Tribological Characteristic of a Ring Seal with Graphite Filler

Abstract

1. Introduction

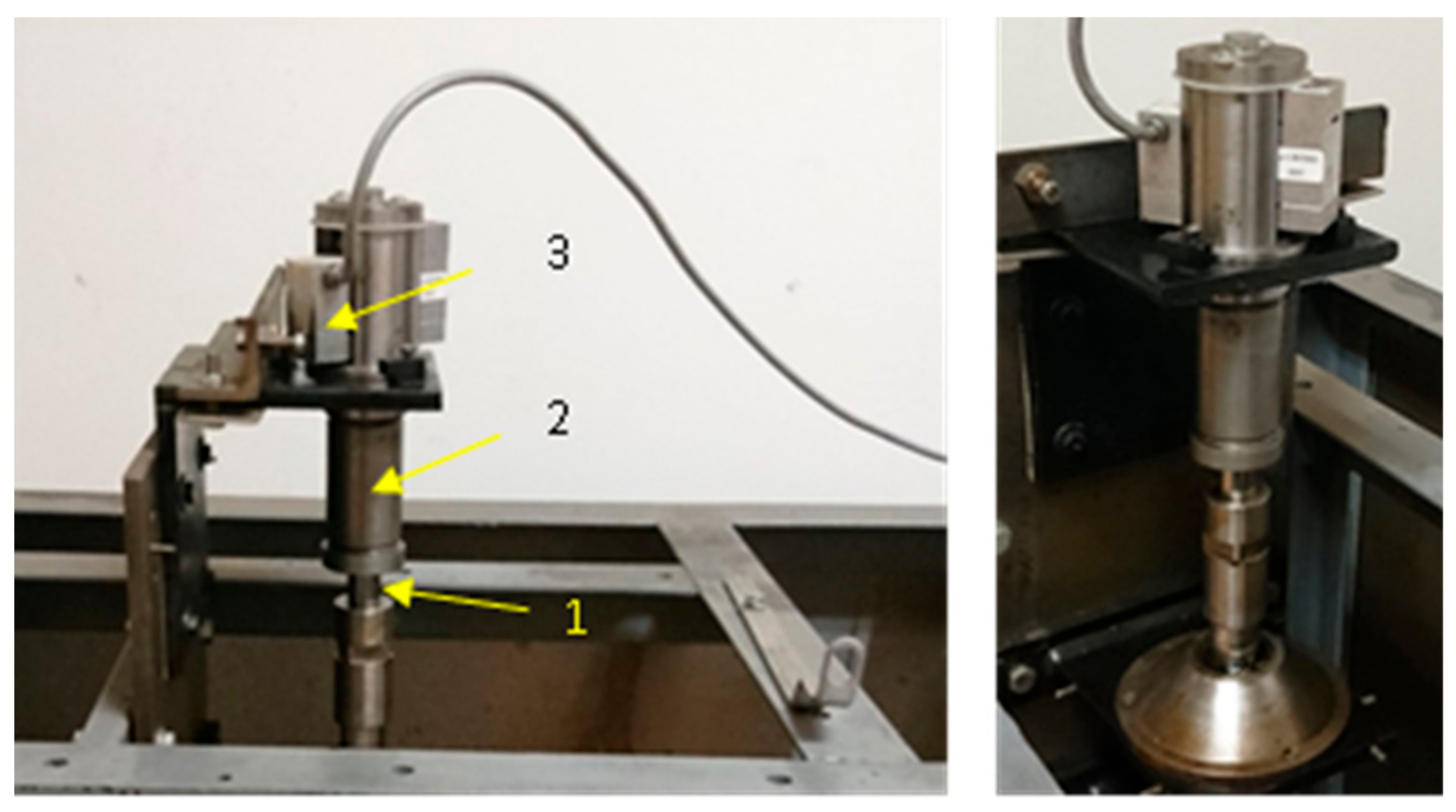

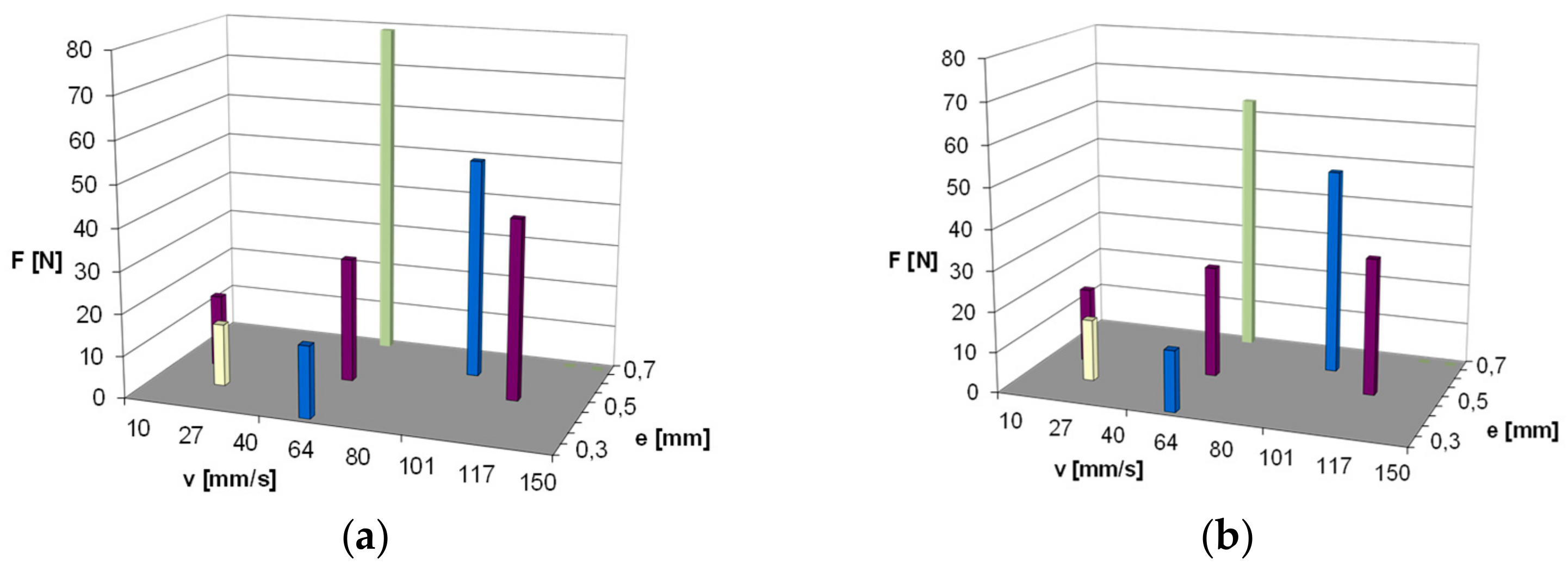

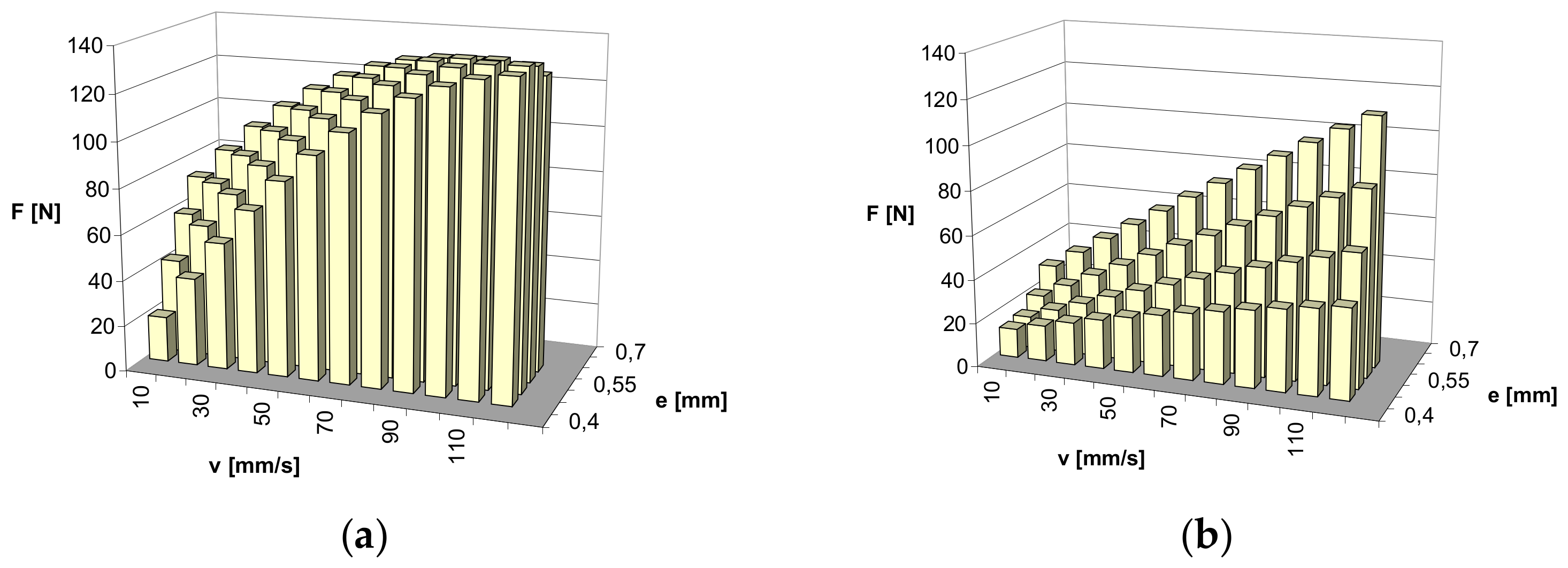

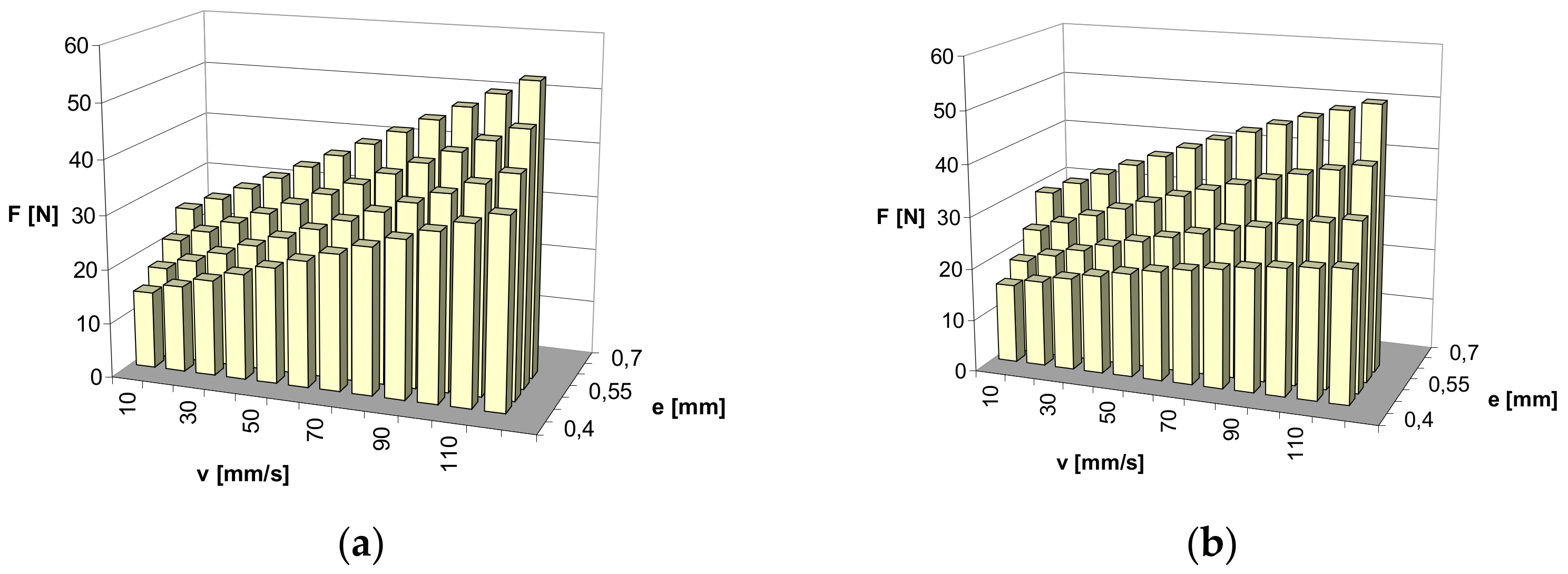

2. Materials and Methods

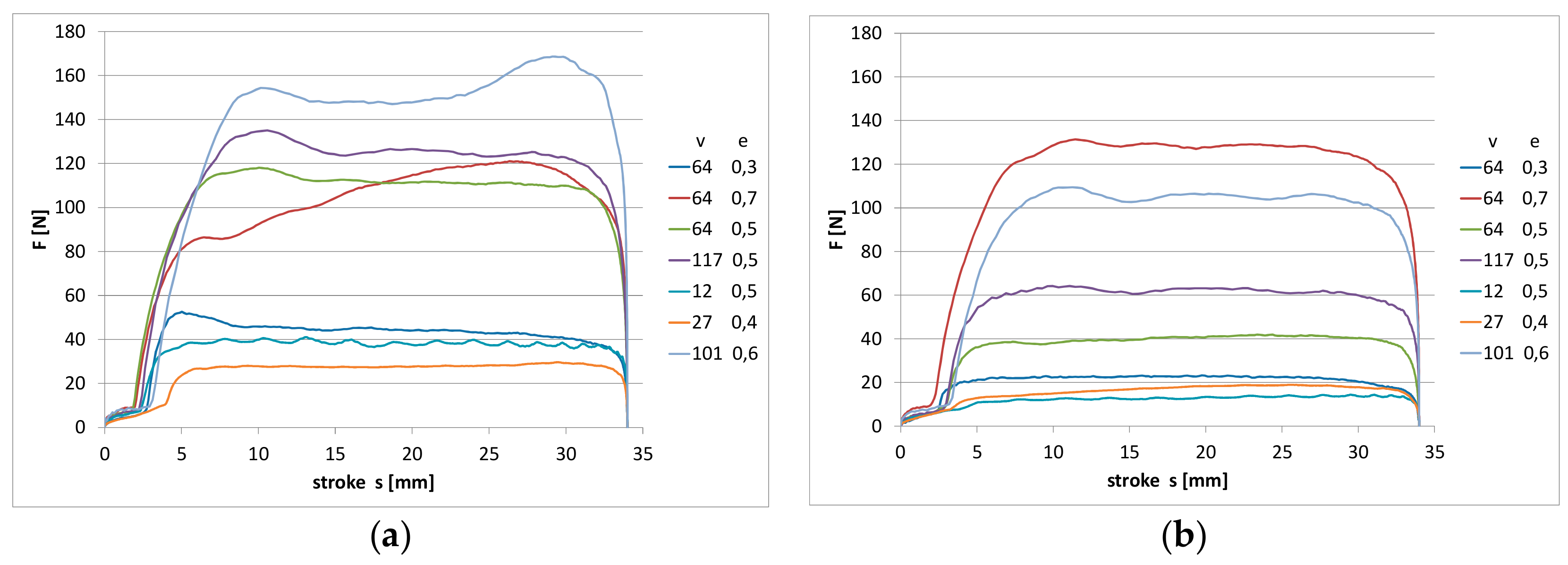

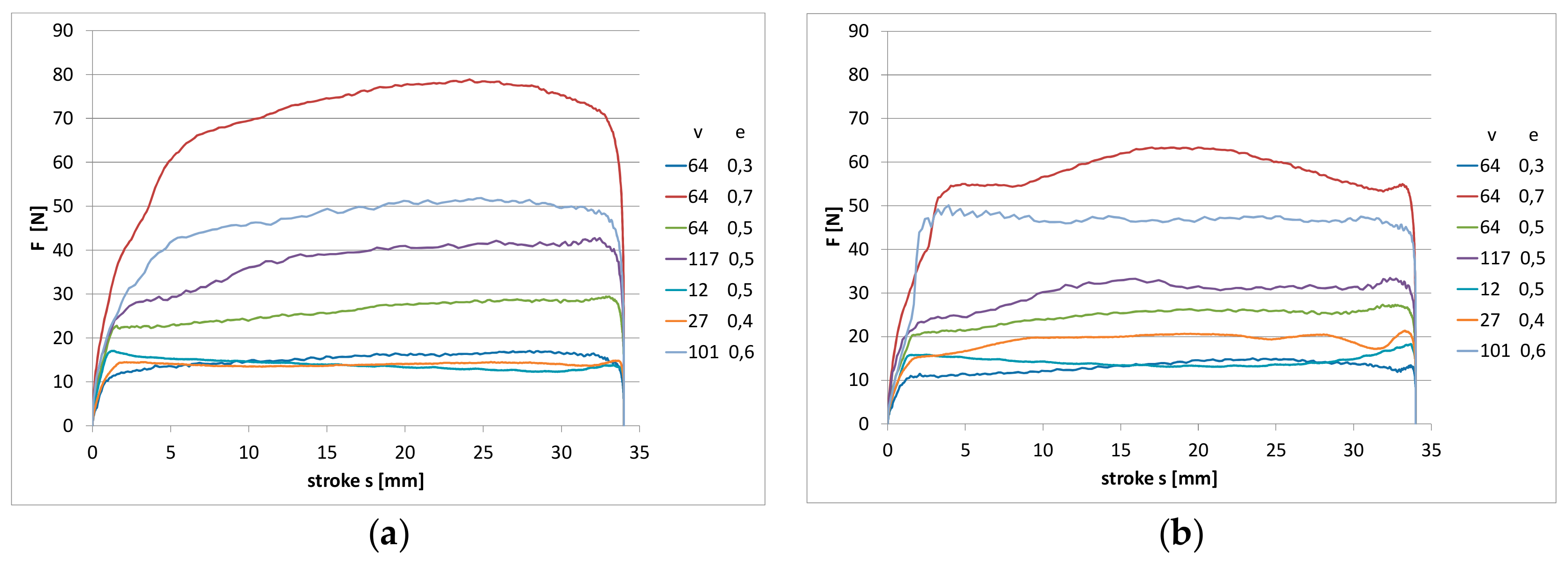

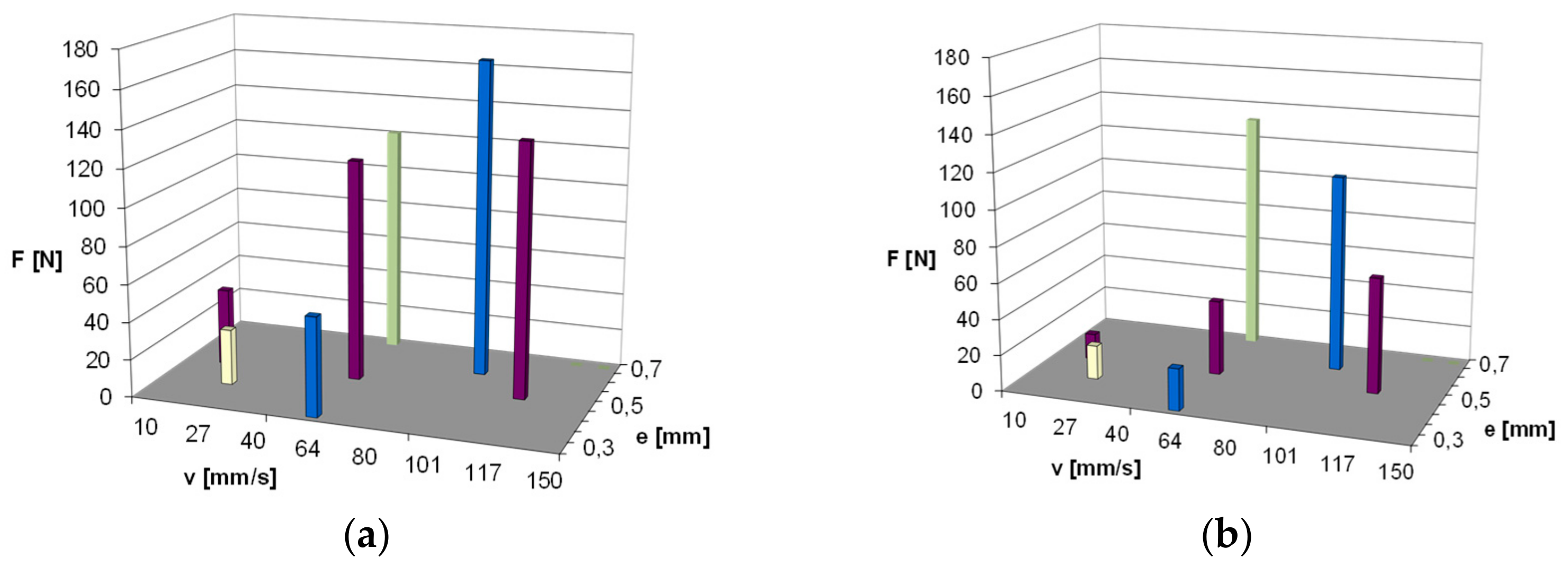

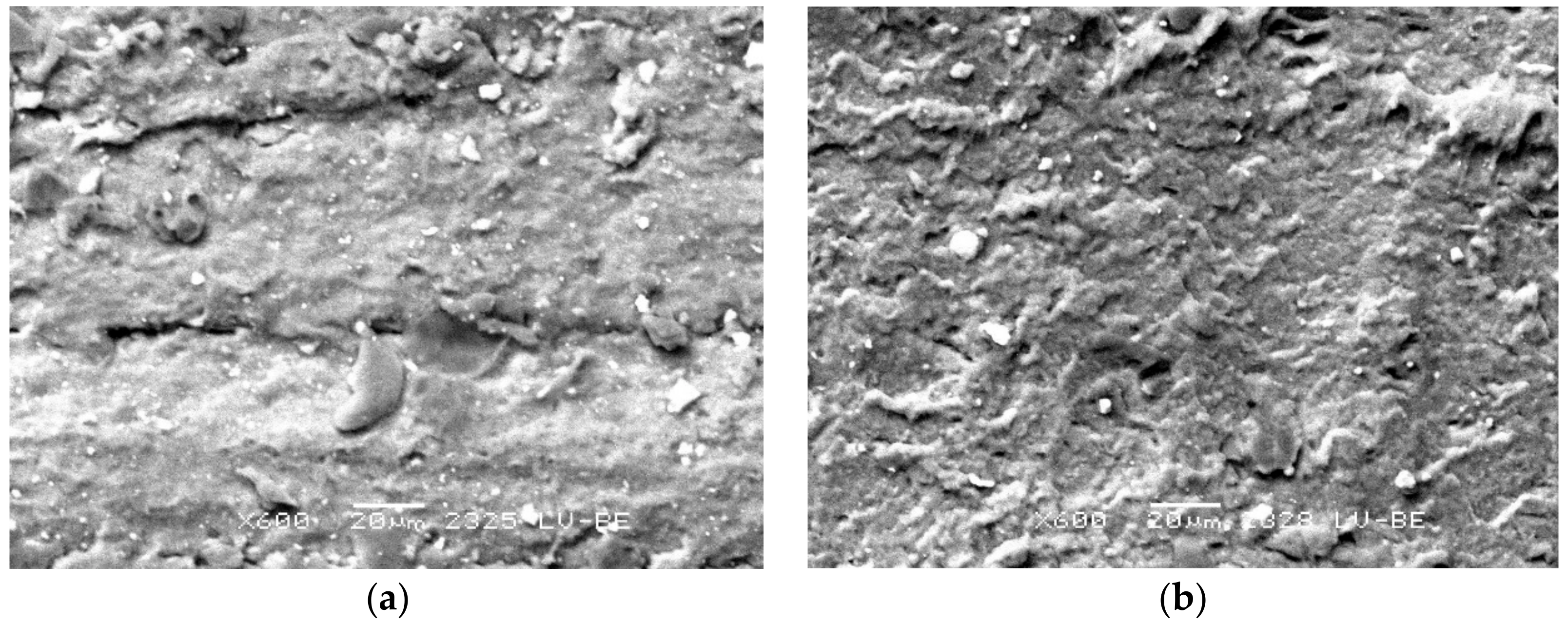

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhou, C.; Zheng, J.; Gu, C.; Zhao, Y.; Liu, P. Sealing performance analysis of rubber O-ring in high-pressure gaseous hydrogen based on finite element method. Int. J. Hydrogen Energy 2017, 42, 11996–12004. [Google Scholar] [CrossRef]

- Liu, J.; Li, X.; Xu, L.; Zhang, P. Investigation of aging behavior and mechanism of nitrile-butadiene rubber (NBR) in the accelerated thermal aging environment. Polym. Test. 2016, 54, 59–66. [Google Scholar] [CrossRef]

- Choi, S.-S.; Kim, J.-C. Lifetime prediction and thermal aging behaviors of SBR and NBR composites using crosslink density changes. J. Ind. Eng. Chem. 2012, 18, 1166–1170. [Google Scholar] [CrossRef]

- Choi, S.S.; Ha, S.H. Water swelling behaviors of silica-reinforced NBR composites in deionized water and salt solution. J. Ind. Eng. Chem. 2010, 16, 238–242. [Google Scholar] [CrossRef]

- Cao, Z.; Wang, D.; Cong, C.; Wang, Y.; Zhou, Q. Dependence of abrasion behavior on cross-linked heterogeneity in unfilled nitrile rubber. Tribol. Int. 2014, 69, 141–149. [Google Scholar] [CrossRef]

- Shit, S.C.; Shah, P. A Review on Silicone Rubber. Natl. Acad. Sci. Lett. USA 2013, 36, 355–365. [Google Scholar] [CrossRef]

- Kömmling, A.; Jaunich, M.; Pourmand, P.; Wolff, D.; Hedenqvist, M. Analysis of O-Ring Seal Failure under Static Conditions and Determination of End-of-Lifetime Criterion. Polymers 2019, 11, 1251. [Google Scholar] [CrossRef]

- Balasooriya, W.; Schrittesser, B.; Pinter, G.; Schwarz, T.; Conzatti, L. The Effect of the Surface Area of Carbon Black Grades on HNBR in Harsh Environments. Polymers 2019, 11, 61. [Google Scholar] [CrossRef]

- Shen, M.X.; Dong, F.; Zhang, Z.X.; Meng, X.K.; Peng, X.D. Effect of abrasive size on friction and wear characteristics of nitrile butadiene rubber (NBR) in two-body abrasion. Tribol. Int. 2016, 103, 1–11. [Google Scholar] [CrossRef]

- Guo, Y.; Wang, J.; Li, K.; Ding, X. Tribological properties and morphology of bimodal elastomeric nitrile butadiene rubber networks. Mater. Des. 2013, 52, 861–869. [Google Scholar] [CrossRef]

- Woo, C.S.; Kim, W.D.; Kim, J.D. A study on the material properties and fatigue life prediction of natural rubber component. Mater. Sci. Eng. 2008, 483, 376–381. [Google Scholar] [CrossRef]

- Fang, Y.F.; Xiong, J.B.; Tee, K.F. Time-variant structural fuzzy reliability analysis under stochastic loads applied several times. Struct. Eng. Mech. 2015, 3, 525–534. [Google Scholar] [CrossRef]

- Zuo, Z.G.; Liu, S.H.; Fan, Y.Z.; Wu, Y.L. Optimization of a centrifugal boiler circulating pump’s casing based on CFD and FEM analyses. Adv. Mech. Eng. 2014, 6, 1–10. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, G.; Xia, P.; Li, H.P.; He, M. Finite element analysis and experimental study on contact pressure of hydraulic support bud-shaped composite sealing ring. Adv. Mech. Eng. 2016, 10, 1–9. [Google Scholar] [CrossRef]

- Liao, B.; Sun, B.; Yan, M.; Ren, Y.; Zhang, W.; Zhou, K. Time-variant reliability analysis for rubber O-ring seal considering both material degradation and random load. Materials 2017, 10, 1211. [Google Scholar] [CrossRef]

- Zhou, W.Y.; Yu, D.M.; Wang, C.F.; An, Q.L.; Qi, S.H. Effect of Filler Size Distribution on the Mechanical and Physical Properties of Alumina-filled Silicone Rubber. Polym. Eng. Sci. 2008, 48, 1381–1388. [Google Scholar] [CrossRef]

- Imiela, M.; Anyszka, R.; Bieliński, D.M.; Masłowski, M.; Pędzich, Z.; Ziąbka, M.; Rybiński, P.; Syrek, B. Effect of graphite and common rubber plasticizers on properties and performance of ceramizable styrene–butadiene rubber-based composites. J. Therm. Anal. Calorim. 2019, 138, 2409–2417. [Google Scholar] [CrossRef]

- Likozar, B.; Major, Z. Morphology, mechanical, cross-linking, thermal, and tribological properties of nitrile and hydrogenated nitrile rubber/multi-walled carbon nanotubes composites prepared by melt compounding: The effect of acrylonitrile content and hydrogenation. Appl. Surf. Sci. 2010, 257, 565. [Google Scholar] [CrossRef]

- Zhang, S.W. Recent developments of green tribology. Surf. Topogr. Metrol. Prop. 2016, 4. [Google Scholar] [CrossRef]

- Guan, Y.; Zhang, L.X.; Zhang, L.Q.; Lu, Y.L. Study on ablative properties and mechanisms of hydrogenated nitrile butadiene rubber (HNBR) composites containing different fillers. Polym. Degrad. Stab. 2011, 96, 808. [Google Scholar] [CrossRef]

- Xu, D.; Karger-Kocsis, J.; Major, Z.; Thomann, R. Unlubricated rolling wear of HNBR/FKM/MWCNT compounds against steel. J. Appl. Polym. Sci. 2009, 112, 1461. [Google Scholar] [CrossRef]

- Pandey, K.N.; Setua, D.K.; Mathur, G.N. Material behavior Fracture topography of rubber surfaces: An SEM study. Polym. Test. 2003, 22, 353–359. [Google Scholar] [CrossRef]

- Delebecq, E.; Hamdani-Devarennes, S.; Raeke, J.; Lopez Cuesta, J.-M.; Ganachaud, F. High residue contents indebted by platinum and silica synergistic action during the pyrolysis of silicone formulations. ACS Appl. Mater. Interfaces 2011, 3, 869. [Google Scholar] [CrossRef] [PubMed]

- Feipeng, L.; Lihong, C.; Qiuying, L.; Ting, W.; Xinyuan, G.; Weihong, G. The combination of glass dust and glass fiber as fluxing agents for ceramifiable silicone rubber composites. RSC Adv. 2017, 7, 38805. [Google Scholar]

- Feipeng, L.; Wei, Y.; Weihong, G.; Ting, W.; Quiying, L. Preparation and properties of ceramifiable flame-retarded silicone rubber composites. J. Therm. Anal. Calorim. 2017, 130, 813. [Google Scholar]

- Xin-Hao, G.; Tao-Yuan, W.; Jie, M.; Dong, Z.; Yu-Cai, S.; Ting-Wei, W. Improved self-supporting property of ceramifying silicone rubber composites by forming crystalline phase at high temperatures. J. Alloys Compd. 2017, 706, 322. [Google Scholar]

- Bieliński, D.M.; Anyszka, R.; Pędzich, Z.; Dul, J. Ceramizable silicone rubber-based composites. Int. J. Adv. Mater. Manuf. Charact. 2012, 1, 17. [Google Scholar]

- Anyszka, R.; Bieliński, D.M.; Pędzich, Z.; Rybiński, P.; Imiela, M.; Siciński, M.; Zarzecka-Napierała, M.; Gozdek, T.; Rutkowski, P. Thermal stability and flammability of styrene-butadiene rubber-based (SBR) ceramifiable composites. Materials 2016, 9, 604. [Google Scholar] [CrossRef]

- Imiela, M.; Anyszka, R.; Bieliński, D.M.; Lipińska, M.; Rybiński, P.; Syrek, B. Synergistic effect of mica, glass frit, and melamine cyanurate for improving fire resistance of styrene-butadiene rubber composites destined for ceramizable coatings. Coatings 2019, 9, 170. [Google Scholar] [CrossRef]

- Anyszka, R.; Bieliński, D.M.; Pędzich, Z.; Zarzecka-Napierała, M.; Imiela, M.; Rybiński, P. Processing and properties of fire resistant EPDM rubber-based ceramifiable composites. High Temp. Mater. Process. 2017, 36, 963. [Google Scholar] [CrossRef]

- Zou, Z.; Qin, Y.; Liu, L.; Huang, Z. Effect of the flux on the fire-resistance properties of cerami-fiable EPDM rubber composites. Adv. Compos. Lett. 2018, 27, 89. [Google Scholar] [CrossRef]

- Rybiński, P.; Syrek, B.; Bradło, D.; Żukowski, W.; Anyszka, R.; Imiela, M. Influence of cenospheric fillers on the thermal properties, ceramisation and flammability of nitrile rubber composites. J. Compos. Mater. 2018, 52, 2815. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, F.; Dai, J.; Huang, Z. Effect of Functionalization of Graphene Nanoplatelets on the Mechanical and Thermal Properties of Silicone Rubber Composites. Materials 2016, 9, 92. [Google Scholar] [CrossRef] [PubMed]

- Qiu, X.; Cai, H.; Fang, X.; Zheng, J. The Improved Thermal Oxidative Stability of Silicone Rubber by Incorporating Reduced Graphene Oxide; Impact Factors and Action Mechanism. Polym. Compos. 2018, 39, 1105–1115. [Google Scholar] [CrossRef]

- Wang, Y.; Qiu, X.; Zheng, J. Effect of the Sheet Size on the Thermal Stability of Silicone Rubber-Reduced Graphene Oxide Nanocomposites. J. Appl. Polym. Sci. 2019, 136, 47034. [Google Scholar] [CrossRef]

- Chen, B.; Ma, N.; Bai, X.; Zhang, H.; Zhang, Y. Effects of graphene oxide on surface energy, mechanical, damping and thermal properties of ethylene-propylene-diene rubber/petroleum resin blends. RSC Adv. 2012, 2, 4683–4689. [Google Scholar] [CrossRef]

- Chwał, M.; Muc, A. Design of Reinforcement in Nano- and Microcomposites. Materials 2019, 12, 1474. [Google Scholar] [CrossRef]

- Muc, A. Design and identification methods of effective mechanical properties for carbon nanotubes. Mater. Des. 2010, 31, 1671–1675. [Google Scholar] [CrossRef]

- Lee, J.Y.; Kumar, V.; Tang, X.W.; Lee, D.J. Mechanical and electrical behavior of rubber nanocomposites under static and cyclic strain. Compos. Sci. Technol. 2017, 142, 1–9. [Google Scholar] [CrossRef]

- Huang, R.H.; Zhang, X.; Tao, W. Study on aging of material for GIS sealing ring. In Proceedings of the TENCON 2015—2015 IEEE Region 10 Conference, Macao, China, 1–4 November 2015; IEEE Asia-Pacific Limited: Singapore, 2015; pp. 1–4. [Google Scholar]

- Marco, Y.; Huneau, B.; Masquelier, I.; Saux, V.L.; Charrier, P. Prediction of fatigue properties of natural rubber based on the descriptions of the cracks population and of the dissipated energy. Polym. Test. 2017, 59, 67–74. [Google Scholar] [CrossRef]

- Lv, X.; Wang, S.; Huo, X. The effect of water content in crude oil on the tribological behavior of screw pump’s stator rubber. Chin. Sci. Bull. 2014, 59, 2868–2874. [Google Scholar] [CrossRef]

- Liang, B.; Yang, X.; Wang, Z.; Su, X.; Liao, B.; Ren, Y.; Sun, B. Influence of Randomness in Rubber Materials Parameters on the Reliability of Rubber O-Ring Seal. Materials 2019, 12, 1566. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.W.; Liu, H.C.; He, R.Y. Mechanisms of wear of steel by natural rubber in water medium. Wear 2004, 256, 226–232. [Google Scholar] [CrossRef]

- Yasmin, A.; Luo, J.J.; Daniel, M.I. Processing of expanded graphite reinforced polymer nanocomposites. Compos. Sci. Technol. 2006, 66, 1182. [Google Scholar] [CrossRef]

- Stankovich, S.; Dikin, D.A.; Piner, R.D.; Kohlhaas, K.A.; Kleinhammes, A.; Jia, Y.; Wu, Y.; Nguyen, S.T.; Ruoff, R.S. Synthesis of graphene-based nanosheets via chemical reduction of exfoliated graphite oxide. Carbon 2007, 45, 1558. [Google Scholar] [CrossRef]

- Song, S.H.; Jeong, H.K.; Kang, Y.G.; Cho, C.T. Physical and thermal properties of acid-graphite/styrene-butadiene-rubber nanocomposites. Korean J. Chem. Eng. 2010, 27, 1296. [Google Scholar] [CrossRef]

- Gatos, K.G.; Karger-Kocsis, J. Effect of the aspect ratio of silicate platelets on the mechanical and barrier properties of hydrogenated acrylonitrile butadiene rubber (HNBR)/layered silicate nanocomposites. Eur. Polym. J. 2007, 43, 1097–1104. [Google Scholar] [CrossRef]

- Aguilar-Bolados, H.; Lopez-Manchado, M.A.; Brasero, J.; Avilés, F.; Yazdani-Pedram, M. Effect of the Morphology of Thermally Reduced Graphite Oxide on the Mechanical and Electrical Properties of Natural Rubber Nanocomposites. Compos. Part B 2016, 87, 350–356. [Google Scholar] [CrossRef]

- Malas, A.; Das, C.K.; Das, A.; Heinrich, G. Development of expanded graphite filled natural rubber vulcanizates in presence and absence of carbon black: Mechanical, thermal and morphological properties. Mater. Des. 2012, 39, 410–417. [Google Scholar] [CrossRef]

- Guo, Y.; Cao, Z.; Wang, D.; Liu, S. Improving the friction and abrasion properties of nitrile rubber hybrid with hollow glass beads. Tribol. Int. 2016, 101, 122–130. [Google Scholar] [CrossRef]

- Guo, Y.; Tan, H.; Cao, Z.; Wang, D.; Zhang, S. Mechanical and Unlubricated Sliding Wear Properties of Nitrile Rubber Reinforced with Micro Glass Flake. Polymers 2018, 10, 705. [Google Scholar] [CrossRef] [PubMed]

- Rezende, C.A.; Bragança, F.C.; Doi, R.T.; Lee, L.T.; Galembeck, F.; Boué, F. Natural rubber-clay nanocomposites: Mechanical and structural properties. Polymer 2010, 51, 3644–3652. [Google Scholar] [CrossRef]

- Tian, M.; Liang, W.; Rao, G.; Zhang, L.; Guo, C. Surface modification of fibrillar silicate and its reinforcing mechanism on FS/rubber composites. Compos. Sci. Technol. 2005, 65, 1129–1138. [Google Scholar] [CrossRef]

- Polanski, Z. Experiment Planning in Technique; PWN: Warszawa, Poland, 1984. (In Polish) [Google Scholar]

- Wang, L.L.; Zhang, L.Q.; Tian, M. Mechanical and tribological properties of acrylonitrile butadiene rubber filled with graphite and carbon black. Mater. Des. 2012, 39, 450–457. [Google Scholar] [CrossRef]

- Persson, B.N.J.; Volokitin, A.I. Rubber friction on smooth surfaces. Eur. Phys. J. 2006, 21, 69–80. [Google Scholar] [CrossRef]

- Briscoe, B.J.; Sinha, S.K. Wear of Polymers. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2002, 216, 401–413. [Google Scholar] [CrossRef]

- Balasooriya, W.; Schrittesser, B.; Wang, C.; Hausberger, A.; Pinter, G.; Schwarz, T. Tribological Behavior of HNBR in Oil and Gas Field Applications. Lubricants 2018, 6, 20. [Google Scholar] [CrossRef]

- Myshkin, N.K.; Petrokovets, M.I.; Kovalev, A.V. Tribology of polymers: Adhesion, friction, wear, and mass-transfer. Tribol. Int. 2005, 38, 910–921. [Google Scholar] [CrossRef]

| Ra (μm) | Rz (μm) | Rq (μm) | |

|---|---|---|---|

| Before test | 0.05 | 0.54 | 0.07 |

| After test | 0.04 | 0.36 | 0.06 |

| Feature | Units | NBR | NBR28 | FKM | FKM28 |

|---|---|---|---|---|---|

| Hardness | °Sh | 71 | 73 | 79 | 82 |

| Tensile strength | MPa | 13.2 | 12.6 | 18.0 | 18.9 |

| Elongation at break | % | 400 | 340 | 200 | 220 |

| U | x1 = v | x2 = e |

|---|---|---|

| 1 | 12 | 0.5 |

| 2 | 27 | 0.4 |

| 3 | 64 | 0.3 |

| 4 | 64 | 0.5 |

| 5 | 64 | 0.7 |

| 6 | 101 | 0.6 |

| 7 | 117 | 0.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szczypinski-Sala, W.; Lubas, J. Tribological Characteristic of a Ring Seal with Graphite Filler. Materials 2020, 13, 311. https://doi.org/10.3390/ma13020311

Szczypinski-Sala W, Lubas J. Tribological Characteristic of a Ring Seal with Graphite Filler. Materials. 2020; 13(2):311. https://doi.org/10.3390/ma13020311

Chicago/Turabian StyleSzczypinski-Sala, Wojciech, and Janusz Lubas. 2020. "Tribological Characteristic of a Ring Seal with Graphite Filler" Materials 13, no. 2: 311. https://doi.org/10.3390/ma13020311

APA StyleSzczypinski-Sala, W., & Lubas, J. (2020). Tribological Characteristic of a Ring Seal with Graphite Filler. Materials, 13(2), 311. https://doi.org/10.3390/ma13020311