A Multifunctional Mineral Binder for Plywood Production: The Effect of Manufacturing Parameters on Bonding Quality

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Binder Synthesis

2.3. Plywood Production

2.4. Panels Variables

- -

- lay-up time (cold-tack time) of the resinated layers;

- -

- compression ratio of the panels;

- -

- veneers with various surface roughness;

- -

- press temperature;

- -

- veneer layouts (the position of middle layers relative to the surface layers).

2.5. Plywood Characterisation

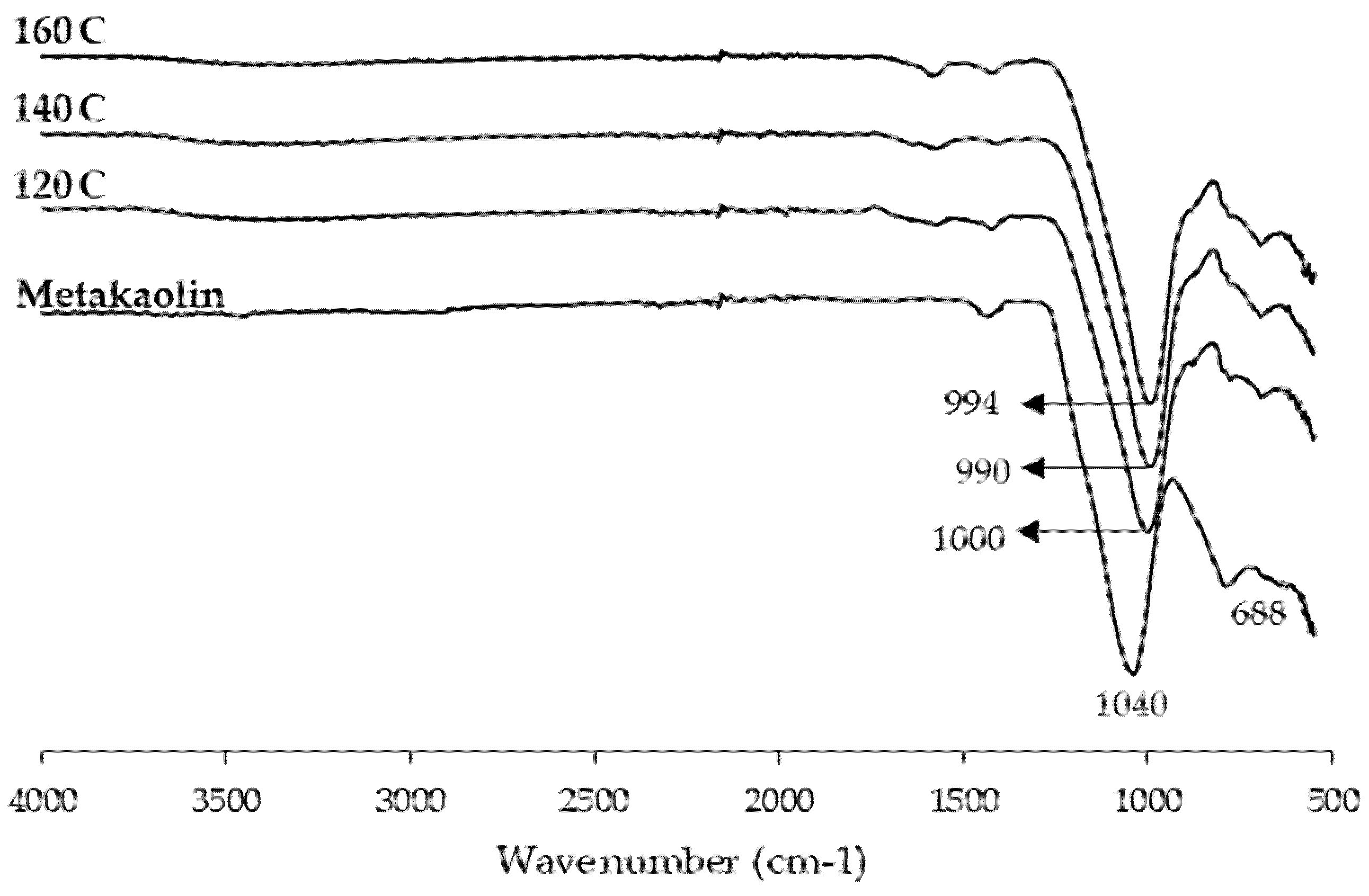

2.6. ATR-FTIR Spectroscopy

3. Results and Discussion

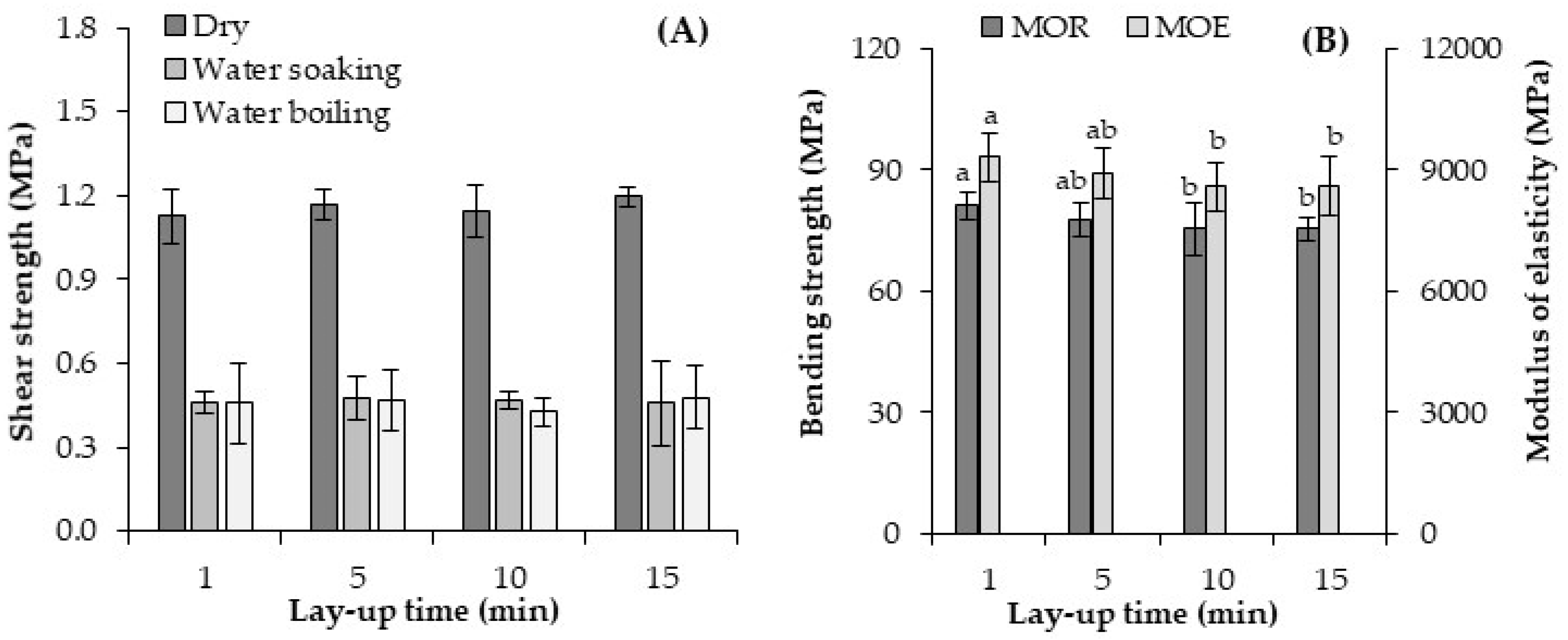

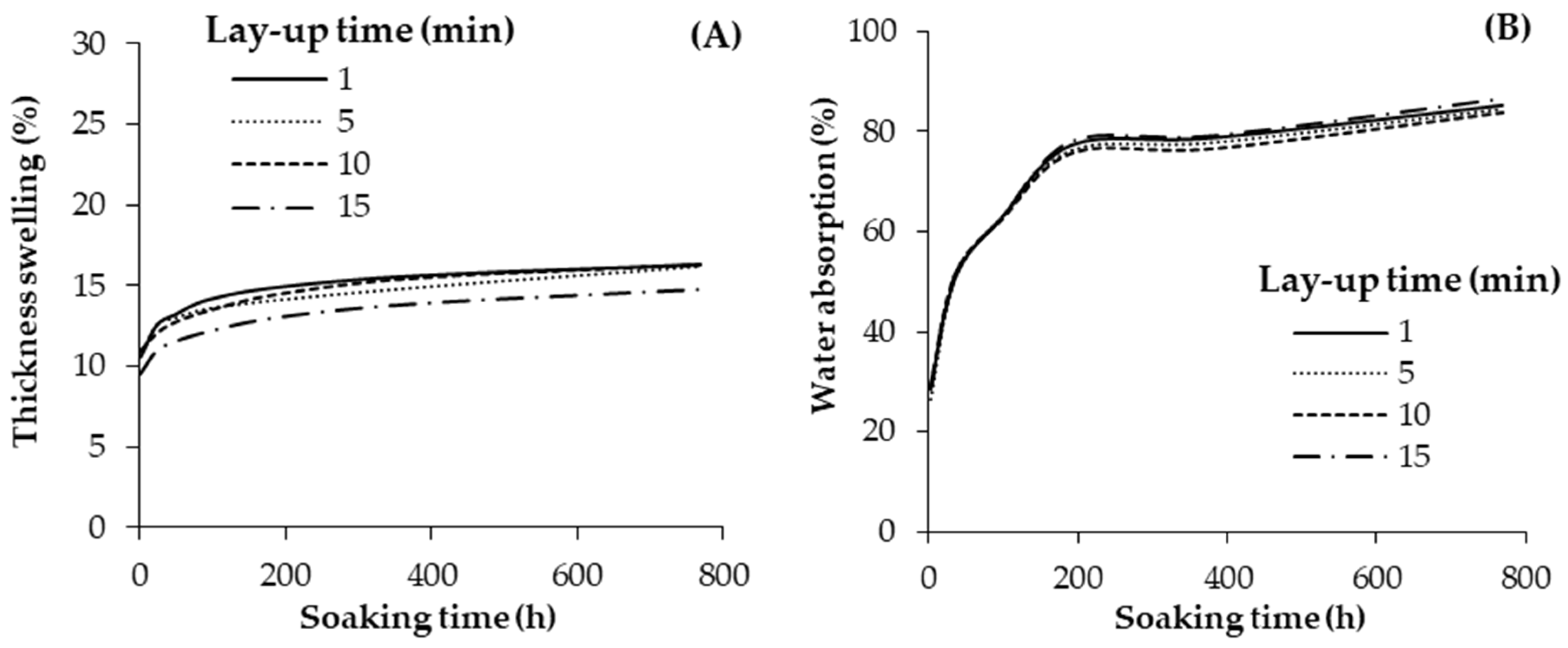

3.1. Lay-Up Time

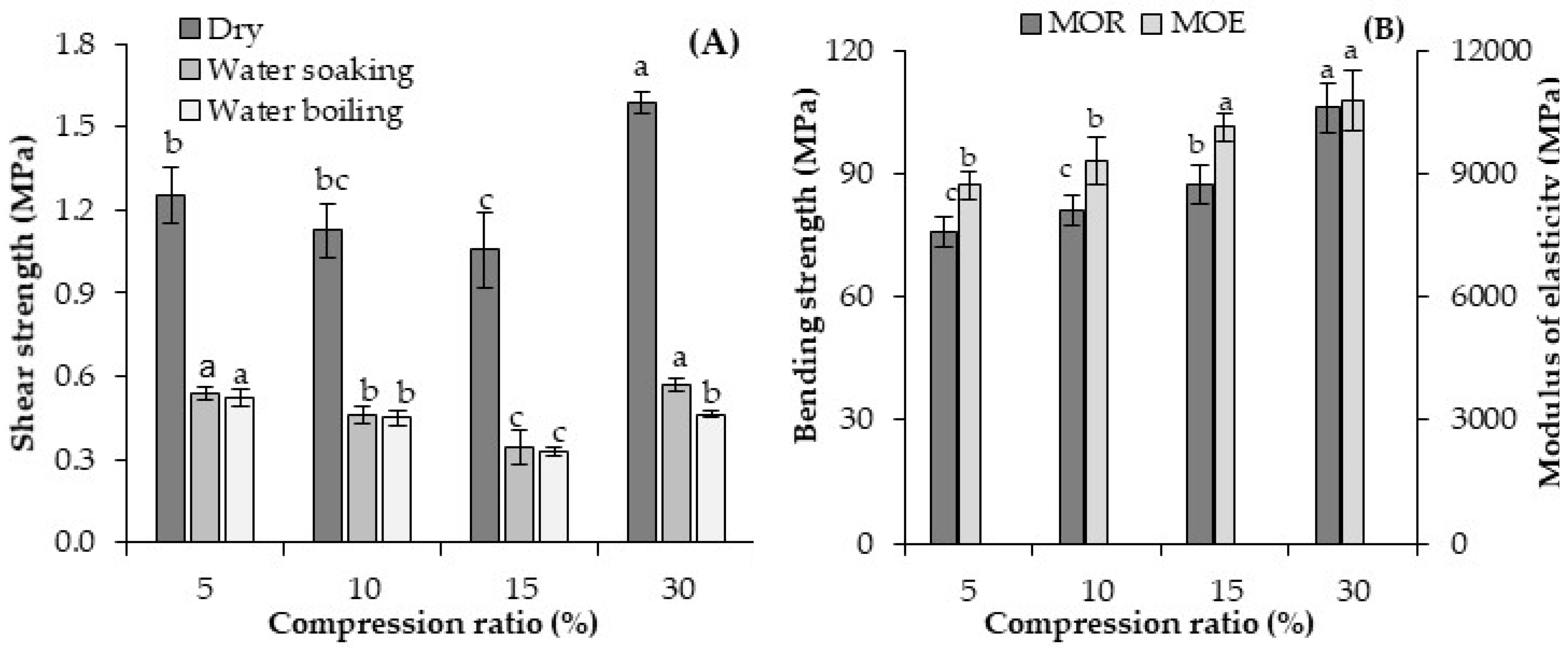

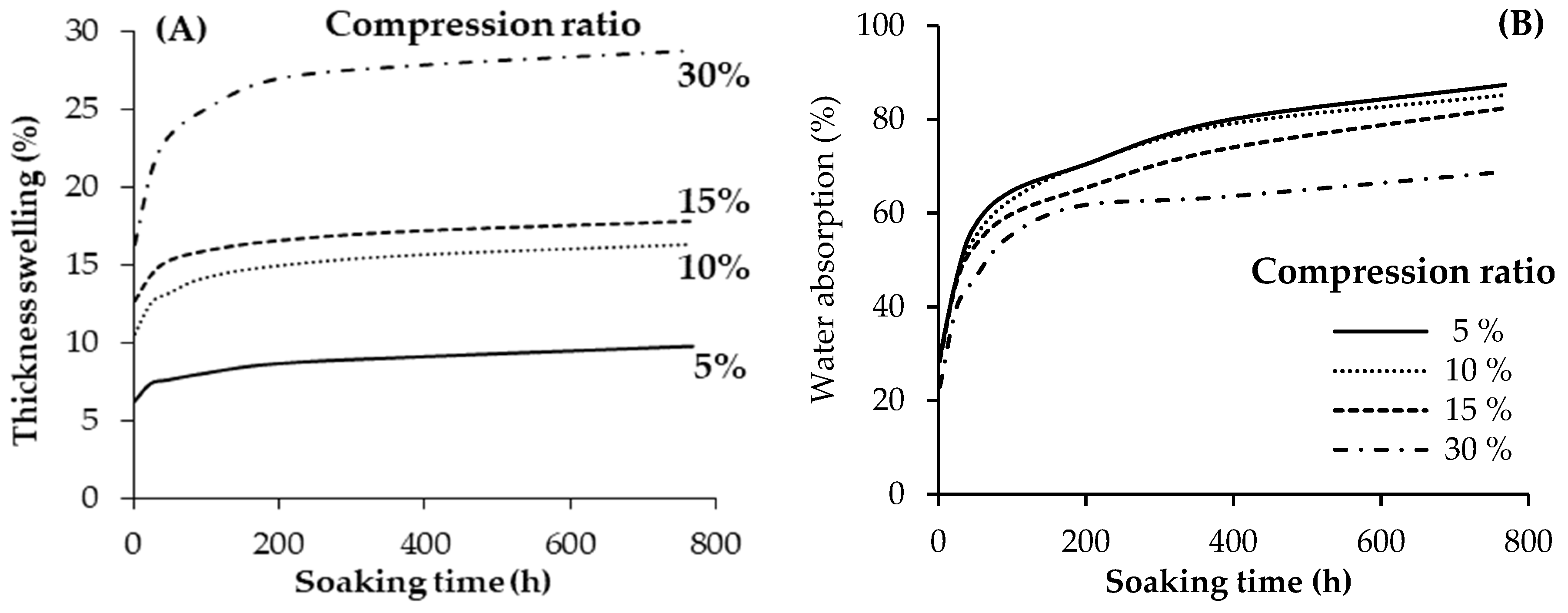

3.2. Compression Ratio of Panels

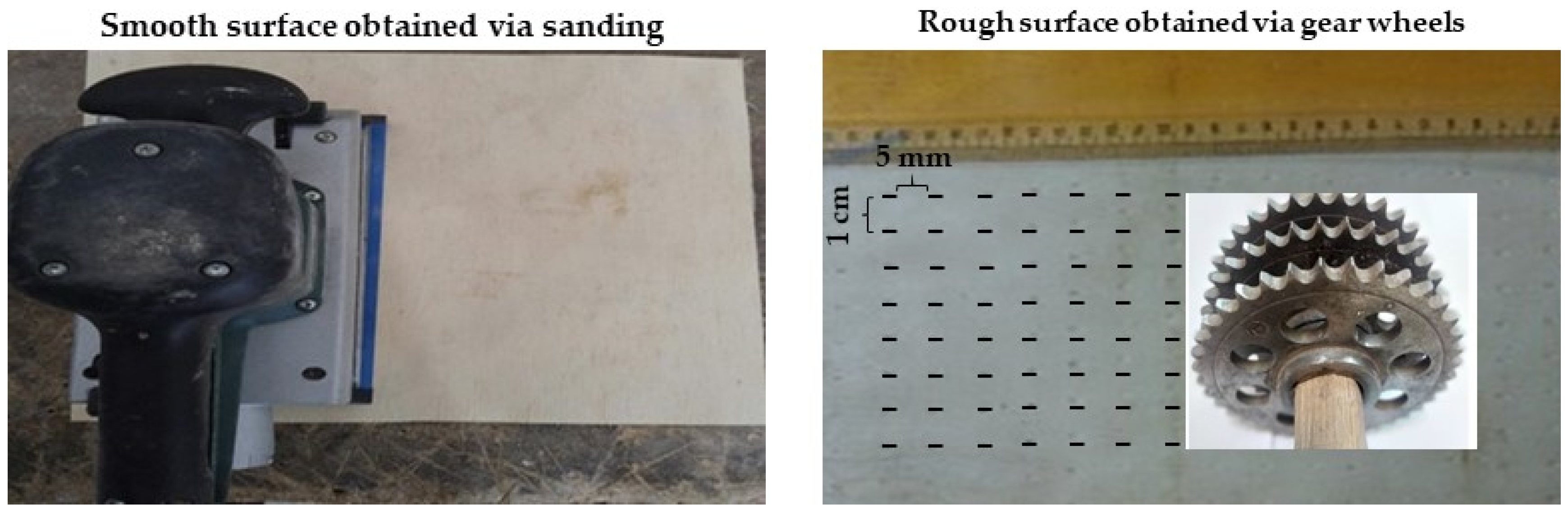

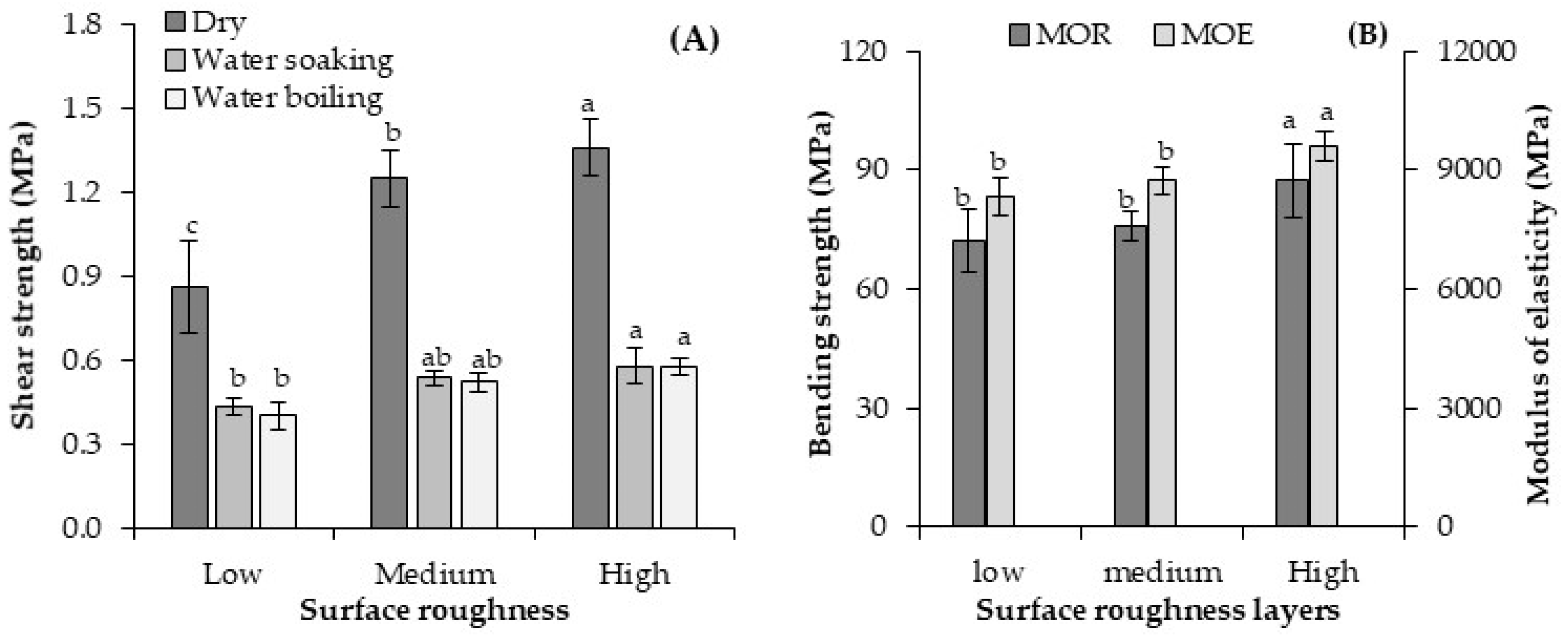

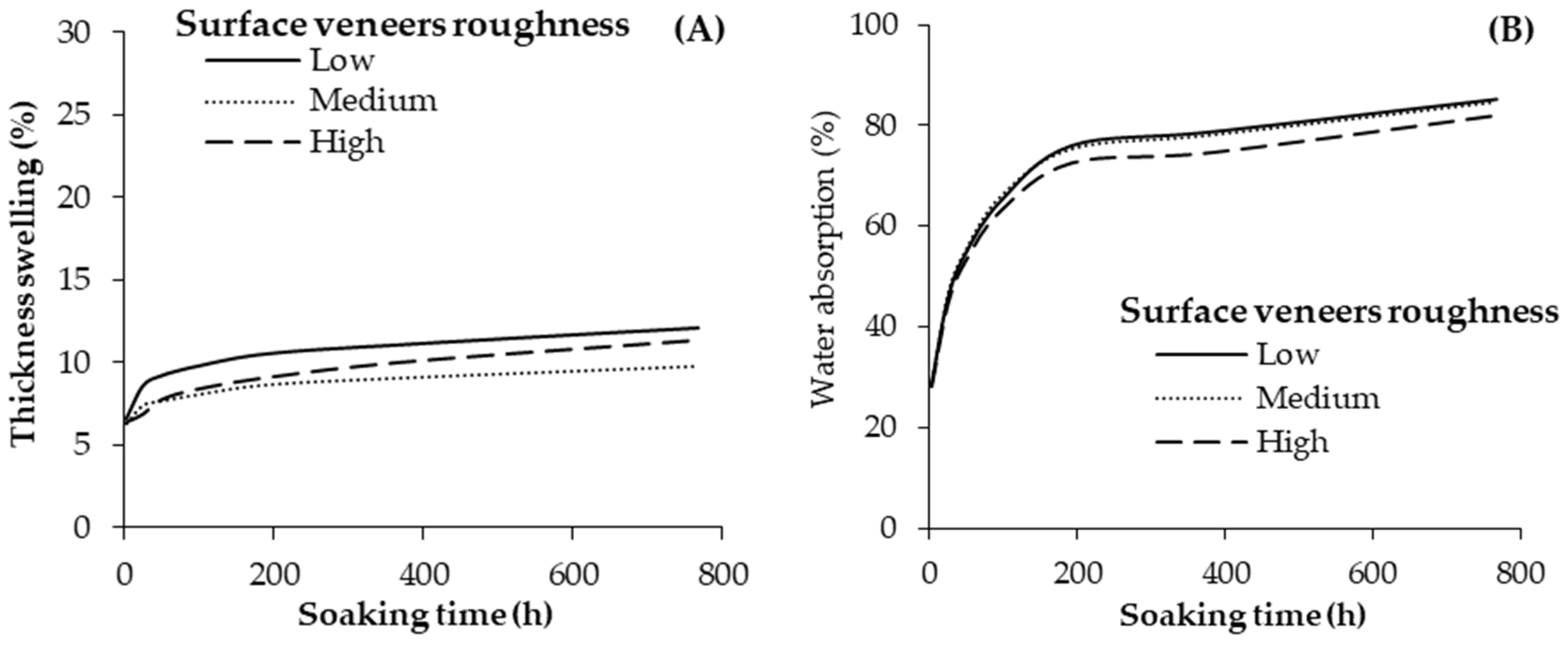

3.3. Veneer Roughness

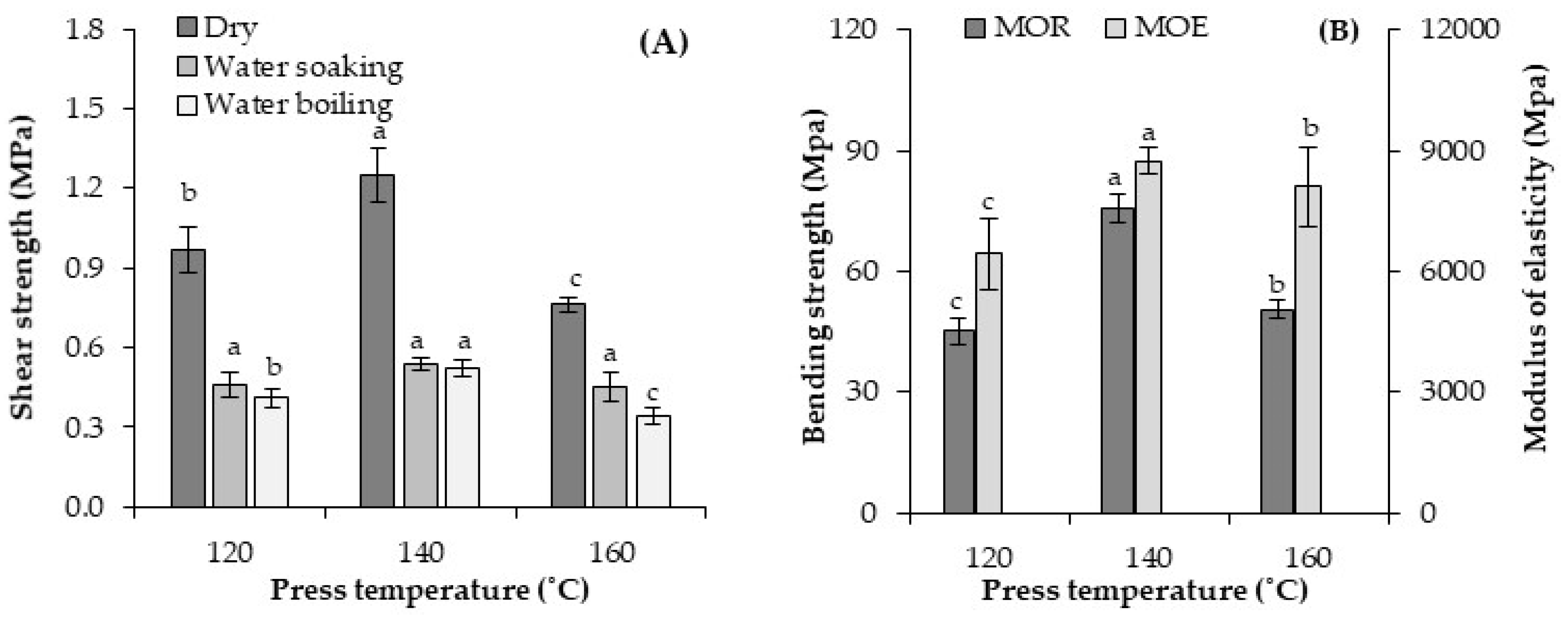

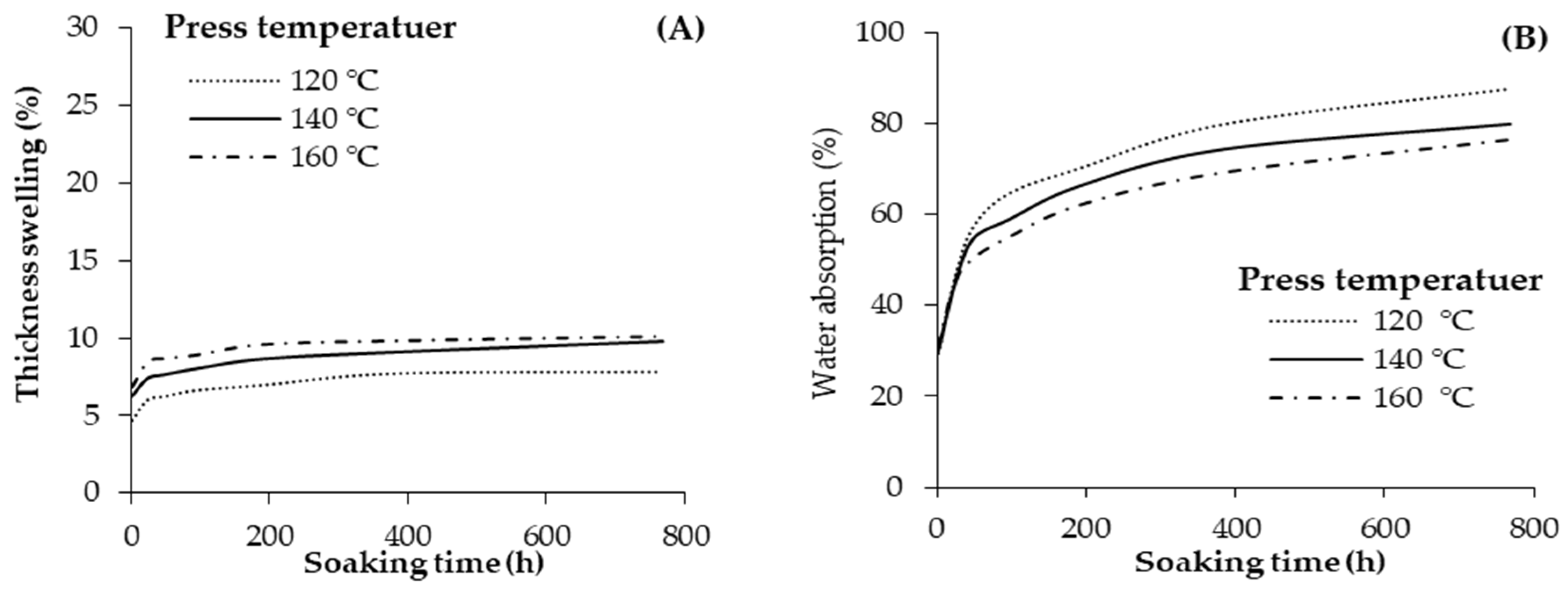

3.4. Hot-Pressing Tempearture

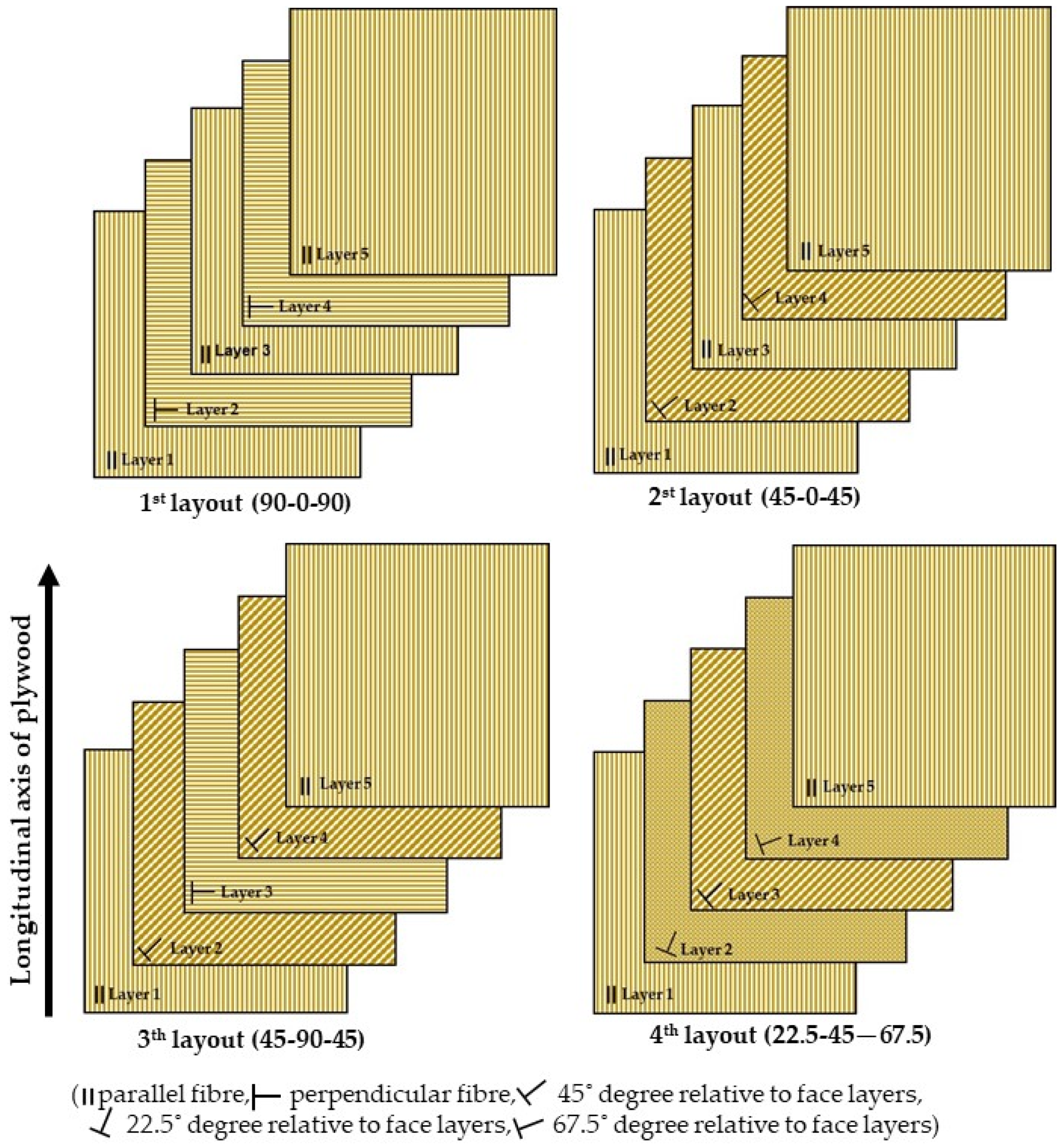

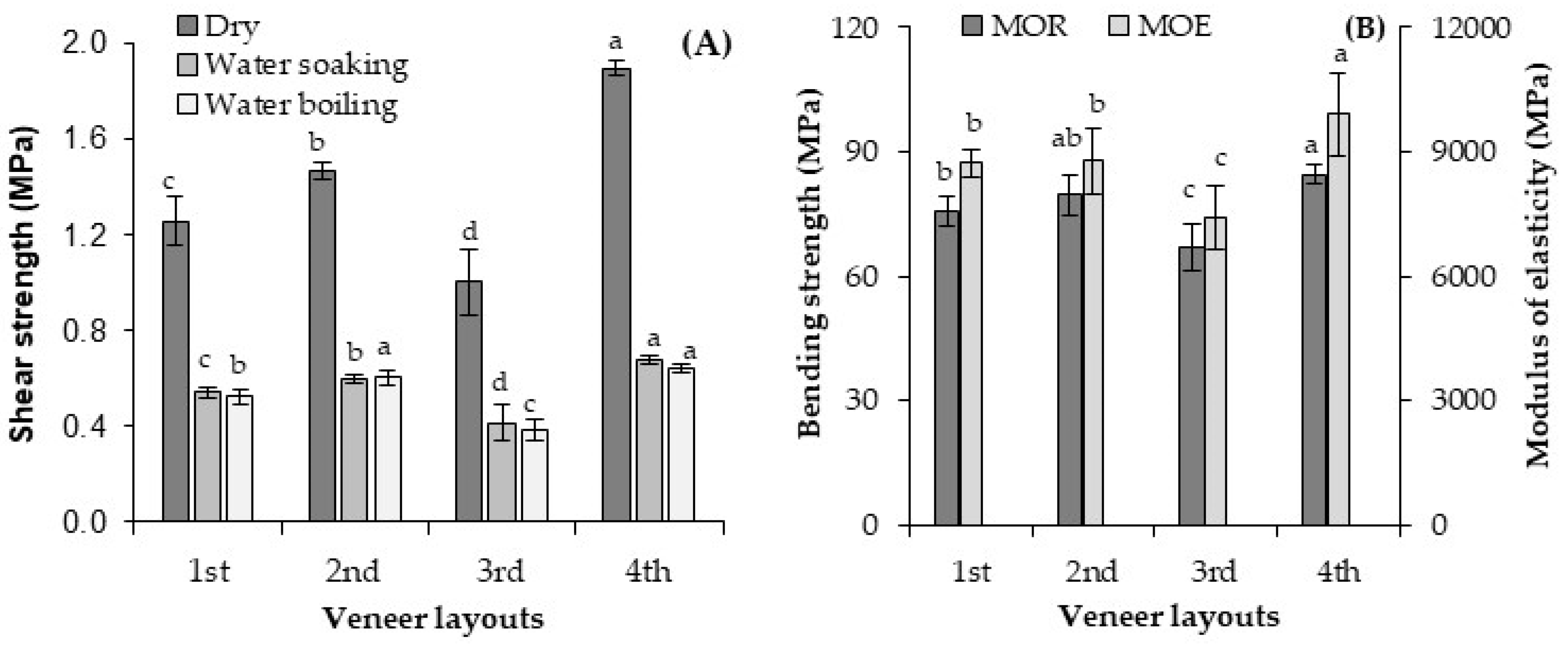

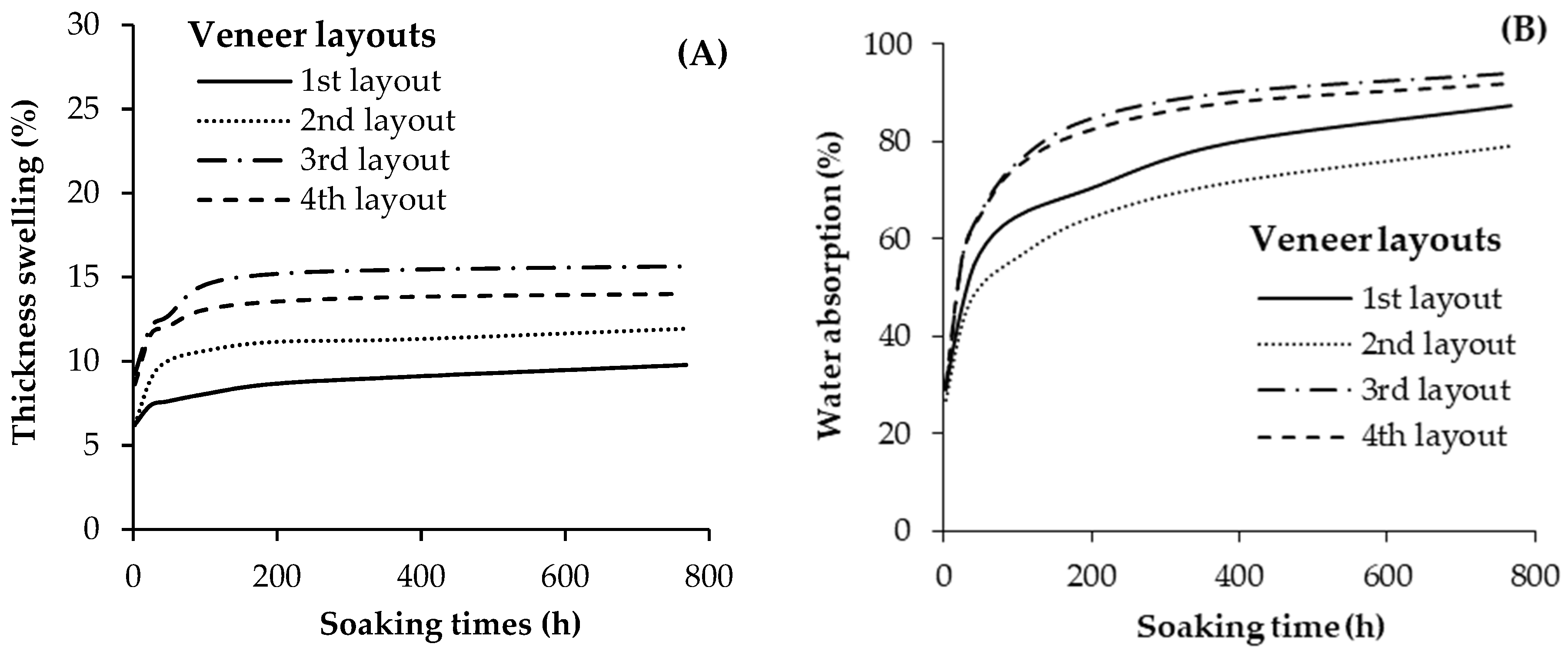

3.5. Veneer Layouts

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hemmilä, V.; Adamopoulos, S.; Karlsson, O.; Kumar, A. Development of sustainable bio-adhesives for engineered wood panels-A Review. RSC Adv. 2017, 7, 38604–38630. [Google Scholar] [CrossRef]

- Pizzi, A.; Mittal, K.L. Handbook of Adhesive Technology; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Chen, Z.X.; Lei, Q.; He, R.L.; Zhang, Z.F.; Chowdhury, A.J.K. Review on antibacterial biocomposites of structural laminated veneer lumber. Saudi J. Biol. Sci. 2016, 23, S142–S147. [Google Scholar] [CrossRef] [PubMed]

- Youngquist, J.A. Wood-based composites and panel products. In Wood Handbook: Wood as an Engineering Material; General technical report FPL; GTR-113: Pages 10.1-10.31; USDA Forest Service, Forest Products Laboratory: Madison, WI, USA, 1999. [Google Scholar]

- Hassannejad, H.; Shalbafan, A.; Rahmaninia, M. Reduction of formaldehyde emission from medium density fiberboard by chitosan as scavenger. J. Adhes. 2018, 8464, 1–17. [Google Scholar] [CrossRef]

- Murata, K.; Watanabe, Y.; Nakano, T. Effect of thermal treatment of veneer on formaldehyde emission of poplar plywood. Materials (Basel) 2013, 6, 410–420. [Google Scholar] [CrossRef]

- Bekhta, P.; Sedliačik, J. Environmentally-friendly high-density polyethylene-bonded plywood panels. Polymers (Basel) 2019, 11, 1166. [Google Scholar] [CrossRef] [PubMed]

- Chang, L.; Tang, Q.; Gao, L.; Fang, L.; Wang, Z.; Guo, W. Fabrication and characterization of HDPE resins as adhesives in plywood. Eur. J. Wood Wood Prod. 2018, 76, 325–335. [Google Scholar] [CrossRef]

- Sarmin, S.N.; Welling, J.; Krause, A.; Shalbafan, A. Investigating the possibility of geopolymer to produce inorganic-bonded wood composites for multifunctional construction material—A review. BioResources 2014, 9, 7941–7950. [Google Scholar]

- Jin, S.; Li, K.; Li, J.; Chen, H. A low-cost, formaldehyde-free and high flame retardancy wood adhesive from inorganic adhesives: Properties and performance. Polymers (Basel) 2017, 9, 513. [Google Scholar] [CrossRef]

- Berzins, A.; Morozovs, A.; Van Den Bulcke, J.; Acker, J. Van Softwood surface compatibility with inorganic geopolymer. Adv. Mater. Proc. 2017, 2, 793–798. [Google Scholar] [CrossRef]

- Shalbafan, A.; Welling, J.; Hasch, J. Geopolymers as potential new binder class for the wood based composite industry. Holzforschung 2016, 70, 755–761. [Google Scholar] [CrossRef]

- Shalbafan, A.; Welling, J.; Hasch, J. Effect of aluminosilicate powders on the applicability of innovative geopolymer binders for wood-based composites. Eur. J. Wood Wood Prod. 2017, 75, 893–902. [Google Scholar] [CrossRef]

- Direske, M.; Wenderdel, C. Detlef KRUG Cement as an inorganic binder for the production of formaldehyde free bonded plywood. PRO Ligno 2018, 14, 16–22. [Google Scholar]

- Hýsek, Š.; Frydrych, M.; Herclík, M.; Louda, P.; Fridrichová, L.; Le Van, S.; Le Chi, H. Fire-resistant sandwich-structured composite material based on alternative materials and its physical and mechanical properties. Materials (Basel) 2019, 12, 1432. [Google Scholar] [CrossRef] [PubMed]

- Davidovits, J. Geopolymer Chemistry and Applications, 2nd ed.; Institute Geopolymere: Saint-Quentin, France, 2008. [Google Scholar]

- Wei, X.; Ming, F.; Li, D.; Chen, L.; Yuhang, L. Influence of water content on mechanical strength and microstructure of alkali-activated fly ash/GGBFS mortars cured at cold and polar regions. Materials (Basel) 2020, 13, 138. [Google Scholar] [CrossRef] [PubMed]

- Steinerova, M.; Matulova, L.; Vermach, P.; Kotas, J. The brittleness and chemical stability of optimized geopolymer composites. Materials (Basel) 2017, 10, 396. [Google Scholar] [CrossRef]

- McLellan, B.C.; Williams, R.P.; Lay, J.; Van Riessen, A.; Corder, G.D. Costs and carbon emissions for geopolymer pastes in comparison to ordinary portland cement. J. Clean. Prod. 2011, 19, 1080–1090. [Google Scholar] [CrossRef]

- Singh, N. Fly ash-based geopolymer binder: A future construction material. Minerals 2018, 8, 299. [Google Scholar] [CrossRef]

- Alomayri, T.; Shaikh, F.U.A.; Low, I.M. Characterisation of cotton fibre-reinforced geopolymer composites. Compos. Part. B Eng. 2013, 50, 1–6. [Google Scholar] [CrossRef]

- Prud’homme, E.; Michaud, P.; Joussein, E.; Peyratout, C.; Smith, A.; Arrii-Clacens, S.; Clacens, J.M.; Rossignol, S. Silica fume as porogent agent in geo-materials at low temperature. J. Eur. Ceram. Soc. 2010, 30, 1641–1648. [Google Scholar] [CrossRef]

- Bahrami, M.; Shalbafan, A.; Welling, J. Development of plywood using geopolymer as binder: Effect of silica fume on the plywood and binder characteristics. Eur. J. Wood Wood Prod. 2019, 77, 981–994. [Google Scholar] [CrossRef]

- Shalbafan, A.; Thoemen, H. Geopolymer-bonded laminated veneer lumber as environmentally friendly and formaldehyde-free product: Effect of various additives on geopolymer binder features. Appl. Sci. 2020, 10, 593. [Google Scholar] [CrossRef]

- Prud’homme, E.; Michaud, P.; Peyratout, C.; Smith, A.; Rossignol, S.; Joussein, E.; Sauvat, N. Geomaterial foam to reinforce wood. Strateg. Mater. Comput. Des. Ceram. Eng. Sci. Proc. 2010, 31, 3–10. [Google Scholar]

- Kollman, F.F.P. Principles of Wood Science and Technology. V 2, Wood Based Materials; Springer: New York, NY, USA, 1975. [Google Scholar]

- Kamke, F.A.; Lee, J.N. Adhesive penetration in wood - A review. Wood Fiber Sci. 2007, 39, 205–220. [Google Scholar]

- Song, W.; Wei, W.; Wang, D.; Zhang, S. Preparation and properties of new plywood composites made from surface modified veneers and polyvinyl chloride films. BioResources 2017, 12, 8320–8339. [Google Scholar]

- Frihart, C.R. Adhesive penetration of wood and its effect on bond strength. In Proceedings of the 39th Annual Meeting of the Adhesion Society, San Antonio, TX, USA, 21–24 February 2016; pp. 1–4. [Google Scholar]

- Gouny, F.; Fouchal, F.; Maillard, P.; Rossignol, S. Study of the effect of siliceous species in the formation of a geopolymer binder: Understanding the reaction mechanisms among the binder, wood, and earth brick. Ind. Eng. Chem. Res. 2014, 53, 3559–3569. [Google Scholar] [CrossRef]

- Berzins, A.; Morozovs, A.; Gross, U.; Iejavs, J. Mechanical properties of wood-geopolymer composite. Eng. Rural Dev. 2017, 16, 1167–1173. [Google Scholar]

- Hogger, E.M.; van Herwijnen, H.W.G.; Moser, J.; Kantner, W.; Konnerth, J. Cold tack of urea formaldehyde resins as an important factor in plywood production. Eur. J. Wood Wood Prod. 2018, 76, 1391–1398. [Google Scholar] [CrossRef]

- Liu, C.; Luo, J.; Li, X.; Gao, Q.; Li, J. Effects of compounded curing agents on properties and performance of urea formaldehyde resin. J. Polym. Environ. 2018, 26, 158–165. [Google Scholar] [CrossRef]

- Kymäläinen, M.; Yamamoto, A.; Sokka, K.; Rautkari, L. The effect of compression and incision on wood veneer and plywood physical and mechanical properties. Wood Mater. Sci. Eng. 2018, 15, 97–103. [Google Scholar] [CrossRef]

- Kurokochi, Y.; Hasegawa, W.; Sato, M. The effects of wetting and scratching pretreatment of veneers on shear strength of binderless plywood made from sugi (Japanese cedar, Cryptomeria japonica). J. Wood Sci. 2019, 65, 1–7. [Google Scholar] [CrossRef]

- Jakimovska Popovska, V.; Iliev, B.; Zlateski, G. Utjecaj položaja furnira u strukturi furnirskih ploča na njihovu vlačnu čvrstoću. Drv. Ind. 2017, 68, 153–161. [Google Scholar] [CrossRef]

- Wang, B.; Dai, C.; Troughton, G. Development of a new incising technology for plywood/LVL production. Part 2. Effect of incising on LVL strength properties. For. Prod. J. 2003, 53, 99–102. [Google Scholar]

- Bekhta, P.; Hiziroglu, S.; Potapova, O.; Sedliacik, J. Shear strength of exterior plywood panels pressed at low temperature. Materials (Basel) 2009, 2, 876–882. [Google Scholar] [CrossRef]

- European Committee for Standardisation. Plywood-Bonding Quality—Part 1: Test Methods; European Norm EN 314-1:2005; European Committee for Standardization: Brussels, Belgium, 2005. [Google Scholar]

- European Committee for Standardisation. Wood-Based Panels—Determination of Modulus of Elasticity in Bending and of Bending Strength; European Norm EN 310:1993; European Committee for Standardization: Brussels, Belgium, 1993. [Google Scholar]

- European Committee for Standardisation. Particleboards and Fibreboards: Determination of Swelling in thickness after immersion in Water; European Norm EN 317:1993; European Committee for Standardization: Brussels, Belgium, 1993. [Google Scholar]

- De Barros Lustosa, E.C.; Del Menezzi, C.H.S.; De Melo, R.R. Production and properties of a new wood laminated veneer/high-density polyethylene composite board. Mater. Res. 2015, 18, 994–999. [Google Scholar] [CrossRef]

- Bekhta, P.; Niemz, P.; Sedliacik, J. Effect of pre-pressing of veneer on the glueability and properties of veneer-based products. Eur. J. Wood Wood Prod. 2012, 70, 99–106. [Google Scholar] [CrossRef]

- Roffael, E.; Rauch, W. Influence of density on the swelling behaviour of phenolic resin bonded particle (In German). Holz als Roh- und Werkst. 1972, 30, 178–181. [Google Scholar] [CrossRef]

- Jafarnezhad, S.; Shalbafan, A.; Luedtke, J. Effect of surface layers compressibility and face-to-core-layer ratio on the properties of lightweight hybrid panels. Int. Wood Prod. J. 2018, 9, 164–170. [Google Scholar] [CrossRef]

- Shi, S.; Walker, J.C.F. Wood-based composites: Plywood and veneer-based products. In Primary Wood Processing: Principles and Practice; Springer: Heidelberg, Germany, 2006; pp. 391–426. [Google Scholar]

- Bing-hui, M.; Zhu, H.; Xue-min, C.; Yan, H.; Si-yu, G. Effect of curing temperature on geopolymerization of metakaolin-based geopolymers. Appl. Clay Sci. 2014, 99, 144–148. [Google Scholar]

- Kljak, J.; Brezović, M. Relationship between bending and tensile stress distribution in veneer plywood. For. Prod. J. 2007, 57, 65–69. [Google Scholar]

| Variables | Lay-Up Time (min) | Compression Ratio of Panels (%) | Veneer Roughness | Press Temperature (°C) | Veneer Layout (Layers Degree) * |

|---|---|---|---|---|---|

| Lay-up time (min) | 1 | 10 | Medium | 140 | 90-0-90 |

| 5 | |||||

| 10 | |||||

| 15 | |||||

| Compression ratio of panels (%) | 1 | 5 | Medium | 140 | 90-0-90 |

| 10 | |||||

| 15 | |||||

| 30 | |||||

| Veneer roughness | 1 | 5 | Low | 140 | 90-0-90 |

| Medium | |||||

| High | |||||

| Press Temperature (°C) | 1 | 5 | High | 120 | 90-0-90 |

| 140 | |||||

| 160 | |||||

| Veneer layout (layers degrees) * | 1 | 5 | High | 140 | [1st] 90-0-90 |

| [2nd] 45-0-45 | |||||

| [3rd] 45-90-45 | |||||

| [4th] 22.5-45-67.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shalbafan, A.; Nadali, A.; Thoemen, H. A Multifunctional Mineral Binder for Plywood Production: The Effect of Manufacturing Parameters on Bonding Quality. Materials 2020, 13, 2360. https://doi.org/10.3390/ma13102360

Shalbafan A, Nadali A, Thoemen H. A Multifunctional Mineral Binder for Plywood Production: The Effect of Manufacturing Parameters on Bonding Quality. Materials. 2020; 13(10):2360. https://doi.org/10.3390/ma13102360

Chicago/Turabian StyleShalbafan, Ali, Amin Nadali, and Heiko Thoemen. 2020. "A Multifunctional Mineral Binder for Plywood Production: The Effect of Manufacturing Parameters on Bonding Quality" Materials 13, no. 10: 2360. https://doi.org/10.3390/ma13102360

APA StyleShalbafan, A., Nadali, A., & Thoemen, H. (2020). A Multifunctional Mineral Binder for Plywood Production: The Effect of Manufacturing Parameters on Bonding Quality. Materials, 13(10), 2360. https://doi.org/10.3390/ma13102360