Methodology for Revealing the Phases and Microstructural Constituents of the CMSX-4 Nickel-Based Superalloy Implicating Their Computer-Aided Detection for Image Analysis

Abstract

:1. Introduction

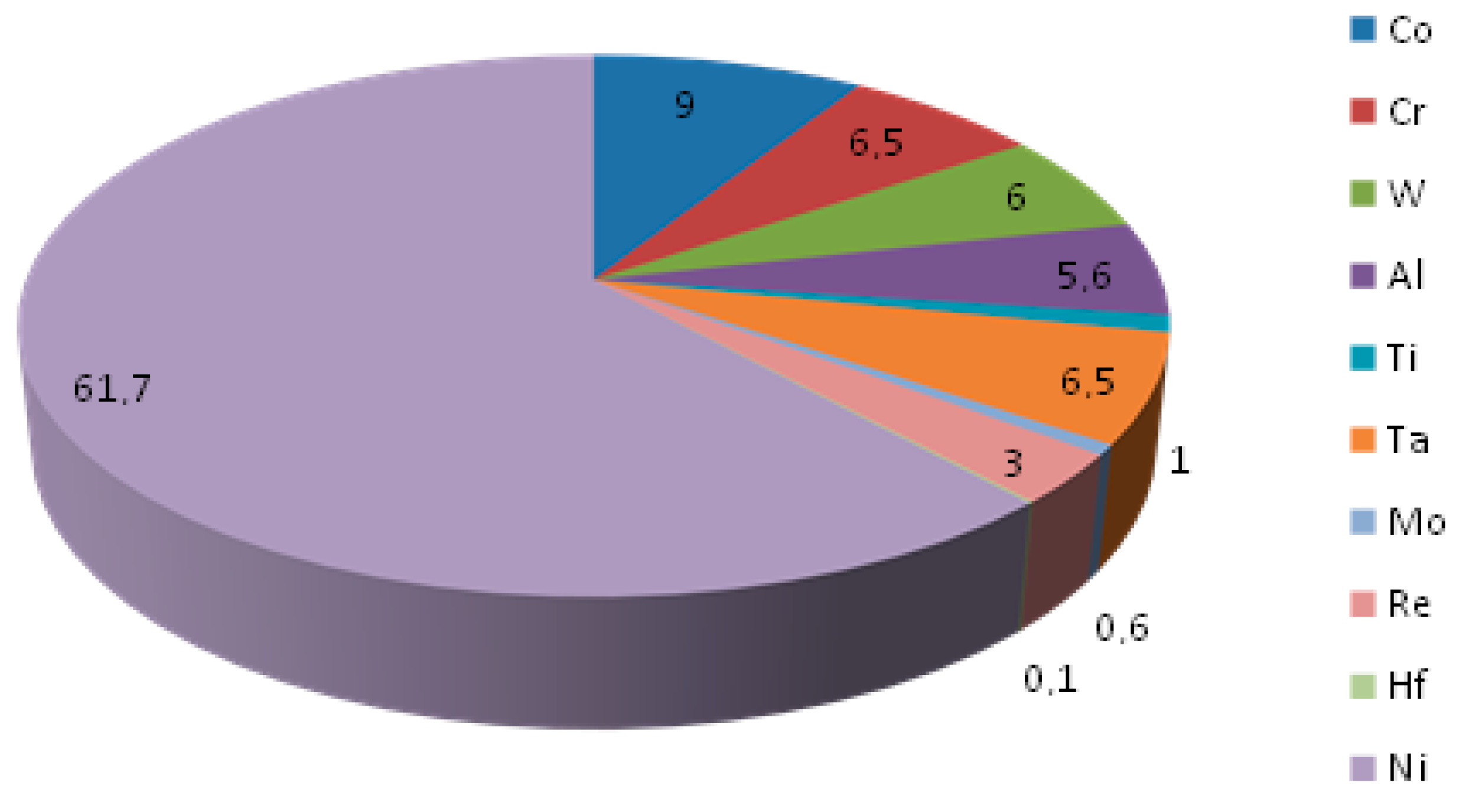

2. Materials and Methods

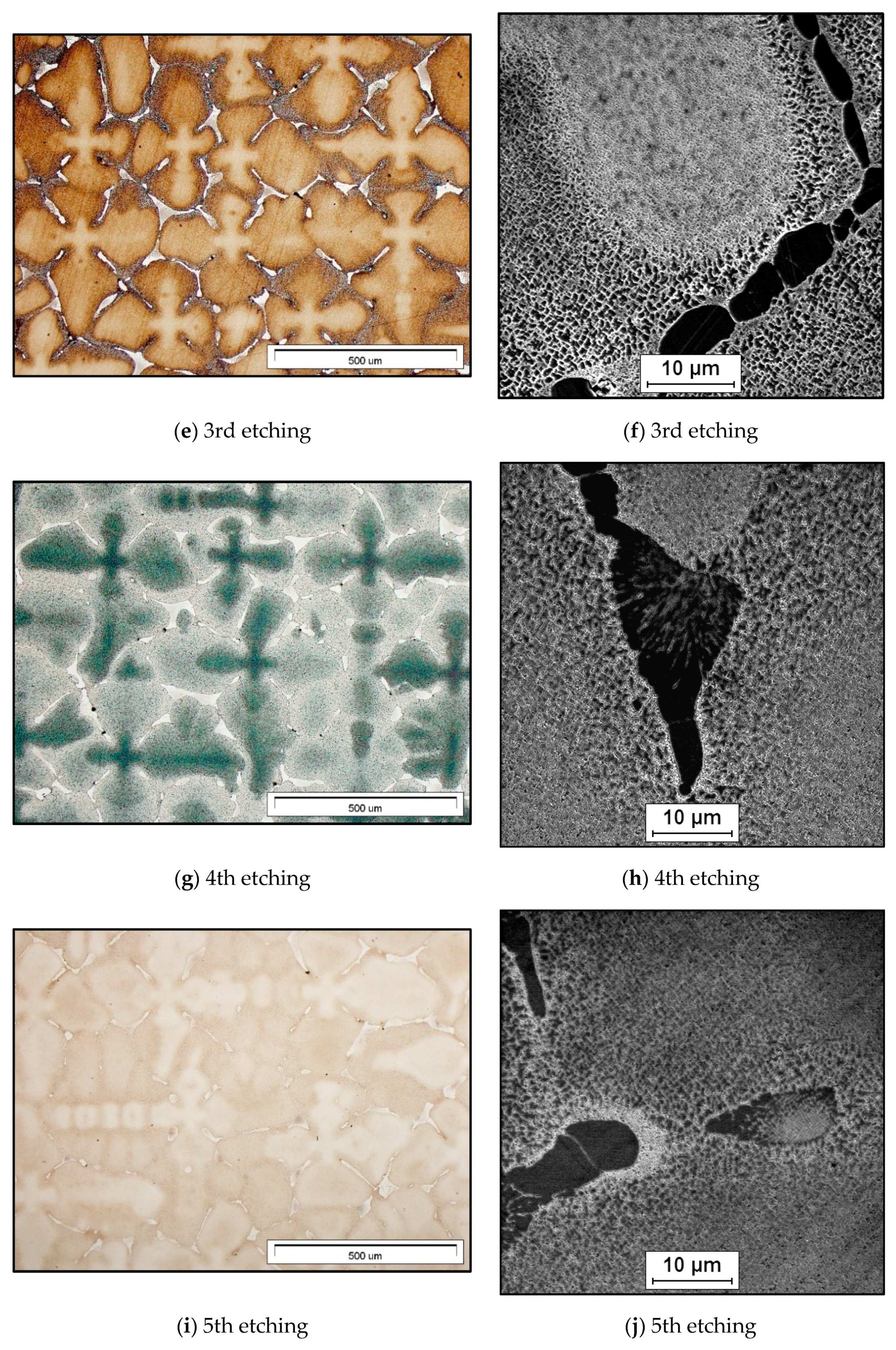

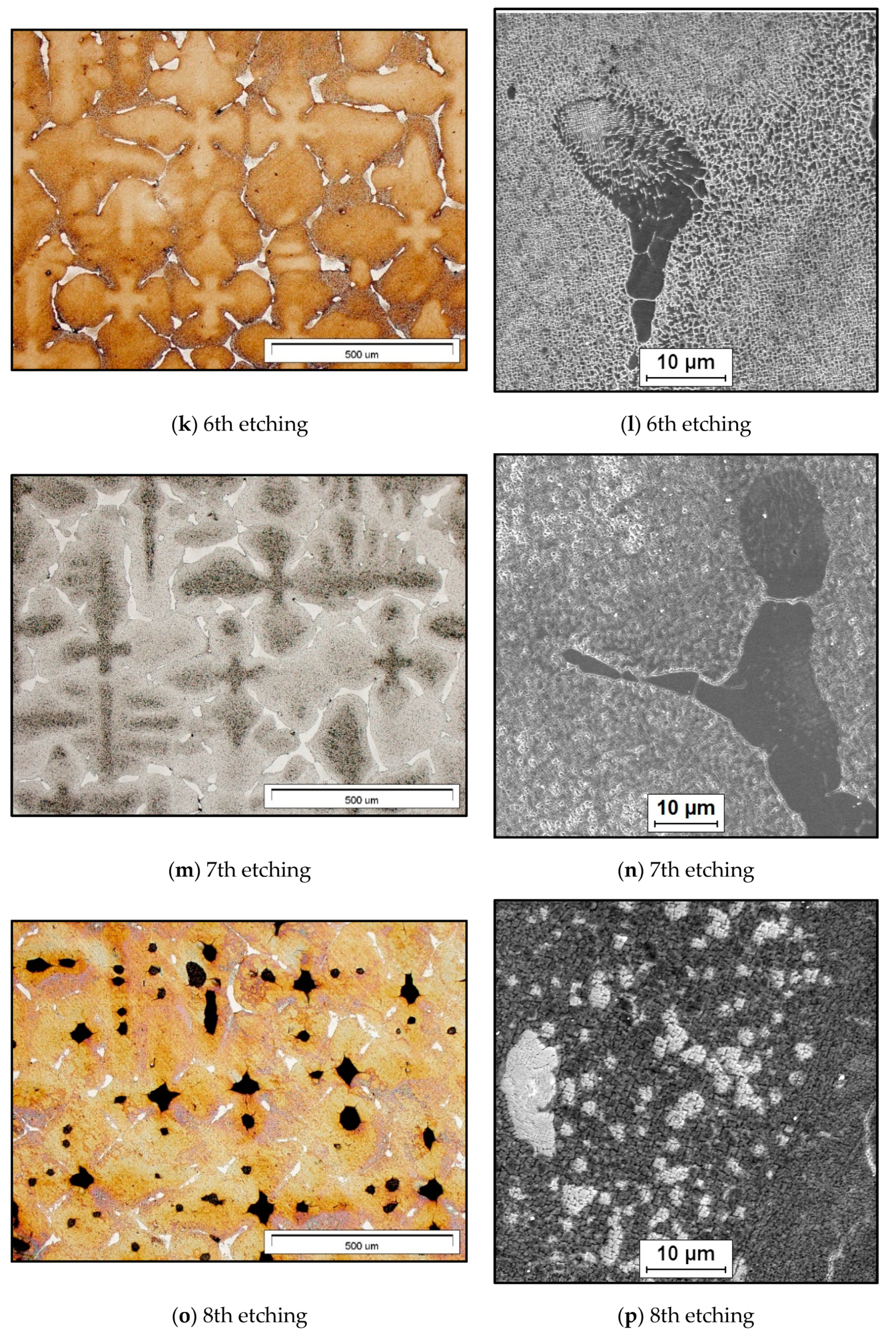

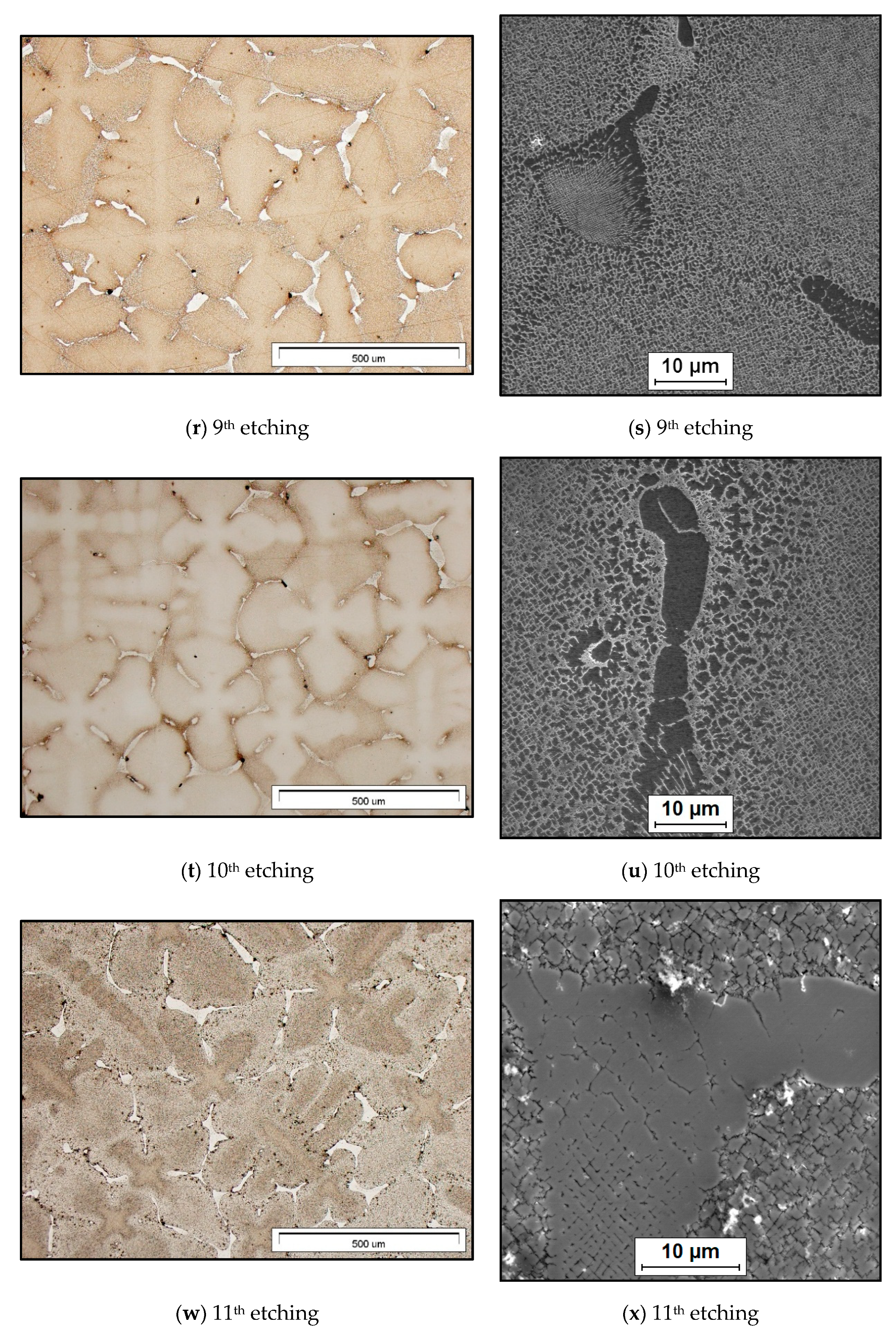

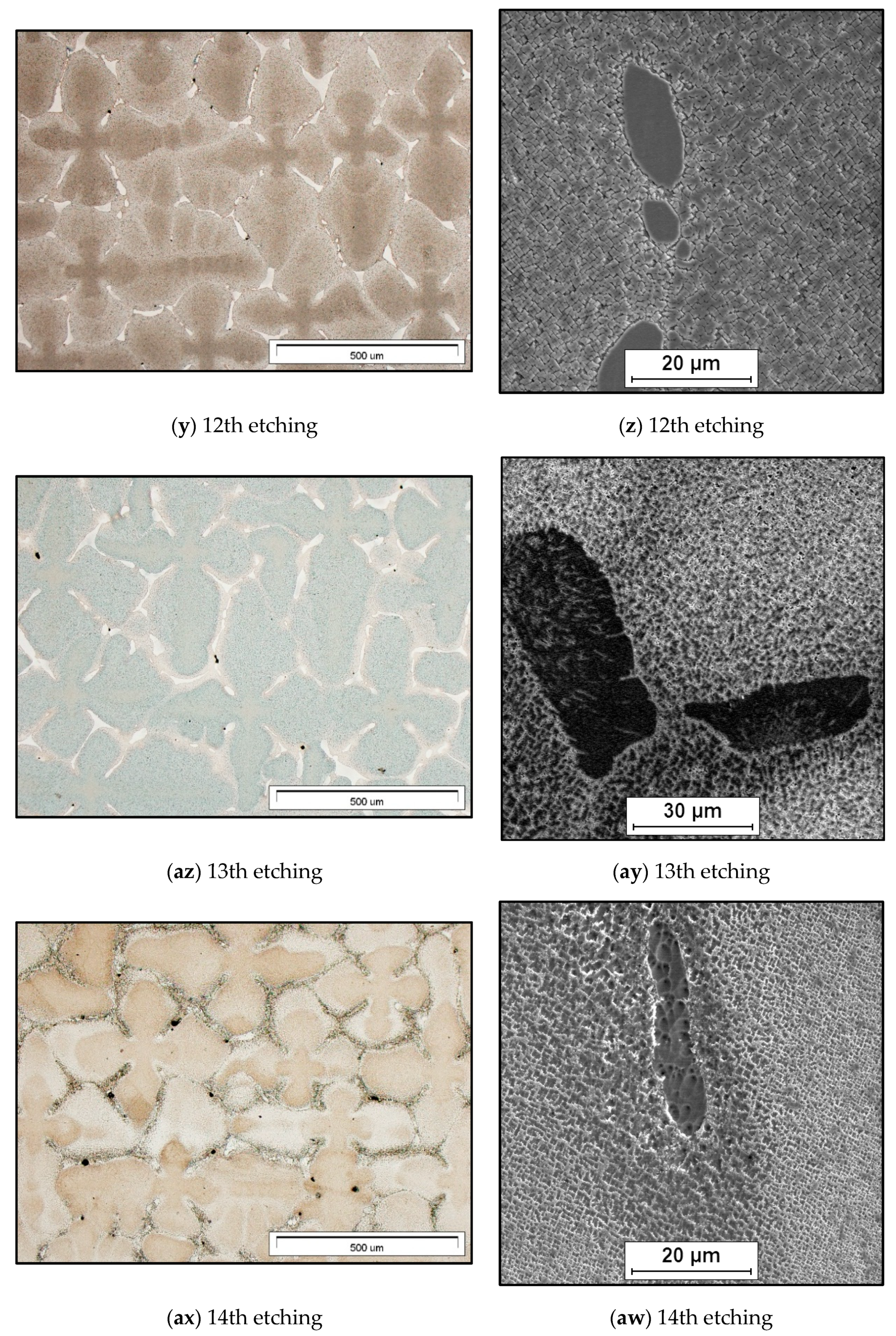

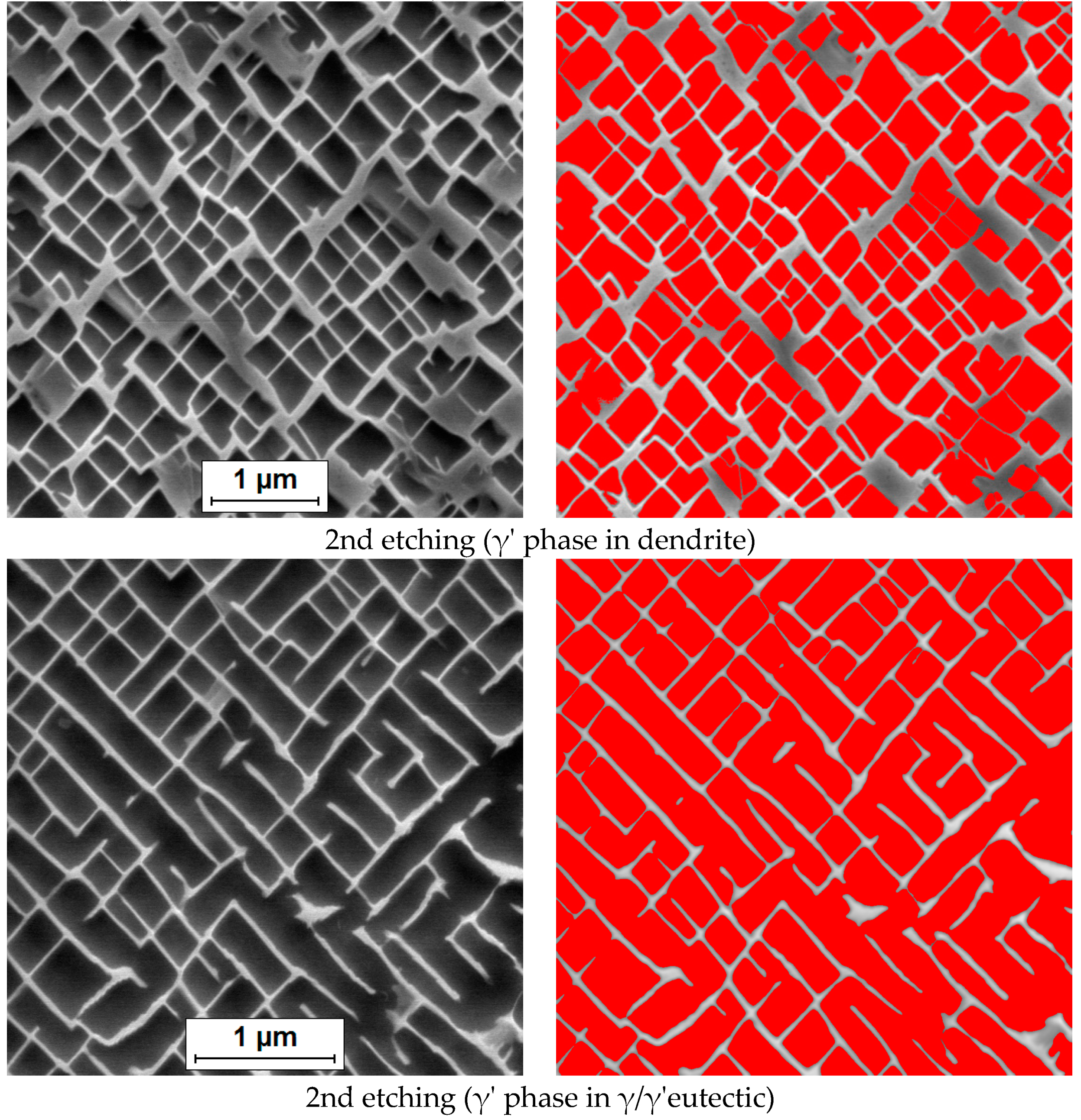

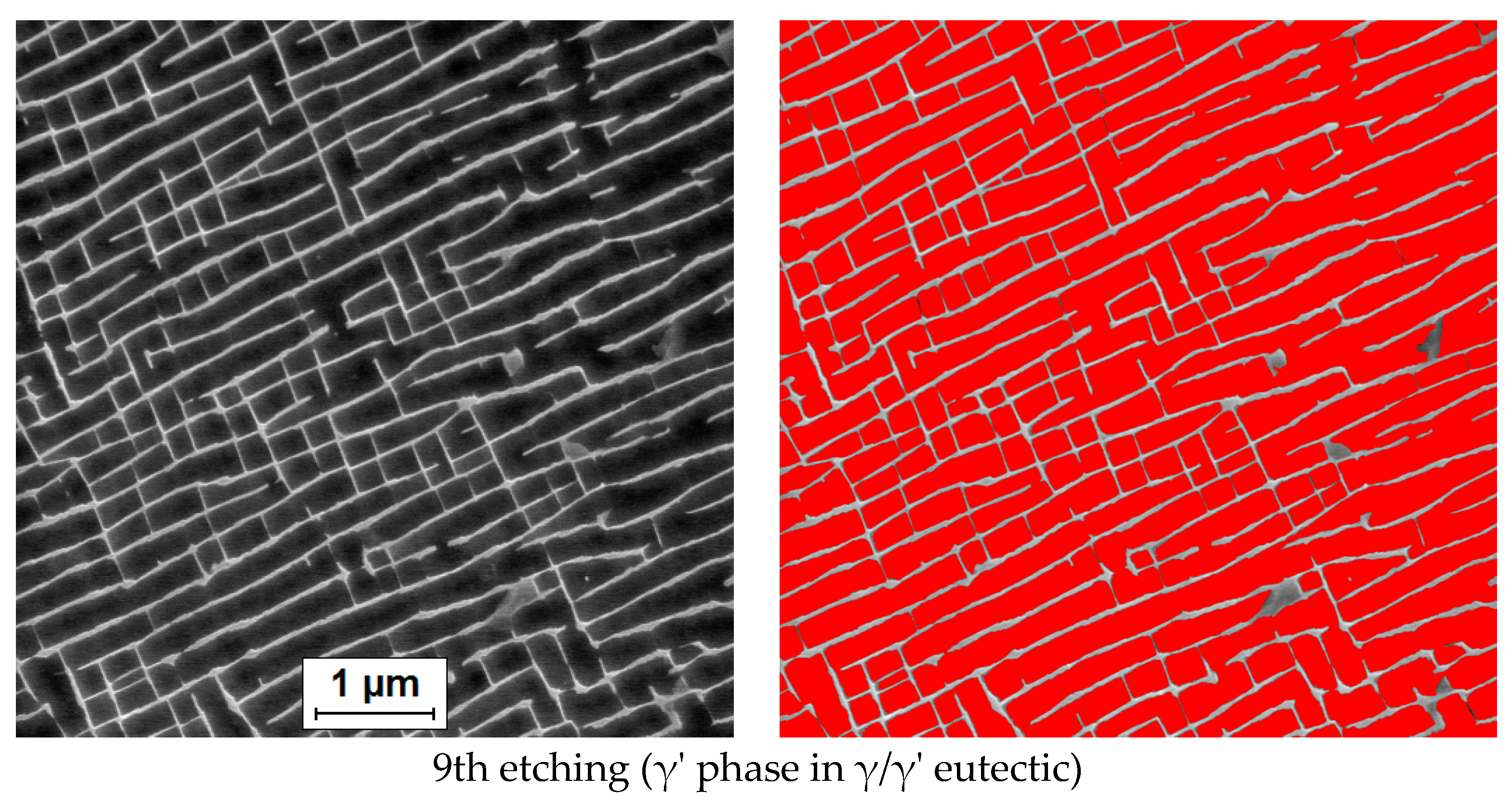

3. Results

4. Discussion

5. Conclusions

- There are difficulties in the ascertaining of the real and clear microstructure of the superalloy (especially for SEM observation), whence some skills and experience are required;

- Most of the applied etchants provided good results in optical microscopy observation, but only few contribute in the ascertaining of the real and clear microstructure of the superalloy for SEM observation;

- The effectiveness of a reagent for etching should be verified experimentally using various conditions of etching and times of etching;

- It is possible to find a reagent which is recommended for a Ni-based superalloy, but in reality, it interacts with the surface of the material too aggressively (etchants no. 8, Table 2); it is usually a good idea to start with the weakest solution;

- In the case of a mounted specimen separation between the specimen and the mounting compound, the result can be ‘bleeding’ of the residual etchant or water and subsequent staining;

- To avoid the presence of unexpected objects on the surface of the sample during observation and imaging, try to rinse the sample after etching carefully;

- If additional etching time is required (especially for SEM observation), start with 1/2 second etching;

- The sample free of scratches and any kind of embedded contaminants has contributed to the increase in the effectiveness of the etching process, as well as the observation and imaging of the microstructure;

- Comparing the results of the application of the 14 reagents, it can be seen (Figure 2) that well visible phases and microstructural constituents in the whole field of view with the use of SEM have been provided by the application of etchants no. 2, 6 and 9.

- The accurate and efficient quantitative analysis of the microstructure in superalloys by means of image analysis is a challenge;

- The etching, as well as ascertaining the real and clear microstructure of the superalloy, has played a vital role in bringing about correct and uncomplicated separation of the features of interest (the γ’ phase precipitates) in an image from the background;

- Preprocessing of the image of the microstructure of the superalloy and segmentation of the γ’ phase precipitates have been associated with difficulties because, in many cases, the etchant used to highlight the γ or the γ’ phase can etch the material at different rates within the metallographic sample, varying the contrast in intensity for the γ and γ’;

- The presented examples of a proposal of the γ’ phase precipitates segmentation (Figure 3) are a good illustration of the ability to enhance features, as well as extract information from the digital image of the microstructure;

- Image segmentation performed by hand in the case of γ’ phase precipitates would be time- and work-consuming, making its quantitative characterization very expensive. That is why the search for semi-automated or automated and simultaneously precise segmentation of the γ’ phase precipitates is so important;

Author Contributions

Funding

Conflicts of Interest

References

- Anderson Materials Evaluation, Inc. Metallography and Metallographic Microscopy. Available online: http://www.andersonmaterials.com/metal_microscopy.html (accessed on 10 December 2019).

- Deacon, R.M. Metallography, Microstructure, and Analysis: Birth of a New Journal. Metallogr. Microstruct. Anal. 2012, 1, 1–2. [Google Scholar] [CrossRef] [Green Version]

- Samuels, L.E. Metallographic Polishing by Mechanical Methods; ASM International: Materials Park, OH, USA, 2003; pp. 2–5. [Google Scholar]

- Payton, E.; Wang, G.; Ma, N.; Wang, Y.; Mills, M.; Whitis, D.; Mourer, D.; Wei, D. Integration of Simulations and Experiments for Modeling Superalloy Grain Growth. In Superalloys 2008; Reed, R.C., Green, K.A., Caron, P., Gabb, T.P., Fahrmann, M.G., Huron, E.S., Woodard, S.A., Eds.; TMS (The Minerals, Metals & Materials Society): Warrendale, PA, USA, 2008; pp. 975–984. [Google Scholar]

- Vander Voort, G.F. Metallography: Principles and Practice; McGraw-Hill: New York, NY, USA, 1984; pp. 66–172. [Google Scholar]

- Durand-Charre, M. The Microstructure of Superalloys; CRC Press: Boca Raton, FL, USA, 1997; p. 29. [Google Scholar]

- Unocic, R.R.; Kovarik, L.; Shen, C.; Sarosi, P.M.; Wang, Y.; Li, J.; Ghosh, S.; Mills, M.J. Deformation Mechanisms in Ni-Base Disk Superalloys at Higher Temperatures. In Superalloys 2008; Reed, R.C., Green, K.A., Caron, P., Gabb, T.P., Fahrmann, M.G., Huron, E.S., Woodard, S.A., Eds.; TMS (The Minerals, Metals & Materials Society): Warrendale, PA, USA. 2008; pp. 377–385. [Google Scholar]

- Escobar-Moreno, I.; Aguirre, M.V.; Andrés-López, E.M.; Viscasillas, M.J.; Barba, D. Microstructural study of nickel-based superalloys through open source software of image analysis. In Proceedings of the 8th European Conference for Aeronautics and Space Sciences (EUCASS), Madrid, Spain, 1–4 July 2019. [Google Scholar] [CrossRef]

- Payton, E.J.; Phillips, P.J.; Mills, M.J. Semi-automated characterization of the phase in Ni-based superalloys via high-resolution backscatter imaging. Mater. Sci. Eng. A 2010, 527, 2684–2692. [Google Scholar] [CrossRef]

- Giamei, A.F.; Anton, D.L. Rhenium Additions to a Ni-Base Superalloy: Effects on Microstructure. Metall. Trans. A 1985, 16, 1997–2005. [Google Scholar] [CrossRef]

- Sajjadi, S.A.; Zebarjad, S.M.; Guthrie, R.I.L.; Isac, M. Microstructure evolution of high-performance Ni-base superalloy GTD-111 with heat treatment parameters. J. Mater. Process. Technol. 2006, 175, 376–381. [Google Scholar] [CrossRef]

- Long, H.; Mao, S.; Liu, Y.; Zhang, Z.; Han, X. Microstructural and compositional design of Ni-based single crystalline superalloys—A review. J. Alloys Compd. 2018, 743, 203–220. [Google Scholar] [CrossRef]

- Nagarajan, B.; Castagne, S. Microstructure Study of Nickel-Based Superalloys after Deep Cold Rolling. Mater. Sci. Forum 2016, 879, 169–174. [Google Scholar] [CrossRef]

- Monastyrskaia, E.V.; Petrov, E.V.; Beljaev, V.E.; Dushkin, A.M. An Influence of Microstructure on The Mechanical Properties of The Corrosion Resistant Superalloy CHS88U. In Superalloys 2004; Green, K.A., Pollock, T.M., Harada, H., Howson, T.E., Reed, R.C., Schirra, J.J., Walston, S., Eds.; TMS (The Minerals, Metals & Materials Society): Warrendale, PA, USA, 2004; pp. 779–786. [Google Scholar]

- Khodabakhshi, A.; Mashreghi, A.; Shajari, Y.; Razavi, S.H. Investigation of Microstructure Properties and Quantitative Metallography by Different Etchants in the Service-Exposed Nickel-Based Superalloy Turbine Blade. Trans. Indian Inst. Met. 2018, 71, 849–859. [Google Scholar] [CrossRef]

- Salehi, R.; Samadi, A.; Savadkoohi, M.K. Influence of Etchants on Quantitative/Qualitative Evaluations of the γ’ Precipitates in a Nickel-Base Superalloy. Metallogr. Microstruct. Anal. 2012, 1, 290–296. [Google Scholar] [CrossRef]

- Ramsperger, M.; Singer, R.F.; Körner, C. Microstructure of the Nickel-Base Superalloy CMSX-4 Fabricated by Selective Electron Beam Melting. Metallur. Mater. Trans. A 2016, 47, 1469–1480. [Google Scholar] [CrossRef] [Green Version]

- CMSX-4. Available online: https://cannonmuskegon.com/cmsx-4/ (accessed on 2 January 2020).

- Dubiel, B.; Indyka, P.; Kalemba-Rec, I.; Moskalewicz, T. Analytical Electron Microscopy Studies of the CMSX–4 Single Crystal Superalloy Subjected to High Temperature Annealing. Acta Phys. Pol. A 2017, 131, 1375–1378. [Google Scholar] [CrossRef]

- Szczotok, A.; Przeliorz, R. Phase transformations in CMSX-4 nickel-base superalloy. IOP Conf. Ser. Mater. Sci. Eng. 2012, 35, 012005. [Google Scholar] [CrossRef] [Green Version]

- Kruk, A.; Dubiel, B.; Czyrska-Filemonowicz, A. Examination of chemical elements partitioning between the γ and γ’ phases in CMSX-4 superalloy using EDS microanalysis and electron tomography. MATEC Web Conf. 2014, 14, 11004. [Google Scholar] [CrossRef]

- ASTM. ASTM Specification E-407-99 “Standard Practice for Microetching Metals and Alloys”; ASTM: West Conshohocken, PA, USA, 1999. [Google Scholar]

- Etchants for Nickel and Alloys. Available online: http://www.steeldata.info/etch/demo/list/ni.html (accessed on 2 January 2020).

- Da Silva, E.A.B.; Mendonça, G.V. Digital Image Processing. In The Electrical Engineering Handbook; Academic Press: Cambridge, MA, USA, 2005; pp. 891–910. [Google Scholar]

- Szala, J. MetIlo Image Analyzer Ver 13; Silesian University of Technology: Katowice, Poland, 2016. [Google Scholar]

- Gonzalez, C.R.; Woods, R. Digital Image Processing; RearsonEduc.: Prentice Hall, NJ, USA, 2002; pp. 634–636. [Google Scholar]

- Soille, P. Morphological Image Analysis: Principle and Applications; Springer: Berlin/Heidelberg, Germany, 2013; pp. 268–269. [Google Scholar]

- Sharghi-Moshatghin, R.; Asgari, S. The effect of thermal exposure on the γ′ characteristics in a Ni-base superalloy. J. Alloys Compd. 2004, 368, 144–151. [Google Scholar] [CrossRef]

- Safari, J.; Nategh, S.; McLean, M. Evolution of microstructure of nickel base superalloy at high temperatures. Mater. Sci. Technol. 2006, 22, 888–898. [Google Scholar] [CrossRef]

- Jackson, M.; Reed, R. Heat treatment of UDIMET 720Li: The effect of microstructure on properties. Mater. Sci. Eng. A 1999, 259, 85–97. [Google Scholar] [CrossRef]

| Stages | Surface | Abrasive/Size | Load (N)/Specimen | Base Speed (rpm)/Direction | Time (Min) |

|---|---|---|---|---|---|

| Stage 1 | Carbimet disc | P180 grit SiC, water cooled | 25 | 350/complementary direction (platen and specimen holder both rotate in the same direction) | Until plane surface |

| Stage 2 | Carbimet disc | P320 grit SiC, water cooled | 25 | 350/complementary direction | 1/2 |

| Stage 3 | Carbimet disc | P600 grit SiC, water cooled | 25 | 350/complementary direction | 1/2 |

| Stage 4 | Ultra-Pol cloth | 9-μm Metadi Supreme–diamond suspension | 25 | 150/opposite direction (platen and specimen holder rotate in opposite direction) | 4 |

| Stage 5 | Trident cloth | 1-μm Metadi Supreme–diamond suspension | 20 | 150/opposite direction | 4 |

| Stage 6 | Chemomet pads | Masterprep 0.05-μm alumina suspension | 20 | 150/opposite direction | 1 |

| Stage 7 | Microcloth | Masterprep 0.05-μm alumina suspension | - | Vibratory polishing | 60 |

| Etchant | Composition | Notes |

|---|---|---|

| 1 | 45 gm FeCl3, 9 gm Cl4CuH8N2, 150 mL HCl, 75 mL distilled H2O | chemical/immerse |

| 2 | 50 mL distilled H2O, 50 mL C2H6O, 50 mL HCl, 10 g CuSO4 | chemical/immerse |

| 3 | 5 mL H2SO4, 3 mL HNO3, 90 mL HCl | chemical/immerse |

| 4 | 10 mL H3PO4, 50 mL H2SO4, 40 mL HNO3 | electrolytic |

| 5 | 5 mL H2SO4, 8g CrO3, 85ml H3PO4 | electrolytic |

| 6 | 20 mL HNO3, 60 mL HCl | chemical/immerse |

| 7 | 5 g FeCl, 2 mL HCl, 100 mL C2H6O 95%, 100 mL CH3OH 95% | chemical/immerse |

| 8 | 10 g C2H2O4, 100 mL distilled H2O | electrolytic |

| 9 | 10 mL HNO3, 50 mL HCl, 60 mL glycerine | chemical/immerse |

| 10 | 50 mL HCl, 50 mL C2H6O 95%, 50 mL CH3OH 95% | chemical/immerse |

| 11 | 1 g CH4N2S, 1 mL H3PO4, 1 l distilled H2O | electrolytic |

| 12 | 2/10 g CrO3, 100 mL distilled H2O | electrolytic |

| 13 | A) 2 g CrO3, 100 mL distilled water | electrolytic chemical/immerse |

| 14 | B) 4 g NaOH, 10 g KMnO4, 85 mL distilled water 100 mL HCl, 0.5 mL H2O2 (30%) | chemical/immerse |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szczotok, A.; Reichel, H. Methodology for Revealing the Phases and Microstructural Constituents of the CMSX-4 Nickel-Based Superalloy Implicating Their Computer-Aided Detection for Image Analysis. Materials 2020, 13, 341. https://doi.org/10.3390/ma13020341

Szczotok A, Reichel H. Methodology for Revealing the Phases and Microstructural Constituents of the CMSX-4 Nickel-Based Superalloy Implicating Their Computer-Aided Detection for Image Analysis. Materials. 2020; 13(2):341. https://doi.org/10.3390/ma13020341

Chicago/Turabian StyleSzczotok, Agnieszka, and Hannah Reichel. 2020. "Methodology for Revealing the Phases and Microstructural Constituents of the CMSX-4 Nickel-Based Superalloy Implicating Their Computer-Aided Detection for Image Analysis" Materials 13, no. 2: 341. https://doi.org/10.3390/ma13020341

APA StyleSzczotok, A., & Reichel, H. (2020). Methodology for Revealing the Phases and Microstructural Constituents of the CMSX-4 Nickel-Based Superalloy Implicating Their Computer-Aided Detection for Image Analysis. Materials, 13(2), 341. https://doi.org/10.3390/ma13020341