Polylactic Acid/Polycaprolactone Blends: On the Path to Circular Economy, Substituting Single-Use Commodity Plastic Products

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Compounding of the Materials

2.3. Injection Molding of the Blends

2.4. Mechanical Testing of the Blends

3. Results and Discussion

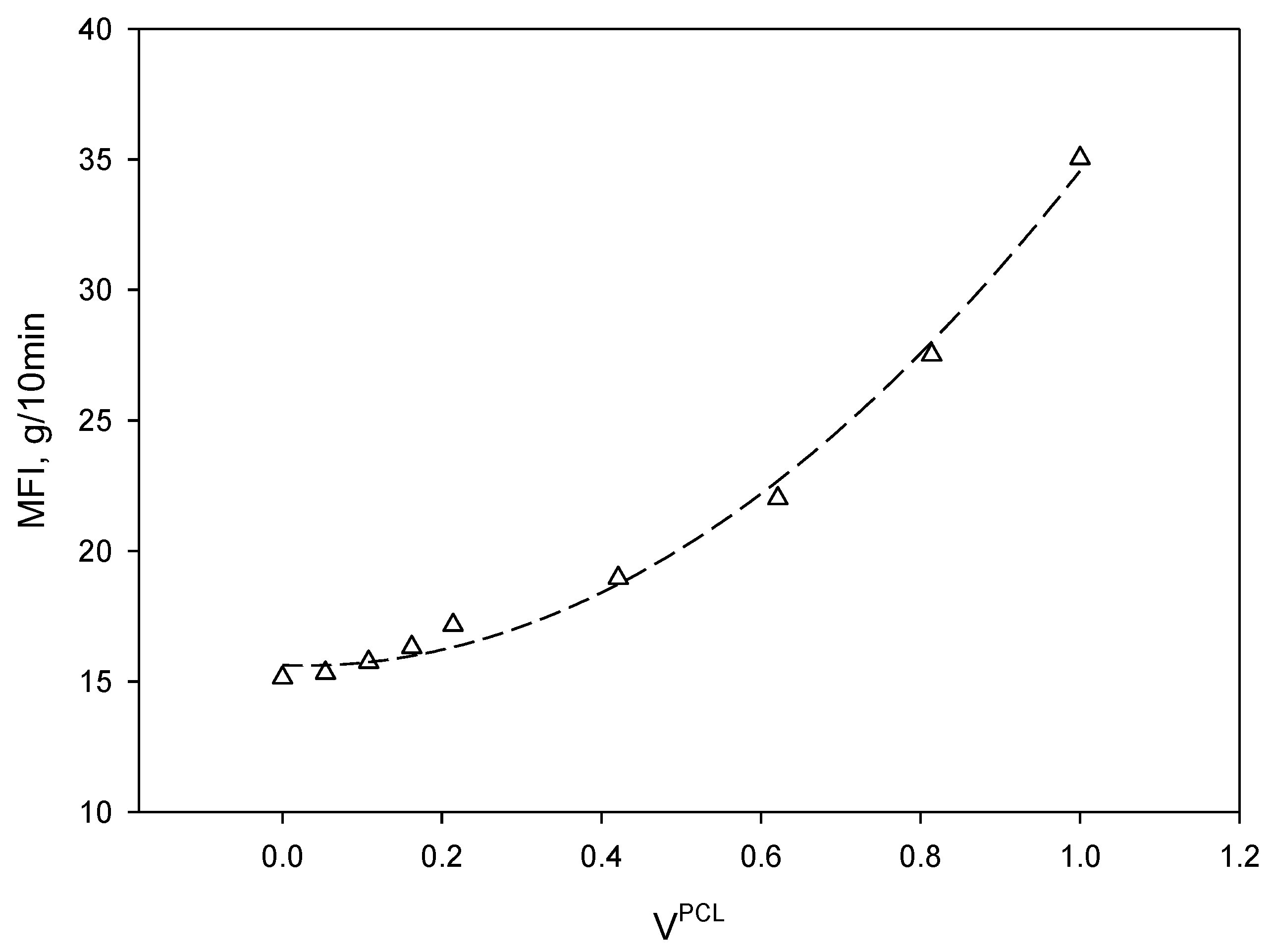

3.1. Melt Flow Index of the Obtained Blends

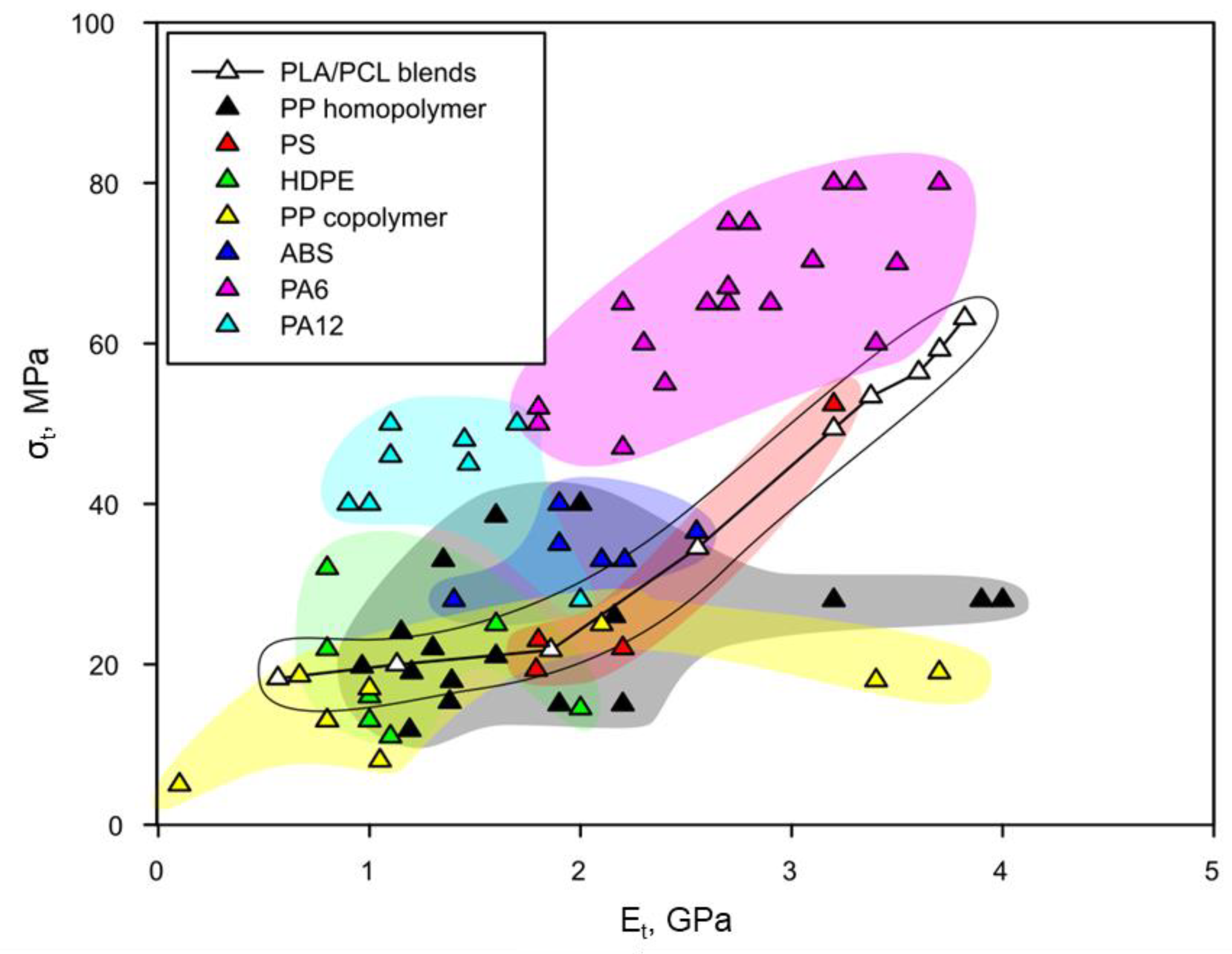

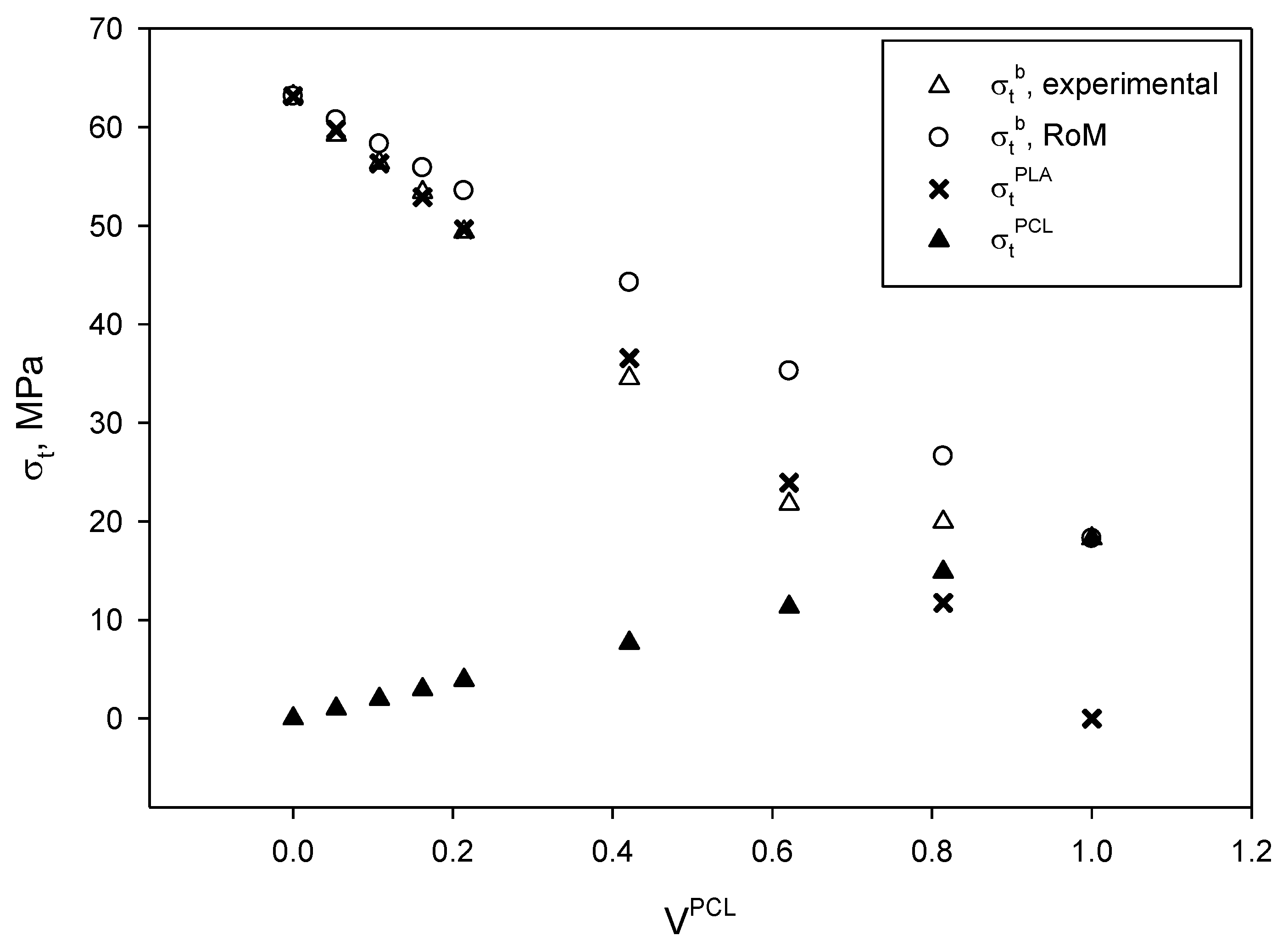

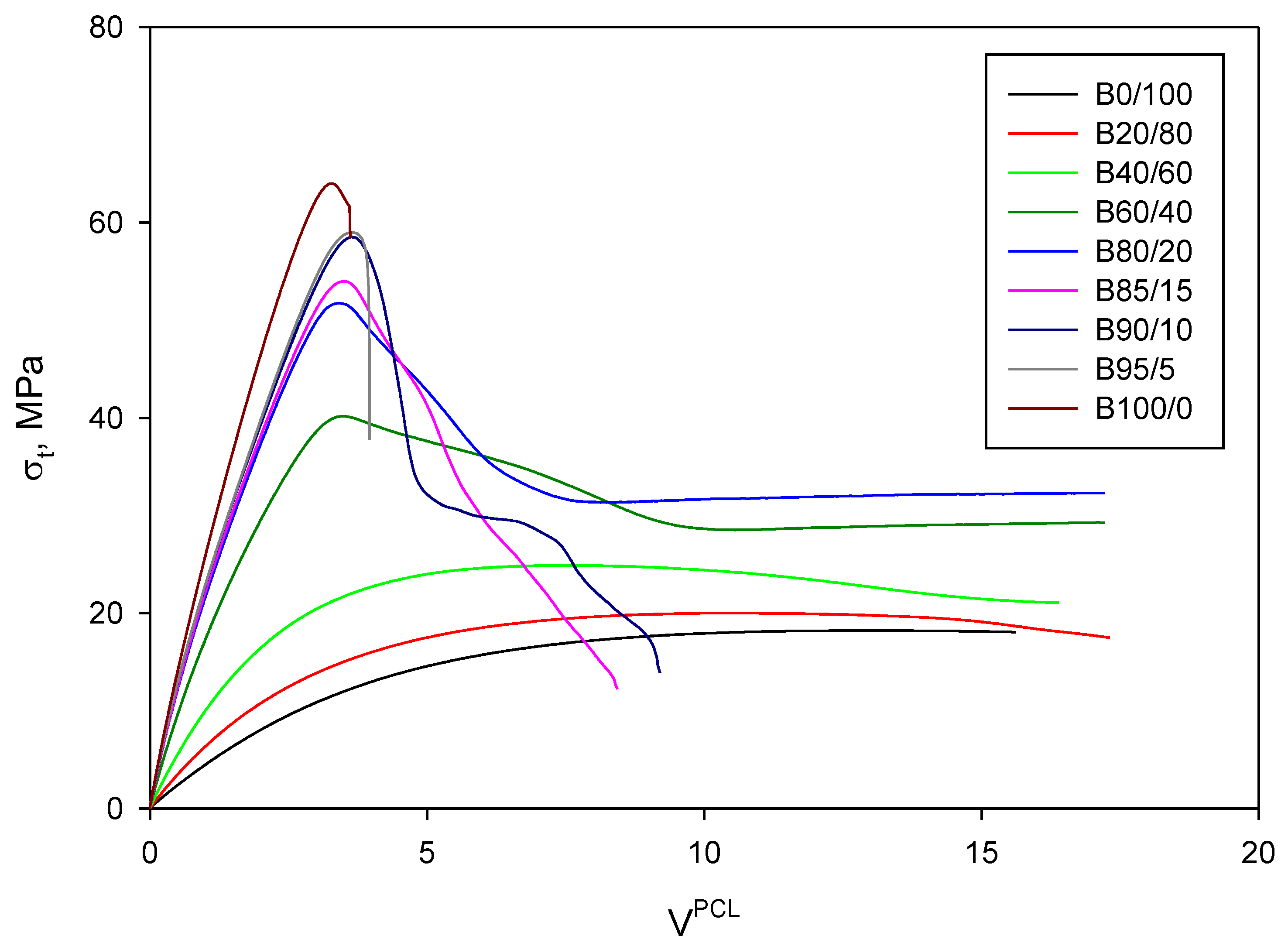

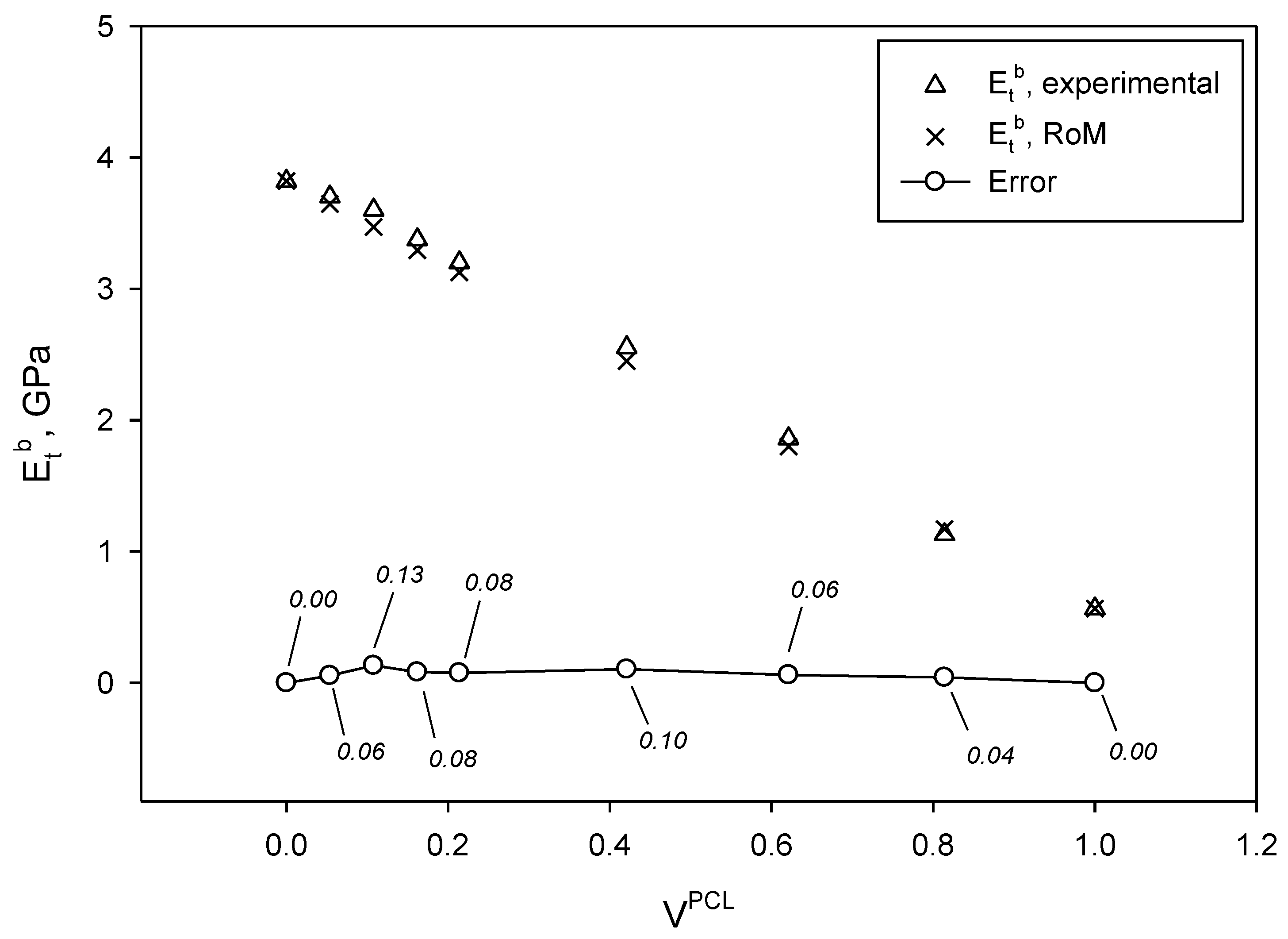

3.2. Tensile Characteristics of the Obtained Blends: Tensile Strength and Young’s Modulus

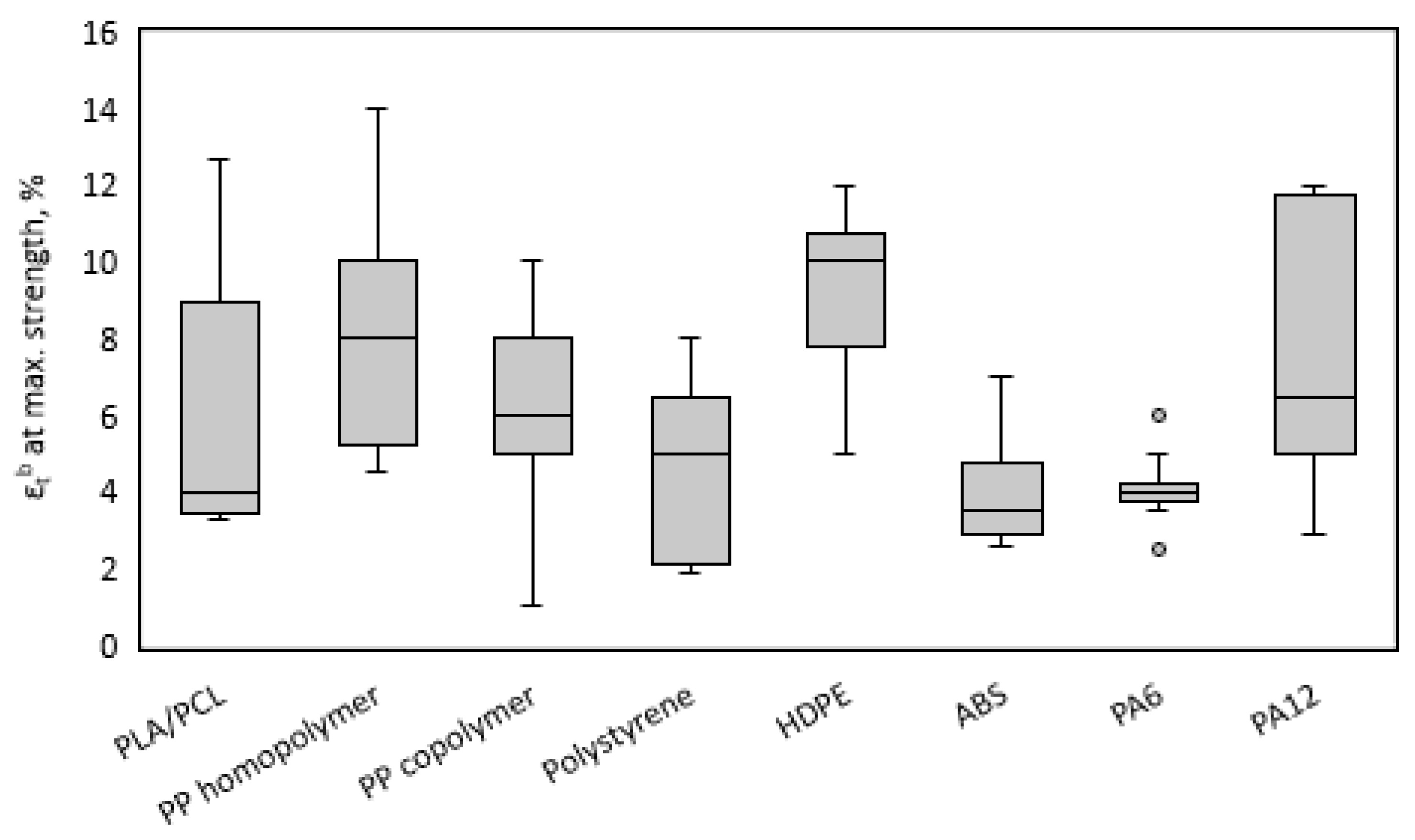

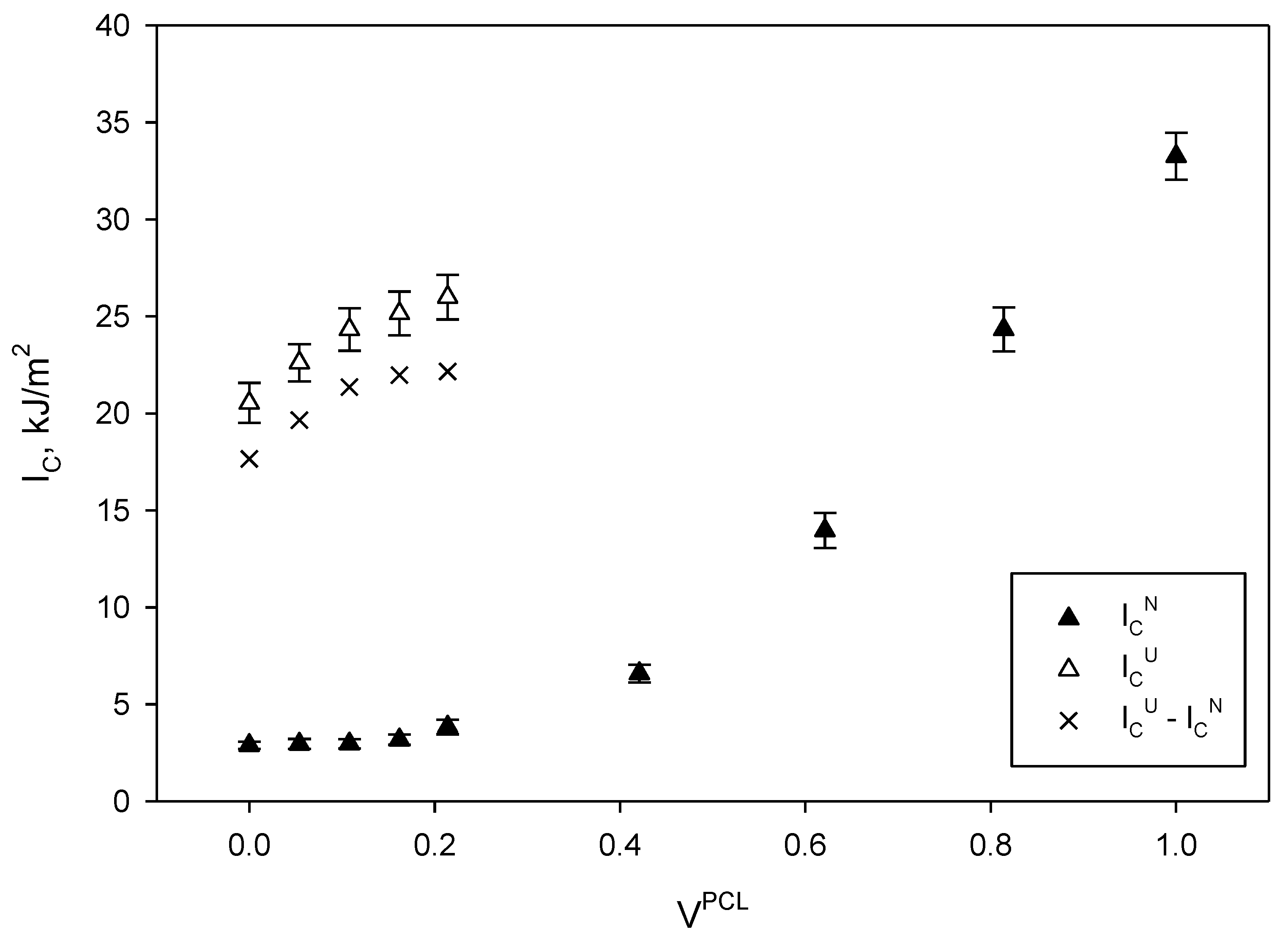

3.3. Impact Properties of the Obtained Blends

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- PlasticsEurope. Plastics—The Facts. Plast.-Facts 2018 2018, 38, 1–60. [Google Scholar]

- European comission. A European Strategy for Plastics in a Circular Economy; European Commission: Brussels, Belgium, 2015. [Google Scholar]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, 25–29. [Google Scholar] [CrossRef] [PubMed]

- Mohan Bhasney, S.; Mondal, K.; Kumar, A.; Katiyar, V. Effect of microcrystalline cellulose [MCC] fibres on the morphological and crystalline behaviour of high density polyethylene [HDPE]/polylactic acid [PLA] blends. Compos. Sci. Technol. 2020, 187, 107941. [Google Scholar] [CrossRef]

- Civancik-Uslu, D.; Puig, R.; Hauschild, M.; Fullana-i-Palmer, P. Life cycle assessment of carrier bags and development of a littering indicator. Sci. Total Environ. 2019, 685, 621–630. [Google Scholar] [CrossRef] [PubMed]

- Andrady, A.L. Plastics and Environment Sustainability; Wiley: Hoboken, NJ, USA, 2015; ISBN 978-1-118-31260-5. [Google Scholar]

- Rochman, C.M.; Browne, M.A.; Underwood, A.J.; Van Franeker, J.A.; Thompson, R.C.; Amaral-Zettler, L.A. The ecological impacts of marine debris: Unraveling the demonstrated evidence from what is perceived. Ecology 2016, 97, 302–312. [Google Scholar] [CrossRef] [PubMed]

- Civancik-Uslu, D.; Ferrer, L.; Puig, R.; Fullana-i-Palmer, P. Are functional fillers improving environmental behavior of plastics? A review on LCA studies. Sci. Total Environ. 2018, 626, 927–940. [Google Scholar] [CrossRef] [PubMed]

- Monier, V.; Hestin, M.; Cavé, J.; Laureysense, I.; Watkins, E.; Reisinger, H.; Porsch, L. Development of Guidance on Extended Producer Responsability (EPR); European Commission: Brussels, Belgium, 2014. [Google Scholar]

- European Commission. Changing the Way we Use Plastics; EU Publications: Luxembourg, Germany, 2018; Volume 4. [Google Scholar] [CrossRef]

- Solé, M.; Watson, J.; Puig, R.; Fullana-i-Palmer, P. Proposal of a new model to improve the collection of small WEEE: A pilot project for the recovery and recycling of toys. Waste Manag. Res. 2012, 30, 1208–1212. [Google Scholar] [CrossRef]

- Abejón, R.; Laso, J.; Margallo, M.; Aldaco, R.; Blanca-Alcubilla, G.; Bala, A.; Fullana-i-Palmer, P. Environmental impact assessment of the implementation of a Deposit-Refund System for packaging waste in Spain: A solution or an additional problem? Sci. Total Environ. 2020, 721, 137744. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Natural Fibers, Biopolymers, and Biocomposites; Taylor & Francis: Abingdon, UK, 2005; ISBN 9780203508206. [Google Scholar]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Sustainable Bio-Composites from Renewable Resources: Opportunities and Challenges in the Green Materials World. J. Polym. Environ. 2002, 10, 19–26. [Google Scholar] [CrossRef]

- Godoi, F.C.; Pereira, N.R.; Rocha, S.C.S. Analysis of the drying process of a biopolymer (poly-hydroxybutyrate) in rotating-pulsed fluidized bed. Chem. Eng. Process. Process. Intensif. 2011, 50, 623–629. [Google Scholar] [CrossRef]

- Hassan, M.A.; Yee, L.-N.; Yee, P.L.; Ariffin, H.; Raha, A.R.; Shirai, Y.; Sudesh, K. Sustainable production of polyhydroxyalkanoates from renewable oil-palm biomass. Biomass Bioenergy 2013, 50, 1–9. [Google Scholar] [CrossRef]

- Tnase, E.E.; Râp, M.; Popa, O. Biopolymers Based on Renewable Resources—A Review. Sci. Bull. Ser. F Biotechnol. 2014, 18, 188–195. [Google Scholar]

- The General Assembly of United Nations. Transforming our world: The 2030 Agenda for Sustainable Development. Available online: https://sustainabledevelopment.un.org/content/documents/21252030%20Agenda%20for%20Sustainable%20Development%20web (accessed on 29 April 2020).

- European Council. Directive (EU) 2019/904. Off. J. Eur. Union 2019, 2019, 1–19. [Google Scholar]

- Blanca-Alcubilla, G.; Bala, A.; de Castro, N.; Colomé, R.; Fullana-i-Palmer, P. Is the reusable tableware the best option? Analysis of the aviation catering sector with a life cycle approach. Sci. Total Environ. 2020, 708, 135121. [Google Scholar] [CrossRef]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions: A European Strategy for Plastics in a Circular Economy. Eur. Comm. Website 2018, 2018, 1–18. [Google Scholar] [CrossRef]

- Civancik-Uslu, D.; Puig, R.; Ferrer, L.; Fullana-i-Palmer, P. Influence of end-of-life allocation, credits and other methodological issues in LCA of compounds: An in-company circular economy case study on packaging. J. Clean. Prod. 2019, 212, 925–940. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Jaszkiewicz, A. Mechanical performance of biocomposites based on PLA and PHBV reinforced with natural fibres—A comparative study to PP. Compos. Sci. Technol. 2010, 70, 1687–1696. [Google Scholar] [CrossRef]

- Carothers, W.H.; Dorough, G.L.; van Natta, F.J. Reversible polymerization of cyclic esters. J. Am. Chem. Soc. 1932, 54, 761–772. [Google Scholar] [CrossRef]

- Garlotta, D. A Literature Review of Poly (Lactic Acid). J. Polym. Environ. 2001, 9, 63–84. [Google Scholar] [CrossRef]

- Walha, F.; Lamnawar, K.; Maazouz, A.; Jaziri, M. Rheological, morphological and mechanical studies of sustainably sourced polymer blends based on poly(lactic acid) and polyamide 11. Polymers 2016, 8, 61. [Google Scholar] [CrossRef]

- Berezina, N.; Landercy, N.; Mariage, P.A.; Morea, B. Large-scale production, properties and commercial applications of polylactic acid polymers. Wold J. Org. Chem. 2013, 1, 20–23. [Google Scholar]

- Gupta, A.P.; Kumar, V. New emerging trends in synthetic biodegradable polymers—Polylactide: A critique. Eur. Polym. J. 2007, 43, 4053–4074. [Google Scholar] [CrossRef]

- Serra, T.; Planell, J.A.; Navarro, M. High-resolution PLA-based composite scaffolds via 3-D printing technology. Acta Biomater. 2013, 9, 5521–5530. [Google Scholar] [CrossRef] [PubMed]

- Yang, T.C. Effect of extrusion temperature on the physico-mechanical properties of unidirectional wood fiber-reinforced polylactic acid composite (WFRPC) components using fused depositionmodeling. Polymers 2018, 10, 976. [Google Scholar] [CrossRef] [PubMed]

- Arao, Y.; Fujiura, T.; Itani, S.; Tanaka, T. Strength improvement in injection-molded jute-fiber-reinforced polylactide green-composites. Compos. Part B Eng. 2015, 68, 200–206. [Google Scholar] [CrossRef]

- Granda, L.A.; Espinach, F.X.; Tarrés, Q.; Méndez, J.A.; Delgado-Aguilar, M.; Mutjé, P. Towards a good interphase between bleached kraft softwood fibers and poly(lactic) acid. Compos. Part B Eng. 2016, 99, 514–520. [Google Scholar] [CrossRef]

- Yussuf, A.A.; Massoumi, I.; Hassan, A. Comparison of Polylactic Acid/Kenaf and Polylactic Acid/Rise Husk Composites: The Influence of the Natural Fibers on the Mechanical, Thermal and Biodegradability Properties. J. Polym. Environ. 2010, 18, 422–429. [Google Scholar] [CrossRef]

- Hartmann, M.H. High Molecular Weight Polylactic Acid Polymers. In Biopolymers from Renewable Resources; Kaplan, D.L., Ed.; Springer Verlag: Berlin/Heidelberg, Germany, 1998; pp. 367–411. ISBN 978-3-642-08341-9. [Google Scholar]

- Lim, L.T.; Auras, R.; Rubino, M. Processing technologies for poly(lactic acid). Prog. Polym. Sci. 2008, 33, 820–852. [Google Scholar] [CrossRef]

- Tsuji, H.; Ikada, Y. Crystallization from the melt of poly(lactide)s with different optical purities and their blends. Macromol. Chem. Phys. 1996, 197, 3483–3499. [Google Scholar] [CrossRef]

- Dorgan, J.R.; Janzen, J.; Clayton, M.P. Melt rheology of variable L-content poly(lactic acid). J. Rheol. 2005, 49, 607. [Google Scholar] [CrossRef]

- Chieng, B.W.; Ibrahim, N.A.; Yunus, W.M.Z.W.; Hussein, M.Z. Poly(lactic acid)/poly(ethylene glycol) polymer nanocomposites: Effects of graphene nanoplatelets. Polymers 2014, 6, 93–104. [Google Scholar] [CrossRef]

- Gregorova, A.; Hrabalova, M.; Kovalcik, R.; Wimmer, R. Surface modification of spruce wood flour and effects on the dynamic fragility of PLA/wood composites. Polym. Eng. Sci. 2011, 51, 143–150. [Google Scholar] [CrossRef]

- Grassia, L.; Pastore Carbone, M.G.; Mensitieri, G.; D’Amore, A. Modeling of density evolution of PLA under ultra-high pressure/temperature histories. Polymer 2011, 52, 4011–4020. [Google Scholar] [CrossRef]

- Balart, J.F.; Fombuena, V.; Fenollar, O.; Boronat, T.; Sánchez-Nacher, L. Processing and characterization of high environmental efficiency composites based on PLA and hazelnut shell flour (HSF) with biobased plasticizers derived from epoxidized linseed oil (ELO). Compos. Part B Eng. 2016, 86, 168–177. [Google Scholar] [CrossRef]

- Lin, Y.; Zhang, K.-Y.; Dong, Z.-M.; Dong, L.-S.; Li, Y.-S. Study of Hydrogen-Bonded blend of Polylactide with Biodegradable Hyperbranched Poly(ester amide). Macromolecules 2007, 40, 6257–6267. [Google Scholar] [CrossRef]

- Fukushima, K.; Abbate, C.; Tabuani, D.; Gennari, M.; Camino, G. Biodegradation of poly(lactic acid) and its composites. Polym. Degrad. Stab. 2009, 94, 1625–1630. [Google Scholar] [CrossRef]

- Wu, D.; Wu, L.; Zhang, M. Rheology and thermal stability of polylactide/clay nanocomposites. Polym. Degrad. Stab. 2006, 91, 3149–3155. [Google Scholar] [CrossRef]

- Delgado-Aguilar, M.; Oliver-Ortega, H.; Alberto Méndez, J.; Camps, J.; Espinach, F.X.; Mutjé, P. The role of lignin on the mechanical performance of polylactic acid and jute composites. Int. J. Biol. Macromol. 2018, 116, 299–304. [Google Scholar] [CrossRef]

- White, J.L.; Bumm, S.H. Polymer Blend Compounding and Processing. In Encyclopedia of Polymer Blends Vol. 2-Processing; Isayev, A.I., Ed.; Wiley-VCH: Weinheim, Germany, 2011; pp. 1–26. ISBN 978-3-527-31930-5. [Google Scholar]

- Wu, T.M.; Wu, C.Y. Biodegradable poly(lactic acid)/chitosan-modified montmorillonite nanocomposites: Preparation and characterization. Polym. Degrad. Stab. 2006, 91, 2198–2204. [Google Scholar] [CrossRef]

- Martin, O.; Avérous, L. Poly(lactic acid): Plasticization and properties of biodegradable multiphase systems. Polymer 2001, 42, 6209–6219. [Google Scholar] [CrossRef]

- Dammak, M.; Fourati, Y.; Tarrés, Q.; Delgado-Aguilar, M.; Mutjé, P.; Boufi, S. Blends of PBAT with plasticized starch for packaging applications: Mechanical properties, rheological behaviour and biodegradability. Ind. Crops Prod. 2020, 144, 144. [Google Scholar] [CrossRef]

- Zhao, H.; Cui, Z.; Wang, X.; Turng, L.S.; Peng, X. Processing and characterization of solid and microcellular poly(lactic acid)/polyhydroxybutyrate-valerate (PLA/PHBV) blends and PLA/PHBV/Clay nanocomposites. Compos. Part B Eng. 2013, 51, 79–91. [Google Scholar] [CrossRef]

- Al-Itry, R.; Lamnawar, K.; Maazouz, A. Improvement of thermal stability, rheological and mechanical properties of PLA, PBAT and their blends by reactive extrusion with functionalized epoxy. Polym. Degrad. Stab. 2012, 97, 1898–1914. [Google Scholar] [CrossRef]

- Armentano, I.; Fortunati, E.; Burgos, N.; Dominici, F.; Luzi, F.; Fiori, S.; Jiménez, A.; Yoon, K.; Ahn, J.; Kang, S.; et al. Processing and characterization of plasticized PLA/PHB blends for biodegradable multiphase systems. Express Polym. Lett. 2015, 9, 583–596. [Google Scholar] [CrossRef]

- Xiang, S.; Feng, L.; Bian, X.; Zhang, B.; Sun, B.; Liu, Y.; Li, G.; Chen, X. Toughening modification of PLLA with PCL in the presence of PCL-b-PLLA diblock copolymers as compatibilizer. Polym. Adv. Technol. 2019, 30, 963–972. [Google Scholar] [CrossRef]

- Zhang, T.; Wu, P.; Yang, Q.; Jiang, J. Fabrication of reinforced and toughened poly(lactic acid)/poly(butylene adipate-co-terephthalate) composites through solid die drawing process. J. Appl. Polym. Sci. 2020, 1–10. [Google Scholar] [CrossRef]

- Chavalitpanya, K.; Phattanarudee, S. Poly(lactic acid)/polycaprolactone blends compatibilized with block copolymer. Energy Procedia 2013, 34, 542–548. [Google Scholar] [CrossRef]

- Karuppuswamy, P.; Reddy Venugopal, J.; Navaneethan, B.; Luwang Laiva, A.; Ramakrishna, S. Polycaprolactone nanofibers for the controlled release of tetracycline hydrochloride. Mater. Lett. 2015, 141, 180–186. [Google Scholar] [CrossRef]

- Song, J.; Gao, H.; Zhu, G.; Cao, X.; Shi, X.; Wang, Y. The preparation and characterization of polycaprolactone/graphene oxide biocomposite nanofiber scaffolds and their application for directing cell behaviors. Carbon 2015, 95, 1039–1050. [Google Scholar] [CrossRef]

- Pagano, S.; Rabbit, M.; Valenti, C.; Negri, P.; Lombardo, G.; Costanzi, E.; Cianetti, S.; Montaseri, A.; Marinucci, L. Biological effects of resin monomers on oral cell populations: Descriptive analysis of literature. Eur. J. Paediatr Dent 2019, 20, 224–232. [Google Scholar]

- Yoshimoto, H.; Shin, Y.M.; Terai, H.; Vacanti, J.P. A biodegradable nanofiber scaffold by electrospinning and its potential for bone tissue engineering. Biomaterials 2003, 24, 2077–2082. [Google Scholar] [CrossRef]

- Fortelny, I.; Ujcic, A.; Fambri, L.; Slouf, M. Phase Structure, Compatibility, and Toughness of PLA/PCL Blends: A Review. Front. Mater. 2019, 6, 1–13. [Google Scholar] [CrossRef]

- Wachirahuttapong, S.; Thongpin, C.; Sombatsompop, N. Effect of PCL and Compatibility Contents on the Morphology, Crystallization and Mechanical Properties of PLA/PCL Blends. Energy Procedia 2016, 89, 198–206. [Google Scholar] [CrossRef]

- Kakroodi, A.R.; Kazemi, Y.; Rodrigue, D.; Park, C.B. Facile production of biodegradable PCL/PLA in situ nanofibrillar composites with unprecedented compatibility between the blend components. Chem. Eng. J. 2018, 351, 976–984. [Google Scholar] [CrossRef]

- Kassos, N.; Kelly, A.L.; Gough, T.; Gill, A.A. Synergistic toughening and compatibisation effect of poly(butylene succinate) in PLA/poly-caprolactone blends. Mater. Res. Express 2019, 6, 35313. [Google Scholar] [CrossRef]

- Gardella, L.; Calabrese, M.; Monticelli, O. PLA maleation: An easy and effective method to modify the properties of PLA/PCL immiscible blends. Colloid Polym. Sci. 2014, 292, 2391–2398. [Google Scholar] [CrossRef]

- López-Rodríguez, N.; López-Arraiza, A.; Meaurio, E.; Sarasua, J.R. Crystallization, morphology, and mechanical behavior of poly(lactide)/poly(ε-caprolactone) blends. Polym. Eng. Sci. 2006, 46, 1299–1308. [Google Scholar] [CrossRef]

- Abdelwahab, M.A.; Flynn, A.; Chiou, B.S.; Imam, S.; Orts, W.; Chiellini, E. Thermal, mechanical and morphological characterization of plasticized PLA-PHB blends. Polym. Degrad. Stab. 2012, 97, 1822–1828. [Google Scholar] [CrossRef]

- Semba, T.; Kitagawa, K.; Ishiaku, U.S.; Hamada, H. The effect of crosslinking on the mechanical properties of polylactic acid/polycaprolactone blends. J. Appl. Polym. Sci. 2006, 101, 1816–1825. [Google Scholar] [CrossRef]

- Navarro-Baena, I.; Sessini, V.; Dominici, F.; Torre, L.; Kenny, J.M.; Peponi, L. Design of biodegradable blends based on PLA and PCL: From morphological, thermal and mechanical studies to shape memory behavior. Polym. Degrad. Stab. 2016, 132, 97–108. [Google Scholar] [CrossRef]

- López, J.P.; Mendez, J.A.; Espinach, F.X.; Julian, F.; Mutjé, P.; Vilaseca, F. Tensile strength characteristics of polypropylene composites reinforced with stone groundwood fibres from softwood. Bioresources 2012, 7, 3188–3200. [Google Scholar] [CrossRef]

- Rao, R.U.; Venkatanarayana, B.; Suman, K.N.S. Enhancement of mechanical properties of PLA/PCL (80/20) blend by reinforcing with MMT nanoclay. Mater. Today Proc. 2019, 18, 85–97. [Google Scholar] [CrossRef]

- Yeh, J.-T.; Wu, C.-J.; Tsou, C.-H.; Chai, W.-L.; Chow, J.-D.; Huang, C.-Y.; Chen, K.-N.; Wu, C.-S. Study on the crystallization, miscibility, morphology, properties of poly (lactic acid)/(ε-caprolactone) blends. Polym. Plast. Technol. Eng. 2009, 48, 571–578. [Google Scholar] [CrossRef]

- Todo, M.; Takayama, T. Toughening of bioabsorbable polymer blend by microstructural modification. In Interface Oral Health Science 2007; Springer: Tokyo, Japen, 2007; pp. 95–104. ISBN 978-4-431-76689-6. [Google Scholar]

- Reuss, A. Berechnung der Fließgrenze von Mischkristallen auf Grund der Plastizitätsbedingung für Einkristalle. Z. Angew. Math. Mech. 1929, 9, 49–58. [Google Scholar] [CrossRef]

- Voigt, W. Ueber die Beziehung zwischen den beiden Elasticitätsconstanten isotroper Körper. Ann. Phys. 1889, 274, 573–578. [Google Scholar] [CrossRef]

- Swan, C.C.; Kosaka, I. Voigt-Reuss topology optimization for structures with nonlinear material behaviors. Int. J. Numer. Methods Eng. 1997, 40, 3785–3814. [Google Scholar] [CrossRef]

- Granda, L.A.; Espinach, F.X.; Mendez, J.A.; Tresserras, J.; Delgado-Aguilar, M.; Mutje, P. Semichemical fi bres of Leucaena collinsii reinforced polypropylene composites: Young’s modulus analysis and fi bre diameter effect on the stiffness. Compos. Part B 2016, 92, 332–337. [Google Scholar] [CrossRef]

- Oliver-Ortega, H.; Granda, L.A.; Espinach, F.X.; Delgado-Aguilar, M.; Duran, J.; Mutjé, P. Stiffness of bio-based polyamide 11 reinforced with softwood stone ground-wood fibres as an alternative to polypropylene-glass fibre composites. Eur. Polym. J. 2016, 84, 481–489. [Google Scholar] [CrossRef]

- Jiménez, A.M.; Delgado-Aguilar, M.; Tarrés, Q.; Quintana, G.; Fullana-i-Palmer, P.; Mutjè, P.; Espinach, F.X. Sugarcane bagasse reinforced composites: Studies on the young’s modulus and macro and micro-mechanics. BioResources 2017, 12, 12. [Google Scholar] [CrossRef]

- Ostafinska, A.; Fortelny, I.; Nevoralova, M.; Hodan, J.; Kredatusova, J.; Slouf, M. Synergistic effects in mechanical properties of PLA/PCL blends with optimized composition, processing, and morphology. RSC Adv. 2015, 5, 98971–98982. [Google Scholar] [CrossRef]

- Hernández-Díaz, D.; Villar-Ribera, R.; Espinach, F.X.; Julián, F.; Hernández-Abad, V.; Delgado-Aguilar, M. Impact Properties and Water Uptake Behavior of Old Newspaper Recycled Fibers-Reinforced. Materials 2020, 13, 1079. [Google Scholar] [CrossRef] [PubMed]

- Granda, L.A.; Espinach, F.X.; Méndez, J.A.; Vilaseca, F.; Delgado-Aguilar, M.; Mutjé, P. Semichemical fibres of Leucaena collinsii reinforced polypropylene composites: Flexural characterisation, impact behaviour and water uptake properties. Compos. Part B Eng. 2016, 97, 176–182. [Google Scholar] [CrossRef]

| Sample | Polylactic Acid (PLA) (wt%) | Polycaprolactone (PCL) (wt%) | VPCL |

|---|---|---|---|

| B100/0 | 100 | 0 | 0.000 |

| B95/5 | 95 | 5 | 0.054 |

| B90/10 | 90 | 10 | 0.108 |

| B85/15 | 85 | 15 | 0.162 |

| B80/20 | 80 | 20 | 0.214 |

| B60/40 | 60 | 40 | 0.421 |

| B40/60 | 40 | 60 | 0.621 |

| B20/80 | 20 | 80 | 0.814 |

| B0/100 | 0 | 100 | 1.000 |

| VPCL | σtB (MPa) | EtB (GPa) | εtB at Break (%) | εtB at Max. Stress (%) |

|---|---|---|---|---|

| 0.000 | 63.13 ± 2.32 | 3.82 ± 0.21 | 3.68 ± 0.12 | 3.27 ± 0.09 |

| 0.054 | 59.22 ± 2.03 | 3.70 ± 0.13 | 4.79 ± 0.21 | 3.39 ± 0.16 |

| 0.108 | 56.38 ± 2.96 | 3.60 ± 0.26 | 6.86 ± 0.32 | 3.64 ± 0.23 |

| 0.162 | 53.39 ± 3.01 | 3.38 ± 0.27 | 10.07 ± 0.29 | 3.50 ± 0.28 |

| 0.214 | 49.37 ± 1.86 | 3.20 ± 0.19 | 15.32 ± 0.56 | 4.01 ± 0.24 |

| 0.421 | 34.51 ± 2.56 | 2.55 ± 0.09 | - | 5.63 ± 0.34 |

| 0.621 | 21.77 ± 1.79 | 1.86 ± 0.11 | - | 7.56 ± 0.45 |

| 0.814 | 19.95 ± 0.96 | 1.13 ± 0.05 | - | 10.39 ± 0.51 |

| 1.000 | 18.25 ± 1.03 | 0.56 ± 0.07 | - | 12.65 ± 0.55 |

| VPCL | σtB exp. (MPa) | σtB Equation (1) (MPa) | σtB Equation (2) (MPa) | σtB−σtPCL* (MPa) 1 |

|---|---|---|---|---|

| 0.000 | 63.13 ± 2.32 | 63.13 | 63.13 | 63.13 |

| 0.054 | 59.22 ± 2.03 | 60.71 | 60.30 | 59.72 |

| 0.108 | 56.38 ± 2.96 | 58.28 | 57.53 | 56.31 |

| 0.162 | 53.39 ± 3.01 | 55.86 | 54.68 | 52.90 |

| 0.214 | 49.37 ± 1.86 | 53.53 | 52.18 | 49.62 |

| 0.421 | 34.51 ± 2.56 | 44.24 | 42.60 | 36.55 |

| 0.621 | 21.77 ± 1.79 | 35.26 | 33.92 | 23.93 |

| 0.814 | 19.95 ± 0.96 | 26.60 | 25.95 | 11.74 |

| 1.000 | 18.25 ± 1.03 | 18.25 | 18.25 | 0.00 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Delgado-Aguilar, M.; Puig, R.; Sazdovski, I.; Fullana-i-Palmer, P. Polylactic Acid/Polycaprolactone Blends: On the Path to Circular Economy, Substituting Single-Use Commodity Plastic Products. Materials 2020, 13, 2655. https://doi.org/10.3390/ma13112655

Delgado-Aguilar M, Puig R, Sazdovski I, Fullana-i-Palmer P. Polylactic Acid/Polycaprolactone Blends: On the Path to Circular Economy, Substituting Single-Use Commodity Plastic Products. Materials. 2020; 13(11):2655. https://doi.org/10.3390/ma13112655

Chicago/Turabian StyleDelgado-Aguilar, Marc, Rita Puig, Ilija Sazdovski, and Pere Fullana-i-Palmer. 2020. "Polylactic Acid/Polycaprolactone Blends: On the Path to Circular Economy, Substituting Single-Use Commodity Plastic Products" Materials 13, no. 11: 2655. https://doi.org/10.3390/ma13112655

APA StyleDelgado-Aguilar, M., Puig, R., Sazdovski, I., & Fullana-i-Palmer, P. (2020). Polylactic Acid/Polycaprolactone Blends: On the Path to Circular Economy, Substituting Single-Use Commodity Plastic Products. Materials, 13(11), 2655. https://doi.org/10.3390/ma13112655