Influence of Laser-Welding on Microstructure and Corrosion Properties of Twinning-Induced Plasticity (TWIP) Steel

Abstract

1. Introduction

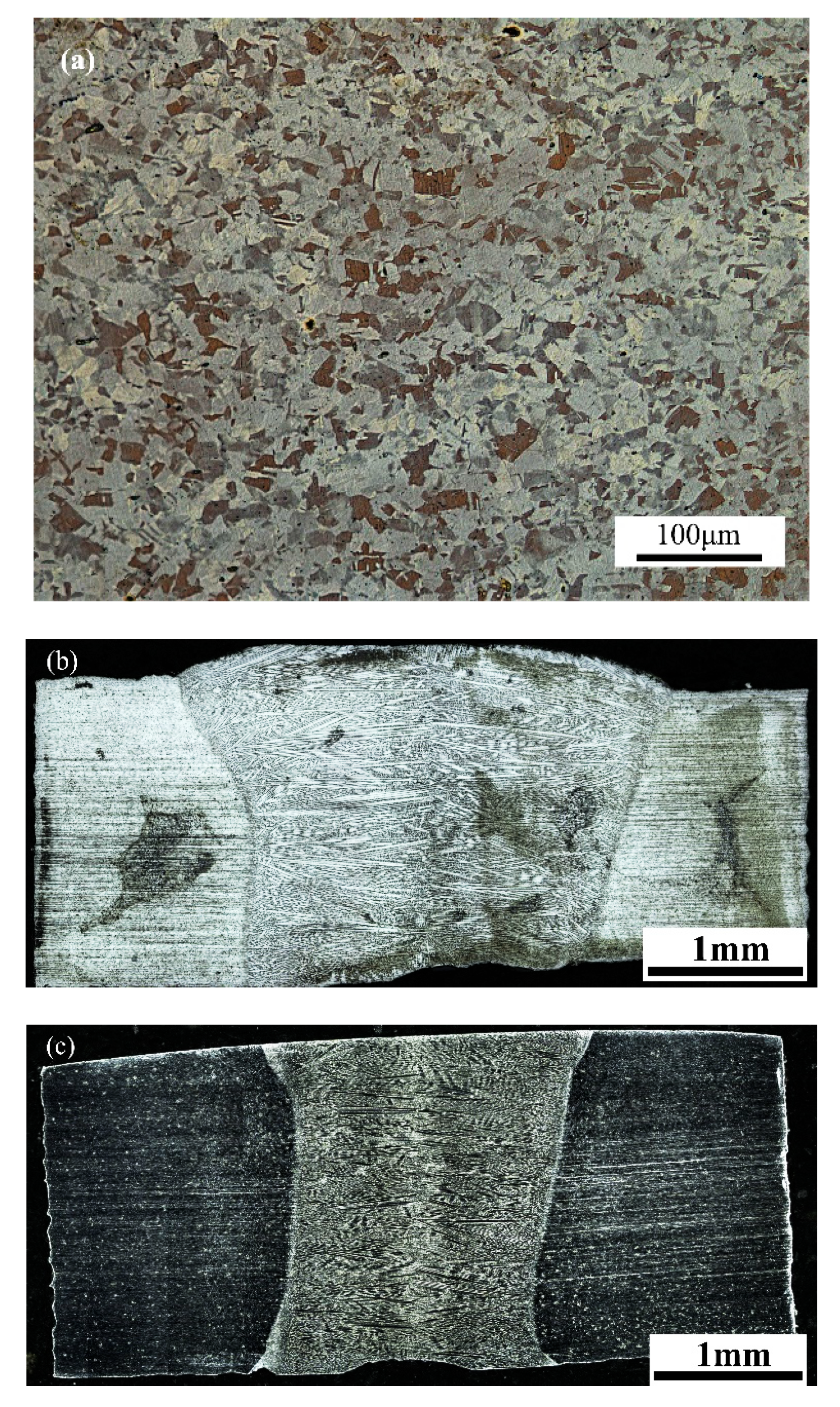

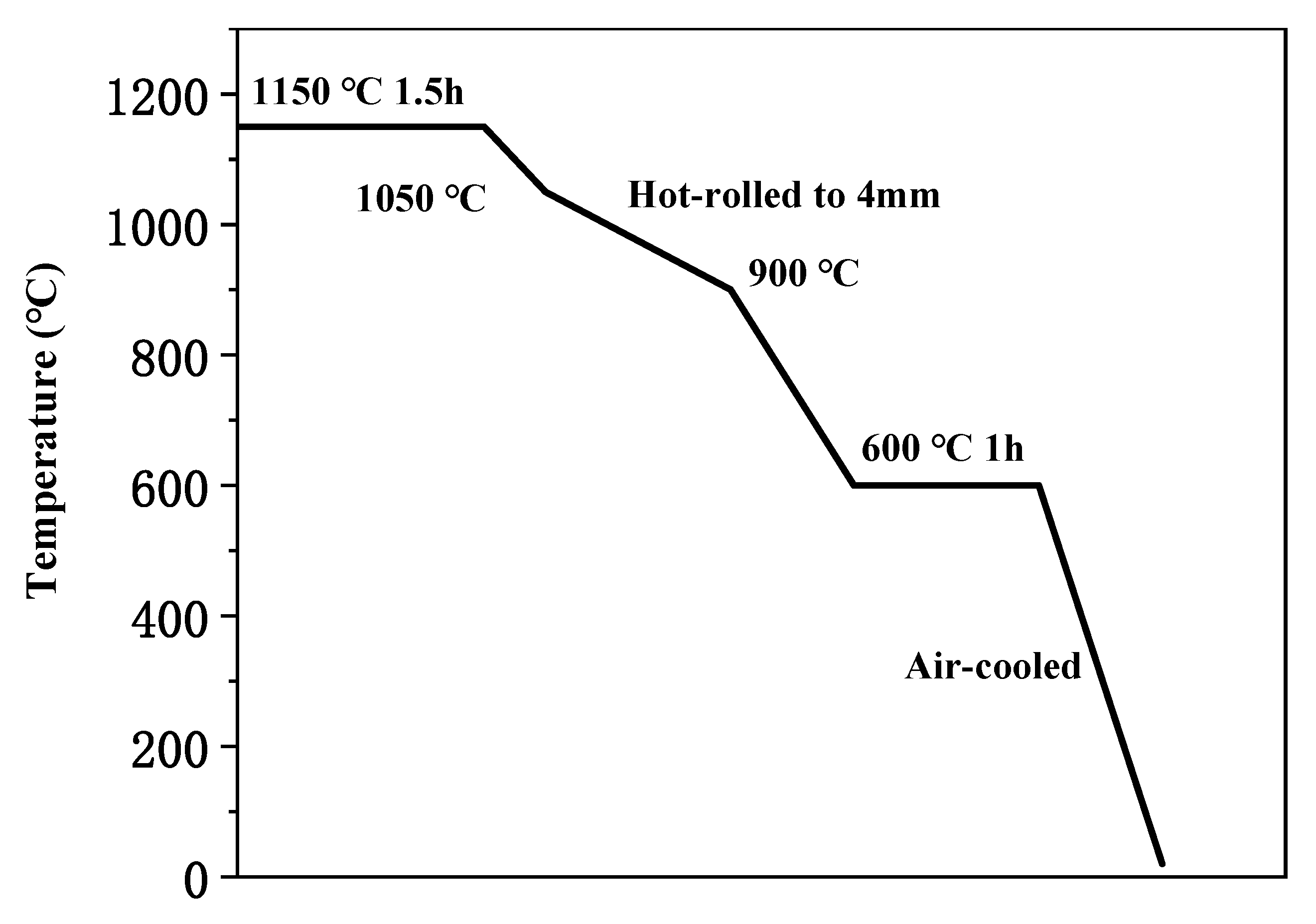

2. Materials and Methods

2.1. Materials and Welding Process

2.2. Structural and Microstructural Characterization

2.3. Corrosion Properties Characterization

3. Results

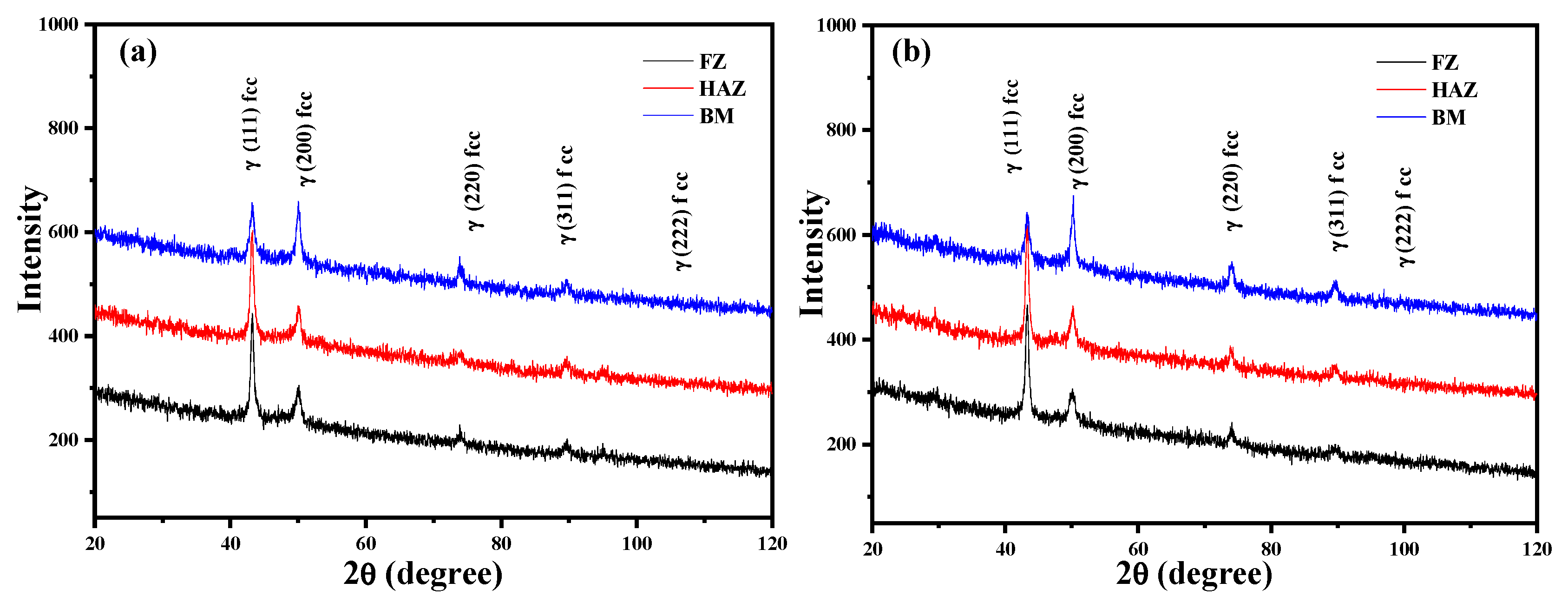

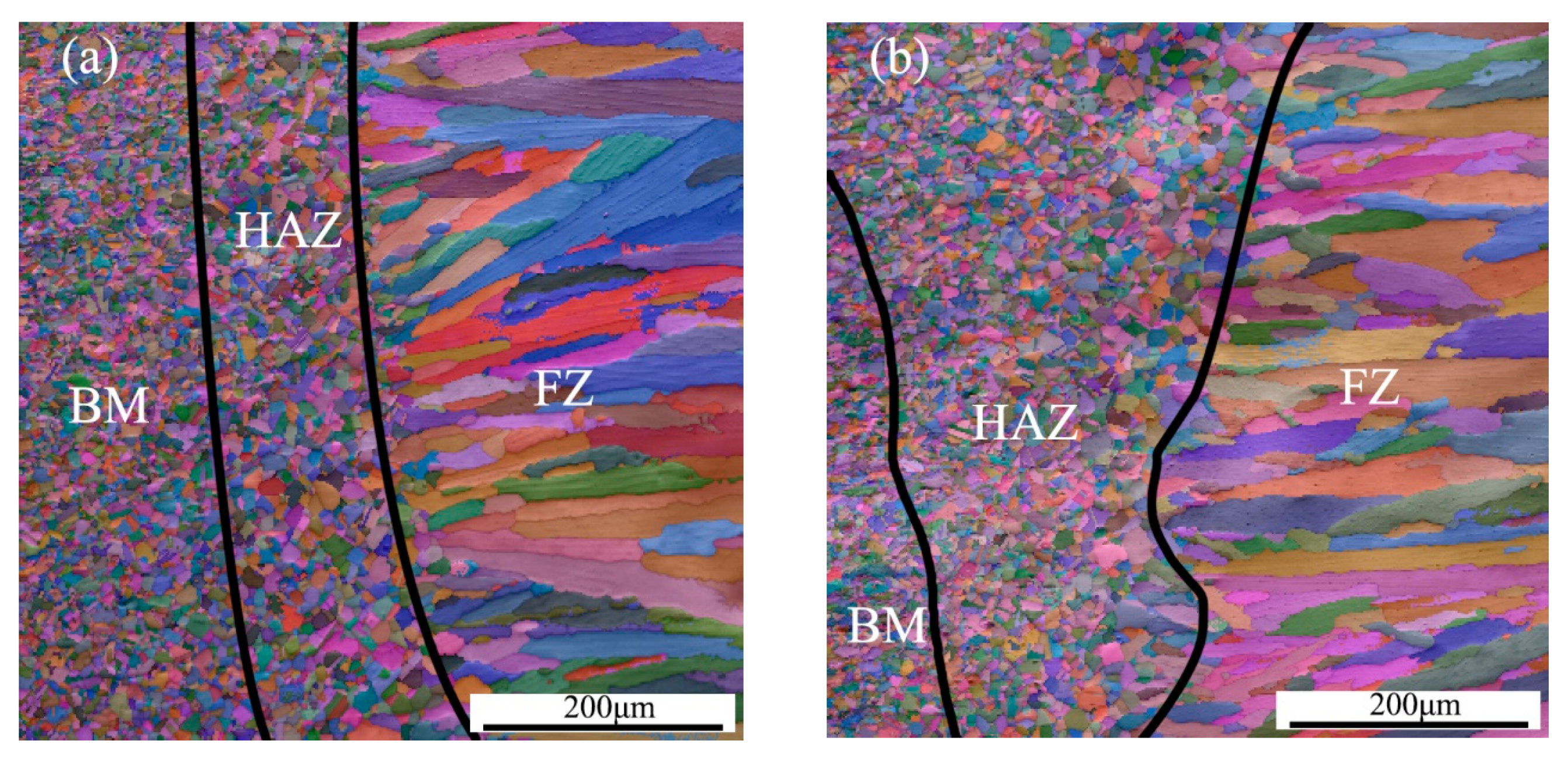

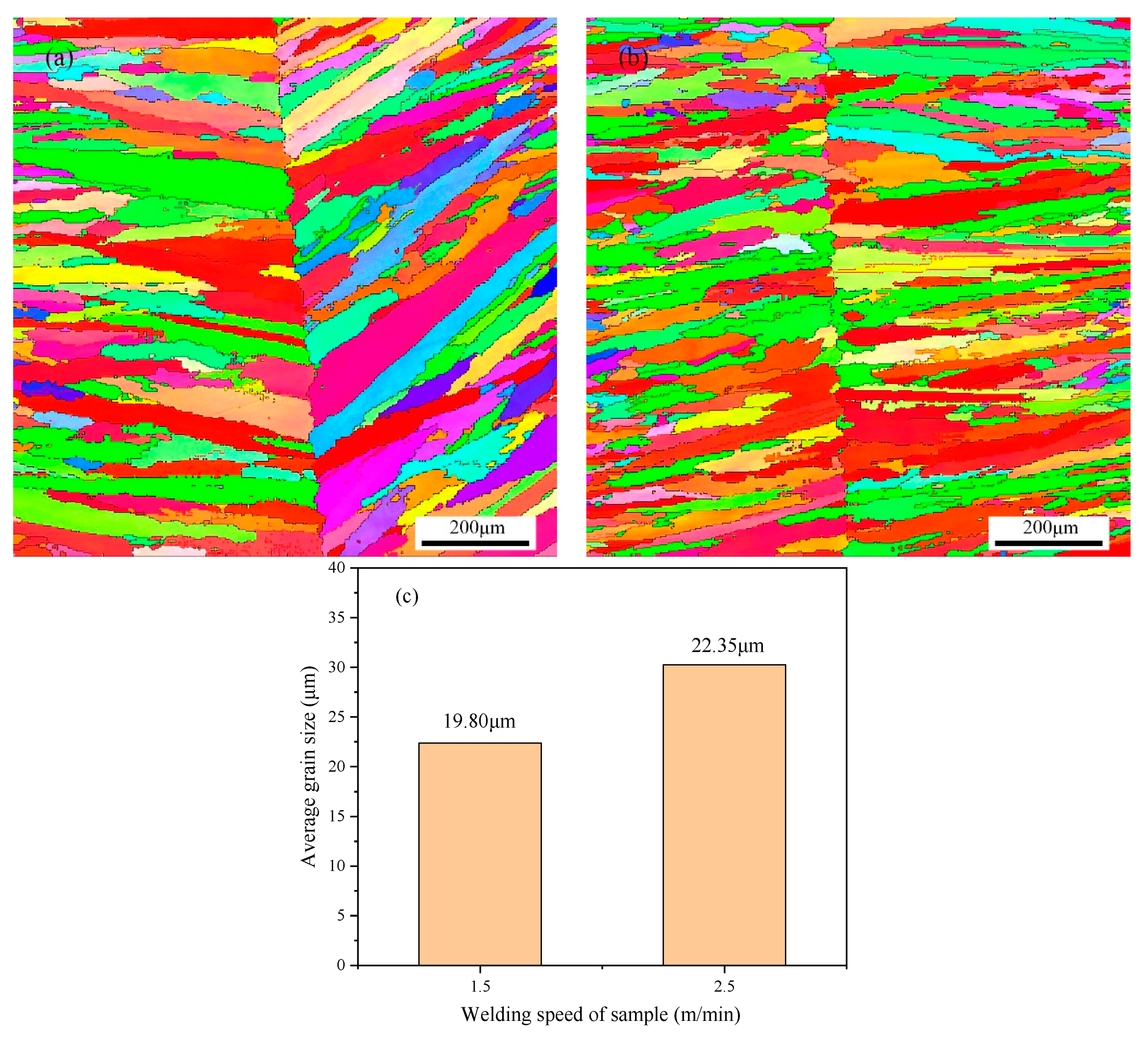

3.1. Structural and Microstructural Analysis

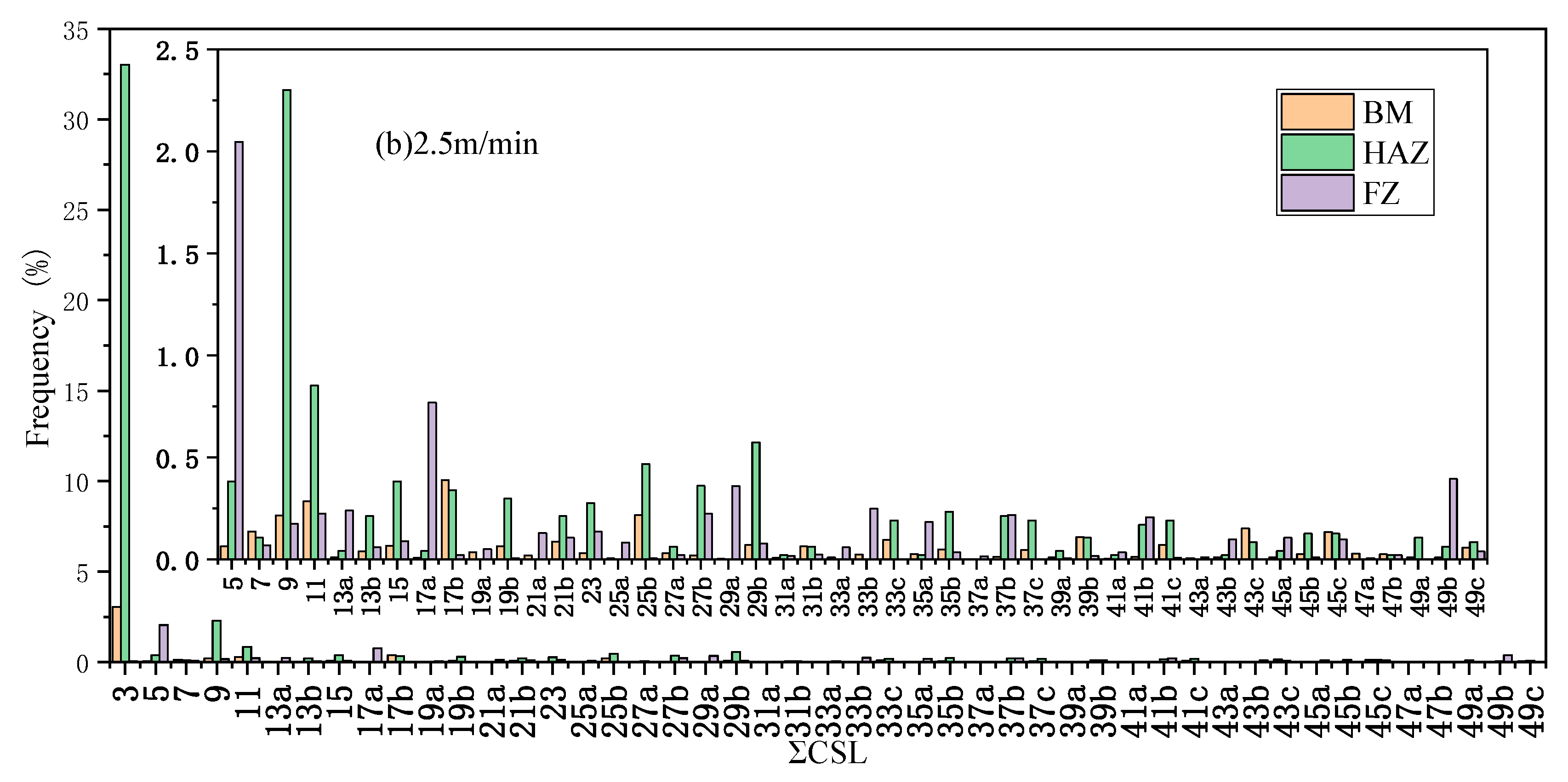

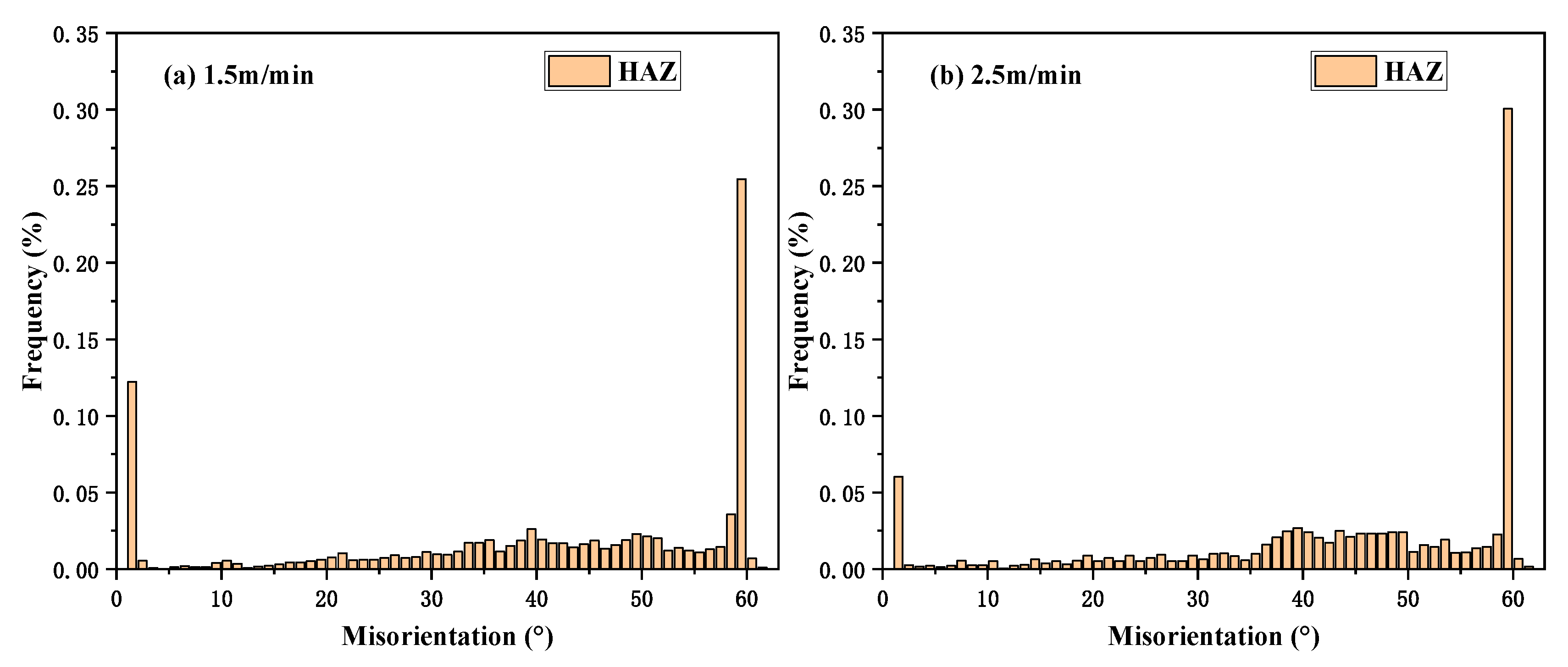

3.2. Grain Boundary Characteristics after Welding

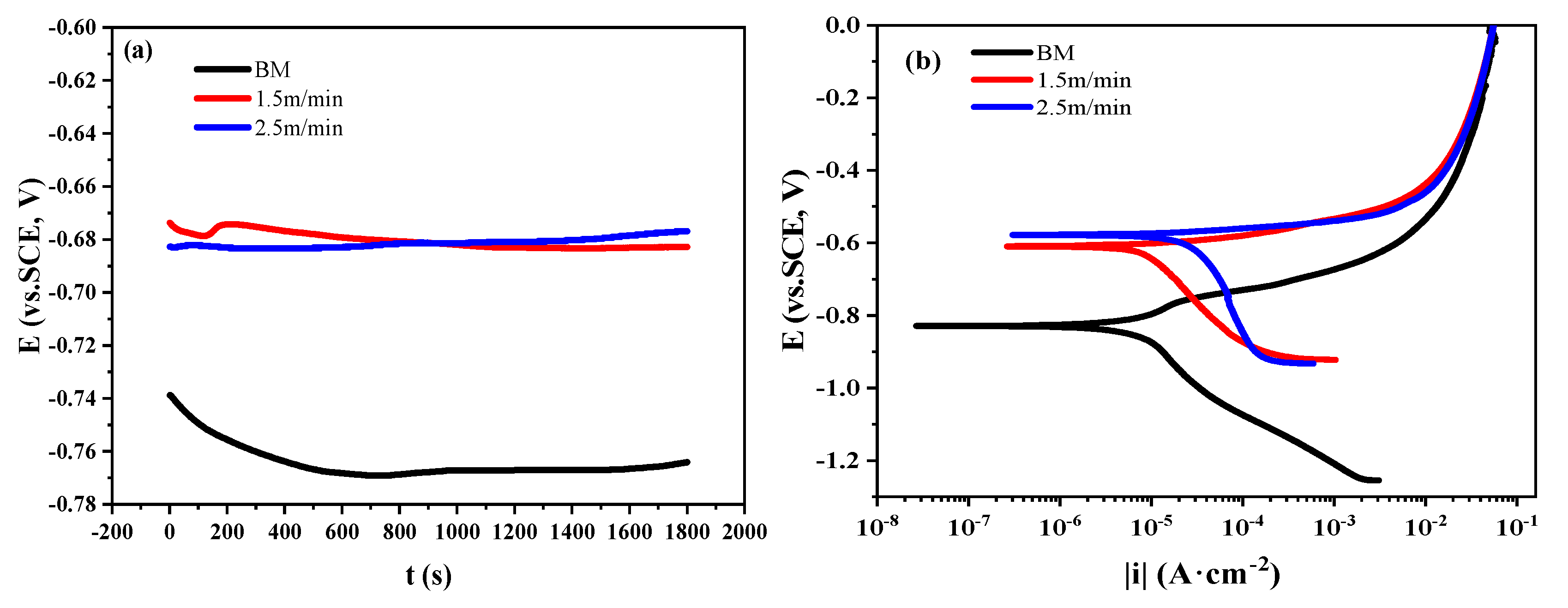

3.3. Potentiodynamic Polarization

3.4. Micro-Area Scanning Kelvin Probe Test

4. Conclusions

- The preferred orientation of grains and the grain size in FZ increased with the increase of welding speed. However, the CSL grain boundary of FZ decreased with increasing welding speed.

- The surface potential of FZ, HAZ, and BM in each welded joint sequentially increased. The corrosion resistance of the BM in laser-welded joints was the best, followed by HAZ, and that of FZ as the worst.

- The 1.5 m/min sample rendered better corrosion resistance, due to the higher frequency of CSL grain boundaries and finer grains in FZ.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Allain, S.; Chateau, J.P.; Dahmoun, D.; Bouaziz, O. Modeling of mechanical twinning in a high manganese content austenitic steel. Mater. Sci. Eng. A 2004, 387–389. [Google Scholar] [CrossRef]

- De Cooman, B.C.; Chen, L.; Kim, H.S.; Estrin, Y.; Kim, S.K.; Voswinckel, H. State-of-the-Science of High Manganese TWIP Steels for Automotive Applications; Springer: London, UK, 2009; pp. 165–183. [Google Scholar]

- Bouaziz, O.; Allain, S.; Scott, C. Effect of grain and twin boundaries on the hardening mechanisms of twinning-induced plasticity steels. Scr. Mater. 2008, 58, 484–487. [Google Scholar] [CrossRef]

- Neu, R.W. Performance and characterization of TWIP steels for automotive applications. Astm Int. 2013, 2, 244–284. [Google Scholar] [CrossRef]

- Chung, K.; Ahn, K.; Yoo, D.H.; Chung, K.H.; Seo, M.H.; Park, S.H. Formability of TWIP (twinning induced plasticity) automotive sheets. Int. J. Plast. 2011, 27, 52–81. [Google Scholar] [CrossRef]

- De Cooman, B.C.; Estrin, Y.; Kim, S.K. Twinning-induced plasticity (TWIP) steels. Acta Mater. 2018, 142, 283–362. [Google Scholar] [CrossRef]

- Landowski, M.; Wierczyńska, A.; Rogalski, G.; Fydrych, D. Autogenous fiber laser welding of 316L austenitic and 2304 lean duplex stainless steels. Materials 2020, 13, 2390. [Google Scholar] [CrossRef]

- Perulli, P.; Dassisti, M.; Casalino, G. Thermo-mechanical simulation of hybrid welding of DP/AISI 316 and TWIP/AISI 316 dissimilar weld. Materials 2020, 13, 2088. [Google Scholar] [CrossRef]

- Kik, T. Heat source models in numerical simulations of laser welding. Materials 2020, 13, 2653. [Google Scholar] [CrossRef]

- Ma, L.-L.; Wei, Y.-H.; Hou, L.; Guo, C.-L. Evaluation on fatigue performance and fracture mechanism of laser welded TWIP steel joint based on evolution of microstructure and micromechanical properties. J. Iron Steel Res. Int. 2016, 23, 677–684. [Google Scholar] [CrossRef]

- Roncery, L.M.; Weber, S.; Theisen, W. Welding of twinning-induced plasticity steels. Scr. Mater. 2012, 66, 997–1001. [Google Scholar] [CrossRef]

- Podany, P.; Reardon, C.; Koukolíková, M.; Prochazka, R.; Franc, A. Microstructure, mechanical properties and welding of low carbon, medium manganese TWIP/TRIP steel. Metals 2018, 8, 263. [Google Scholar] [CrossRef]

- Madivala, M.; Schwedt, A.; Prahl, U.; Bleck, W. Anisotropy and strain rate effects on the failure behavior of TWIP steel: A multiscale experimental study. Int. J. Plast. 2019, 115, 178–199. [Google Scholar] [CrossRef]

- Madivala, M.; Bleck, W. Strain rate dependent mechanical properties of TWIP steel. JOM 2019, 71, 1291–1302. [Google Scholar] [CrossRef]

- Vidilli, A.; Otani, L.; Botta, W.; Kiminami, C.; Bolfarini, C.; Coury, F.G.; Wolf, W. Design of a FeMnAlC steel with TWIP effect and evaluation of its tensile and fatigue properties. J. Alloy. Compd. 2020, 831, 154806. [Google Scholar] [CrossRef]

- Martin, S.; Wolf, S.; Martin, U.; Krüger, L.; Rafaja, D. Deformation mechanisms in austenitic TRIP/TWIP steel as a function of temperature. Metall. Mater. Trans. A 2016, 47, 49–58. [Google Scholar] [CrossRef]

- Kang, J.-H.; Ingendahl, T.; Bleck, W. A constitutive model for the tensile behaviour of TWIP steels: Composition and temperature dependencies. Mater. Des. 2016, 90, 340–349. [Google Scholar] [CrossRef]

- Wang, K.; Wei, A.; Shi, Z.; Chen, X.; Lin, J.; Tong, X.; Tao, Z.; Chen, X. The preparation and performance of grain size gradient TWIP steel fabricated by laser heat treatment. Mater. Sci. Eng. A 2019, 743, 294–300. [Google Scholar] [CrossRef]

- Park, I.J.; Lee, S.M.; Jeon, H.H.; Lee, Y.K. The advantage of grain refinement in the hydrogen embrittlement of Fe–18Mn–0.6C twinning-induced plasticity steel. Corros. Sci. 2015, 93, 63–69. [Google Scholar] [CrossRef]

- Gadelhaq, M.; Hamada, A.; Järvenpää, A.; Jaskari, M.; Hossam, M. Effect of Grain structure on the mechanical and corrosion behavior of advanced medium Mn stainless TWIP steel. Mater. Sci. Forum 2020, 998, 15–20. [Google Scholar] [CrossRef]

- Park, I.J.; Jo, S.Y.; Kang, M.; Lee, S.M.; Lee, Y.K. The effect of Ti precipitates on hydrogen embrittlement of Fe–18Mn–0.6C–2Al–xTi twinning-induced plasticity steel. Corros. Sci. 2014, 89, 38–45. [Google Scholar] [CrossRef]

- Dieudonne, T.; Marchetti, L.; Wery, M.; Chene, J.; Allely, C.; Cugy, P.; Scott, C.P. Role of copper and aluminum additions on the hydrogen embrittlement susceptibility of austenitic Fe–Mn–C TWIP steels. Corros. Sci. 2014, 82, 218–226. [Google Scholar] [CrossRef]

- Kwon, Y.J.; Seo, H.J.; Kim, J.N.; Lee, C.S. Effect of grain boundary engineering on hydrogen embrittlement in Fe-Mn-C TWIP steel at various strain rates. Corros. Sci. 2018, 142, 213–221. [Google Scholar] [CrossRef]

- Jung, J.K.; Kim, N.K.; Yeon, Y.S.; Kim, H.H.; Lee, O.Y. Effect of annealing temperature and alloying elements on the mechanical properties of Fe-Mn-C TWIP steels. Korean J. Mater. Res. 2010, 20, 385–391. [Google Scholar] [CrossRef][Green Version]

- Mujica, L.; Weber, S.; Pinto, H.; Thomy, C.; Vollertsen, F. Microstructure and mechanical properties of laser-welded joints of TWIP and TRIP steels. Mater. Sci. Eng. A 2010, 527, 2071–2078. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, M.; Xiong, W.; Liu, R.; Shi, W.; Li, L. Microstructure and tensile properties of the laser welded TWIP steel and the deformation behavior of the fusion zone. Mater. Des. 2015, 83, 103–111. [Google Scholar] [CrossRef]

- Zhu, J.; Xu, L.; Feng, Z.; Frankel, G.S.; Lu, M.; Chang, W. Galvanic corrosion of a welded joint in 3Cr low alloy pipeline steel. Corros. Sci. 2016, 111, 391–403. [Google Scholar] [CrossRef]

- Wint, N.; Leung, J.; Sullivan, J.H.; Penney, D.J.; Gao, Y. The galvanic corrosion of welded ultra-high strength steels used for automotive applications. Corros. Sci. 2018, 136, 366–373. [Google Scholar] [CrossRef]

- Aldalur, E.; Veiga, F.; Suárez, A.; Bilbao, J.; Lamikiz, A. Analysis of the wall geometry with different strategies for high deposition wire arc additive manufacturing of mild steel. Metals 2020, 10, 892. [Google Scholar] [CrossRef]

- Schuh, C.A.; Kumar, M.; King, W.E. Analysis of grain boundary networks and their evolution during grain boundary engineering. Acta Mater. 2003, 51, 687–700. [Google Scholar] [CrossRef]

- Watanabe, T. An approach to grain boundary design of strong and ductile polycrystals. Res. Mech. 1984, 11, 47–84. [Google Scholar]

- Watanabe, T. The importance of grain boundary character distribution (GBCD) to recrystallization, grain growth and texture. Scr. Metall. Mater. 1992, 27, 1497–1502. [Google Scholar] [CrossRef]

- Randle, V. Twinning-related grain boundary engineering. Acta Mater. 2004, 52, 4067–4081. [Google Scholar] [CrossRef]

- Niendorf, T.; Rubitschek, F.; Maier, H.J.; Niendorf, J.; Richard, H.A.; Frehn, A. Fatigue crack growth—Microstructure relationships in a high-manganese austenitic TWIP steel. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2010, 527, 2412–2417. [Google Scholar] [CrossRef]

- Ping, Y. Electron Backscatter Diffraction Technology and Its Application; Metallurgical Industry Press: Beijing, China, 2007. [Google Scholar]

- Sasaki, M.; Ohsasa, K.; Kudoh, M.; Matsuura, K. Refinement of austenite grain in carbon steel by addition of titanium and boron. ISIJ Int. 2008, 48, 340–343. [Google Scholar] [CrossRef]

- Stratmann, M. The investigation of the corrosion properties of metals, covered with adsorbed electrolyte layers—A new experimental technique. Corros. Sci. 1987, 27, 869–872. [Google Scholar] [CrossRef]

- Stratmann, M.; Streckel, H. On the atmospheric corrosion of metals which are covered with thin electrolyte layers—I. Verification of the experimental technique. Corros. Sci. 1990, 30, 681–696. [Google Scholar] [CrossRef]

- Stratmann, M.; Streckel, H. On the atmospheric corrosion of metals which are covered with thin electrolyte layers—II. Experimental results. Corros. Sci. 1990, 30, 715–734. [Google Scholar] [CrossRef]

- Song, G.; Johannesson, B.; Hapugoda, S.; Stjohn, D. Galvanic corrosion of magnesium alloy AZ91D in contact with an aluminium alloy, steel and zinc. Corros. Sci. 2004, 46, 955–977. [Google Scholar] [CrossRef]

- Berthome, G.; Malki, B.; Baroux, B. Pitting transients analysis of stainless steels at the open circuit potential. Corros. Sci. 2006, 48, 2432–2441. [Google Scholar] [CrossRef]

- Yuan, X.; Chen, L. Effect of grain and grain boundary featureson anti-corrosion ability of a high manganese austenitic TWIP steel. Acta Metall. Sin. 2016, 52, 1345–1352. [Google Scholar]

- Gollapudi, S. Grain size distribution effects on the corrosion behaviour of materials. Corros. Sci. 2012, 62, 90–94. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | Al | P | S | RE | Cr | Fe |

|---|---|---|---|---|---|---|---|---|---|

| TWIP steel | 0.6 | 0.3 | 18 | 1.5 | <0.01 | <0.01 | <0.01 | 0 | Bal. |

| Sample | BM | HAZ | FZ |

|---|---|---|---|

| 1.5 m/min | 3.92% | 30.25% | 1.27% |

| 2.5 m/min | 3.33% | 35.74% | 0.47% |

| Sample | Ecorr (mV vs. SCE) | Icorr (A·cm−2) |

|---|---|---|

| 1.5 m/min | −609.18 | 2.73 × 10−4 |

| 2.5 m/min | −592.95 | 8.97 × 10−4 |

| BM | −829.01 | 3.42 × 10−5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, C.; Zhang, Y.; Liu, W.; Jin, Y.; Wen, L.; Sun, D. Influence of Laser-Welding on Microstructure and Corrosion Properties of Twinning-Induced Plasticity (TWIP) Steel. Materials 2020, 13, 4315. https://doi.org/10.3390/ma13194315

Xu C, Zhang Y, Liu W, Jin Y, Wen L, Sun D. Influence of Laser-Welding on Microstructure and Corrosion Properties of Twinning-Induced Plasticity (TWIP) Steel. Materials. 2020; 13(19):4315. https://doi.org/10.3390/ma13194315

Chicago/Turabian StyleXu, Chengcheng, Youkang Zhang, Wanlei Liu, Ying Jin, Lei Wen, and Dongbai Sun. 2020. "Influence of Laser-Welding on Microstructure and Corrosion Properties of Twinning-Induced Plasticity (TWIP) Steel" Materials 13, no. 19: 4315. https://doi.org/10.3390/ma13194315

APA StyleXu, C., Zhang, Y., Liu, W., Jin, Y., Wen, L., & Sun, D. (2020). Influence of Laser-Welding on Microstructure and Corrosion Properties of Twinning-Induced Plasticity (TWIP) Steel. Materials, 13(19), 4315. https://doi.org/10.3390/ma13194315