1. Introduction

Naturally occurring MoS

2 crystals, molybdenites, have been widely used as solid lubricants [

1]. The most common 2H molybdenite has three other polytypes: 3R, 1T and 1T’, which differ in structure and electronic properties [

2,

3]. 2H and 3R molybdenites can be easily peeled off mechanically to yield atomically flat MoS

2 crystals with thickness down to one monolayer [

2]. Easiness of mechanical exfoliation and semiconducting properties of 2H MoS

2 crystals have opened up a possibility to use them in a new generation of thin transistors [

4]. Today, thin 2H MoS

2 crystals contribute tremendously to vigorous growth of flexible nanoelectronics, particularly in sensing, optoelectronics and energy harvesting [

2,

5,

6,

7]. In order to exploit all of these applications, the surface reactivity of single 2H MoS

2 microscopic flakes needs to be understood. The simplest and most widely applicable surface reactions pertain to their oxidation in ambient conditions and in the presence of water.

It has been confirmed both experimentally and theoretically that bulk MoS

2 oxidation is not readily observed at ambient conditions due to high energy barriers for such reactions [

8,

9,

10,

11,

12,

13,

14,

15]. Nevertheless, all kinds of thin and thick microscopic MoS

2 crystals are etched by oxygen within the time scales of minutes when heated to temperatures of at least 320 °C. Such etching progresses according to a following stoichiometry [

8,

9,

10,

11,

12]:

Equation (1) states that out of all the possible Mo oxides, only the MoO

3 is produced. Exclusive presence of MoO

3 on the oxidized MoS

2 samples has been observed in many oxidative processes carried out in oxygen or in air. Transparent MoO

3 crystals change into yellow and grayish-blue, only when oxygen defects yielding Mo

5+ and Mo

4+ species, respectively, are purposefully introduced, e.g., via hydrogen adsorption [

16]. XPS and XRD experiments on thin Mo films have shown that all defective MoO

3 species with Mo

4+ and Mo

5+ became fully oxidized to MoO

3 already at more than 5% of oxygen in reactive gases [

17]. The majority of the published studies, mostly using the XPS measurements, detect exclusively Mo

6+ oxides—i.e., MoO

3, onto thermally oxidized MoS

2 samples [

12,

18,

19]. Furthermore, by performing thermodynamic calculations and using enthalpies of bulk reactions, Walter et al. have calculated that for a closed system consisting of the MoS

2 crystals in air, Equation (1) is indeed an exclusive reaction pathway, but only till system temperature of 470 °C [

12]. Above 470 °C, volatile (MoO

3)

3 and (MoO

3)

4 species started to appear in their simulations due to sublimation of the MoO

3(s). At 525 °C none of the MoO

3 was predicted to stay on the oxidized MoS

2 samples.

Somewhat different MoS

2 oxidation outcomes, however, are expected in the presence of water or humid air. Ross and Sussman experimented with pulverized bulk MoS

2 crystals and showed that water vapors helped in producing substantially more MoO

3 than expected from Equation (1). They verified that an additional MoO

3 was produced in the course of a following reaction [

20]:

Furthermore, volatile molybdenum(VI) hydroxyoxides, MoO

2(OH)

2(g), have been predicted to appear above 300 °C in the calculations of Walter et al. (There, partial pressure of water vapors was set to the saturared water vapor pressure at room temperature, or to 100% relative humidity at 25 °C (298K)) [

12]. It is not clear whether MoO

2(OH)

2 originated directly from water-mediated oxidation of the MoS

2 crystals or rather from water reacting with the MoO

3 adsorbed on the MoS

2 crystals, which seemed more likely. Noteworthily, bulk MoO

3 has been shown by inorganic chemistry books to dissolve slightly in water. Finally, yet other Mo species, the MoO

3 hydrates such as MoO

3·H

2O, have been recently suggested to appear on the MoS

2 crystals after their immersion in water for many hours [

21].

Not only is the chemistry of the MoO

3 complicated, but its appearance and surface distribution on microscopic 2H MoS

2 crystals are elusive too. In the case of very thin MoS

2 flakes some loose islands of the MoO

3 oxides have been presumably observed directly in the AFM topographs overlaid with AFM-based magnetic force imaging [

9]. Therein, MoO

3 was reported to be a non-magnetic material. In one of our earlier AFM and micro-Raman studies we pointed out that during initial 10–15 min of heating at temperatures ranging from 320 to 390 °C, in air, a predominantly observed outcome on thick microscopic MoS

2 flakes was triangular etch pits within the basal MoS

2 surface [

11]. Similar triangular etch pits were observed several years earlier on very thin MoS

2 samples heated either in oxygen or in oxygen/argon flow or in air [

8,

9,

10]. In all of those studies a typical depth of triangular etch pits was exactly one MoS

2 monolayer; i.e., 0.7 nm. Beyond triangular etch pits, very few morphological changes of the MoS

2 flakes have been noticed [

11]. Since MoO

3 crystals are transparent, it is not clear whether MoO

3 stayed with those samples at all and/or covered the pits and a surrounding area uniformly. Particularly, almost the same thickness is expected for the MoO

3 and MoS

2 single layers [

22,

23,

24].

It is not only difficult to detect MoO

3 via its physical properties, but according to our knowledge, none of the published results provided a direct chemical proof of the local MoO

3 existence on a single microscopic 2H MoS

2 flake. Typical XPS measurements are not so local and encompass at least several MoS

2 flakes. Raman measurements do not help either. The majority of the published Raman studies show either miniscule shifts of the Raman modes fingerprinting the MoS

2 crystals, i.e., the A

1g and E

12g modes [

10,

11], or an exclusive presence of the MoO

3 crystals on fully oxidized single 2H MoS

2 flakes [

8]. This is likely due to a very small thickness of the oxide layer. Overall, the MoO

3 layers produced during gentle oxidation of single 2H MoS

2 crystals are transparent, thin and difficult to be differentiated both physically and chemically from an underlying MoS

2 substrate. In addition, such MoO

3 layers might contain MoO

3 derivatives, such as molybdenum(VI) hydroxyoxides and/or MoO

3 hydrates. Clearly, proper identification and surface distribution of the MoO

3 species and their derivatives on single 2H MoS

2 flakes deserve substantially more attention.

In this study we detected and differentiated the MoO3 oxides and their derivatives from an underlying MoS2 crystal on single and microscopic 2H MoS2 flakes. We used a series of the MoS2 samples, which were oxidized gently, each one at a different temperature between 205 to 410 °C, in dry or humid air. First, using XPS measurements we show how the content of the MoO3 species on the MoS2 samples changes with oxidization temperature. Next, by carefully manipulating AFM tips we created nanoscale ripples within the MoO3 layer and scratched them out from single MoS2 flakes. We related the thickness of the scratched out MoO3 layer to its structure and used a model for formation of nanoscale ripples to obtain its compressive breaking strength. Next, we proved that oxidation on the edges of the MoS2 crystals provides most of the needed MoO3 to cover the MoS2 flakes. Finally, we study sublimation of the MoO3 oxide layer and its formation in high relative humidity conditions.

3. Results and Discussion

To investigate the presence of Mo oxides on the MoS

2 crystals, we prepared single 2H MoS

2 crystals on silicon/silica substrates, as explained in the Materials and Methods. We have studied flakes thicker than 10 nm, i.e., of more than 15 MoS

2 monolayers due to known dependencies of several physico-chemical properties of the MoS

2 flakes on their thickness, particularly for the flakes thinner than 10 monolayers [

27]. First, the MoS

2 flakes were localized using light microscopy and AFM; see

Figure 1. Next, we selected five samples with MoS

2 flakes for the XPS studies of their thermal oxidation. One of the samples served as our reference sample. Four other samples were separately heated on a hot plate for 10–15 min each: first at 320, second at 350, third at 370 and fourth at 410 °C.

Figure 2 shows the results of our XPS investigations on the samples prepared and oxidized in air. The Mo 3d core line XPS spectra were used in order to probe an oxidation process. Each such XPS spectrum contains four maxima, which have been related to the presence of two different oxidation states of the Mo ions. The applied peak fitting procedure yielded the binding energies of each maxima at 229.0 eV, 232.2 eV, 232.8 eV and 236.0 eV, respectively. The first two maxima were related to the spin-orbit doublet (Mo 3d 5/2 and 3/2) of the Mo

4+ oxidation state, which is characteristic for the MoS

2 sample. The second two maxima were related to the presence of the Mo

6+ oxidation state doublet, which within our reaction conditions has been predicted to be characteristic of the MoO

3. During peak fitting procedures, the Gaussian–Lorentzian peak shapes were used and the relative peak areas were fixed to a 2:3 ratios for each set of the respective 3/2 and 5/2 pairs. This procedure and the resulting binding energies are consistent with previous works [

12,

18,

19].

The oxidation of a single MoS

2 flake has been suggested to start already above 200 °C, as inferred from electronic density shifts within the MoS

2 monolayers via micro-Raman measurements [

8]. However, earlier reports have shown through visualization of the obtained triangular etch pits that meaningful MoS

2 oxidation occurs in air only above 320 °C [

8,

9,

10,

11,

28]. Such conclusions agree our XPS analysis in

Figure 2. The presented results clearly show that during heating to a certain temperature the concentration of the Mo

4+ ions decrease, which is visible when comparing the spectra after heating at 320, 350 and 370 °C; see

Figure 2A–C. However, somewhere above 370 °C this trend is stopped or even reversed, as is visible in the XPS spectra obtained after heating the sample in 410 °C; see

Figure 2D. The XPS results, however, are averaged over an investigated area, which is typically between several tens to a hundred of µm

2. Therefore, we decided to investigate the distribution of the Mo oxides on the surface of MoS

2 flakes using local AFM measurements.

After many trials and using high resolution, contact non-contact/tapping AFM imaging, we could not detect any obvious MoO

3 islands on and/or in the vicinity of the triangular etch pits on the XPS studied samples till heating them at 370 °C. We did not quit searching for the surface-bound MoO

3 layers on the prepared batch of samples; XPS results in

Figure 2 clearly show the prevailing presence of oxides on the samples heated between 350 and 410 °C. Furthermore, the XPS results did not change upon sample annealing at 210 °C for 30 min, confirming that the Mo oxide stayed there even after annealing. This is why we decided to locally scratch several samples heated between 350 and 370 °C. Indeed, after several passages of a scanning AFM tip, we managed, at least in several cases, to break through a complete layer of the likely MoO

3 oxide after applying normal forces of up to several nN. While continuing the scratching process, we managed to remove any remaining pieces of the scratched layer and to expose a fresh basal plane of the Mo disulfide.

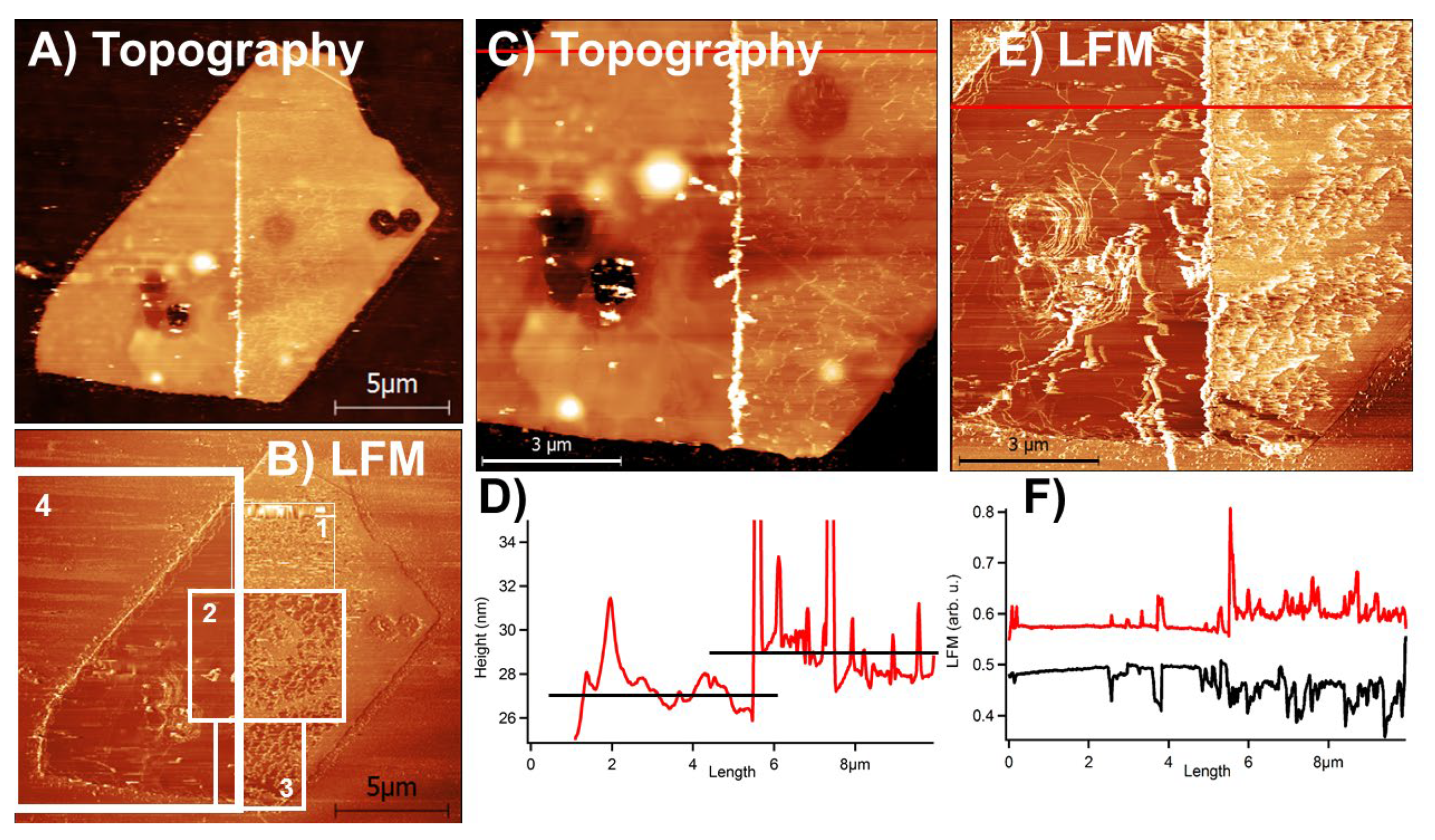

Figure 3 presents the results of removing a surface-bound MoO

3 oxide layer with help of an AFM tip. It shows the AFM recorded surface topography and corresponding lateral force microscopy (LFM) signals to visualize changes provoked on the sample during scratching. The investigated MoS

2 flake was ca. 30 nm thick. It was oxidized in five cycles of 10-minute heating at 350 °C and subsequent cooling to room temperature. The oxidized flake was continuously scratched in the zones denoted respectively by numbers “1,” “2,” “3” and “4” in

Figure 3b. In the zone “1” the MoS

2 flake was rastered several times only, but it was enough to break continuity of the top oxide layer and produce lasting and visible indents in this layer. In the zones “2” and “3” the flake was scratched several more times than in “1,” so that visible surface ripples appeared within the oxidized MoS

2 surface. In the zone “4” a portion of the MoS2 flake was rescanned more than 10 times, resulting in a complete removal of an oxide layer.

AFM topographs cannot provide direct information about the local chemistry of the investigated samples. Nevertheless, with their help we can discuss the thickness of the scratched out MoO

3 layer. To start with, after averaging several cross-sectional lines in local surface topography in

Figure 3c, we obtained that a removed oxide layer was 2 ± 1 nm in height; see

Figure 3d.

Next, we explain how an obtained thickness of the oxide layer corresponds to its structure. The most thermodynamically stable MoO

3 polymorph existing in nature is the α-MoO

3 called molybdite. Refined molybdite crystal structure shows a true layered arrangement of the MoO

6 octahedra with an orthorhombic unit cell belonging to a

Pbnm space group [

24]. Any given MoO

3 layer is a double layer composed of MoO

6 octahedra at two height levels. Within each level the MoO

6 octahedra are connected by shared lateral ends only. Connections between a ground level and an upper level are realized by sharing one edge between any two octahedra from ground and upper levels, respectively. Such an arrangement yields an overall height of a single α-MoO

3 layer,

h, it being 3/2 of the height of a single MoO

6 octahedron plus any necessary spacing between the layers. Consequently, we estimate

h to be ca. 0.8 nm [

24]. On the other hand, we can also estimate the value of

h differently. To provide for dense spatial packing within the α-MoO

3 structure, a second (upper) α-MoO

3 layer is laterally shifted with respect to a first (lower) layer, but a third MoO

3 layer is positioned like a first layer. Such an arrangement yields the height of a respective α-MoO

3 unit cell stretching from first to third layer to be 1.4 nm. The thickness of an α-MoO

3 monolayer atop another α-MoO

3 monolayer is half of this value; i.e., 0.7 nm. Again, a slightly larger value is expected for the height of the α-MoO

3 monolayer on the 2H MoS

2 crystal due to non-matching lateral dimensions between α-MoO

3 and 2H MoS

2. Thus, the expected thickness of a single MoO

3 layer atop the MoS

2 basal surface is between 0.7 and 0.8 nm, which makes it extremely close to the thickness of a single MoS

2 monolayer of ca. 0.7 nm. Consequently, the detected thickness of the MoO

3 layer corresponds to something between one to four MoO

3 monolayers.

Another important difference between MoS

2 crystals and detected MoO

3 oxide layers observed in

Figure 3e,f is the substantially larger, ca. 1.5 times larger, friction on the surface containing rippled oxides comparing to a cleaned MoS

2 surface. A substantial friction increase was expected on the oxidized vs. pristine MoS

2 surface. MoS

2 surfaces are known for low friction and their moderately hydrophobic behavior acquired from the pristine MoS

2 surface after its quick passivation by hydrocarbons [

29]. On the contrary, Mo oxides and their derivatives are strongly hydrophilic, which facilitates formation of water capillary bridges between these surfaces and a scanning AFM tip in ambient conditions. Such capillary bridges are known to account for substantial friction increase in air [

30,

31,

32].

The results are presented in

Figure 3, and more of such results together with accompanying high resolution XPS spectra, presented in the

Supplementary Materials (Figures S1 and S2), confirm that the Mo oxide layer can be indented and scratched away from MoS

2 basal planes of single MoS

2 crystals. Let

σMoO3 denote the compressive mechanical stress at the plastic yield of that layer. It is also referred to as the compressive breaking strength. The value of

σMoO3 can be estimated from our experimental results presented in

Figure 3b using the Dugdale model of pressure-induced formation of cracks in solid surfaces [

33], which was adopted for conditions of indenting a material with a scanning AFM tip [

34]. In brief, the model assumes that a scanning AFM tip performs a stick-and-slip motion between the cracks, which are generated just underneath the very surface of a material and become visible within the indents within the material created by an AFM tip. Any given indent grows when a tip of an AFM cantilever “sticks” to it by exerting a normal load. At the same time the tip shifts laterally in the process of surface scanning. Thus, the tip will “slip” by the lateral distance,

Δ, to a new indentation point once mechanical energy stored in the cantilever, due to its increasing lateral bending, exceeds the tip-material surface energy over the contact area. The value of

Δ is later measured as the distance between consecutive indents. The lateral length of a given indent within a material is denoted as

δt. The local breaking strength of a material,

σ, is calculated from a following equation:

In Equation (3),

D is the depth of a crack;

H is the height of a material pile removed during indentation within a crack;

R is the tip curvature radius of an AFM cantilever and

klat is its lateral (elastic) stiffness.

After careful examination of the zones “1” and “2” in

Figure 3b we have observed that the values of

Δ and

δt are similar and typically equal several hundreds of nanometers. Following this observation we simplify Equation (3) to yield:

σMoO3 = 0.0663(

Δ ·

klat) / (

R · (

D +

H)). The values of (

D +

H) are limited in our case by a small thickness of an oxide layer. We have estimated (

D +

H)

= 5 ± 2 nm; see

Figure 3b. For the used here MLCT-E cantilever,

R was estimated as 50 ± 10 nm and

klat = 71 ± 45 N/m was obtained, as explained in the Materials and Methods. Consequently, we obtained values of

σMoO3 between 0.3 and 7.8 GPa. An upper limit of ca. 8 GPa is likely overestimated, since our values of (

D +

H) are smaller than in the case of a thick MoO

3 layer.

The value of

σMoO3 can be explained quite well using some previously published data and our experimental details. We did not find the value of

σMoO3 in the literature; however, the MoO

6 octahedra within each single MoO

3 layer are slightly deformable under pressure along one of the lateral directions [

24]. On the contrary, the MoS

2 surface exhibits nice honeycomb lattices within each of the respective S and Mo-planes, which are not easy to break through [

22,

23]. Thus, one expects the value of

σMoO3 to be much lower than a respective value of

σMoS2. In fact, within our experimental conditions, we did not observe any breaking through the underlying MoS

2 layer under the maximum loading forces applied. Those forces were of up to four times of the loads applied to generate scratches presented in

Figure 3. Therefore, up to several-times-lower values of

σMoO3 than

σMoS2 are expected. Several published experimental and theoretical studies reported the values of

σMoS2 between 20 and 30 GPa [

35,

36]. Consequently, our values of

σMoO3 might indeed relate to the presence of thin α-MoO

3 layers. In conclusion, despite not being easily noticeable, a thin α-MoO

3 layer can be differentiated via creating surface ripples and scratching out the oxide layer via repetitive scanning on the MoS

2 samples with appropriate AFM cantilevers.

Next, we address the origins of the Mo oxide layer, which deposits on the MoS

2 surfaces. Etched triangular pits would account for only a very small amount of the produced oxides and there must be other sources of it. In

Figure 4 one can see an example of the MoS

2 flake with MoS

2 monolayers of thickness between 15 and 20 depending on a position along the flake. The flake was imaged at ambient conditions just after 12 min of its thermal oxidation at 390 °C in air. One can clearly notice triangular etch pits within the basal surface of the flake in

Figure 4a, and a clean area surrounding the bottom of the flake in

Figure 4b.

The clean area around the MoS

2 flake observed in

Figure 4b has been freshly produced, since it contains no spots. This should be compared with many small spots visible on the Si substrate due to its prolonged handling in air. Thus, such a clean area must have originated from lateral shrinking of the flake during thermal oxidation. At the same time, not too many triangular etch pits were produced on this flake; see

Figure 4a. Consequently, the amount of the Mo oxides produced by volumetric oxidation at edges of the flake must was substantially greater than the amount of oxides produced from its basal surface oxidation. Thus, oxidation on edges of the MoS

2 flakes is a primary source of the MoO

3, particularly at heating temperatures of 350 °C and above. This result agrees with already published observations made by angle-resolved XPS, but on macroscopic MoS

2 crystallites [

37]. We have observed similar effects on many other MoS

2 flakes, which were not too thick. On thick MoS

2 flakes this effect is barely visible due to substantial volume of the MoS

2 material enclosed within only slight shrinking of the lateral dimensions of such flakes due to heating.

Consequently, the only way to reconcile our data, i.e., volumetric oxidation, triangular surface etching and formation of an eventual thin Mo oxide layer, is to suggest that freshly-produced MoO3 must escape directly to the gas phase, but some portion of it can deposit back on the surface to form islands and even organized layers under appropriate conditions. In this sense, we have validated microscopically that the MoO3 produced through Equation (1) is initially in the gas form, at least within our experimental conditions.

Following the hypothesis that originally produced MoO

3 goes to the gas phase first, we continued to notice that the amount of the MoO

3 oxides, which are deposited back on the MoS

2 surfaces, decreases as oxidation temperature rises above 370 °C; see

Figure 3e. While more “energetic”—i.e., produced at higher temperatures—MoO

3 particles in the gas phase have less of a tendency for surface adsorption, such results admit as well a possibility that the MoO

3 particles, which have adsorbed on the surface, might quickly sublimate at those conditions. Indeed, high quality MoO

3 crystals grown on gold have been showed to sublimate above 400 °C [

38] and monolayers of amorphous MoO

3 grown on MoS

2 via O

2 plasma exposure have sublimated completely at 500 °C [

39]. Furthermore, thermodynamic calculations of Walter et al. [

12] predicted MoO

3 sublimation to start above 470 °C. Below, we provide an experimental proof for sublimation of the surface-bound MoO

3 layers already at 320 °C.

Figure 5 presents an MoS

2 flake heated for several minutes at 370 °C to promote oxidation and then left for about a month inside of a humid desiccator. In

Figure 5a one can see an initial MoS

2 flake. In

Figure 5b one observes clearly some additional build-ups, likely MoO

3 layers, which have deposited on various portions of the flake after its prolonged stay in desiccator. In

Figure 5c one can notice that an entire oxide layer sublimated after the sample was heated at 320 °C for only four minutes. Such a low sublimation temperature does not compare even with lowest sublimation temperatures of 400 °C observed in the aforementioned studies [

38]. However, one can quickly realize that the aforementioned MoO

3 sublimation studies were conducted under vacuum and/or in highly controlled environments [

38,

39], whereas our results were obtained in far less clean conditions. In other words, surface adsorbed hydrocarbons and other surface contaminants on the pristine MoS

2 surface might have prevented the formation of a well-organized and crystalline MoO

3 layer. Alternatively, however, the slowly grown-up MoO

3 layer might have contained some MoO

3 derivatives, such as molybdenum(VI) hydroxyoxides and MoO

2(OH)

2, which have been predicted to be formed, when water was present. If fact, the height of the formed MoO

3 layer in

Figure 5b is ca. 5 nm, which is much larger than thickness of the MoO

3 layer obtained in air. This suggests slow formation of either an additional MoO

3 in humid air due to Equation (2), or some additional MoO

2(OH)

2 species crystallizing on the sample. The MoO

2(OH)

2 species are far more volatile than a MoO

3 layer [

12] and sublimate at lower temperature than MoO

3. We had no means to test for the presence of the hydroxyoxides on the MoS

2 flake presented in

Figure 5, but we decided to follow up on an unclear role of water in degradation and thermal oxidation of the MoS

2 flakes.

To start with, we investigated, again by AFM, the microscopic surface topography of several thermally oxidized MoS

2 samples after their submergence in water for the times ranging from a few minutes to several hours. We did not observe any topographical changes on those previously oxidized MoS

2 flakes. However, we could have incubated them in water for too little time in order to dissolve any MoO

3 oxide layers and/or create any etch pits in the MoS

2 [

21]. Nevertheless, our results suggest that a thin layer of the MoO

3 species, which originated on surfaces of the oxidized MoS

2 flakes, prevented their further deterioration in water, at least within the time scale of several hours.

In order to start addressing the role of water during thermal oxidation of the single MoS2 crystals from a different perspective, we decided to perform thermal oxidation at high relative humidity. One must acknowledge that our previous thermal oxidation studies above 300 °C, even in very humid air, occurred always at local relative humidity of being almost zero per cent. This is because the saturated water vapor pressure in vicinity of a hot surface, psat(T), is a very strongly rising function of the temperature, so that any partial water pressure, p, in an open container in humid air produces a vanishingly small relative humidity, RH = p / psat(T), above 200 °C. Thus, in order to study an effect of relative humidity in thermal oxidation of single MoS2 flakes, one must utilize an enclosed chemical reactor, which assures the same pressure and relative humidity everywhere on the sample.

In

Figure 6, we present the results of thermal oxidation of single MoS

2 crystals at

RH = 80 ± 7%. The reaction was conducted within a custom-built chemical reactor. The sample was thermally oxidized for 5 min at mean pressure of 16 bar and mean temperature of 205 °C. It took 14 min to reach the reaction conditions and several more minutes to cool the reactor below 100 °C. A likely oxide layer was formed on the MoS

2 samples, because we were able to scratch this layer away (see

Figure 6c) at similar forces as for the data presented in

Figure 3. Furthermore, the measured thickness of the likely Mo oxide layer was 2.2 ± 0.2 nm, which is also similar to the data presented in

Figure 3.

One can notice that for thermal oxidation in air, when

RH was almost zero, the MoO

3 oxides were not detected below 320 °C; see

Figure 2. Thus, water must substantially accelerate oxidation at high relative humidity, as predicted by Equation (2). If water was acting only like a catalyst in Equation (1), then one would expect some associated triangular etch pits on the oxidized MoS

2 surface. However, for several samples and several scratches investigated within this study we observed no triangular etch pits within the oxidized MoS

2 layers and the underlying MoS

2 surface, i.e., within the scratch. Thus, water does indeed induce an additional oxidation pathway, as in Equation (2). In such a case, however, a thick MoO

3 layer would have been observed in

Figure 6, which was not the case. Thus, the situation is likely more complicated.

One of the recently published studies suggested that water degrades MoS

2 crystals by partially dissolving them to yield pits and to produce non-transparent grains of insoluble crystals of the MoO

3 monohydrate, MoO

3·H

2O [

21]. We have indeed observed some discoloration on the oxidized samples. Several MoO

3 hydrates have been characterized till now [

40,

41,

42]; in particular, MoO

3·

nH

2O with

n = 2, 1, 1/2 and 1/3. Mono and di-hydrates have been found to be most stable structurally [

40,

41]. The MoO

3·2H

2O is most stable at room temperature and MoO

3·H

2O was found to exist between 60 to 140 °C. Above 140 °C the MoO

3 hydrates convert to α-MoO

3 [

41]. We have conducted our experiments above 200 °C, i.e., where any hydrates shall already convert to oxides. The only way for them to appear in our experiments would be to form exclusively at room temperature or during reactor cooling. The MoO

3 hydrates, however, are typically produced via crystallization from slowly acidified solutions of molybdate ions [

40,

41,

42]. Thus, in order for the MoO

3 hydrates to appear, the molybdate ions, such as MoO

42−, need to be produced first. These anions are typically produced from reactions with MoO

3 in alkali solutions, which is not the case in our oxidation conditions. Consequently, we are of the opinion that no MoO

3 hydrates have been produced on MoS

2 in humid air.

Despite a predicted lack of the MoO

3 hydrates, we suggest that what it takes place in high relative humidity conditions is an accelerated production of the MoO

3 via Equation (2), as in bulk, but together with substantial conversion of the MoO

3 layer to volatile MoO

2(OH)

2 species. Said hypothesis agrees with the following observations. Smolik et al. reported experimental data and thermodynamical calculations on oxidation, volatilization and re-deposition of molybdenum oxide species formed from a certain molybdenum alloy between 400 and 800 °C in flowing air [

43]. The Mo oxide species on their Mo alloy underwent volatilization, which was dominated by the appearance of the MoO

3 above 550 °C and by the appearance of the MoO

2(OH)

2, formed from the small ingress of water vapor, at temperatures below 550 °C. Furthermore, within conditions closer to our experimental conditions Walter et al. [

12] calculated that MoO

2(OH)

2 is produced in thermal oxidation of the bulk MoS

2 crystals already at 300 °C. This is much earlier than in results of Smolik et al., but similarly to Smolik et al., also for a small ingress of water vapor. Thus, it is expected that at high relative humidity appearance, and fast volatilization of the MoO

2(OH)

2 species occurs already at much lower temperatures than 300 °C. Consequently, at high relative humidity a crossover is expected from the MoS

2 oxidation governed by Equation (1) to oxidation governed by Equation (2), but together with formation and sublimation of the MoO

3 hydroxyoxides. In this way, large amounts of MoO

3 are produced quickly and a complete basal MoS

2 surface is transformed in Mo oxide species very fast, so that no triangular etch pits are observed. At the same time a large portion of the newly produced MoO

3 is converted into volatile MoO

2(OH)

2 species, which leave the reaction environment. Overall, not much of the produced MoO

3 stays on the MoS

2 surface. However, systematic studies of thermal oxidation as a function of relative humidity and oxidation temperature are needed to address this hypothesis in detail.

Finally, we compare our results with laser-induced oxidation and thinning of MoS

2 crystals. To do so, we chose two seminal studies [

44,

45]. The first study discussed lased induced thinning and oxidation in air [

44]. The other study was focused on laser-induced electrochemical thinning of the MoS

2 in electrochemical, although aqueous, solutions [

45]. In none of these studies, however, have Mo oxides been detected. In [

44] the Authors went to great lengths to exclude any MoO

3 presence via Raman, photoluminescence and electronic transport studies. Nevertheless, thin MoO

3 layers are not necessarily insulating [

46] and micro-Raman studies have been notorious for not showing the local presence of MoO

3 layers [

10,

11]. A major reason for difficulty when trying to see any MoO

3 on the laser-oxidized MoS

2 flakes is certainly that laser-thinning studies are quite local. This means that only a tiny portion of each single MoS

2 flake is heated each time and extremely small amounts of the MoO

3 are produced. Furthermore, locally obtained temperatures achieved by laser heating of the MoS

2 surface are likely much above sublimation temperatures of the MoO

3 oxides. This is facilitated by poor (normal) thermal conductivity between subsequently stacked MoS

2 layers within a crystal. This effect, however, does not play a major role for globally heated MoS

2 samples, as in our case here. Thus, we expect different outcomes between laser-induced heating and thermally induced oxidation, and in particular more of the MoO

3 staying on the samples oxidized thermally than in the laser-induced studies. Nevertheless, that all depends on particular experimental conditions. Consequently, it would be extremely interesting to extend the nanomechanical testing for the local presence of the MoO

3, such as presented within our paper, to the laser-thinned MoS

2 samples.