The Stress Concentration Mechanism of Pores Affecting the Tensile Properties in Vacuum Die Casting Metals

Abstract

1. Introduction

2. Materials and Methods

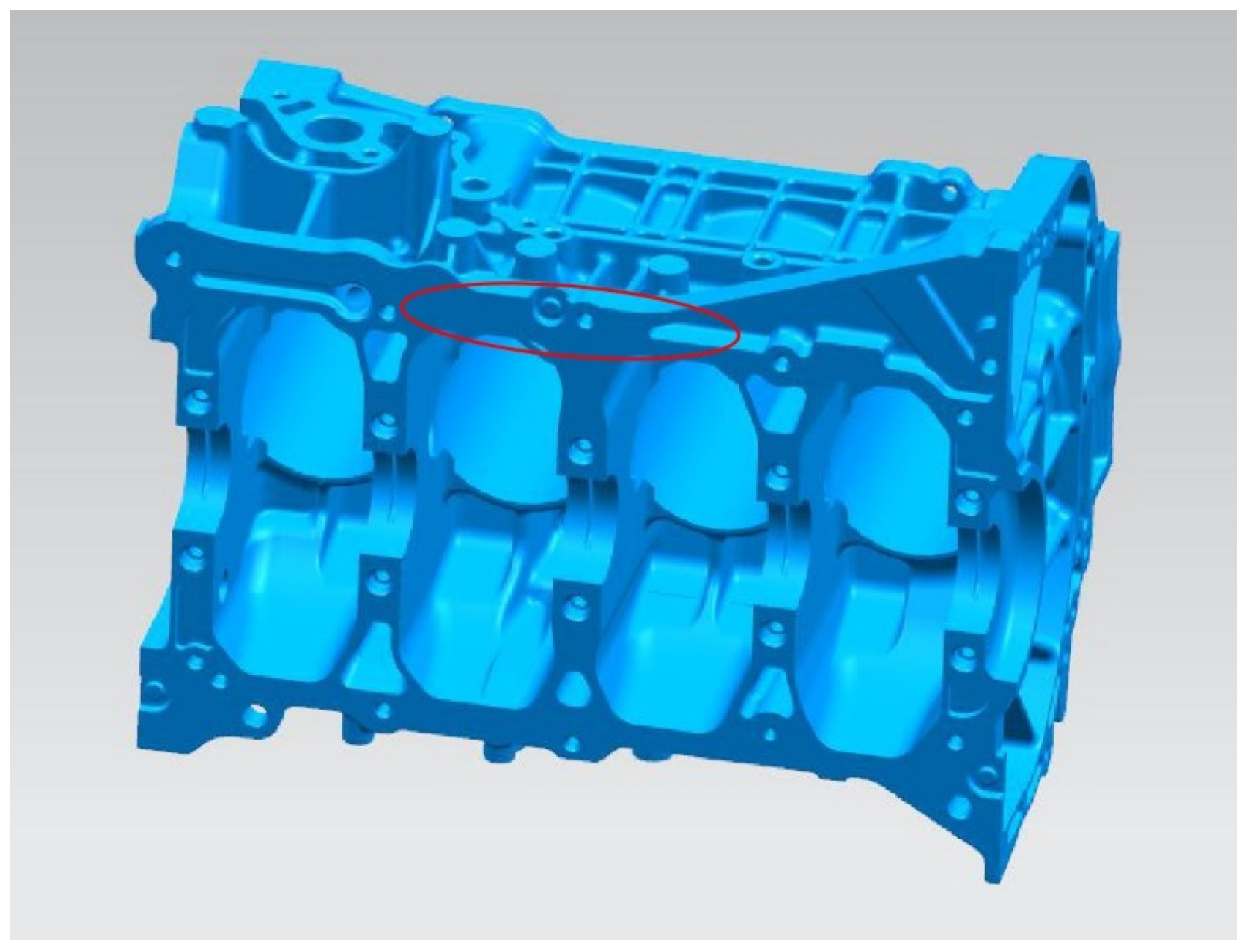

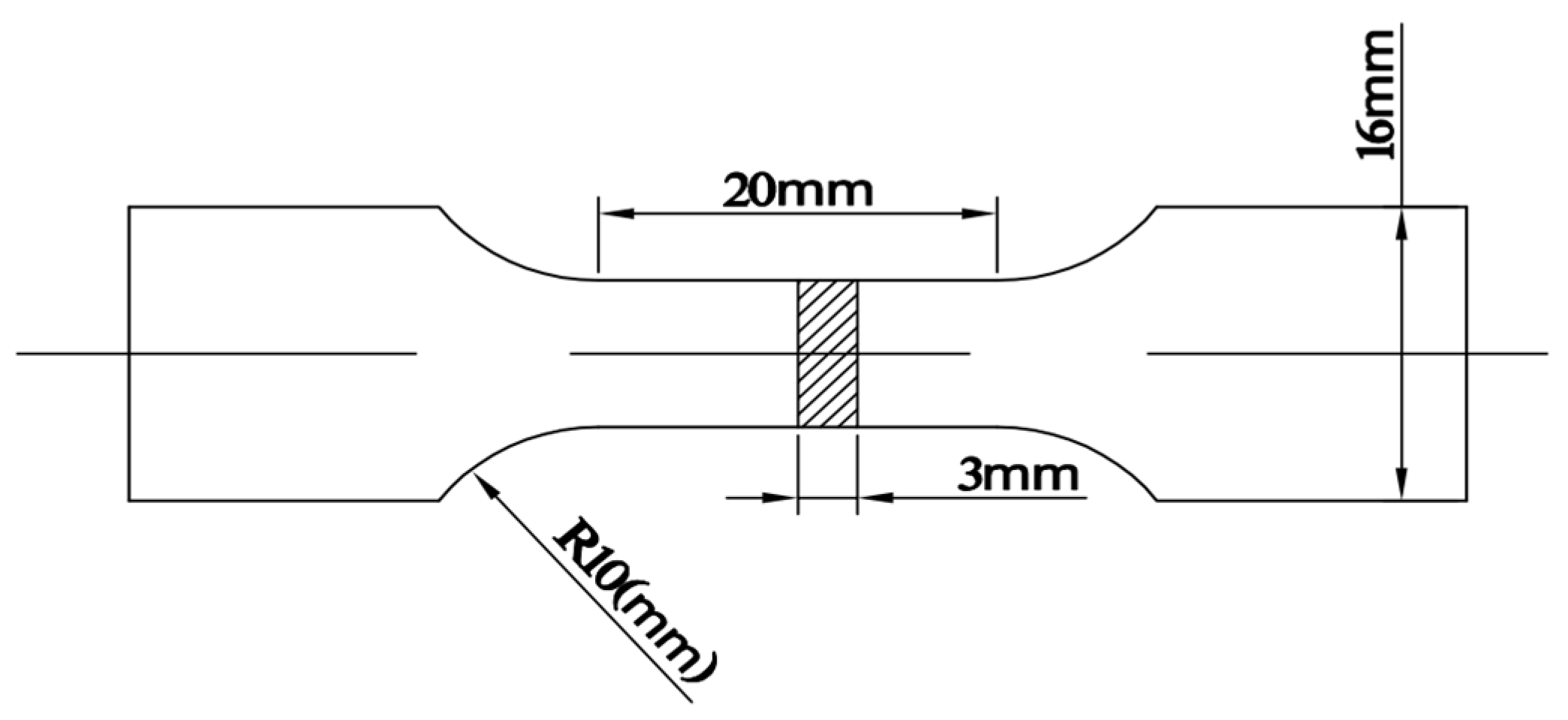

Experiments

3. Results and Discussion

3.1. Calculation of Density and Porosity

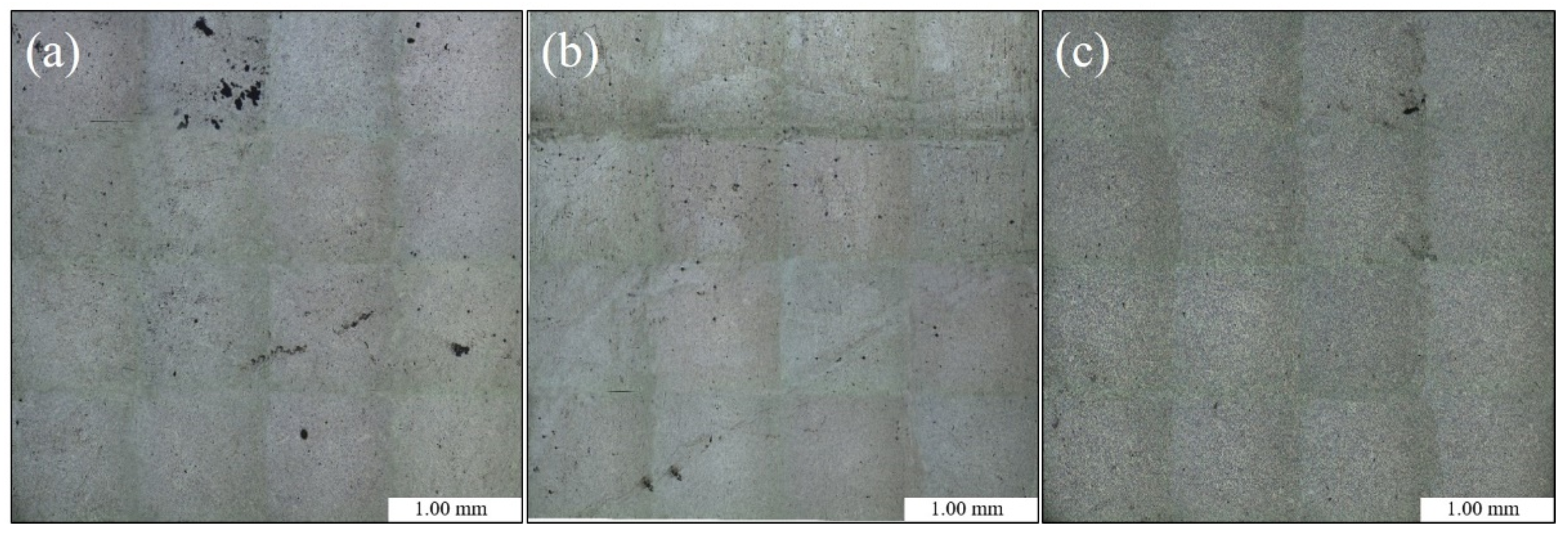

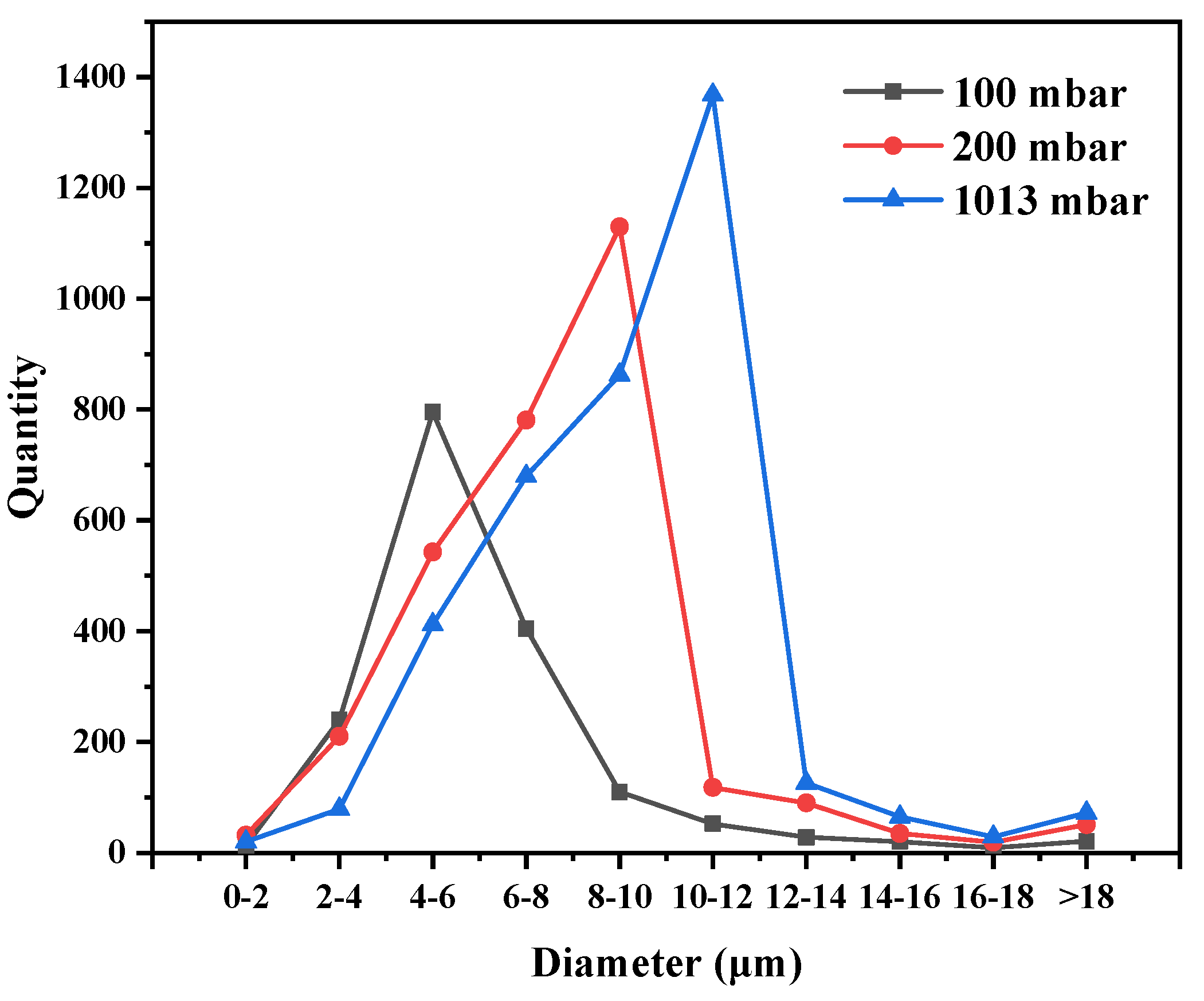

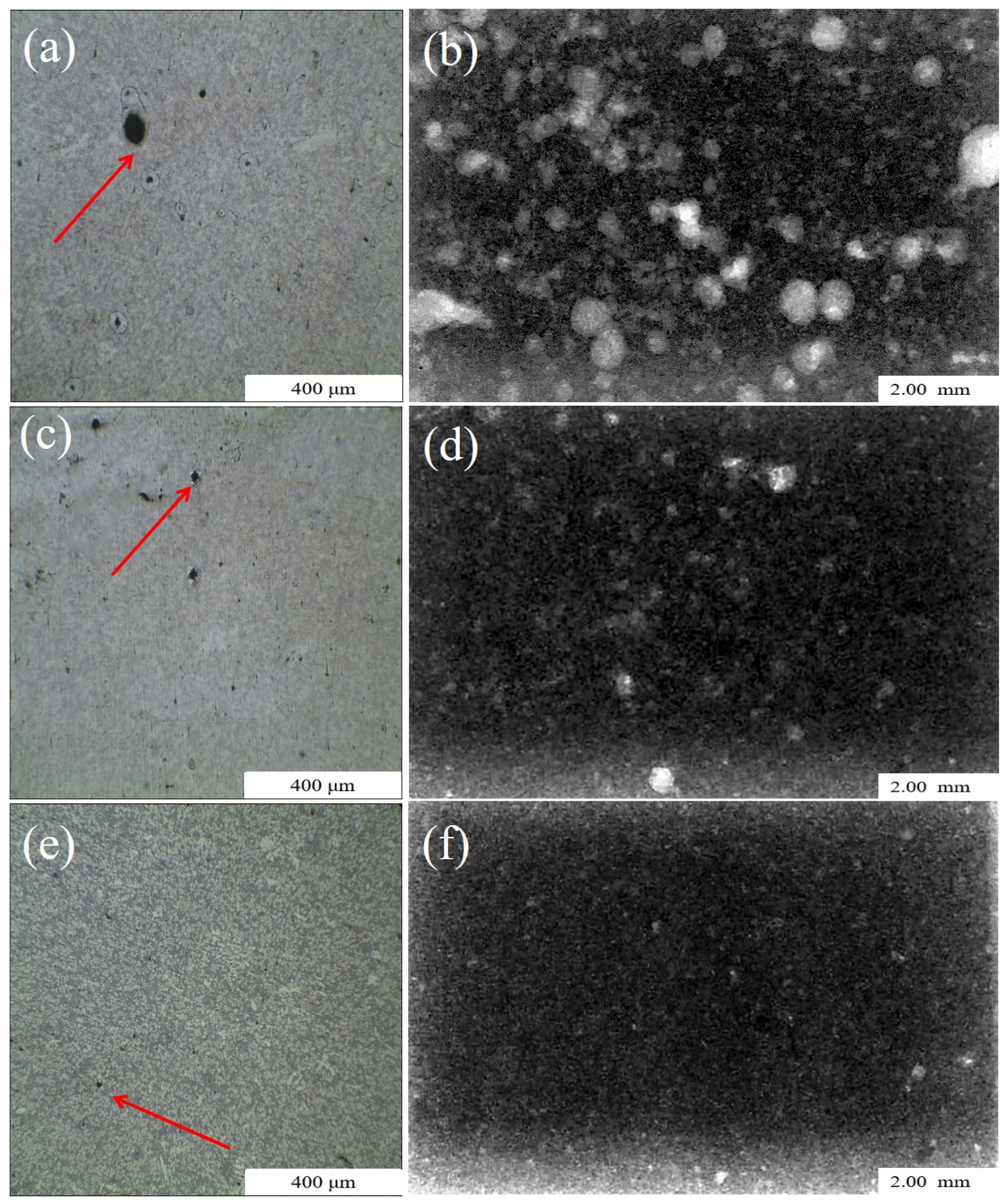

3.2. Characterization of Pore Defects

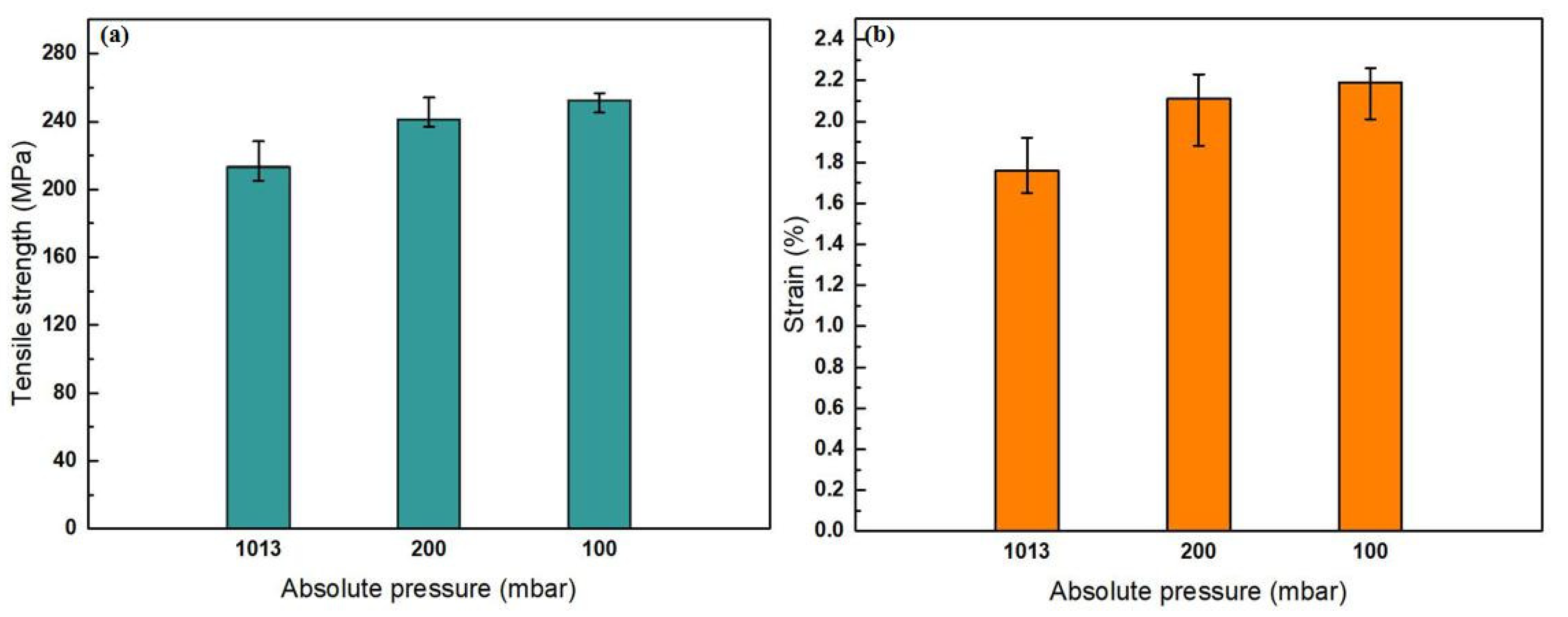

3.3. Measurement of Tensile Strength and Elongation

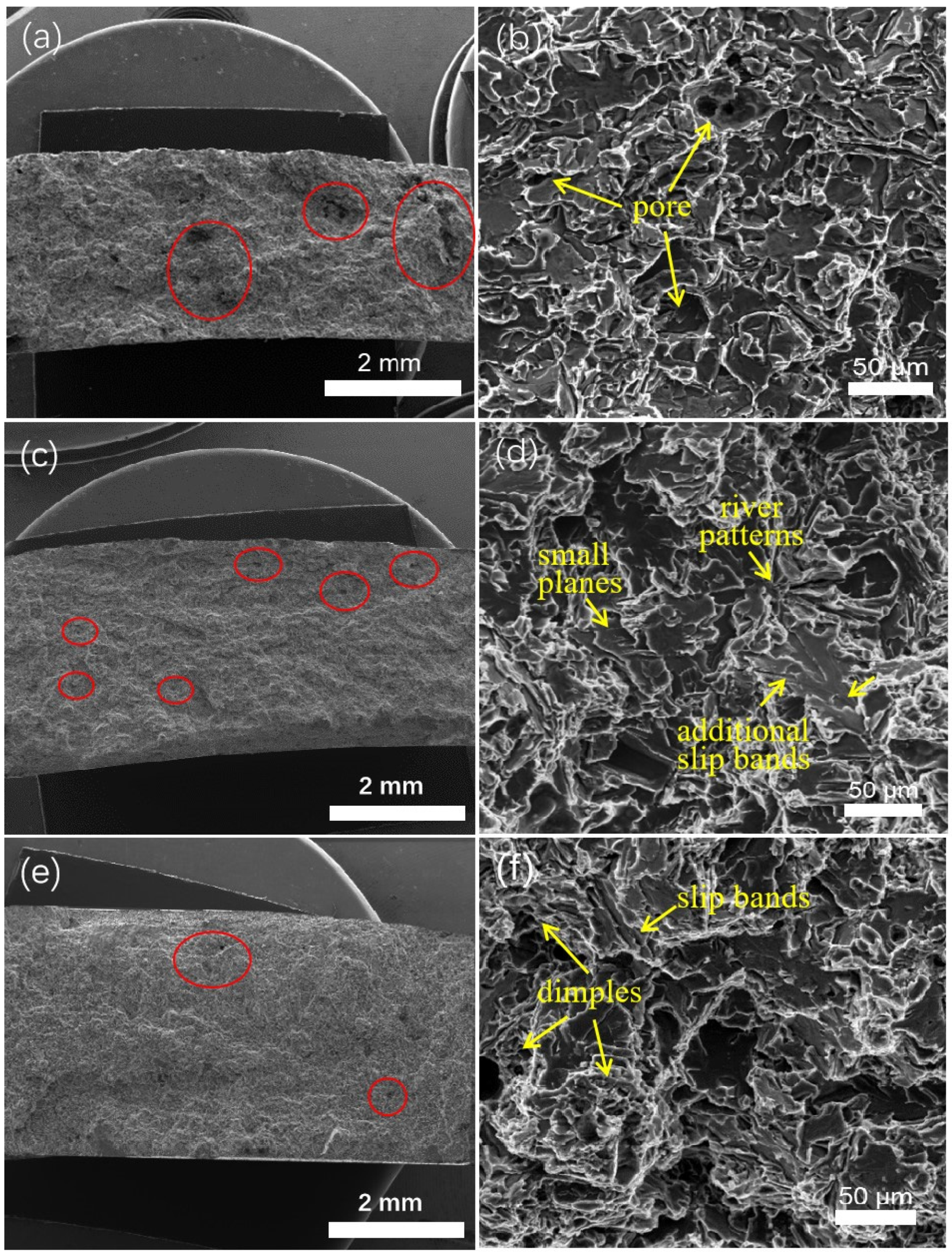

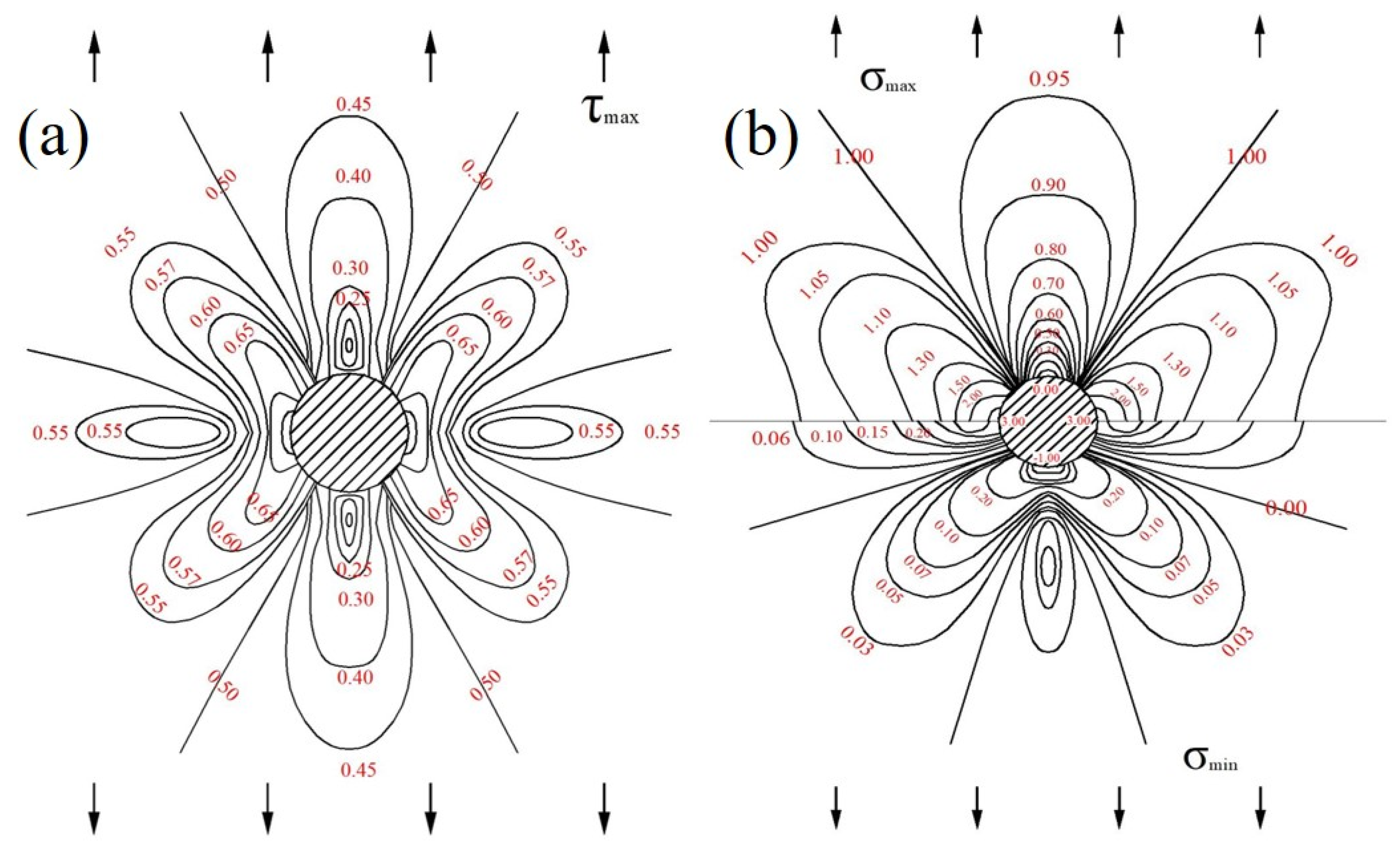

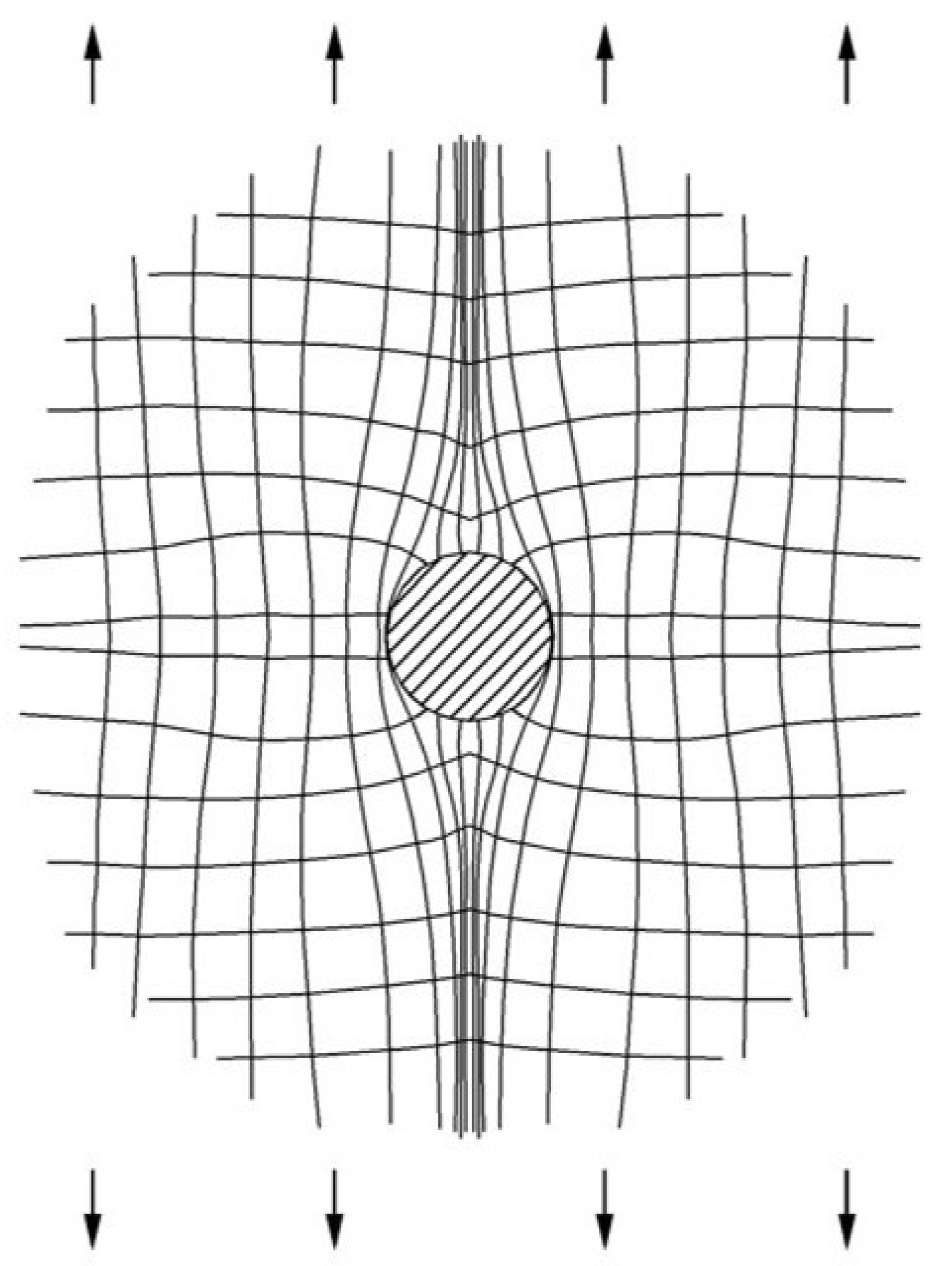

3.4. The Stress Concentration Mechanism of Tensile Fracture

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Arsha, A.G.; Jayakumar, E.; Rajan, T.P.D.; Antony, V.; Pai, B.C. Design and fabrication of functionally graded in-situ aluminium composites for automotive pistons. Mater. Des. 2015, 88, 1201–1209. [Google Scholar] [CrossRef]

- Lasa, L.; Rodriguez-Ibabe, J.M. Wear behaviour of eutectic and hypereutectic Al-Si-Cu-Mg casting alloys tested against a composite brake pad. Mater. Sci. Eng. A 2003, 363, 193–202. [Google Scholar] [CrossRef]

- Yamagata, H. The Science and Technology of Materials in Automotive Engines; Woodhead Publishing: Cambridge, UK, 2005; pp. 40–95. [Google Scholar]

- Timelli, G.; Fabrizi, A. The Effects of Microstructure Heterogeneities and Casting Defects on the Mechanical Properties of High-Pressure Die-Cast AlSi9Cu3(Fe) Alloys. Met. Mater. Trans. A Phys. Met. Mater. Sci. 2014, 45, 5486–5498. [Google Scholar] [CrossRef]

- Niklas, A.; Bakedano, A.; Orden, S.; da Silva, M.; Nogués, E.; Fernández-Calvo, A.I. Effect of Microstructure and Casting Defects on the Mechanical Properties of Secondary AlSi10MnMg(Fe) Test Parts Manufactured by Vacuum Assisted high Pressure Die Casting Technology; Elsevier Ltd.: Amsterdam, The Netherlands, 2015; Volume 2. [Google Scholar]

- Ahamed, A.K.M.A.; Kato, H. Influence of casting defects on tensile properties of ADC12 aluminum alloy die-castings. Mater. Trans. 2008, 49, 1621–1628. [Google Scholar] [CrossRef]

- Cáceres, C.H.; Selling, B.I. Casting defects and the tensile properties of an Al-Si-Mg alloy. Mater. Sci. Eng. A 1996, 220, 109–116. [Google Scholar] [CrossRef]

- Ghosh, P.K.; Ray, S. Effect of porosity and alumina content on the mechanical properties of compocast aluminium alloy-alumina particulate composite. J. Mater. Sci. 1986, 21, 1667–1674. [Google Scholar] [CrossRef]

- Dahle, A.K.; Sannes, S.; St. John, D.H.; Westengen, H. Formation of defect bands in high pressure die cast magnesium alloys. J. Light Met. 2001, 1, 99–103. [Google Scholar] [CrossRef]

- Balasundaram, A.; Gokhale, A.M. Digital Image Analysis Technique for Characterization of Shrinkage and Gas (Air) Porosity in Cast Magnesium Alloys. Magnes. Technol. 2001, 155–159. [Google Scholar]

- Lee, S.G.; Gokhale, A.M. Formation of gas induced shrinkage porosity in Mg-alloy high-pressure die-castings. Scr. Mater. 2006, 55, 387–390. [Google Scholar] [CrossRef]

- Hu, B.; Xiong, S.; Murakami, M.; Matsumoto, Y.; Ikeda, S. Experimental Study of Vacuum Die Casting Process of AZ91D Magnesium Alloy. Magnes. Technol. 2006, 51–55. [Google Scholar]

- Yu, W.B.; Yuan, Z.H.; Guo, Z.P.; Xiong, S.M. Characterization of A390 aluminum alloy produced at different slow shot speeds using vacuum assisted high pressure die casting. Trans. Nonferrous Met. Soc. China 2017, 27, 2529–2538. [Google Scholar] [CrossRef]

- Dong, X.; Zhu, X.; Ji, S. Effect of super vacuum assisted high pressure die casting on the repeatability of mechanical properties of Al-Si-Mg-Mn die-cast alloys. J. Mater. Process. Technol. 2019, 266, 105–113. [Google Scholar] [CrossRef]

- Dong, X.; Youssef, H.; Zhang, Y.; Wang, S.; Ji, S. High performance Al/TiB2 composites fabricated by nanoparticle reinforcement and cutting-edge super vacuum assisted die casting process. Compos. Part B Eng. 2019, 177, 107453. [Google Scholar] [CrossRef]

- Shi, X.; Li, D.; Luo, A.A.; Hu, B.; Li, L.; Zeng, X.; Ding, W. Microstructure and mechanical properties of Mg-7Al-2Sn alloy processed by super vacuum die-casting. Met. Mater. Trans. A Phys. Met. Mater. Sci. 2013, 44, 4788–4799. [Google Scholar] [CrossRef]

- Wolodkowicz, A.; Enterprises, A. Vacuum die casting: Its benefits and guidelines. In Proceedings of the Transactions of 16th International Die Casting Congress and Exposition, Detroit, MI, USA, 30 September–3 October 1991; pp. 189–192. [Google Scholar]

- Cao, H.; Hao, M.; Shen, C.; Liang, P. The influence of different vacuum degree on the porosity and mechanical properties of aluminum die casting. Vacuum 2017, 146, 278–281. [Google Scholar] [CrossRef]

- Koru, M.; Serçe, O. The Effects of Thermal and Dynamical Parameters and Vacuum Application on Porosity in High-Pressure Die Casting of A383 Al-Alloy. Int. J. Met. 2018, 12, 797–813. [Google Scholar] [CrossRef]

- Zyska, A.; Konopka, Z.; Łągiewka, M.; Nadolski, M. Porosity of castings produced by the vacuum assisted pressure die casting method. Arch. Foundry Eng. 2015, 15, 125–130. [Google Scholar] [CrossRef]

- Niu, X.P.; Hu, B.H.; Pinwill, I.; Li, H. Vacuum assisted high pressure die casting of aluminium alloys. J. Mater. Process. Technol. 2000, 105, 119–127. [Google Scholar] [CrossRef]

- Qin, X.Y.; Su, Y.; Chen, J.; Liu, L. jun Finite element analysis for die casting parameters in high-pressure die casting process. China Foundry 2019, 16, 272–276. [Google Scholar] [CrossRef]

- Concer, D.; Marcondes, P.V.P. Experimental and numerical simulation study of porosity on high-pressure aluminum die casting process. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 3079–3088. [Google Scholar] [CrossRef]

- Yang, H.M.; Guo, Z.P.; Yang, H.Z.; Fu, Z.H.; Pu, Z.M.; Xiong, S.M. Effect of vacuum on porosity and mechanical properties of high-pressure die-cast pure copper. China Foundry 2019, 16, 232–237. [Google Scholar] [CrossRef]

- Yoo, M.H.; Song, J.H.; Oh, J.H.; Kang, S.J.; Kim, K.S.; Yang, S.M.; Moon, M.S. Development of a bus armrest fabrication process with a high-vacuum, high-pressure die-casting process using the AM60 alloy. Robot. Comput. Integr. Manuf. 2019, 55, 154–159. [Google Scholar] [CrossRef]

- Zhao, H.D.; Wang, F.; Li, Y.Y.; Xia, W. Experimental and numerical analysis of gas entrapment defects in plate ADC12 die castings. J. Mater. Process. Technol. 2009, 209, 4537–4542. [Google Scholar] [CrossRef]

- Pratten, N.A. The precise measurement of the density of small samples. J. Mater. Sci. 1981, 16, 1737–1747. [Google Scholar] [CrossRef]

- Cao, H.; Wang, C.; Shan, Q.; Che, J.; Luo, Z.; Wang, L.; Huang, M. Kinetic analysis of pore formation in die-cast metals and influence of absolute pressure on porosity. Vacuum 2019, 168, 108828. [Google Scholar] [CrossRef]

- Chen, J.H.; Cao, R. Micromechanism of Cleavage Fracture of Metals: A Comprehensive Microphysical Model for Cleavage Cracking in Metals; Butterworth-Heinemann: Oxford, UK, 2015. [Google Scholar]

- Weiler, J.P.; Wood, J.T.; Klassen, R.J.; Maire, E.; Berkmortel, R.; Wang, G. Relationship between internal porosity and fracture strength of die-cast magnesium AM60B alloy. Mater. Sci. Eng. A 2005, 395, 315–322. [Google Scholar] [CrossRef]

- Surappa, M.K.; Blank, E.; Jaquet, J.C. Effect of macro-porositu on the strength and ductility of cast Al-7Si-0.3Mg alloy. Scr. Metall. 1986, 20, 1281–1286. [Google Scholar] [CrossRef]

- Savin, G.N.; Kosmodamianskii, A.S.; Guz, A.N. Stress Concentrations Near Holes, Naukova Dumka: Kiev, Ukraine, 1976. (In Russian)

- Balasundaram, A.; Gokhale, A.M.; Graham, S.; Horstemeyer, M.F. Three-dimensional particle cracking damage development in an Al-Mg-base wrought alloy. Mater. Sci. Eng. A 2003, 355, 368–383. [Google Scholar] [CrossRef]

- Lu, Y.; Taheri, F.; Gharghouri, M.A.; Han, H.P. Experimental and numerical study of the effects of porosity on fatigue crack initiation of HPDC magnesium AM60B alloy. J. Alloy. Compd. 2009, 470, 202–213. [Google Scholar] [CrossRef]

- Srivatsan, T.S. Microstructure, tensile properties and fracture behaviour of aluminium alloy 7150. J. Mater. Sci. 1992, 27, 4772–4781. [Google Scholar] [CrossRef]

- Cao, R.; Zhu, H.; Chen, J.H.; Zhang, J. Effects of microcrack-damage on fracture behavior of TiAl alloy. Part II: Load-controlled tensile test. J. Mater. Sci. 2008, 43, 299–311. [Google Scholar] [CrossRef]

| Element | Si | Cu | Mn | Zn | Fe | Al |

|---|---|---|---|---|---|---|

| wt % | 10.03 | 2.92 | 0.32 | 1.00 | 0.71 | REM |

| Absolute Pressure (mbar) | Number | Average Size (μm) | Porosity (P) (%) | Maximum Diameter (μm) | Minimum Diameter (μm) | Density (g/cm3) |

|---|---|---|---|---|---|---|

| 1013 | 3714 | 11.65 | 6.8 | 142.3 | 2.24 | 2.526 |

| 200 | 3009 | 8.12 | 4.4 | 127.59 | 1.98 | 2.605 |

| 100 | 1694 | 5.61 | 2.8 | 111.9 | 1.44 | 2.682 |

| Absolute Pressure | Stress (MPa) | Elongation (%) |

|---|---|---|

| 1013 mbar | 213.14 | 1.76 |

| 200 mbar | 241.09 | 2.11 |

| 100 mbar | 252.28 | 2.19 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, H.; Luo, Z.; Wang, C.; Wang, J.; Hu, T.; Xiao, L.; Che, J. The Stress Concentration Mechanism of Pores Affecting the Tensile Properties in Vacuum Die Casting Metals. Materials 2020, 13, 3019. https://doi.org/10.3390/ma13133019

Cao H, Luo Z, Wang C, Wang J, Hu T, Xiao L, Che J. The Stress Concentration Mechanism of Pores Affecting the Tensile Properties in Vacuum Die Casting Metals. Materials. 2020; 13(13):3019. https://doi.org/10.3390/ma13133019

Chicago/Turabian StyleCao, Hanxue, Ziwei Luo, Chengcheng Wang, Jing Wang, Tao Hu, Lang Xiao, and Junqi Che. 2020. "The Stress Concentration Mechanism of Pores Affecting the Tensile Properties in Vacuum Die Casting Metals" Materials 13, no. 13: 3019. https://doi.org/10.3390/ma13133019

APA StyleCao, H., Luo, Z., Wang, C., Wang, J., Hu, T., Xiao, L., & Che, J. (2020). The Stress Concentration Mechanism of Pores Affecting the Tensile Properties in Vacuum Die Casting Metals. Materials, 13(13), 3019. https://doi.org/10.3390/ma13133019