Superiority of Cellulose Non-Solvent Chemical Modification over Solvent-Involving Treatment: Application in Polymer Composite (part II)

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Modification of Cellulose Fibres

2.2.1. Solvent-Involving Modification

2.2.2. Non-Solvent Treatment

2.3. Preparation of Polymer Composite Samples

2.4. Characterization of Cellulose-Filled Polymer Composites

2.4.1. Fourier-Transform Infrared Spectroscopy (FT-IR)

2.4.2. Static Mechanical Analysis (SMA)

2.4.3. Differential Scanning Calorimetry (DSC)

2.4.4. Surface Free Energy (SFE)

- —total surface free energy [mJ/m2]

- —polar part of surface free energy [mJ/m2]

- —dispersive part of surface free energy [mJ/m2]

- —total liquid surface tension [mN/m]

- —respectively: polar and dispersive part of liquid surface tension [mN/m]

- —respectively: polar and dispersive part of solid surface tension [mN/m]

- —contact angle [◦]

2.5. Characterization of Cellulose Fibres

Dynamic Light Scattering (DLS)

3. Results and Discussion

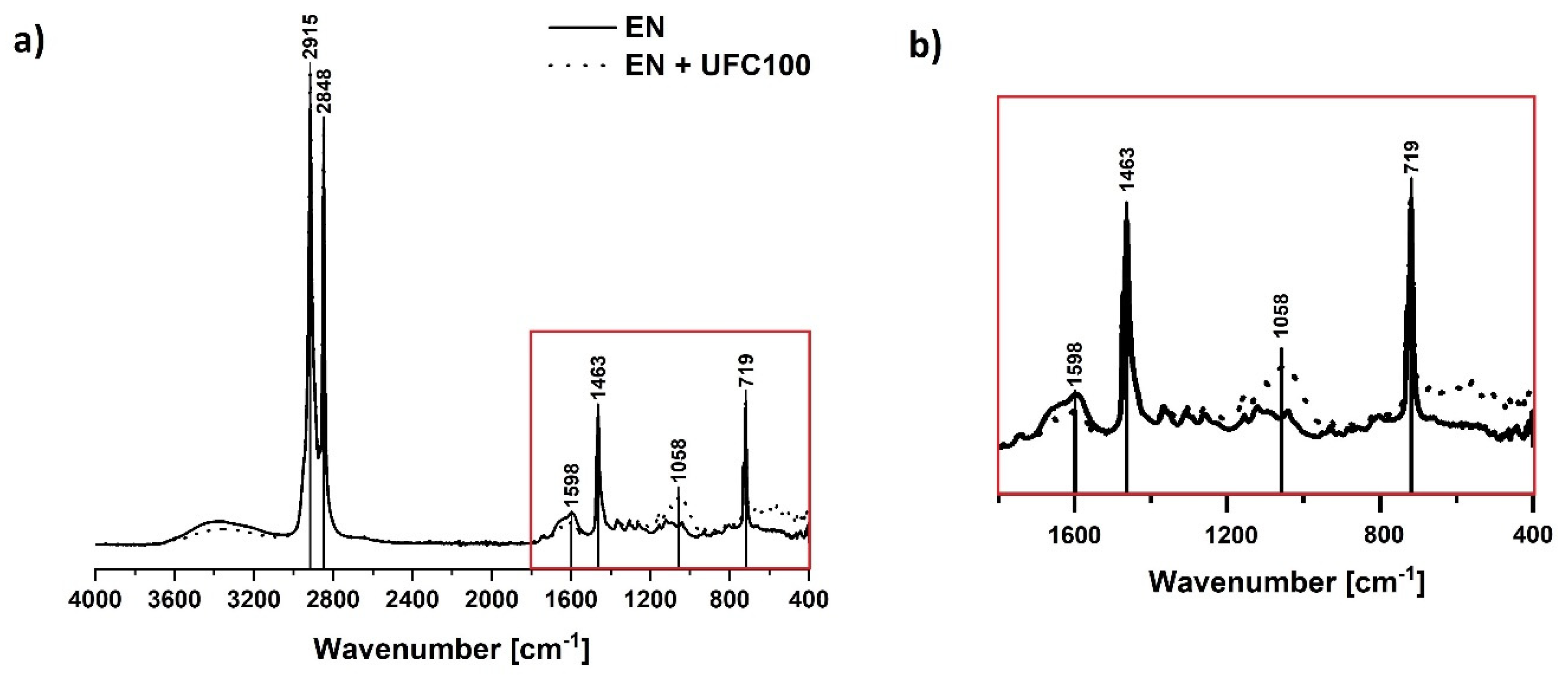

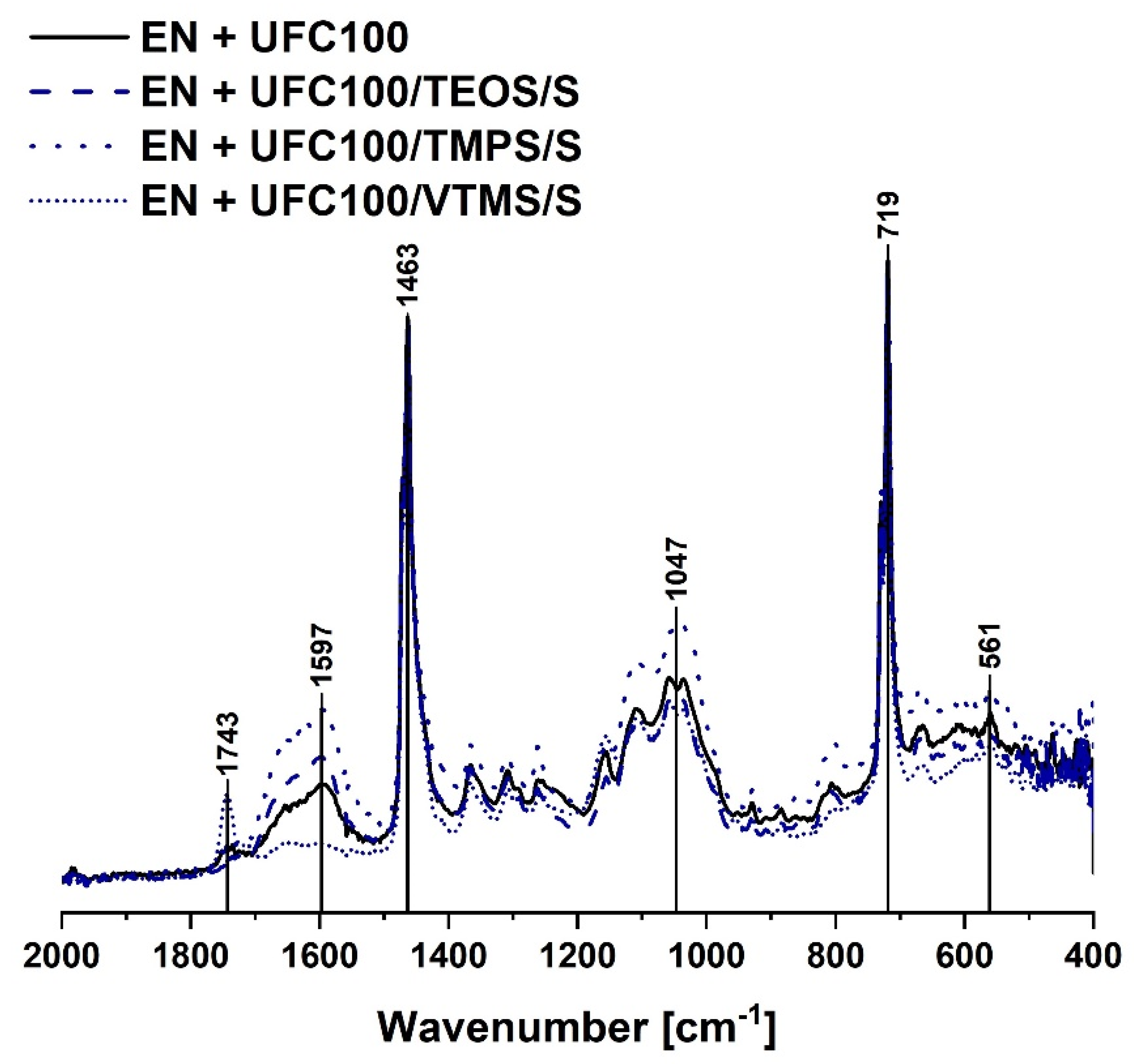

3.1. Fourier-Transform Infrared Spectra Investigation

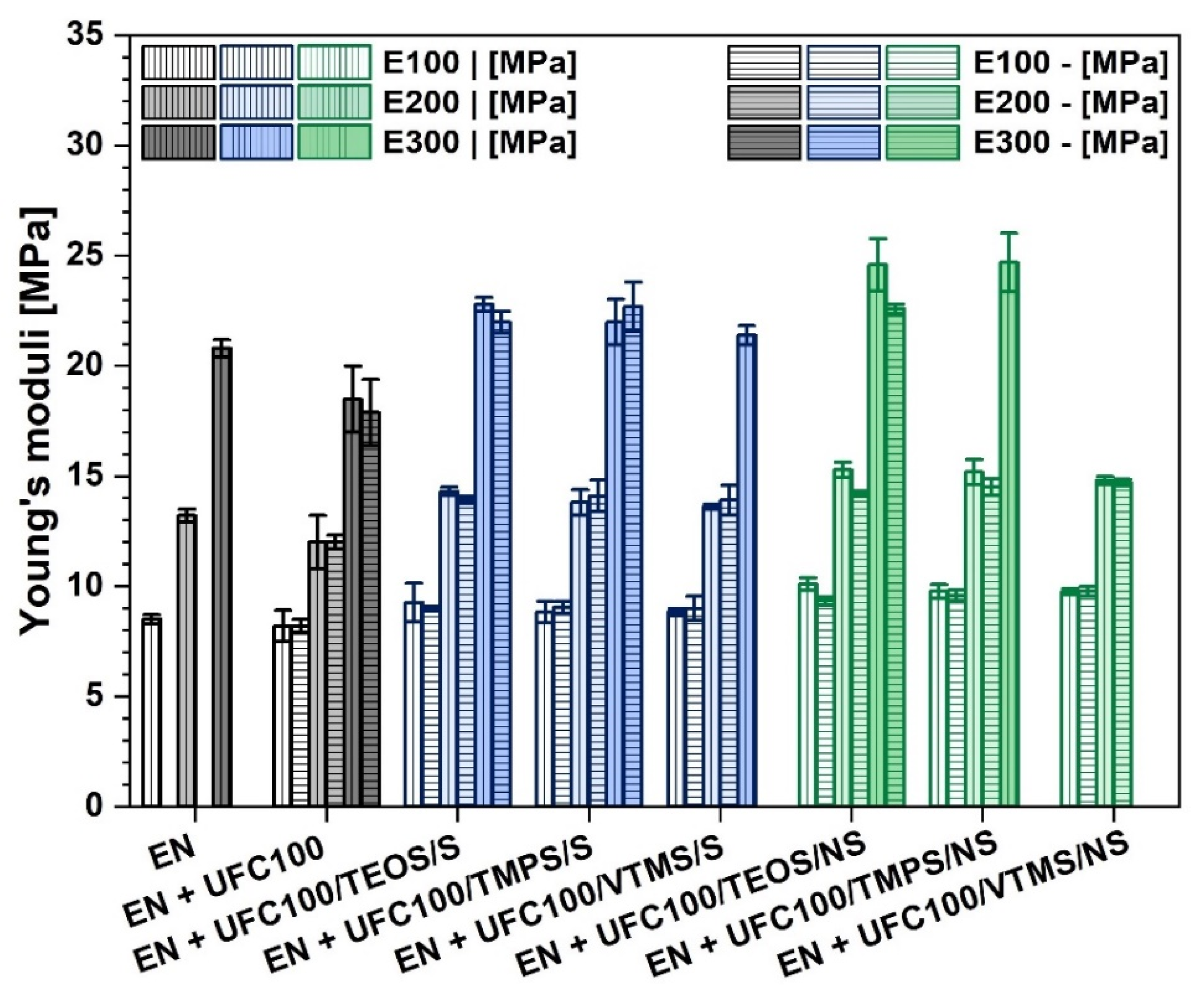

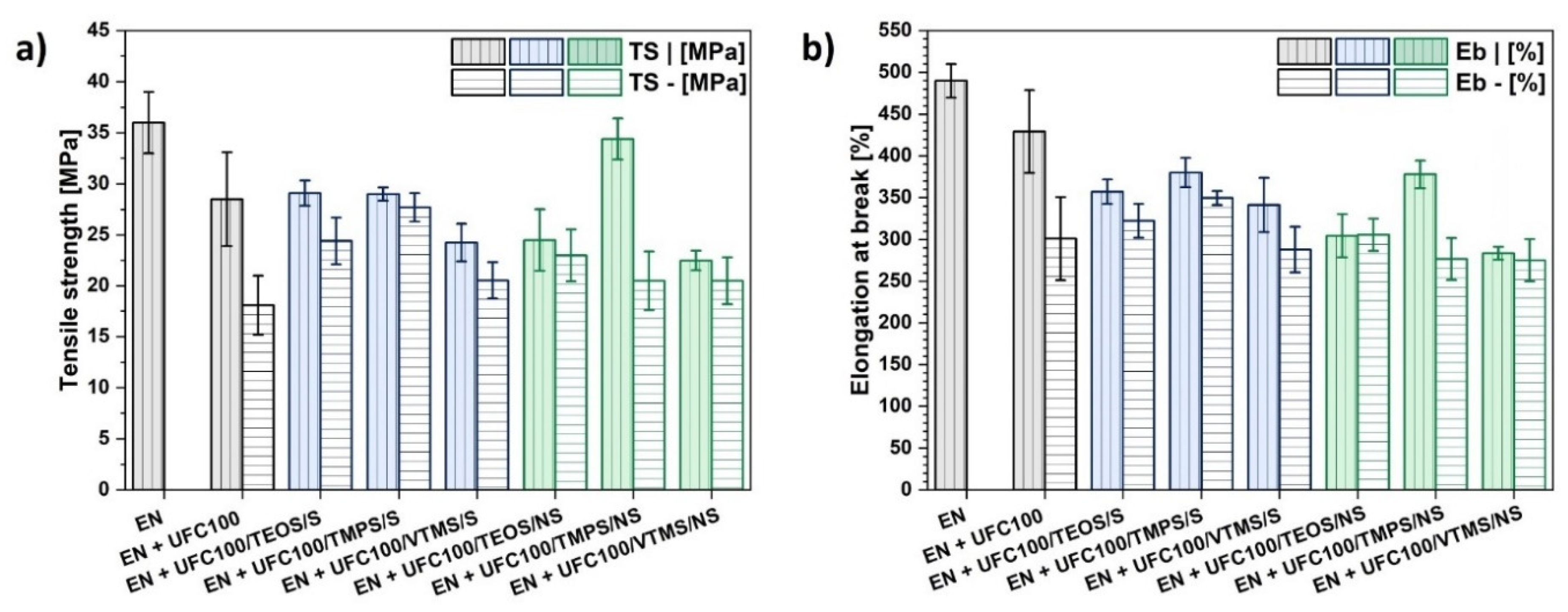

3.2. Static Mechanical Analysis

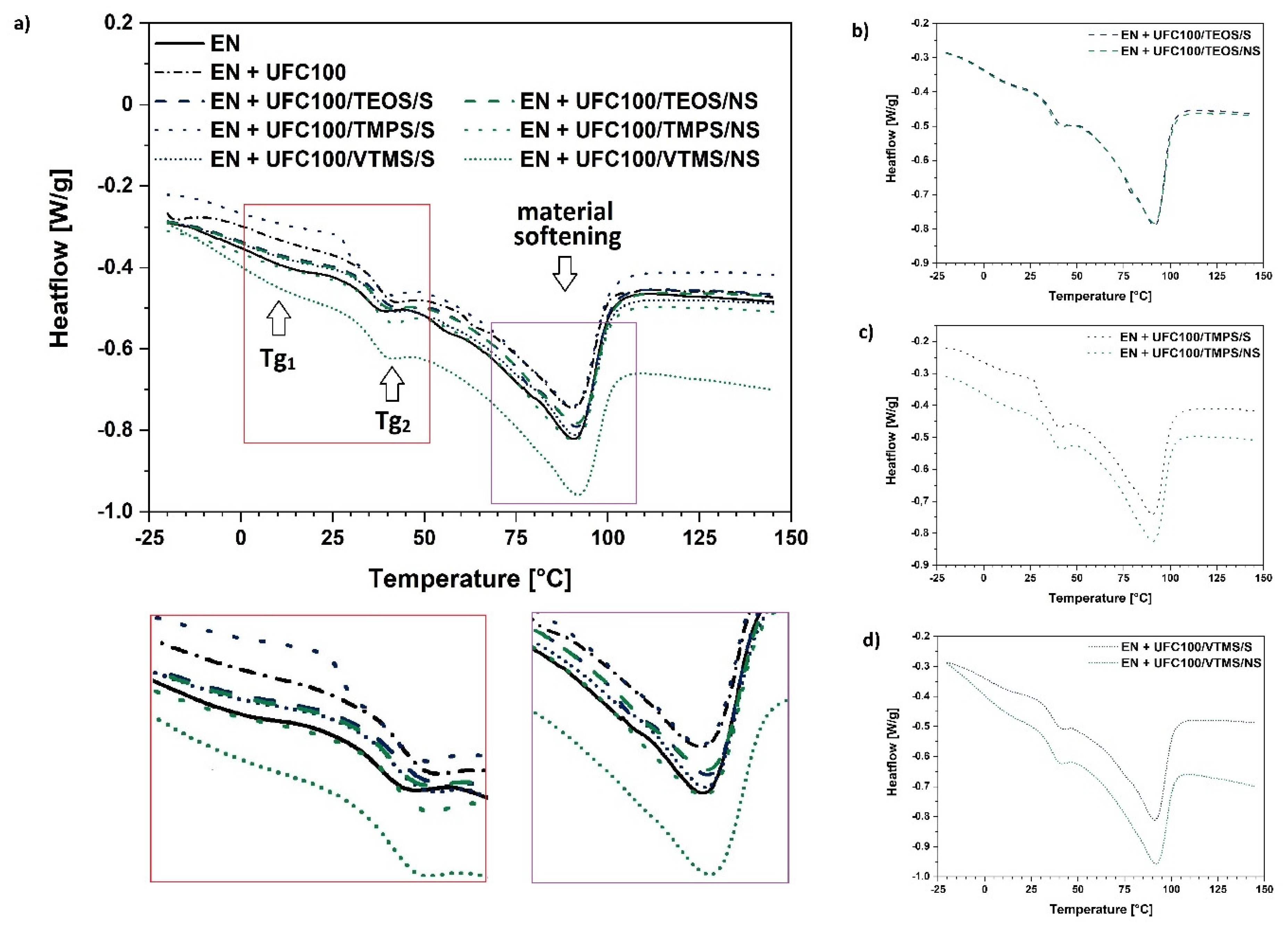

3.3. Differential Scanning Calorimetry Analysis

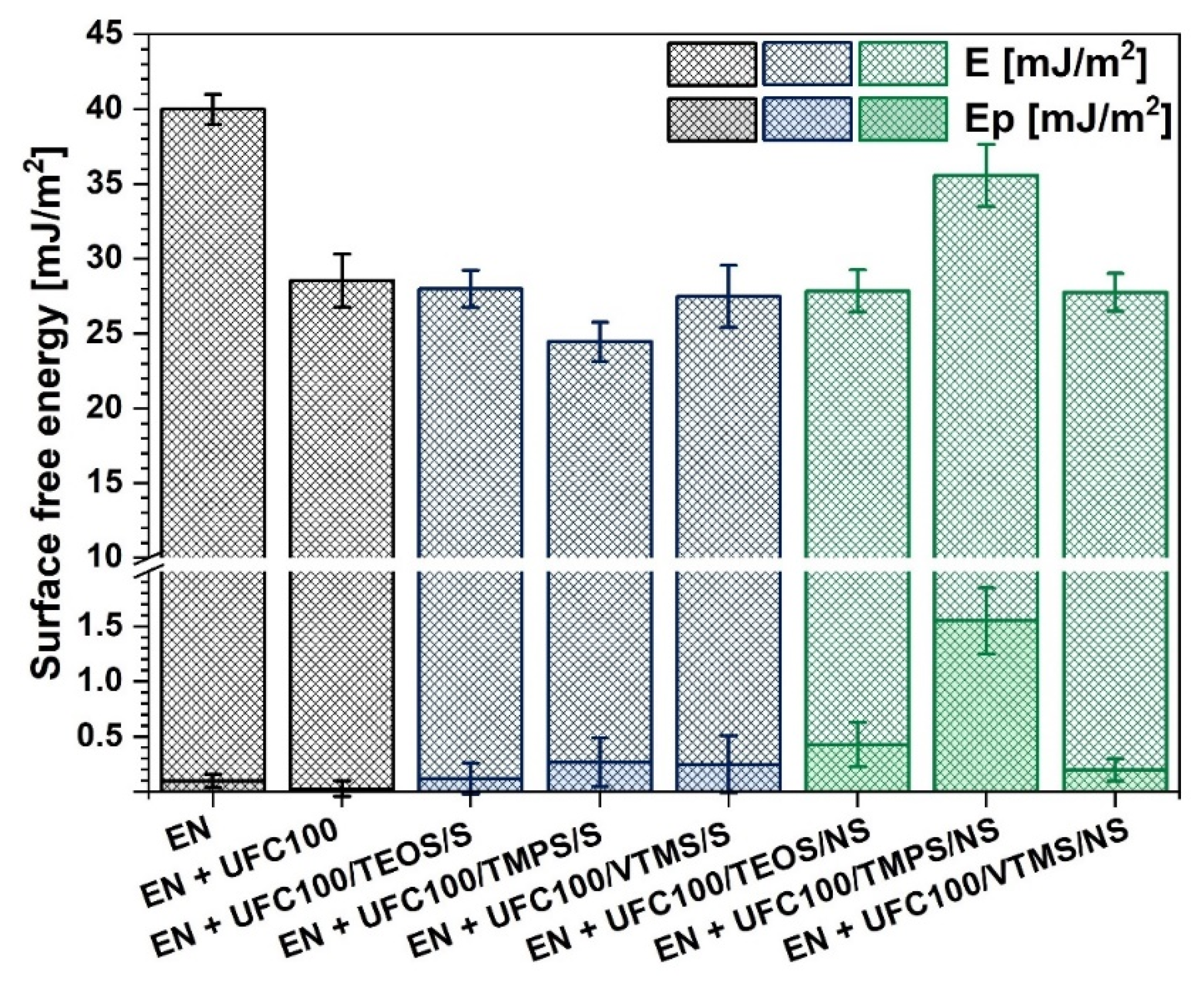

3.4. Surface Free Energy Analysis

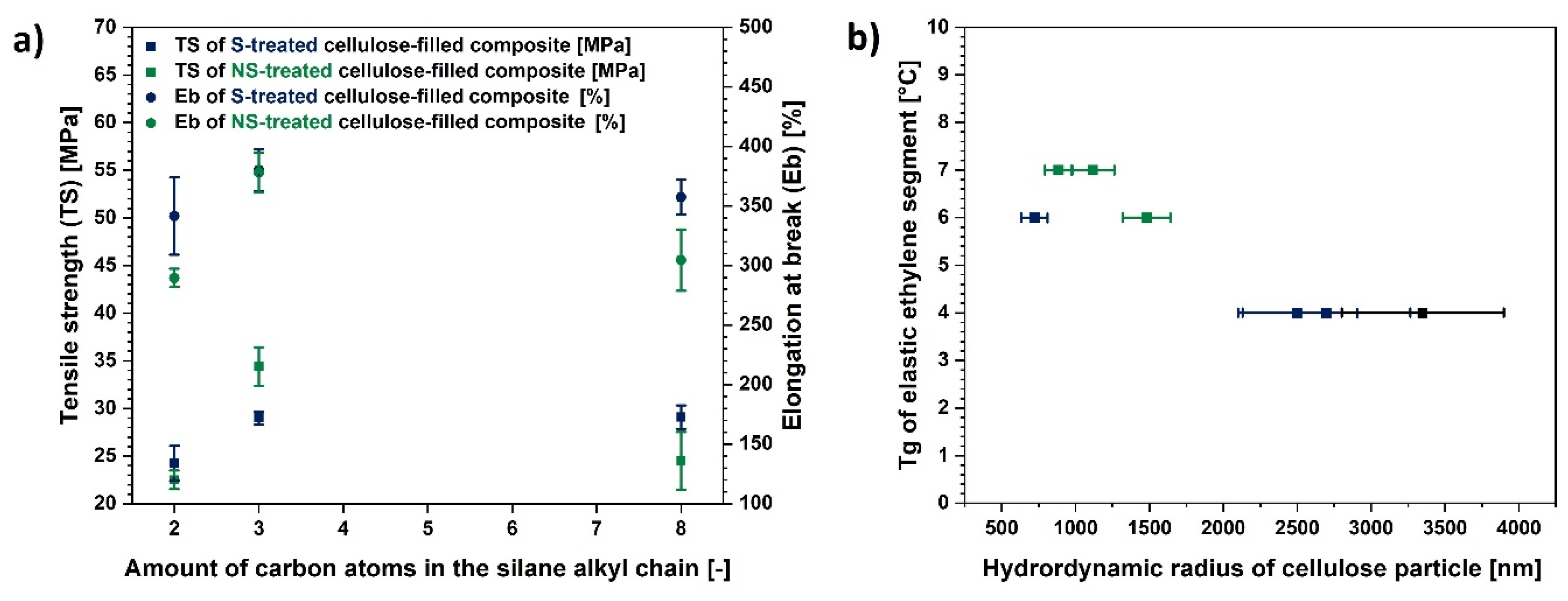

3.5. Influence of Cellulose Characteristics on the Properties of Polymer Composite Sample

3.6. Comparison of Prepared Composite Properties with LDPE

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ramamoorthy, S.K.; Skrifvars, M.; Rissanen, M. Effect of alkali and silane surface treatments on regenerated cellulose fibre type (Lyocell) intended for composites. Cellulose 2015, 22, 637–654. [Google Scholar] [CrossRef]

- Liao, C.Z.; Li, K.; Wong, H.M.; Tong, W.Y.; Yeung, K.W.K.; Tjong, S.C. Novel polypropylene biocomposites reinforced with carbon nanotubes and hydroxyapatite nanorods for bone replacements. Mater. Sci. Eng. C 2013, 33, 1380–1388. [Google Scholar] [CrossRef] [PubMed]

- Chieng, B.W.; Ibrahim, N.A.; Wan Yunus, W.M.Z.; Hussein, M.Z.; Silverajah, V.S.G. Graphene nanoplatelets as novel reinforcement filler in poly(lactic acid)/epoxidized palm oil green nanocomposites: Mechanical Properties. Int. J. Mol. Sci. 2012, 13, 10920–10934. [Google Scholar] [CrossRef] [PubMed]

- Pak, S.Y.; Kim, H.M.; Kim, S.Y.; Youn, J.R. Synergistic improvement of thermal conductivity of thermoplastic composites with mixed boron nitride and multi-walled carbon nanotube fillers. Carbon N. Y. 2012, 50, 4830–4838. [Google Scholar] [CrossRef]

- Hu, L.; Desai, T.; Keblinski, P. Thermal transport in graphene-based nanocomposite. J. Appl. Phys. 2011, 110, 033517. [Google Scholar] [CrossRef]

- Shen, J.; Liu, J.; Li, H.; Gao, Y.; Li, X.; Wu, Y.; Zhang, L. Molecular dynamics simulations of the structural, mechanical and visco-elastic properties of polymer nanocomposites filled with grafted nanoparticles. Phys. Chem. Chem. Phys. 2015, 17, 7196–7207. [Google Scholar] [CrossRef]

- Athreya, S.R.; Kalaitzidou, K.; Das, S. Processing and characterization of a carbon black-filled electrically conductive Nylon-12 nanocomposite produced by selective laser sintering. Mater. Sci. Eng. A 2010, 527, 2637–2642. [Google Scholar] [CrossRef]

- Zhang, H.B.; Zheng, W.G.; Yan, Q.; Yang, Y.; Wang, J.W.; Lu, Z.H.; Ji, G.Y.; Yu, Z.Z. Electrically conductive polyethylene terephthalate/graphene nanocomposites prepared by melt compounding. Polymer (Guildf) 2010, 51, 1191–1196. [Google Scholar] [CrossRef]

- Stassi, S.; Canavese, G. Spiky nanostructured metal particles as filler of polymeric composites showing tunable electrical conductivity. J. Polym. Sci. Part B Polym. Phys. 2012, 50, 984–992. [Google Scholar] [CrossRef]

- Hamdani, S.; Longuet, C.; Lopez-Cuesta, J.M.; Ganachaud, F. Calcium and aluminium-based fillers as flame-retardant additives in silicone matrices. I. Blend preparation and thermal properties. Polym. Degrad. Stab. 2010, 95, 1911–1919. [Google Scholar] [CrossRef]

- Yew, M.C.; Ramli Sulong, N.H.; Yew, M.K.; Amalina, M.A.; Johan, M.R. Eggshells: A novel bio-filler for intumescent flame-retardant coatings. Prog. Org. Coat. 2015, 81, 116–124. [Google Scholar] [CrossRef]

- Wang, X.; Yao, C.; Wang, F.; Li, Z. Cellulose-Based Nanomaterials for Energy Applications. Small 2017, 13, 1702240. [Google Scholar] [CrossRef] [PubMed]

- Klemm, D.; Cranston, E.D.; Fischer, D.; Gama, M.; Kedzior, S.A.; Kralisch, D.; Kramer, F.; Kondo, T.; Lindström, T.; Nietzsche, S.; et al. Nanocellulose as a natural source for groundbreaking applications in materials science: Today’s state. Mater. Today 2018, 21, 720–748. [Google Scholar] [CrossRef]

- Vuoti, S.; Laatikainen, E.; Heikkinen, H.; Johansson, L.S.; Saharinen, E.; Retulainen, E. Chemical modification of cellulosic fibers for better convertibility in packaging applications. Carbohydr. Polym. 2013, 96, 549–559. [Google Scholar] [CrossRef]

- Beaugrand, J.; Berzin, F. Lignocellulosic fiber reinforced composites: Influence of compounding conditions on defibrization and mechanical properties. J. Appl. Polym. Sci. 2013, 128, 1227–1238. [Google Scholar] [CrossRef]

- Ibrahim, M.M.; Dufresne, A.; El-Zawawy, W.K.; Agblevor, F.A. Banana fibers and microfibrils as lignocellulosic reinforcements in polymer composites. Carbohydr. Polym. 2010, 81, 811–819. [Google Scholar] [CrossRef]

- Deng, H.; Lin, P.; Xin, S.; Huang, R.; Li, W.; Du, Y.; Zhou, X.; Yang, J. Quaternized chitosan-layered silicate intercalated composites based nanofibrous mats and their antibacterial activity. Carbohydr. Polym. 2012, 89, 307–313. [Google Scholar] [CrossRef]

- Rattanasak, U.; Chindaprasirt, P.; Suwanvitaya, P. Development of high volume rice husk ash alumino silicate composites. Int. J. Miner. Metall. Mater. 2010, 17, 654–659. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Progress report on natural fiber reinforced composites. Macromol. Mater. Eng. 2014, 299, 9–26. [Google Scholar] [CrossRef]

- Singh, S.; Mohanty, A.K. Wood fiber reinforced bacterial bioplastic composites: Fabrication and performance evaluation. Compos. Sci. Technol. 2007, 67, 1753–1763. [Google Scholar] [CrossRef]

- Salim, B.; Sorya, N. Effects of chemical treatments on the structural, mechanical and morphological properties of poly(vinyl chloride)/Spartium junceum fiber composites. Cellul. Chem. Technol. 2015, 49, 375–385. [Google Scholar]

- Członka, S.; Strąkowska, A.; Kairytė, A.; Kremensas, A. Nutmeg filler as a natural compound for the production of polyurethane composite foams with antibacterial and anti-aging properties. Polym. Test. 2020, 86, 106479. [Google Scholar] [CrossRef]

- Sienkiewicz, N.; Członka, S.; Kairyte, A.; Vaitkus, S. Curcumin as a natural compound in the synthesis of rigid polyurethane foams with enhanced mechanical, antibacterial and anti-ageing properties. Polym. Test. 2019, 79, 106046. [Google Scholar] [CrossRef]

- Chen, W.J.; Gu, J.; Xu, S.H. Exploring nanocrystalline cellulose as a green alternative of carbon black in natural rubber/butadiene rubber/styrene-butadiene rubber blends. Express Polym. Lett. 2014, 8, 659–668. [Google Scholar] [CrossRef]

- Missoum, K.; Belgacem, M.N.; Bras, J. Nanofibrillated cellulose surface modification: A review. Materials (Basel) 2013, 6, 1745–1766. [Google Scholar] [CrossRef]

- Zhu, H.; Luo, W.; Ciesielski, P.N.; Fang, Z.; Zhu, J.Y.; Henriksson, G.; Himmel, M.E.; Hu, L. Wood-Derived Materials for Green Electronics, Biological Devices, and Energy Applications. Chem. Rev. 2016, 116, 9305–9374. [Google Scholar] [CrossRef]

- Peng, Y.; Gardner, D.J.; Han, Y. Drying cellulose nanofibrils: In search of a suitable method. Cellulose 2012, 19, 91–102. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A.; Pospiech, P.; Strzelec, K. Effects of Chemically Treated Eucalyptus Fibers on Mechanical, Thermal and Insulating Properties of Polyurethane Composite Foams. Materials (Basel) 2020, 13, 1781. [Google Scholar]

- Sannino, A.; Demitri, C.; Madaghiele, M. Biodegradable cellulose-based hydrogels: Design and applications. Materials (Basel) 2009, 2, 353–373. [Google Scholar] [CrossRef]

- Poletto, M.; Ornaghi Júnior, H.L.; Zattera, A.J. Native cellulose: Structure, characterization and thermal properties. Materials (Basel) 2014, 7, 6105–6119. [Google Scholar] [CrossRef]

- Nourbakhsh, A.; Ashori, A.; Kazemi Tabrizi, A. Characterization and biodegradability of polypropylene composites using agricultural residues and waste fish. Compos. Part B Eng. 2014, 56, 279–283. [Google Scholar] [CrossRef]

- Selke, S.; Auras, R.; Nguyen, T.A.; Castro Aguirre, E.; Cheruvathur, R.; Liu, Y. Evaluation of biodegradation-promoting additives for plastics. Environ. Sci. Technol. 2015, 49, 3769–3777. [Google Scholar] [CrossRef] [PubMed]

- Nasri-Nasrabadi, B.; Mehrasa, M.; Rafienia, M.; Bonakdar, S.; Behzad, T.; Gavanji, S. Porous starch/cellulose nanofibers composite prepared by salt leaching technique for tissue engineering. Carbohydr. Polym. 2014, 108, 232–238. [Google Scholar] [CrossRef] [PubMed]

- Pracella, M.; Haque, M.M.U.; Puglia, D. Morphology and properties tuning of PLA/cellulose nanocrystals bio-nanocomposites by means of reactive functionalization and blending with PVAc. Polymer (Guildf) 2014, 55, 3720–3728. [Google Scholar] [CrossRef]

- Olejnik, O.; Masek, A.; Kiersnowski, A. Thermal analysis of aliphatic polyester blends with natural antioxidants. Polymers (Basel) 2020, 12, 74. [Google Scholar] [CrossRef]

- Vieira, M.G.A.; Da Silva, M.A.; Dos Santos, L.O.; Beppu, M.M. Natural-based plasticizers and biopolymer films: A review. Eur. Polym. J. 2011, 47, 254–263. [Google Scholar] [CrossRef]

- Shumigin, D.; Tarasova, E.; Krumme, A.; Meier, P. Rheological and Mechanical Properties of Poly ( lactic ) Acid/Cellulose and LDPE/Cellulose Composites. Mater. Sci. 2011, 17, 32–37. [Google Scholar] [CrossRef]

- Ifuku, S.; Yano, H. Effect of a silane coupling agent on the mechanical properties of a microfibrillated cellulose composite. Int. J. Biol. Macromol. 2015, 74, 428–432. [Google Scholar] [CrossRef]

- Qian, S.; Sheng, K. PLA toughened by bamboo cellulose nanowhiskers: Role of silane compatibilization on the PLA bionanocomposite properties. Compos. Sci. Technol. 2017, 148, 59–69. [Google Scholar] [CrossRef]

- Ferreira, S.R.; de Andrade Silva, F.; Lima, P.R.L.; Toledo Filho, R.D. Effect of hornification on the structure, tensile behavior and fiber matrix bond of sisal, jute and curauá fiber cement based composite systems. Constr. Build. Mater. 2017, 139, 551–561. [Google Scholar] [CrossRef]

- Sato, A.; Kabusaki, D.; Okumura, H.; Nakatani, T.; Nakatsubo, F.; Yano, H. Surface modification of cellulose nanofibers with alkenyl succinic anhydride for high-density polyethylene reinforcement. Compos. Part A Appl. Sci. Manuf. 2016, 83, 72–79. [Google Scholar] [CrossRef]

- George, J.; Sreekala, M.S.; Thomas, S. A review on interface modification and characterization of natural fiber reinforced plastic composites. Polym. Eng. Sci. 2001, 41, 1471–1485. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Effects of chemical treatments on hemp fibre structure. Appl. Surf. Sci. 2013, 276, 13–23. [Google Scholar] [CrossRef]

- Rojo, E.; Alonso, M.V.; Oliet, M.; Del Saz-Orozco, B.; Rodriguez, F. Effect of fiber loading on the properties of treated cellulose fiber-reinforced phenolic composites. Compos. Part B Eng. 2015, 68, 185–192. [Google Scholar] [CrossRef]

- Shateri-Khalilabad, M.; Yazdanshenas, M.E. One-pot sonochemical synthesis of superhydrophobic organic-inorganic hybrid coatings on cotton cellulose. Cellulose 2013, 20, 3039–3051. [Google Scholar] [CrossRef]

- Arrakhiz, F.Z.; El Achaby, M.; Kakou, A.C.; Vaudreuil, S.; Benmoussa, K.; Bouhfid, R.; Fassi-Fehri, O.; Qaiss, A. Mechanical properties of high density polyethylene reinforced with chemically modified coir fibers: Impact of chemical treatments. Mater. Des. 2012, 37, 379–383. [Google Scholar] [CrossRef]

- Xie, Y.; Hill, C.A.S.; Xiao, Z.; Militz, H.; Mai, C. Silane coupling agents used for natural fiber/polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 806–819. [Google Scholar] [CrossRef]

- Abdelmouleh, M.; Boufi, S.; ben Salah, A.; Belgacem, M.N.; Gandini, A. Interaction of silane coupling agents with cellulose. Langmuir 2002, 18, 3203–3208. [Google Scholar] [CrossRef]

- Simon, M.O.; Li, C.J. Green chemistry oriented organic synthesis in water. Chem. Soc. Rev. 2012, 41, 1415–1427. [Google Scholar] [CrossRef]

- Cichosz, S.; Masek, A. Superiority of Cellulose Non-Solvent Chemical Modification over Solvent-Involving Treatment: Solution for Green Chemistry (Part I). Materials (Basel) 2020, 13, 2552. [Google Scholar] [CrossRef]

- Encinas, N.; Pantoja, M.; Abenojar, J.; Martínez, M.A. Control of wettability of polymers by surfaceroughness modification. J. Adhes. Sci. Technol. 2010, 24, 1869–1883. [Google Scholar] [CrossRef]

- Morán, J.I.; Alvarez, V.A.; Cyras, V.P.; Vázquez, A. Extraction of cellulose and preparation of nanocellulose from sisal fibers. Cellulose 2008, 15, 149–159. [Google Scholar] [CrossRef]

- Nakade, K.; Nagai, Y.; Ohishi, F. Photodegradation of some ethylene-norbornene random copolymers. Polym. Degrad. Stab. 2010, 95, 2654–2658. [Google Scholar] [CrossRef]

- De Geyter, N.; Morent, R.; Leys, C. Surface characterization of plasma-modified polyethylene by contact angle experiments and ATR-FTIR spectroscopy. Surf. Interface Anal. 2008, 40, 608–611. [Google Scholar] [CrossRef]

- Salmén, L.; Bergström, E. Cellulose structural arrangement in relation to spectral changes in tensile loading FTIR. Cellulose 2009, 16, 975–982. [Google Scholar] [CrossRef]

- Gulmine, J.; Janissek, P.; Heise, H.; Akcelrud, L. Polyethylene characterization by FTIR. Polym. Test. 2002, 21, 557–563. [Google Scholar] [CrossRef]

- Stenstad, P.; Andresen, M.; Tanem, B.S.; Stenius, P. Chemical surface modifications of microfibrillated cellulose. Cellulose 2008, 15, 35–45. [Google Scholar] [CrossRef]

- Łojewska, J.; Miśkowiec, P.; Łojewski, T.; Proniewicz, L.M. Cellulose oxidative and hydrolytic degradation: In situ FTIR approach. Polym. Degrad. Stab. 2005, 88, 512–520. [Google Scholar] [CrossRef]

- Tian, D.; Zhang, X.; Lu, C.; Yuan, G.; Zhang, W.; Zhou, Z. Solvent-free synthesis of carboxylate-functionalized cellulose from waste cotton fabrics for the removal of cationic dyes from aqueous solutions. Cellulose 2014, 21, 473–484. [Google Scholar] [CrossRef]

- Solala, I.; Henniges, U.; Pirker, K.F.; Rosenau, T.; Potthast, A.; Vuorinen, T. Mechanochemical reactions of cellulose and styrene. Cellulose 2015, 22, 3217–3224. [Google Scholar] [CrossRef]

- Barbash, V.A.; Yaschenko, O.V.; Alushkin, S.V.; Kondratyuk, A.S.; Posudievsky, O.Y.; Koshechko, V.G. The Effect of Mechanochemical Treatment of the Cellulose on Characteristics of Nanocellulose Films. Nanoscale Res. Lett. 2016, 11, 16–23. [Google Scholar] [CrossRef]

- Abushammala, H.; Mao, J. A Review of the Surface Modification of Cellulose and Nanocellulose Using Aliphatic and Aromatic Mono- and Di-Isocyanates. Molecules 2019, 24, 2782. [Google Scholar] [CrossRef]

- Klonos, P.; Pissis, P. Effects of interfacial interactions and of crystallization on rigid amorphous fraction and molecular dynamics in polylactide/silica nanocomposites: A methodological approach. Polymer (Guildf) 2017, 112, 228–243. [Google Scholar] [CrossRef]

- Freire, C.S.R.; Silvestre, A.J.D.; Neto, C.P.; Gandini, A.; Martin, L.; Mondragon, I. Composites based on acylated cellulose fibers and low-density polyethylene: Effect of the fiber content, degree of substitution and fatty acid chain length on final properties. Compos. Sci. Technol. 2008, 68, 3358–3364. [Google Scholar] [CrossRef]

- Marcovich, N.E.; Villar, M.A. Thermal and mechanical characterization of linear low-density polyethylene/wood flour composites. J. Appl. Polym. Sci. 2003, 90, 2775–2784. [Google Scholar] [CrossRef]

- Pasquini, D.; de Morais Teixeira, E.; da Silva Curvelo, A.A.; Belgacem, M.N.; Dufresne, A. Surface esterification of cellulose fibres: Processing and characterisation of low-density polyethylene/cellulose fibres composites. Compos. Sci. Technol. 2008, 68, 193–201. [Google Scholar] [CrossRef]

- Lodha, P.; Netravali, A.N. Thermal and mechanical properties of environment-friendly “green” plastics from stearic acid modified-soy protein isolate. Ind. Crops Prod. 2005, 21, 49–64. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, Y.; Abidi, N.; Cabrales, L. Wettability and Surface Free Energy of Graphene Films. Langmuir 2009, 25, 11078–11081. [Google Scholar] [CrossRef]

- Cantero, G.; Arbelaiz, A.; Llano-ponte, R. Effects of fibre treatment on wettability and mechanical behaviour of flax/polypropylene composites. Compos. Sci. Technol. 2003, 63, 1247–1254. [Google Scholar] [CrossRef]

- Rudawska, A.; Jakubowska, P.; Kloziński, A. Surface free energy of composite materials with high calcium carbonate filler content. Polimery 2017, 62, 434–440. [Google Scholar] [CrossRef]

- Arbelaiz, A.; Fernández, B.; Ramos, J.A.; Retegi, A.; Llano-Ponte, R.; Mondragon, I. Mechanical properties of short flax fibre bundle/polypropylene composites: Influence of matrix/fibre modification, fibre content, water uptake and recycling. Compos. Sci. Technol. 2005, 65, 1582–1592. [Google Scholar] [CrossRef]

- Aranberri-Askargorta, I.; Lampke, T.; Bismarck, A. Wetting behavior of flax fibers as reinforcement for polypropylene. J. Colloid Interface Sci. 2003, 263, 580–589. [Google Scholar] [CrossRef]

- Nakatani, H.; Iwakura, K.; Miyazaki, K.; Okazaki, N.; Terano, M. Effect of Chemical Structure of Silane Coupling Agent on Interface Adhesion Properties of Syndiotactic Polypropylene/Cellulose Composite. J. Appl. Polym. Sci. 2011, 119, 1732–1741. [Google Scholar] [CrossRef]

- Chee, P.E.; Talib, R.A.; Yusof, Y.A.; Chin, N.L.; Ratnam, C.T.; Khalid, M.; Chuah, T.G. Mechanical and Physical Properties of Oil Palm Derived Cellulose-Ldpe Biocomposites As Packaging Material. Int. J. Eng. Technol. 2010, 7, 26–32. [Google Scholar]

- Mastalygina, E.E.; Popov, A.A. Mechanical properties and stress-strain behaviour of binary and ternary composites based on polyolefins and vegetable fillers. Solid State Phenom. 2017, 265, 221–226. [Google Scholar] [CrossRef]

| Sample | Silane | Modification Type | |||

|---|---|---|---|---|---|

| TEOS | TMPS | VTMS | Solvent-Involving Approach (S) | Non-Solvent Approach (NS) | |

| UFC100/TEOS/S | ✔ | ----- | ----- | ✔ | ----- |

| UFC100/TMPS/S | ----- | ✔ | ----- | ✔ | ----- |

| UFC100/VTMS/S | ----- | ----- | ✔ | ✔ | ----- |

| UFC100/TEOS/NS | ✔ | ----- | ----- | ----- | ✔ |

| UFC100/TMPS/NS | ----- | ✔ | ----- | ----- | ✔ |

| UFC100/VTMS/NS | ----- | ----- | ✔ | ----- | ✔ |

| Wavenumber [cm−1] | Chemical Group | Ref. |

|---|---|---|

| 719 | CH2 rocking vibrations in –(CH2)n– | [54] |

| 1100–1000 | CO-O-CO | [55] |

| 1050 | C–O stretching vibration | [54] |

| 1100 | –OH, Si–O-Si | [21,56] |

| 1160 | C–O stretching vibration | [54] |

| 1300–1100 | C–O, C=O, C=C, COOH | [56] |

| 1460 | C–H deformation vibrations in – (CH2)n– | [54] |

| 1700–1500 | C=C | [53,57] |

| 2850 | C–H symmetric stretching vibration in –CH2– | [52,53] |

| 2915 | C–H asymmetric stretching vibration in –CH2– | [53,54] |

| 3600–3200 | –OH stretching vibrations | [53,58] |

| Sample | Tg1 [°C] | Tg2 [°C] | ΔH [J/g] | Tpeak [°C] |

|---|---|---|---|---|

| EN | 9 | 36 | 53,76 | 90 |

| EN + UFC100 | 4 | 38 | 40,09 | 90 |

| EN + UFC100/TEOS/S | 4 | 38 | 46,26 | 91 |

| EN + UFC100/TMPS/S | 4 | 38 | 46,47 | 90 |

| EN + UFC100/VTMS/S | 6 | 37 | 47,93 | 91 |

| EN + UFC100/TEOS/NS | 6 | 36 | 46,24 | 91 |

| EN + UFC100/TMPS/NS | 7 | 38 | 46,85 | 91 |

| EN + UFC100/VTMS/NS | 7 | 37 | 45,24 | 92 |

| Property | LDPE | EN + UFC100/TMPS/NS |

|---|---|---|

| tensile strength [MPa] | 10–20 [74,75] | 34 ± 2 |

| elongation at break [%] | 100–600 [74,75] | 380 ± 20 |

| degradation potential | low | higher |

| Analysis | Solvent-Involving Cellulose Modification (S) | Non-Solvent Cellulose Modification (NS) |

|---|---|---|

| FT-IR | chemical structure of a composite unaffected; possible filler-polymer matrix interaction changes | chemical structure of a composite unaffected; possible changes in filler-polymer matrix interactions |

| static mechanical tests | material of a performance slightly higher than untreated cellulose-filled polymer composite | material becomes stiffer; the highest improvement in mechanical properties |

| DSC | effect similar to the neat UFC100 incorporation | elastic ethylene segment Tg slight increase |

| surface free energy | slight increase of surface free energy polar part | higher changes in polar part of surface free energy; easier wetting |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cichosz, S.; Masek, A. Superiority of Cellulose Non-Solvent Chemical Modification over Solvent-Involving Treatment: Application in Polymer Composite (part II). Materials 2020, 13, 2901. https://doi.org/10.3390/ma13132901

Cichosz S, Masek A. Superiority of Cellulose Non-Solvent Chemical Modification over Solvent-Involving Treatment: Application in Polymer Composite (part II). Materials. 2020; 13(13):2901. https://doi.org/10.3390/ma13132901

Chicago/Turabian StyleCichosz, Stefan, and Anna Masek. 2020. "Superiority of Cellulose Non-Solvent Chemical Modification over Solvent-Involving Treatment: Application in Polymer Composite (part II)" Materials 13, no. 13: 2901. https://doi.org/10.3390/ma13132901

APA StyleCichosz, S., & Masek, A. (2020). Superiority of Cellulose Non-Solvent Chemical Modification over Solvent-Involving Treatment: Application in Polymer Composite (part II). Materials, 13(13), 2901. https://doi.org/10.3390/ma13132901