Comparison between the UV and X-ray Photosensitivities of Hybrid TiO2-SiO2 Thin Layers

Abstract

1. Introduction

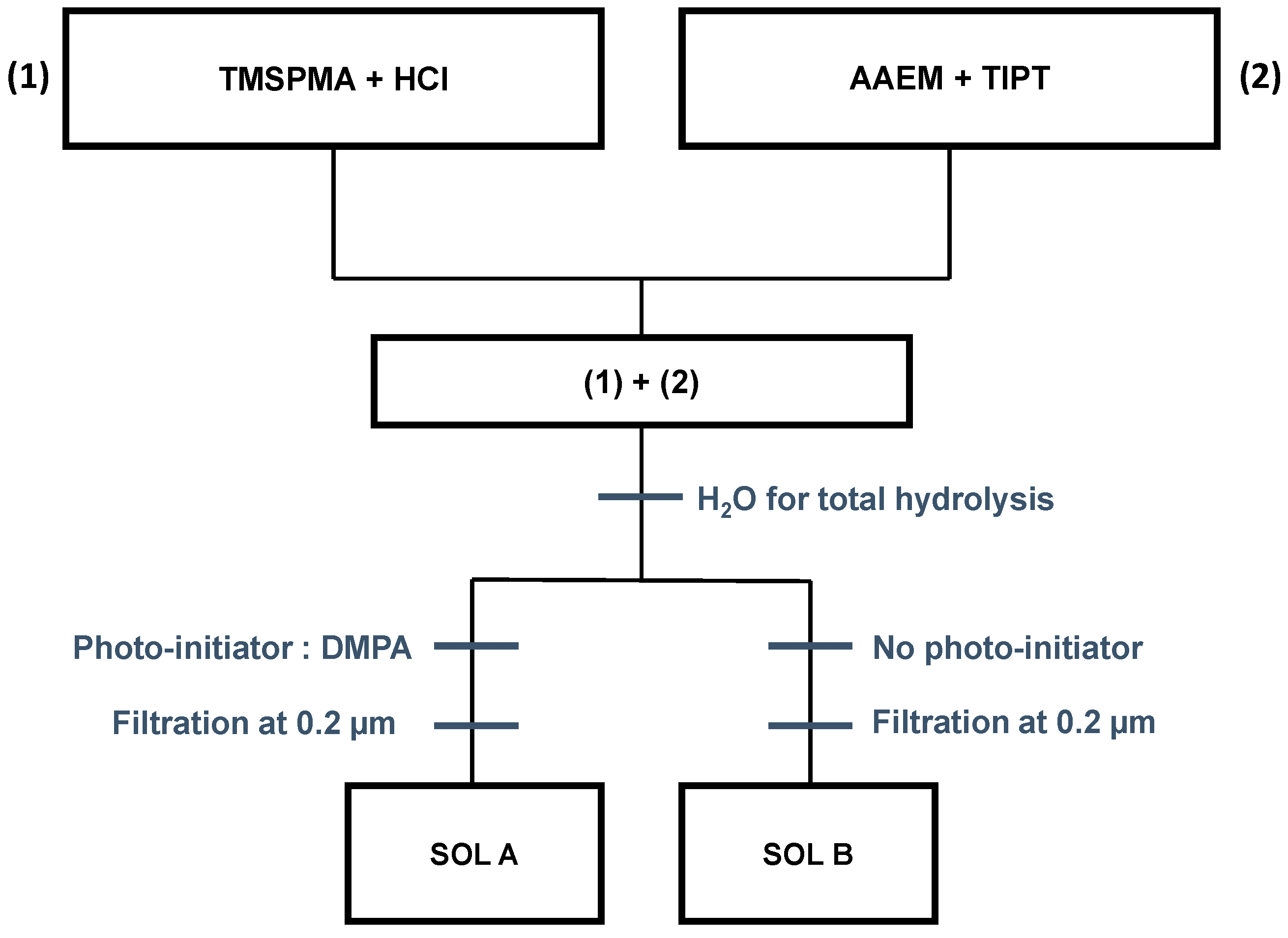

2. Materials and Methods

3. Results

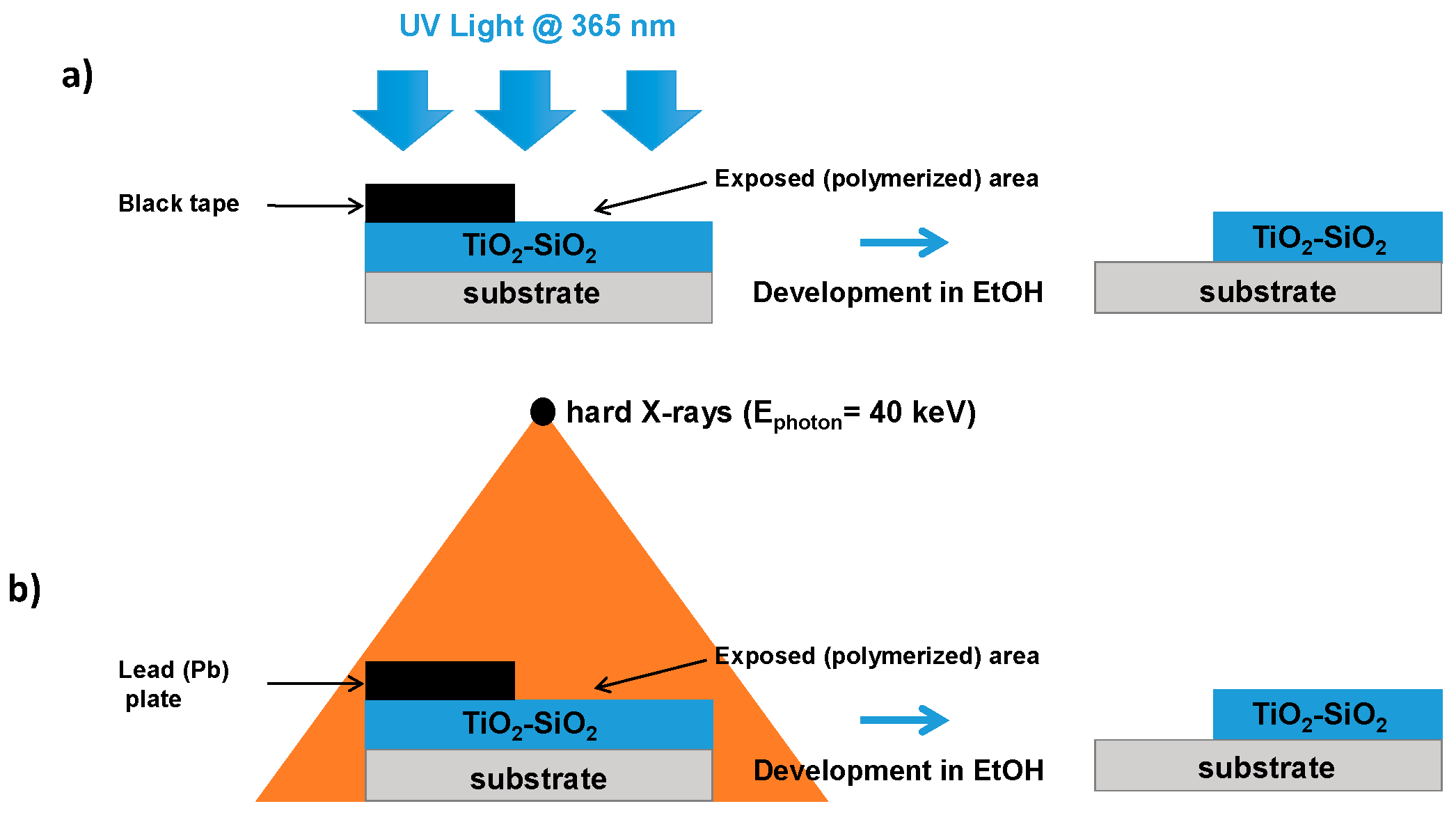

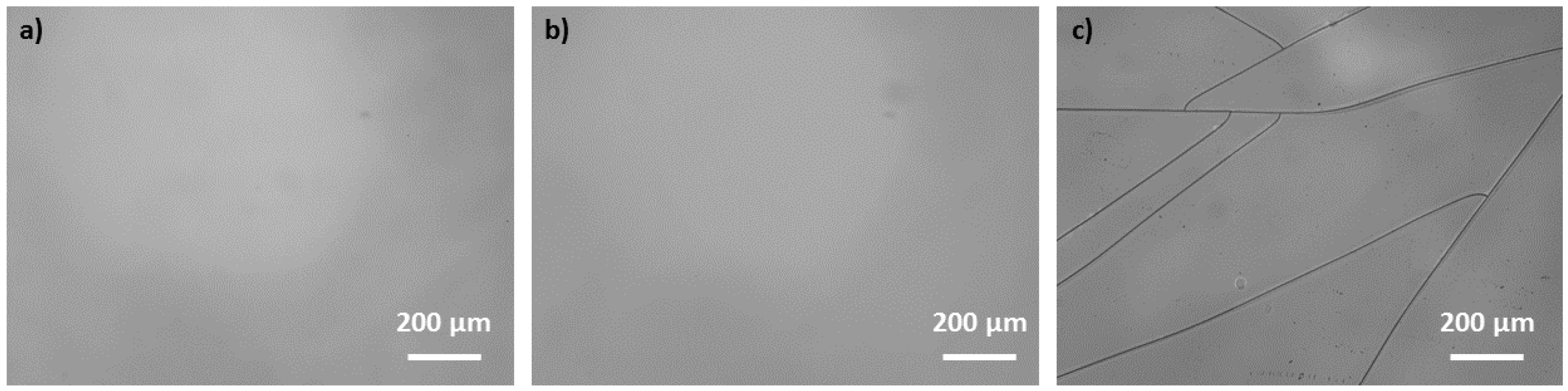

3.1. Photosensitivity Tests

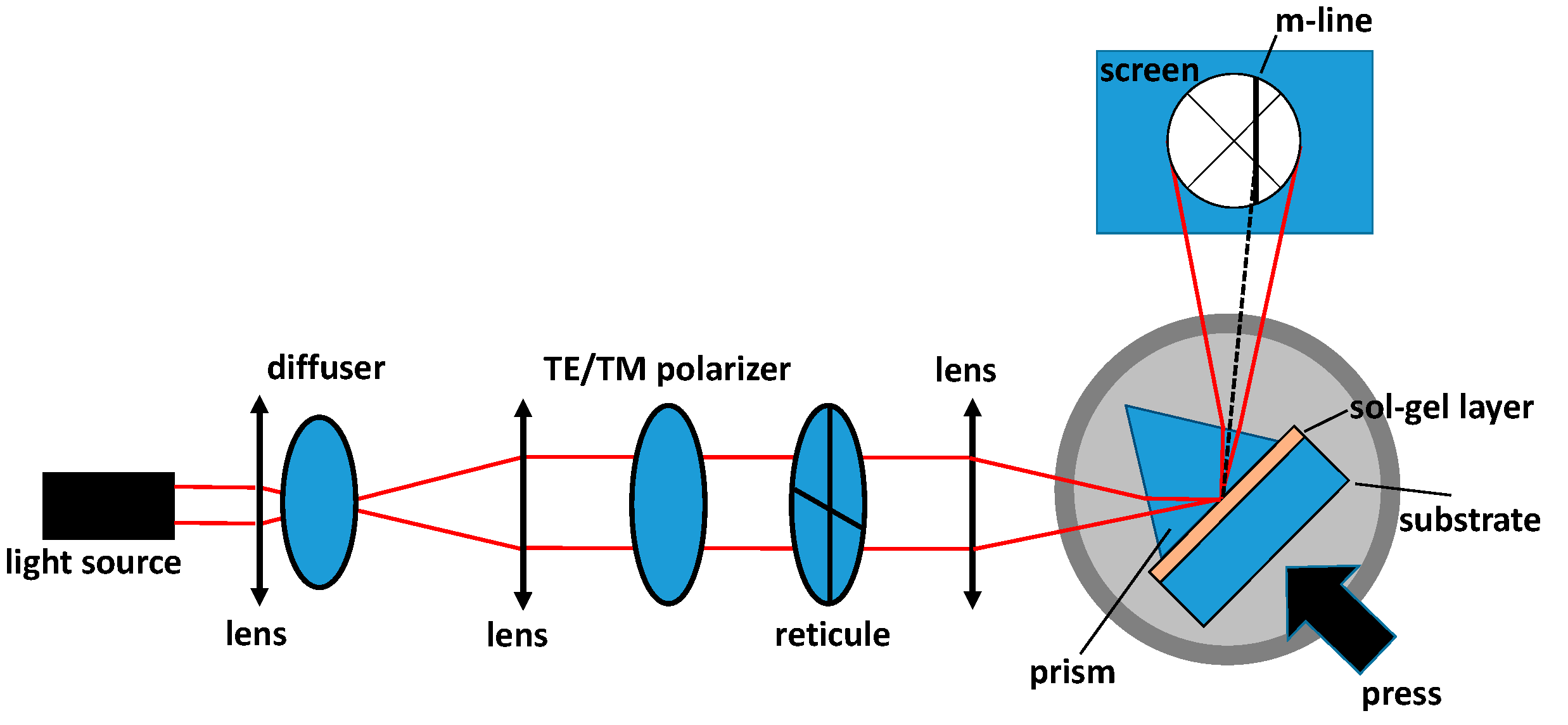

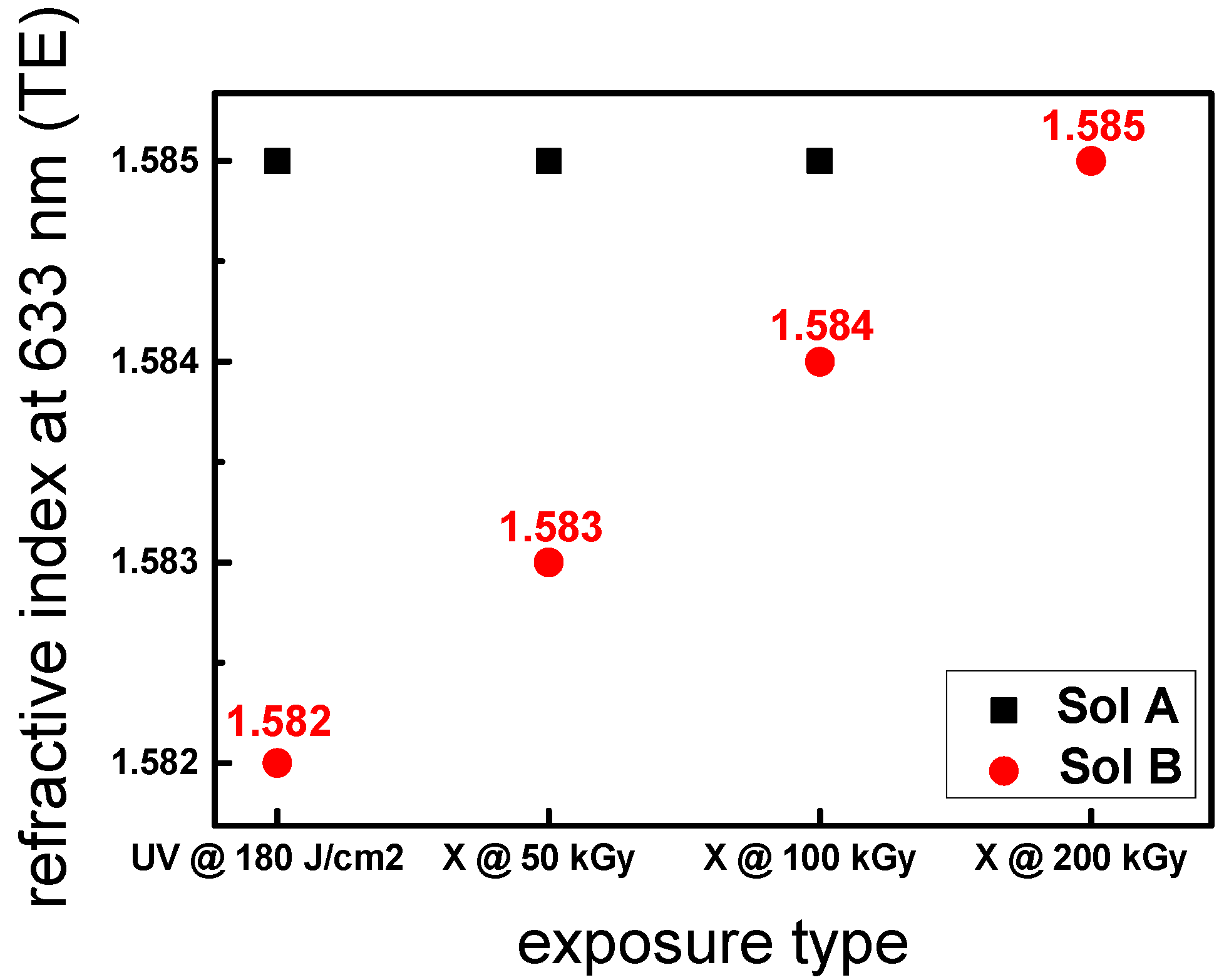

3.2. Refractive Indexes Measurements

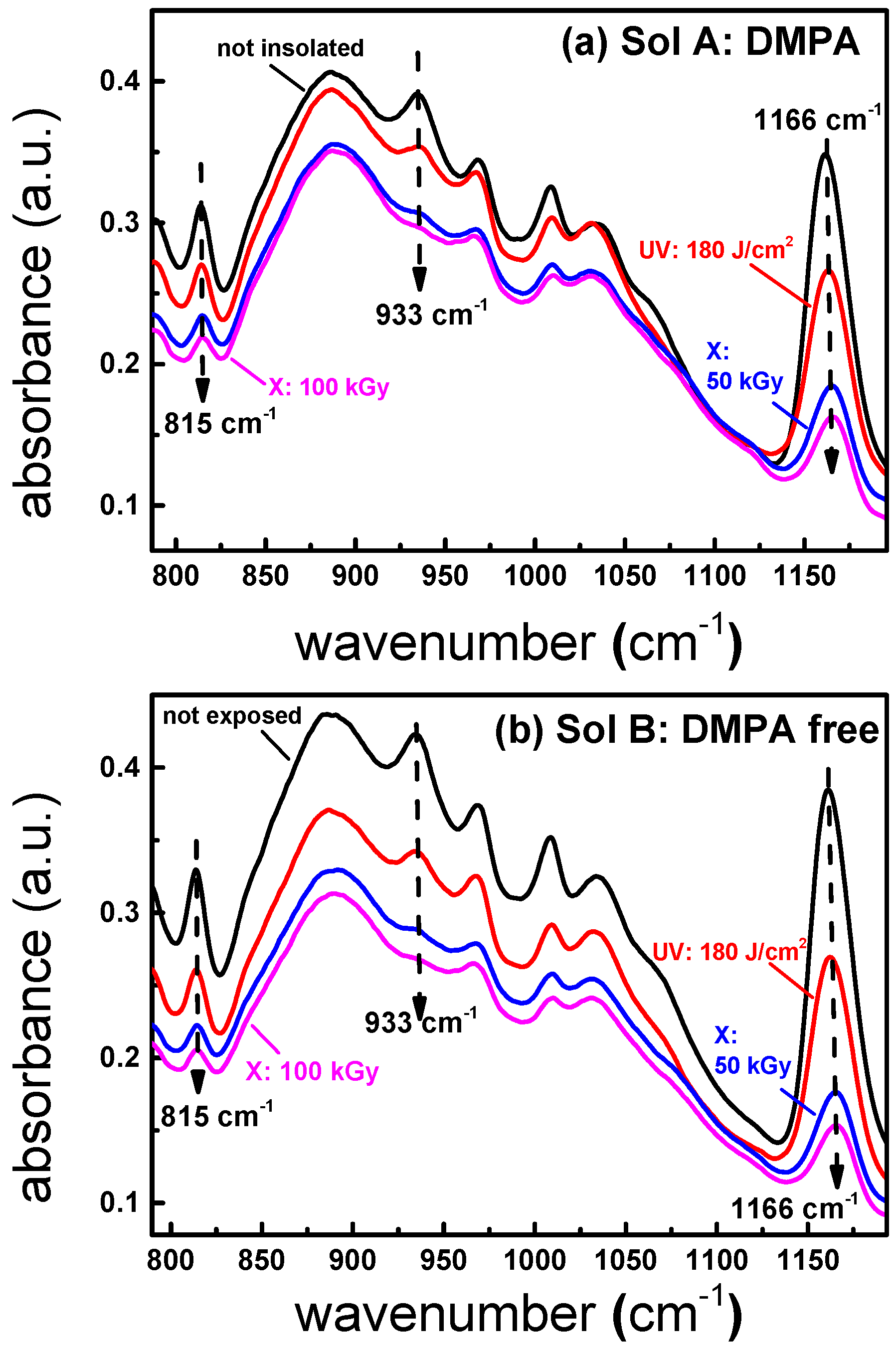

3.3. FTIR Spectroscopy

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hench, L.L.; West, J.K. The sol-gel process. Chem. Rev. 1990, 90, 33–72. [Google Scholar] [CrossRef]

- Coudray, P.; Etienne, P.; Moreau, Y.; Porque, J.; Najafi, S. Sol-gel channel waveguide on silicon: Fast direct imprinting and low cost fabrication. Opt. Commun. 1997, 143, 199–202. [Google Scholar] [CrossRef]

- Oubaha, M.; Kribich, R.K.; Copperwhite, R.; Etienne, P.; O’Dwyer, K.; MacCraith, B.D.; Moreau, Y. New inorganic sol-gel material with high transparency at 1.55 µm. Opt. Commun. 2005, 253, 346–351. [Google Scholar] [CrossRef]

- Versace, D.; Oubaha, M.; Copperwhite, R.; Croutxé-Barghorn, C.; MacCraith, B. Waveguide fabrication in UV-photocurable sol–gel materials: Influence of the photoinitiating system. Thin Solid Film 2008, 516, 6448–6457. [Google Scholar] [CrossRef][Green Version]

- Gâté, V.; Jourlin, Y.; Vocanson, F.; Dellea, O.; Vercasson, G.; Reynaud, S.; Riassetto, D.; Langlet, M. Sub-micrometric patterns written using a DIL method coupled to a TiO2 photo-resist. Opt. Mater. 2013, 35, 1706–1713. [Google Scholar] [CrossRef]

- Gâté, V.; Bernaud, G.; Veillas, C.; Cazier, A.; Vocanson, F.; Jourlin, Y.; Langlet, M. Fast dynamic interferometric lithography for large submicrometric period diffraction gratings production. Opt. Eng. 2013, 52, 091712. [Google Scholar] [CrossRef]

- Gombert, A.; Rose, K.; Heinzel, A.; Horbelt, W.; Zanke, C.; Bläsi, B.; Wittwer, V. Antireflective submicrometer surface-relief gratings for solar applications. Sol. Energy Mater. Sol. Cells 1998, 54, 333–342. [Google Scholar] [CrossRef]

- Casalboni, M.; Dominici, L.; Foglietti, V.; Michelotti, F.; Orsini, E.; Palazzesi, C.; Stella, F.; Prosposito, P. Bragg Grating Optical Filters by UV Nanoimprinting. J. Nanomater. 2012, 2012, 1–5. [Google Scholar] [CrossRef]

- Royon, M.; Piétroy, D.; Marin, E.; Saulot, A. A thermomechanical sensor using photo-inscribed volume Bragg gratings. Tribol. Int. 2017, 115, 417–423. [Google Scholar] [CrossRef]

- Hill, K.; Meltz, G. Fiber Bragg grating technology fundamentals and overview. J. Light. Technol. 1997, 15, 1263–1276. [Google Scholar] [CrossRef]

- Sanchez, C.; Julián, B.; Belleville, P.; Popall, M.; Julián-López, B. Applications of hybrid organic–inorganic nanocomposites. J. Mater. Chem. 2005, 15, 3559–3592. [Google Scholar] [CrossRef]

- Kaczmarek, H.; Galka, P. Effect of irgacure 651 initiator on poly(methyl methacryltate) photostability studied by UV-Vis spectroscopy. Open Process Chem. J. 2008, 1, 8–11. [Google Scholar] [CrossRef]

- Segurola, J.; Allen, N.S.; Edge, M.; Roberts, I. Photochemistry and photoinduced chemical crosslinking activity of acrylated prepolymers by several commercial type I far UV photoinitiators. Polym. Degrad. Stab. 1999, 65, 153–160. [Google Scholar] [CrossRef]

- Grigorescu, A.E.; Hagen, C.W. Resists for sub-20-nm electron beam lithography with a focus on HSQ: State of the art. Nanotechnology 2009, 20, 292001. [Google Scholar] [CrossRef]

- Brigo, L.; Pistore, A.; Grenci, G.; Carpentiero, A.; Romanato, F.; Brusatin, G. New hybrid organic–inorganic sol–gel positive resist. Microelectron. Eng. 2010, 87, 947–950. [Google Scholar] [CrossRef]

- Brigo, L.; Grenci, G.; Carpentiero, A.; Pistore, A.; Tormen, M.; Guglielmi, M.; Brusatin, G. Positive resist for UV and X-ray lithography synthesized through sol–gel chemistry. J. Sol-Gel Sci. Technol. 2011, 60, 400–407. [Google Scholar] [CrossRef]

- Brusatin, G.; Della Giustina, G.; Romanato, F.; Guglielmi, M. Design of hybrid sol–gel films for direct x-ray and electron beam nanopatterning. Nanotechnol. 2008, 19, 175306. [Google Scholar] [CrossRef]

- Innocenzi, P.; Malfatti, L.; Kidchob, T.; Costacurta, S.; Falcaro, P.; Marmiroli, B.; Cacho-Nerin, F.; Amenitsch, H. Densification of sol–gel silica thin films induced by hard X-rays generated by synchrotron radiation. J. Synchrotron Radiat. 2011, 18, 280–286. [Google Scholar] [CrossRef]

- Soppera, O.; Croutxé-Barghorn, C. Real-time Fourier transform infrared study of the free-radical ultraviolet-induced polymerization of a hybrid sol-gel. II. The effect of physicochemical parameters on the photopolymerization kinetics. J. Polym. Sci. Part A: Polym. Chem. 2003, 41, 831–840. [Google Scholar] [CrossRef]

- Girard, S.; Kuhnhenn, J.; Gusarov, A.; Brichard, B.; Van Uffelen, M.; Ouerdane, Y.; Boukenter, A.; Marcandella, C. Radiation Effects on Silica-Based Optical Fibers: Recent Advances and Future Challenges. IEEE Trans. Nucl. Sci. 2013, 60, 2015–2036. [Google Scholar] [CrossRef]

- Royon, M.; Marin, E.; Girard, S.; Boukenter, A.; Ouerdane, Y.; Stoian, R. X-ray preconditioning for enhancing refractive index contrast in femtosecond laser photo-inscription of embedded waveguides in pure silica. Opt. Mater. Express 2019, 9, 65–74. [Google Scholar] [CrossRef]

- Ulrich, R.; Torge, R. Measurement of Thin Film Parameters with a Prism Coupler. Appl. Opt. 1973, 12, 2901–2908. [Google Scholar] [CrossRef] [PubMed]

- Pevere, F.; Von Treskow, C.; Marino, E.; Anwar, M.; Bruhn, B.; Sychugov, I.; Linnros, J. X-ray radiation hardness and influence on blinking in Si and CdSe quantum dots. Appl. Phys. Lett. 2018, 113, 253103. [Google Scholar] [CrossRef]

- Murashkevich, A.N.; Lavitskaya, A.S.; Barannikova, T.I.; Zharskii, I.M. Infrared absorption spectra and structure of TiO2-SiO2 composites. J. Appl. Spectrosc. 2008, 75, 730–734. [Google Scholar] [CrossRef]

- Franc, J.; Blanc, D.; Zerroukhi, A.; Chalamet, Y.; Last, A.; Destouches, N. Organo-silica–titania nanocomposite elaborated by sol–gel processing with tunable optical properties. Mater. Sci. Eng. B 2006, 129, 180–185. [Google Scholar] [CrossRef]

- Huang, C.; Bai, H.; Huang, Y.; Liu, S.; Yen, S.; Tseng, Y. Synthesis of neutral SiO2/TiO2 hydrosol and its application as antireflective self-cleaning thin film. Int. J. Photoenergy 2012, 12, 620764. [Google Scholar]

| Accumulated Dose (kGy) | Sol A Polymerization | Sol B Polymerization |

|---|---|---|

| 0.5 | No | No |

| 5 | No | No |

| 10 | No | No |

| 15 | Partial | Partial |

| 25 | Full | Full |

| 50 | Full | Full |

| 100 | Full | Full |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Royon, M.; Vocanson, F.; Jamon, D.; Marin, E.; Morana, A.; Boukenter, A.; Girard, S.; Ouerdane, Y.; Royer, F.; Jourlin, Y. Comparison between the UV and X-ray Photosensitivities of Hybrid TiO2-SiO2 Thin Layers. Materials 2020, 13, 3730. https://doi.org/10.3390/ma13173730

Royon M, Vocanson F, Jamon D, Marin E, Morana A, Boukenter A, Girard S, Ouerdane Y, Royer F, Jourlin Y. Comparison between the UV and X-ray Photosensitivities of Hybrid TiO2-SiO2 Thin Layers. Materials. 2020; 13(17):3730. https://doi.org/10.3390/ma13173730

Chicago/Turabian StyleRoyon, Maxime, Francis Vocanson, Damien Jamon, Emmanuel Marin, Adriana Morana, Aziz Boukenter, Sylvain Girard, Youcef Ouerdane, François Royer, and Yves Jourlin. 2020. "Comparison between the UV and X-ray Photosensitivities of Hybrid TiO2-SiO2 Thin Layers" Materials 13, no. 17: 3730. https://doi.org/10.3390/ma13173730

APA StyleRoyon, M., Vocanson, F., Jamon, D., Marin, E., Morana, A., Boukenter, A., Girard, S., Ouerdane, Y., Royer, F., & Jourlin, Y. (2020). Comparison between the UV and X-ray Photosensitivities of Hybrid TiO2-SiO2 Thin Layers. Materials, 13(17), 3730. https://doi.org/10.3390/ma13173730