Effect of Oxygen Variation on High Cycle Fatigue Behavior of Ti-6Al-4V Titanium Alloy

Abstract

1. Introduction

2. Materials and Experimental Procedure

2.1. Materials

2.2. Microstructural Characteristics

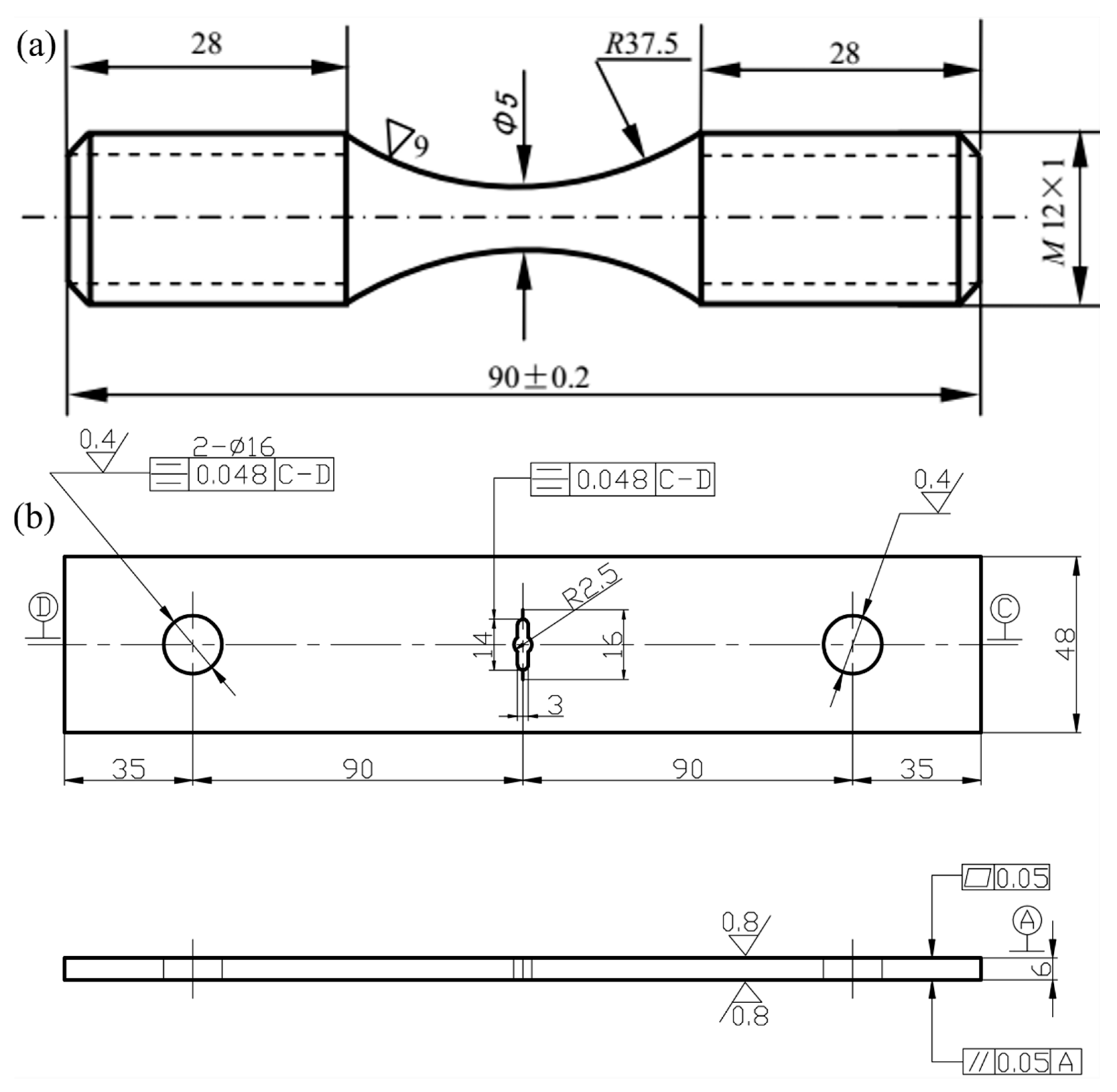

2.3. High Cycle Fatigue Preformance Test

2.4. Fracture Characteristics Observation and Nano-Indentation Test

3. Results and Discussion

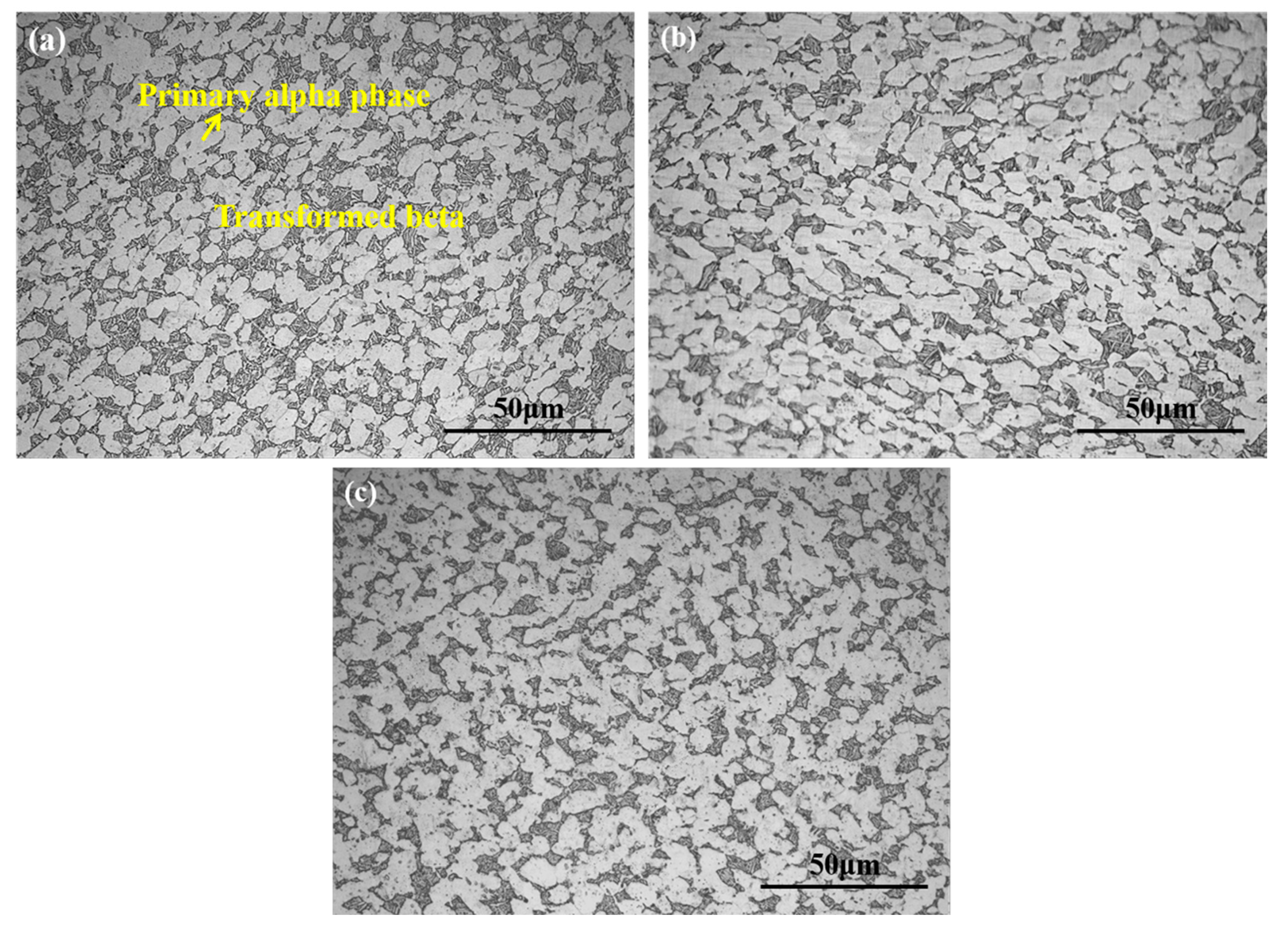

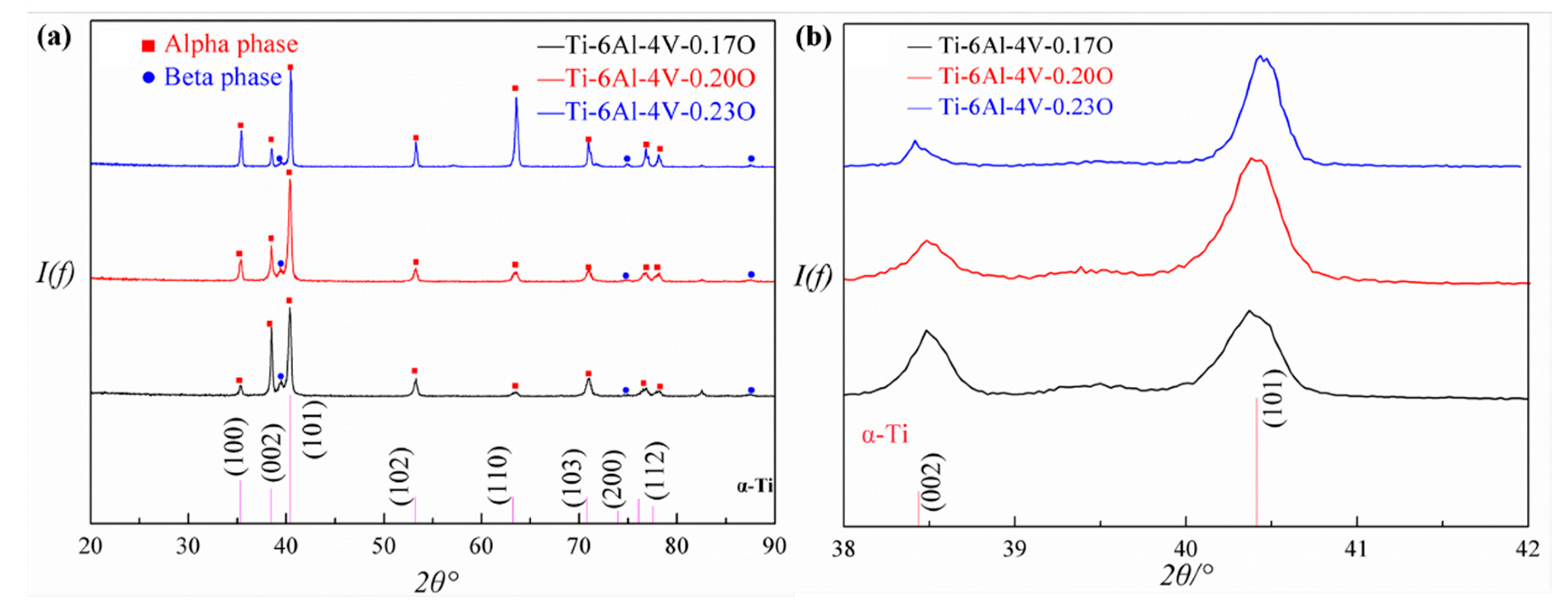

3.1. Microstructural Characteristics of Ti-6Al-4V Alloy

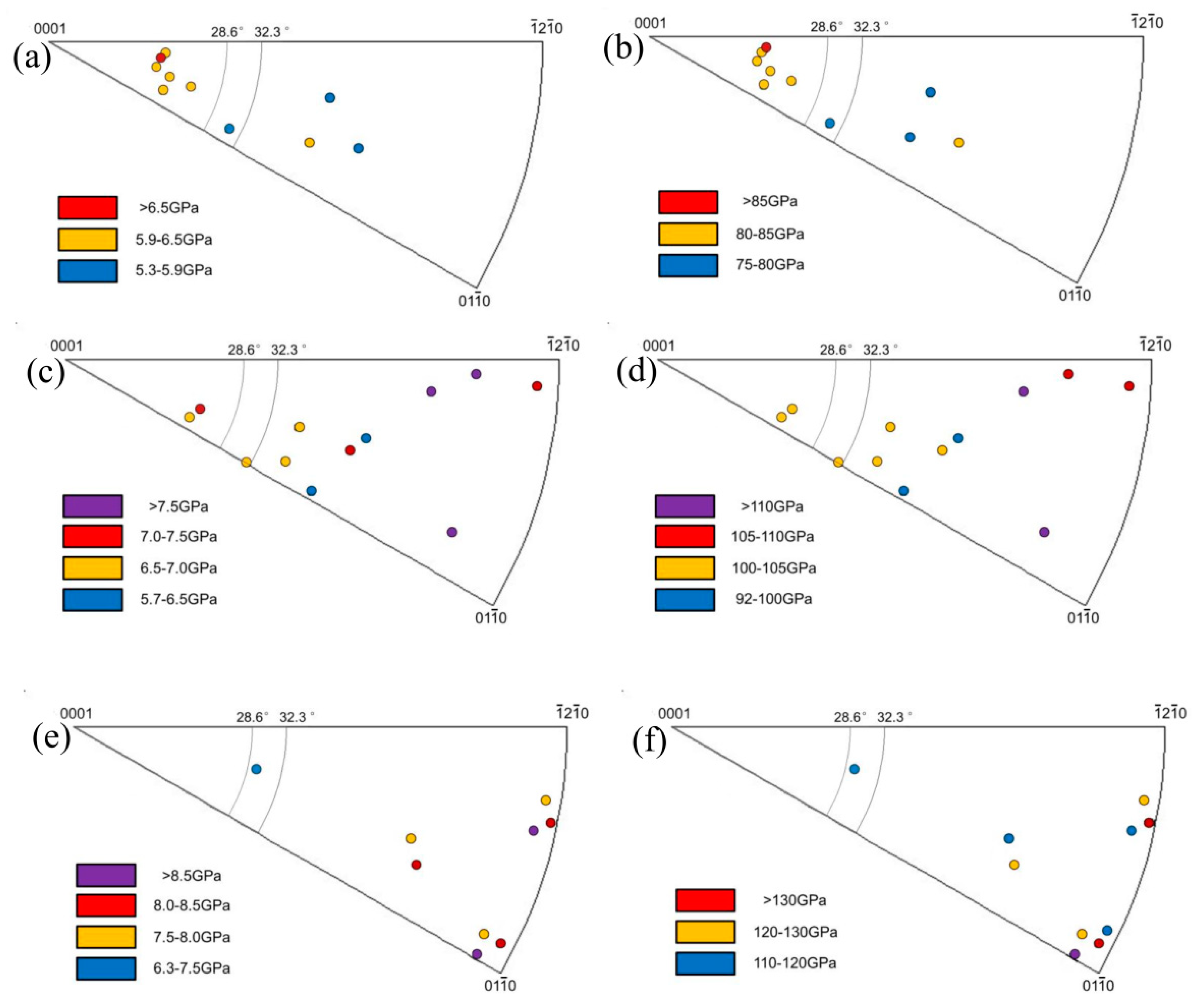

3.2. Effect of Oxygen Variation on the Micro-Mechanical Properties of Alpha Phase

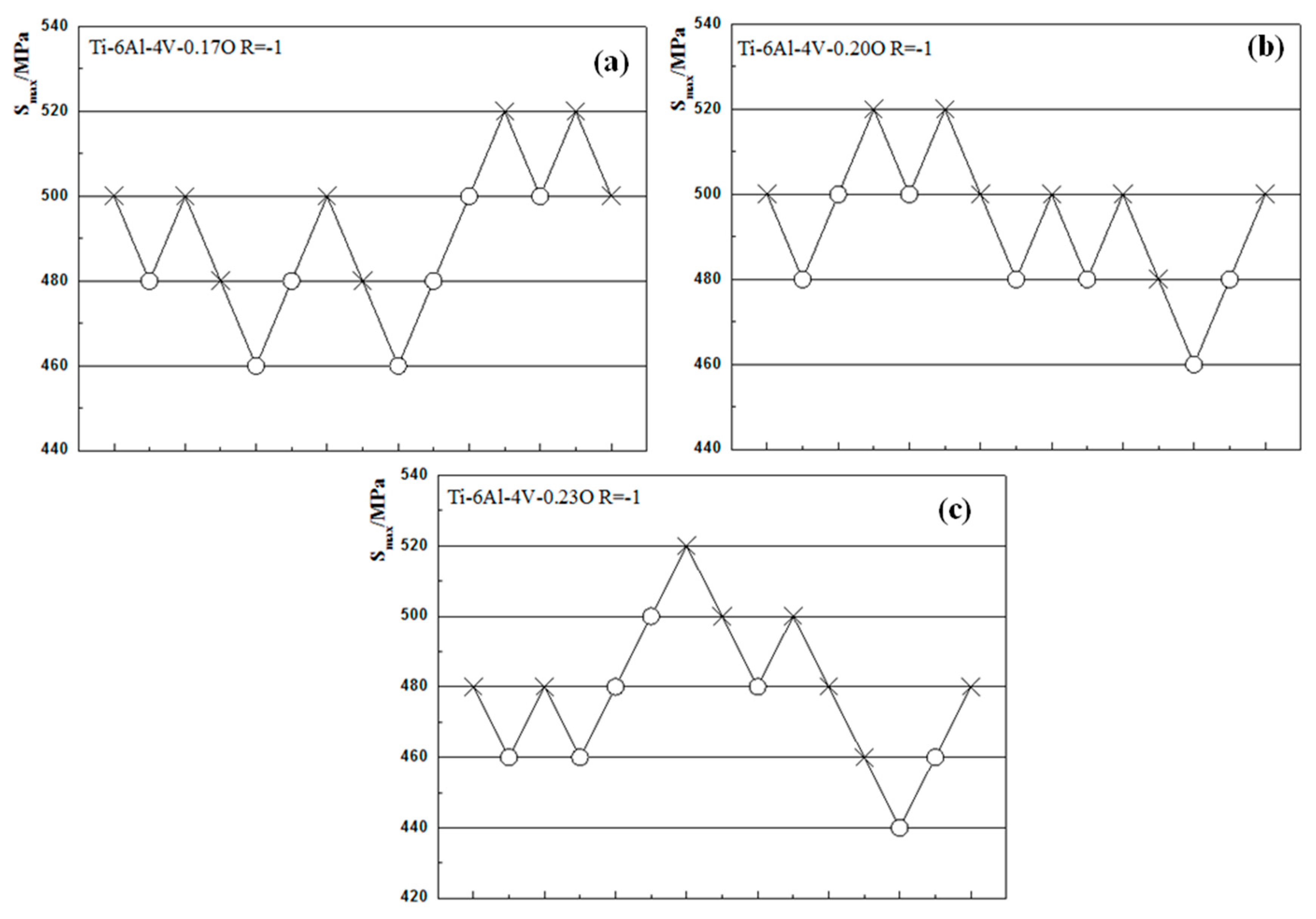

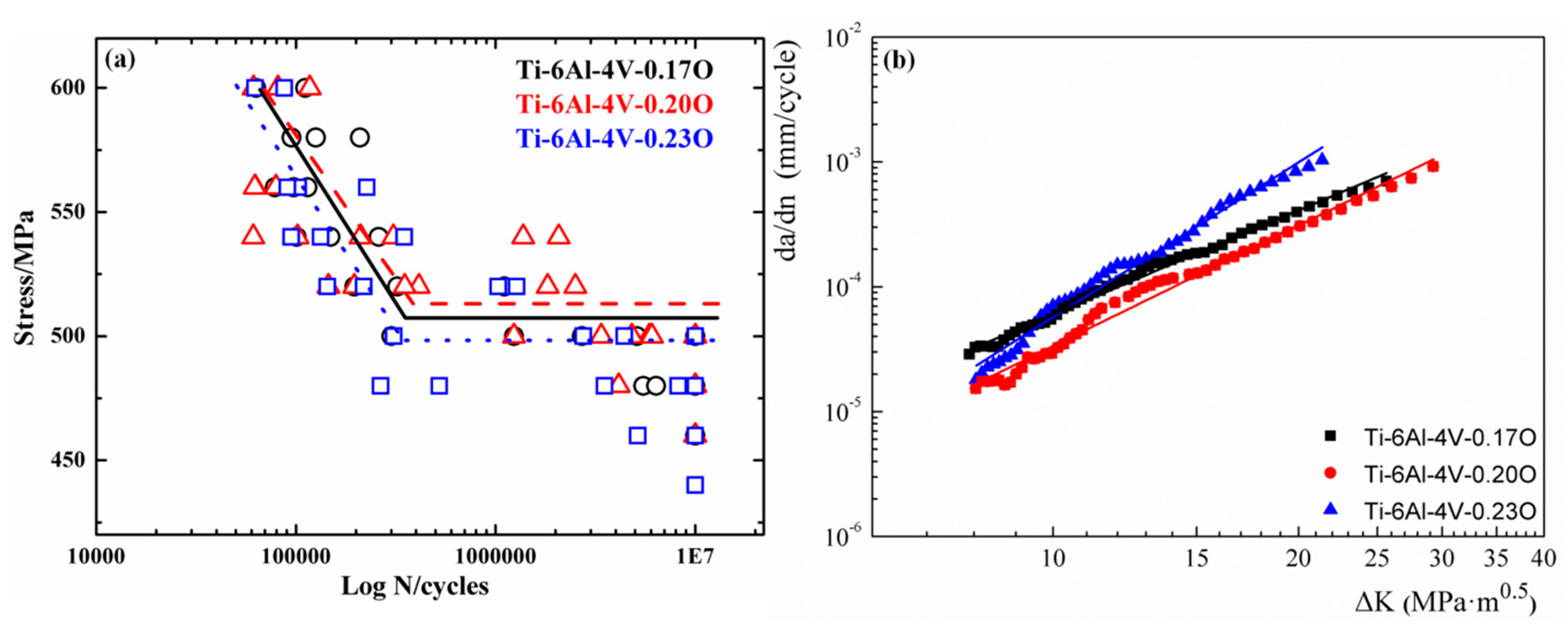

3.3. Effect of Oxygen Variation on Fatigue Properties

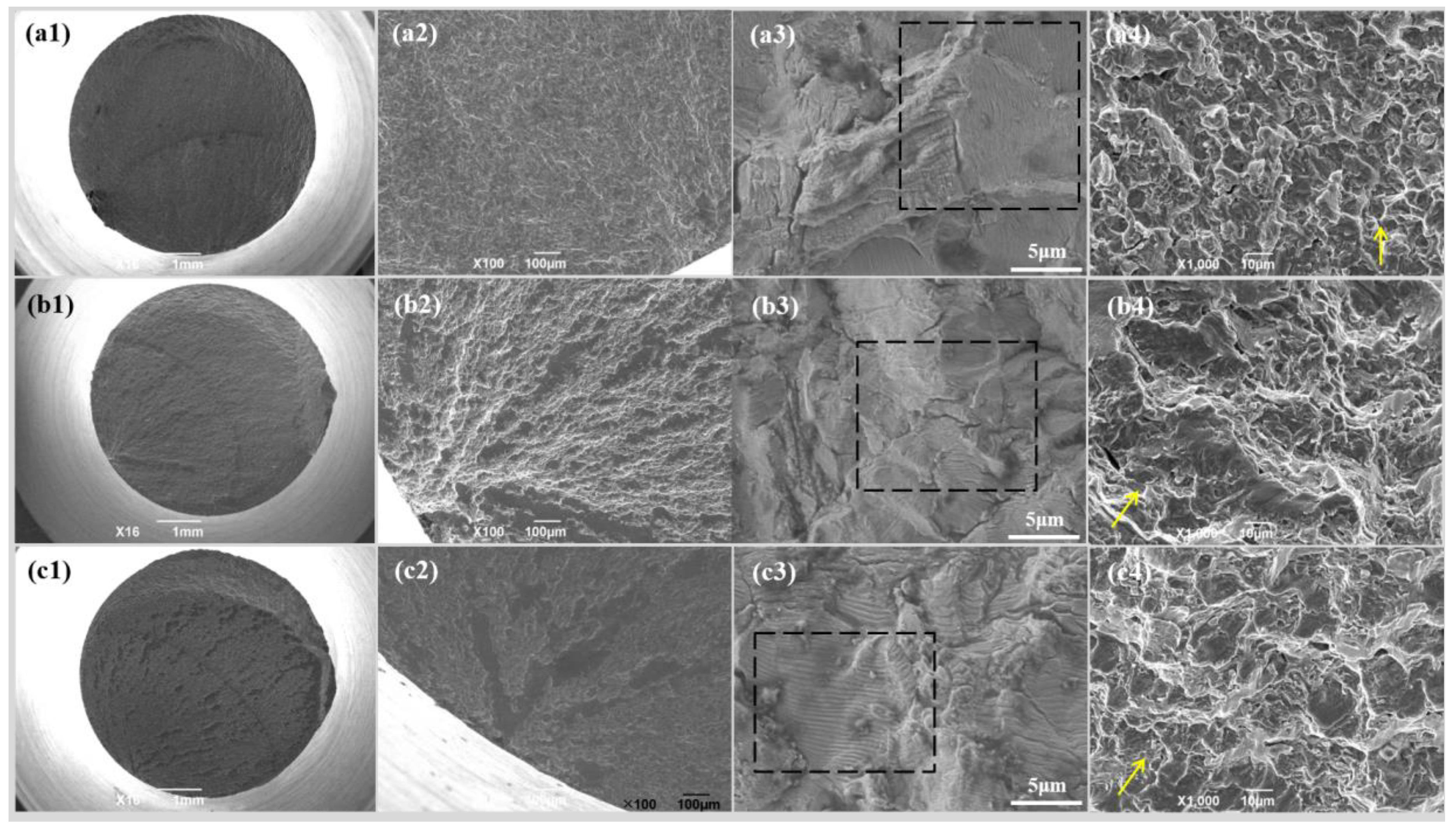

3.4. Characterization of Fatigue Fracture Morphologies

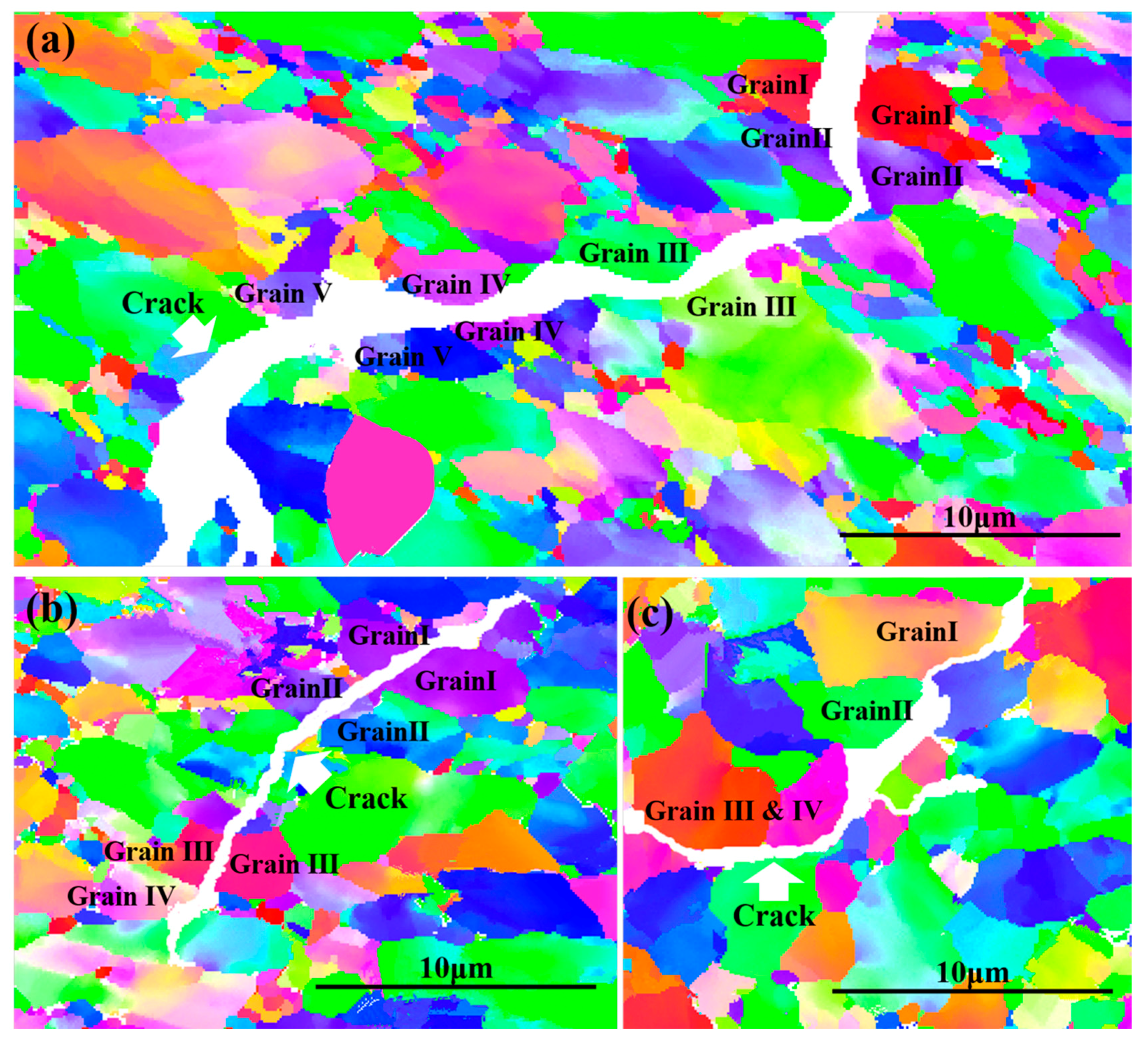

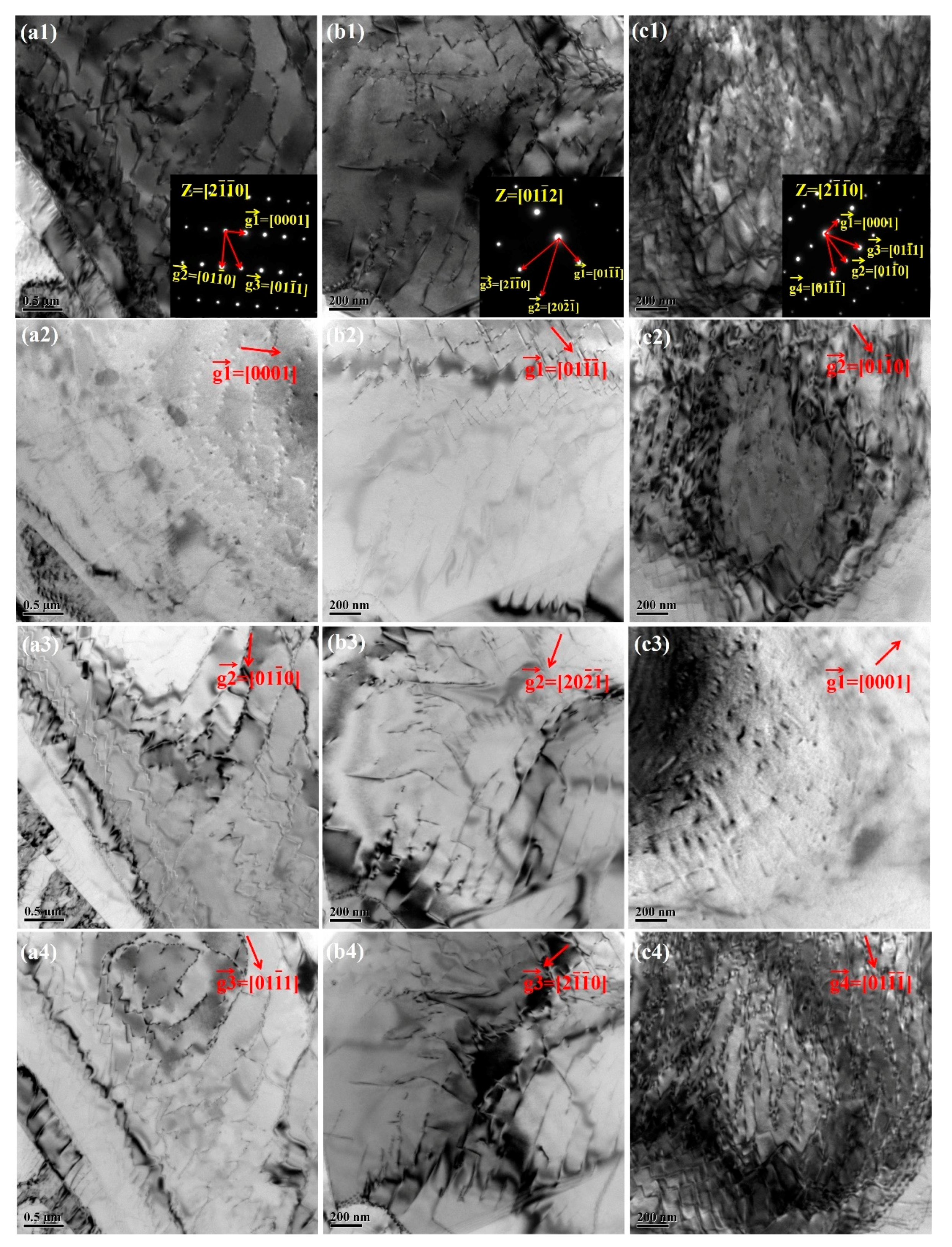

3.5. Dislocation Structure Features of the Ti-6Al-4V Alloy after Fatigue Loading

4. Conclusions

- The volume fraction of primary alpha phase and the alpha-Ti lattice constants (a, c) and the c/a ratio increased a little with increasing oxygen content. The microstructure characteristics (alpha phase volume fraction and grain size) of the Ti-6Al-4V alloy were not significantly changed by the fine adjustment of the oxygen content.

- The values of elasticity modulus and nano-hardness increased with the oxygen content in Ti-6Al-4V alloys. The HIPFs and MIPFs illustrated that the variation of oxygen content in Ti-6Al-4V alloys would lead to the variation of the CRSS in different slip system. Such results aligned well with the fact that the pyramidal slip exceeded the prismatic slip and became the dominating slip system when the oxygen content increased in Ti-6Al-4V alloys.

- By controlling the oxygen content in the Ti-6Al-4V alloy, both the fatigue performance and the fatigue performance scatter of the Ti-6Al-4V alloy can be controlled. The fatigue performance of the Ti-6Al-4V-0.20O alloy was relatively better, compared with the Ti-6Al-4V alloy with other oxygen contents, and the dispersion of high cycle fatigue life was the lowest. Fatigue cracks propagated transgranularly in both Ti-6Al-4V-017O and Ti-6Al-4V-0.20O alloys, and the cracks tended to extend intergranularly in the Ti-6Al-4V-0.23O alloy. Such phenomenon indicated that the fatigue fracture micro-mechanisms varied from transcrystalline fracture to intercrystalline fracture.

- The dislocations were corrugated and fluctuated more intensely with the increasing oxygen content. The number of dislocations increased obviously with increasing oxygen content, which suggested that the number of the activated prismatic slip systems increased in Ti-6Al-4V alloys.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Leyens, C.; Peters, M. Titanium and Titanium Alloys: Fundamentals and Applications; Wiley-VCH: Weinheim, Germany, 2003. [Google Scholar]

- Lütjering, G.; Williams, J.C. Titanium. Engineering Materials Processes, 2nd ed.; Springer International Publishing: Cham, Switzerland, 2010. [Google Scholar]

- Cowles, B.A. High cycle fatigue in aircraft gas turbines—An industry perspective. Int. J. Fract. 1996, 80, 147–163. [Google Scholar] [CrossRef]

- Chan, K.S. Roles of microstructure in fatigue crack initiation. Int. J. Fatigue 2010, 32, 1428–1447. [Google Scholar] [CrossRef]

- Murray, J.L.; Wriedt, H.A. The O−Ti (Oxygen-Titanium) system. J. Phase Equilibria Diffus. 1987, 8, 148–165. [Google Scholar] [CrossRef]

- Yan, M.; Dargusch, M.S.; Ebel, T.; Qian, M. A transmission electron microscopy and three-dimensional atom probe study of the oxygen-induced fine microstructural features in as-sintered Ti–6Al–4V and their impacts on ductility. Acta Mater. 2014, 68, 196–206. [Google Scholar] [CrossRef]

- Wei, Q.; Wang, L.; Fu, Y.; Qin, J.; Lu, W.; Zhang, D. Influence of oxygen content on microstructure and mechanical properties of Ti–Nb–Ta–Zr alloy. Mater. Des. 2011, 32, 2934–2939. [Google Scholar] [CrossRef]

- Welsch, G.; Bunk, W. Deformation modes of the α-phase of ti-6al-4v as a function of oxygen concentration and aging temperature. Met. Mater. Trans. A 1982, 13, 889–899. [Google Scholar] [CrossRef]

- Shen, R.; Chen, F.; Yu, X.Q.; Zhang, Y.F.; Li, G.; Li, Q. Influence of Oxygen Content on Microstructure and Mechanical Properties of Ti-35Nb-3.7Zr-1.3Mo-xO alloys. Southeast Univ. Nat. Sci. Ed. 2015, 3, 478–483. [Google Scholar]

- Hu, G.X.; Cai, X. Foundation of Material Science; Shanghai Jiaotong University Press: Shanghai, China, 2000. [Google Scholar]

- Wu, H.H.; Trinkle, D. Direct Diffusion through Interpenetrating Networks: Oxygen in Titanium. Phys. Rev. Lett. 2011, 107. [Google Scholar] [CrossRef]

- Kwaśniak, P.; Muzyk, M.; Garbacz, H.; Kurzydlowsk, K. Influence of oxygen content on the mechanical properties of hexagonal Ti—First principles calculations. Mater. Sci. Eng. A 2014, 590, 74–79. [Google Scholar] [CrossRef]

- Yu, Q.; Qi, L.; Tsuru, T.; Traylor, R.; Rugg, D.; Morris, J.W.; Asta, M.; Chrzan, D.C.; Minor, A.M. Origin of dramatic oxygen solute strengthening effect in titanium. Science 2015, 347, 635–639. [Google Scholar] [CrossRef]

- Jia, M.; Zhang, D.; Gabbitas, B.; Liang, J.; Kong, C. A novel Ti–6Al–4V alloy microstructure with very high strength and good ductility. Scr. Mater. 2015, 107, 10–13. [Google Scholar] [CrossRef]

- Liu, Z.; Welsch, G. Effects of oxygen and heat treatment on the mechanical properties of alpha and beta titanium alloys. Met. Mater. Trans. A 1988, 19, 527–542. [Google Scholar] [CrossRef]

- Yoder, G.R.; Cooley, L.A.; Crooker, T.W. Fatigue crack propagation resistance of beta-annealed Ti-6AI-4V alloys of differing interstitial oxygen contents. Met. Mater. Trans. A 1978, 9, 1413–1420. [Google Scholar] [CrossRef]

- Hornberger, H.; Randow, C.; Fleck, C. Fatigue and surface structure of titanium after oxygen diffusion hardening. Mater. Sci. Eng. A 2015, 630, 51–57. [Google Scholar] [CrossRef]

- Komoda, R.; Kubota, M.; Kondo, Y.; Furtado, J. Effect of oxygen addition on fretting fatigue strength in hydrogen of JIS SUS304 stainless steel. Tribol. Int. 2014, 76, 92–99. [Google Scholar] [CrossRef]

- Bache, M.; Evans, W.; McElhone, M. The effects of environment and internal oxygen on fatigue crack propagation in ti-6al-4v. Mater. Sci. Eng. A 1997, 234, 918–922. [Google Scholar] [CrossRef]

- Robinson, J.L.; Beevers, C.J. The Effects of Load Ratio, Interstitial Content, and Grain Size on Low-Stress Fatigue-Crack Propagation in α-Titanium. Met. Sci. J. 1973, 7, 153–159. [Google Scholar] [CrossRef]

- Ghamarian, I.; Hayes, B.; Samimi, P.; Welk, B.; Fraser, H.; Collins, P. Developing a phenomenological equation to predict yield strength from composition and microstructure in β processed Ti-6Al-4V. Mater. Sci. Eng. A 2016, 660, 172–180. [Google Scholar] [CrossRef]

- Dong, J.Z. Experimental Study on Microstructure and Mechanical Properties of TC4 Titanium Alloy. Ph.D. Thesis, Northwestern Polytechnical University, Xi’an, China, 2013. [Google Scholar]

- Firstov, S.; Kulikovsky, V.; Rogul’, T.G.; Ctvrtlik, R. Effect of small concentrations of oxygen and nitrogen on the structure and mechanical properties of sputtered titanium films. Surf. Coat. Technol. 2012, 206, 3580–3585. [Google Scholar] [CrossRef]

- Oliver, W.; Pharr, G. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Gong, J.; Wilkinson, A.J. Anisotropy in the plastic flow properties of single-crystal α titanium determined from micro-cantilever beams. Acta Mater. 2009, 57, 5693–5705. [Google Scholar] [CrossRef]

- Fizanne-Michel, C.; Cornen, M.; Castany, P.; Péron, I.; Gloriant, T. Determination of hardness and elastic modulus inverse pole figures of a polycrystalline commercially pure titanium by coupling nanoindentation and EBSD techniques. Mater. Sci. Eng. A 2014, 613, 159–162. [Google Scholar] [CrossRef]

- Churchman, A.T. The slip modes of titanium and the effect of purity on their occurrence during tensile deformation of single crystals. Proc. R. Soc. Lond. Ser. A, Math. Phys. Sci. 1954, 226, 216–226. [Google Scholar] [CrossRef]

- Gao, Z.T.; Xiong, J.J. Fatigue Reliability; Beijing University of Aeronautics and Astronautics Press: Beijing China, 2000; pp. 366–372. [Google Scholar]

- Smith, S.S.; Piascik, R. Fatigue Crack Growth Characteristics of Thin Sheet Titanium Alloy Ti 6-2-2-2-2; Langley Research Center: Hampton, VA, USA, March 2001.

- Pham, M.-S.; Solenthaler, C.; Janssens, K.; Holdsworth, S. Dislocation structure evolution and its effects on cyclic deformation response of AISI 316L stainless steel. Mater. Sci. Eng. A 2011, 528, 3261–3269. [Google Scholar] [CrossRef]

- Yan, X. Effect of the α Phase Characteristics on High Cycle Fatigue Property of Ti-6Al-4V-O Alloy. Ph.D. Thesis, Northwestern Polytechnical University, Xi’an, China, 2016. [Google Scholar]

- Zaefferer, S. A study of active deformation systems in titanium alloys: Dependence on alloy composition and correlation with deformation texture. Mater. Sci. Eng. A 2003, 344, 20–30. [Google Scholar] [CrossRef]

| Alloy | Ti | Al | V | O | Fe | C | N | Si | H |

|---|---|---|---|---|---|---|---|---|---|

| Ti-6Al-4V-0.17O | Bal. | 6.19 | 4.13 | 0.17 | 0.17 | 0.008 | 0.011 | 0.017 | <0.001 |

| Ti-6Al-4V-0.20O | Bal. | 6.36 | 4.19 | 0.20 | 0.18 | 0.008 | 0.013 | 0.014 | <0.001 |

| Ti-6Al-4V-0.23O | Bal. | 6.22 | 4.11 | 0.23 | 0.18 | 0012 | 0.013 | 0.013 | <0.001 |

| Alloy | a/nm | c/nm | c/a |

|---|---|---|---|

| Ti-6Al-4V-0.17O | 0.2944 | 0.4677 | 1.58865 |

| Ti-6Al-4V-0.20O | 0.2945 | 0.4679 | 1.58879 |

| Ti-6Al-4V-0.23O | 0.2948 | 0.4685 | 1.58921 |

| Alloy | Fatigue Limit /MPa | K of the Inclined Portion S-N Curves | Standard Deviation | 90% Percentiles of the Fatigue Limit Distribution |

|---|---|---|---|---|

| Ti-6Al-4V-0.17O | 510.00 | 9.396 | 19.45 | 480 |

| Ti-6Al-4V-0.20O | 512.86 | 10.887 | 14.16 | 480 |

| Ti-6Al-4V-0.23O | 498.57 | 9.715 | 27.39 | 468 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, L.; Fan, J.; Kou, H.; Tang, B.; Li, J. Effect of Oxygen Variation on High Cycle Fatigue Behavior of Ti-6Al-4V Titanium Alloy. Materials 2020, 13, 3858. https://doi.org/10.3390/ma13173858

Tang L, Fan J, Kou H, Tang B, Li J. Effect of Oxygen Variation on High Cycle Fatigue Behavior of Ti-6Al-4V Titanium Alloy. Materials. 2020; 13(17):3858. https://doi.org/10.3390/ma13173858

Chicago/Turabian StyleTang, Luyao, Jiangkun Fan, Hongchao Kou, Bin Tang, and Jinshan Li. 2020. "Effect of Oxygen Variation on High Cycle Fatigue Behavior of Ti-6Al-4V Titanium Alloy" Materials 13, no. 17: 3858. https://doi.org/10.3390/ma13173858

APA StyleTang, L., Fan, J., Kou, H., Tang, B., & Li, J. (2020). Effect of Oxygen Variation on High Cycle Fatigue Behavior of Ti-6Al-4V Titanium Alloy. Materials, 13(17), 3858. https://doi.org/10.3390/ma13173858