Compressive Properties of Al-Si Alloy Lattice Structures with Three Different Unit Cells Fabricated via Laser Powder Bed Fusion

Abstract

1. Introduction

2. Materials and Methods

2.1. Powder Characteristics and Fabrication Process

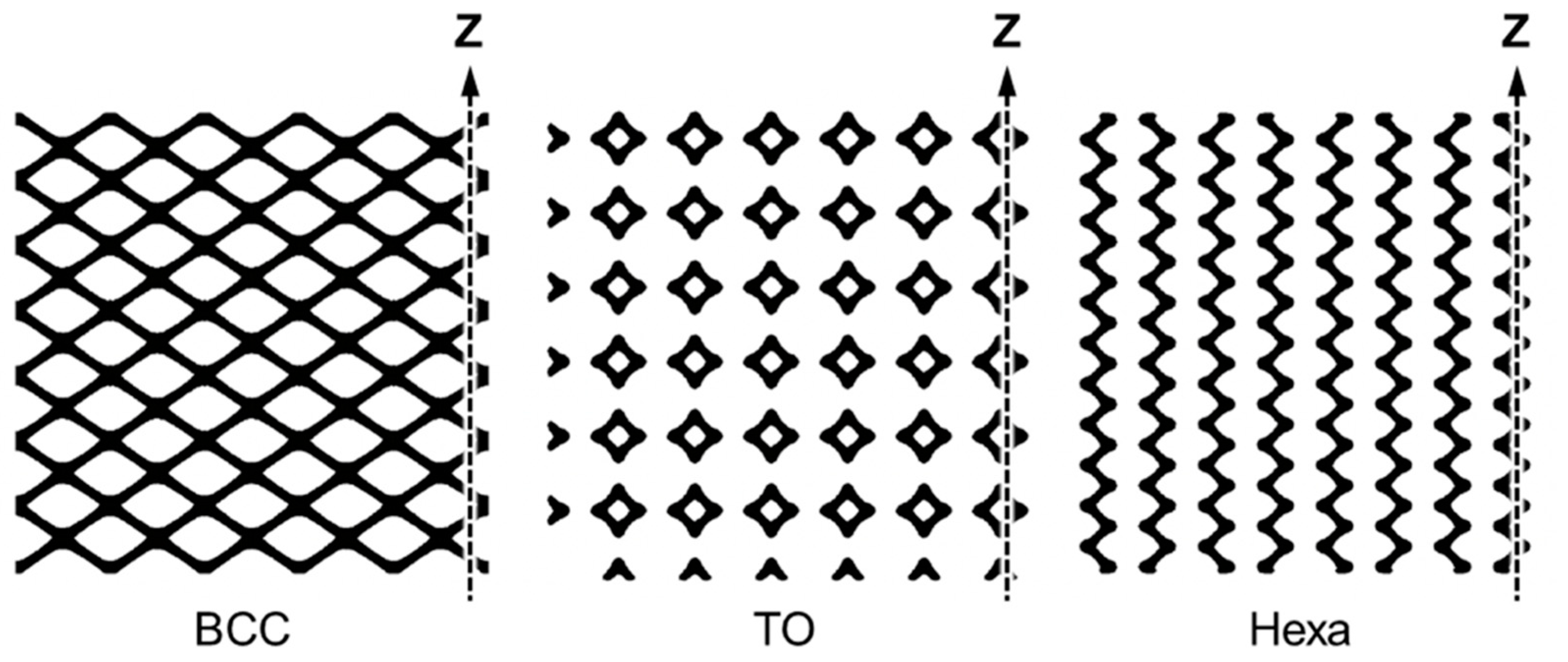

2.2. Designs of Lattice Structure

2.3. Measurements

2.4. Finite Element Method

3. Results

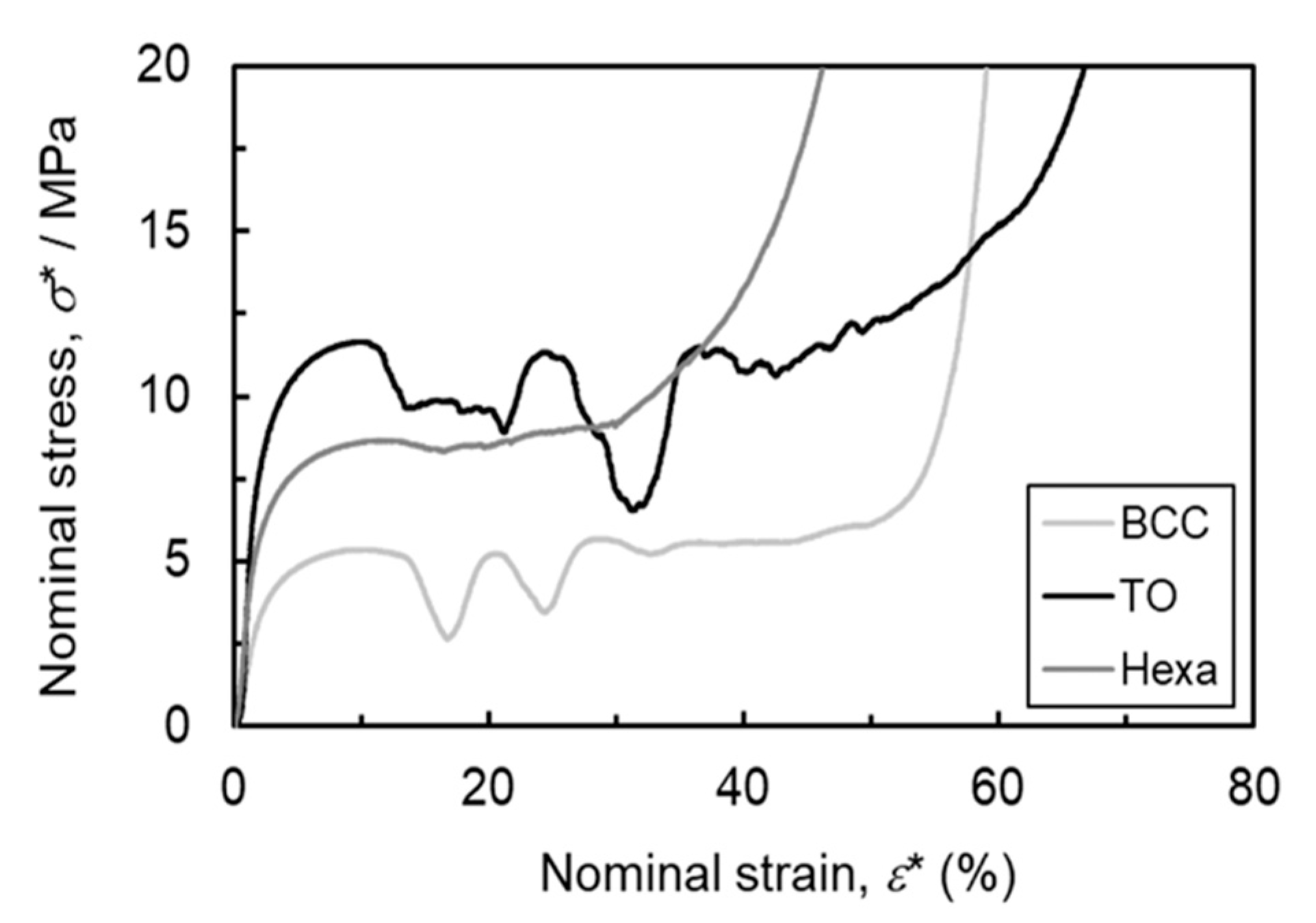

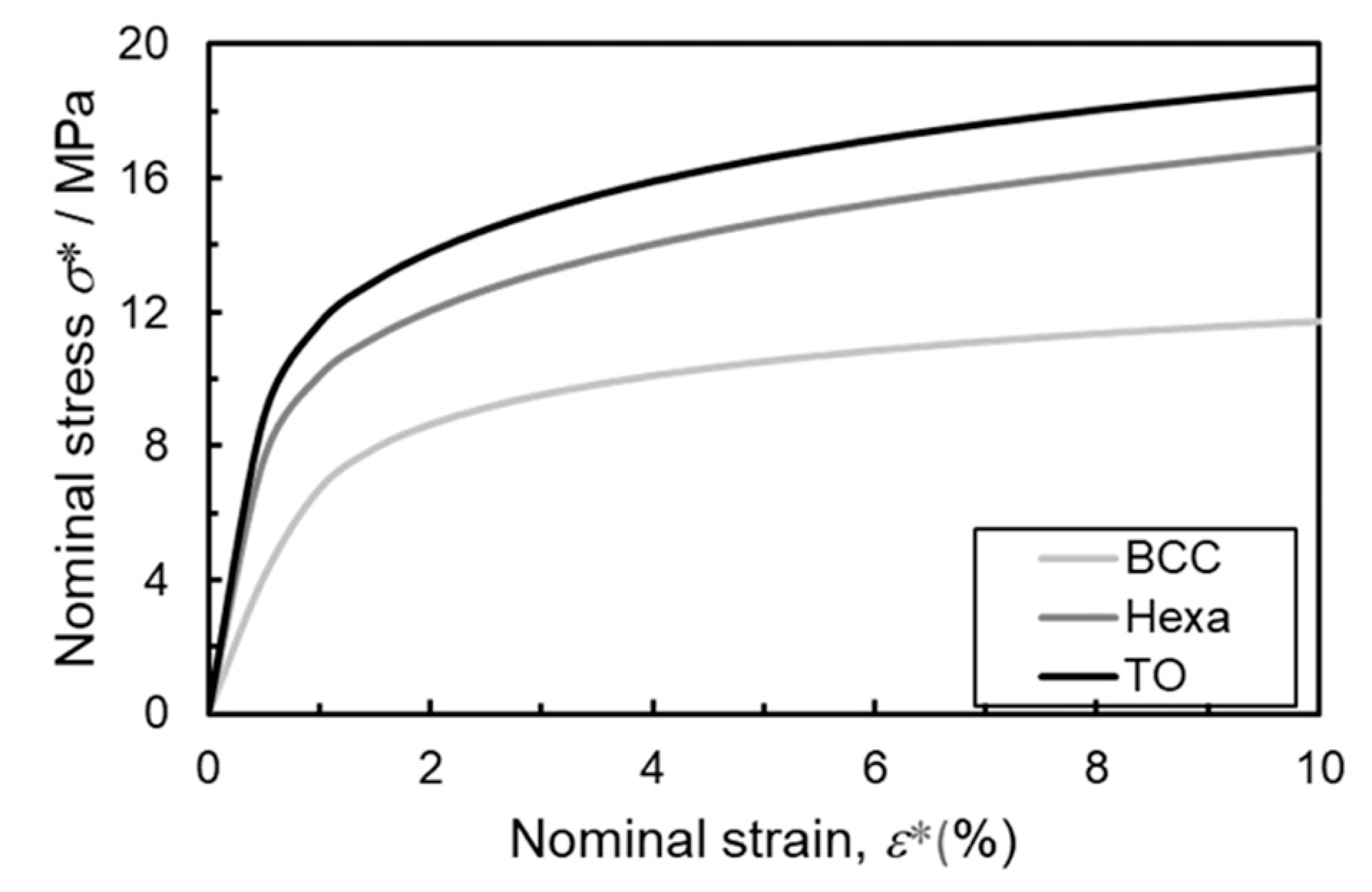

3.1. Mechanical Behavior

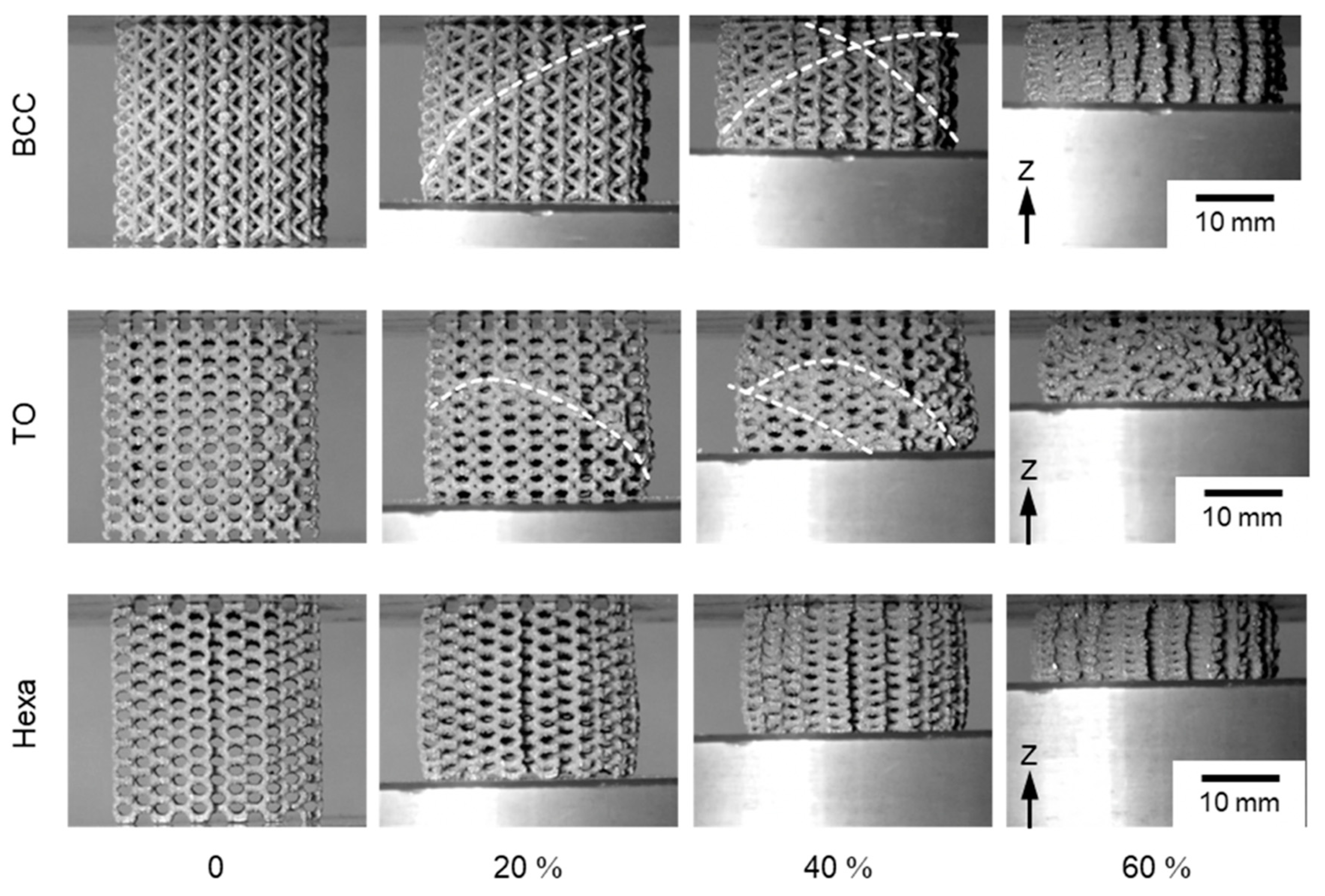

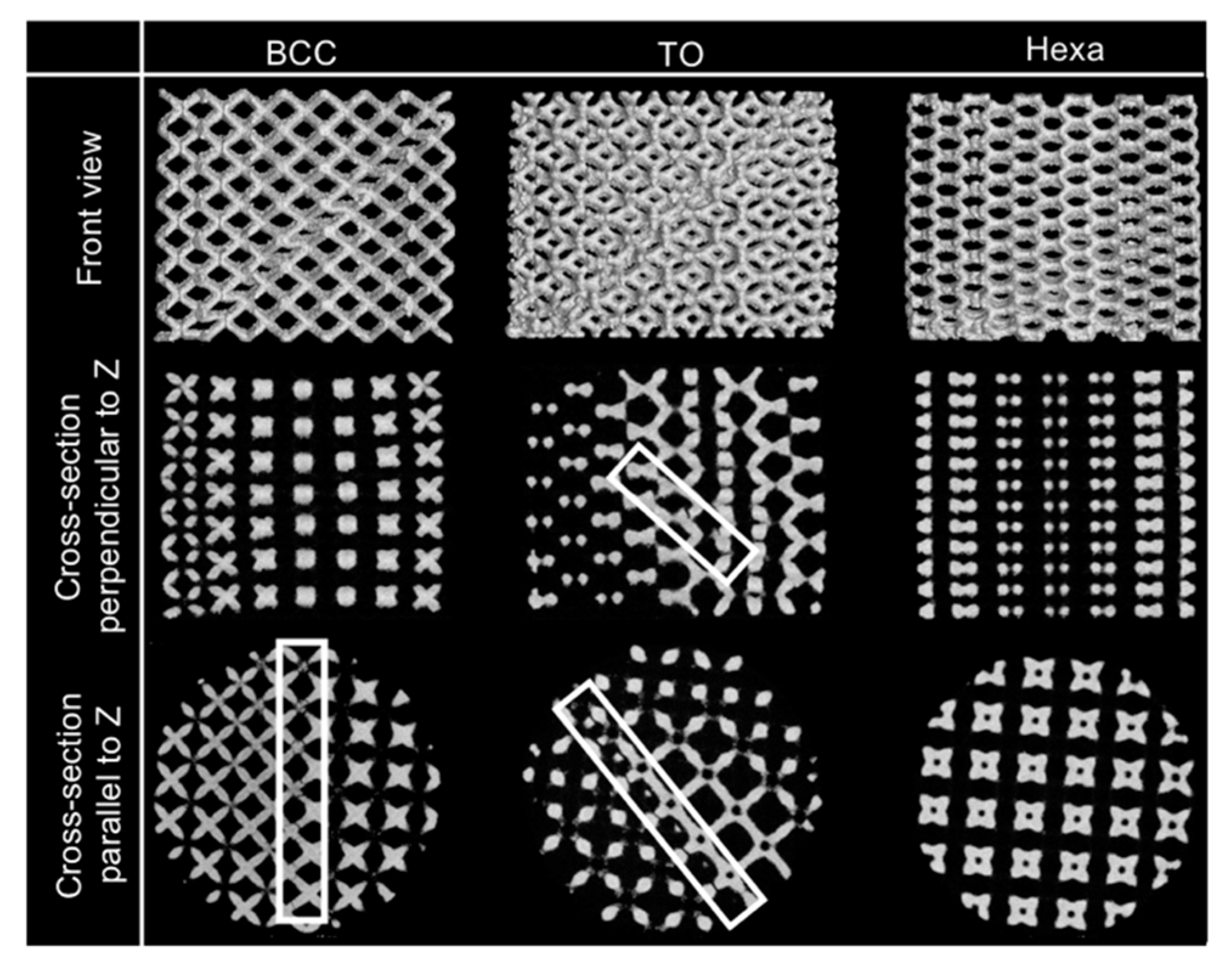

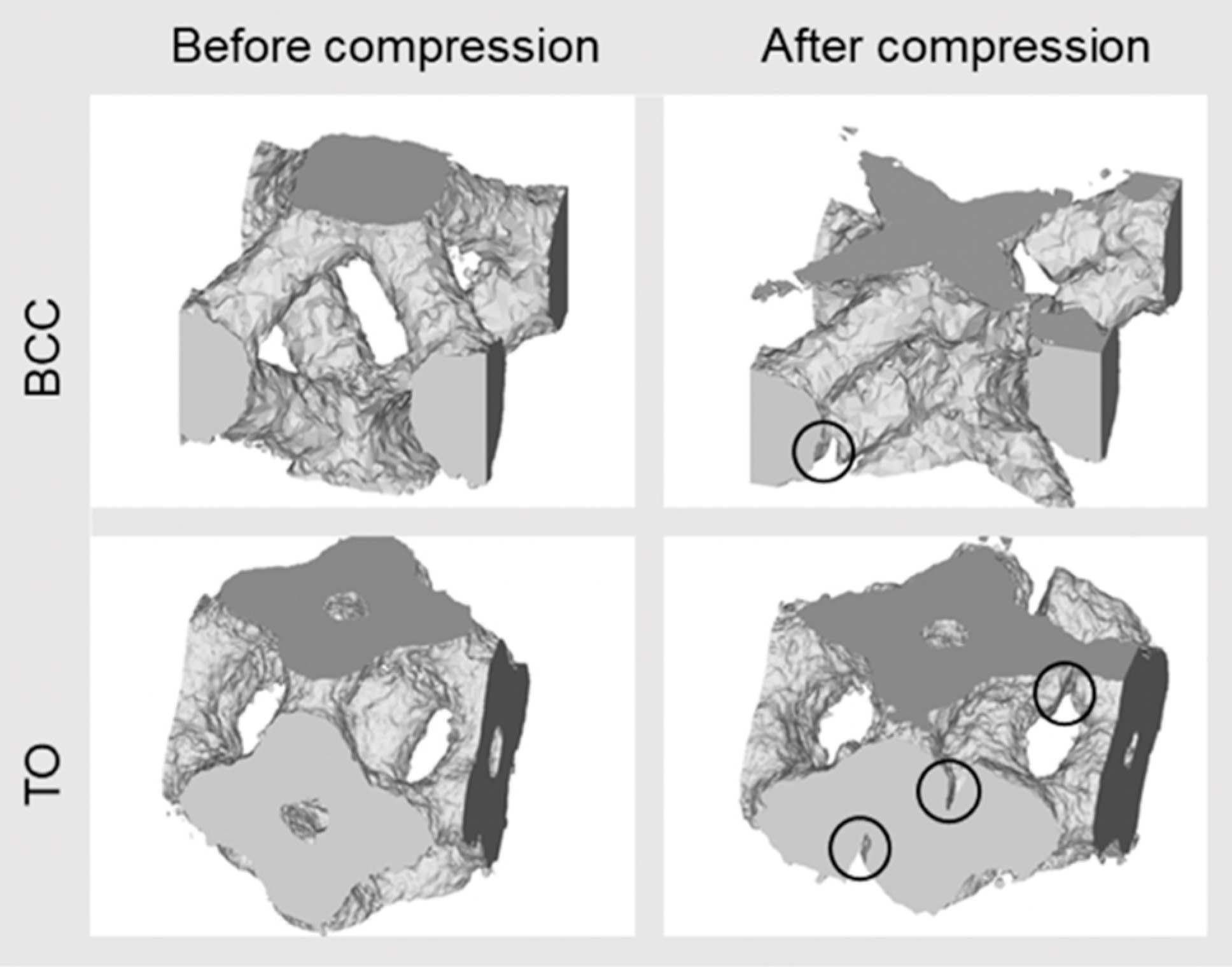

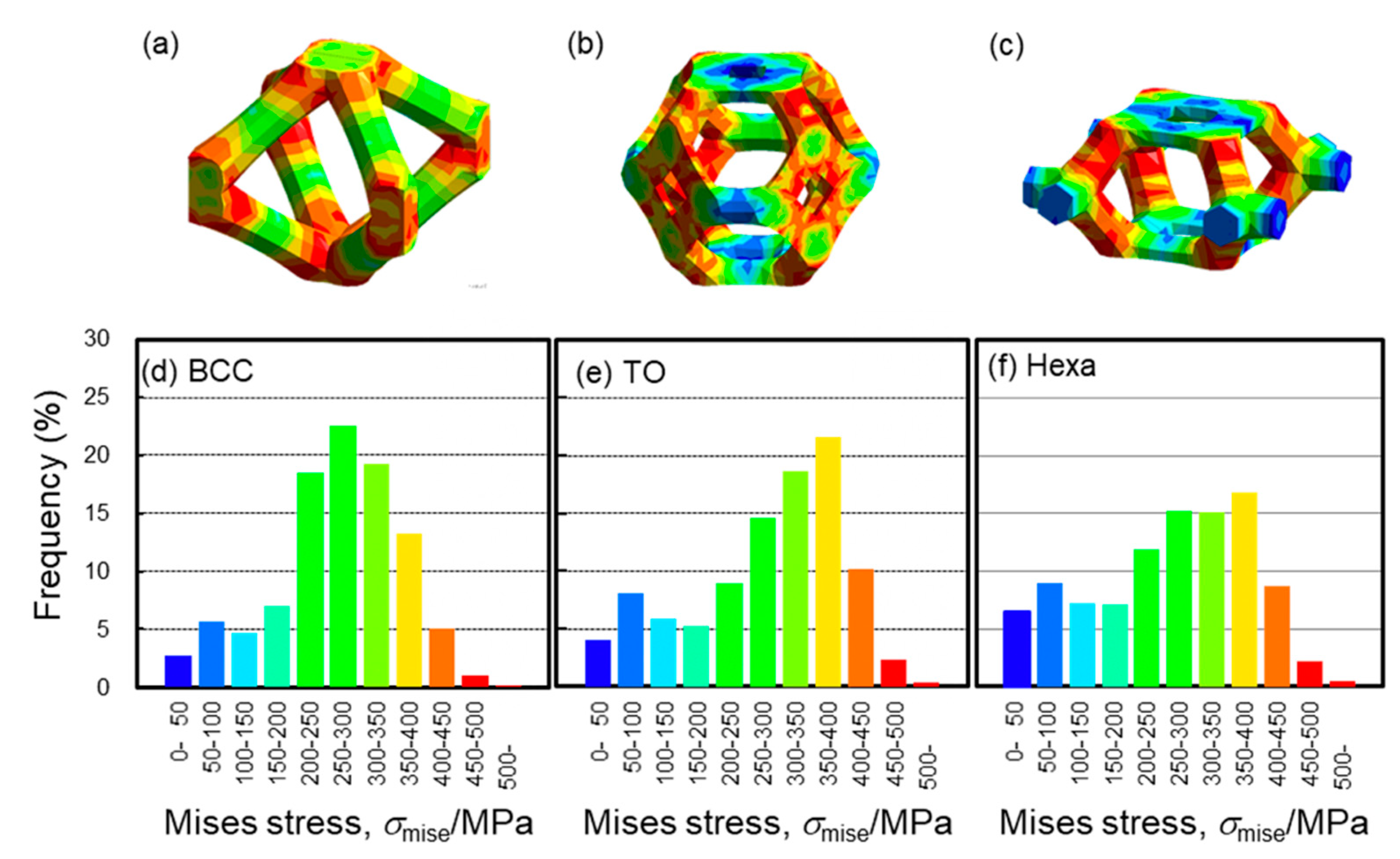

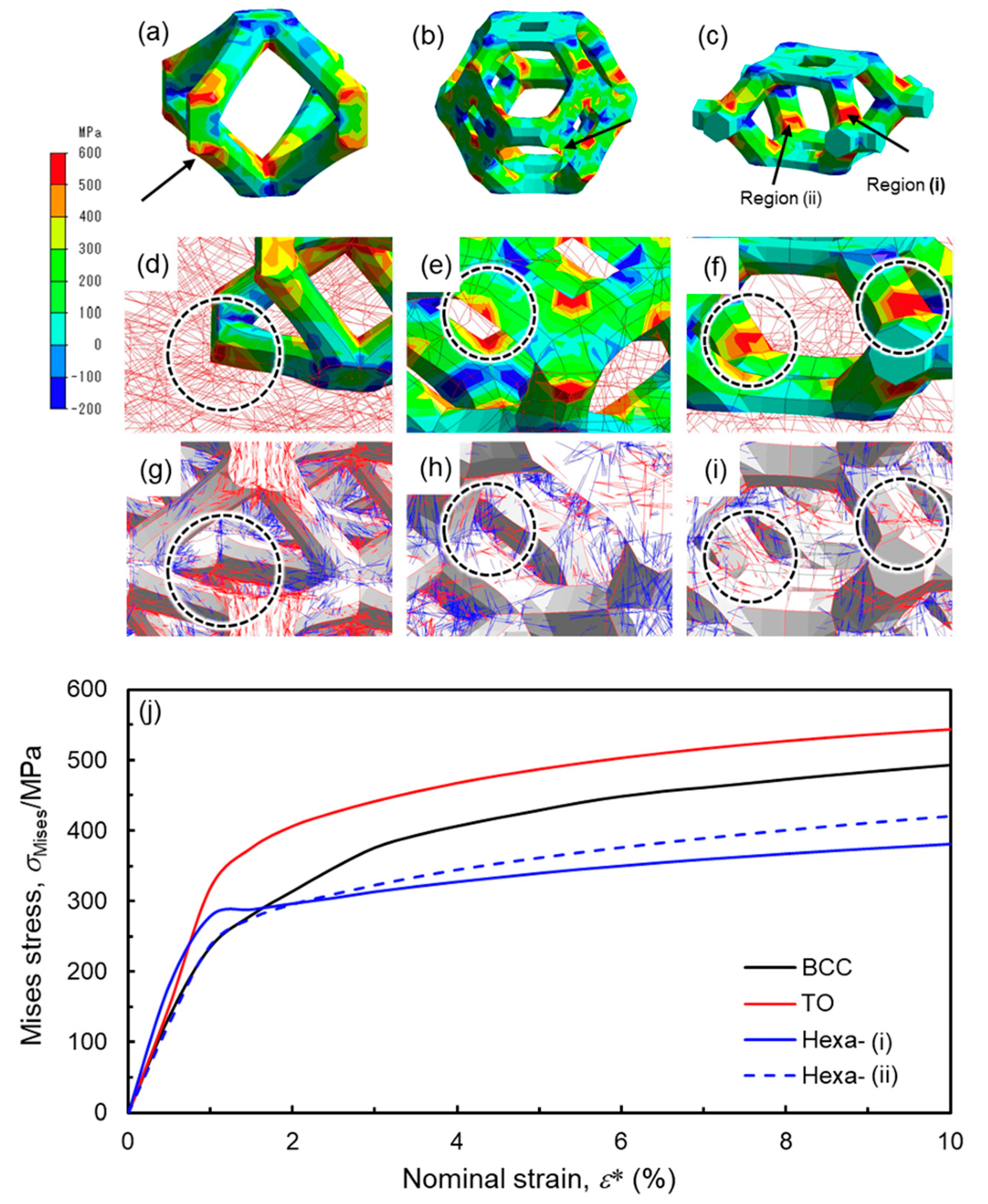

3.2. Deformation Behavior

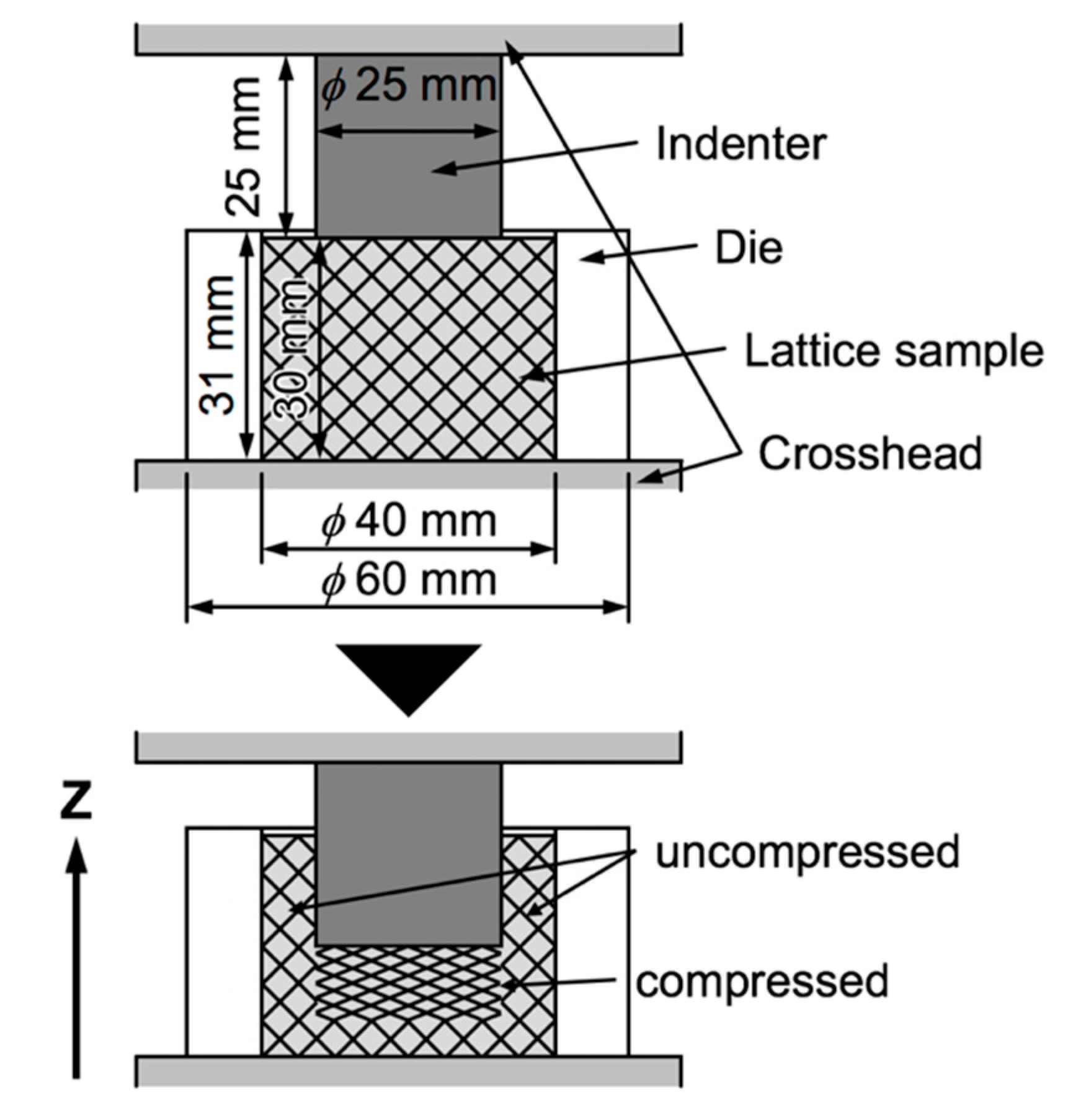

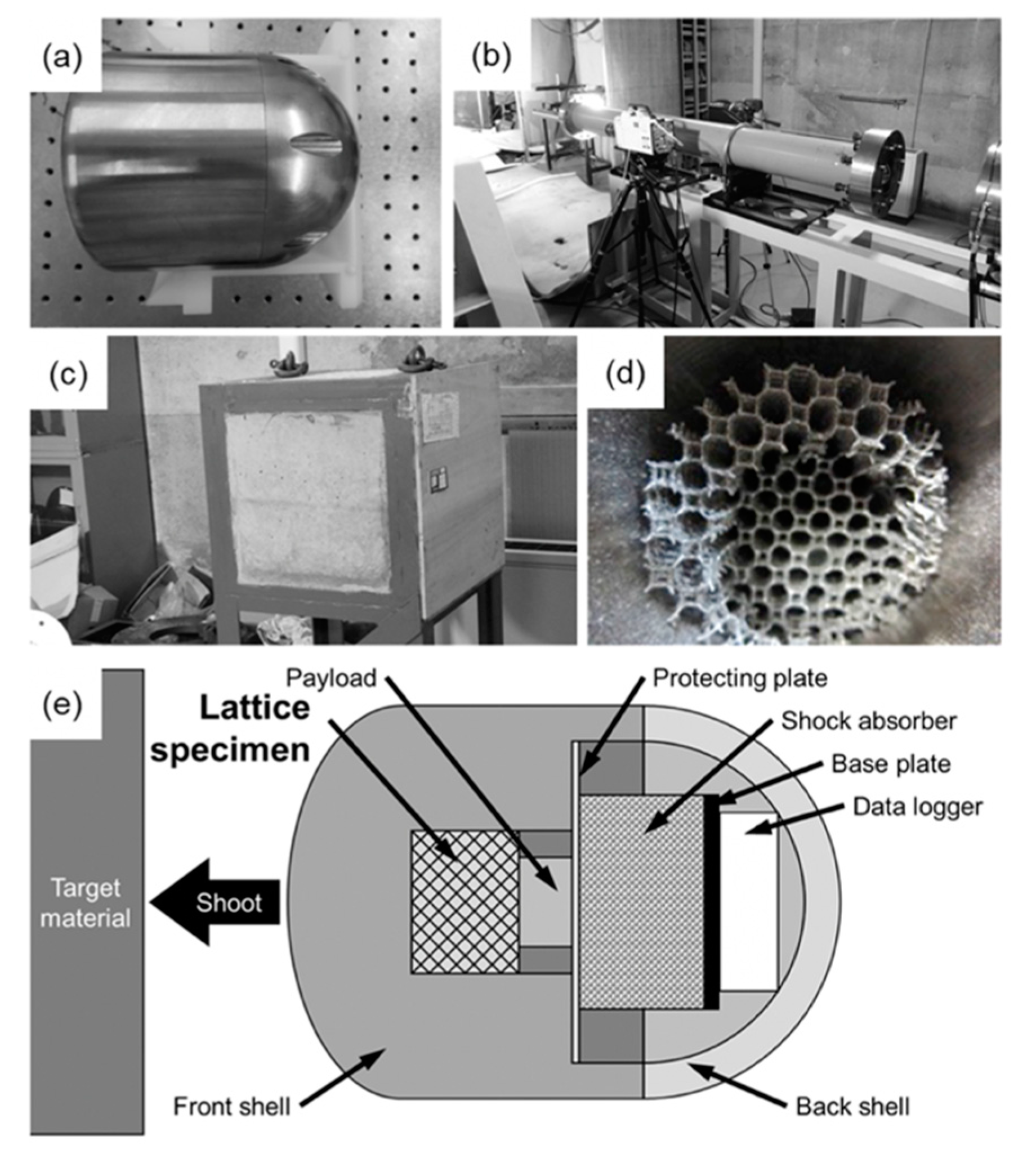

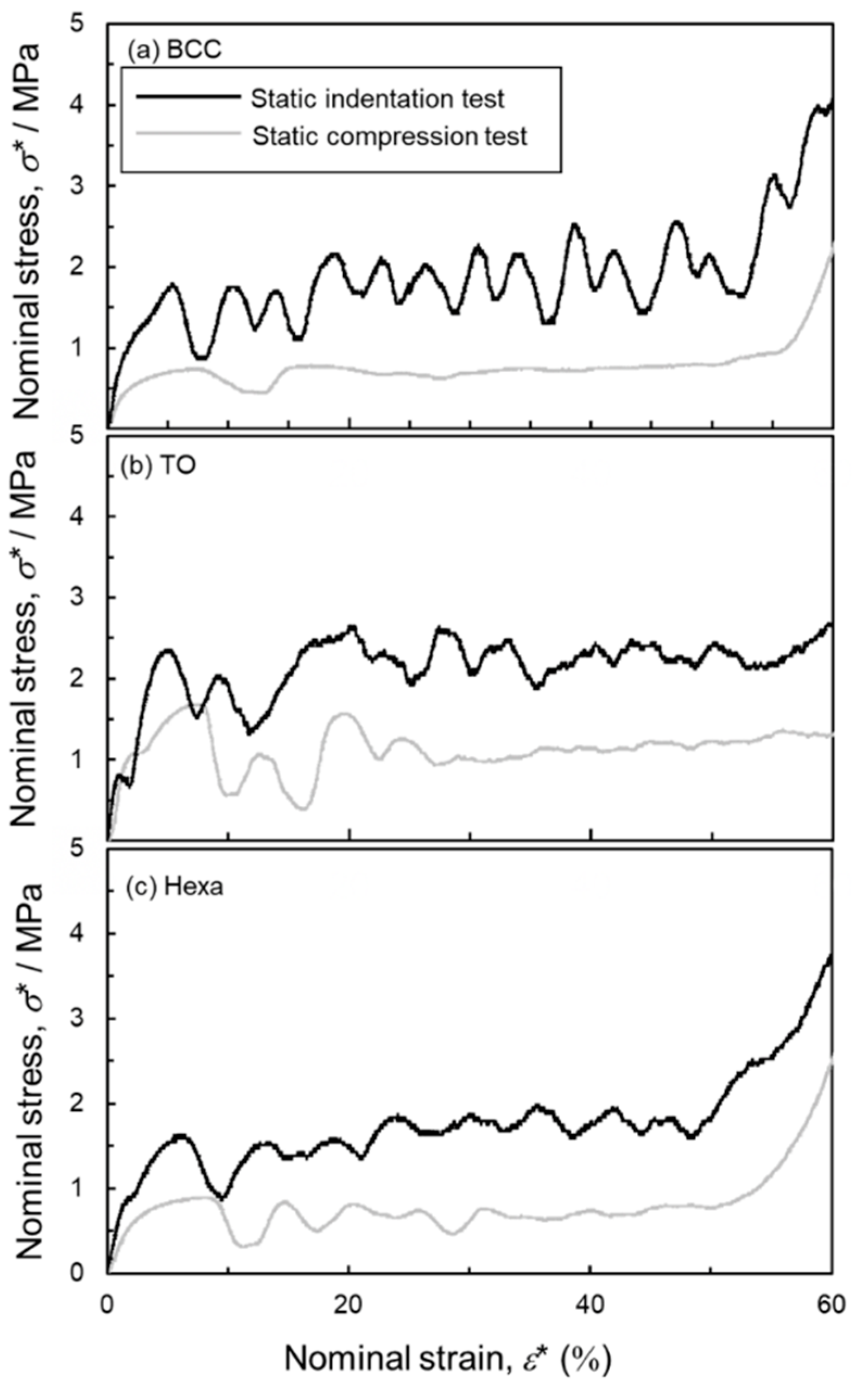

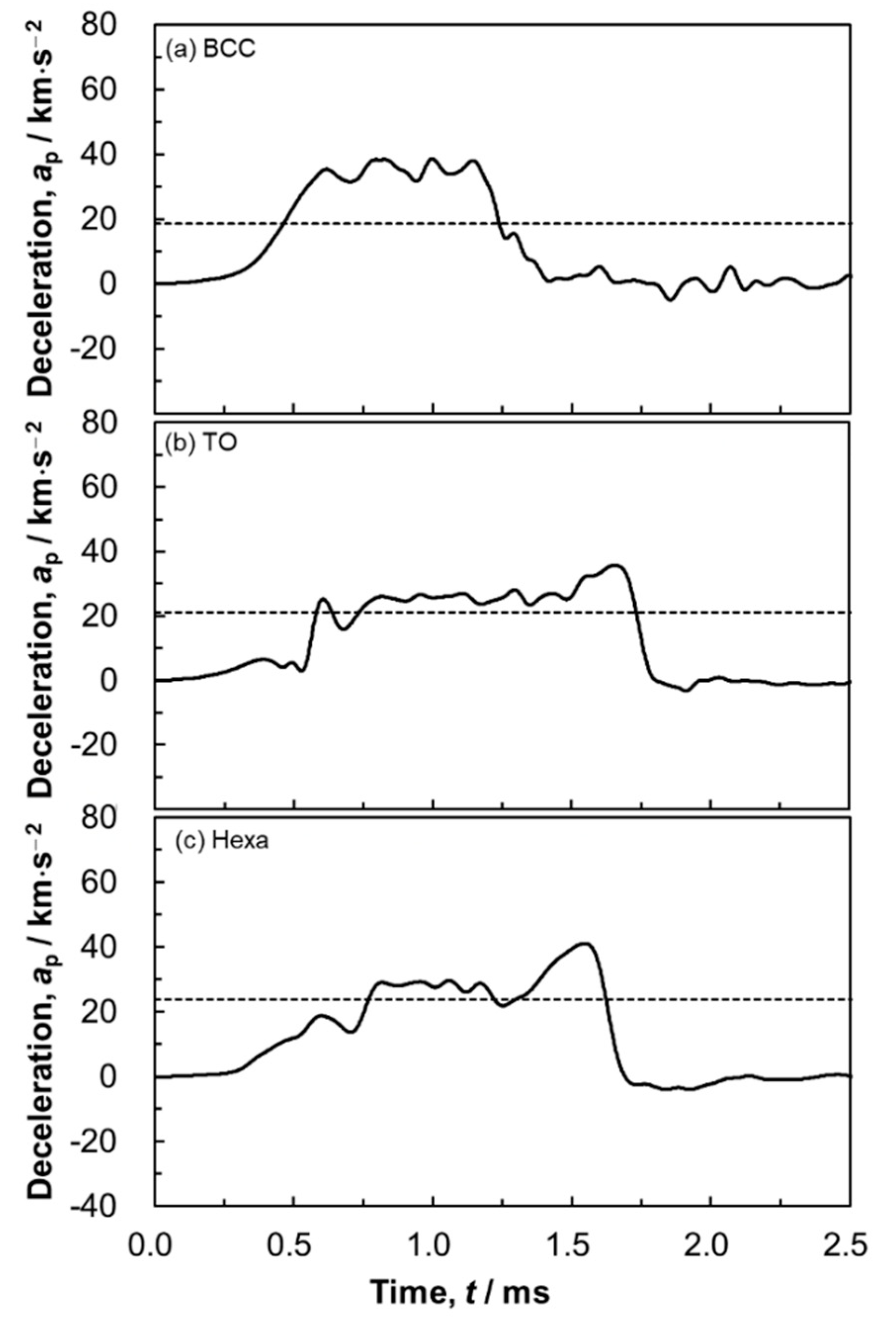

3.3. Static and High-Speed Indentation Tests

4. Discussion

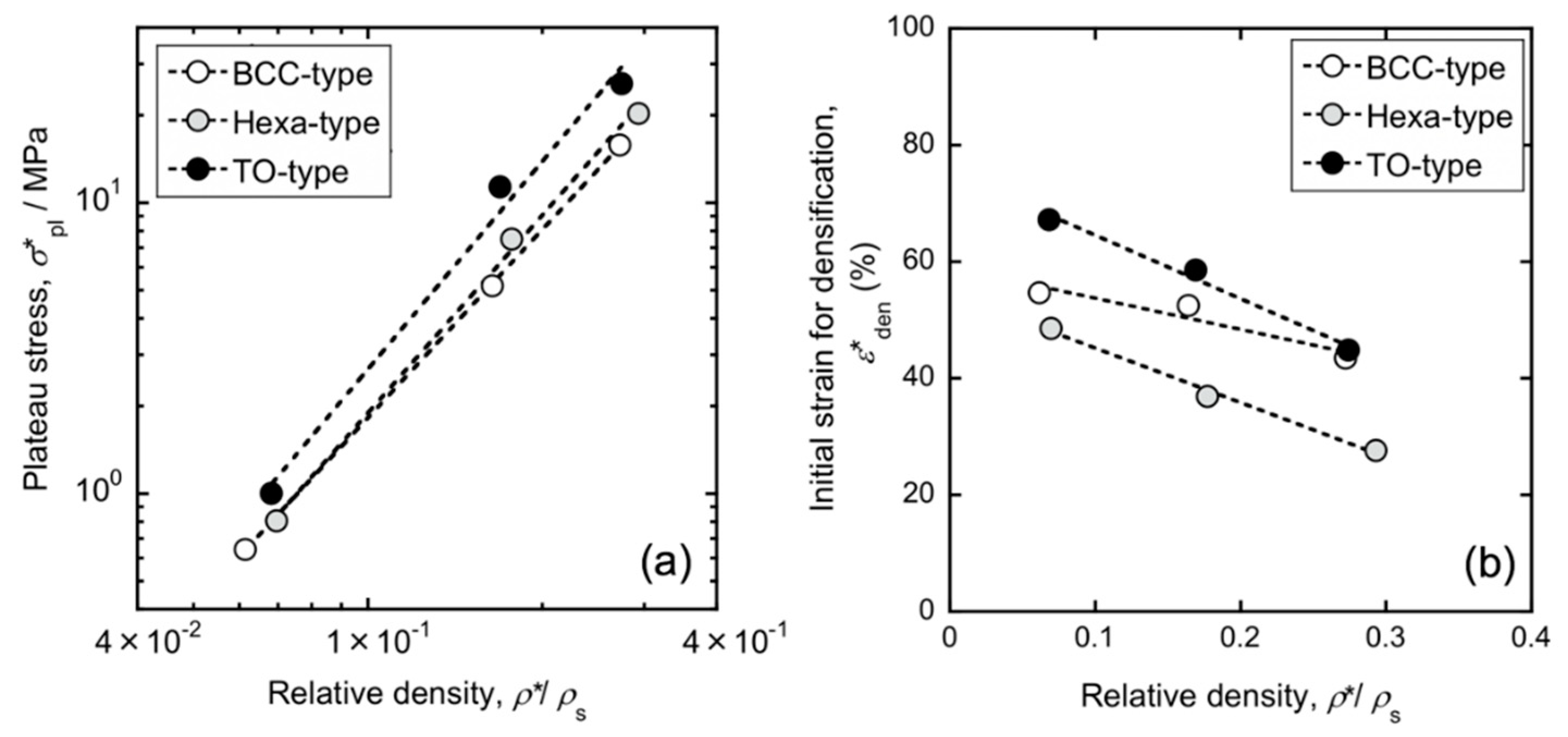

4.1. Compressive Behavior

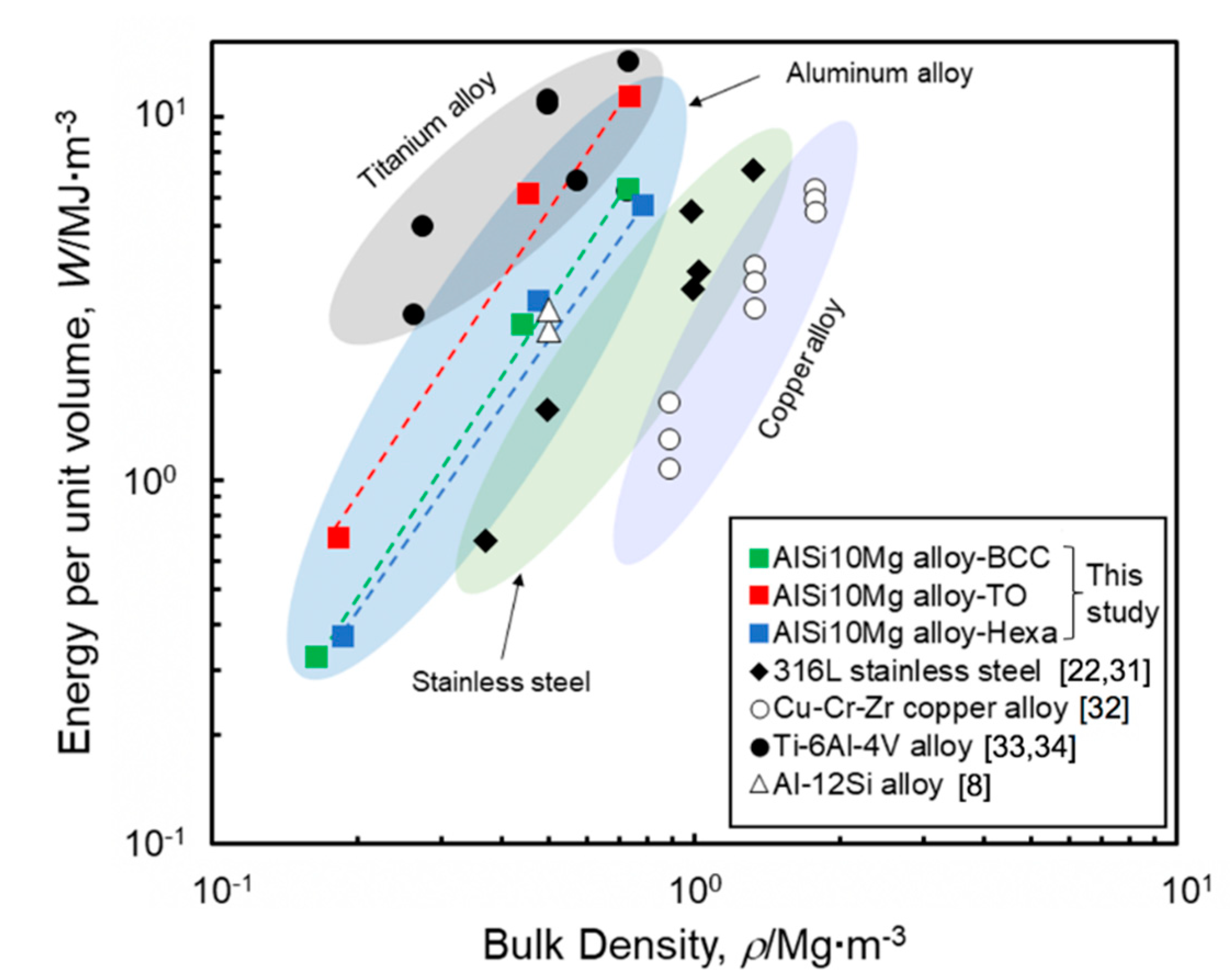

4.2. Energy Absorption Capacity

5. Conclusions

- Experimental results reveal that TO lattice specimen exhibited higher stiffness and plateau stress in comparison to BCC and Hexa lattice specimen. Based on the stress distribution from FEM analysis, most elements in the TO model showed high Mises stress, while low Mises stress dominated in the BCC model.

- During the compression test, two sequential diagonal shear bands were observed in the BCC and TO specimen, along with the fluctuation of abrupt stress drops. Cracks and fracture of struts in severely deformed unit cells were found in X-ray CT images. However, Hexa specimen experienced continuous deformation behavior, and inside struts remained intact. The low concentrated Mises stress in Hexa lattice model contributed to the deformation behavior without shear band formation.

- The Hexa lattice specimen densified at a smaller strain. Multiple struts in loading direction in the Hexa lattice specimen resulted in struts overlapping and early densification.

- High-speed indentation tests revealed that the energy absorption properties of the TO and Hexa lattice specimens under practical conditions could be predicted by static indentation tests.

- Aluminum alloy lattice structures exhibited higher energy absorption capacity compared to the stainless steel and copper alloy lattice structures. The AlSi10Mg lattice structures with the TO unit cell showed their superiority in absorbing energy reaching the level of titanium alloy lattice structures.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nazir, A.; Abate, K.M.; Kumar, A.; Jeng, J.Y. A state-of-the-art review on types, design, optimization, and additive manufacturing of cellular structures. Int. J. Adv. Manuf. Technol. 2019, 104, 3489–3510. [Google Scholar] [CrossRef]

- Mazur, M.; Leary, M.; Sun, S.; Vcelka, M.; Shidid, D.; Brandt, M. Deformation and failure behaviour of Ti-6Al-4V lattice structures manufactured by selective laser melting (SLM). Int. J. Adv. Manuf. Technol. 2016, 84, 1391–1411. [Google Scholar] [CrossRef]

- Rashed, M.G.; Ashraf, M.; Mines, R.A.W.; Hazell, P.J. Metallic microlattice materials: A current state of the art on manufacturing, mechanical properties and applications. Mater. Des. 2016, 95, 518–533. [Google Scholar] [CrossRef]

- Vilardell, A.M.; Takezawa, A.; du Plessis, A.; Takata, N.; Krakhmalev, P.; Kobashi, M.; Yadroitsava, I.; Yadroitsev, I. Topology optimization and characterization of Ti6Al4V ELI cellular lattice structures by laser powder bed fusion for biomedical applications. Mater. Sci. Eng. A 2019, 766, 138330. [Google Scholar] [CrossRef]

- Cuadrado, A.; Yánez, A.; Martel, O.; Deviaene, S.; Monopoli, D. Influence of load orientation and of types of loads on the mechanical properties of porous Ti6Al4V biomaterials. Mater. Des. 2017, 135, 309–318. [Google Scholar] [CrossRef]

- Ahmadi, S.M.; Yavari, S.A.; Wauthle, R.; Pouran, B.; Schrooten, J.; Weinans, H.; Zadpoor, A.A. Additively manufactured open-cell porous biomaterials made from six different space-filling unit cells: The mechanical and morphological properties. Materials 2015, 8, 1871–1896. [Google Scholar] [CrossRef] [PubMed]

- Farzinazar, S.; Schaedler, T.; Valdevit, L.; Lee, J. Thermal transport in hollow metallic microlattices. APL Mater. 2019, 7, 101108. [Google Scholar] [CrossRef]

- Al-Saedi, D.S.; Masood, S.H.; Faizan-Ur-Rab, M.; Alomarah, A.; Ponnusamy, P. Mechanical properties and energy absorption capability of functionally graded F2BCC lattice fabricated by SLM. Mater. Des. 2018, 144, 32–44. [Google Scholar] [CrossRef]

- Haruyama, J.; Sawai, S.; Mizuno, T.; Yoshimitsu, T.; Fukuda, S.; Nakatani, I. Exploration of lunar holes, possible skylights of underlying lava tubes, by smart lander for investigating moon (slim). Trans. JSASS Aerosp. Technol. Jpn. 2012, 10, 7–10. [Google Scholar] [CrossRef]

- Kitazono, K. Design of impact energy absorbing system based on porous aluminum. J. Jpn. Inst. Light Met. 2017, 67, 559–563. [Google Scholar] [CrossRef]

- Zhao, X.; Li, S.; Zhang, M.; Liu, Y.; Sercombe, T.B.; Wang, S.; Hao, Y.; Yang, R.; Murr, L.E. Comparison of the microstructures and mechanical properties of Ti–6Al–4V fabricated by selective laser melting and electron beam melting. Mater. Des. 2016, 95, 21–31. [Google Scholar] [CrossRef]

- Bonatti, C.; Mohr, D. Smooth-shell metamaterials of cubic symmetry: Anisotropic elasticity, yield strength and specific energy absorption. Acta. Mater. 2019, 164, 301–321. [Google Scholar] [CrossRef]

- Zhou, H.; Zhao, M.; Ma, Z.; Zhang, D.Z.; Fu, G. Sheet and network based functionally graded lattice structures manufactured by selective laser melting: Design, mechanical properties, and simulation. Int. J. Mech. Sci. 2020, 175, 105480. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F. Cellular Solids: Structure and Properties, 2nd ed.; Cambridge University Press: Cambridge, UK, 1999. [Google Scholar]

- Leary, M.; Mazur, M.; Elambasseril, J.; McMillan, M.; Chirent, T.; Sun, Y.; Qian, M.; Easton, M.; Brandt, M. Selective laser melting (SLM) of AlSi12Mg lattice structures. Mater. Des. 2016, 98, 344–357. [Google Scholar] [CrossRef]

- Suzuki, A.; Sekizawa, K.; Liu, M.; Takata, N.; Kobashi, M. Effect of heat treatments on compressive deformation behaviors of lattice-structured AlSi10Mg alloy fabricated by selective laser melting. Adv. Eng. Mater. 2019, 21, 1900571. [Google Scholar] [CrossRef]

- Tsopanos, S.; Mines, R.A.W.; McKown, S.; Shen, Y.; Cantwell, W.J.; Brooks, W.; Sutcliffe, C.J. The influence of processing parameters on the mechanical properties of selectively laser melted stainless steel microlattice structures. J. Manuf. Sci. Eng. 2010, 132, 041011. [Google Scholar] [CrossRef]

- Choy, S.Y.; Sun, C.N.; Leong, K.F.; Wei, J. Compressive properties of Ti-6Al-4V lattice structures fabricated by selective laser melting: Design, orientation and density. Addit. Manuf. 2017, 16, 213–224. [Google Scholar] [CrossRef]

- Mines, R.A.W.; Tsopanos, S.; Shen, Y.; Hasan, R.; McKown, S.T. Drop weight impact behaviour of sandwich panels with metallic micro lattice cores. Int. J. Impact. Eng. 2013, 60, 120–132. [Google Scholar] [CrossRef]

- Shen, Y.; Cantwell, W.; Mines, R.; Li, Y. Low-velocity impact performance of lattice structure core based sandwich panels. J. Compos. Mater. 2014, 48, 3153–3167. [Google Scholar] [CrossRef]

- Geng, X.; Lu, Y.; Liu, C.; Li, W.; Yue, Z. Fracture characteristic analysis of cellular lattice structures under tensile load. Int. J. Solids. Struct. 2019, 163, 170–177. [Google Scholar] [CrossRef]

- McKown, S.; Shen, Y.; Brookes, W.K.; Sutcliffe, C.J.; Cantwell, W.J.; Langdon, G.S.; Nurick, G.N.; Theobald, M.D. The quasi-static and blast loading response of lattice structures. Int. J. Impact. Eng. 2008, 35, 795–810. [Google Scholar] [CrossRef]

- Takata, N.; Kodaira, H.; Sekizawa, K.; Suzuki, A.; Kobashi, M. Change in microstructure of selectively laser melted AlSi10Mg alloy with heat treatments. Mater. Sci. Eng. A 2017, 704, 218–228. [Google Scholar] [CrossRef]

- Liu, M.; Takata, N.; Suzuki, A.; Kobashi, M. Development of gradient microstructure in the lattice structure of AlSi10Mg alloy fabricated by selective laser melting. J. Mater. Sci. Technol. 2020, 36, 106–107. [Google Scholar] [CrossRef]

- Liu, M.; Takata, N.; Suzuki, A.; Kobashi, M. Effect of heat treatment on gradient microstructure of AlSi10Mg lattice structure manufactured by laser powder bed fusion. Materials 2020, 13, 2487. [Google Scholar] [CrossRef]

- International Organization for Standardization. ISO 13314 Metallic Materials-Ductility Testing-Compression Test for Porous and Cellular Metals; ISO: Geneva, Switzerland, 2011. [Google Scholar]

- Al-Ketan, O.; Rowshan, R.; Al-Rub, R.K.A. Topology-mechanical property relationship of 3D printed strut, skeletal, and sheet based periodic metallic cellular materials. Addit. Manuf. 2018, 19, 167–183. [Google Scholar] [CrossRef]

- Zhao, M.; Zhang, D.Z.; Liu, F.; Li, Z.; Ma, Z.; Ren, Z. Mechanical and energy absorption characteristics of additively manufactured functionally graded sheet lattice structures with minimal surfaces. Int. J. Mech. Sci. 2020, 167, 105262. [Google Scholar] [CrossRef]

- Amani, Y.; Dancette, S.; Delroisse, P.; Simar, A.; Maire, E. Compression behavior of lattice structures produced by selective laser melting: X-ray tomography based experimental and finite element approaches. Acta. Mater. 2018, 159, 395–407. [Google Scholar] [CrossRef]

- Yang, L.; Yan, C.; Cao, W.; Liu, Z.; Song, B.; Wen, S.; Zhang, C.; Shi, Y.; Yang, S. Compression–compression fatigue behaviour of gyroid-type triply periodic minimal surface porous structures fabricated by selective laser melting. Acta. Mater. 2019, 181, 49–66. [Google Scholar] [CrossRef]

- Zhong, T.; He, K.; Li, H.; Yang, L. Mechanical properties of lightweight 316L stainless steel lattice structures fabricated by selective laser melting. Mater. Des. 2019, 181, 108076. [Google Scholar] [CrossRef]

- Ma, Z.; Zhang, D.Z.; Liu, F.; Jiang, J.; Zhao, M.; Zhang, T. Lattice structures of Cu-Cr-Zr copper alloy by selective laser melting: Microstructures, mechanical properties and energy absorption. Mater. Des. 2020, 187, 108406. [Google Scholar] [CrossRef]

- Xiao, L.; Song, W.; Wang, C.; Liu, H.; Tang, H.; Wang, J. Mechanical behavior of open-cell rhombic dodecahedron Ti–6Al–4V lattice structure. Mater. Sci. Eng. A 2015, 640, 375–384. [Google Scholar] [CrossRef]

| Young’s modulus, E/GPa | 60 |

| Poisson’s ratio, | 0.3 |

| Yield stress, σYS/MPa | 200 |

| Work hardening coefficient, n | 0.2 |

| C/MPa | n | |

|---|---|---|

| BCC | 257 | 2.1 |

| TO | 345 | 2.3 |

| Hexa | 633 | 2.4 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Sekizawa, K.; Suzuki, A.; Takata, N.; Kobashi, M.; Yamada, T. Compressive Properties of Al-Si Alloy Lattice Structures with Three Different Unit Cells Fabricated via Laser Powder Bed Fusion. Materials 2020, 13, 2902. https://doi.org/10.3390/ma13132902

Liu X, Sekizawa K, Suzuki A, Takata N, Kobashi M, Yamada T. Compressive Properties of Al-Si Alloy Lattice Structures with Three Different Unit Cells Fabricated via Laser Powder Bed Fusion. Materials. 2020; 13(13):2902. https://doi.org/10.3390/ma13132902

Chicago/Turabian StyleLiu, Xiaoyang, Keito Sekizawa, Asuka Suzuki, Naoki Takata, Makoto Kobashi, and Tetsuya Yamada. 2020. "Compressive Properties of Al-Si Alloy Lattice Structures with Three Different Unit Cells Fabricated via Laser Powder Bed Fusion" Materials 13, no. 13: 2902. https://doi.org/10.3390/ma13132902

APA StyleLiu, X., Sekizawa, K., Suzuki, A., Takata, N., Kobashi, M., & Yamada, T. (2020). Compressive Properties of Al-Si Alloy Lattice Structures with Three Different Unit Cells Fabricated via Laser Powder Bed Fusion. Materials, 13(13), 2902. https://doi.org/10.3390/ma13132902