1. Introduction

Reactive Powder Concretes (RPC) are one of the most significant achievements in the field of the concrete technology in recent years [

1,

2]. They achieve considerable compressive strength values reaching even over 200 MPa in normal conditions, whereas with application of the hydrothermal treatment the strength values are much higher (from 300 to 500 MPa) [

3,

4,

5]. Such high compressive strength values were achieved by elimination of coarse aggregate, which was replaced with fine ground quartz with particle size from 1 μm to 4 μm, and with sand with particle size from 200 μm to 400 μm. Apart from the increased quantity of cement (the cement content is usually 900 kg/m

3), the use of silica fumes, finely ground quartz powder, ground granulated blast furnace slag and fly ash at a low w/b ratio (from 0.20 to 0.23) allows to provide the maximum particle packing in the concrete. Whereas a larger quantity of steel fibers, in amount from 1.5 to 3.0%, assures achievement of the relatively high flexural and tensile strength of this concrete. Steel fibers play an important role in shaping of mechanical properties of this material [

6,

7]. Nowadays, the interest in modification of RPC properties grows through the application of various types of fibers, including basalt ones [

8], and even of polypropylene [

9]. Basalt fibers, due to their mechanical properties and resistance to high temperatures, are a subject of greater interest by concrete technologists. The tensile strength of basalt fibers is 700–1680 MPa, and the Young’s modulus fluctuates within 70–90 MPa [

10,

11]. The advantages also include resistance to corrosion, both basic and acidic corrosion. Fibers are resistant to low and high temperatures, the range of working temperatures of application fluctuates from −260 °C to +750 °C [

12].

To assess impact of the basalt fibers on the concrete properties, we have taken into account fibers content, size and the water-to-cement (w/c) ratio [

13,

14,

15,

16]. The influence of the experimental results of the basalt fibers concrete strength are ambiguous [

14,

17,

18].

Kabay [

15] tested the influence of basalt fibers in quantity 2% and 4% by mass, length 12 and 24 mm in high strength and normal strength concretes with w/c ratio equal to 0.45, and 0.60, respectively. He found that the addition of fibers caused the decrease in compressive strength and increase of the flexural strength and the fracture energy rose along with the increase in the fiber content of concrete.

Barabanshchikov and Gutskalov [

13], while testing the impact of various quantity of basalt fibers (from 0.93% to 3.24% by volume) of various length 12.7 and 24.5 mm on properties of cement pastes, also found reduction of the compressive strength, whereas the increase of the flexural strength of specimens was the higher, the higher the fiber content was. It shall be noted, however, that the higher fiber content required the increase of w/c ratio from 0.31 to 0.40, which undoubtedly influenced the compressive strength. Furthermore, authors found that there was an optimum quantity of basalt fibers with the given length, which caused the highest increase of the flexural strength. In case of specimens tested, that quantity for fibers 12.7 mm long was 1.6% by volume.

Chaohua et al. [

16] investigated the influence of basalt fibers, 12 and 22 mm long, in amount from 0.05% to 0.5% of the total volume of the concrete mix, with a relatively high w/c ratio equal to 0.6. They found a visible increase of flexural and tensile strength, but a slight increase of the compressive strength, and even its reduction at a later time. They stated that the content of fibers in amount of 0.3% in volume fraction was the most suitable in terms of the growth of the concrete mechanical parameters tested.

Tehmina Ayub et al. [

14] observed a slight increase of the compressive strength of the High Performance Concrete with basalt fiber content 1% and 2% of volume fraction, and then the drop with a higher amount of fibers (3 vol.%). They noted the strength decrease occurred with addition of metakaolin and silica fumes. Authors observed the gradual increase of splitting tensile strength along with the increase of fiber content (from 1% to 3% by volume).

The increase of both compressive and flexural strength along with the increase of basalt fiber content from 0.25% to 1% by weight of cement, while keeping the same w/c ratio = 0.42, was found by authors of the paper [

17]. The similar relation was observed by the authors of the paper [

19] at the fiber content increase from 1% to 3% by weight of cement in sand basalt-fiber concrete, while keeping the w/c ratio within the range 0.32–0.35.

Not many papers on the RPC with addition of basalt fibers have been published so far. Such research was conducted by authors of the paper [

8], who found that introduction of basalt fibers to RPC (w/c = 0.25) caused the increase of the compressive and flexural strength, when the content was from 1 kg/m

3 to 3 kg/m

3, whereas when the content of fibers increased to 5 kg/m

3, the gradual decrease of the compressive and flexural strength occurred.

Table 1 shows results of compressive and flexural strength tests of various types of concretes, with a different content of basalt fibers from 6 mm to 25 mm long, conducted by various authors [

8,

13,

14,

15,

16,

17,

19]. The analysis of test results of flexural strength of concretes presented in

Table 1 shows that, along with the fiber content increase in the concrete, the increase in the flexural strength also occurs to a various extent. [

15,

16,

17]. The higher growth in the flexural strength (within the range from 54% to 64%) is achieved by samples with the w/c ratio 0.34–0.42 and the higher content of fibers, above 15 kg/m

3 [

13,

17]. In the case of RPC and hardened cement paste, which have a much higher content of fine particles, the flexural strength increases to a certain amount of basalt fibers in the material, and then it goes down with the further increase of the fiber content [

8,

13]. Application of the low w/c ratio (0.25) in RPC allows to introduce much smaller amount of fibers (up to 5 kg/m

3), than to the cement paste with the higher w/c (0.4).

In case of the compressive strength, the increase can be also observed [

17,

19], as well as reduction of the strength along with the basalt fiber content in the concrete [

13,

14,

15], and also the increase of the strength, and then its drop when a specific amount of fibers in the concrete is exceeded [

8,

16]. Reduction of the concrete compressive strength is observed both in case the fiber content is lower: 4.0 kg/m

3 by 18% [

15], and in case the fiber content is higher: 94 kg/m

3 by 50% [

13]. In general, the increase of fiber content makes their proper distribution in the concrete mix more difficult and may lead to higher concrete porosity, resulting in the reduction of the compressive strength [

16,

20]. Furthermore, the higher content of basalt fibers in the mix, to provide its workability, requires the increase of the w/c ratio, which in consequence also leads to reduction of the concrete compressive strength.

There are many factors mentioned above, which have the impact on the strength of concretes with basalt fibers, but the impact of the concrete composition cannot be ignored, including the influence of mineral admixtures to seal the cement matrix and the matrix contact with fibers.

There are multiple factors that affect the strength of concrete, and with addition of fibers, it is difficult to determine the impact on each of them individually. Based on research conducted by various authors, general trends in the change in strength can be indicated under the influence of basalt fibers introduced to the concrete. Although, most researchers use basalt fibers with an optimal length of 12 mm due to the strength of concrete [

15], this parameter should also be taken into accoung when the strength of concrete with fibers are analysed.

Few papers referring to tests of RPC with basalt fibers have resulted in research to be undertaken, in order to determine the optimum quantity of basalt fibers in RPC, in terms of the compressive and flexural strength. Testing included the impact of basalt fibers on the RPC strength, resistance to abrasion and porosity.

Taking the basalt fibers resistance to high temperatures into account, the objective of tests performed was to determine composition of the RPC with the highest compressive and flexural strength, which will be subject to high temperatures, as in case of tests of RPC with steel fibers, conducted by the authors of this paper [

7].

2. Materials and Methods

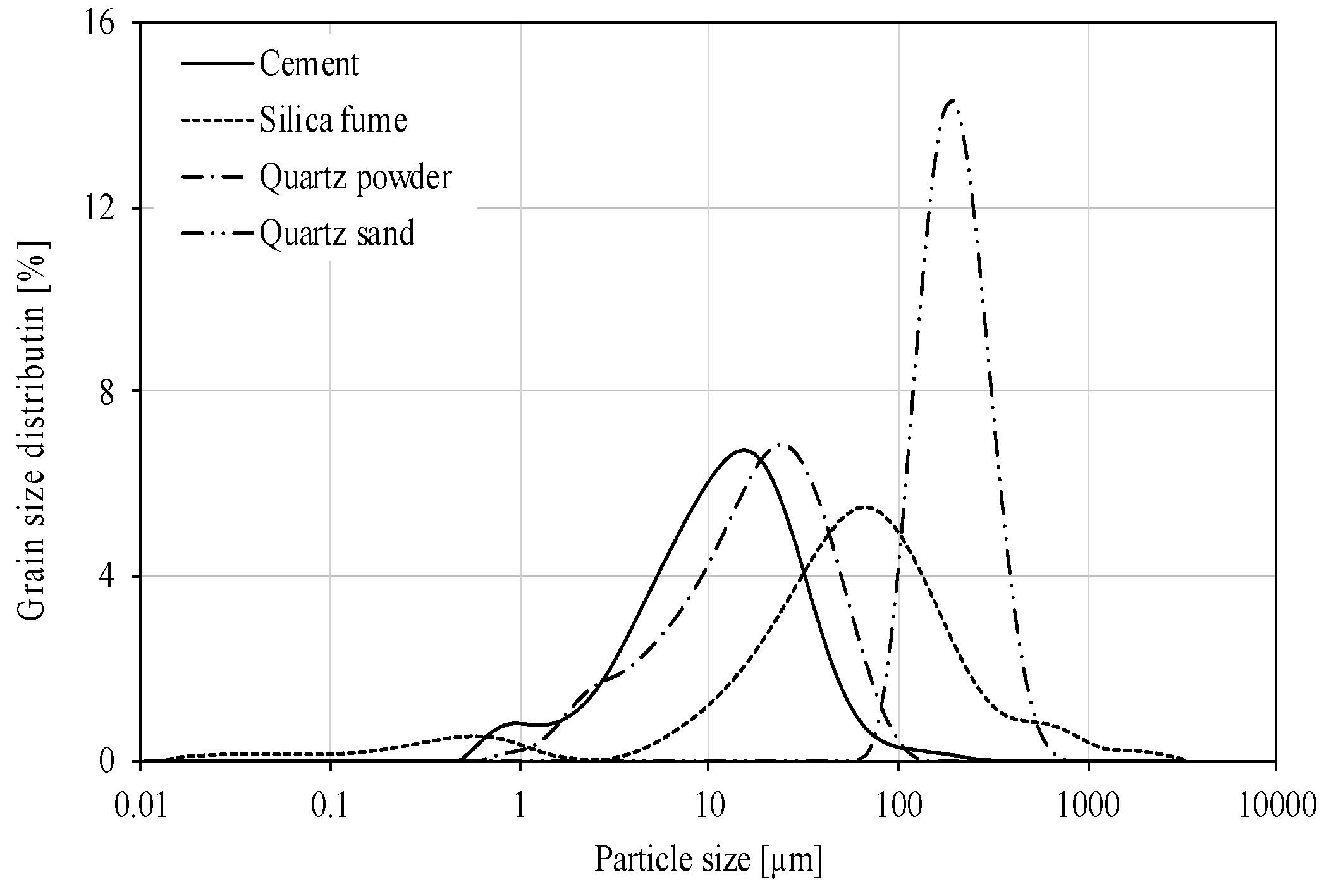

To prepare the Reactive Powder Concrete (RPC), the following ingredients were used: Portland cement CEM I 52,5 R (Cement Plant, Rejowiec, Poland) with specific surface area 410 m

2/kg, silica fumes, quartz powder 0/0.2 mm, quartz sand 0/0.4 mm and basalt fibers 12 mm long and diameter 18 µm. Polycarboxylate superplasticizer was added in quantity of 2.5 wt.% of cement. The chemical composition of the cement, silica fumes, quartz powder and quartz sand is given in

Table 2, and

Figure 1 and

Figure 2 shows the particle size distribution of the cement, silica fumes, quartz powder and quartz sand determined by means of a laser size analyzer Mastersizer 3000 (Malvern, UK). Waste silica fume containing more than 62% particle > 40 μm.

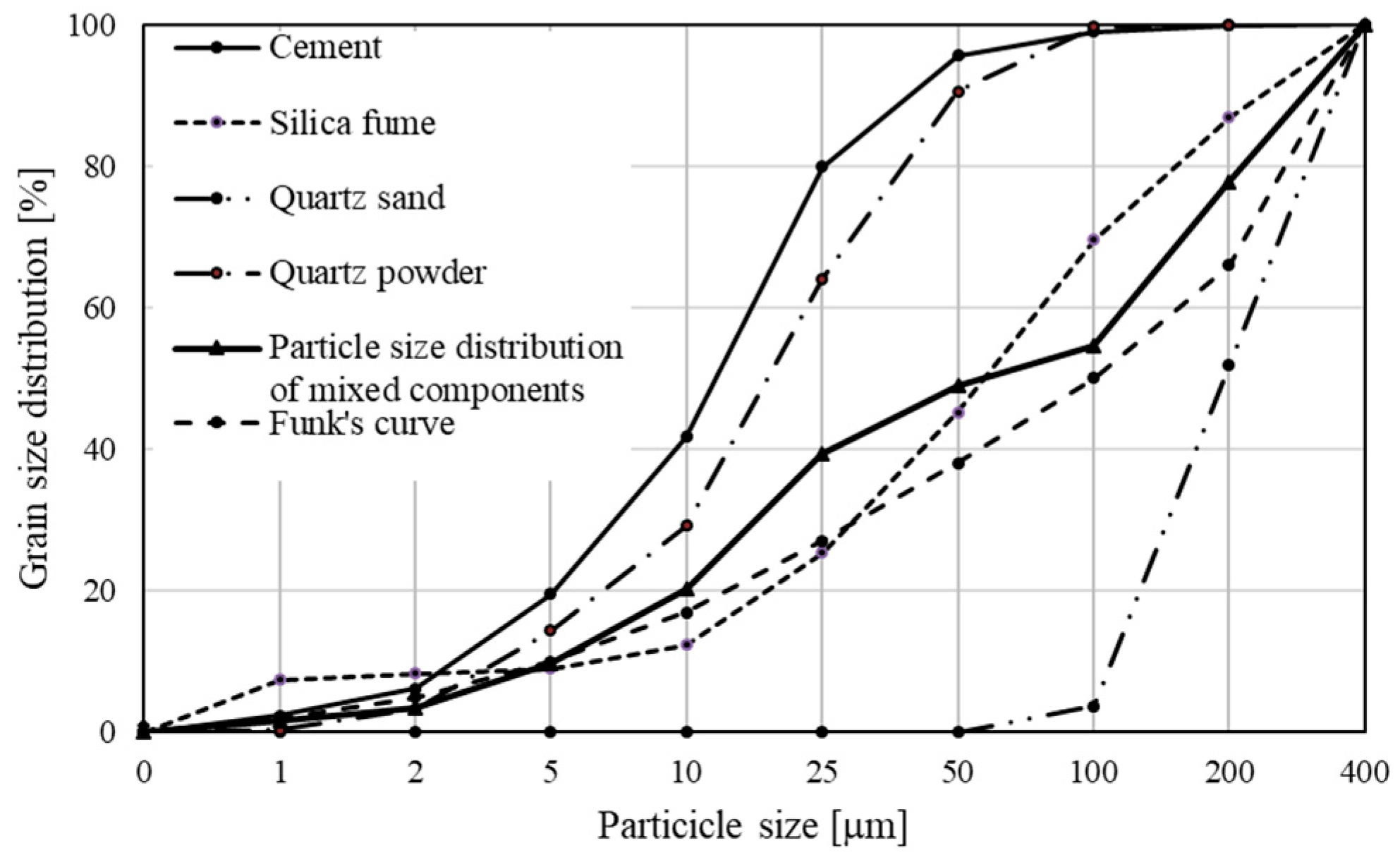

Optimization of the concrete mix composition that assured the maximum packing density of particles, was performed based on Funk and Dinger’s curve [

21] (

Figure 3) following formula,

where y

i—cumulative percentage of i-fraction content, d

i—i-fraction diameter [μm], d

Max—maximum particle diameter [μm], d

Min—minimum particle diameter [μm], n—constant value equal to 0.37.

For that purpose, also other computational models are used [

22,

23].

Composition of RPC mixes is given in

Table 3. The content of basalt fibers in the mix were 2; 3; 6; 8 and 10 kg/m

3, at the same w/c ratio amounting to 0.24.

The particle size distribution of the concrete was determined by means of the particle size laser analyzer Mastersizer 3000 within the range 0.01–3500 μm.

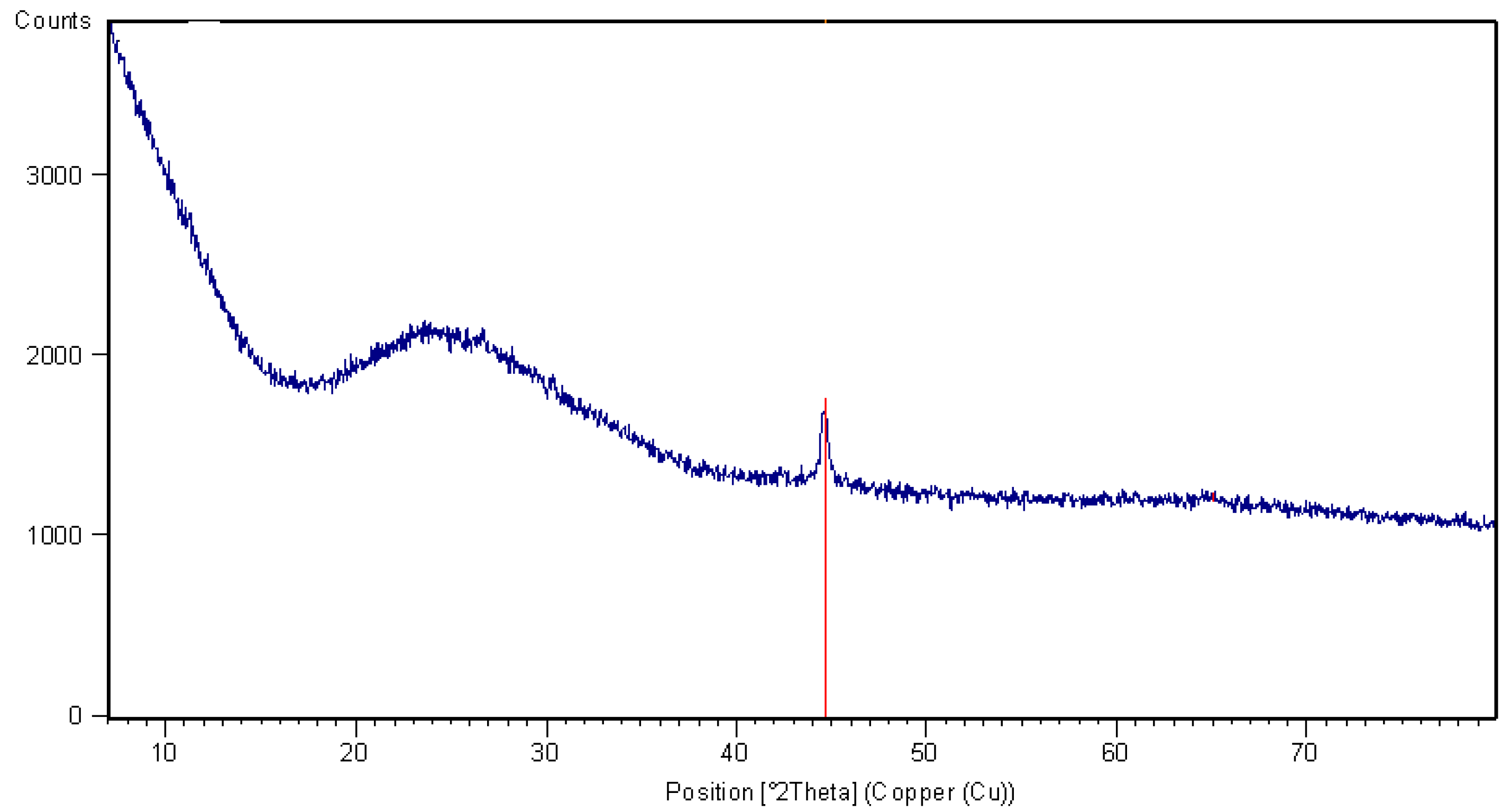

X-ray diffraction (XRD) tests were conducted by means of Philips X’PertSystem diffractometer (Amsterdam, The Netherlands). The measurement was conducted within a range from 5° to 60° 2θ. CuKα radiation was used.

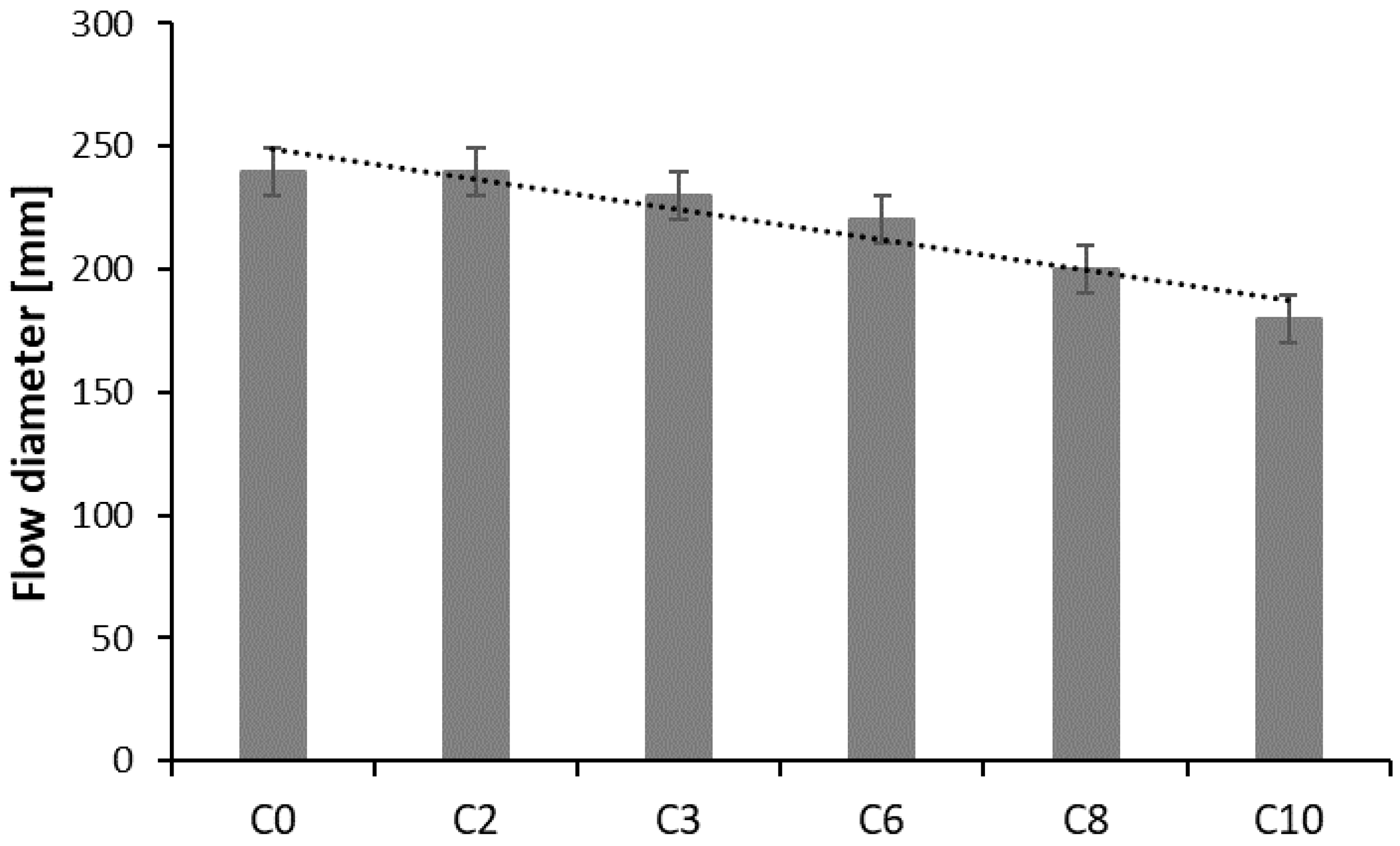

Tests of RPC consistence were performed in line with PN-EN 1015-3 standard (Methods of test for mortar for masonry. Part 3: Determination of consistence of fresh mortar (by flow table)) [

24]. Consistence was determined based on measurement of the concrete flow diameter.

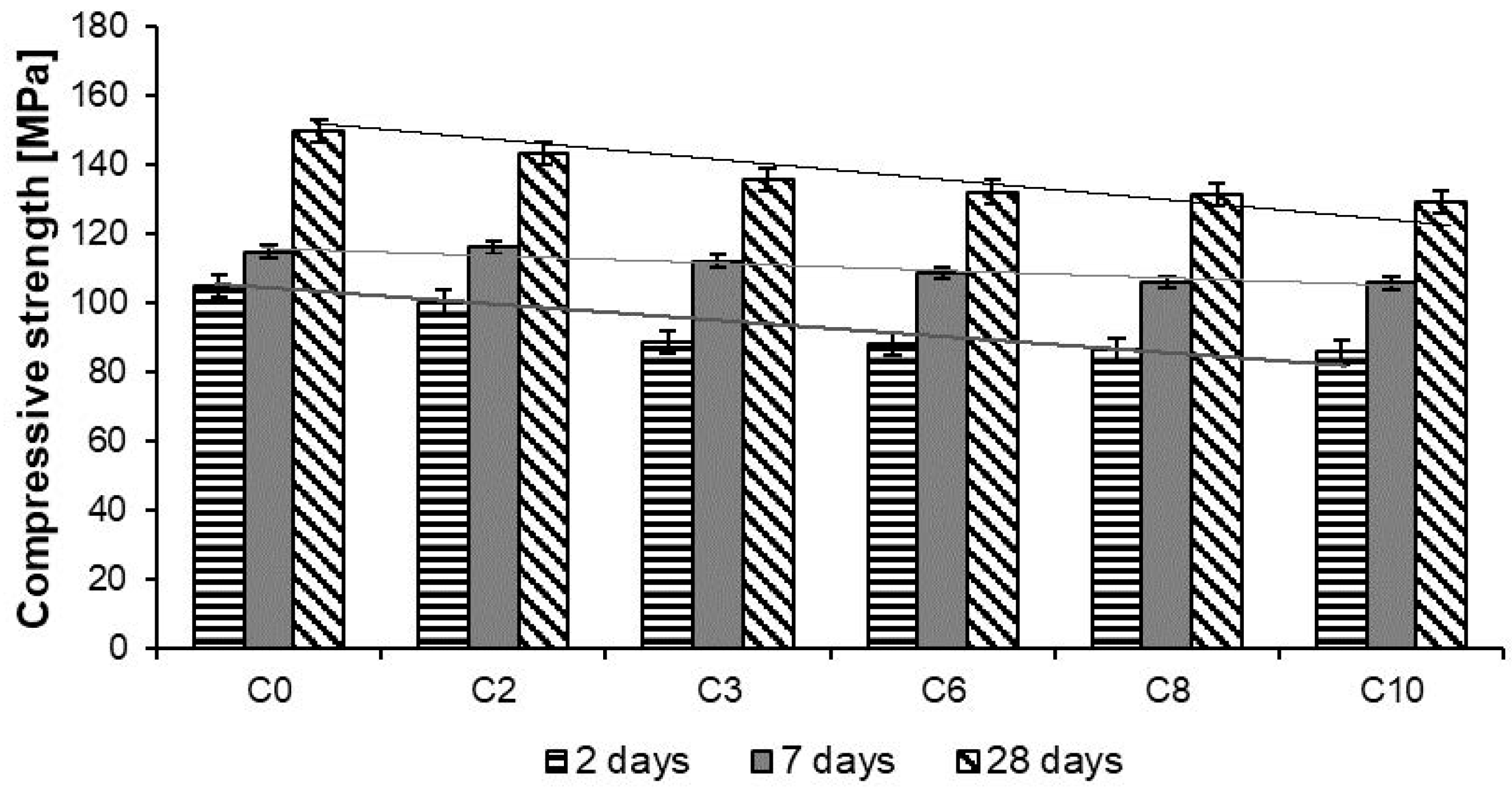

The tests of compressive strength and flexural strength of RPC specimens were performed in line with PN-EN 1015-11 standard (Methods of test for mortar for masonry. Part 11: Determination of flexural and compressive strength of hardened mortar) [

25]. Tests were performed on specimens 40 mm × 40 mm × 160 mm each time. The flexural strength was calculated according to the following formula,

where f—flexural strength [MPa], F—maximum load [N], l—distance between axes of cylinders [mm], b—width of specimen [mm], d—height of specimen [mm].

The compressive strength was calculated according to the following formula:

where: fc—compressive strength [MPa], F—maximum load [N] and A

c—section area of specimen [mm

2].

Resistance to abrasion of RPC specimens was tested in accordance with PN-EN 1338 standard (Concrete paving blocks. Requirements and test methods) [

26]. Measurement of abrasion was performed on Böhme’s disc (EMEL, Poland). Specimens were subject to abrasion load equal to 294 ± 3 N during 16 cycles. The abrasion resistance was calculated according to the following formula,

where ∆m—specimen mass loss (wastage) after 16 cycles [g], ρ

R—specimen density [g/mm

3].

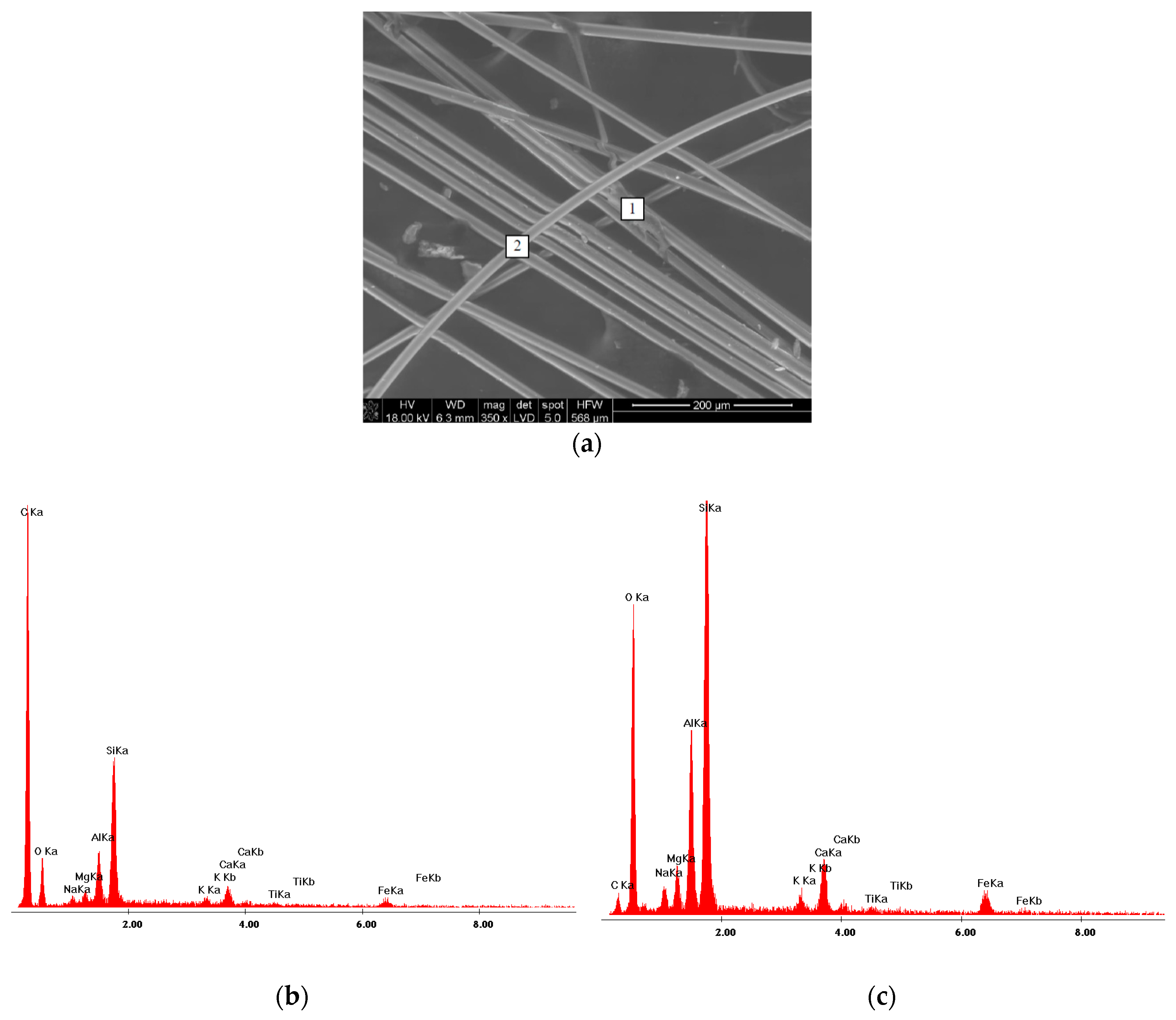

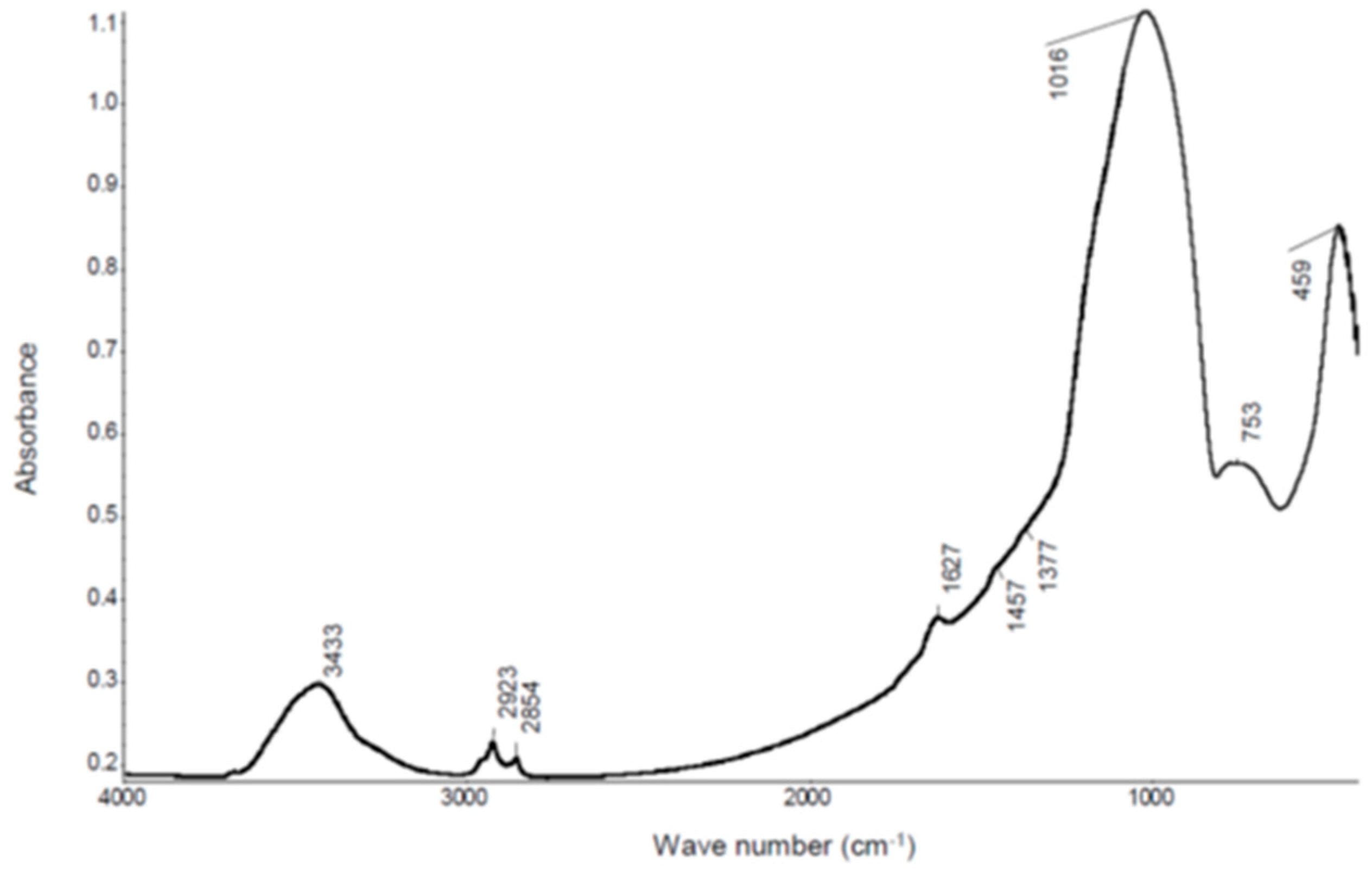

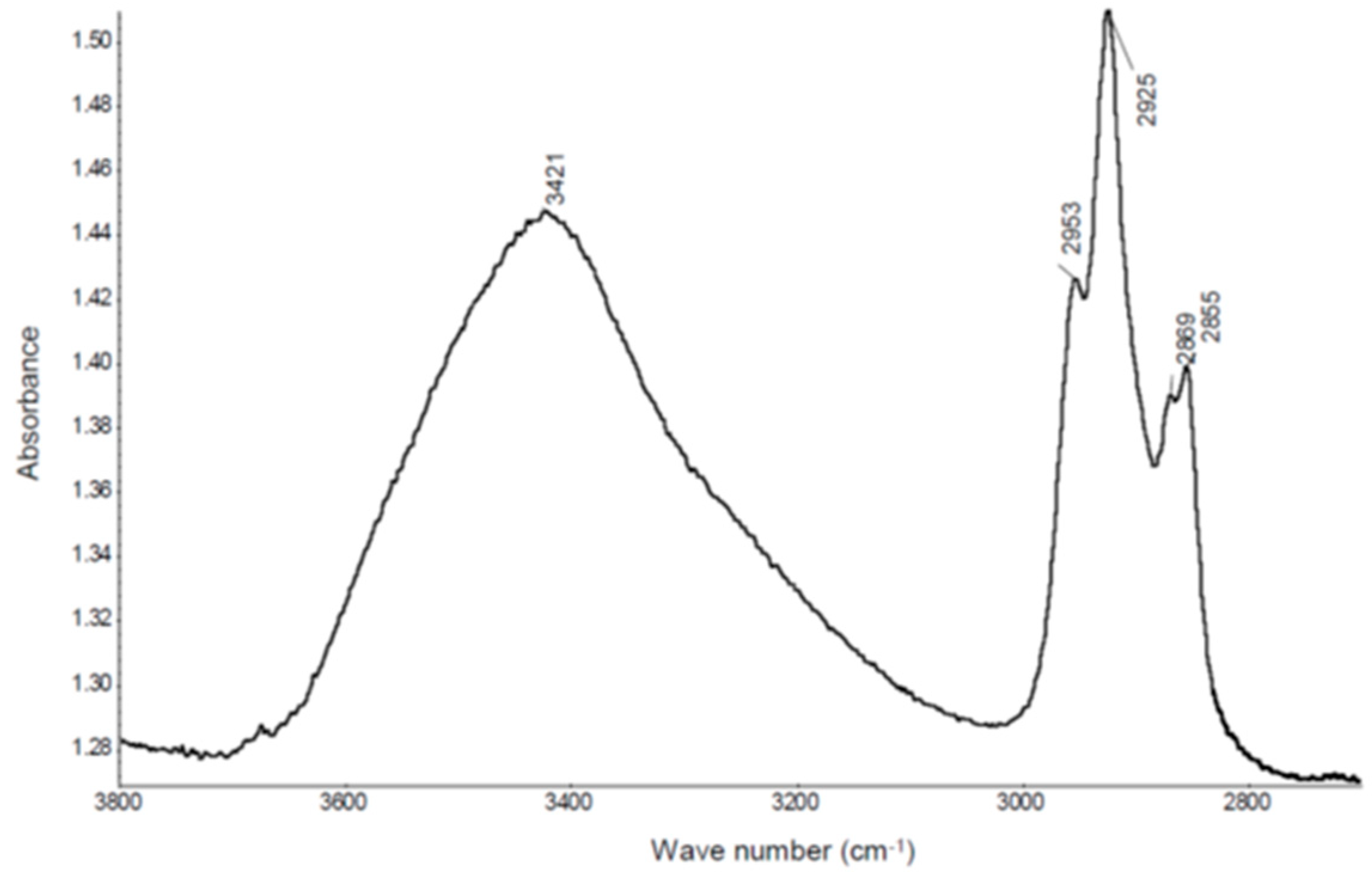

Infrared Spectra (IR) of basalt fiber specimen in the form of potassium bromide pellets (5 mg/500 mg KBr) recorded on Thermo Nicolet spectrophotometer (ThermoFisher Scientific, Waltham, MA, USA), Nexus model.

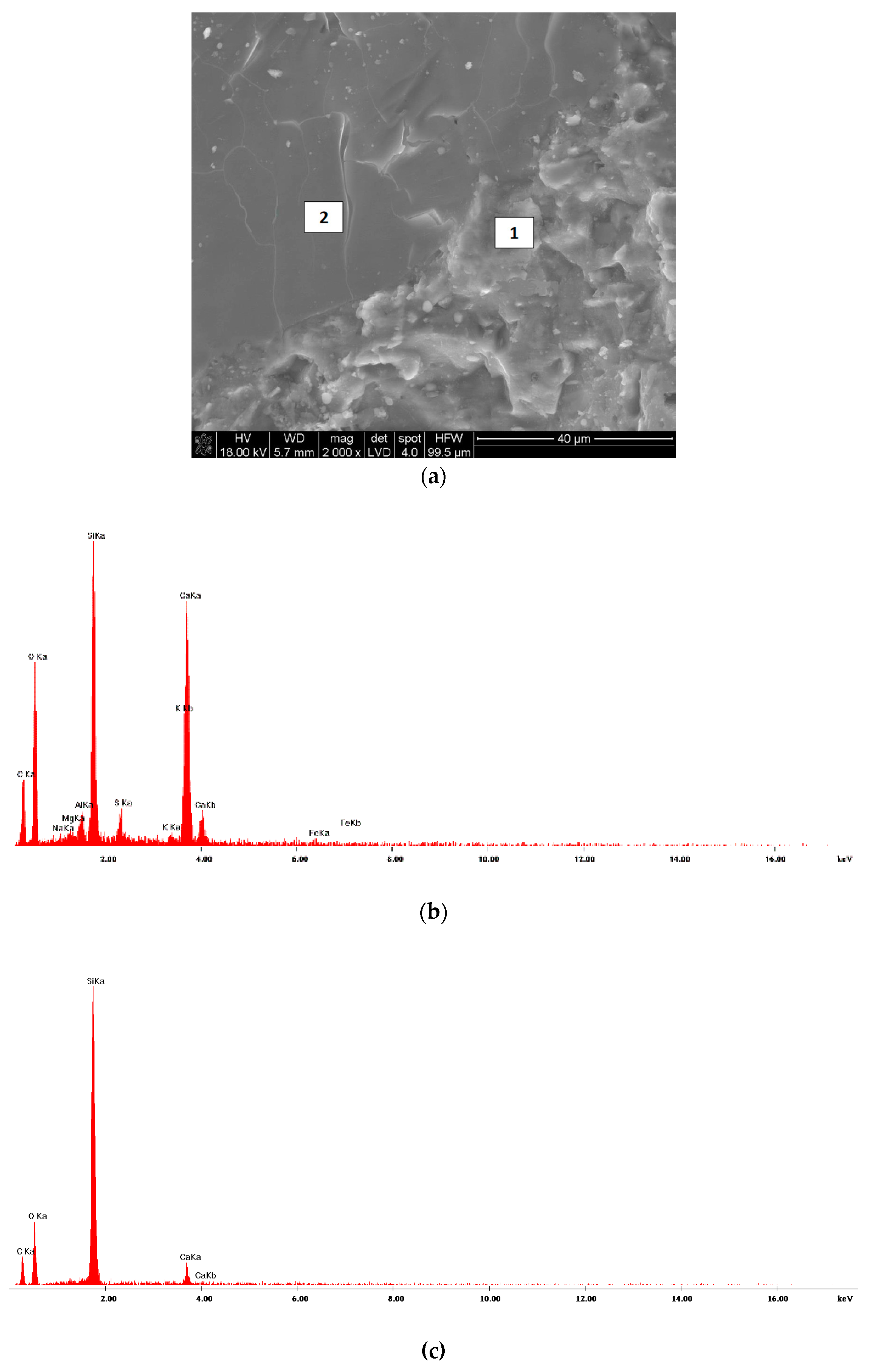

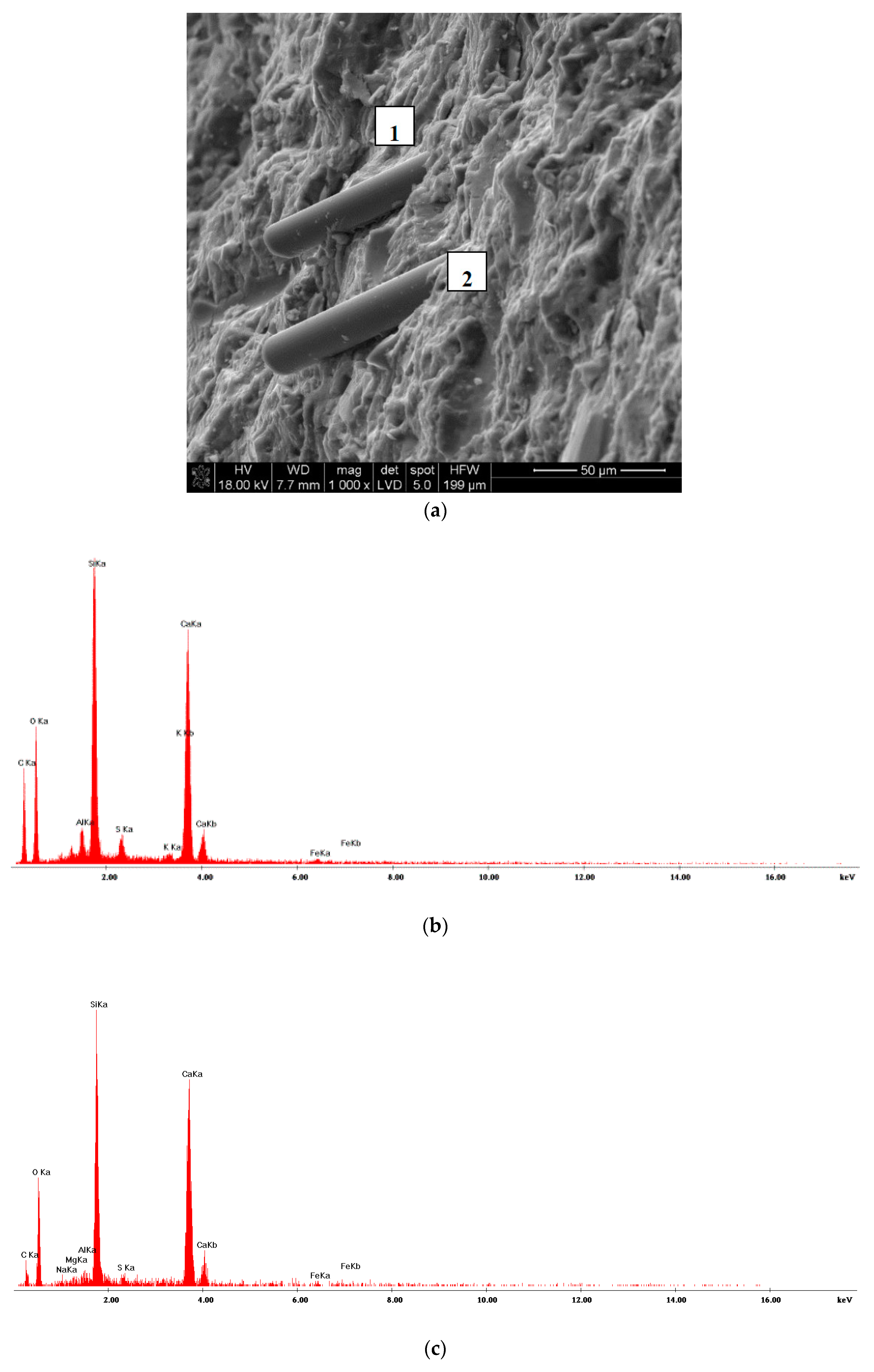

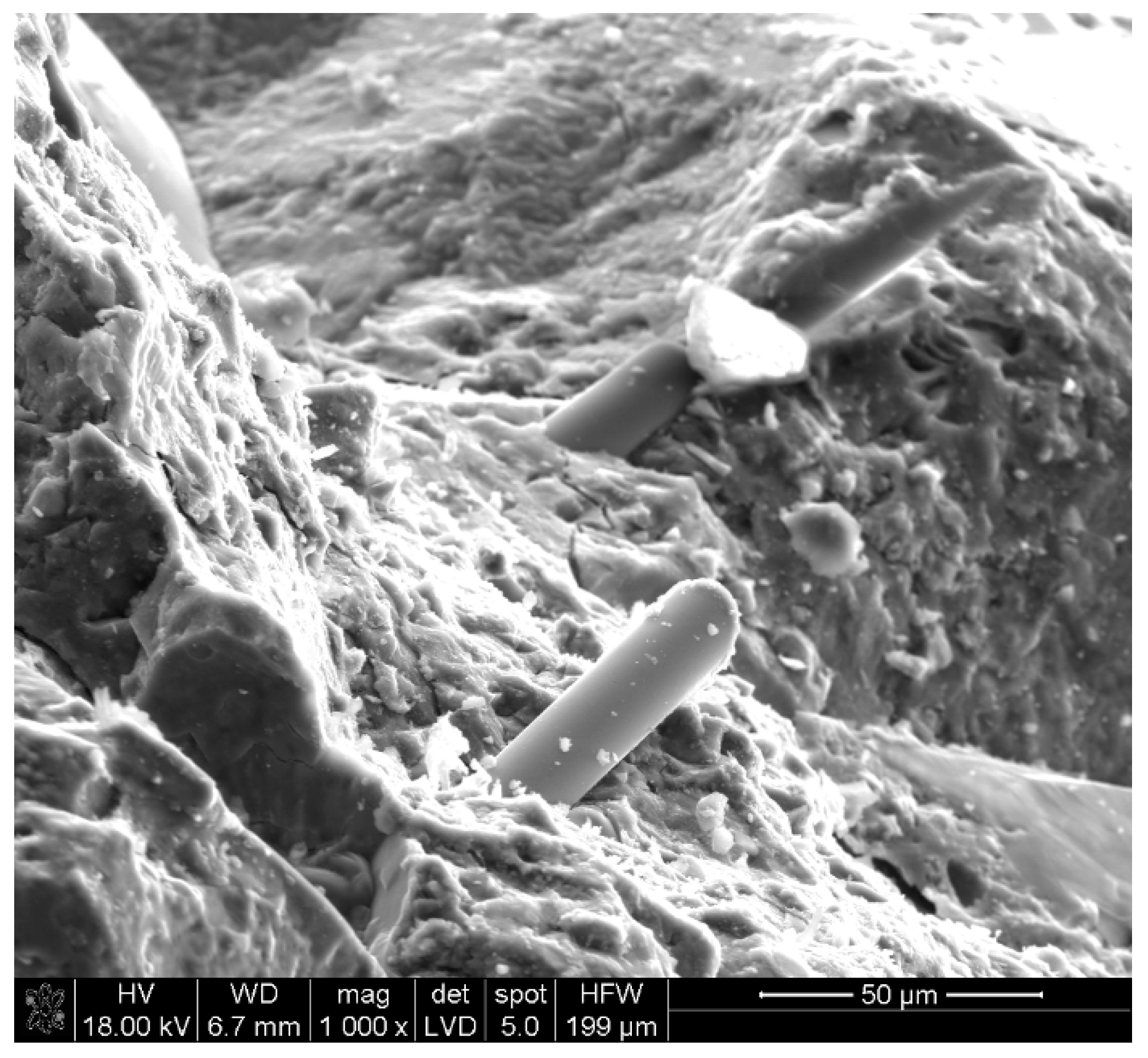

The microstructure of RPC was tested by scanning electron microscopy (SEM). Analyses were performed by means of the scanning microscope NOVA NANO SEM 200 (FEI Europe B.V., Eindhoven, The Netherlands). Observations were conducted with magnification from 200 to 10,000. Specimens for testing were prepared by spraying a layer of gold on the surface in high vacuum conditions. Energy Dispersive X-Ray Spectra (EDS) were obtained for selected points.

Testing of RPC porosity were performed with the use of a mercury porosimeter PoreMaster 60 (Quantachrome Instruments, Boynton Beach, FL, USA), within a pressure range from 1 to 400 MPa. The results of the tests were presented in a form of differential curves and volumetric distribution curves of pores with different size.

4. Conclusions

The paper impact of basalt fiber on the properties of the RPC mix and hardened concrete.

The results obtained show that the addition of basalt fibers to the RPC leads to a decrease in the workability of concrete mix. It results from a commonly known fact of a larger water demand of concrete mixes with addition of fibers in order to get the required workability.

While keeping the same w/c ratio equal to 0.24, the compressive strength of RPC containing basalt fibers reduces along with the increase of the fiber content in the concrete. The highest drop of the compressive strength from 15.5% to 18.2% with the fiber content increase from 2 kg/m3 to 10 kg/m3 is observed after two days. A similar relation is observed after 7 and 28 days of specimen curing, however, the reduction of the compressive strength along with the fiber content increase occurs in a lesser extent over time and it is: 7.8%, and 13.6%, respectively for specimens containing the highest quantity of basalt fibers (10 kg/m3). A reduction of RPC compressive strength is caused by the presence of a larger quantity of pores along with the increase of the fiber content in this concrete. Whereas, the clear reduction of the total porosity of specimens over time (from 2 to 28 days), due to the increase of cement hydration products formed, weakens the impact of fiber quantity on reduction of RPC compressive strength.

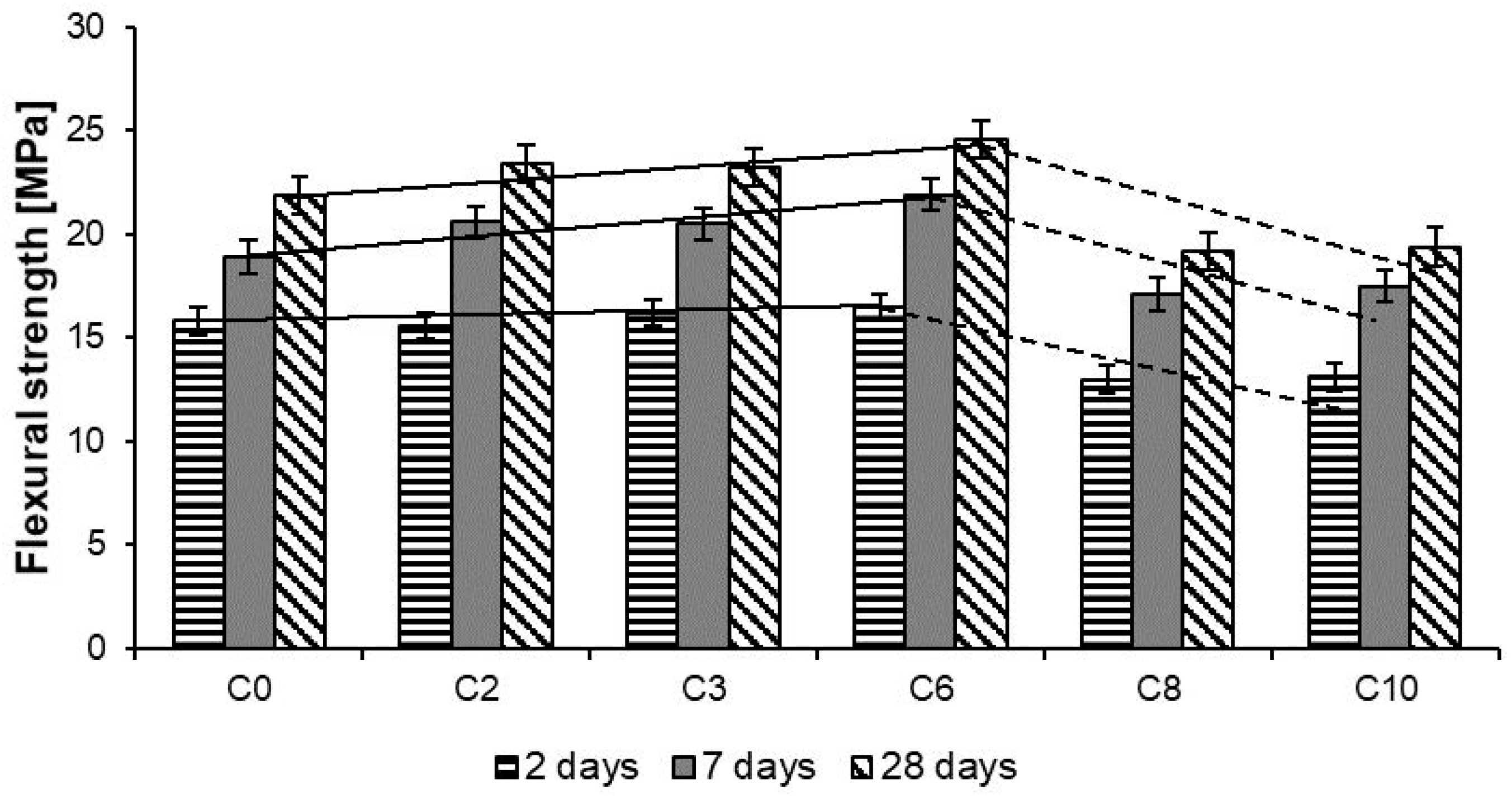

Introduction of basalt fibers to RPC in quantity up to 6 kg/m3 causes a slight gradual growth in the flexural strength (maximum by 15.9%). Whereas, with the higher content of fibers (8 and 10 kg/m3), reduction of the flexural strength occurs (maximum by 17.7%), but the differences in flexural strength of RPC specimen with the content 8 kg/m3 and 10 kg/m3 are minimal and they are from 0.1 MPa to 0.4 MPa. The increase of the flexural strength along with the increase of the fiber content up to 6 kg/m3 goes up over time and after 2, 7 and 28 days it amounts to: 4.4%, 15.9%, and 12.3%, respectively. The higher content of basalt fibers in the RPC mix at the lower w/c ratio used (0.24), deteriorates their dispersion, which in consequence, may cause a reduction of the flexural strength.

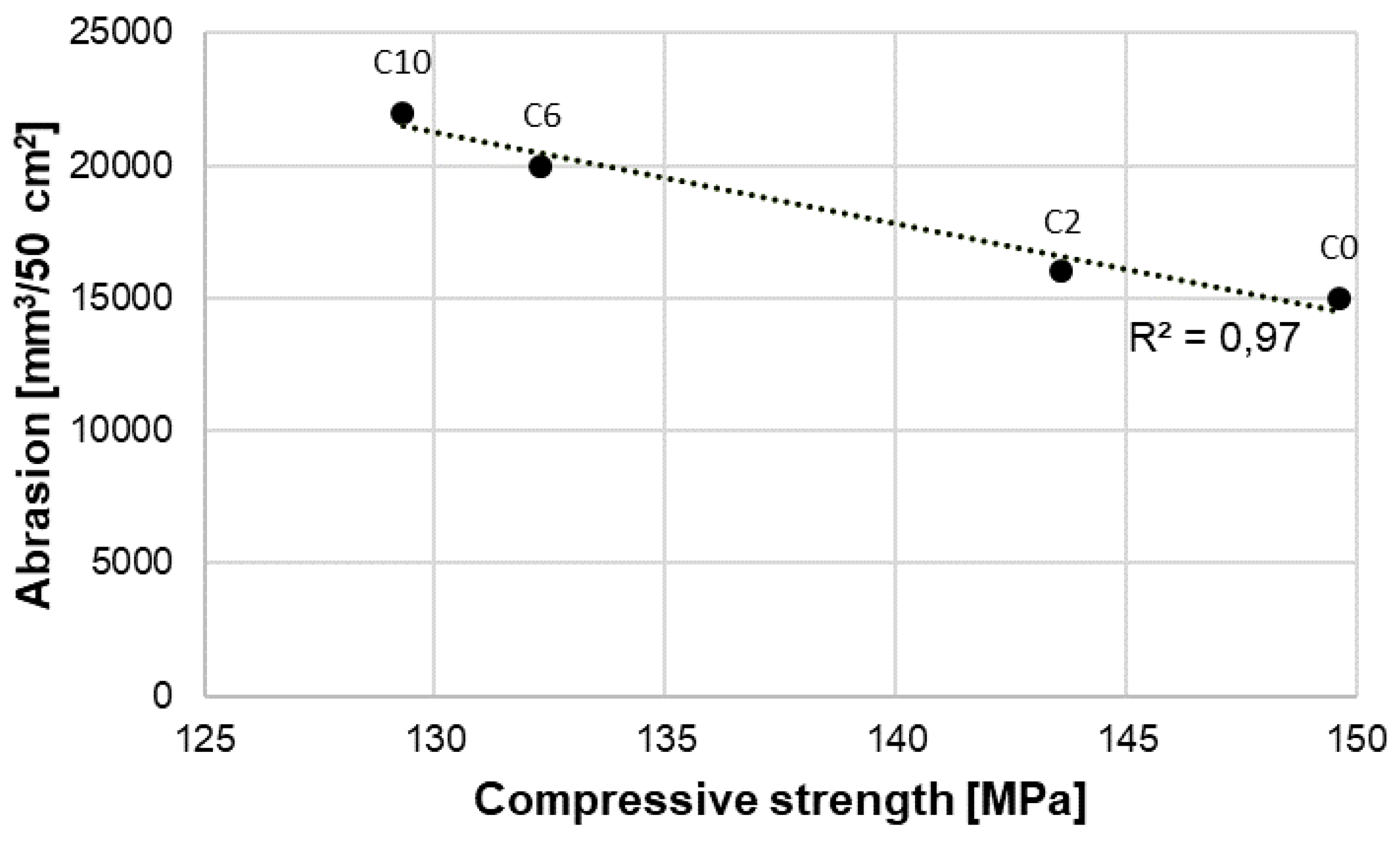

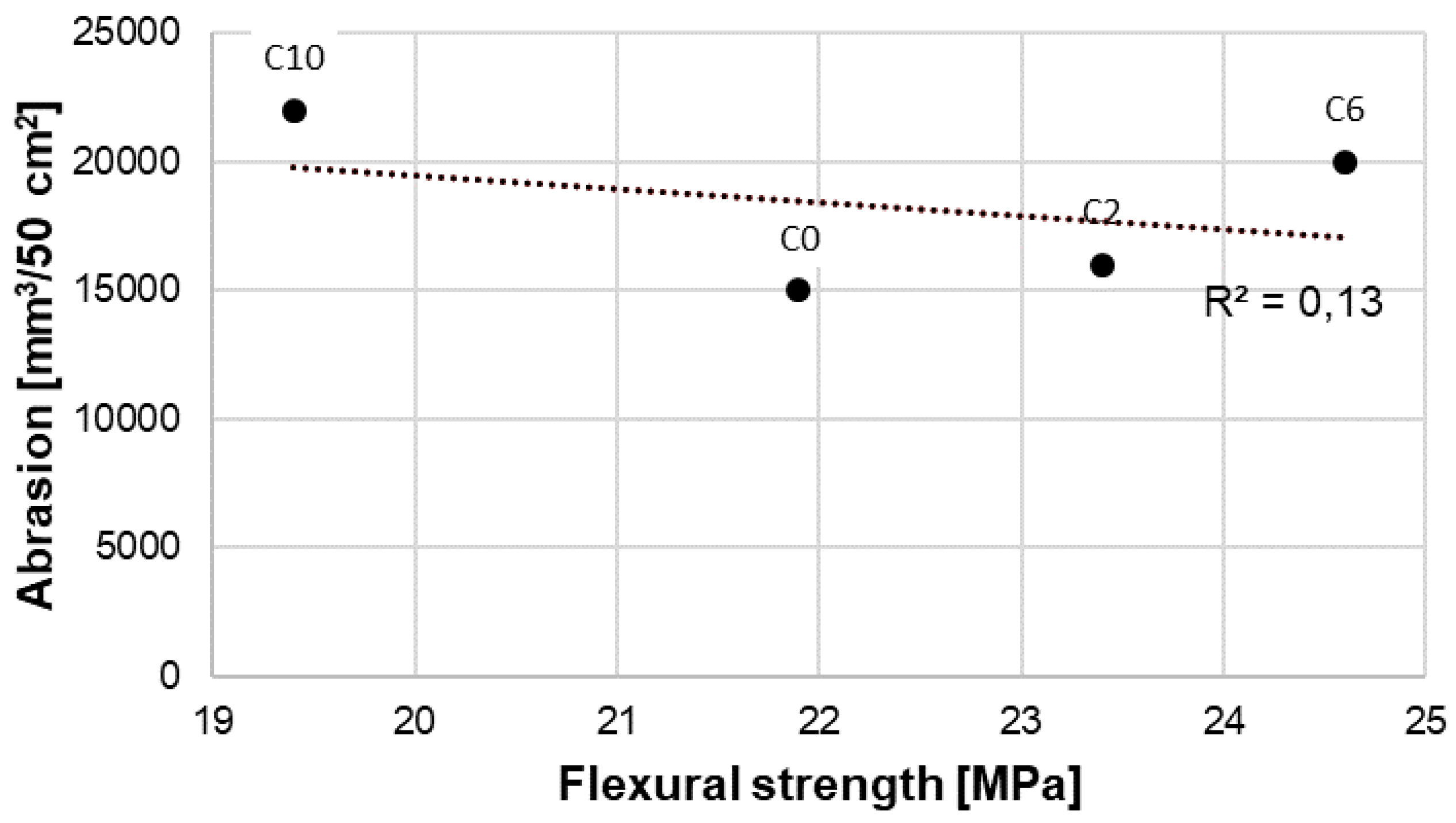

The reduced resistance to abrasion resistance of RPC along with the increase of basalt fibers content is caused by the reduction of the concrete compressive strength. A strong relationship was found between the RPC resistance to abrasion and its compressive strength. The determination coefficient R2 for this relationship is 0.97. Whereas, there was no significant relationship between the resistance to abrasion and the flexural strength (R2 = 0.13). The compressive strength is generally recognized as the most important factor that affects the concrete resistance to abrasion. The results abrasion resistance tests of RPC with basalt fibers also confirmed this relationship.

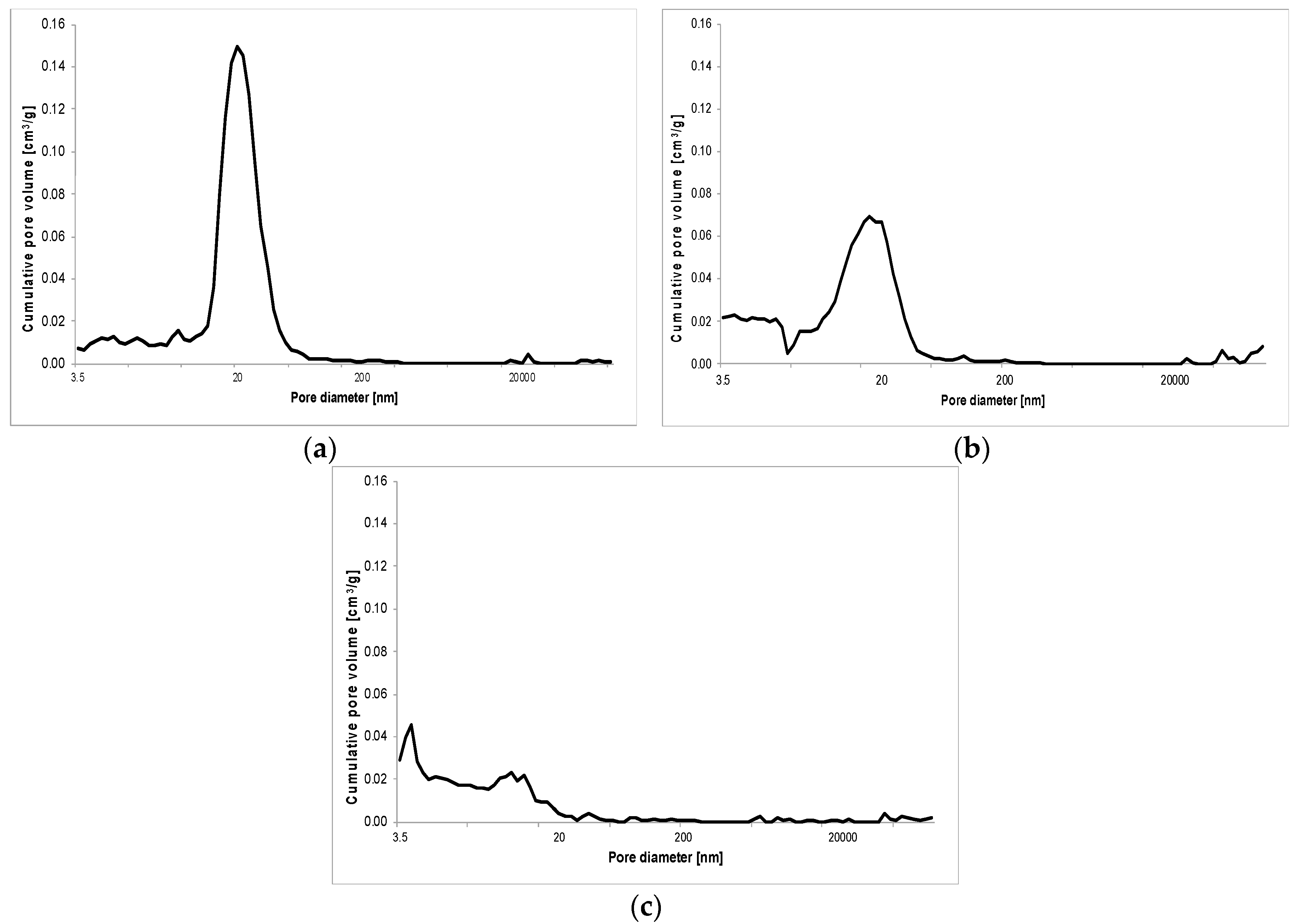

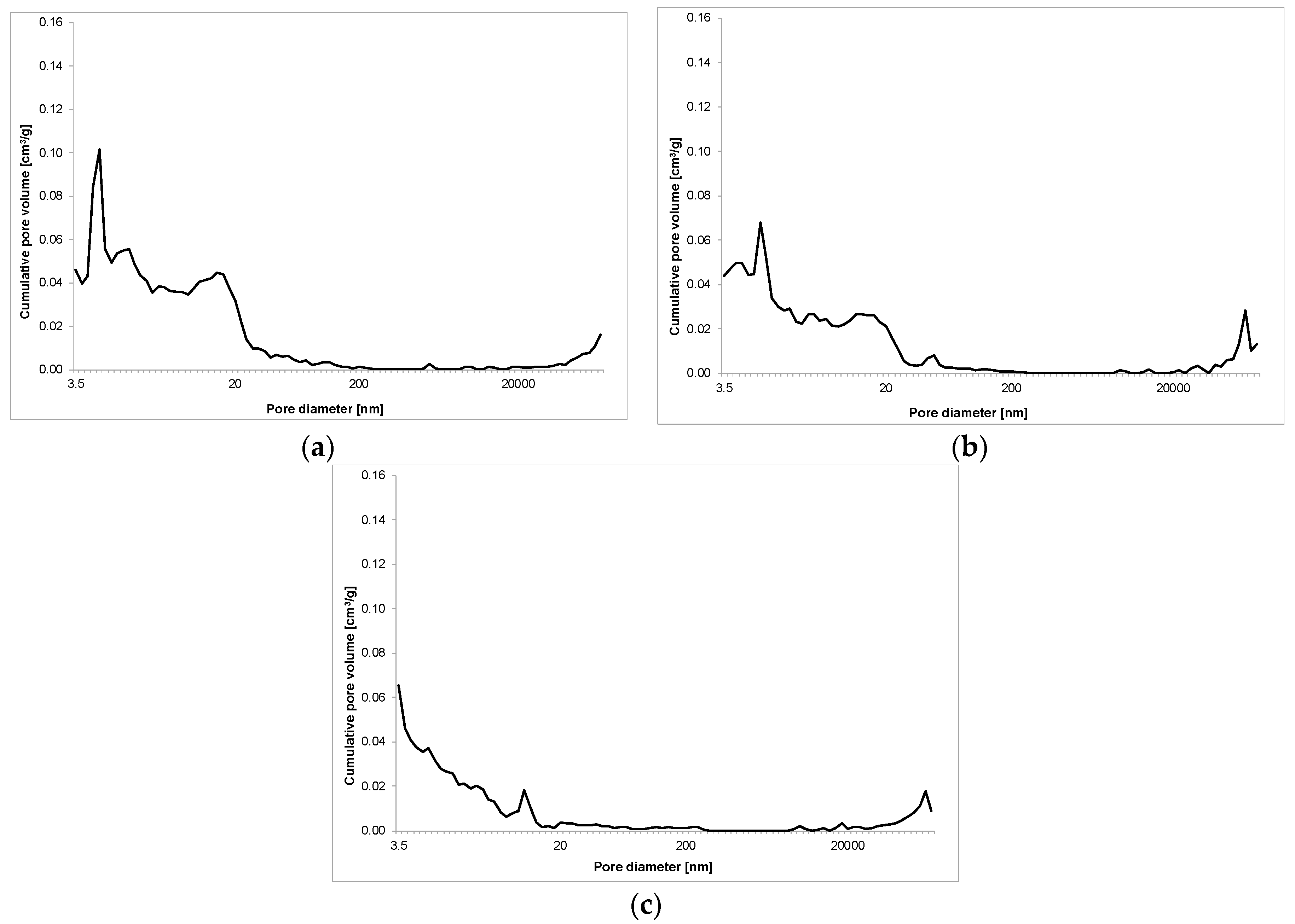

The introduction of basalt fibers to RPC causes the increase of the total porosity, as well as the change in distribution of pores as the content of basalt fibers grows. At the fiber content of 2 kg/m3, the content of larger pores > 20,000 nm grows, and the content of 20–200 nm pores goes down. Whereas at the higher content of fibers (6 kg/m3 and 10 kg/m3), reduction of pores below 20 nm occurs, as well as the increase of pores within a range 200–2000 nm, but the content of pores above 20,000 nm goes down. The above changes in the total quantity of pores and their distribution correspond well with the reduction of RPC compressive strength, as the content of basalt fibers in that concrete increases.