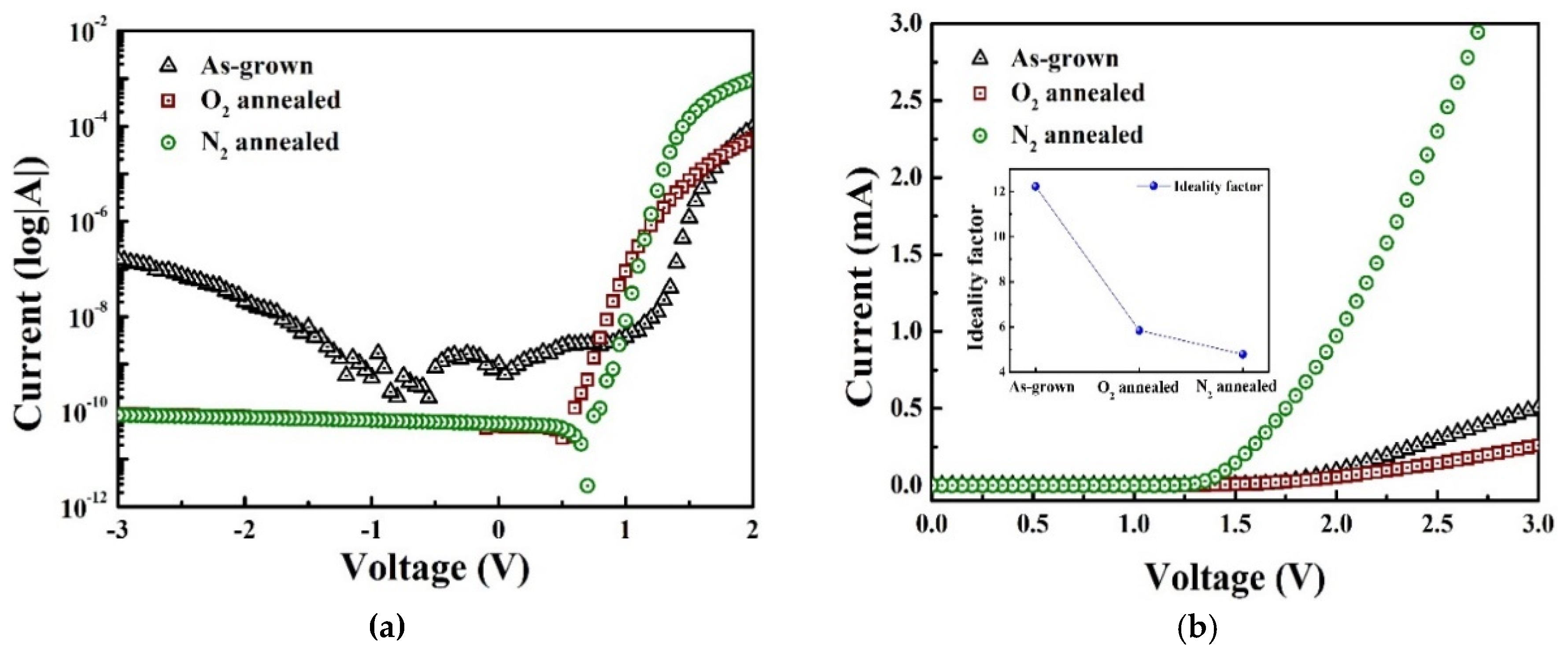

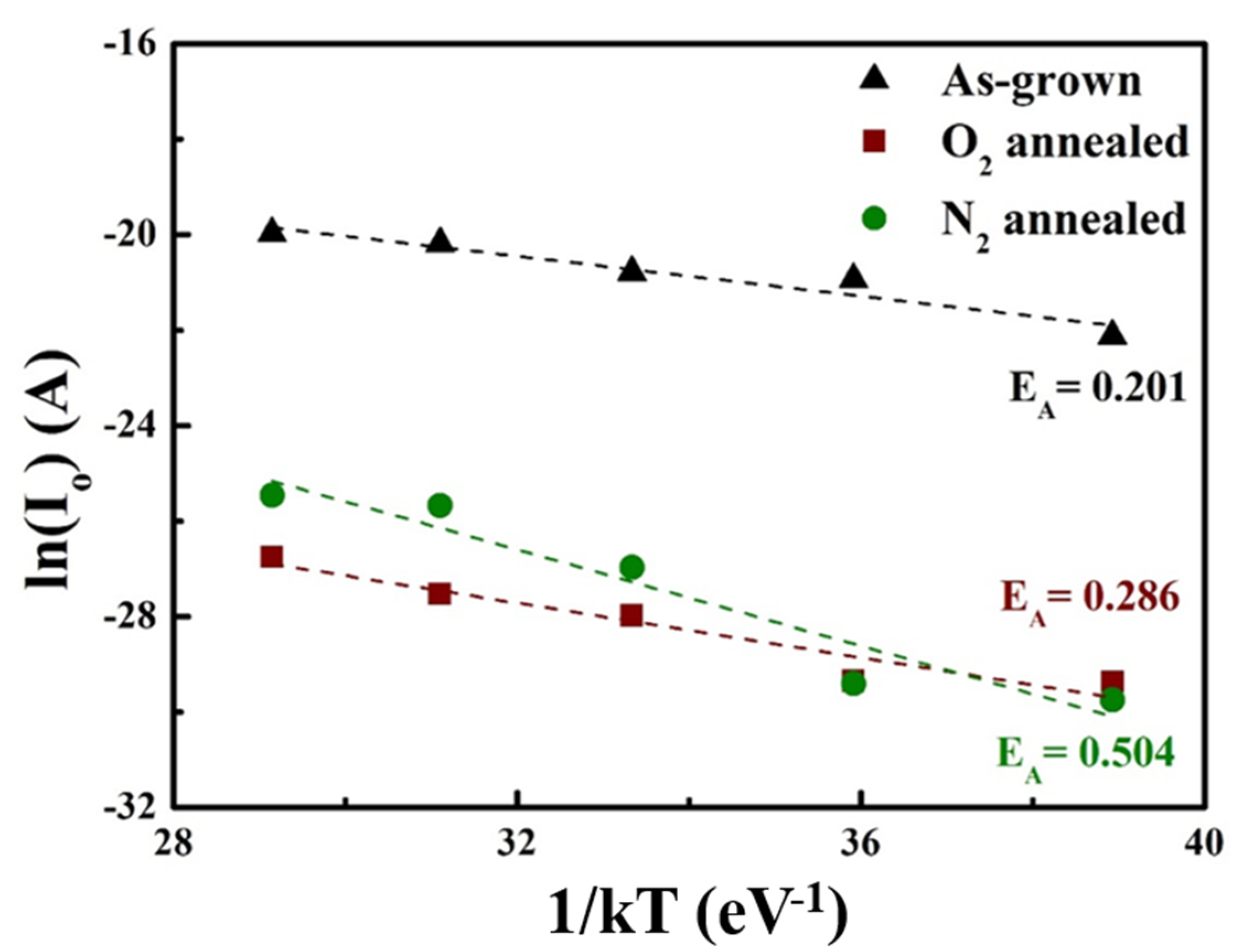

3.2. Electrical Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Oshima, T.; Okuno, T.; Arai, N.; Suzuki, N.; Ohira, S.; Fujita, S. Vertical Solar-Blind Deep-Ultraviolet Schottky Photodetectors Based on β-Ga2O3 Substrates. Appl. Phys. Express 2008, 1, 011202. [Google Scholar] [CrossRef]

- Feng, Z.; Huang, L.; Feng, Q.; Li, X.; Zhang, H.; Tang, W.; Zhang, J.; Hao, Y. MOCVD grown β-Ga2O3 metal-oxide-semiconductor field effect transistors on sapphire. Appl. Phys. Express 2018, 8, 8. [Google Scholar]

- An, Y.H.; Guo, D.Y.; Li, S.Y.; Wu, Z.P.; Huang, Y.Q.; Li, P.G.; Li, L.H.; Tang, W.H. Influence of oxygen vacancies on the photoresponse of β-Ga2O3 /SiC n–n type heterojunctions. J. Phys. D Appl. Phys. 2016, 49, 285111. [Google Scholar] [CrossRef]

- Guo, Y.; Li, A.; Feng, Q.; Hu, Z.; Feng, Z.; Zhang, K.; Lu, X.; Zhang, C.; Zhou, H.; Mu, W.; et al. High-Voltage β-Ga2O3 Schottky Diode with Argon-Implanted Edge Termination. Nanoscale Res. Lett. 2019, 14, 8. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Sparks, Z.; Ren, F.; Pearton, S.J.; Tadjer, M. Effect of surface treatments on electrical properties of β-Ga2O3. J. Vac. Sci. Technol. B 2018, 36, 061201. [Google Scholar] [CrossRef]

- Dong, L.; Jia, R.; Xin, B.; Zhang, Y. Effects of post-annealing temperature and oxygen concentration during sputtering on the structural and optical properties of β-Ga2O3 films. J. Vac. Sci. Technol. A Vac. Surf. Films 2016, 34, 060602. [Google Scholar] [CrossRef]

- Zhang, H.; Deng, J.; Pan, Z.; Bai, Z.; Kong, L.; Wang, J. Structural and optical properties of Nb-doped β-Ga2O3 thin films deposited by RF magnetron sputtering. Vacuum 2017, 146, 93–96. [Google Scholar] [CrossRef]

- Zhang, Y.; Yan, J.; Li, Q.; Qu, C.; Zhang, L.; Xie, W. Optical and structural properties of Cu-doped β-Ga2O3 films. Mater. Sci. Eng. B 2011, 176, 846–849. [Google Scholar] [CrossRef]

- Takeuchi, T.; Ishikawa, H.; Takeuchi, N.; Horikoshi, Y. High resolution X-ray photoelectron spectroscopy of beta gallium oxide films deposited by ultra high vacuum radio frequency magnetron sputtering. Thin. Solid Films 2008, 516, 4593–4597. [Google Scholar] [CrossRef]

- Ishibashi, K.; Aida, R.; Takahara, M.; Kudo, J.; Tsunoda, I.; Takakura, K.; Nakashima, T.; Shibuya, M.; Murakami, K. Investigation of the crystalline quality of a gallium oxide thick film grown by RF magnetron sputtering. Phys. Status Solidi 2013, 10, 1588–1591. [Google Scholar]

- Donmez, I.; Akgun, C.O.; Biyikli, N. Fabrication of AlN/BN bishell hollow nanofibers by electrospinning and atomic layer deposition. J. Vac. Sci. Technol. A 2014, 32, 4. [Google Scholar]

- Battu, A.K.; Ramana, C.V. Mechanical Properties of Nanocrystalline and Amorphous Gallium Oxide Thin Films. Adv. Eng. Mater. 2018, 20, 1701033. [Google Scholar] [CrossRef]

- Varley, J.; Weber, J.R.; Janotti, A.; van de Walle, C.G. Oxygen vacancies and donor impurities in β-Ga2O3. Appl. Phys. Lett. 2018, GAO2018, 142106. [Google Scholar] [CrossRef]

- Rebien, M.; Henrion, W.; Hong, M.; Mannaerts, J.P.; Fleischer, M. Optical properties of gallium oxide thin films. Appl. Phys. Lett. 2002, 81, 250. [Google Scholar] [CrossRef]

- Ghose, S. Structural and optical properties of β-Ga2O3 thin films grown by plasma-assisted molecular beam epitaxy. J. Vac. Sci. Technol. B Nanotechnol. Microelectron. Mater. Process. Meas. Phenom. 2016, 34, 02L109. [Google Scholar] [CrossRef]

- Kang, H.C. Heteroepitaxial growth of multidomain Ga2O3/sapphire(001) thin films deposited using radio frequency magnetron sputtering. Mater. Lett. 2014, 119, 123–126. [Google Scholar] [CrossRef]

- Nakagomi, S.; Sakai, T.; Kikuchi, K.; Kokubun, Y. β-Ga2O3/p-Type 4H-SiC Heterojunction Diodes and Applications to Deep-UV Photodiodes. Phys. Status Solidi. A 2018, 216, 1700796. [Google Scholar] [CrossRef]

- Trukhanov, S.V.; Trukhanov, A.V.; Panina, L.V.; Kostishyn, V.G.; Turchenko, V.A.; Trukhanova, E.L.; Trukhanov, A.V.; Zubar, T.I.; Ivanov, V.M.; Tishkevich, D.I.; et al. Temperature evolution of the structure parameters and exchange interactions in BaFe12−xInxO19. J. Magn. Magn. Mater. 2018, 466, 393–405. [Google Scholar] [CrossRef]

- Pashchenko, A.V.; Liedienov, N.A.; Li, Q.; Tatarchuk, D.D.; Turchenko, V.A.; Makoed, I.I.; Sycheva., V.Y.; Voznyak, A.V.; Kladko, V.P.; Gudimenko, A.I.; et al. Structure, non-stoichiometry, valence of ions, dielectric and magnetic properties of single-phase Bi0.9La0.1FeO3−δ multiferroics. J. Magn. Magn Mater. 2019, 483, 100–113. [Google Scholar] [CrossRef]

- Zhang, Z.; Farzana., E.; Arehart., A.R.; Ringel, S.A. Deep level defects throughout the bandgap of (010) β-Ga2O3 detected by optically and thermally stimulated defect spectroscopy. Appl. Phys. Lett. 2016, 108, 052105. [Google Scholar] [CrossRef]

- Rafique, S.; Han, L.; Zhao, H. Thermal annealing effect on β-Ga2O3 thin film solar blind photodetector heteroepitaxially grown on sapphire substrate. Phys. Status Solidi. A. 2017, 214, 8. [Google Scholar] [CrossRef]

- Wang, J.; Ye, L.; Wang, X.; Zhang, H.; Li, L.; Kong, C.; Li, W. High transmittance β-Ga2O3 thin films deposited by magnetron sputtering and post-annealing for solar-blind ultraviolet photodetector. J. Alloys Compd. 2019, 803, 9–15. [Google Scholar] [CrossRef]

- Sun, R.; Zhang, H.Y.; Wang, G.G.; Han, J.C.; Wang, X.Z.; Kuang, X.P.; Cui, L.; Jin, L.; Tia, J.L. Influence of annealing atmosphere on the structure, morphology and transmittance of N-incorporated Ga2O3 films. Superlattices Microstruct. 2013, 60, 257–262. [Google Scholar] [CrossRef]

- Trukhanov, S.V.; Lobanovski, L.S.; Bushinsky, M.V.; Khomchenko, V.A.; Pushkarev, N.V.; Troyanchuk, I.O.; Maignan, A.; Flahaut, D.; Szymczak, H.; Szymczak, R. Influence of oxygen vacancies on the magnetic and electrical properties of La1−xSrxMnO3−x/2 manganites. Eur. Phys. J. B – Condens. Matter Complex Syst. 2004, 42, 51–61. [Google Scholar] [CrossRef]

- Shang, C.; Xia, Z.C.; Zhai, X.A.; Liu, D.W.; Wang, Y.Q. Percolation like transitions in phase separated manganites La0.5Ca0.5Mn1−xAlxO3−δ. Ceram. Int. 2019, 45, 18632–18639. [Google Scholar] [CrossRef]

- Higashiwaki, M.; Sasaki, K.; Murakami, H.; Kumagai, Y.; Koukitu, A.; Kuramata, A.; Masui, T.; Yamakoshi, S. Recent progress in Ga2O3 power devices. Semicond. Sci. Technol. 2016, 31, 034001. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, Y.-J.; Schweitz, M.A.; Oh, J.-M.; Koo, S.-M. Influence of Annealing Atmosphere on the Characteristics of Ga2O3/4H-SiC n-n Heterojunction Diodes. Materials 2020, 13, 434. https://doi.org/10.3390/ma13020434

Lee Y-J, Schweitz MA, Oh J-M, Koo S-M. Influence of Annealing Atmosphere on the Characteristics of Ga2O3/4H-SiC n-n Heterojunction Diodes. Materials. 2020; 13(2):434. https://doi.org/10.3390/ma13020434

Chicago/Turabian StyleLee, Young-Jae, Michael A. Schweitz, Jong-Min Oh, and Sang-Mo Koo. 2020. "Influence of Annealing Atmosphere on the Characteristics of Ga2O3/4H-SiC n-n Heterojunction Diodes" Materials 13, no. 2: 434. https://doi.org/10.3390/ma13020434

APA StyleLee, Y.-J., Schweitz, M. A., Oh, J.-M., & Koo, S.-M. (2020). Influence of Annealing Atmosphere on the Characteristics of Ga2O3/4H-SiC n-n Heterojunction Diodes. Materials, 13(2), 434. https://doi.org/10.3390/ma13020434