Effect of Electrode Waterproof Coating on Quality of Underwater Wet Welded Joints

Abstract

1. Introduction

2. Materials and Methods

2.1. Used Materials

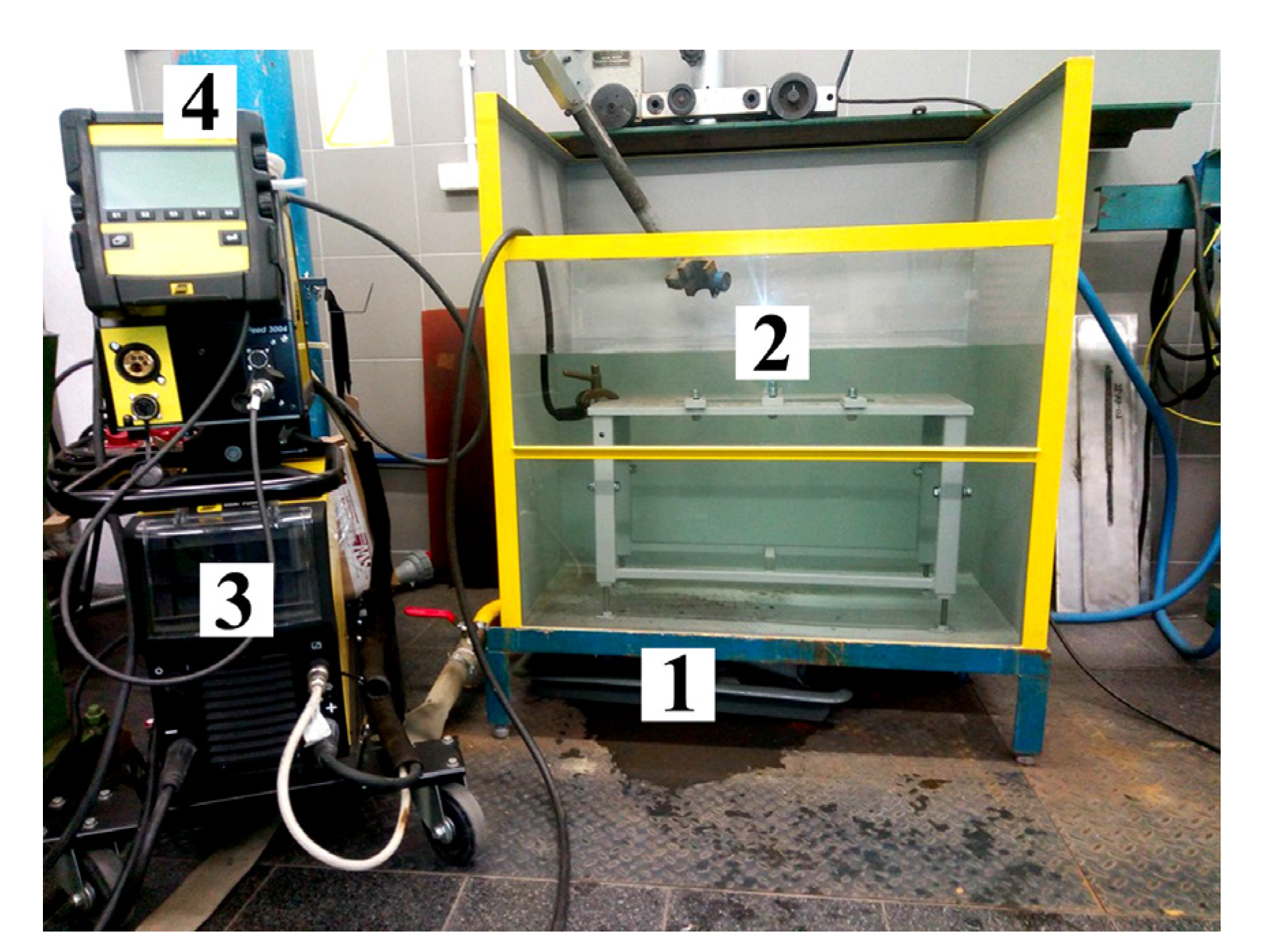

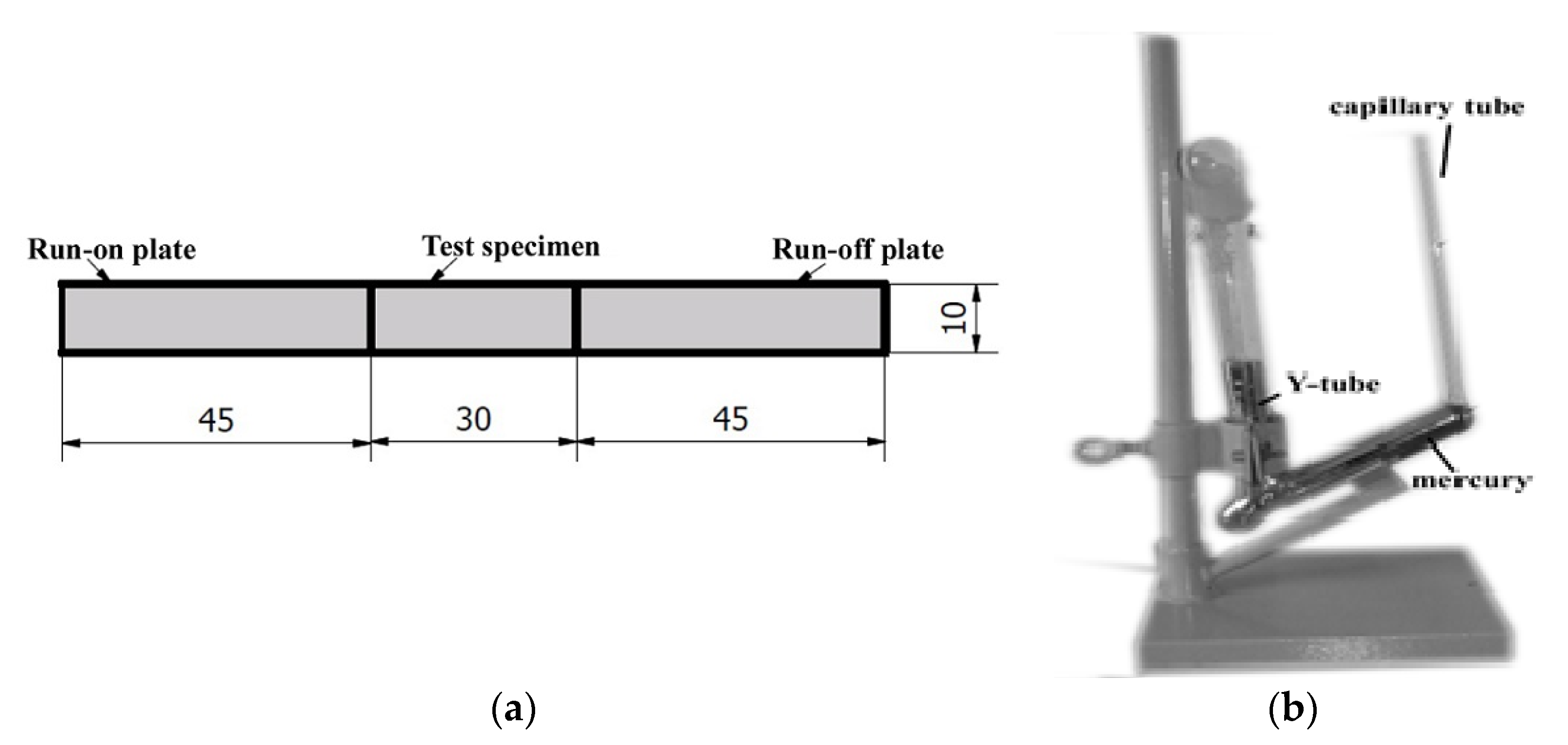

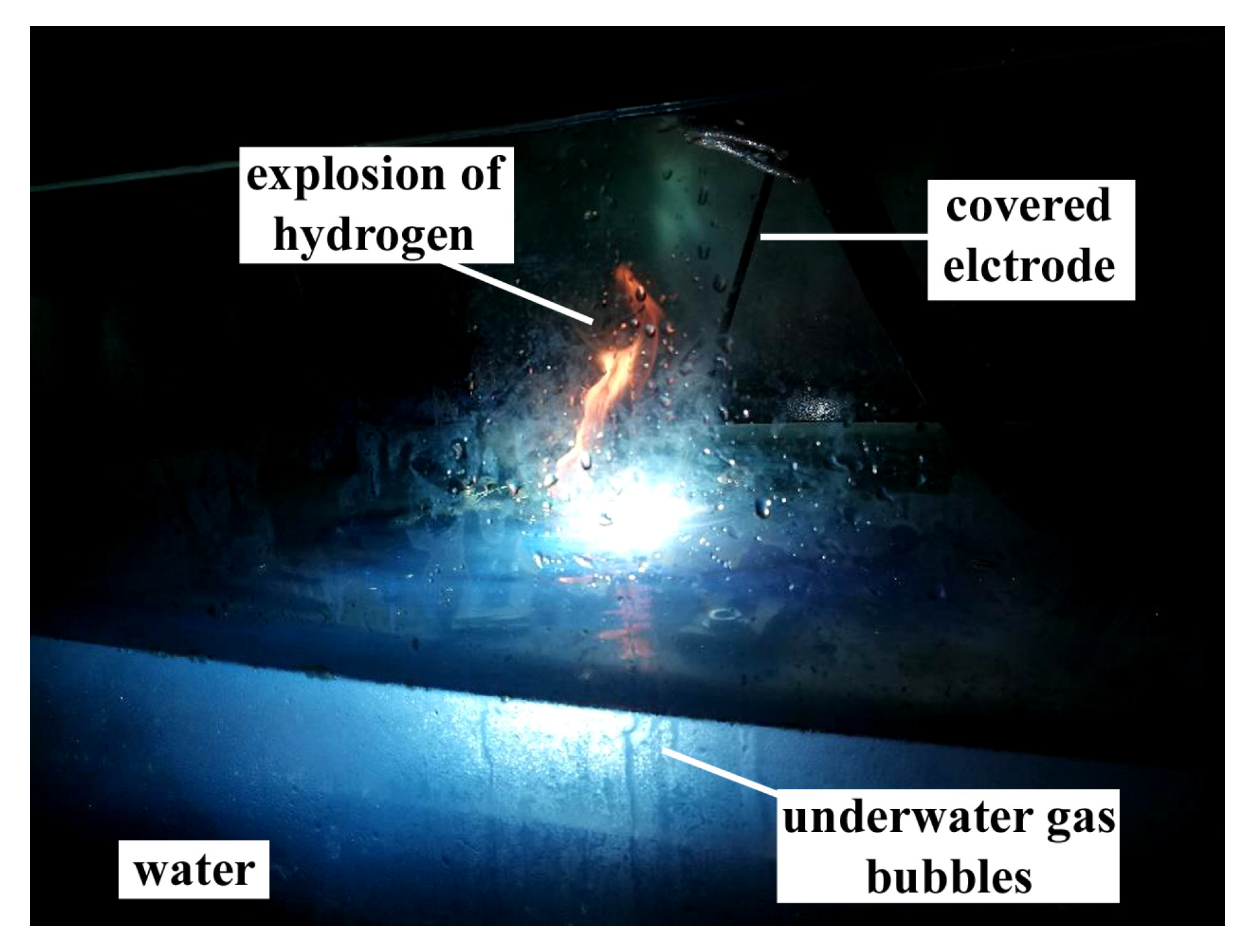

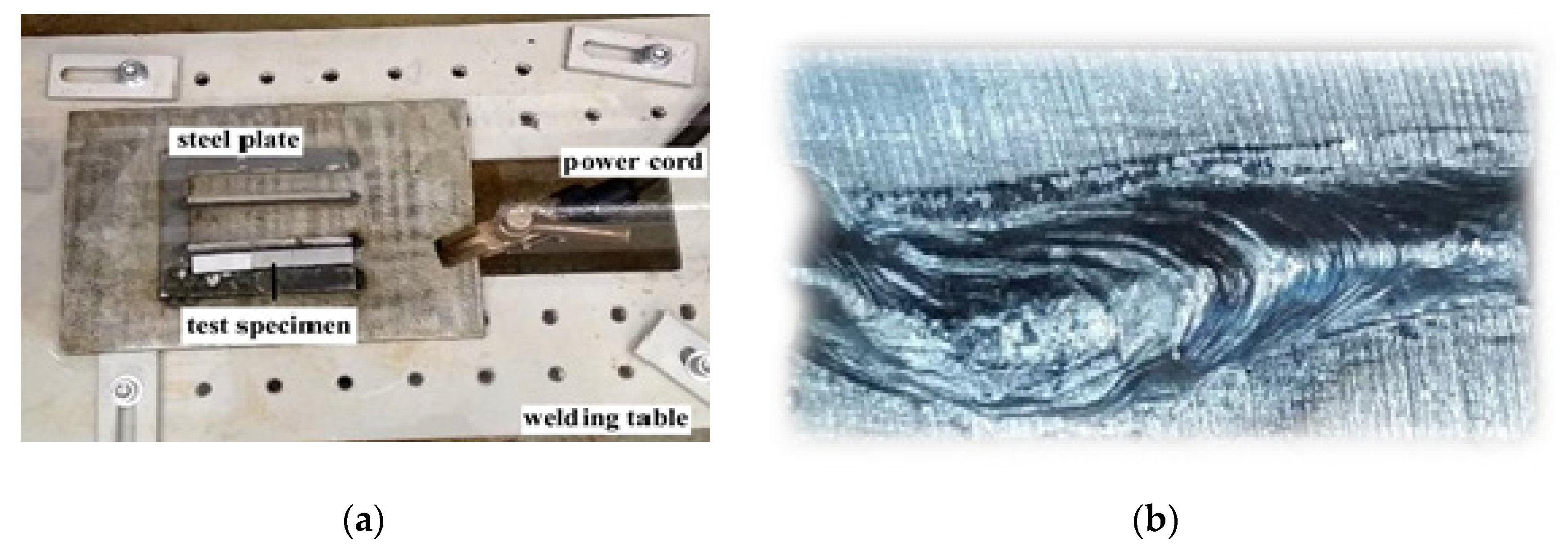

2.2. Experimental Procedure and Methodology

3. Results and Discussion

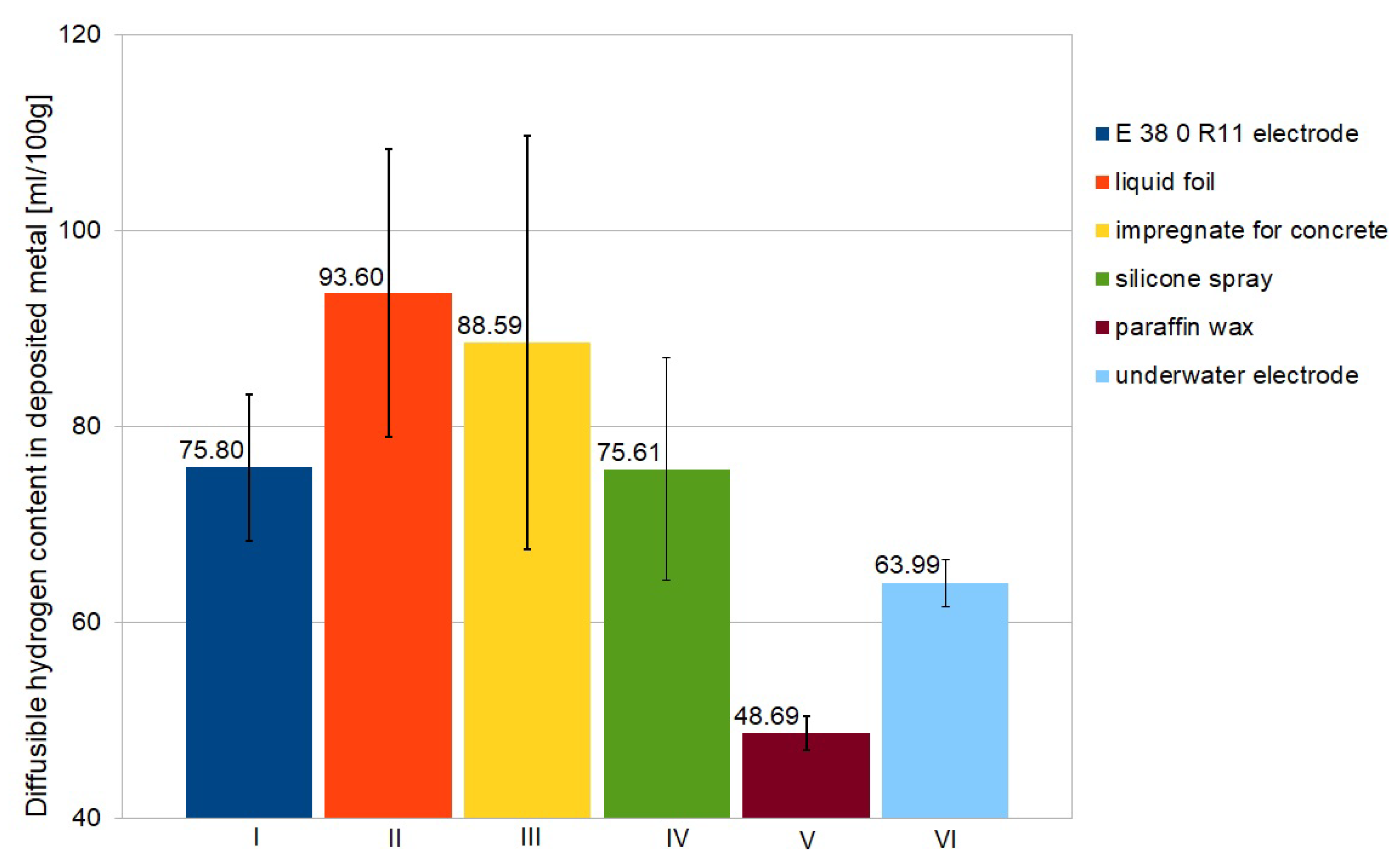

3.1. Diffusible Hydrogen Measurements

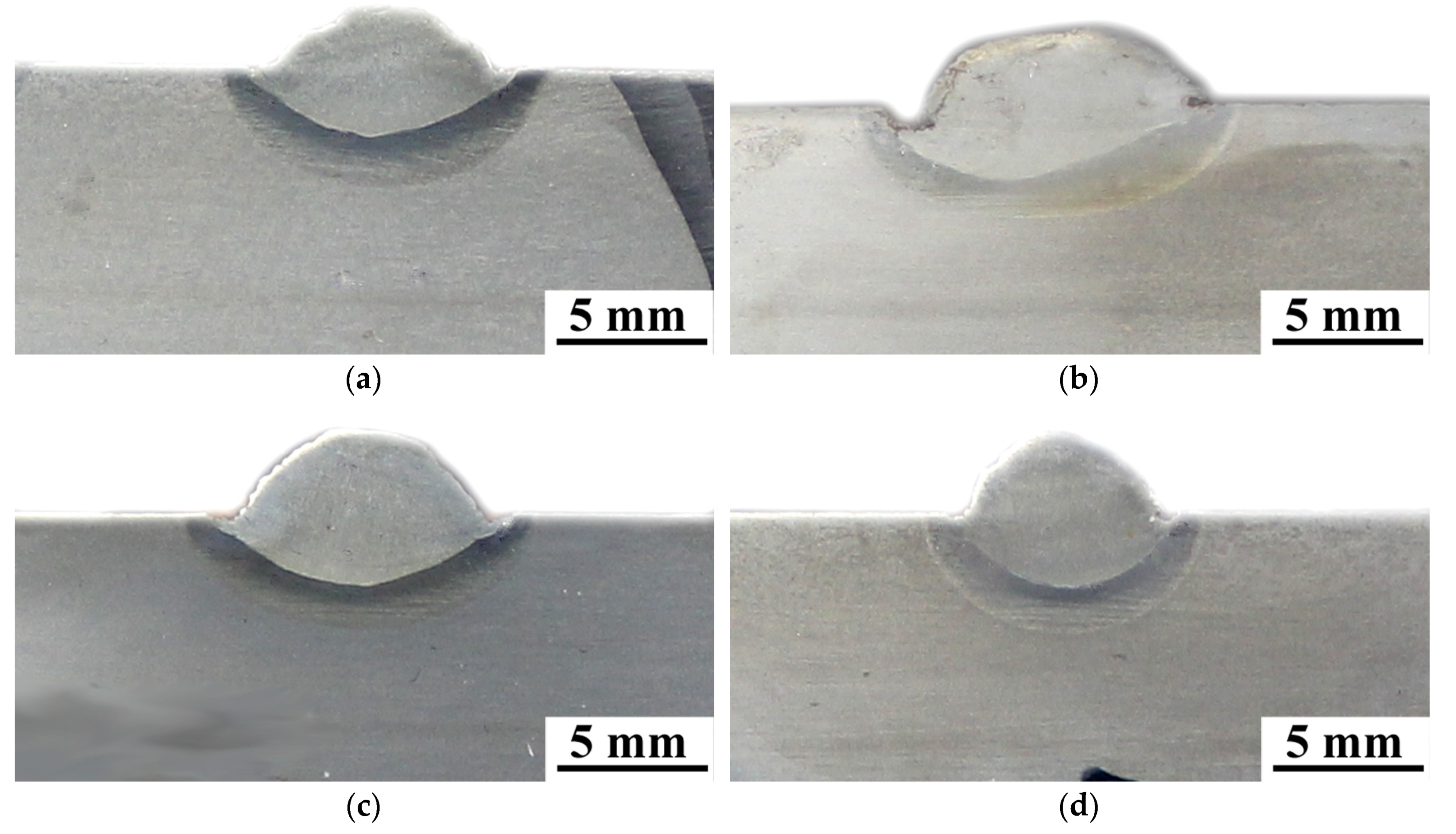

3.2. Macroscopic Testing

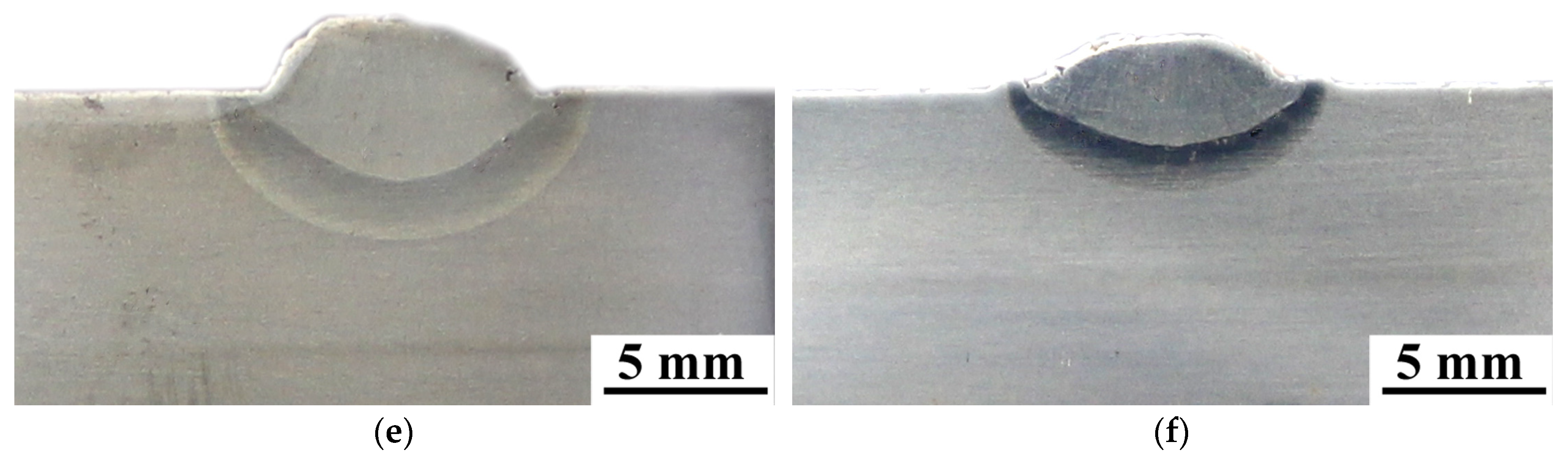

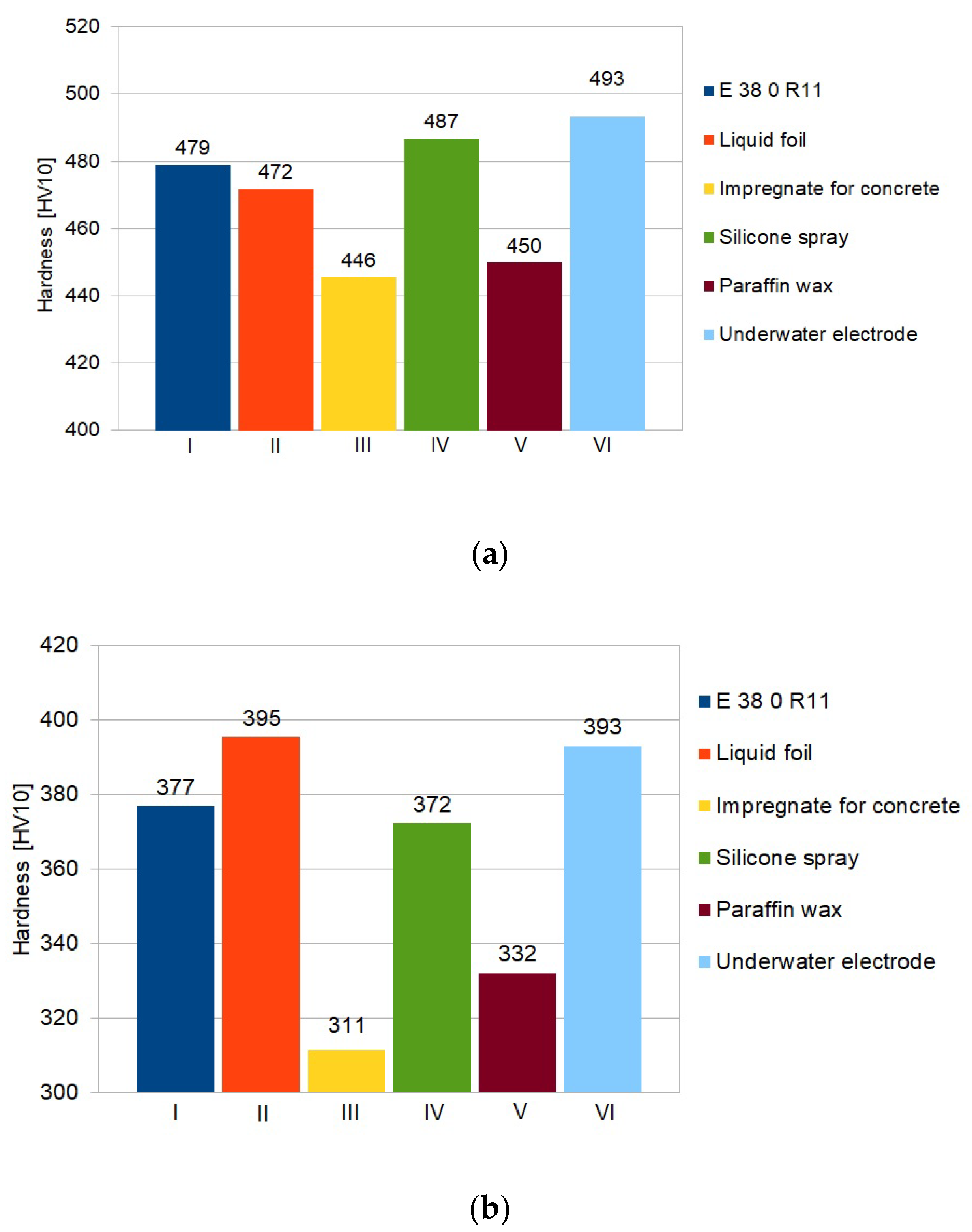

3.3. Hardness Measurements

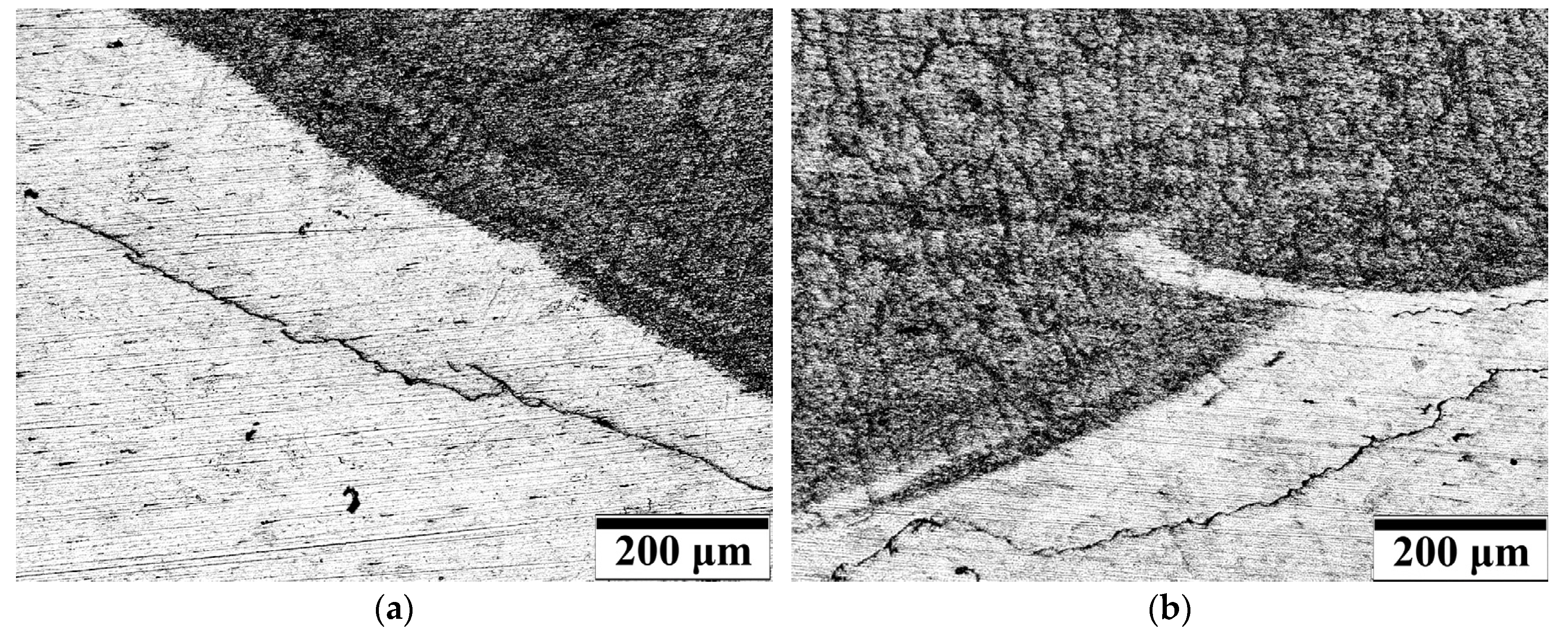

3.4. Microscopic Testing

4. Conclusions

- Some of the used waterproof coatings (impregnate for concrete and liquid foil) increased the diffusible hydrogen content. This was a result of production of hydrogen due to their thermal decomposition in welding conditions.

- Specimens welded by electrodes with paraffin wax were characterized by 40–50 HV10 lower hardness in HAZ than specimens performed by commercial E 38 0 R11 electrode. Paraffin wax as a waterproof coating led to obtain hardness values lower than observed in specimens welded by electrode for underwater processes.

- The lowest hardness was observed in specimens welded with the use of silicone spray. However, the usage of this hydrophobic substance results in long cracks in weld. Paraffin wax as a waterproof coating led to significant decrease in the number of cracks in the HAZ. The other waterproof coatings did not reduce the number of cracks in the HAZ.

- From proposed waterproof coatings laid on the surface of covered electrode the best results were observed for paraffin wax. The paraffin wax allows to reduce the susceptibility of S460N HSLA steel to cold cracking in wet welding conditions and can be used as a potential method for improving the weldability of steel in underwater welding.

Author Contributions

Funding

Conflicts of Interest

References

- Łabanowski, J.; Fydrych, D.; Rogalski, G.; Samson, K. Underwater welding of duplex stainless steel. Solid State Phenom. 2012, 183, 101–106. [Google Scholar] [CrossRef]

- Hu, J.; Shi, Y.; Sun, K.; Shen, X. Effect of filler Si content on the microstructure and properties of underwater hyperbaric welded duplex stainless steel. J. Mater. Process. Technol. 2019, 279, 116548. [Google Scholar] [CrossRef]

- Han, L.; Wu, X.; Chen, G.; Wang, Z.; Fan, W. Local dry underwater welding of 304 stainless steel based on a microdrain cover. J. Mater. Process. Technol. 2019, 268, 47–53. [Google Scholar] [CrossRef]

- Xing, C.; Jia, C.; Han, Y.; Dong, S.; Yang, J.; Wu, C. Numerical analysis of the metal transfer and welding arc behaviors in underwater flux-cored arc welding. Int. J. Heat Mass Tran. 2020, 153, 119570. [Google Scholar] [CrossRef]

- Tomków, J.; Fydrych, D.; Rogalski, G.; Łabanowski, J. Temper bead welding of S460N steel in wet welding conditions. Adv. Mater. Sci. 2018, 18, 5–14. [Google Scholar] [CrossRef]

- Rathinasuriyan, C.; Pavithra, E.; Sankar, R.; Senthil Kumar, V.S. Current status and development of submerged friction stir welding: A review. Int. J. Pr. Eng. Man-GT. 2020, 1–15. [Google Scholar] [CrossRef]

- Fu, Y.; Guo, N.; Cheng, O.; Zhang, D.; Feng, J. In-situ formation of laser-cladded layer on Ti-6Al-4V titanium alloy in underwater environment. Opt. Laser. Eng. 2020, 131, 106104. [Google Scholar] [CrossRef]

- Xu, C.; Guo, N.; Zhang, X.; Chen, H.; Fu, Y.; Zhou, L. Internal characteristic of droplet and its influence on the underwater wet welding process stability. J. Mater. Process. Technol. 2020, 280, 116593. [Google Scholar] [CrossRef]

- Wei, P.; Li, H.; Liu, J.; Li, S.; Zhang, Y.; Zhu, Q.; Lei, Y. The effect of water environment on microstructural characteristics, compositional heterogeneity and microhardness distribution of 16Mn/304L dissimilar welded joints. J. Manuf. Process. 2020, 56, 417–427. [Google Scholar] [CrossRef]

- Zhang, X.; Guo, N.; Xu, C.; Tan, Y.; Chen, H.; Zhang, D. Flux cored arc welding of 304L stainless steel within glycerol environment. J. Mater. Process. Technol. 2020, 283, 116729. [Google Scholar] [CrossRef]

- Zhang, X.; Guo, N.; Xu, C.; Kan, H.; Tan, Y.; Chen, H. Effect of filling rate on underwater wet welding process and weld appearance. Materials 2020, 13, 1061. [Google Scholar] [CrossRef]

- Yang, Q.; Han, Y.; Jia, C.; Dong, S.; Wu, C. Visual investigation on the arc burning behaviors and features in underwater wet FCAW. J. Offshore Mech. Arc. Eng. 2020, 142, 041401. [Google Scholar] [CrossRef]

- Tomków, J.; Łabanowski, J.; Fydrych, D.; Rogalski, G. Cold cracking of S460N steel welded in water environment. Pol. Marit. Res. 2018, 25, 131–136. [Google Scholar] [CrossRef]

- Schaupp, T.; Ernst, W.; Spindler, H.; Kannengiesser, T. Hydrogen-assisted stacking of GMA welded 960 MPA grade high-strength steels. Int. J. Hydrog. Energy 2020. [Google Scholar] [CrossRef]

- Wu, D.; Cheng, B.; Liu, J.; Liu, D.; Ma, G.; Yao, Z. Water cooling assisted laser dissimilar welding with filler wire of nickel-based alloy/austenitic stainless steel. J. Manuf. Process. 2019, 45, 652–660. [Google Scholar] [CrossRef]

- Ma, L.; Niu, S.; Ji, S.; Gong, P. Comparative study of 2060-T8 Al-Li alloy friction stir welded joints between natural cooling and water cooling. Arch. Metall. Mater. 2020, 65, 305–312. [Google Scholar]

- Wasim, M.; Djukic, M.B. Hydrogen embrittlement of low carbon structural steel at macro-, micro- and nan-levels. Int. J. Hydrog. Energy 2020, 45, 2145–2156. [Google Scholar] [CrossRef]

- Djukic, M.B.; Bakic, G.M.; Sijacki Zarevic, V.; Sedmak, A.; Rajicic, B. The synergistic action and interplay of hydrogen embrittlement mechanisms in steels and iron: Localized plasticity and decohesion. Eng. Fract. Mech. 2019, 216, 106528. [Google Scholar] [CrossRef]

- Świerczyńska, A.; Fydrych, D.; Landowski, M.; Rogalski, G.; Łabanowski, J. Hydrogen embrittlement of X2CRNiMoCuN25-6-2 super duplex stainless steel welded joints under cathodic protection. Constr. Build. Mater. 2020, 238, 117697. [Google Scholar] [CrossRef]

- Li, X.; Ma, X.; Zhang, J.; Akiyama, E.; Wang, Y.; Song, X. Review of hydrogen embrittlement in metals: Hydrogen diffusion, hydrogen characterization, hydrogen embrittlement mechanism and prevention. Acta Metall. Sin.-Engl. 2020, 33, 40195. [Google Scholar] [CrossRef]

- Padhy, G.K.; Ramasubbu, V.; Parvatharthini, N.; Wu, C.S.; Albert, S.K. Influence of temperature and alloying on the apparent diffusivity of hydrogen in high strength steel. Int. J. Hydrog. Energy 2015, 40, 6714–6725. [Google Scholar] [CrossRef]

- Brätz, O.; Henkel, K.-M. Investigation of diffusible hydrogen content in drawn arc stud weld metal. Weld. World 2019, 63, 957–965. [Google Scholar] [CrossRef]

- Tashiro, S.; Mukai, N.; Inoue, Y.; Murphy, A.B.; Suga, T.; Tanaka, M. Numerical simulation of the behavior of hydrogen source in a novel welding process to reduce diffusible hydrogen. Materials 2020, 13, 1619. [Google Scholar] [CrossRef]

- Świerczyńska, A.; Fydrych, D.; Rogalski, G. Diffusible hydrogen management in underwater wet self-shielded flux cored arc welding. Int. J. Hydrog. Energy 2017, 42, 24532–24540. [Google Scholar] [CrossRef]

- Chen, H.; Guo, N.; Liu, C.; Zhang, X.; Xu, C.; Wang, G. Insight into hydrostatic pressure effects on diffusible hydrogen content in wet welding joints using in-situ X-ray imaging method. Int. J. Hydrog. Energy 2020, 45, 10219–10226. [Google Scholar] [CrossRef]

- Da Silva, W.C.D.; Bracarense, A.Q.; Pessoa, E.C.P. Effect of water depth on diffusible hydrogen on wet welds. Soldagem Insp. 2012, 17, 298–305. [Google Scholar]

- Fydrych, D.; Świerczyńska, A.; Rogalski, G. Effect of underwater wet welding conditions on the diffusible hydrogen content in deposited metal. Metall. Ital. 2015, 106, 47–52. [Google Scholar]

- Chen, H.; Guo, N.; Xu, K.; Xu, C.; Zhou, L.; Wang, G. In-situ observations of melt degassing and hydrogen removal enhanced by ultrasonics in underwater wet welding. Mater. Des. 2020, 188, 108482. [Google Scholar] [CrossRef]

- Fangnon, E.; Malitckii, E.; Yagodzinskyy, Y.; Vilaça, P. Improved accuracy of thermal desorption spectroscopy by specimen cooling during measurement of hydrogen concentration in a high-strength steel. Materials 2020, 13, 1252. [Google Scholar] [CrossRef]

- Klett, J.; Hassel, T. Reducing the risk of hydrogen-inducted cold cracks in hyperbaric wet welding of high strength steels by using austenitic welding consumables. Weld. Cut. 2020, 19, 54–60. [Google Scholar]

- Tomków, J.; Fydrych, D.; Rogalski, G.; Łabanowski, J. Effect of welding environment and storage time of electrodes on the diffusible hydrogen content in deposited metal. Rev. Metal. 2019, 55, e140. [Google Scholar] [CrossRef]

- Chen, H.; Guo, N.; Xu, K.; Liu, C.; Wang, G. Investigating the advantages of ultrasonic-assisted welding technique applied in underwater wet welding by in-situ X-ray imaging method. Materials 2020, 13, 1442. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Sun, Q.; Hou, S.; Zhang, T.; Jin, P.; Feng, J. Dynamic control of current and voltage waveforms and droplet transfer for ultrasonic-wave-assisted underwater wet welding. Mater. Des. 2019, 181, 108051. [Google Scholar] [CrossRef]

- Wang, J.; Sun, Q.; Ma, J.; Jin, P.; Sun, T.; Feng, J. Correlation between wire feed speed and external mechanical constraint for enhanced process stability in underwater wet flux-cored arc welding. Proc. Inst. Mech. Eng. Part B-J. Eng. Manuf. 2018, 233, 2061–2073. [Google Scholar] [CrossRef]

- Wang, J.; Sun, Q.; Zhang, T.; Xu, P.; Feng, J. Experimental study of arc bubble growth and detachment from underwater wet FCAW. Weld. World 2019, 63, 1747–1759. [Google Scholar] [CrossRef]

- Tomków, J.; Janeczek, A. Underwater in situ local heat treatment by additional stitches for improving the weldability of steel. Appl. Sci. 2020, 10, 1823. [Google Scholar] [CrossRef]

- Yasinta, S.; Triyono, J.; Muhayat, N.; Saputro, C.N. Effect of water depth and water flow on the physics and mechanic properties of underwater wet welded low carbon steel with post weld heat treatment. AIP Conf. Proc. 2020, 2217, 030093. [Google Scholar]

- Łatka, L.; Szala, M.; Michalak, M.; Pałka, T. Impact of atmospheric plasma spray parameters on cavitation erosion resistance of Al2O3–13% TiO2 coatings. Acta Phys. Pol. A 2019, 136, 342–347. [Google Scholar] [CrossRef]

- Chmielewski, T.; Siwek, P.; Chmielewski, M.; Piątkowska, A.; Grabias, A.; Golański, D. Structure and selected properties of arc sprayed coatings containing in-situ fabricated Fe-Al intermetallic phases. Metals 2018, 8, 1059. [Google Scholar] [CrossRef]

- Górka, J.; Czupryński, A.; Żuk, M.; Adamiak, M.; Kopyść, A. Properties and structure of deposited monocrystalline coatings in relation to selected construction materials resistant to abrasive wear. Materials 2018, 11, 1184. [Google Scholar] [CrossRef]

- Zhang, Y.; Blawert, C.; Tang, S.; Hu, J.; Mohedano, M.; Zheludkevich, M.L.; Kainer, K.U. Influence of surface pre-treatment on the deposition and corrosion properties of hydrophobic coatings on a magnesium alloy. Corros. Sci. 2016, 112, 483–494. [Google Scholar] [CrossRef]

- Gnedenkov, S.V.; Sinebryukhov, S.L.; Mashtalyar, D.V.; Egorkin, V.S.; Sidorova, M.V.; Gnedenkov, A.S. Composite polymer-containing protective coatings on magnesium alloy MA8. Corros. Sci. 2014, 85, 52–59. [Google Scholar] [CrossRef]

- Gnedenkov, A.S.; Sinebryukhov, S.L.; Mashtalyar, D.V.; Vyaliy, I.E.; Egorkin, V.S.; Gnedenkov, S.V. Corrosion of the welded aluminium alloy in 0.5 m NaCl solution. Part 2: Coating protection. Materials 2018, 11, 2177. [Google Scholar] [CrossRef] [PubMed]

- Menezes, P.H.R.; Pessoa, E.C.P.; Bracarense, A.Q. Comparison of underwater wet welding performed with silicate and polymer agglomerated electrodes. J. Mater. Process. Technol. 2019, 266, 63–72. [Google Scholar] [CrossRef]

- Fydrych, D.; Łabanowski, J. An experimental study of high-hydrogen welding process. Rev. Metal. 2015, 51, 1–7. [Google Scholar] [CrossRef]

- ISO 3690:2018 Welding and Allied Processes—Determination of Hydrogen Content in Arc Weld Metal; ISO: Geneva, Switzerland, 2018.

- EN ISO 17639:2013 Destructive Tests on Welds in Metallic Materials. Macroscopic and Microscopic Examination of Welds; ISO: Geneva, Switzerland, 2013.

- EN ISO 9015-1:2011 Destructive Tests on Welds in Metallic Materials. Hardness Testing. Hardness Test on Arc Welded Joint; ISO: Geneva, Switzerland, 2011.

- Kandavelu, V.; Yoshihara, S.; Kumaravel, M.; Murugananthan, M. Anodic oxidation of isothiazolin-3-ones in aqueous medium by using boron-doper diamond electrode. Diam. Relat. Mater. 2016, 69, 152–159. [Google Scholar] [CrossRef]

- Xiao-Xiong, W.; Qi-Qi, Z.; Yin-Hu, W.; Guo-Hua, D.; Tian-Yuan, Z.; Yi, T.; Hong-Ying, H. The light-dependent lethal effects of 1,2-benzisothiazol-3(2H)-one and its biodegradation by freshwater microalgae. Sci. Total. Environ. 2019, 672, 563–571. [Google Scholar]

- Klett, J.; Hecht-Linowitzki, V.; Grünzel, O.; Schmidt, E.; Maier, H.J.; Hassel, T. Effect of the water depth on the hydrogen content in SMAW wet welded joints. SN Appl. Sci. 2020, 2, 1269. [Google Scholar] [CrossRef]

- Garg, S.; Kakkar, I.; Pandey, A.; Gupta, M.; Kishor, N. Effect of different coating composition’s rutile-type welding electrodes on undercut defect in manual electric arc welding. Int. J. Mech. Eng. Res. 2013, 3, 381–388. [Google Scholar]

- Tomków, J.; Czupryński, A.; Fydrych, D. The abrassive wear resistance of coating manufactured on high-strength low-alloy (HSLA) offshore steel in wet welding conditions. Coatings 2020, 10, 219. [Google Scholar] [CrossRef]

- Tomków, J.; Fydrych, D.; Rogalski, G. Dissimilar underwater wet welding of HSLA steels. Int. J. Adv. Manuf. Tech. 2020, in press. [Google Scholar]

- Muhayat, N.; Marien, Y.A.; Sukanto, H.; Saputro, Y.C.N. Fatigue life on underwater wet welded low carbon steel SS400. Heliyon 2020, 6, e03366. [Google Scholar] [CrossRef] [PubMed]

- Yin, S.; Sun, Z.; Chen, Z.; Zhang, J.; Shang, J.; Lv, Y.; Huang, M. Current status and prospects of underwater welding technology for key sensitive equipment in nuclear power plants. IOP Conf. Ser. Mater. Sci. Eng. 2020, 730, 012015. [Google Scholar] [CrossRef]

| Material | C | Mn | Si | P | Ni | Cr | Cu | CeIIW 1 |

|---|---|---|---|---|---|---|---|---|

| S460N | 0.16 | 1.51 | 0.53 | 0.020 | 0.05 | 0.07 | 0.13 | 0.464 |

| E 38 0 R11 rutile electrode 2 | 0.07 | 0.55 | 0.44 | 0.010 | - | 0.04 | 0.05 | - |

| E 42 2 1Ni RR 51 electrode 2 | 0.05 | 0.50 | 0.45 | 0.025 | 0.30 | - | - | - |

| Material | Yield Point, Re (MPa) | Tensile Strength, Rm (MPa) | Elongation, A5 (%) |

|---|---|---|---|

| S460N | 511 | 626 | 27.3 |

| E 38 0 R11 electrodes deposit | 503 | 538 | 26.0 |

| E 42 2 1Ni RR 51 electrodes deposit | - | 540 | 26.0 |

| Group | Electrode Grade | Type of Waterproof Coating | Waterproof Coating Composition |

|---|---|---|---|

| I | E 38 0 R11 | none | |

| II | E 38 0 R11 | liquid foil | used in architecture, contains 1,2-benzisothiazol-3(2H)-on, 3:1 isothiazoline mixture |

| III | E 38 0 R11 | impregnate for concrete | based on silane-siloxane resins |

| IV | E 38 0 R11 | silicone spray | for rubber seals, contains hydrocarbons, C6, isoalkanes, <5% n-hexane |

| V | E 38 0 R11 | paraffin wax | consists of a mixture of hydrocarbon molecules containing between twenty and forty carbon atoms |

| VI | E 42 2 1Ni RR 51 | none |

| Group | Type of Waterproof Coating | Specimen | m1 (g) | m2 (g) | H (mm) | HW (mm) | T (°C) | P (hPa) | V (mL) | Hd (mL/100g) |

|---|---|---|---|---|---|---|---|---|---|---|

| I | none | 1 | 33.72 | 35.53 | 33.95 | 110.10 | 21 | 1014 | 1.228 | 67.82 |

| 2 | 32.45 | 33.50 | 40.73 | 78.48 | 21 | 1014 | 0.867 | 82.56 | ||

| 3 | 32.56 | 33.92 | 49.23 | 89.12 | 22 | 1011 | 1.048 | 77.03 | ||

| II | liquid foil | 1 | 33.86 | 34.59 | 59.73 | 72.57 | 21 | 1011 | 0.778 | 106.56 |

| 2 | 32.91 | 34.04 | 56.32 | 81.41 | 21 | 1011 | 0.877 | 77.61 | ||

| 3 | 33.88 | 34.86 | 60.24 | 88.41 | 21 | 1011 | 0.947 | 96.63 | ||

| III | impregnate for concrete | 1 | 34.03 | 35.67 | 44.53 | 112.53 | 21 | 1011 | 1.233 | 75.15 |

| 2 | 33.41 | 34.08 | 67.10 | 91.33 | 21 | 1011 | 0.757 | 112.92 | ||

| 3 | 33.46 | 34.58 | 54.31 | 80.86 | 23 | 1014 | 0.870 | 77.71 | ||

| IV | silicone spray | 1 | 33.83 | 35.89 | 4.07 | 114.60 | 23 | 1014 | 1.321 | 64.14 |

| 2 | 33.60 | 34.68 | 83.15 | 90.86 | 23 | 1014 | 0.938 | 86.86 | ||

| 3 | 34.33 | 35.37 | 82.72 | 76.37 | 23 | 1014 | 0.789 | 75.86 | ||

| V | paraffin wax | 1 | 33.80 | 35.55 | 80.55 | 81.32 | 23 | 1014 | 0.843 | 48.16 |

| 2 | 33.26 | 34.83 | 65.78 | 77.32 | 21 | 1014 | 0.824 | 52.50 | ||

| 3 | 33.86 | 35.22 | 158.88 | 66.90 | 21 | 1014 | 0.618 | 45.42 | ||

| VI | none | 1 | 33.12 | 34.87 | 20.31 | 95.62 | 21 | 1011 | 1.083 | 62.59 |

| 2 | 32.89 | 33.99 | 40.40 | 68.10 | 21 | 1011 | 0.750 | 68.20 | ||

| 3 | 33.12 | 34.71 | 39.99 | 88.25 | 21 | 1011 | 0.973 | 61.18 |

| Group | Type of Waterproof Coating | Average Hd (mL/100g) | Standard Deviation (mL/100g) |

|---|---|---|---|

| I | none | 75.80 | 7.45 |

| II | liquid foil | 93.60 | 14.71 |

| III | impregnate for concrete | 88.59 | 21.11 |

| IV | silicone spray | 75.61 | 11.37 |

| V | paraffin wax | 48.69 | 3.57 |

| VI | none (underwater electrode) | 63.99 | 3.71 |

| Group | Electrode | Specimen | HAZ | Weld | HAZ | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | |||

| I | E 38 0 R11 | 1 | 479 | 470 | 463 | 376 | 366 | 354 | 494 | 467 | 477 |

| 2 | 486 | 461 | 456 | 404 | 373 | 388 | 532 | 493 | 470 | ||

| II | liquid foil | 1 | 475 | 463 | 464 | 402 | 378 | 371 | 475 | 460 | 480 |

| 2 | 481 | 477 | 466 | 421 | 407 | 393 | 476 | 473 | 470 | ||

| III | impregnate for concrete | 1 | 456 | 450 | 436 | 312 | 310 | 300 | 453 | 441 | 446 |

| 2 | 440 | 438 | 440 | 330 | 313 | 303 | 453 | 451 | 442 | ||

| IV | silicone spray | 1 | 493 | 491 | 482 | 370 | 368 | 360 | 487 | 489 | 484 |

| 2 | 500 | 490 | 495 | 380 | 375 | 380 | 495 | 485 | 450 | ||

| V | paraffin wax | 1 | 451 | 454 | 447 | 340 | 307 | 307 | 453 | 459 | 457 |

| 2 | 450 | 449 | 443 | 366 | 342 | 330 | 450 | 445 | 440 | ||

| VI | underwater electrode | 1 | 507 | 503 | 471 | 430 | 465 | 407 | 492 | 489 | 462 |

| 2 | 493 | 498 | 483 | 331 | 359 | 365 | 532 | 507 | 484 | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tomków, J.; Fydrych, D.; Wilk, K. Effect of Electrode Waterproof Coating on Quality of Underwater Wet Welded Joints. Materials 2020, 13, 2947. https://doi.org/10.3390/ma13132947

Tomków J, Fydrych D, Wilk K. Effect of Electrode Waterproof Coating on Quality of Underwater Wet Welded Joints. Materials. 2020; 13(13):2947. https://doi.org/10.3390/ma13132947

Chicago/Turabian StyleTomków, Jacek, Dariusz Fydrych, and Kamil Wilk. 2020. "Effect of Electrode Waterproof Coating on Quality of Underwater Wet Welded Joints" Materials 13, no. 13: 2947. https://doi.org/10.3390/ma13132947

APA StyleTomków, J., Fydrych, D., & Wilk, K. (2020). Effect of Electrode Waterproof Coating on Quality of Underwater Wet Welded Joints. Materials, 13(13), 2947. https://doi.org/10.3390/ma13132947