Micromachining of Invar with 784 Beams Using 1.3 ps Laser Source at 515 nm

Abstract

:1. Introduction

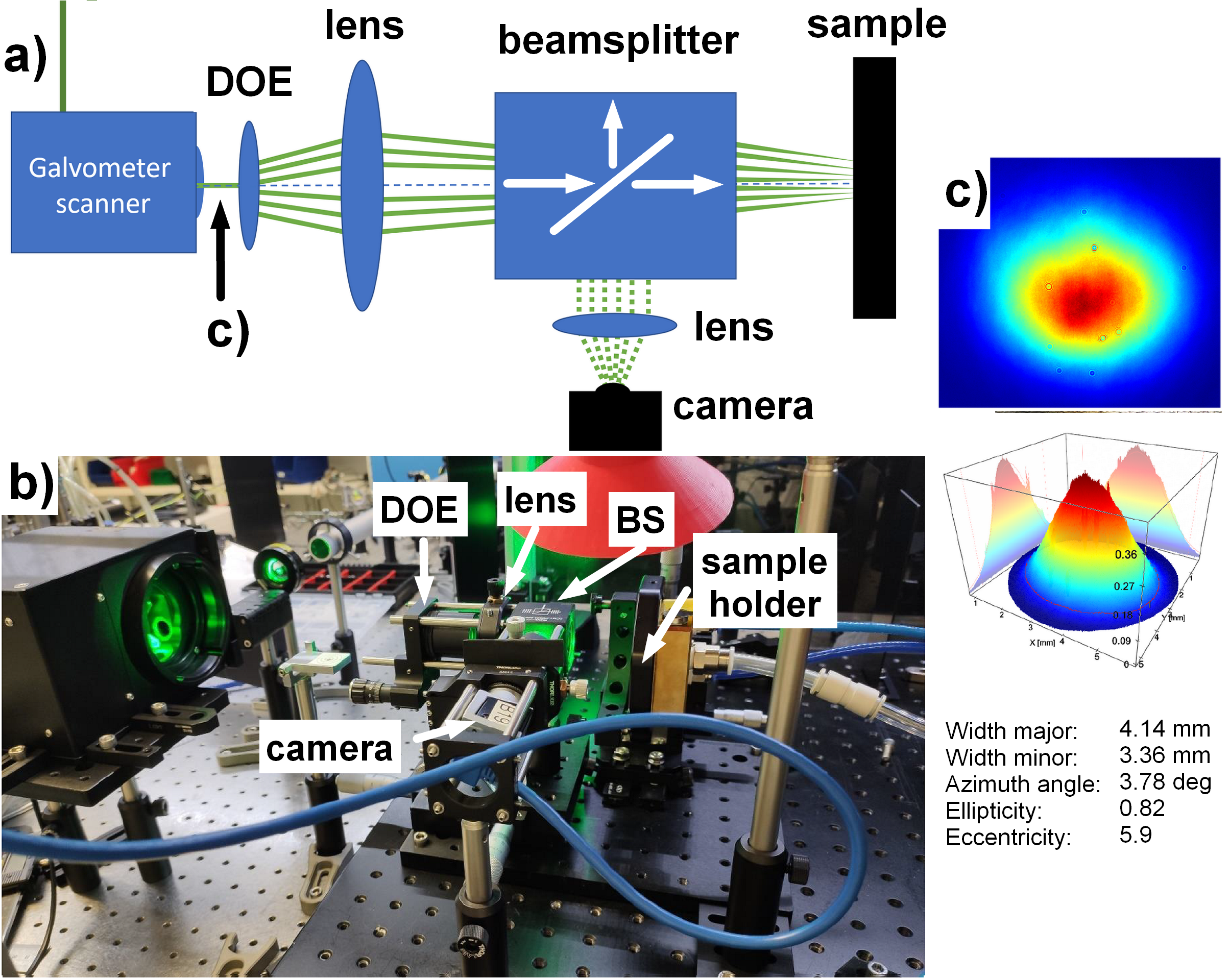

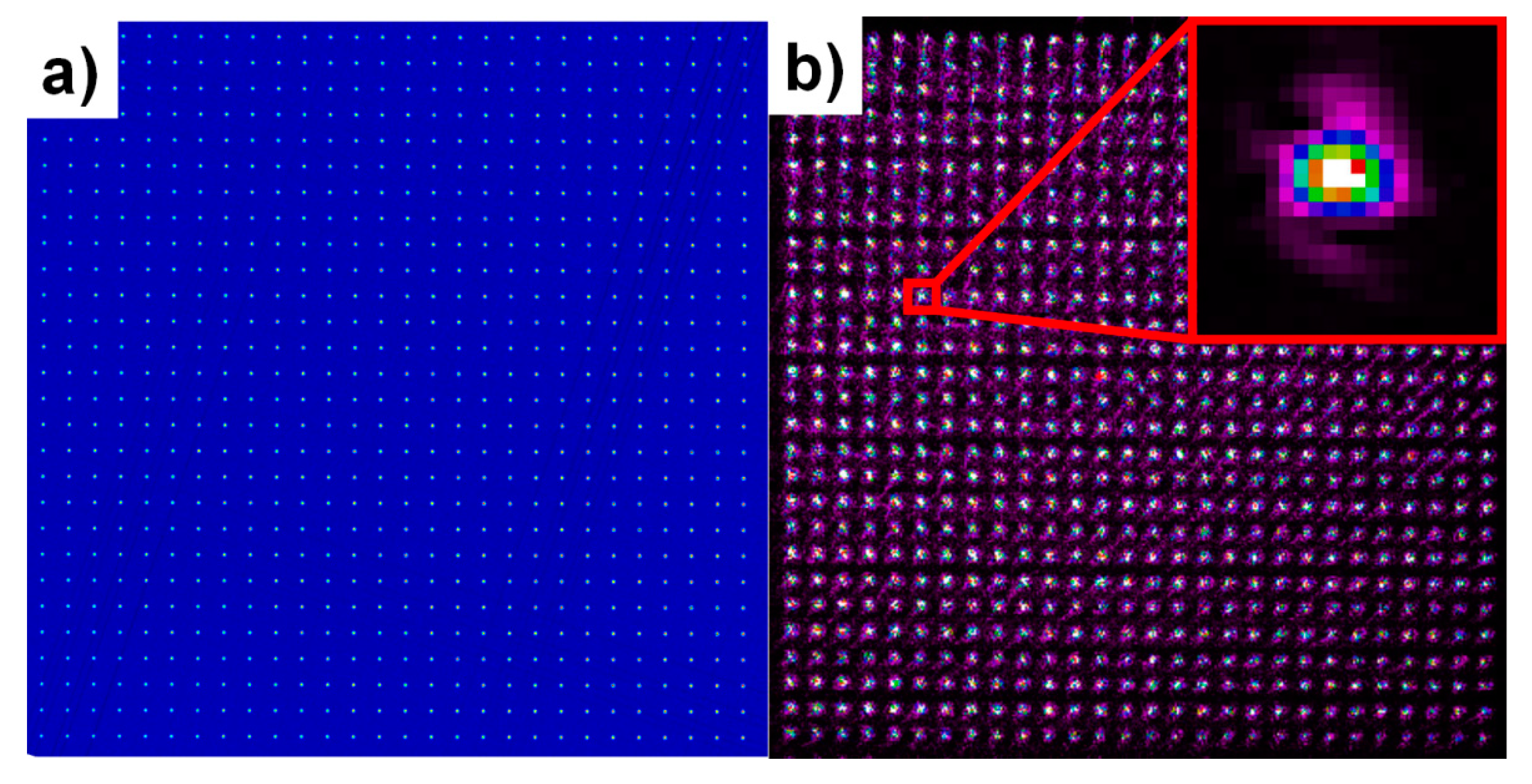

2. Materials and Methods

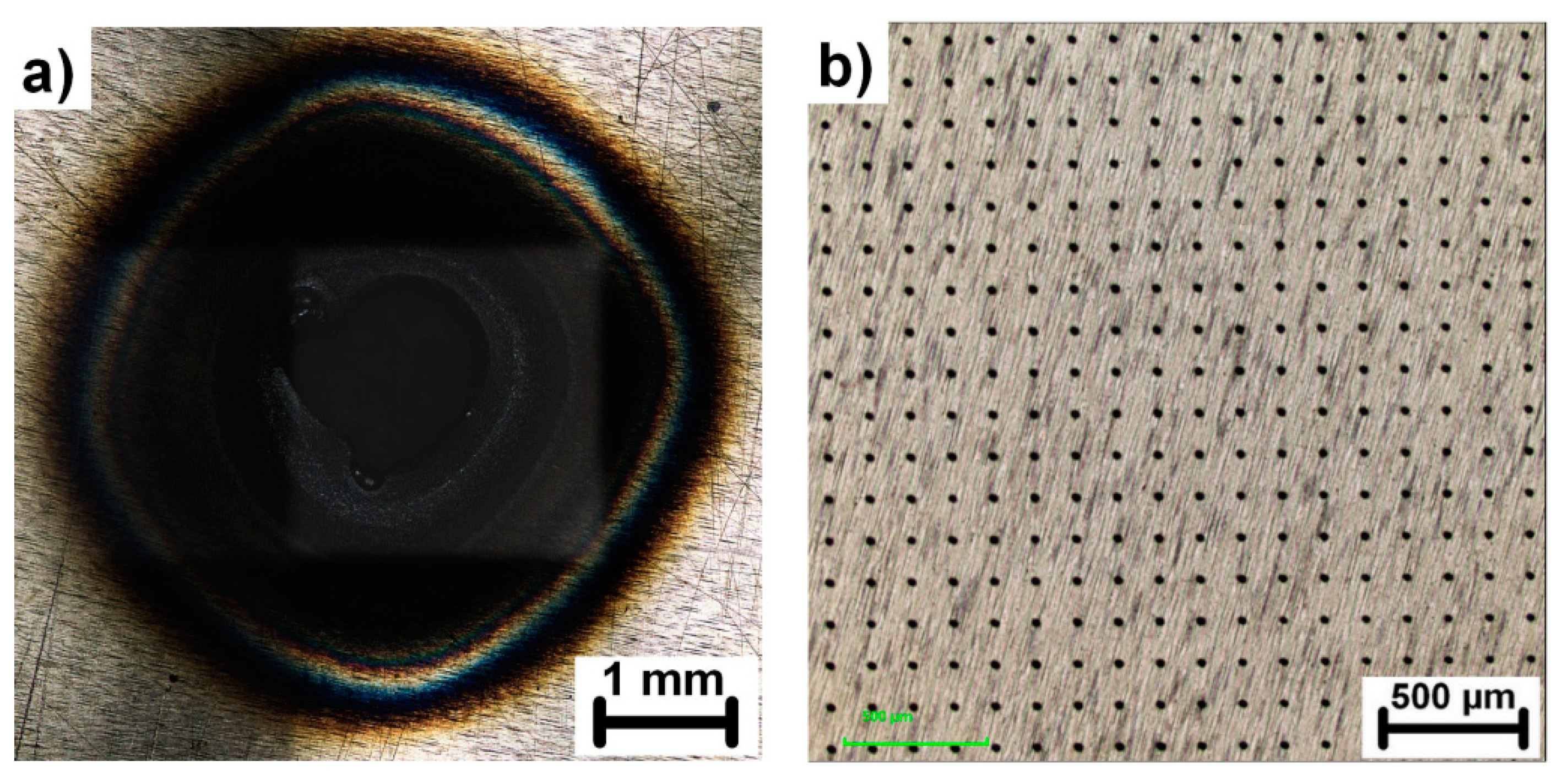

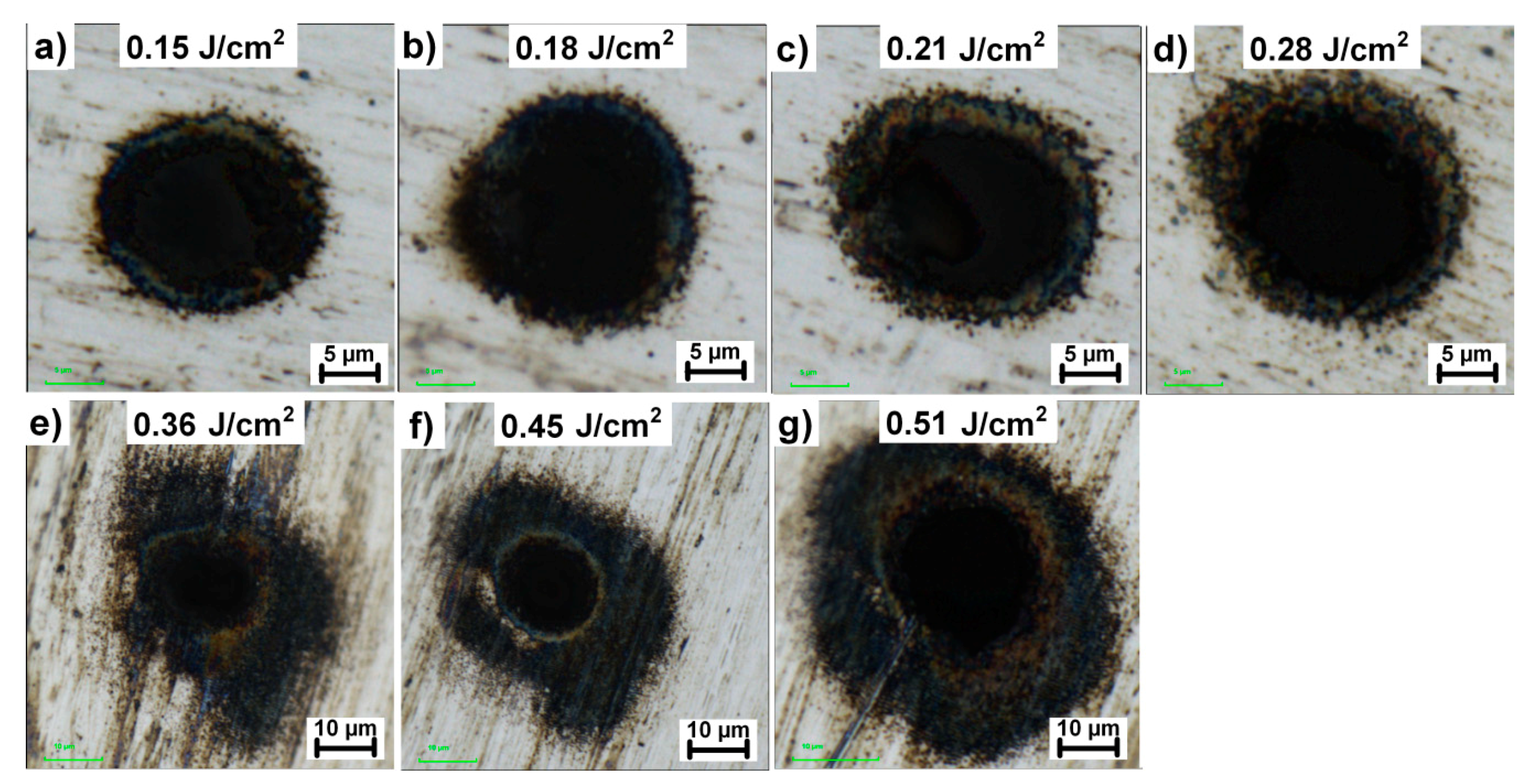

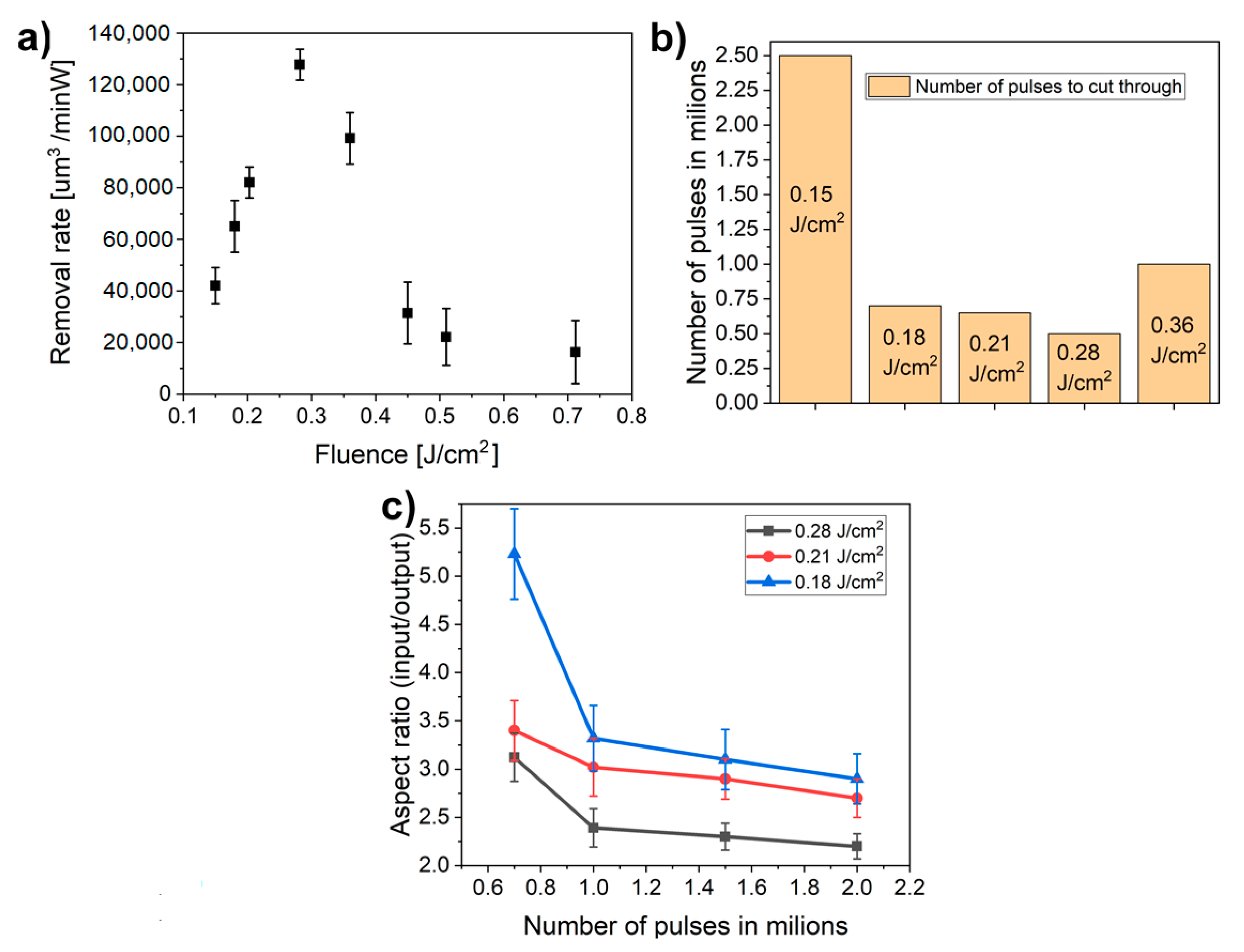

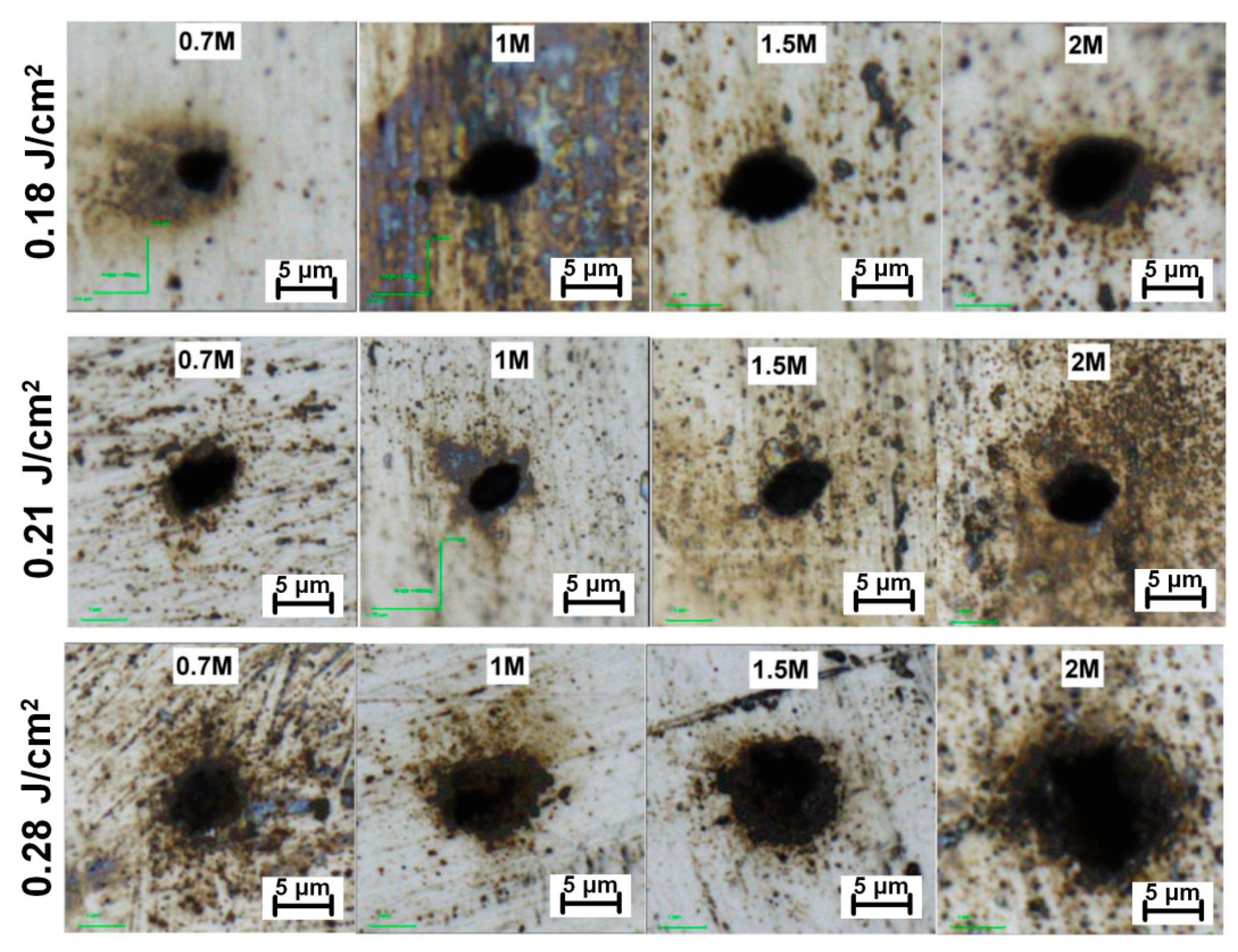

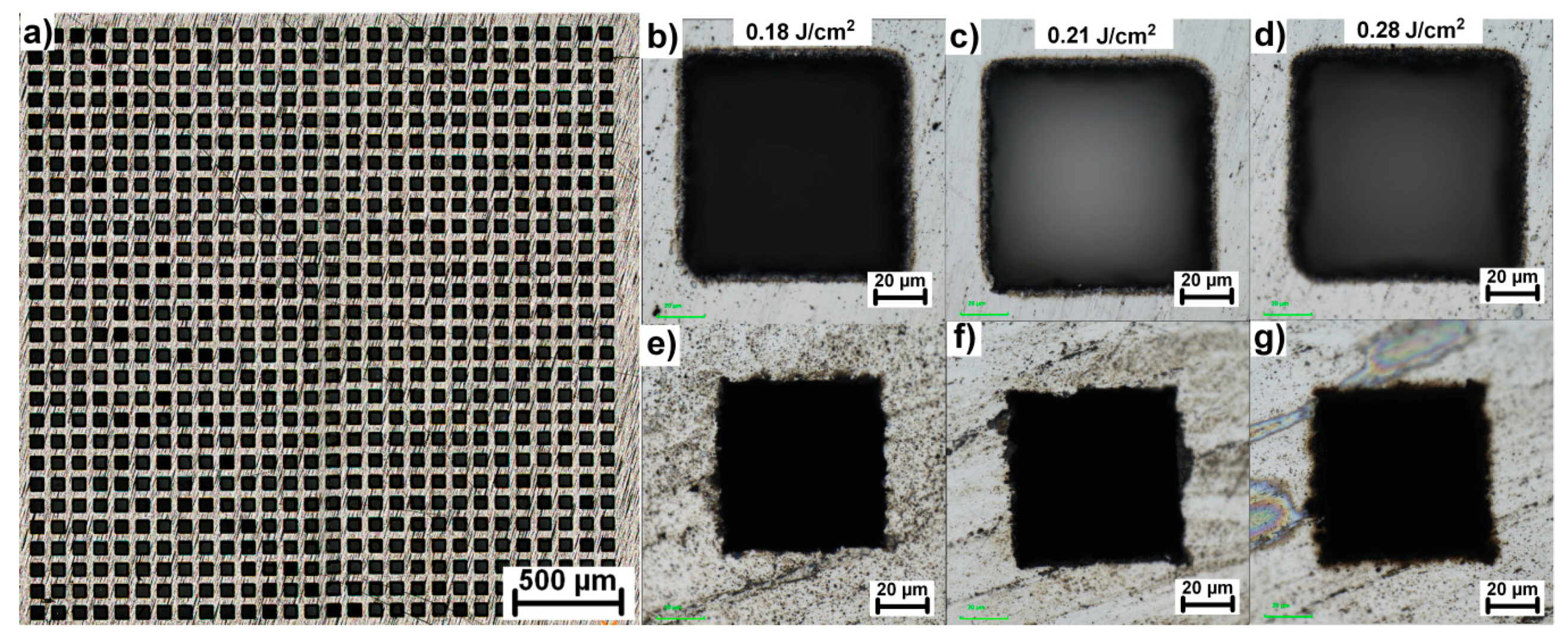

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ono, F.; Hamatani, Y.; Mukumoto, Y.; Komatsu, S.; Ishikawa, N.; Chimi, Y.; Iwase, A.; Kambara, T.; Mueller, C.; Neumann, R. Modification of Fe–Ni Invar alloys by high-energy ion beams. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interac. Mater. At. 2003, 206, 295–298. [Google Scholar] [CrossRef]

- Kim, C. Production of shadow-mask-improved technology. J. Mater. Process. Technol. 2002, 127, 409–418. [Google Scholar] [CrossRef]

- Shin, H.Y.; Suh, M.C. A study on full color organic light emitting diodes with blue common layer under the patterned emission layer. Org. Electron. 2014, 15, 2932–2941. [Google Scholar] [CrossRef]

- Chung, I.-Y.; Kim, J.-D.; Kang, K.-H. Ablation drilling of invar alloy using ultrashort pulsed laser. Int. J. Precis. Eng. Manuf. 2009, 10, 11–16. [Google Scholar] [CrossRef]

- Kim, S.H.; Choi, S.G.; Choi, W.K.; Yang, B.Y.; Lee, E.S. Pulse electrochemical machining on Invar alloy: Optical microscopic/SEM and non-contact 3D measurement study of surface analyses. Appl. Surf. Sci. 2014, 314, 822–831. [Google Scholar] [CrossRef]

- Choi, W.; Kim, H.Y.; Jeon, J.W.; Chang, W.S.; Cho, S.H. Vibration-assisted femtosecond Laser drilling with controllable taper angles for AMOLED fine metal mask fabrication. Materials 2017, 10, 212. [Google Scholar] [CrossRef] [Green Version]

- Klank, H.; Kutter, J.P.; Geschke, O. CO2-laser micromachining and back-end processing for rapid production of PMMA-based microfluidic systems. Lab Chip 2002, 2, 242–246. [Google Scholar] [CrossRef]

- Fan, Y.; Li, H.; Yi, Y.; Foulds, I.G. Laser micromachined wax-covered plastic paper as both sputter deposition shadow masks and deep-ultraviolet patterning masks for polymethylmethacrylate-based microfluidic systems. J. Micro/Nanolithogr. MEMS MOEMS 2013, 12, 049701. [Google Scholar] [CrossRef] [Green Version]

- Tahir, B.A.; Ahmed, R.; Ashiq, M.G.; Ahmed, A.; Saeed, M.A. Cutting of nonmetallic materials using Nd: YAG laser beam. Chin. Phys. B 2012, 21, 044201. [Google Scholar] [CrossRef]

- Shiu, P.; Knopf, G.; Ostojic, M.; Nikumb, S. Rapid fabrication of tooling for microfluidic devices via laser micromachining and hot embossing. J. Micromech. Microeng. 2008, 18, 025012. [Google Scholar] [CrossRef] [Green Version]

- Rizvi, N.H.; Apte, P. Developments in laser micro-machining techniques. J. Mater. Process. Technol. 2002, 127, 206–210. [Google Scholar] [CrossRef]

- Kumar, A.; Gupta, A.; Kant, R.; Akhtar, S.N.; Tiwari, N.; Ramkumar, J.; Bhattacharya, S. Optimization of laser machining process for the preparation of photomasks, and its application to microsystems fabrication. J. Micro/Nanolithogr. MEMS MOEMS 2013, 12, 041203. [Google Scholar] [CrossRef]

- Heo, J.; Min, H.; Lee, M. Laser micromachining of permalloy for fine metal mask. Int. J. Precis. Eng. Manuf. Green Technol. 2015, 2, 225–230. [Google Scholar] [CrossRef] [Green Version]

- Smrž, M.; Novák, O.; Mužík, J.; Turčičová, H.; Chyla, M.; Nagisetty, S.S.; Vyvlečka, M.; Roškot, L.; Miura, T.; Černohorská, J.; et al. Advances in high-power, ultrashort pulse DPSSL technologies at HiLASE. Appl. Sci. 2017, 7, 1016. [Google Scholar] [CrossRef] [Green Version]

- Mincuzzi, G.; Gemini, L.; Faucon, M.; Kling, R. Extending ultra-short pulse laser texturing over large area. Appl. Surf. Sci. 2016, 386, 65–71. [Google Scholar] [CrossRef]

- De Loor, R. Polygon scanner system for ultra short pulsed laser micro-machining applications. Phys. Proced. 2013, 41, 544–551. [Google Scholar] [CrossRef] [Green Version]

- Voisiat, B.; Gedvilas, M.; Indrišiūnas, S.; Račiukaitis, G. Picosecond-laser 4-beam-interference ablation as a flexible tool for thin film microstructuring. Phys. Proced. 2011, 12, 116–124. [Google Scholar] [CrossRef] [Green Version]

- Hauschwitz, P.; Jagdheesh, R.; Alamri, S.; Rostohar, D.; Kunze, T.; Brajer, J.; Kopeček, J.; Mocek, T. Fabrication of functional superhydrophobic surfaces on carbon fibre reinforced plastics by IR and UV direct laser interference patterning. Appl. Surf. Sci. 2019, 508, 144817. [Google Scholar] [CrossRef]

- Gillner, A.; Finger, J.; Gretzki, P.; Niessen, M.; Bartels, T.; Reininghaus, M. High power laser processing with ultrafast and multi-parallel beams. J. Laser Micro Nanoeng. 2019, 14, 129–137. [Google Scholar]

- Katz, S.; Kaplan, N.; Grossinger, I. Using Diffractive Optical Elements: DOEs for beam shaping–fundamentals and applications. Opt. Photonik 2018, 13, 83–86. [Google Scholar] [CrossRef] [Green Version]

- Holtkamp, J.; Eifel, S.; Ryll, J. Material Processing with Ultrashort-pulsed Lasers: Potentials—Requirements—Approaches. Laser Tech. J. 2014, 11, 36–39. [Google Scholar] [CrossRef]

- Holtkamp, J. Pulsar Photonics: Innovative Beam Forming Concepts, Swissphotonics. Available online: https://swissphotonics.net/libraries.files/holtkamp (accessed on 1 July 2020).

- Duda, M.; Novák, O.; Chyla, M.; Smrž, M.; Mocek, T. Balancing the conversion efficiency and beam quality of second harmonic generation of a two-picosecond Yb: YAG thin-disk laser. Laser Phys. 2020, 30, 025405. [Google Scholar] [CrossRef] [Green Version]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hauschwitz, P.; Stoklasa, B.; Kuchařík, J.; Turčičová, H.; Písařík, M.; Brajer, J.; Rostohar, D.; Mocek, T.; Duda, M.; Lucianetti, A. Micromachining of Invar with 784 Beams Using 1.3 ps Laser Source at 515 nm. Materials 2020, 13, 2962. https://doi.org/10.3390/ma13132962

Hauschwitz P, Stoklasa B, Kuchařík J, Turčičová H, Písařík M, Brajer J, Rostohar D, Mocek T, Duda M, Lucianetti A. Micromachining of Invar with 784 Beams Using 1.3 ps Laser Source at 515 nm. Materials. 2020; 13(13):2962. https://doi.org/10.3390/ma13132962

Chicago/Turabian StyleHauschwitz, Petr, Bohumil Stoklasa, Jiří Kuchařík, Hana Turčičová, Michael Písařík, Jan Brajer, Danijela Rostohar, Tomáš Mocek, Martin Duda, and Antonio Lucianetti. 2020. "Micromachining of Invar with 784 Beams Using 1.3 ps Laser Source at 515 nm" Materials 13, no. 13: 2962. https://doi.org/10.3390/ma13132962

APA StyleHauschwitz, P., Stoklasa, B., Kuchařík, J., Turčičová, H., Písařík, M., Brajer, J., Rostohar, D., Mocek, T., Duda, M., & Lucianetti, A. (2020). Micromachining of Invar with 784 Beams Using 1.3 ps Laser Source at 515 nm. Materials, 13(13), 2962. https://doi.org/10.3390/ma13132962