Prediction of Optimum Process Parameters Fabricated by Direct Laser Interference Patterning Based on Central Composite Design

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

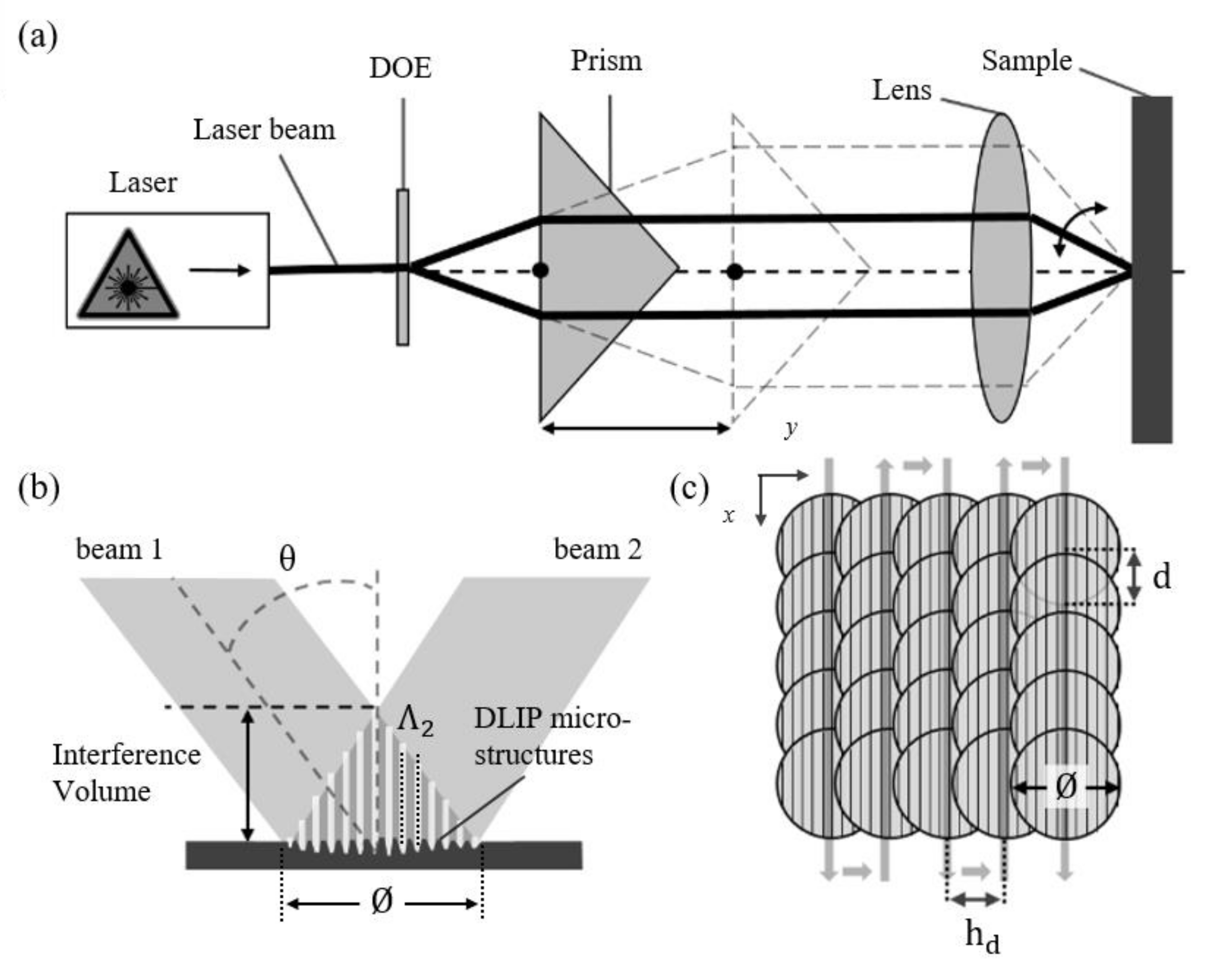

2.2. Nanosecond Two-Beam-DLIP Setup and Process Strategy

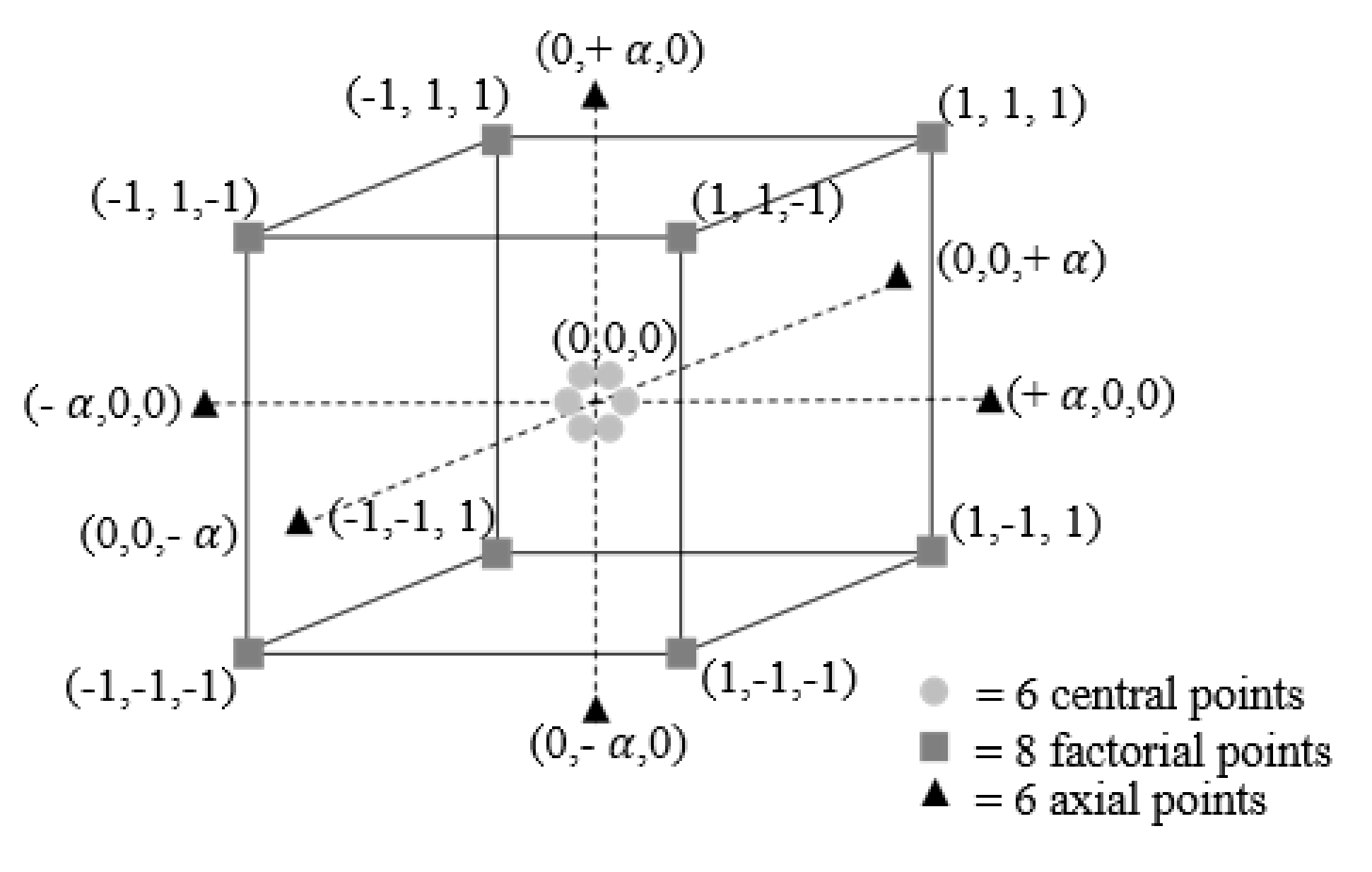

2.3. Central Composite Design Method

2.4. Surface Characterization

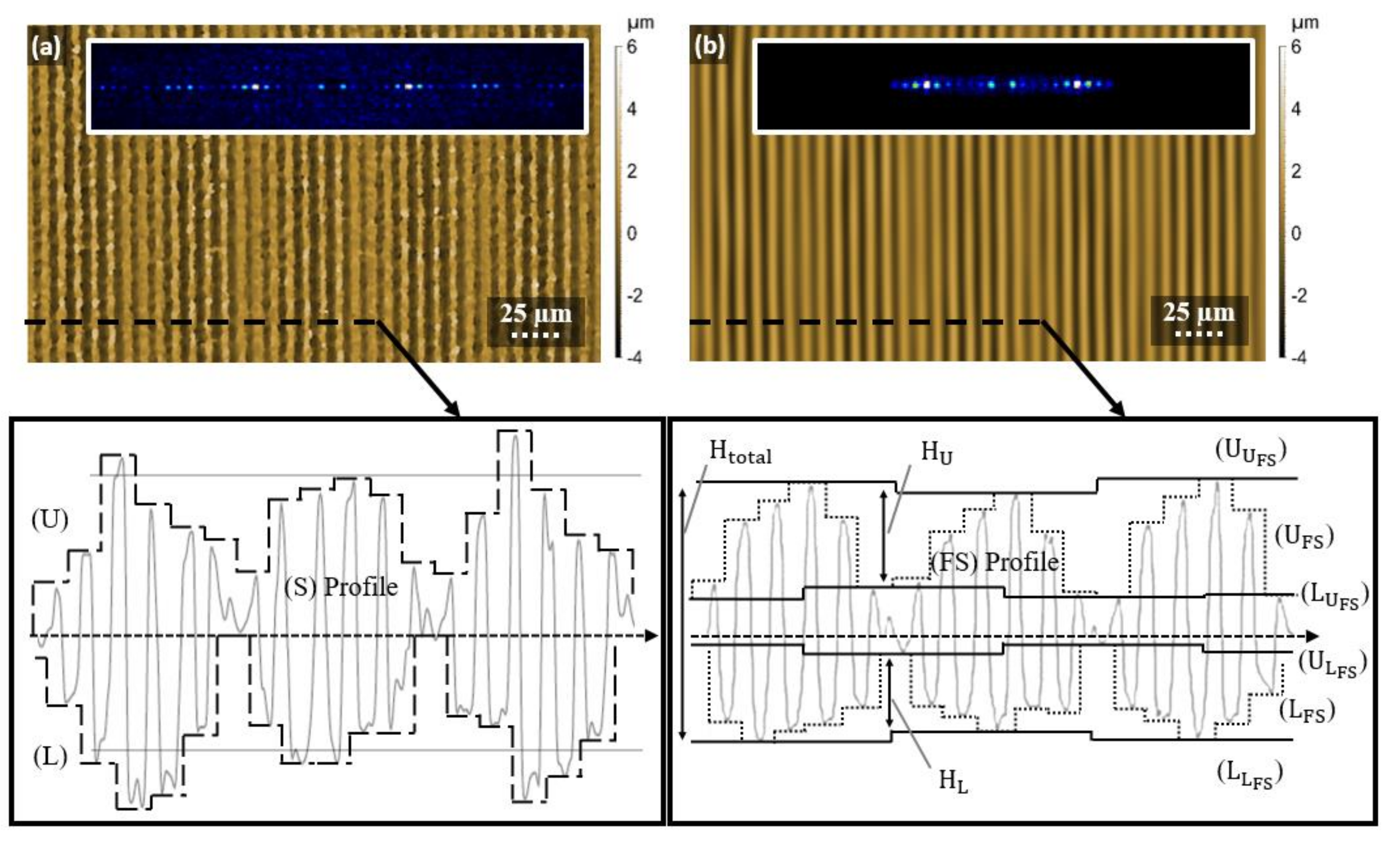

2.5. Development of a Topographical Analysis Method

3. Results and Discussions

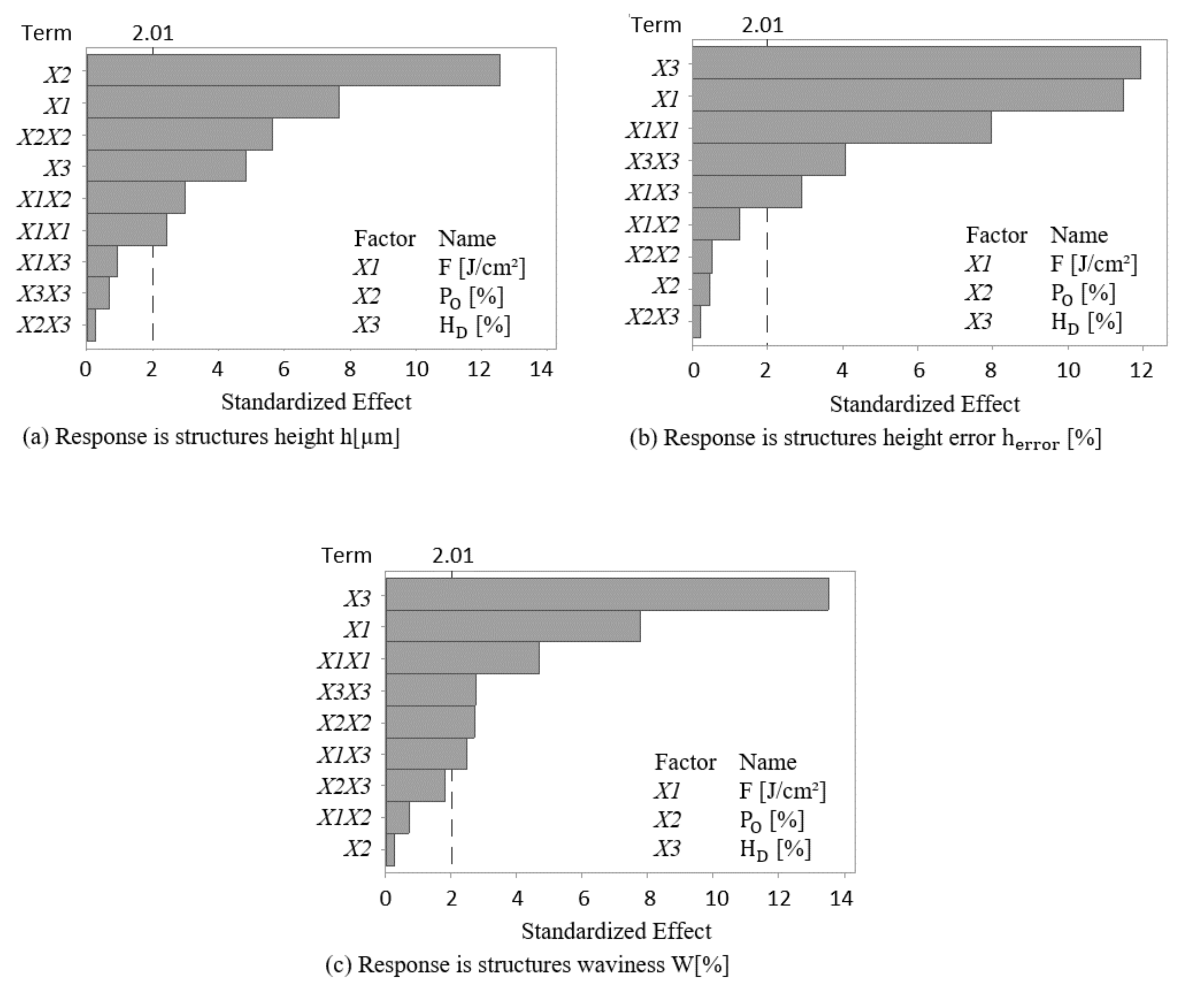

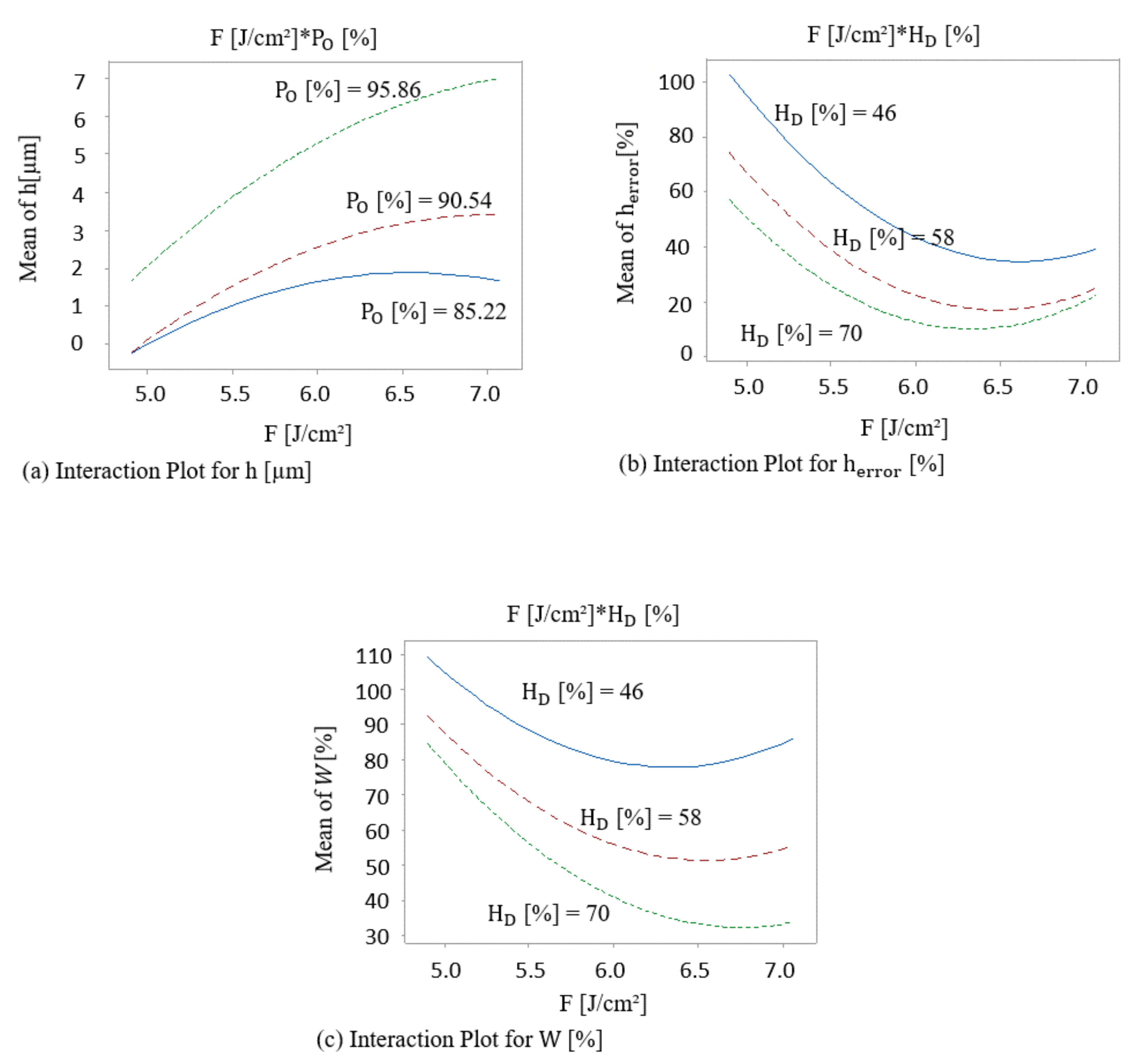

3.1. Statistical Analysis of Results

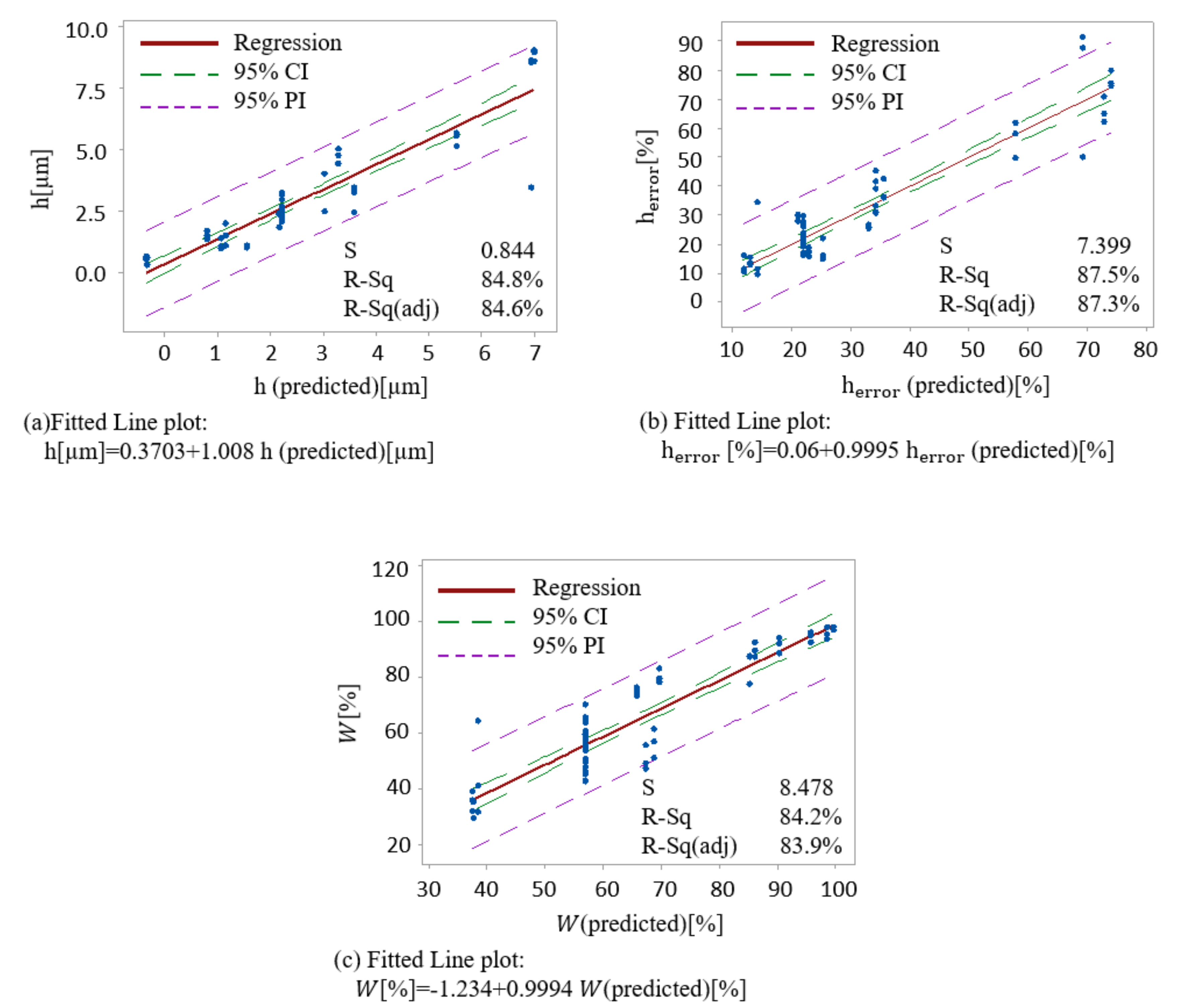

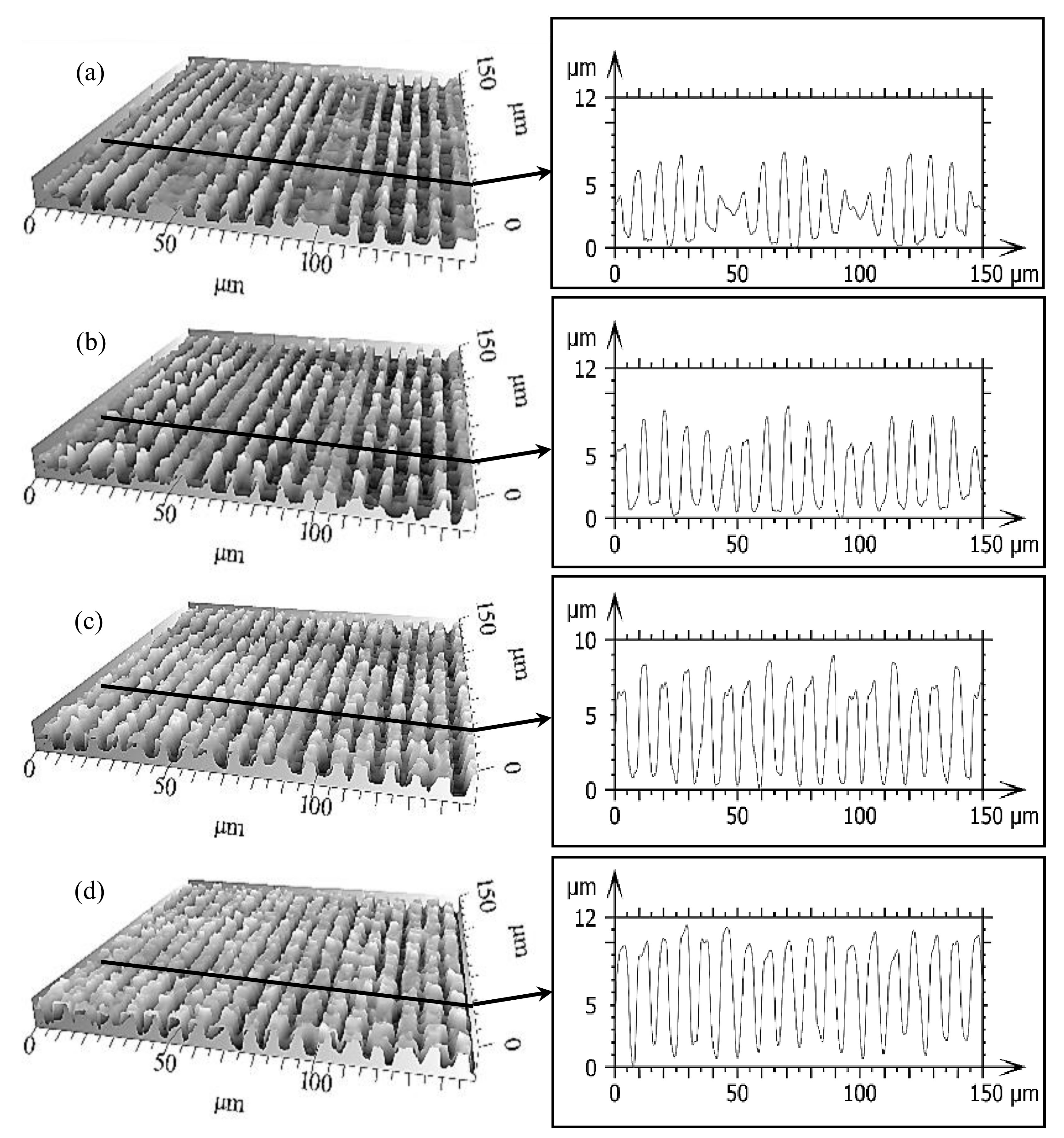

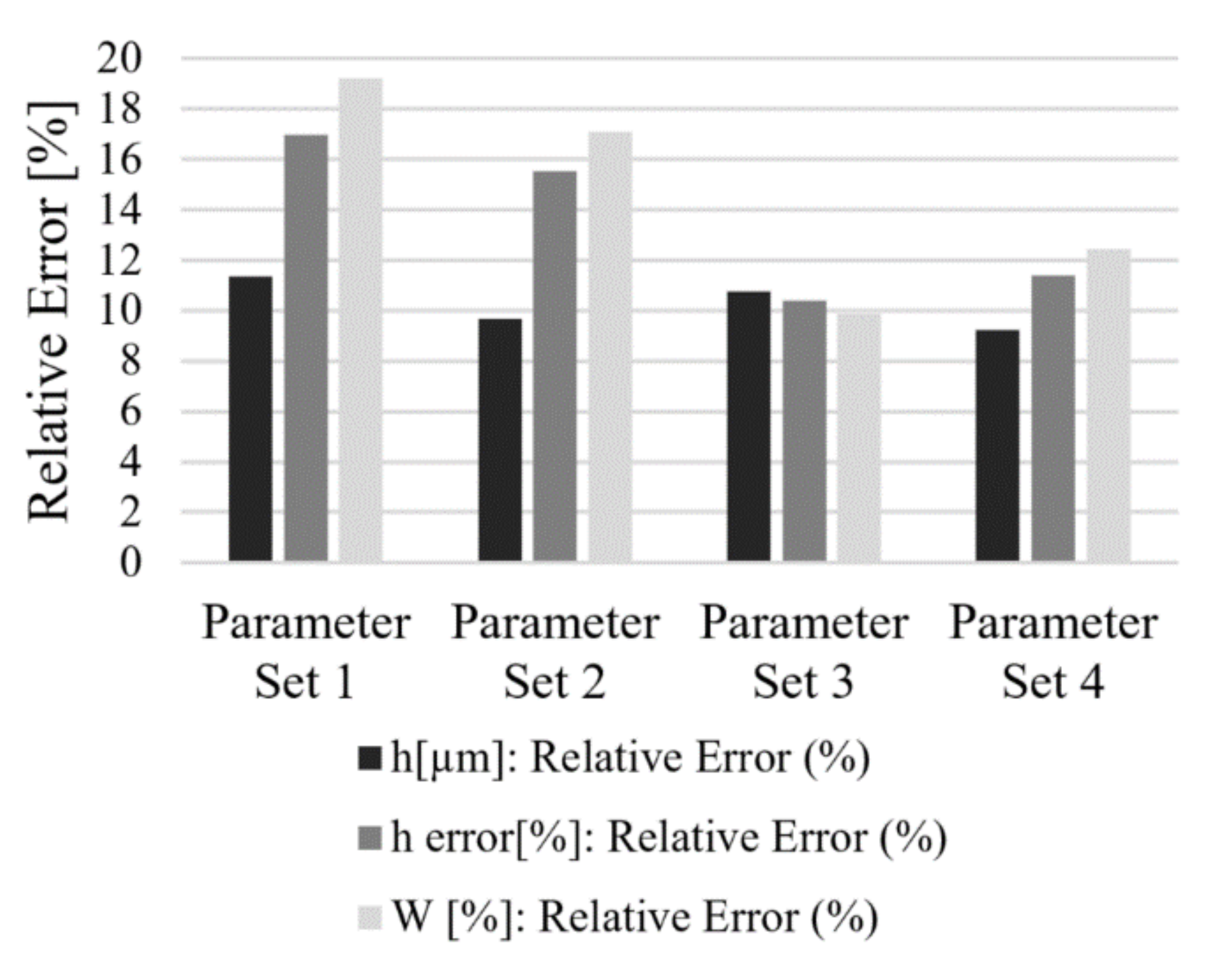

3.2. Model Validation

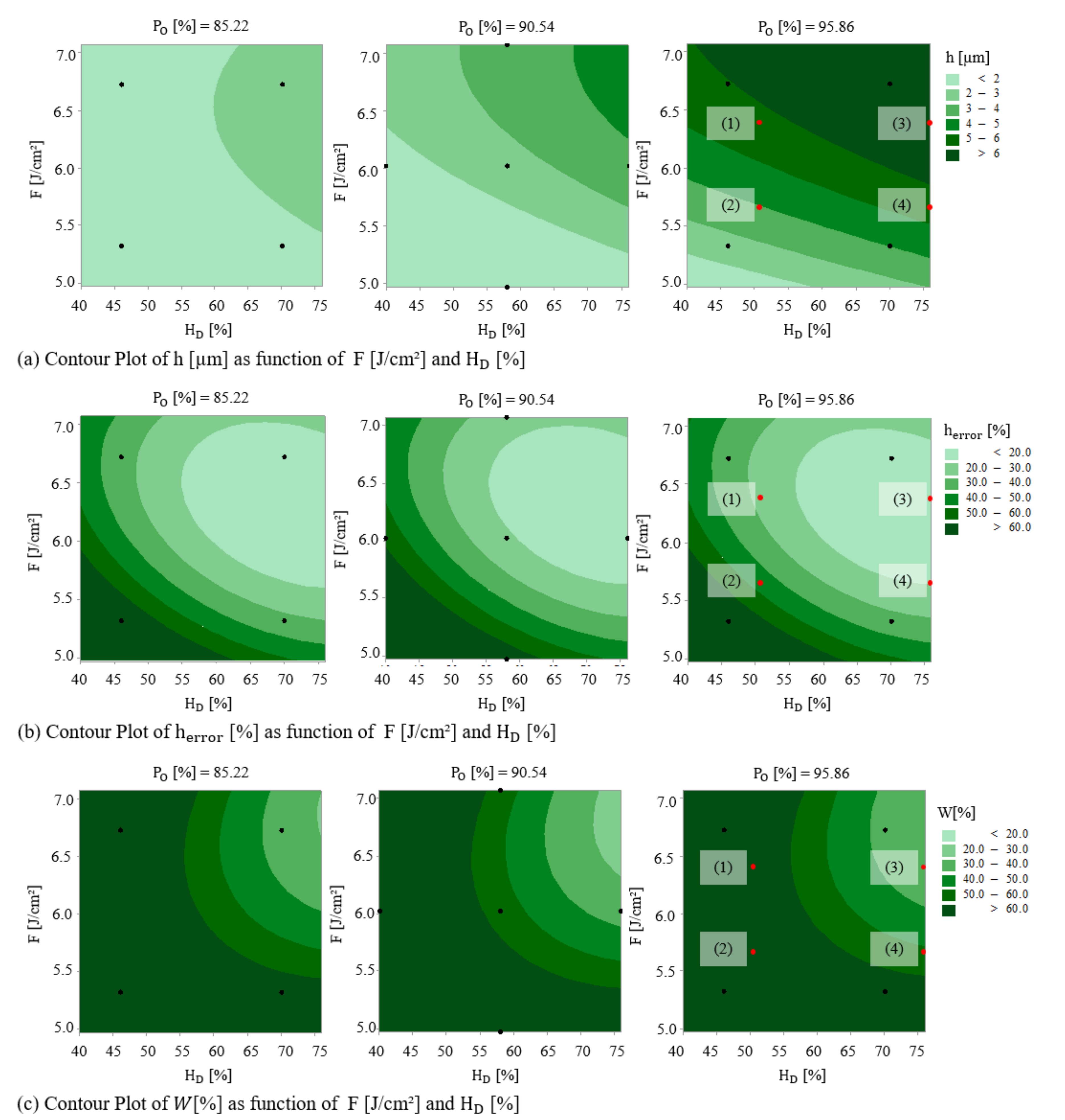

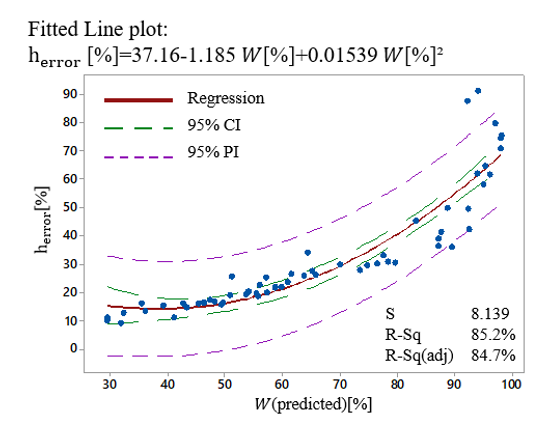

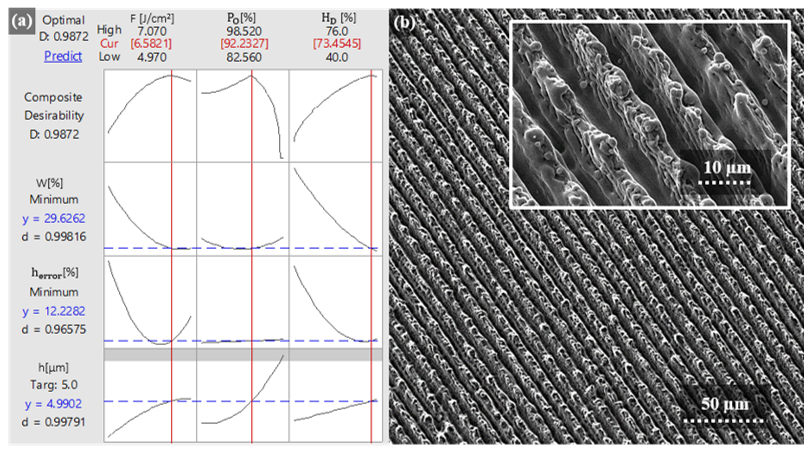

3.3. Multi-Objective Optimization

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Favret, E.A.; Fuentes Néstor, O. Functional Properties of Bio-Inspired Surfaces: Characterization and Technological Applications; World Scientific: Hackensack, NJ, USA, 2009. [Google Scholar]

- Han, Z.; Mu, Z.; Yin, W.; Li, W.; Niu, S.; Zhang, J.; Ren, L. Biomimetic multifunctional surfaces inspired from animals. Adv. Colloid Interface Sci. 2016, 234, 27–50. [Google Scholar] [CrossRef] [PubMed]

- Müller, F.; Kunz, C.; Gräf, S. Bio-Inspired Functional Surfaces Based on Laser-Induced Periodic Surface Structures. Materials 2016, 9, 476. [Google Scholar] [CrossRef] [PubMed]

- Rosenkranz, A.; Hans, M.; Gachot, C.; Thome, A.; Bonk, S.; Mücklich, F. Direct Laser Interference Patterning: Tailoring of Contact Area for Frictional and Antibacterial Properties. Lubricants 2016, 4, 2. [Google Scholar] [CrossRef]

- Alamri, S.; Aguilar-Morales, A.I.; Lasagni, A.F. Controlling the wettability of polycarbonate substrates by producing hierarchical structures using Direct Laser Interference Patterning. Eur. Polym. J. 2018, 99, 27–37. [Google Scholar] [CrossRef]

- Cardoso, J.; Aguilar-Morales, A.; Alamri, S.; Huerta-Murillo, D.; Cordovilla, F.; Lasagni, A.; Ocaña, J. Superhydrophobicity on hierarchical periodic surface structures fabricated via direct laser writing and direct laser interference patterning on an aluminium alloy. Opt. Lasers Eng. 2018, 111, 193–200. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Stratmann, A.; Gachot, C.; Burghardt, G.; Jacobs, G.; Mücklich, F. Improved Wear Behavior of Cylindrical Roller Thrust Bearings by Three-Beam Laser Interference. Adv. Eng. Mater. 2015, 18, 854–862. [Google Scholar] [CrossRef]

- Costa, H.; Hutchings, I. Some innovative surface texturing techniques for tribological purposes. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2014, 229, 429–448. [Google Scholar] [CrossRef]

- Guo, L.; Wong, P.; Gachot, C. Facilitating the Study of the Texturing Effect on Hydrodynamic Lubrication. Lubricants 2018, 6, 18. [Google Scholar] [CrossRef]

- Kasem, H.; Stav, O.; Grützmacher, P.; Gachot, C. Effect of Low Depth Surface Texturing on Friction Reduction in Lubricated Sliding Contact. Lubricants 2018, 6, 62. [Google Scholar] [CrossRef]

- Heilmann, S.; Zwahr, C.; Knape, A.; Zschetzsche, J.; Lasagni, A.F.; Füssel, U. Improvement of the Electrical Conductivity between Electrode and Sheet in Spot Welding Process by Direct Laser Interference Patterning. Adv. Eng. Mater. 2018, 20, 1700755. [Google Scholar] [CrossRef]

- Zwahr, C.; Günther, D.; Brinkmann, T.; Gulow, N.; Oswald, S.; Holthaus, M.G.; Lasagni, A.F. Laser Surface Pattering of Titanium for Improving the Biological Performance of Dental Implants. Adv. Healthc. Mater. 2016, 6, 1600858. [Google Scholar] [CrossRef] [PubMed]

- Voisiat, B.; Teutoburg-Weiss, S.; Rank, A.; Lasagni, A.F. DLIP holographic structuring: From basic concept to advanced monitoring methods and industrial scale production. In Proceedings of the Laser-Based Micro- and Nanoprocessing XIII, San Francisco, CA, USA, 4 March 2019. [Google Scholar]

- Teutoburg-Weiss, S.; Sonntag, F.; Günther, K.; Lasagni, A.F. Multiple method micromachining laser platform for fabricating anti-counterfeit elements with multiple-scaled features. Opt. Laser Technol. 2019, 115, 465–476. [Google Scholar] [CrossRef]

- Waugh, D.G.; Lawrence, J. Laser Surface Engineering: Processes and Applications; Woodhead: Cambridge, UK, 2016. [Google Scholar]

- Bonse, J.; Krüger, J.; Höhm, S.; Rosenfeld, A. Femtosecond laser-induced periodic surface structures. J. Laser Appl. 2012, 24, 042006. [Google Scholar] [CrossRef]

- Nakata, Y. Interference laser processing. Adv. Opt. Technol. 2016, 5, 29–38. [Google Scholar] [CrossRef]

- Indrišiūnas, S.; Voisiat, B.; Gedvilas, M.; Račiukaitis, G. New opportunities for custom-shape patterning using polarization control in confocal laser beam interference setup. J. Laser Appl. 2017, 29, 011501. [Google Scholar] [CrossRef]

- Lasagni, A.F.; Gachot, C.; Trinh, K.E.; Hans, M.; Rosenkranz, A.; Roch, T.; Eckhardt, S.; Kunze, T.; Bieda, M.; Günther, D.; et al. Direct laser interference patterning, 20 years of development: From the basics to industrial applications. In Proceedings of the Laser-Based Micro- and Nanoprocessing XI, San Francisco, CA, USA, 7 March 2017. [Google Scholar]

- Lasagni, A.F. Advanced Design of Periodical Structures by Laser Interference Metallurgy in the Micro, Nano Scale on Macroscopic Areas. Ph.D. Thesis, Shaker Verlag GmbH, Aachen, Germany, 2007. [Google Scholar]

- He, C.; Steger, M.; Gillner, A. High-Efficiency Nanostructuring using Multi-Beam Interference by Con-secutively Deposited Ultrashort Laser Pulses on Tool Steel. J. Laser Micro/Nanoeng. 2018, 13, 1–5. [Google Scholar]

- Aguilar-Morales, A.I.; Alamri, S.; Kunze, T.; Lasagni, A.F. Influence of processing parameters on surface texture homogeneity using Direct Laser Interference Patterning. Opt. Laser Technol. 2018, 107, 216–227. [Google Scholar] [CrossRef]

- Chichkov, B.N.; Momma, C.; Nolte, S.; Alvensleben, F.; Tünnermann, A. Femtosecond, picosecond and nanosecond laser ablation of solids. Appl. Phys. A Mater. Sci. Process. 1996, 63, 109–115. [Google Scholar] [CrossRef]

- Volkov, A.N.; Zhigilei, L.V. Melt dynamics and melt-through time in continuous wave laser heating of metal films: Contributions of the recoil vapor pressure and Marangoni effects. Int. J. Heat Mass Transf. 2017, 112, 300–317. [Google Scholar] [CrossRef]

- Czitrom, V. One-Factor-at-a-Time versus Designed Experiments. Am. Stat. 1999, 53, 126. [Google Scholar]

- Siebertz, K.; Bebber, D.V.; Hochkirchen, T. Statistische. In Versuchsplanung Design of Experiments (DoE); Springer: Berlin, Germany, 2017. [Google Scholar]

- Dean, A.M.; Voss, D.; Danel, D. Design and Analysis of Experiments; Springer: Cham, Switzerland, 2017. [Google Scholar]

- Montgomery, D.C. Design and Analysis of Experiments; Wiley: Hoboken, NJ, USA, 2020. [Google Scholar]

- Tanco, M.; Viles, E.; Pozueta, L. Comparing Different Approaches for Design of Experiments (DoE). In Lecture Notes in Electrical Engineering Advances in Electrical Engineering and Computational Science; Springer: Dordrecht, The Netherlands, 2009; pp. 611–621. [Google Scholar]

- Genna, S.; Tagliaferri, F.; Papa, I.; Leone, C.; Palumbo, B. Multi-response optimization of CFRP laser milling process based on response surface methodology. Polym. Eng. Sci. 2017, 57, 595–605. [Google Scholar] [CrossRef]

- Kibria, G.; Sen, A.; Aziz, H.M.T.; Doloi, B.; Bhattacharyya, B. Pulsed Nd:YAG Laser Surface Texturing of Pure Titanium Material. In Lecture Notes on Multidisciplinary Industrial Engineering Precision Product-Process Design and Optimization; Springer: Singapore, 2018; pp. 361–390. [Google Scholar]

- Moradi, M.; Karamimoghadam, M. High power diode laser surface hardening of AISI 4130; statistical modelling and optimization. Opt. Laser Technol. 2019, 111, 554–570. [Google Scholar] [CrossRef]

- Witek-Krowiak, A.; Chojnacka, K.; Podstawczyk, D.; Dawiec, A.; Pokomeda, K. Application of response surface methodology and artificial neural network methods in modelling and optimization of biosorption process. Bioresour. Technol. 2014, 160, 150–160. [Google Scholar] [CrossRef]

- Diler, E.A.; Ipek, R. An experimental and statistical study of interaction effects of matrix particle size, reinforcement particle size and volume fraction on the flexural strength of Al–SiCp composites by P/M using central composite design. Mater. Sci. Eng. A 2012, 548, 43–55. [Google Scholar] [CrossRef]

- Box, G.E.P.; Hunter, J.S. Multi-Factor Experimental Designs for Exploring Response Surfaces. Ann. Math. Stat. 1957, 28, 195–241. [Google Scholar] [CrossRef]

- Mathews, P.G. Design of Experiments with MINITAB; New Age: New Dehli, India, 2010. [Google Scholar]

- Khan, R.M. Problem Solving and Data Analysis Using Minitab: A Clear and Easy Guide to Six Sigma Methodology; Wiley: Chichester, UK, 2013. [Google Scholar]

- Wu, C.F.J.; Hamada, M. Experiments: Planning, Analysis, and Parameter Design Optimization; Wiley: New York, NY, USA, 2000. [Google Scholar]

- Dietzsch, M.; Gerlach, M.; Gröger, S. Back to the envelope system with morphological operations for the evaluation of surfaces. Wear 2008, 264, 411–415. [Google Scholar] [CrossRef]

- Kumar, J.; Shunmugam, M. A new approach for filtering of surface profiles using morphological operations. Int. J. Mach. Tools Manuf. 2006, 46, 260–270. [Google Scholar] [CrossRef]

- Raja, J.; Muralikrishnan, B.; Fu, S. Recent advances in separation of roughness, waviness and form. Precis. Eng. 2002, 26, 222–235. [Google Scholar] [CrossRef]

- International standard: Geometrical Product Specifications (GPS)—Filtration—Part 41: Morphological Profile Filters: Disc and Horizontal Line-Segment Filters; ISO 16610-41:2015; ISO: Geneva, Switzerland, 2015.

- Roch, T.; Benke, D.; Lasagni, A.F. Method and Arrangement for Forming a Structuring on Surfaces of Components by Means of a Laser Beam 2014. US 9,764,424 B2, 19 September 2017. [Google Scholar]

- Liu, J.M. Simple technique for measurements of pulsed Gaussian-beam spot sizes. Opt. Lett. 1982, 7, 196. [Google Scholar] [CrossRef] [PubMed]

- Hecht, E. Optics; Pearson: Harlow, UK, 2017. [Google Scholar]

- Indrisiunas, S.; Voisiat, B.; Žukauskas, A.; Račiukaitis, G. Direct laser beam interference patterning technique for fast high aspect ratio surface structuring. In Proceedings of the Laser Applications in Microelectronic and Optoelectronic Manufacturing (LAMOM) XX, San Francisco, CA, USA, 4 March 2015. [Google Scholar]

- Alamri, S.; Lasagni, A.F. Development of a general model for direct laser interference patterning of polymers. Opt. Express 2017, 25, 9603. [Google Scholar] [CrossRef]

- Furlan, V.; Biondi, M.; Demir, A.G.; Pariani, G.; Previtali, B.; Bianco, A. Sub-micrometric surface texturing of AZ31 Mg-alloy through two-beam direct laser interference patterning with a ns-pulsed green fiber laser. Appl. Surf. Sci. 2017, 423, 619–629. [Google Scholar]

- Moore, D.S.; McCabe, G.P.; Craig, B.A. Introduction to the Practice of Statistics; W.H. Freeman, Macmillan Learning: New York, NY, USA, 2017. [Google Scholar]

- El-Khoury, M.; Alamri, S.; Voisiat, B.; Kunze, T.; Lasagni, A.F. Fabrication of hierarchical surface textures using multi-pulse direct laser interference patterning with nanosecond pulses. Mater. Lett. 2020, 258, 126743. [Google Scholar]

| Symbol | Coded: | −1.5 | −1 | 0 | +1 | +1.5 | |

|---|---|---|---|---|---|---|---|

| Uncoded Values of Coded Levels: | |||||||

| Peak-Fluence: F (J/cm2) | X1 | 4.97 | 5.32 | 6.02 | 6.72 | 7.07 | |

| Pulse Overlap: PO (%) | X2 | 82.56 | 85.22 | 90.54 | 95.86 | 98.52 | |

| Hatch Distance: HD (%) | X3 | 40 | 46 | 58 | 70 | 76 | |

| Response | X1 | X2 | X3 | X1X1 | X2X2 | X3X3 | X1X2 | X1X3 | X2X3 | Error |

|---|---|---|---|---|---|---|---|---|---|---|

| Factors | ||||||||||

| h (µm) | 17.5 | 46.56 | 6.96 | 1.74 | 9.49 | 0.13 | 2.69 | 0.25 | 0.02 | 14.78 |

| (%) | 31.64 | 0.05 | 34.24 | 15.25 | 0.06 | 3.99 | 0.37 | 2.02 | 0.01 | 12.02 |

| W (%) | 17.75 | 0.03 | 53.5 | 6.43 | 2.15 | 2.2 | 0.15 | 1.8 | 0.96 | 14.67 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

El-Khoury, M.; Voisiat, B.; Kunze, T.; Lasagni, A.F. Prediction of Optimum Process Parameters Fabricated by Direct Laser Interference Patterning Based on Central Composite Design. Materials 2020, 13, 4101. https://doi.org/10.3390/ma13184101

El-Khoury M, Voisiat B, Kunze T, Lasagni AF. Prediction of Optimum Process Parameters Fabricated by Direct Laser Interference Patterning Based on Central Composite Design. Materials. 2020; 13(18):4101. https://doi.org/10.3390/ma13184101

Chicago/Turabian StyleEl-Khoury, Mikhael, Bogdan Voisiat, Tim Kunze, and Andrés Fabián Lasagni. 2020. "Prediction of Optimum Process Parameters Fabricated by Direct Laser Interference Patterning Based on Central Composite Design" Materials 13, no. 18: 4101. https://doi.org/10.3390/ma13184101

APA StyleEl-Khoury, M., Voisiat, B., Kunze, T., & Lasagni, A. F. (2020). Prediction of Optimum Process Parameters Fabricated by Direct Laser Interference Patterning Based on Central Composite Design. Materials, 13(18), 4101. https://doi.org/10.3390/ma13184101