Mechanical Behavior and Failure Mode of Steel–Concrete Connection Joints in a Hybrid Truss Bridge: Experimental Investigation

Abstract

1. Introduction

2. Experimental Program

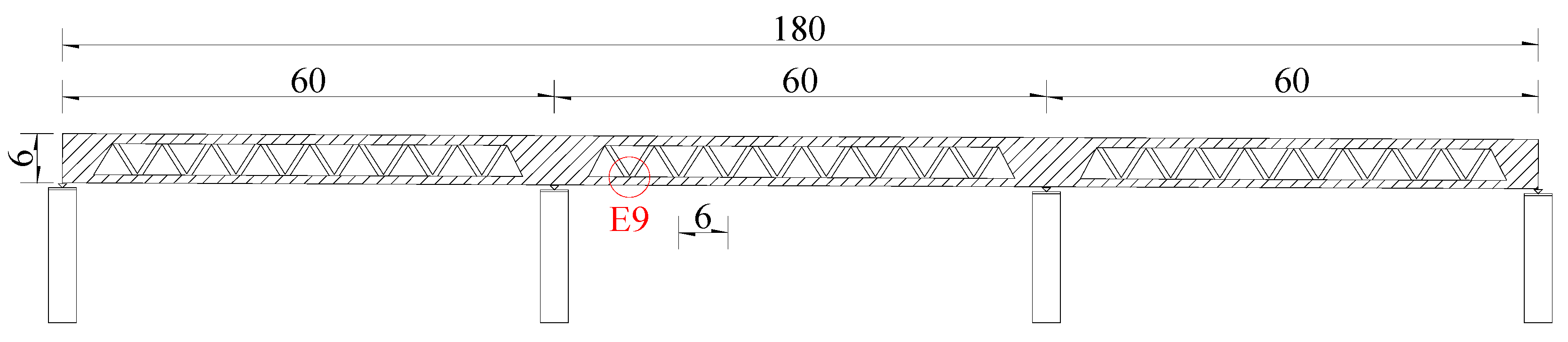

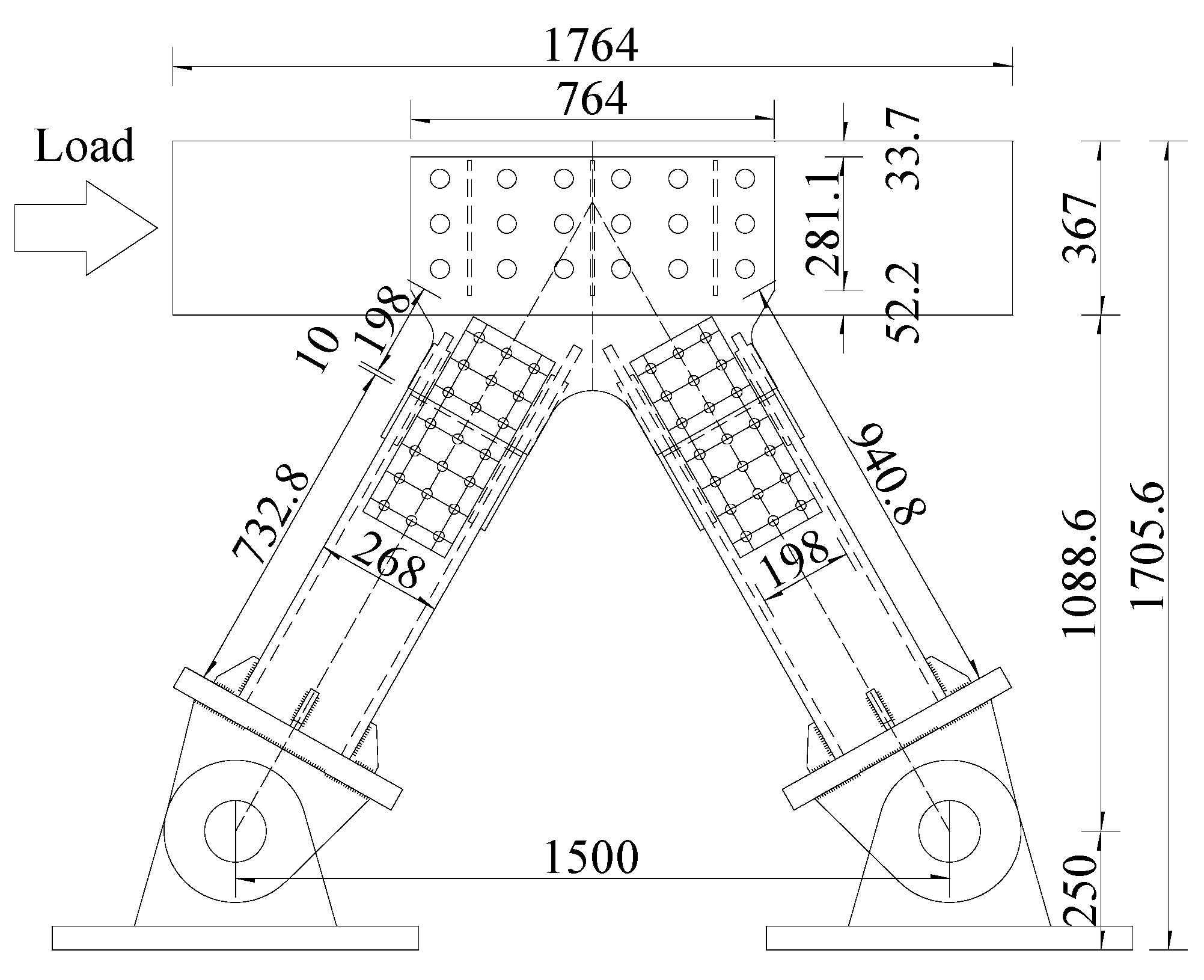

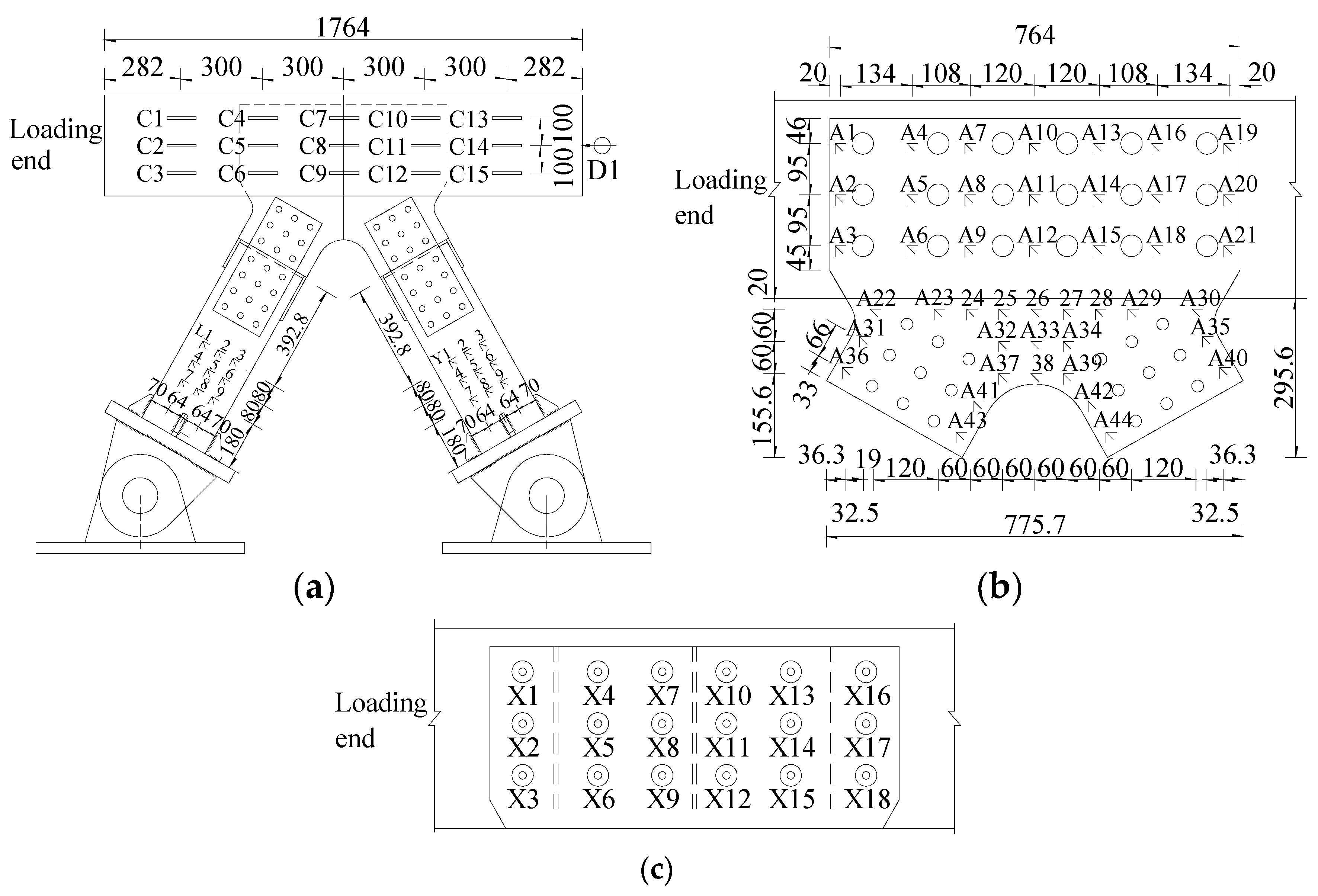

2.1. Specimens

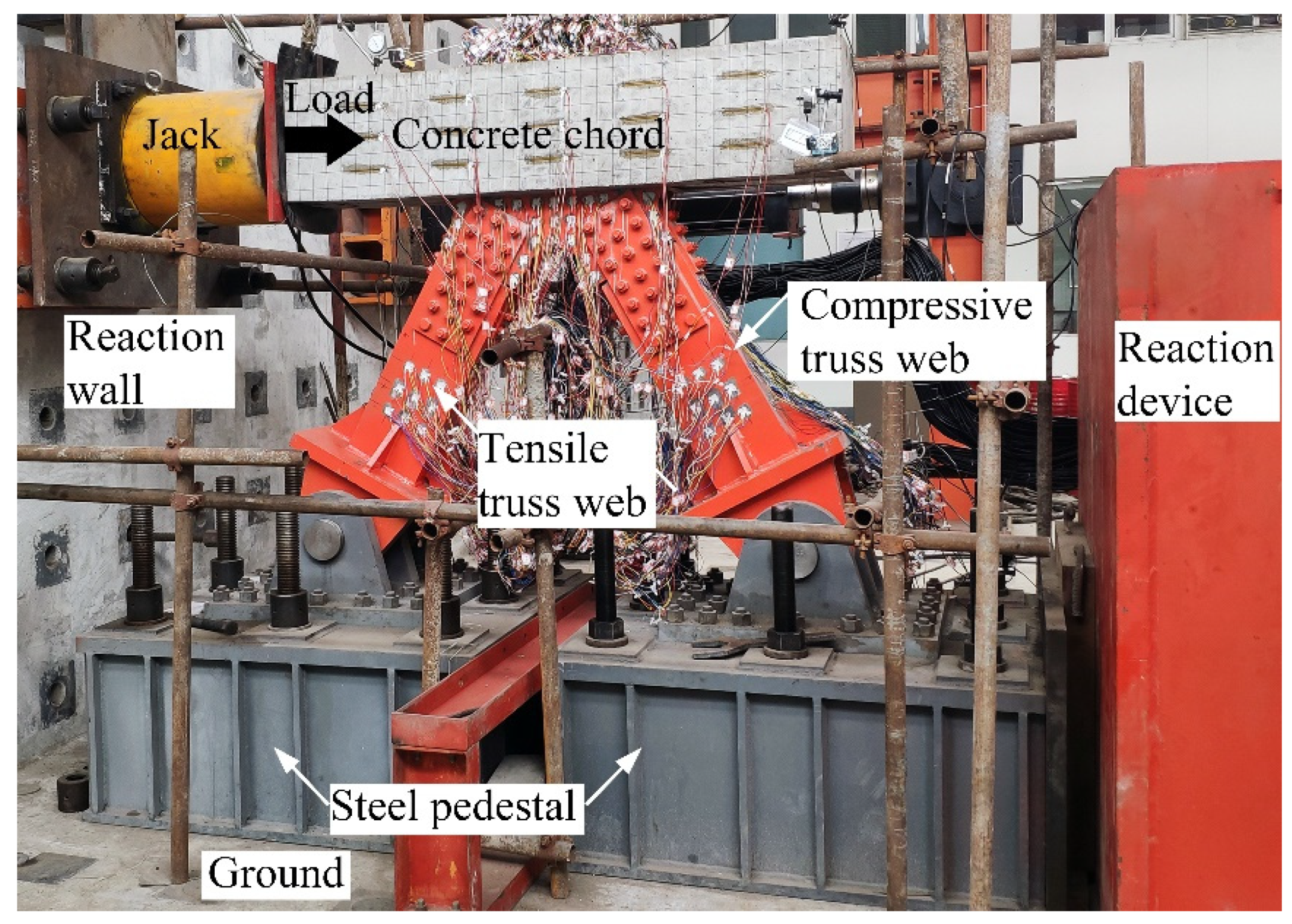

2.2. Experimental Setup and Testing Procedure

3. Experimental Results and Discussions

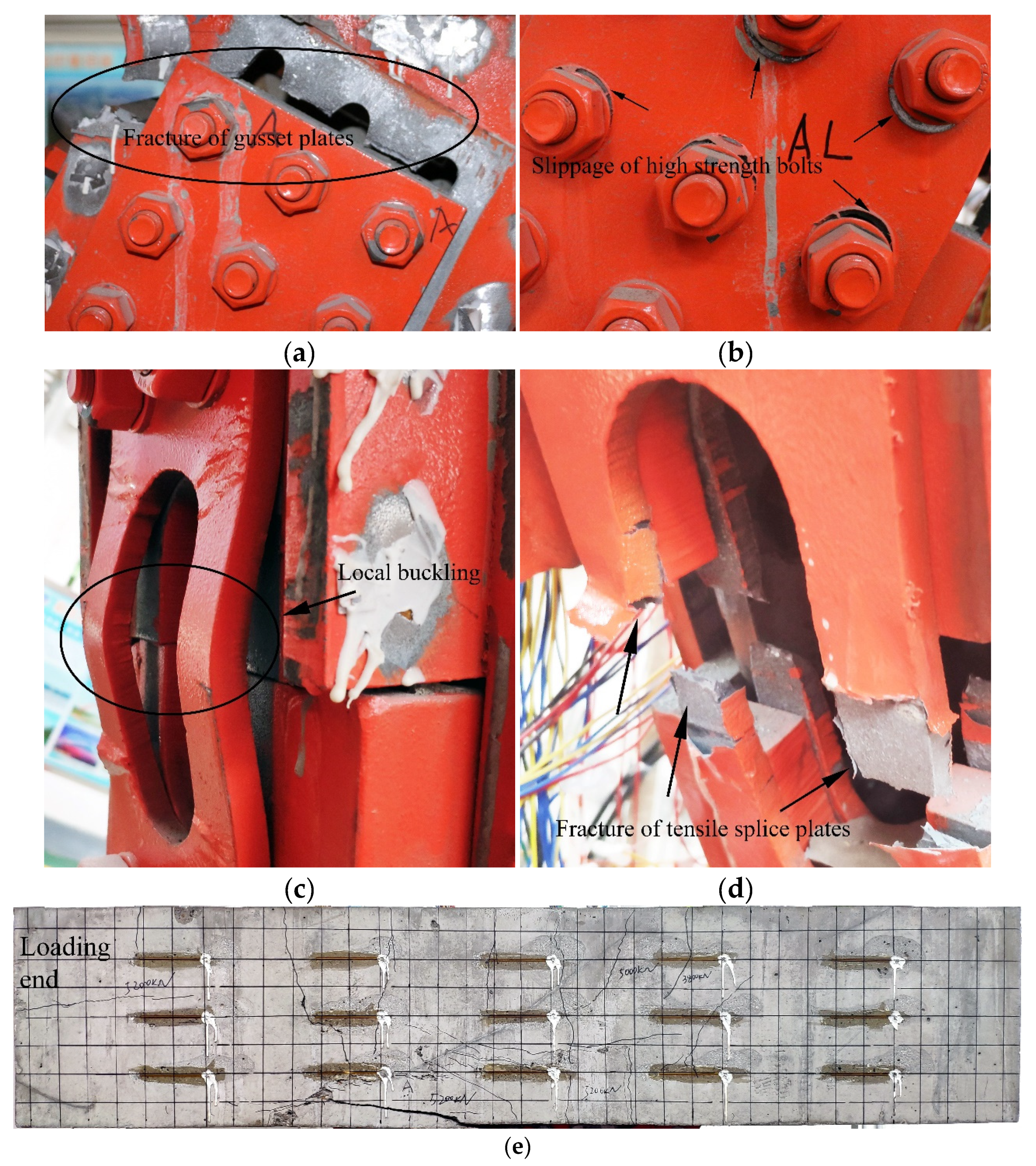

3.1. Experimental Phenomena and Failure Modes

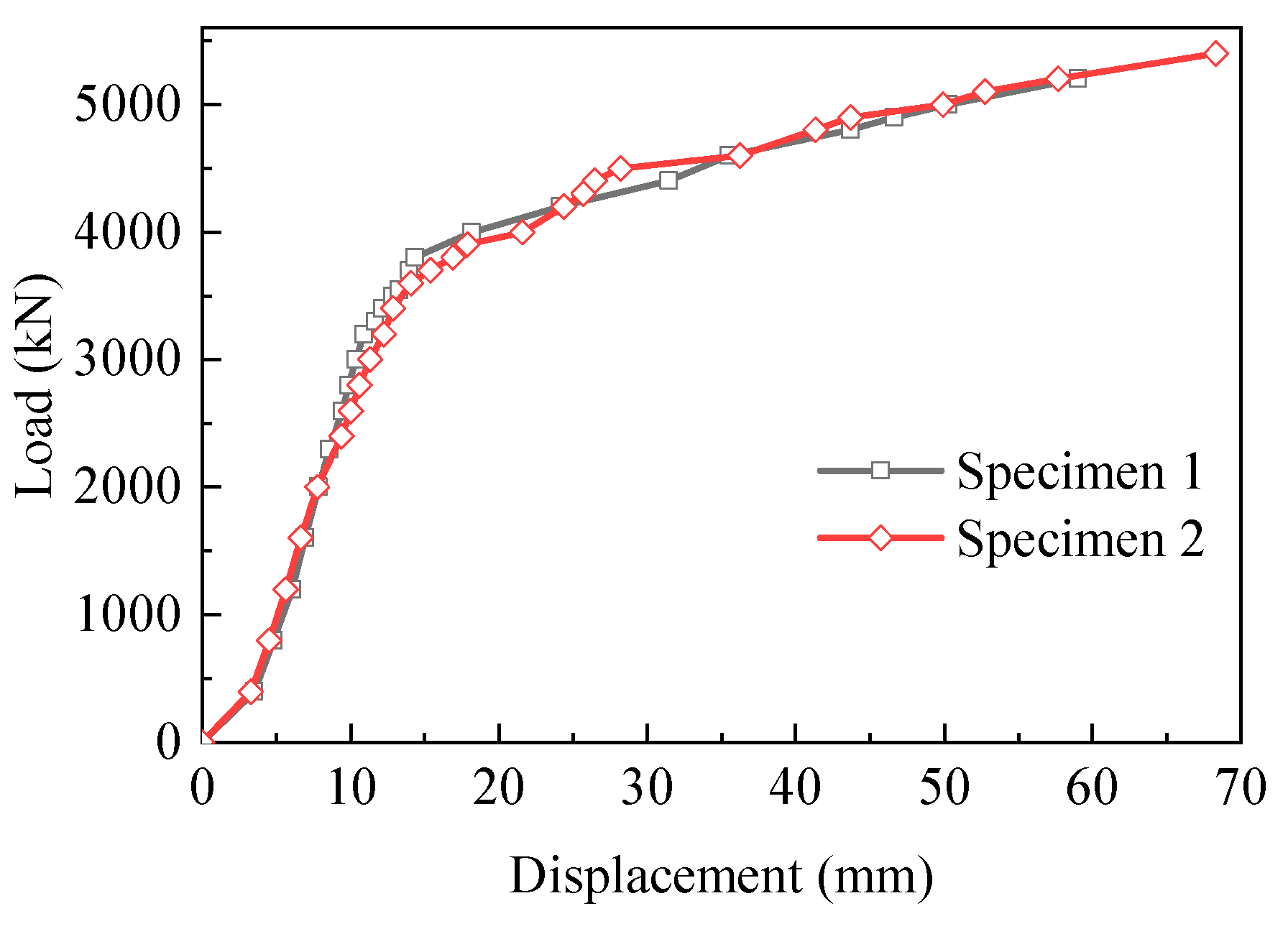

3.2. Load–Displacement Curves

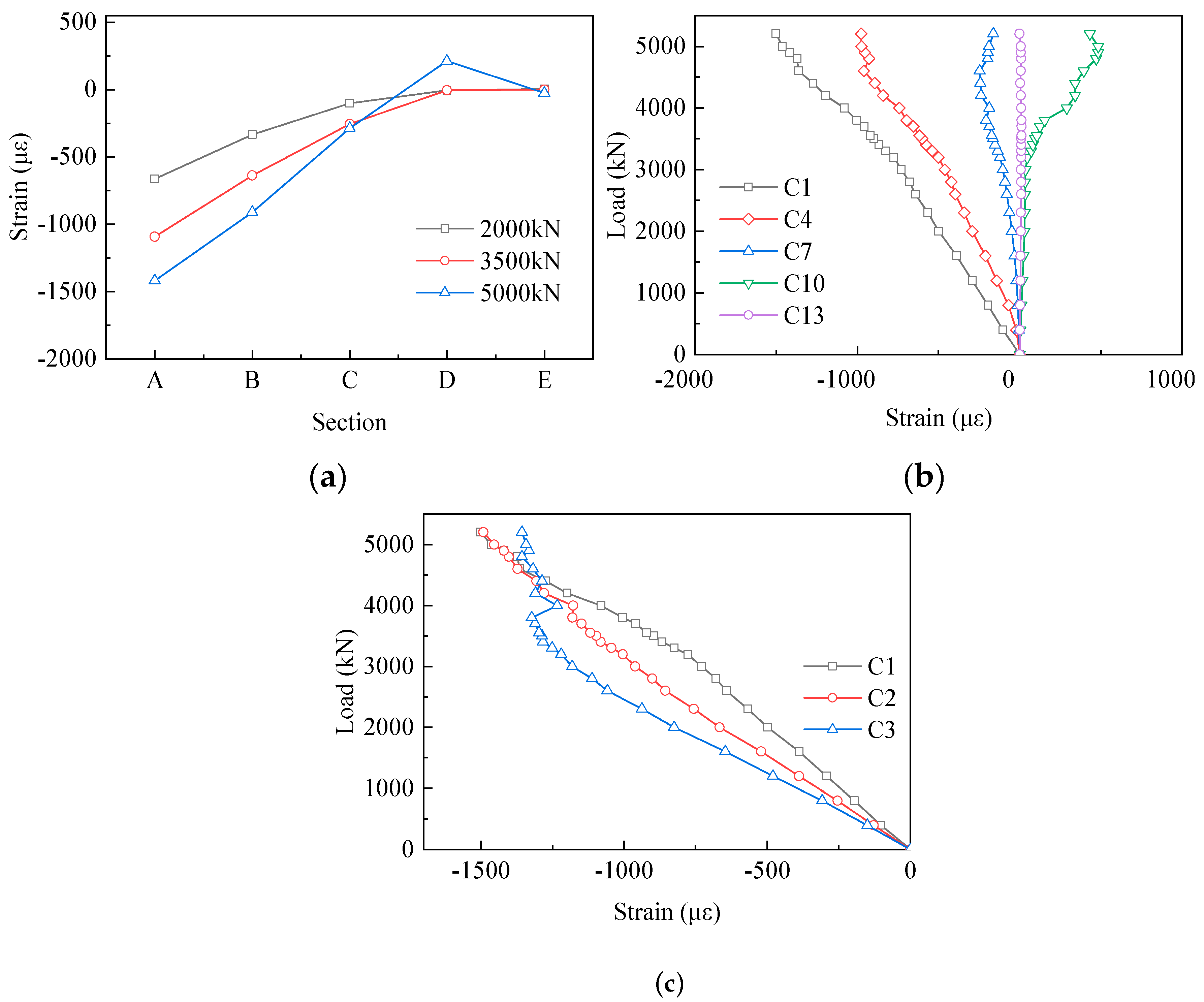

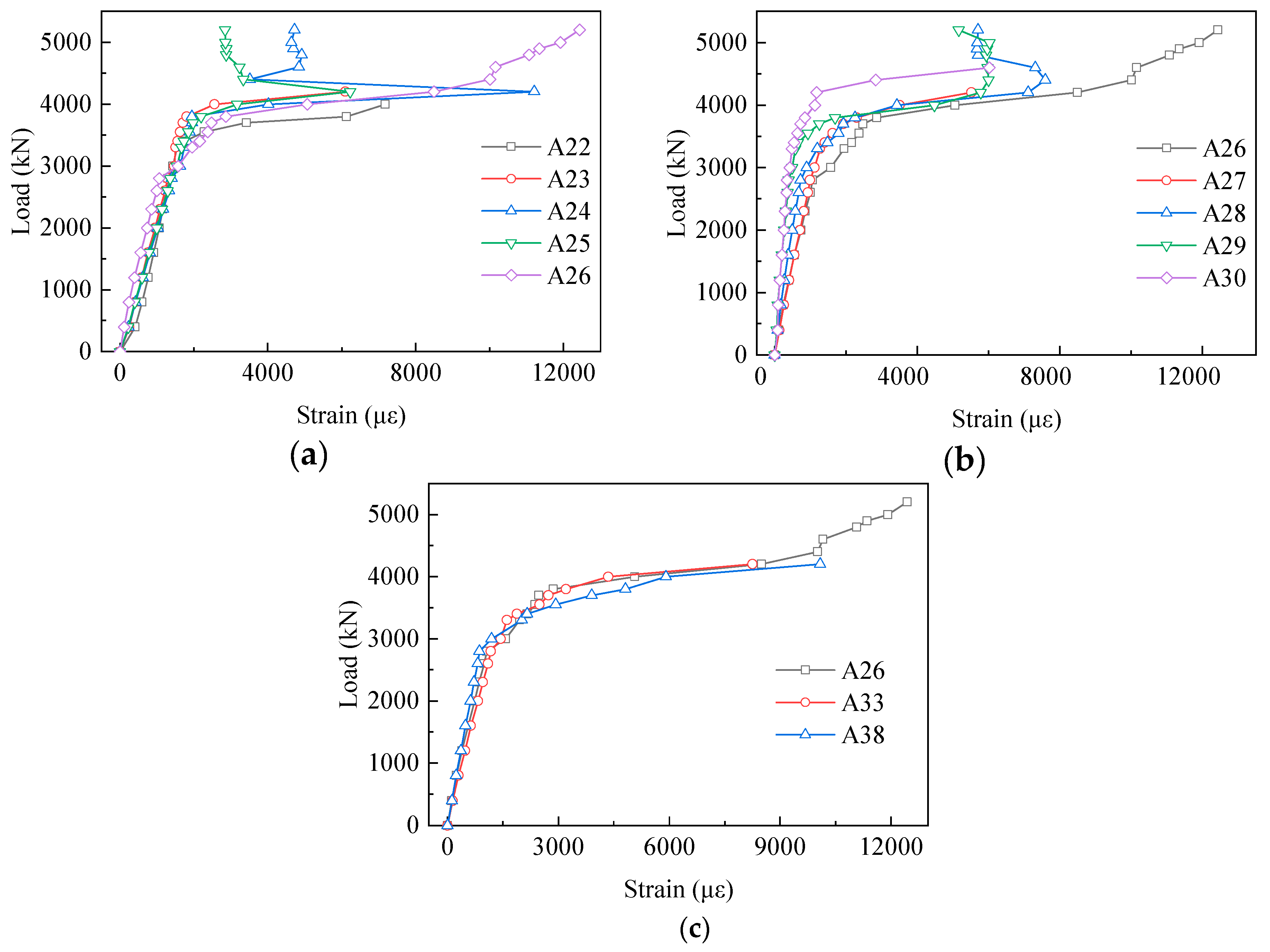

3.3. Load–Strain Curves of the Concrete Chord

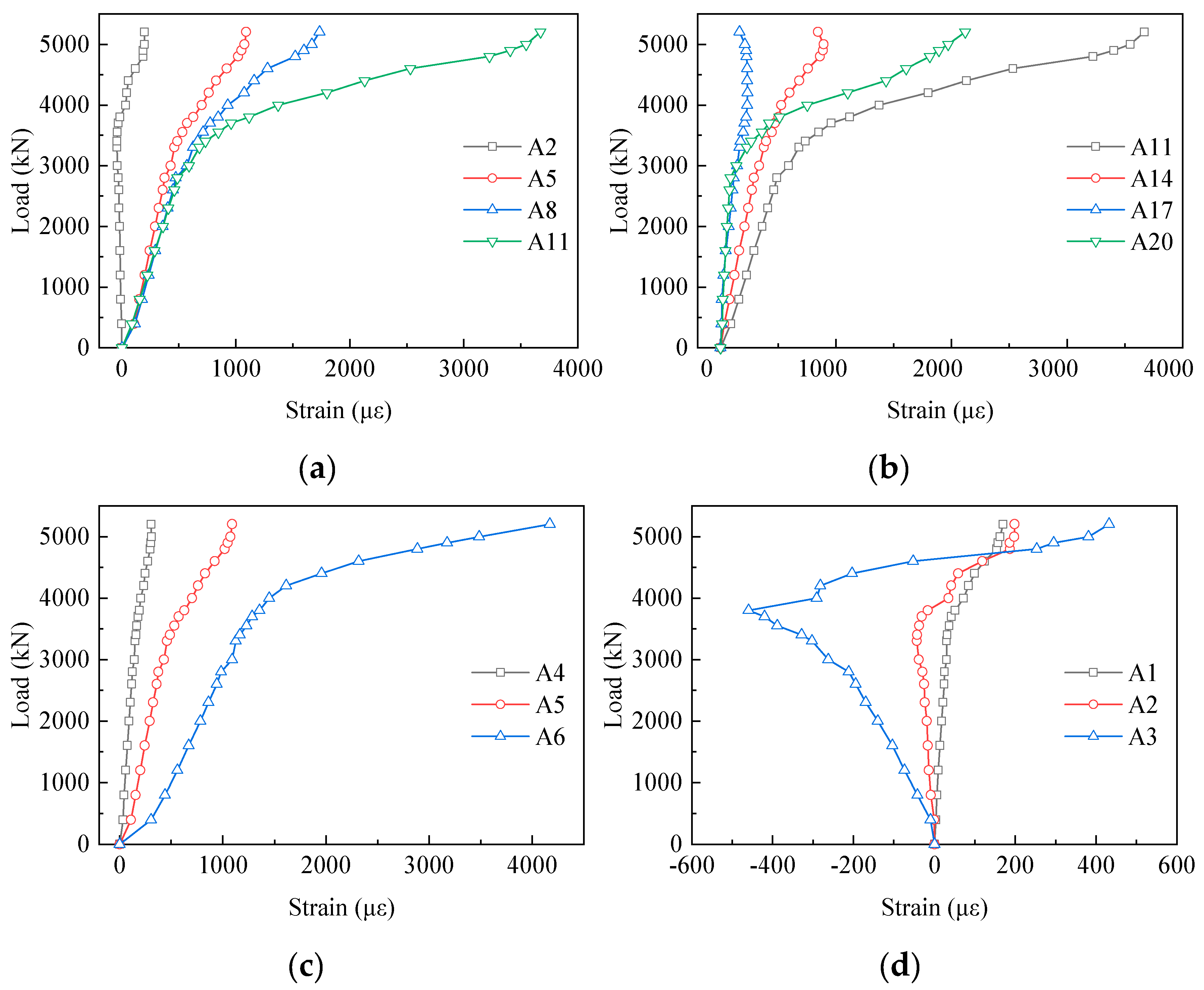

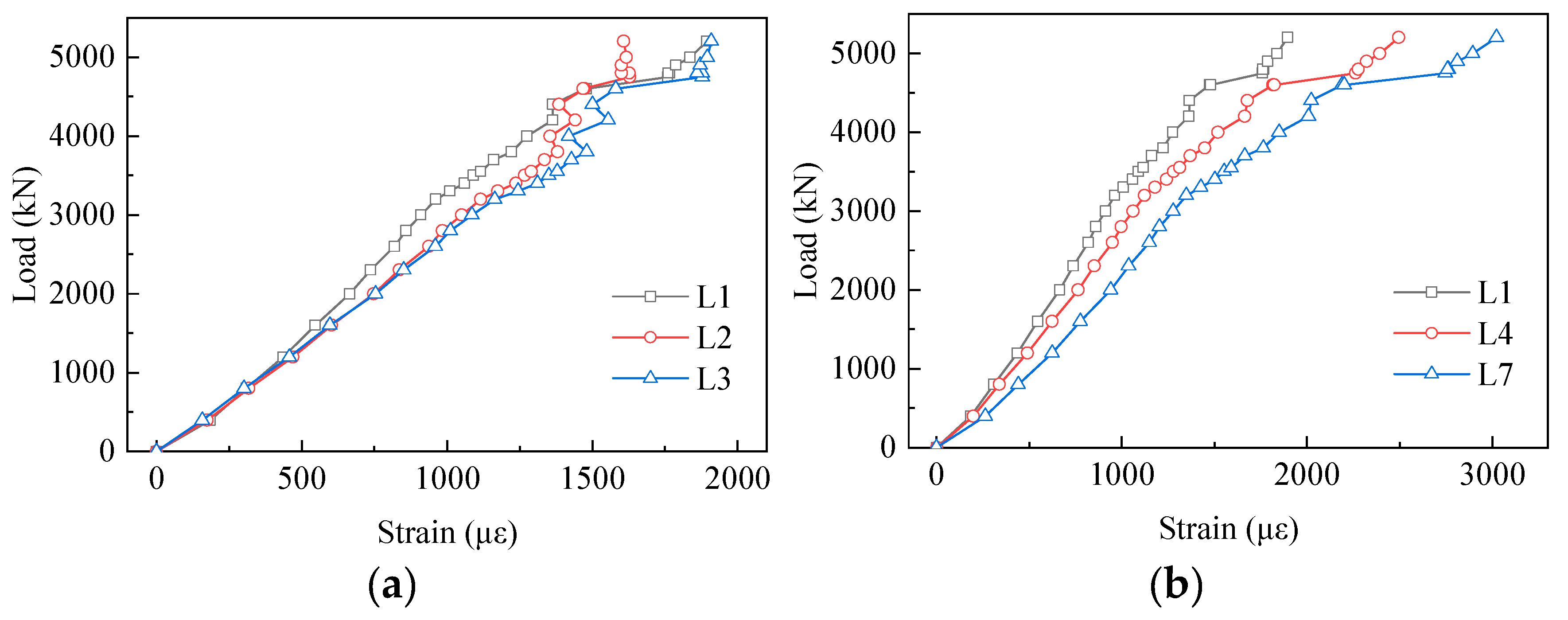

3.4. Load–Strain Curves of the Gusset Plates

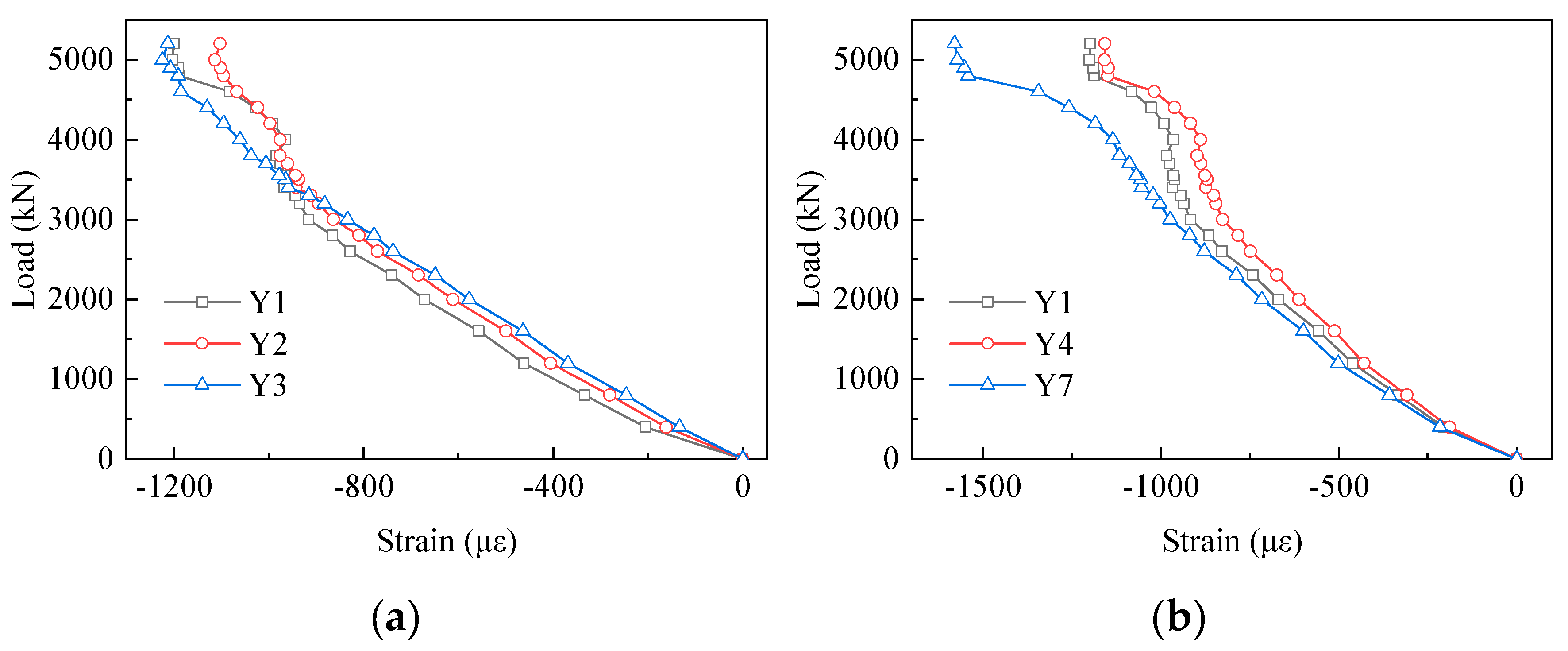

3.5. Load–Strain Curves of the Truss-Web Members

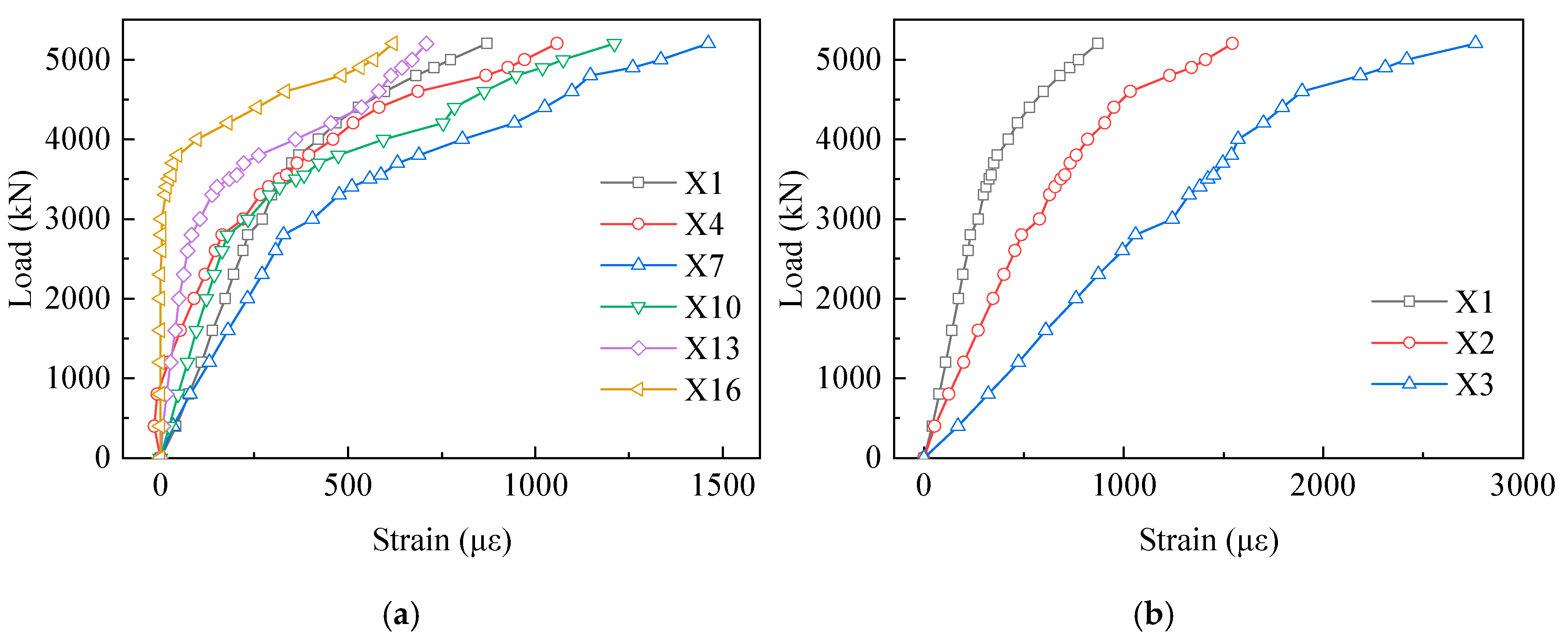

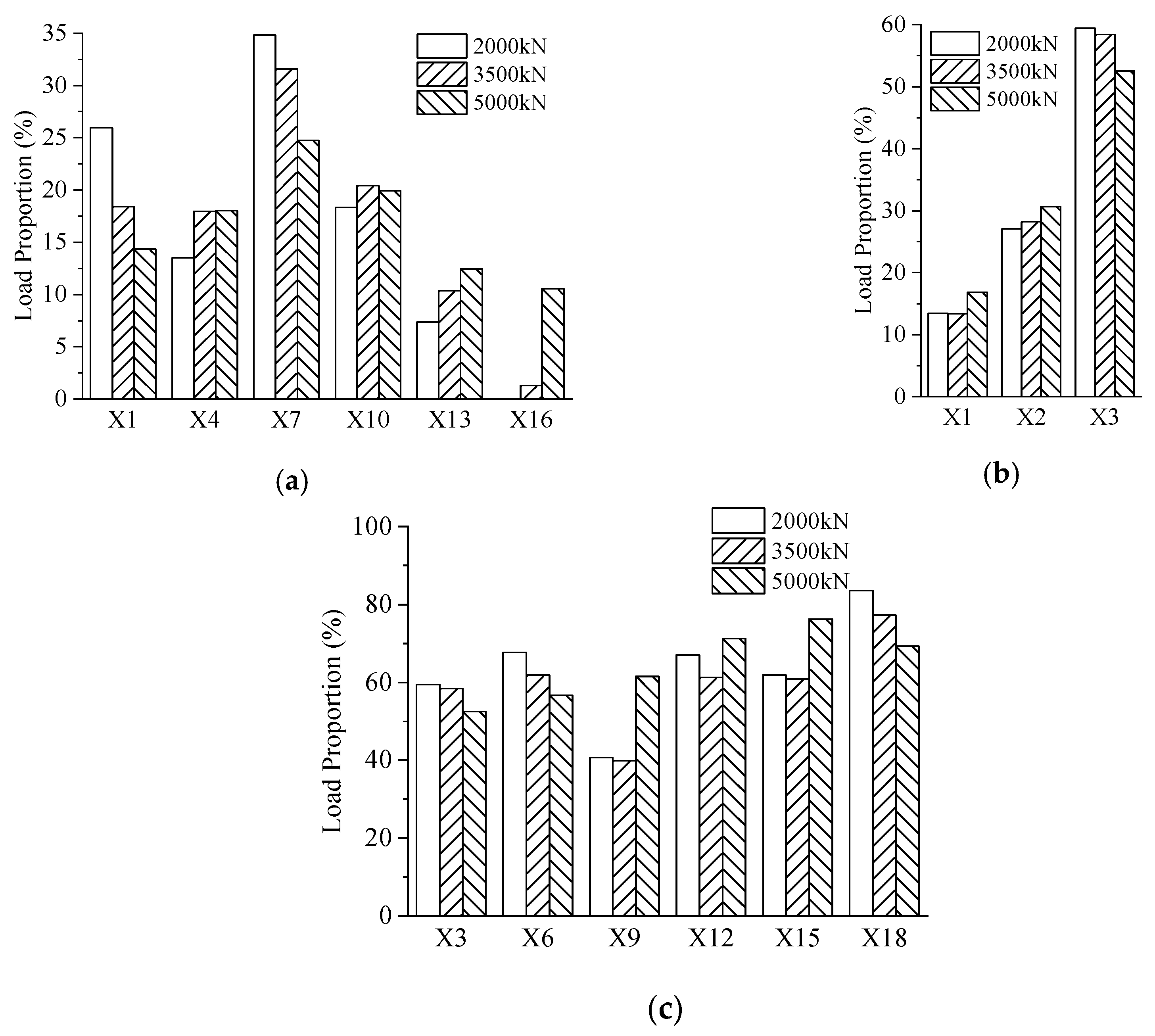

3.6. Load–Strain Curves of PBL Shear Connectors

4. Conclusions

- Compared with the previous experimental results in Table 3, the present results indicated that the proposed joints showed excellent bearing capacity and deformability. The yield load of Specimen 1 and Specimen 2 was 3200 kN and 3400 kN, respectively. The ultimate load of Specimen 1 and Specimen 2 was 5200 kN and 5400 kN, respectively. Furthermore, the ultimate displacement of Specimen 1 was 59.01 mm and the ultimate displacement of Specimen 2 reached 68.31 mm.

- In the experiments, Specimen 1 and Specimen 2 shared similar failure modes, such as the fracture of gusset plates, the slippage of high-strength bolts, the local buckling of compressive splice plates, the fracture of tensile splice plates and concrete cracking. In particular, the fracture of gusset plates, the slippage of high-strength bolts and concrete cracking were the most prominent failure modes. Moreover, it can be seen from the comparison of the failure modes between the proposed joints and the previous test specimens that the fracture of the gusset plates and the slippage of the high-strength bolts seemed to be two typical failure modes of such connection joints with high-strength bolts.

- The strain distribution of the steel–concrete connection joint followed certain rules. For the concrete chord, the strains decreased quickly in the loading direction. On the contrary, the strains increased in the vertical direction. For the gusset plates, in the loading direction, the strains reduced gradually from the middle to the edge. In the vertical direction, strains of the embedded gusset plate enhanced from the top to the bottom, but the strain variation tendency of the exposed gusset plate was not obvious. For the steel truss-web members, the areas near the inside of the angle between the tensile truss web and the compressive truss web had greater strain values than in other areas. For PBL shear connectors, the strain distribution patterns were in keeping with the patterns of the embedded gusset plates. The third-row PBL shear connectors resisted most of the load rather than the other two-row connectors.

- The exposed gusset plate was the key component of the steel–concrete connection joint to resist the load. The exposed gusset plate was at a higher strain level than the other members at the same loading step. Under the extreme condition, the exposed gusset plates of both specimens experienced a severe tensile fracture and were therefore unable to continue to bear the load. Furthermore, in the ultimate state, the fracture of the gusset plates prevented the specimen from continuing to bear the external load.

Author Contributions

Funding

Conflicts of Interest

References

- Jung, K.H.; Lee, S.H.; Yi, J.W.; Kim, J.H.J.; Ha, J.H. Fatigue capacity of a new connection system for a prestressed concrete hybrid truss web girder. Mag. Concr. Res. 2012, 64, 665–672. [Google Scholar] [CrossRef]

- Pham, X.T. A new generation of composite bridges, The Boulonnais Viaducts in France. Proc. FIP Symp. Lisbon Port. 1997, 2, 909–916. [Google Scholar]

- Tanis, J.-M. Bras de la Plaine Bridge, Reunion Island, France. Struct. Eng. Int. 2003, 13, 259–262. [Google Scholar] [CrossRef]

- Dauner, H.; Oribasi, A.; Wery, D. The Lully Viaduct, a composite bridge with steel tube truss. J. Constr. Steel Res. 1998, 46, 67–68. [Google Scholar] [CrossRef]

- Bacchetta, A.; Dauner, H.G. The Dreirosenbridge over the Rhine at Basel. In Proceedings of the IABSE Congress Report, Lucerne, Switzerland, 1 January 2000; International Association for Bridge and Structural Engineering. pp. 440–447. [Google Scholar]

- Reis, A.J.; Pedro, J.J.O. The Europe Bridge in Portugal: Concept and structural design. J. Constr. Steel Res. 2004, 60, 363–372. [Google Scholar] [CrossRef]

- Liu, Y.; Xiong, Z.; Luo, Y.; Cheng, G.; Liu, G.; Yang, J. Double-composite rectangular truss bridge and its joint analysis. J. Traffic Transp. Eng.-Engl. Ed. 2015, 2, 249–257. [Google Scholar] [CrossRef][Green Version]

- Hanswille, G. Composite bridges in Germany designed according to Eurocode 4-2. In Composite Construction in Steel and Concrete VI; American Society of Civil Engineers: Reston, VA, USA, 2001; pp. 391–405. [Google Scholar]

- Aoki, K.; Takatoku, Y.; Notoya, H.; Uehira, Y.; Kato, T.; Yamaguchi, T. Design and construction of Sarutagawa bridge and Tomoegawa bridge. Bridge Found. 2005, 39, 2–11. [Google Scholar]

- Minami, H.; Yamamura, M.; Taira, Y.; Furuichi, K. Design of the Kinokawa viaduct composite truss bridge. In Proceedings of the 1st JSCE Congress, Composite Structures, Osaka, Japan, 13–19 October 2002; pp. 371–380. [Google Scholar]

- Jung, K.H.; Kim, J.H.J.; Yi, J.W.; Lee, S.H. Development and Evaluation of New Connection Systems for Hybrid Truss Bridges. J. Adv. Concr. Technol. 2013, 11, 61–79. [Google Scholar] [CrossRef]

- Furuichi, K.; Yamamura, M.; Nagumo, H.; Yoshida, K.; Eligehausen, R. Experimental study on a new joint for prestressed concrete composite bridge with steel truss web. In Proceedings of the International Symposium on Connections between Steel and Concrete, RILEM Publications SARL, Bagneux, France, 10–12 September 2001; pp. 1250–1259. [Google Scholar]

- Jung, K.H.; Yi, J.W.; Kim, J.H.J. Structural safety and serviceability evaluations of prestressed concrete hybrid bridge girders with corrugated or steel truss web members. Eng. Struct. 2010, 32, 3866–3878. [Google Scholar] [CrossRef]

- Yoshioka, T. The latest technologies of prestressed concrete bridges in Japan. In Proceedings of the JSCE-VIFCEA Joint Seminar on Concrete Engineering in Vietnam, Ho Chi Minh City, Vietnam, 8–9 December 2005; pp. 72–86. [Google Scholar]

- Furuichi, K.; Hishiki, Y.; Yoshida, K.; Honda, T.; Yamamura, M.; Minami, H. The proposal of a design method of the joint structure for the steel/concrete truss bridge. Proc. Jpn. Soc. Civ. Eng. 2006, 62, 349–366. [Google Scholar] [CrossRef]

- Weiguo, Y. Study on New Joint Structure in Steel Truss-web Bridge. J. Highw. Transp. Res. Dev. 2013, 30, 61–66. [Google Scholar]

- Xue, D.; Liu, Y.; He, J.; Ma, B. Experimental study and numerical analysis of a composite truss joint. J. Constr. Steel Res. 2011, 67, 957–964. [Google Scholar] [CrossRef]

- Zhou, L.; He, G. Model test for the end joint of long-span steel-concrete composite truss railway bridges. China Civ. Eng. J. 2012, 45, 92–99. [Google Scholar]

- He, J.; Xin, H.; Liu, Y.; Ma, B.; Han, B. Mechanical Performance of Composite Truss Bridge with Double Decks. IABSE Congr. Rep. 2012, 18, 1025–1032. [Google Scholar] [CrossRef]

- Choi, J.-H.; Jung, K.-H.; Kim, T.-K.; Kim, J.-H.J. Analytical and Experimental Studies on Torsional Behavior of Hybrid Truss Bridge Girders with Various Connection Joints. J. Adv. Concr. Technol. 2014, 12, 478–495. [Google Scholar] [CrossRef]

- Liu, Y.; Xin, H.; He, J.; Xue, D.; Ma, B. Experimental and analytical study on fatigue behavior of composite truss joints. J. Constr. Steel Res. 2013, 83, 21–36. [Google Scholar] [CrossRef]

- Jung, K.-H.; Lee, S.-H.; Yi, J.-W.; Choi, J.-H.; Kim, J.-H.J. Torsional Behavior of Hybrid Truss Bridge according to Connection Systems. J. Korea Concr. Inst. 2013, 25, 63–72. [Google Scholar] [CrossRef][Green Version]

- Yin, G.; Ding, F.; Wang, H.; Bai, Y.; Liu, X. Connection Performance in Steel-Concrete Composite Truss Bridge Structures. J. Bridge Eng. 2016, 22, 04016126. [Google Scholar] [CrossRef]

- Tan, Y.; Zhu, B.; Yan, T.; Huang, B.; Wang, X.; Yang, W.; Huang, B. Experimental Study of the Mechanical Behavior of the Steel-Concrete Joints in a Composite Truss Bridge. Appl. Sci. 2019, 9, 854. [Google Scholar] [CrossRef]

- Miwa, H. Experimental Study on the Mechanical Behaviour of Panel Joints in PC Hybrid Truss Bridges. J. Struct. Eng. 1998, 44, 1475–1483. [Google Scholar]

- Sakai, Y.; Hosaka, T.; Isoe, A.; Ichikawa, A.; Mitsuki, K. Experiments on concrete filled and reinforced tubular K-joints of truss girder. J. Constr. Steel Res. 2004, 60, 683–699. [Google Scholar] [CrossRef]

- Shoji, A.; Kondo, T.; Osugi, T.; Sonoda, K. A Study on Panel Point of a PC Bridge with Steel Truss Webs. Proc. Jpn. Soc. Civ. Eng. 2004, 2004, 75–89. [Google Scholar]

- Toshio, N.; Satoru, O.; Toshiaki, K. A study on structural performance of joint in PC hybrid truss bridge. Rep. Obayashi Corp. Tech. Res. Inst. 2004, 68, 1–6. [Google Scholar]

- Sato, Y.; Hino, S.I.; Sonoda, Y.; Yamaguchi, K.; Cheon, S.B. Study on load transfer mechanism of the joint in hybrid truss bridge. J. Struct. Eng. A 2008, 54, 778–785. [Google Scholar] [CrossRef]

- Yin, G.; Wang, H. Study on ultimate bearing capacity of steel-concrete composite truss bridge bottom-chord joints. China Civ. Eng. J. 2016, 49, 88–95. [Google Scholar]

- Zhou, L.; He, G. Experimental research on end joint of steel-concrete composite truss. Balt. J. Road Bridge E 2012, 7, 305–313. [Google Scholar] [CrossRef]

- Maojun, D.; Zhao, L.; Jiandong, Z.; Duo, L. Experimental Study on New PBL-Steel Tube Joint for Steel Truss-Webbed Concrete Slab Composite Bridges. J. Southeast Univ. (Nat. Sci. Ed.) 2016, 46, 572–577. [Google Scholar]

| Member | Material | (MPa) | or (MPa) | or (GPa) |

|---|---|---|---|---|

| Concrete | C50 | N/A | 61.3 | 34.6 |

| Gusset plate | Q370qE | 452 | 583 | 206 |

| Steel web | Q370qE | 439 | 557 | 206 |

| Reinforcement | HRB400 | 458 | 640 | 203 |

| Joint Type | Specimen | Concrete Chord (mm) | Gusset Plate (mm) | Truss Web (mm) | Failure Modes |

|---|---|---|---|---|---|

| A | RGP-1 [23,30] | 517 × 833 | 12 | 217 × 183 × 12 | 5,7 |

| RGP-2,3 [23,30] | 517 × 833 | 12 | 217 × 183 × 22 | 1,2 | |

| SJ-1 [18] | 367 × 400 | 8 | 217 × 183 × 12 | 8 | |

| SJ-2 [18] | 367 × 400 | 8 | 217 × 183 × 12 | 1,2 | |

| Specimen 1 | 334 × 367 | 16 | 268 × 184 × 20 | 1,2,3,4,6 | |

| Specimen 2 | 334 × 367 | 16 | 268 × 184 × 20 | 1,2,3,4,6 | |

| B | JSGP-1 [23] | 517 × 833 | N/A | 217 × 183 × 12 | 5 |

| JSGP-2 [23] | 517 × 833 | N/A | 217 × 183 × 22 | 6 | |

| PSGP-1 [23] | 517 × 833 | N/A | 217 × 183 × 12 | 5 | |

| PSGP-2,3 [23] | 517 × 833 | N/A | 217 × 183 × 22 | 6 | |

| ZHJD-1,2 [31] | 367 × 400 | N/A | 217 × 183 × 12 | 5,6 | |

| EHT [11] | 2200 × 250 | N/A | Φ318 × 15 | 6 | |

| T1 [32] | 225 × 325 | N/A | Φ180 × 8 | 6 |

| Specimen | Ny | Nu | Nu/Ny | Dy | Du | Du/Dy | EI |

|---|---|---|---|---|---|---|---|

| RGP-1 [23] | 3200 | 3500 | 1.09 | 27.03 | - | - | 11.84 |

| RGP-2 [23] | 3400 | 4200 | 1.24 | 23.50 | 42.79 | 1.82 | 14.47 |

| RGP-3 [23] | 3400 | 4500 | 1.32 | 23.43 | 43.46 | 1.85 | 14.51 |

| SJ-1 [18] | 2156 | 2548 | 1.18 | 16.13 | 34.49 | 2.14 | 13.37 |

| SJ-2 [18] | 2156 | 2940 | 1.36 | 15.92 | 40.12 | 2.52 | 13.54 |

| Specimen 1 | 3200 | 5200 | 1.63 | 10.90 | 59.01 | 5.41 | 29.36 |

| Specimen 2 | 3400 | 5400 | 1.59 | 12.89 | 68.31 | 5.30 | 26.38 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, Y.; Zhu, B.; Qi, L.; Yan, T.; Wan, T.; Yang, W. Mechanical Behavior and Failure Mode of Steel–Concrete Connection Joints in a Hybrid Truss Bridge: Experimental Investigation. Materials 2020, 13, 2549. https://doi.org/10.3390/ma13112549

Tan Y, Zhu B, Qi L, Yan T, Wan T, Yang W. Mechanical Behavior and Failure Mode of Steel–Concrete Connection Joints in a Hybrid Truss Bridge: Experimental Investigation. Materials. 2020; 13(11):2549. https://doi.org/10.3390/ma13112549

Chicago/Turabian StyleTan, Yingliang, Bing Zhu, Le Qi, Tingyi Yan, Tong Wan, and Wenwei Yang. 2020. "Mechanical Behavior and Failure Mode of Steel–Concrete Connection Joints in a Hybrid Truss Bridge: Experimental Investigation" Materials 13, no. 11: 2549. https://doi.org/10.3390/ma13112549

APA StyleTan, Y., Zhu, B., Qi, L., Yan, T., Wan, T., & Yang, W. (2020). Mechanical Behavior and Failure Mode of Steel–Concrete Connection Joints in a Hybrid Truss Bridge: Experimental Investigation. Materials, 13(11), 2549. https://doi.org/10.3390/ma13112549