Axial Compression Experiments and Finite Element Analysis of Basalt Fiber/Epoxy Resin Three-Dimensional Tubular Woven Composites

Abstract

1. Introduction

2. Experiment

2.1. Materials and Equipment

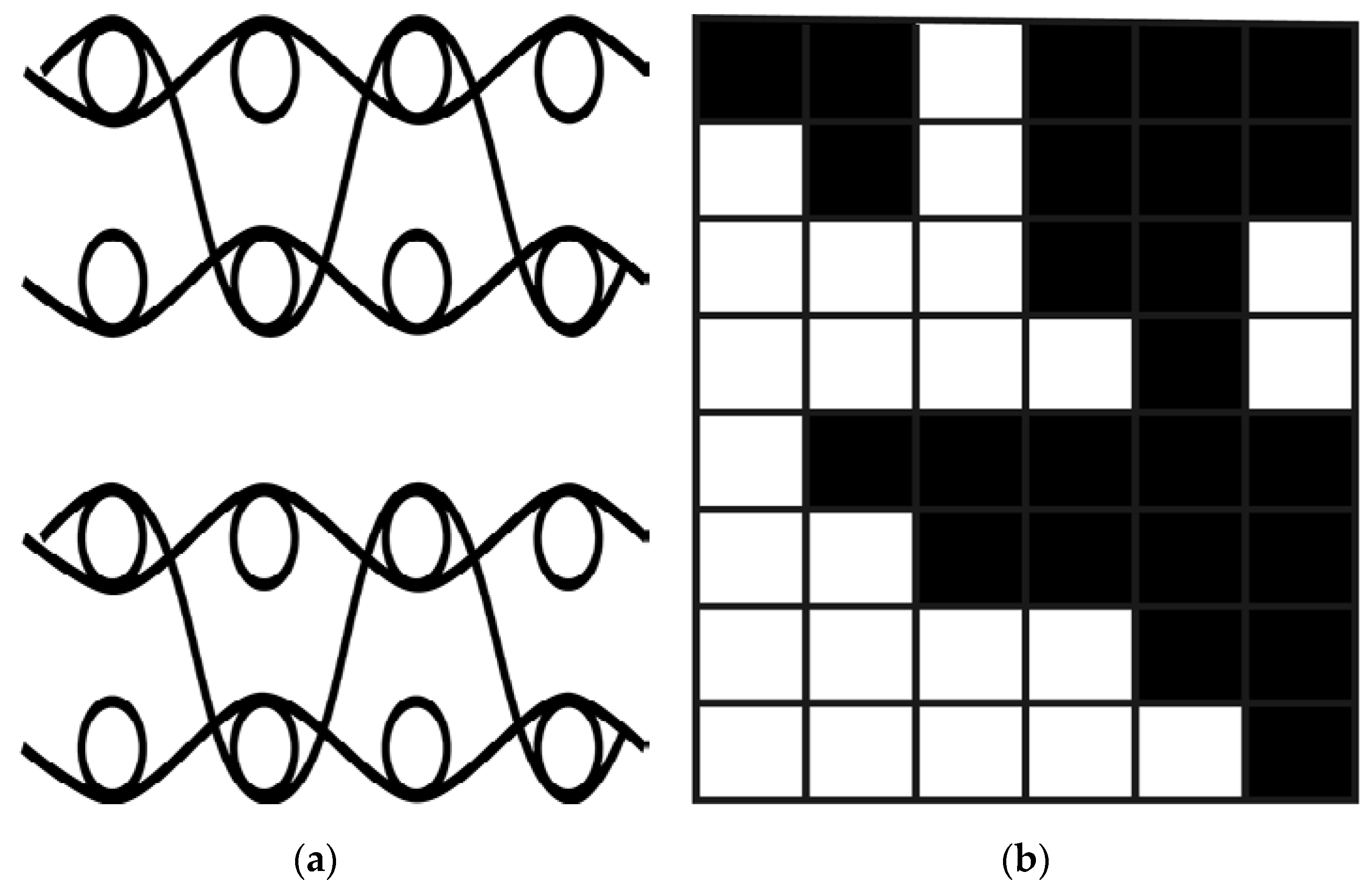

2.2. Design of the 3D Tubular Woven Fabric

2.3. Preparation of the 3D Tubular Woven Composites

3. Axial Compression Performance Testing

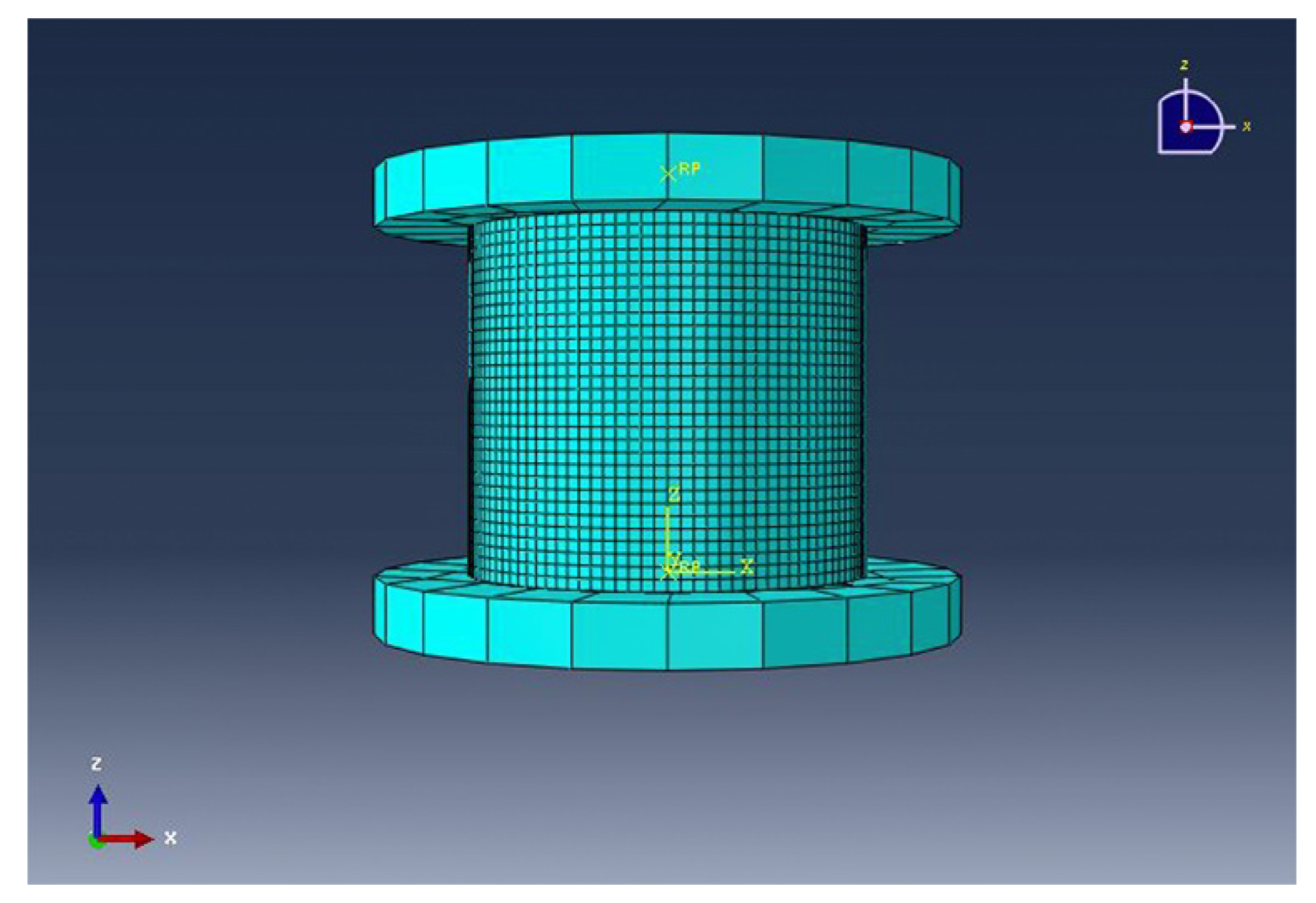

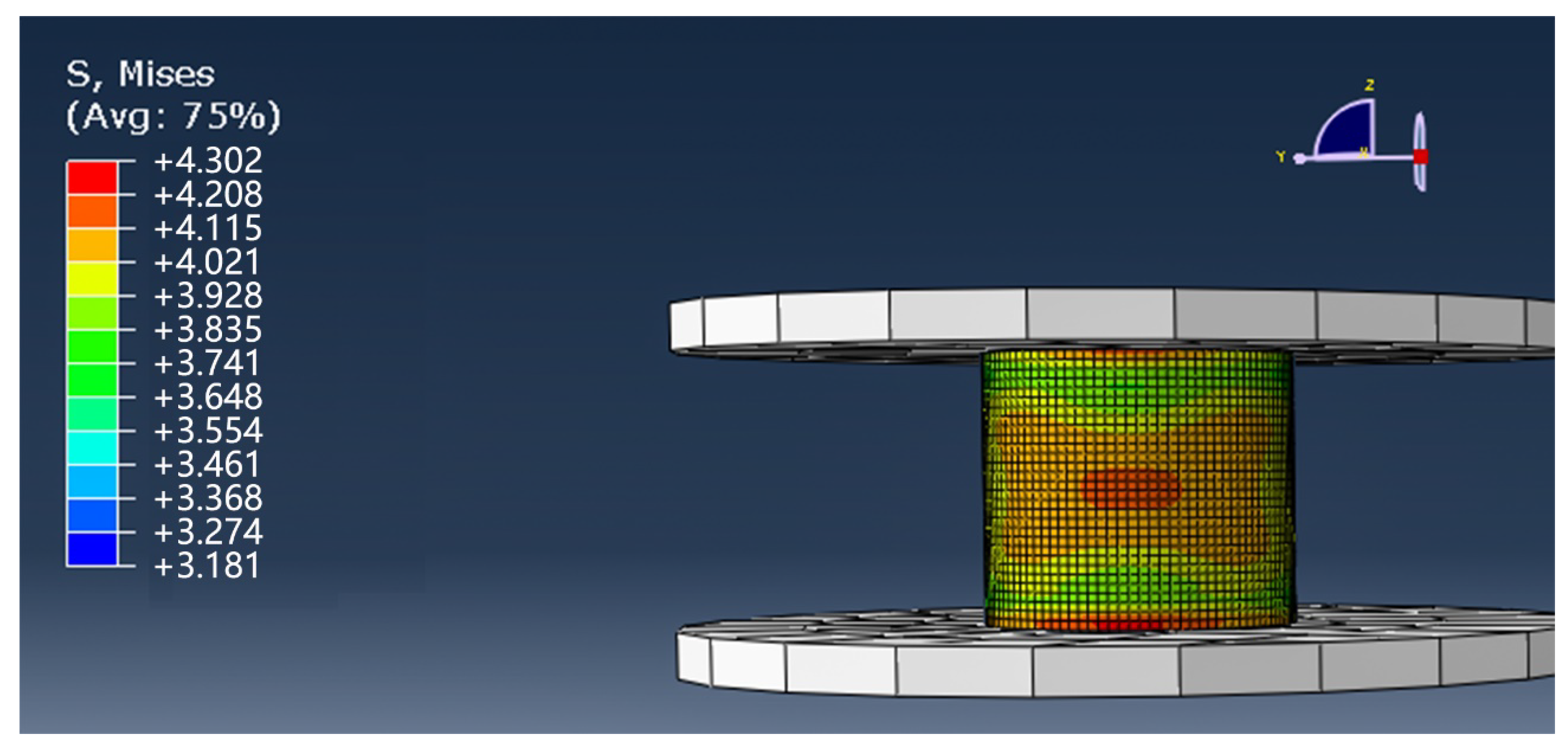

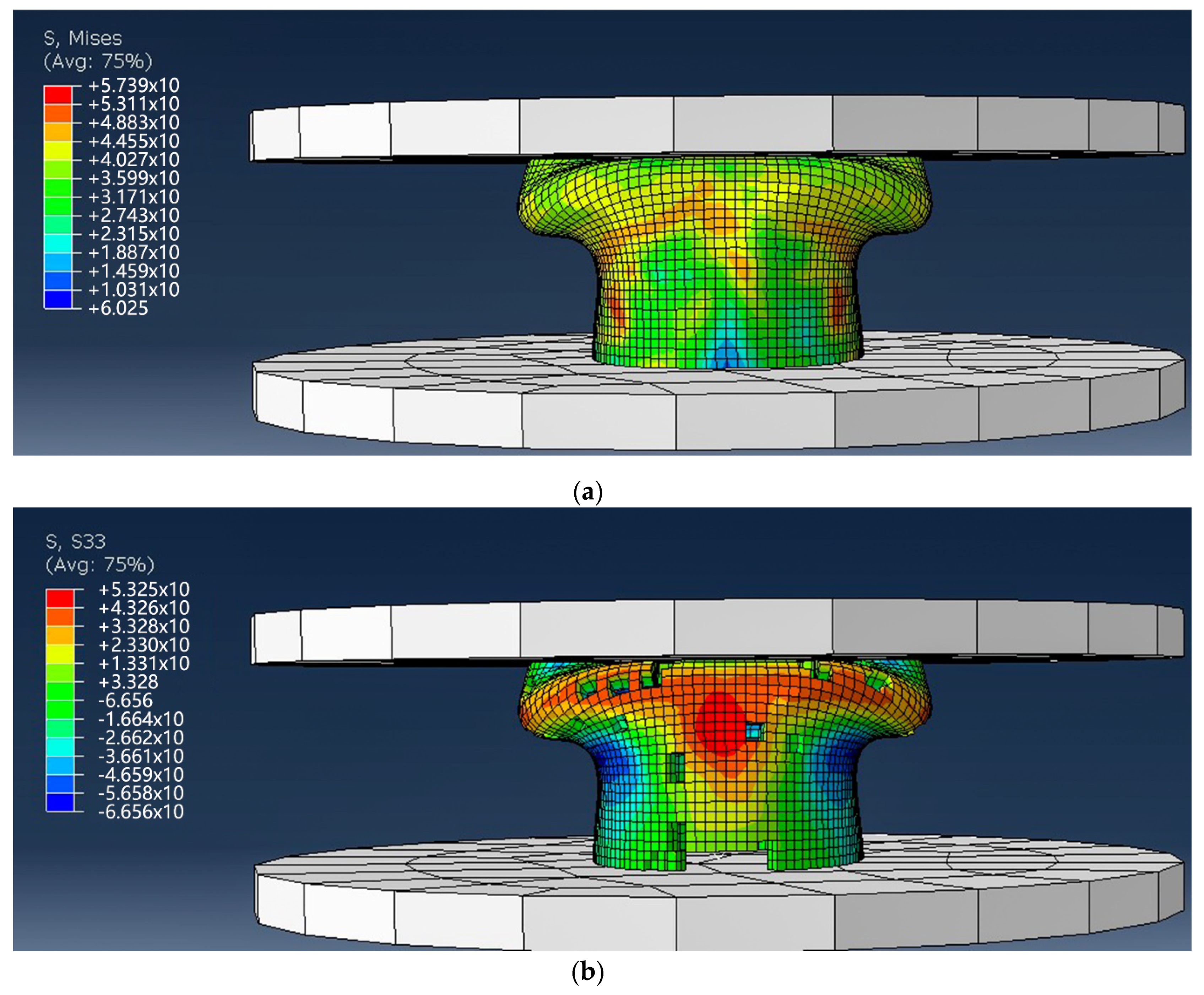

4. Finite Element Simulation and Analysis

4.1. Material Model

4.2. Mechanical Properties of Material

5. Results and Discussion

5.1. Load-Displacement Curve

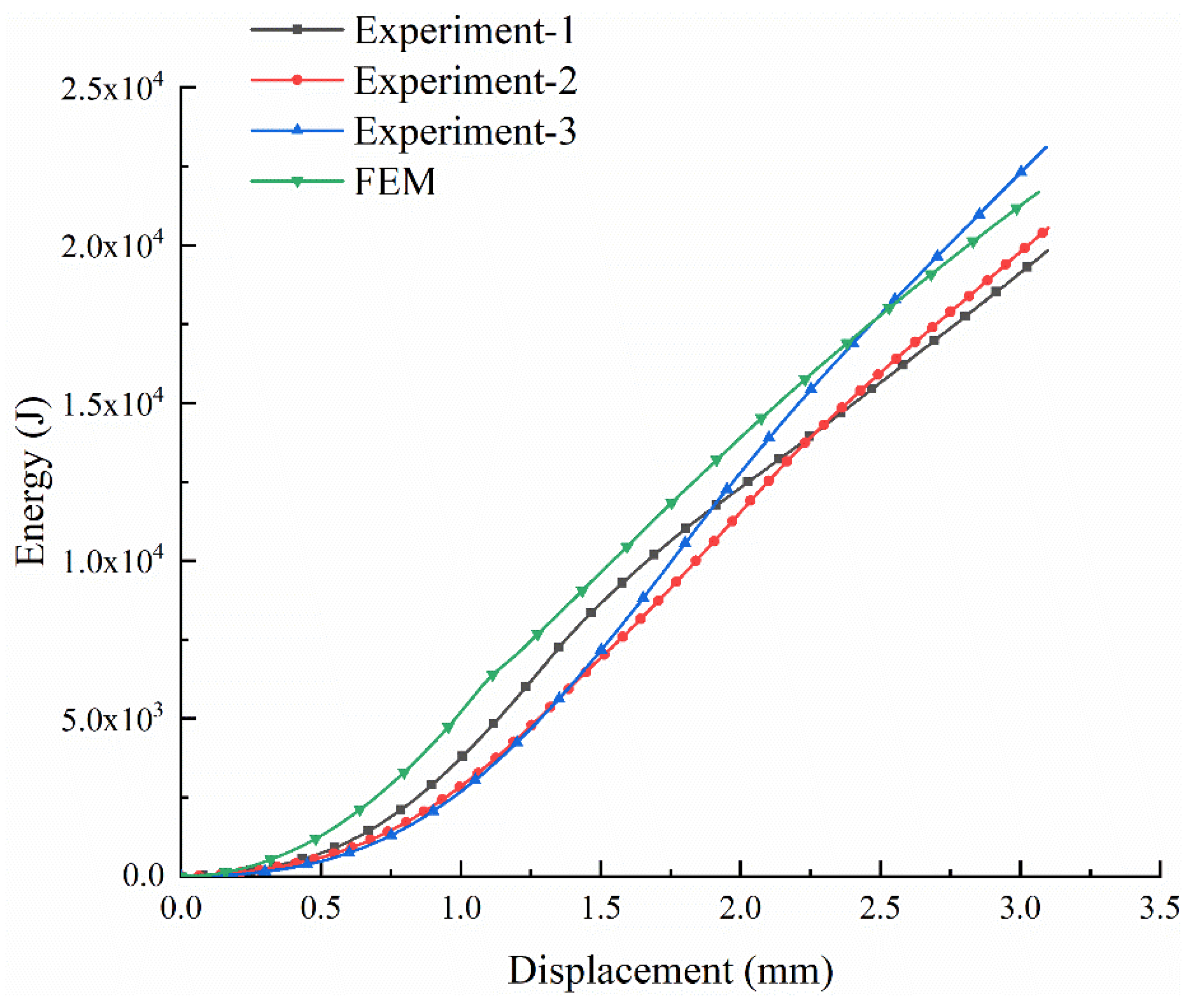

5.2. Energy Displacement Curve

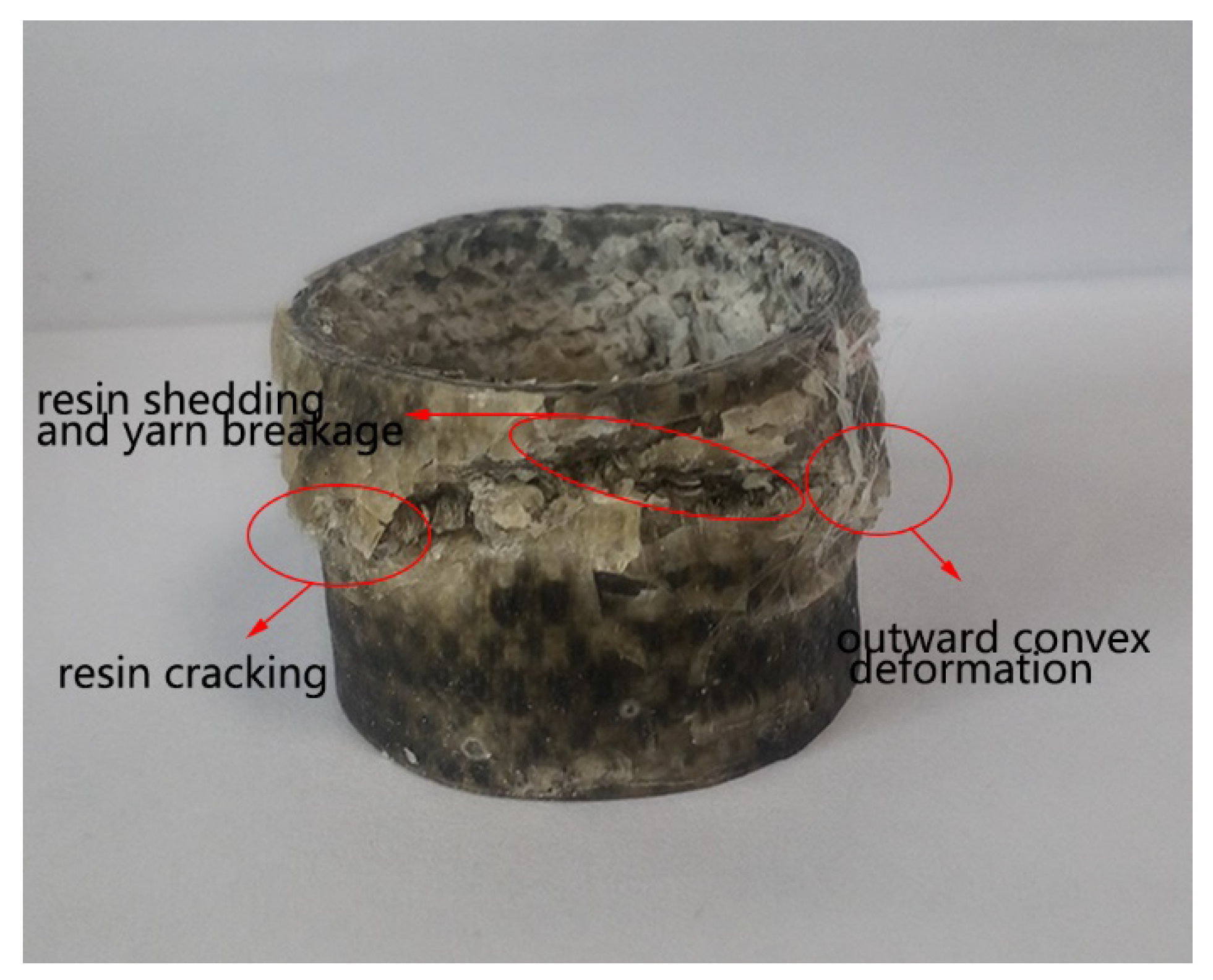

5.3. Failure Mode and Mechanism

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sinapius, M.; Jux, M.; Rolfes, R.; Fankhänel, J.; Daum, B.; Mahrholz, T. Mechanical properties of epoxy/boehmite nanocomposites in dependency of mass fraction and surface modification—An experimental and numerical approach. Polym. Int. J. Sci. Technol. Polym. 2018, 141, 34–45. [Google Scholar]

- Wang, L.L.; Xu, A.C.; Zhang, S.Y. Study on tensile mechanical properties of three-dimensional tubular composites. J. Wuhan Text. Univ. 2017, 30, 12–16. [Google Scholar]

- Zhang, S.J.; Wang, R.; Wang, H. Design principle of intensity of tubular textile composite material applied to pipeline rehabilitation. Acta Mater. Compos. Sin. 2008, 25, 161–165. [Google Scholar]

- Zhong, W.X.; Sun, X.L.; Ma, P.B. Application and development of tubular structural composites. Fiber Glass 2005, 1, 47–52. [Google Scholar]

- Bai, Y. New design of tubular fabric. Shanghai Text. Sci. Technol. 2004, 32, 28–29. [Google Scholar]

- Zhang, Q.L.; Zhou, R.; Fan, L. Research on hollow fabric design. J. Henan Text. Coll. 2001, 3, 13–15. [Google Scholar]

- Zheng, T.; Li, S.; Jing, S.; Ou, Y. Designing of 3D woven integrated T-joint tube. Text. Res. J. 2012, 83, 1143–1155. [Google Scholar] [CrossRef]

- Huang, H.L.; Shen, L.P.; Qi, M. Design of 3D shaped orthogonal polyester woven fabrics. Shanghai Text. Sci. Technol. 2015, 43, 68–70. [Google Scholar]

- Bilisik, K.; Mohamed, M.H. Multiaxis Three-dimensional Flat Woven Preform (Tube Rapier Weaving) and Circular Woven Preform (Radial Crossing Weaving). Text. Res. J. 2009, 79, 1067–1084. [Google Scholar] [CrossRef]

- Luo, S.H.; Yang, C.Y. Research progress on the mechanical properties of tubular composite. Tech. Text. 2015, 33, 1–5. [Google Scholar]

- Palanivelu, S.; Van Paepegem, W.; Degrieck, J.; Van Ackeren, J.; Kakogiannis, D.; Van Hemelrijck, D.; Wastiels, J.; Vantomme, J. Experimental study on the axial crushing behaviour of pultruded composite tubes. Polym. Test. 2010, 29, 224–234. [Google Scholar] [CrossRef]

- Rabiee, A.; Ghasemnejad, H. Progressive Crushing of Polymer Matrix Composite Tubular Structures: Review. Open J. Compos. Mater. 2017, 7, 14–48. [Google Scholar] [CrossRef]

- Palanivelu, S.; Van Paepegem, W.; Degrieck, J.; Kakogiannis, D.; Van Ackeren, J.; Van Hemelrijck, D.; Wastiels, J.; Vantomme, J. Comparative study of the quasi-static energy absorption of small-scale composite tubes with different geometrical shapes for use in sacrificial cladding structures. Polym. Test. 2010, 29, 381–396. [Google Scholar] [CrossRef]

- Zhang, Z.; Sun, W.; Zhao, Y.; Hou, S. Crashworthiness of different composite tubes by experiments and simulations. Compos. Part B Eng. 2018, 143, 86–95. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N. Crashworthiness characteristics of flax fibre reinforced epoxy tubes for energy absorption application. Mater. Des. 2013, 51, 629–640. [Google Scholar] [CrossRef]

- Abdewi, E.F.; Sulaiman, S.; Hamouda, A.; Mahdi, E. Quasi-static axial and lateral crushing of radial corrugated composite tubes. Thin Walled Struct. 2008, 46, 320–332. [Google Scholar] [CrossRef]

- Chambe, J.; Bouvet, C.; Dorival, O.; Ferrero, J. Energy absorption capacity of composite thin-wall circular tubes under axial crushing with different trigger initiations. J. Compos. Mater. 2019, 54, 1281–1304. [Google Scholar] [CrossRef]

- Kim, J.-S.; Yoon, H.-J.; Shin, K.B. A study on crushing behaviors of composite circular tubes with different reinforcing fibers. Int. J. Impact Eng. 2011, 38, 198–207. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Jayaraman, K. Lateral crushing of empty and polyurethane-foam filled natural flax fabric reinforced epoxy composite tubes. Compos. Part B Eng. 2014, 63, 15–26. [Google Scholar] [CrossRef]

- Sun, Z.H.; Chen, Y.; Zhou, S.H. Prediction of elasticity of circular woven 3D tubular carbon fiber composites. J. Text. Res. 2014, 35, 56–61. [Google Scholar]

- Han, H.P.; Taheri, F.; Pegg, N.; Lu, Y. A numerical study on the axial crushing response of hybrid pultruded and ±45° braided tubes. Compos. Struct. 2007, 80, 253–264. [Google Scholar] [CrossRef]

- Fan, P.; Chen, W.; Zhao, B.; Hu, J.; Gao, J.; Fang, G.; Peng, F. Formulation and numerical implementation of tensile shape memory process of shape memory polymers. Polymer 2018, 148, 370–381. [Google Scholar] [CrossRef]

- Zhu, L.; Lyu, L.; Zhang, X.; Wang, Y.; Guo, J.; Xiong, X. Bending Properties of Zigzag-Shaped 3D Woven Spacer Composites: Experiment and FEM Simulation. Materials 2019, 12, 1075. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.; Pan, Z.; Gideon, R.K.; Gu, B.; Sun, B. Experimental and numerical investigation of the transverse impact damage and deformation of 3-D circular braided composite tubes from meso-structure approach. Compos. Part B Eng. 2016, 86, 243–253. [Google Scholar] [CrossRef]

- Zhang, P.; Gui, L.; Fan, Z.-J.; Yu, Q.; Li, Z.-K. Finite element modeling of the quasi-static axial crushing of braided composite tubes. Comput. Mater. Sci. 2013, 73, 146–153. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, G.; Zhu, Y.; Zhang, L.; Shi, X.; Wang, W. Theoretical analysis of braiding strand trajectories and simulation of three-dimensional parametric geometrical models for multilayer interlock three-dimensional tubular braided preforms. Text. Res. J. 2019, 89, 4306–4322. [Google Scholar] [CrossRef]

- Sliseris, J.; Yan, L.; Kasal, B. Numerical Simulation and Experimental Verification of Hollow and Foam-Filled Flax-Fabric-Reinforced Epoxy Tubular Energy Absorbers Subjected to Crashing. Mech. Compos. Mater. 2017, 53, 487–496. [Google Scholar] [CrossRef]

- Wang, Y.-B.; Liu, Z.-G.; Liu, N.; Hu, L.; Wei, Y.-C.; Ou, J.-J. A new geometric modelling approach for 3D braided tubular composites base on Free Form Deformation. Compos. Struct. 2016, 136, 75–85. [Google Scholar] [CrossRef]

- Jang, K.-S. Mechanics and rheology of basalt fiber-reinforced polycarbonate composites. Polymer 2018, 147, 133–141. [Google Scholar] [CrossRef]

- Li, Z.; Ma, J. Experimental Study on Mechanical Properties of the Sandwich Composite Structure Reinforced by Basalt Fiber and Nomex Honeycomb. Materials 2020, 13, 1870. [Google Scholar] [CrossRef]

- Tan, J.T.; Ma, X.H.; Qin, Z.G. Study on axial compression properties of two-dimensional braided composite pipe fittings. Fiber Reinf. Plast. Compos. 2017, 12, 57–59. [Google Scholar]

- GB/T 1446-2005. Fiber-Reinforced Plastics Composites-The Generals for Determination of Properties; China Standard Press: Beijing, China, 2005. [Google Scholar]

| E11/Gpa | E22/Gpa | E33/Gpa | ν12 | ν23 | ν13 | G12/Gpa | G13/Gpa | G23/Gpa |

|---|---|---|---|---|---|---|---|---|

| 11.6 | 1.5 | 1.5 | 0.25 | 0.25 | 0.18 | 9.5 | 9.5 | 6 |

| Test Velocity/(mm × min−1) | FEM/KN | Experiment/KN | Error/% |

|---|---|---|---|

| 10 | 11,285 | 10,578 | 6.68 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, L.; Zhang, H.; Guo, J.; Wang, Y.; Lyu, L. Axial Compression Experiments and Finite Element Analysis of Basalt Fiber/Epoxy Resin Three-Dimensional Tubular Woven Composites. Materials 2020, 13, 2584. https://doi.org/10.3390/ma13112584

Zhu L, Zhang H, Guo J, Wang Y, Lyu L. Axial Compression Experiments and Finite Element Analysis of Basalt Fiber/Epoxy Resin Three-Dimensional Tubular Woven Composites. Materials. 2020; 13(11):2584. https://doi.org/10.3390/ma13112584

Chicago/Turabian StyleZhu, Liming, Huawei Zhang, Jing Guo, Ying Wang, and Lihua Lyu. 2020. "Axial Compression Experiments and Finite Element Analysis of Basalt Fiber/Epoxy Resin Three-Dimensional Tubular Woven Composites" Materials 13, no. 11: 2584. https://doi.org/10.3390/ma13112584

APA StyleZhu, L., Zhang, H., Guo, J., Wang, Y., & Lyu, L. (2020). Axial Compression Experiments and Finite Element Analysis of Basalt Fiber/Epoxy Resin Three-Dimensional Tubular Woven Composites. Materials, 13(11), 2584. https://doi.org/10.3390/ma13112584