AlxIn1−xN on Si (100) Solar Cells (x = 0–0.56) Deposited by RF Sputtering

Abstract

1. Introduction

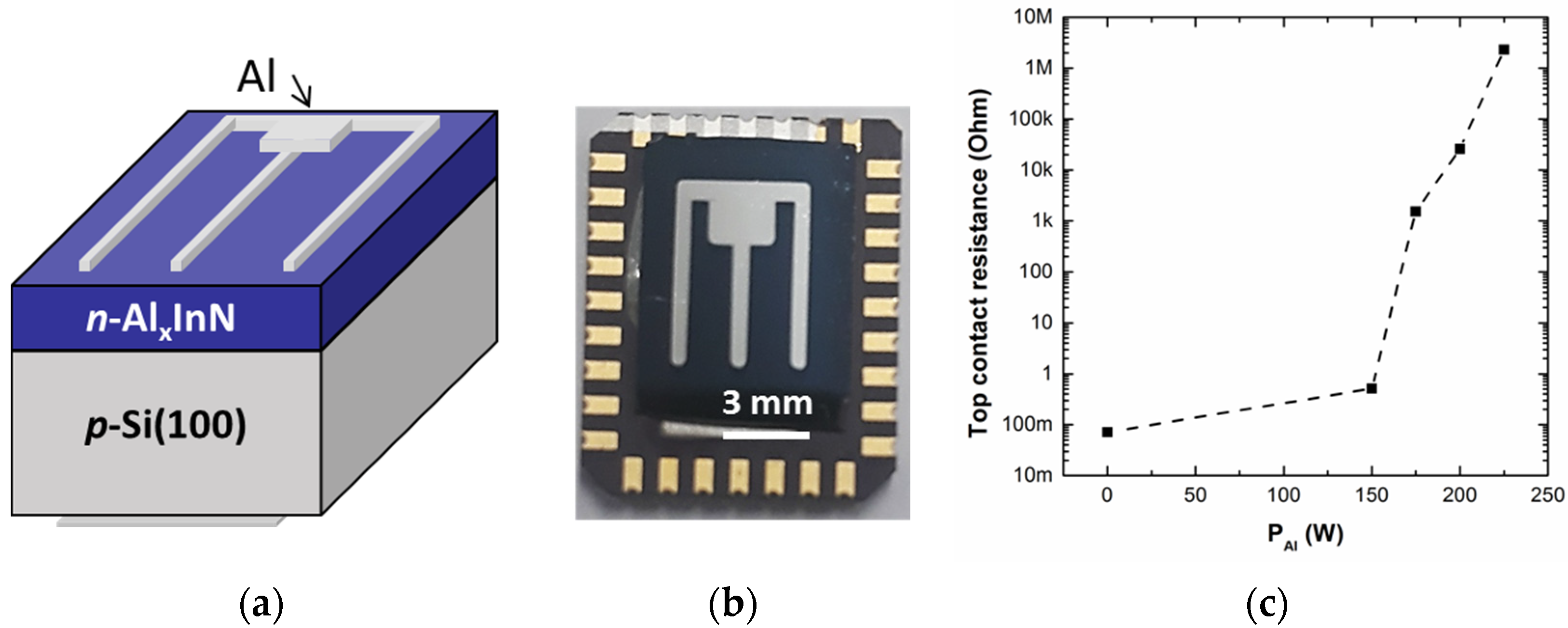

2. Materials and Methods

2.1. AlxIn1−xN Deposition by RF Sputtering

2.2. Material Characterization

2.3. Device Fabrication

2.4. Device Characterization Techniques

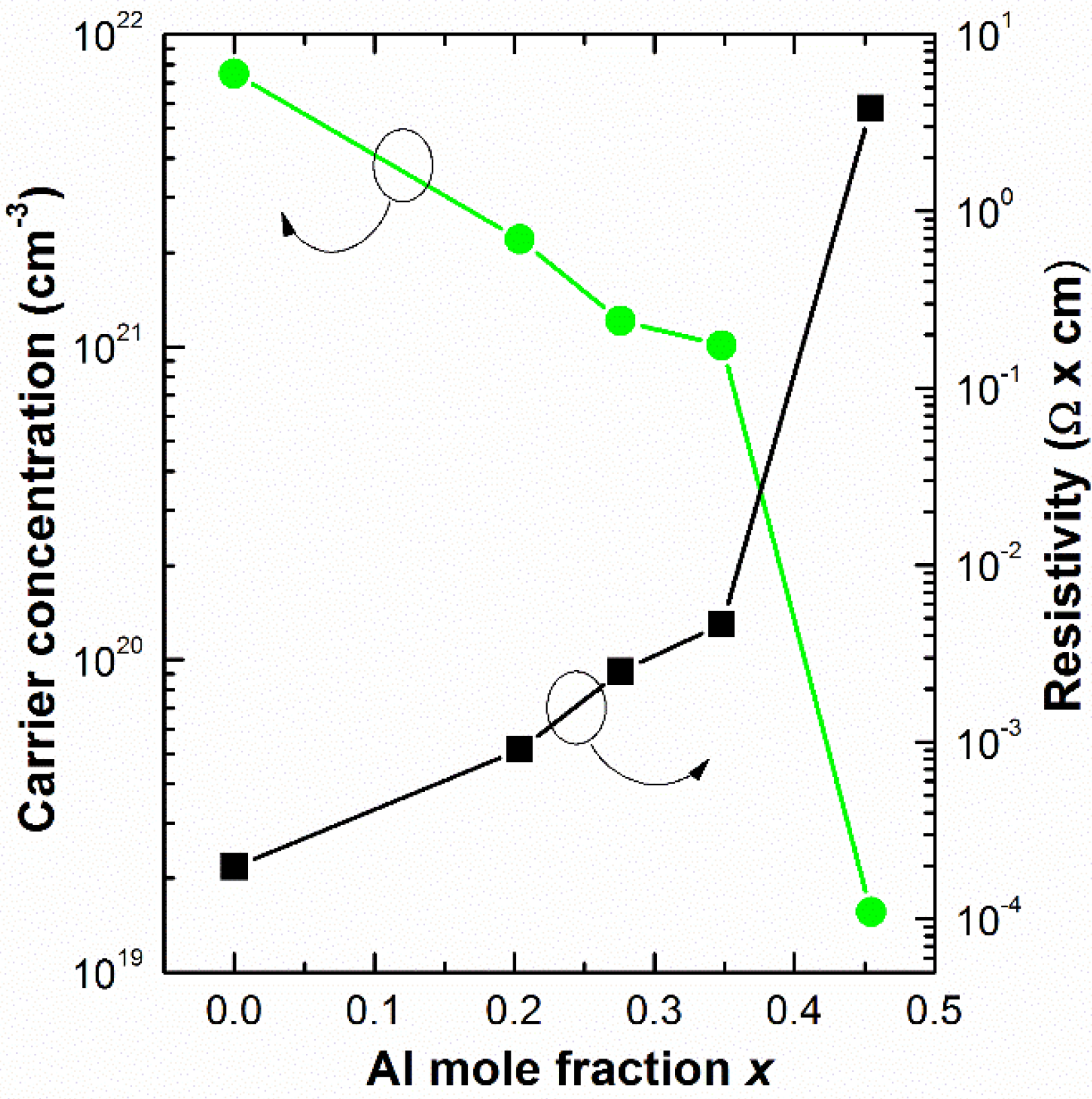

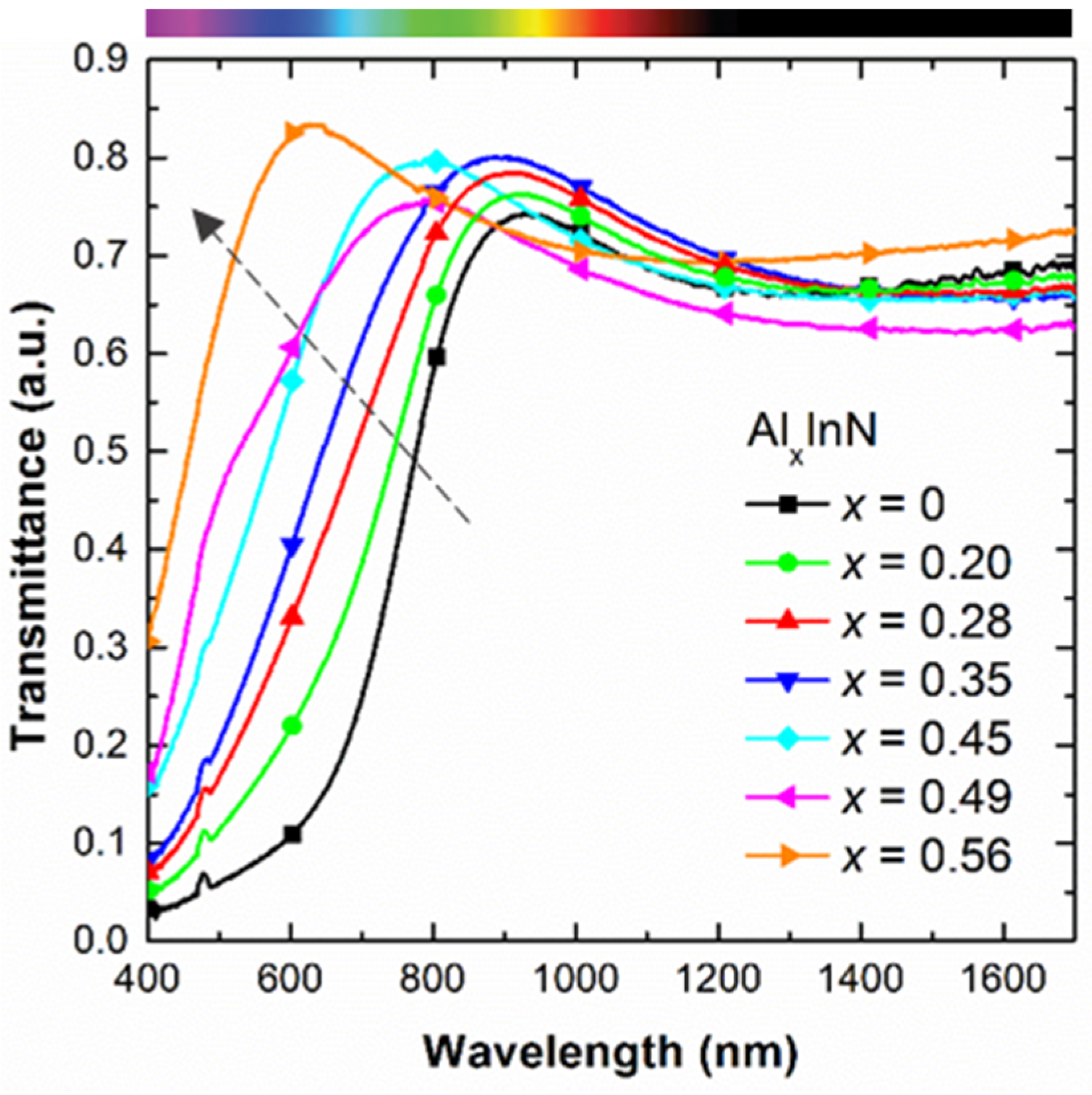

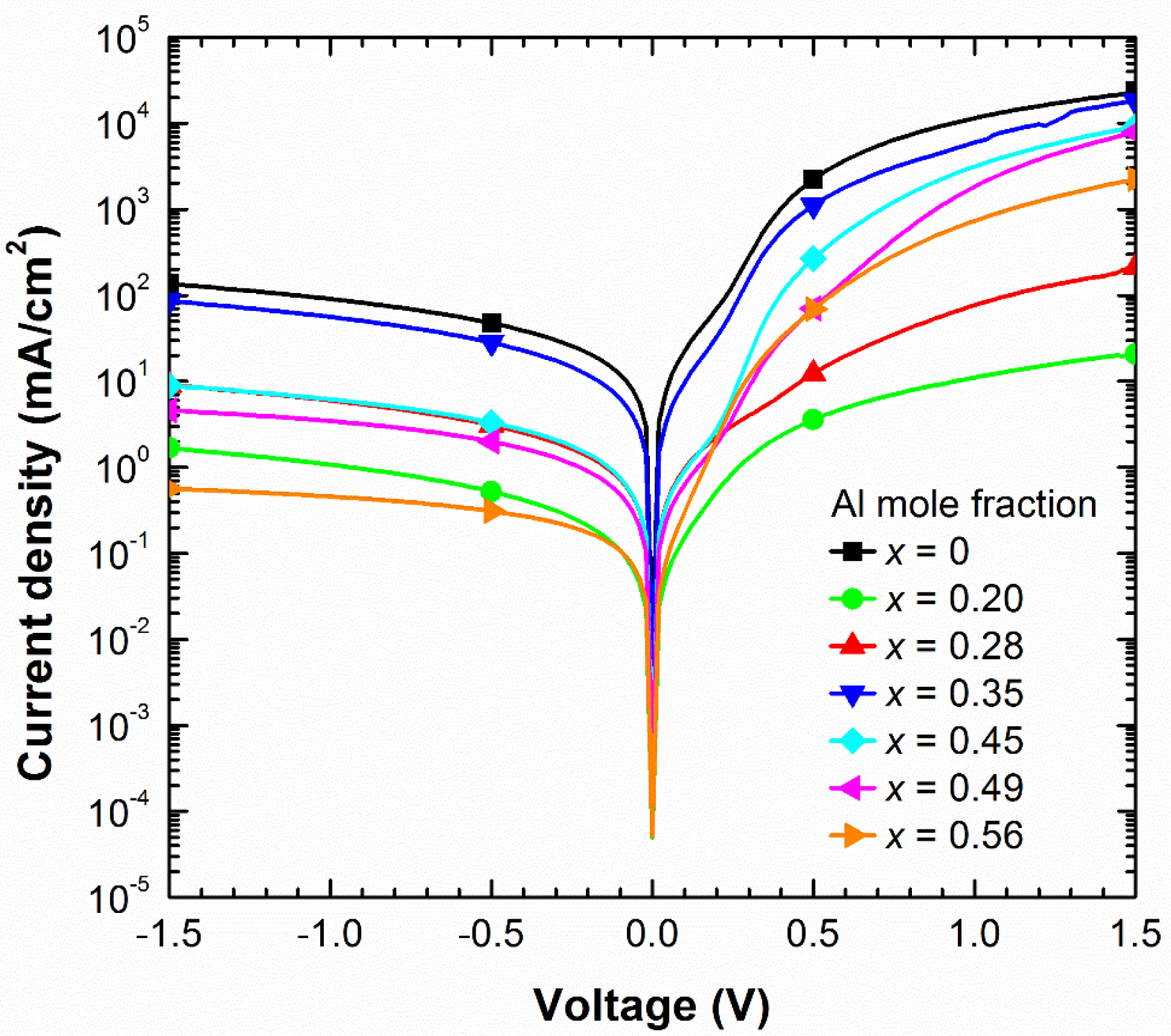

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Palmstrom, A.F.; Eperon, G.E.; Leijtens, T.; Prasanna, R.; Habisreutinger, S.N.; Nemeth, W.; Gaulding, E.A.; Dunfield, S.P.; Reese, M.; Nanayakkara, S.; et al. Enabling flexible all-perovskite tandem solar cells. Joule 2019, 3, 2193. [Google Scholar] [CrossRef]

- Veinberg-Vidal, E.; Vauche, L.; Medjoubi, K.; Weick, C.; Besançon, C.; Garcia-Linares, P.; Datas, A.; Kaminski-Cachopo, A.; Voarino, P.; Mur, P.; et al. Characterization of dual-junction III-V on Si tandem solar cells with 23.7% efficiency under low concentration. Prog. Photovolt. Res. Appl. 2019, 27, 652. [Google Scholar] [CrossRef]

- Bhuiyan, A.G.; Sugita, K.; Hashimoto, A.; Yamamoto, A. InGaN solar cells: Present state of the art and important challenges. IEEE J. Photovolt. 2012, 2, 3. [Google Scholar] [CrossRef]

- Irvine, S.; Capper, P. Metalorganic Vapor Phase Epitaxy (MOVPE): Growth, Materials Properties and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2019. [Google Scholar]

- Dinh, D.V.; Hu, N.; Honda, Y.; Amano, H.; Pristovsek, M. Indium incorporation and optical properties of polar, semipolar and nonpolar InAlN. Semicond. Sci. Technol. 2020, 35, 035004. [Google Scholar] [CrossRef]

- Borovac, D.; Sun, W.; Song, R.; Wierer, J.J., Jr.; Tansu, N. On the thermal stability of nearly lattice-matched AlInN films grown on GaN via MOVPE. J. Cryst. Growth 2020, 533, 125469. [Google Scholar] [CrossRef]

- Miyoshi, M.; Yamanaka, M.; Egawa, T.; Takeuchi, T. Epitaxial growth and characterization of approximately 300-nm-thick AlInN films nearly lattice-matched to c-plane GaN grown on sapphire. Appl. Phys. Express 2018, 11, 051001. [Google Scholar] [CrossRef]

- Engel, Z.; Clinton, E.A.; Matthews, C.M.; Doolittle, W.A. Controlling surface adatom kinetics for improved structural and optical properties of high indium content aluminum indium nitride. J. Appl. Phys. 2020, 127, 125301. [Google Scholar] [CrossRef]

- Gacevic, Z.; Fernández-Garrido, S.; Rebled, J.M.; Estrade, S.; Peiro, F.; Calleja, E. High quality InAlN single layers lattice-matched to GaN grown by molecular beam epitaxy. Appl. Phys. Lett. 2011, 99, 031103. [Google Scholar] [CrossRef]

- Terashima, W.; Che, S.-B.; Ishitani, Y.; Yoshikawa, A. Growth and characterization of AlInN ternary alloys in whole composition range and fabrication of InN/AlInN multiple quantum wells by RF molecular beam epitaxy. Jpn. J. Appl. Phys. 2006, 45, L539. [Google Scholar] [CrossRef]

- Izyumskaya, N.; Avrutin, V.; Ding, K.; Özgür, Ü.; Morkoç, H.; Fujioka, H. Emergence of high quality sputtered III-nitride semiconductors and devices. Semicond. Sci. Technol. 2019, 34, 093003. [Google Scholar] [CrossRef]

- Lv, W.; Shen, L.; Liu, J.; Chen, J.; Wu, L.; Qi, D.; Zhang, G.; Li, X. Mechanical properties of single-phase Al1-xInxN films across the compositional range (0 ≤ x ≤ 0.7) grown by radio-frequency magnetron sputtering. Appl. Surf. Sci. 2020, 504, 144335. [Google Scholar] [CrossRef]

- Han, Q.; Duan, C.; Du, G.; Shi, W.; Ji, L. Magnetron sputter epitaxy and characterization of wurtzite AlInN on Si (111) substrates. J. Electron. Mater. 2010, 39, 489. [Google Scholar] [CrossRef]

- Núñez-Cascajero, A.; Blasco, R.; Valdueza-Felip, S.; Montero, D.; Olea, J.; Naranjo, F.B. High quality Al0.37In0.63N layers grown at low temperature (<300 °C) by radio-frequency sputtering. Mater. Sci. Semicond. Process 2019, 100, 8. [Google Scholar]

- Núñez-Cascajero, A.; Monteaguso-Lerma, L.; Valdueza-Felip, S.; Navío, C.; Monroy, E.; Gonzalez-Herráez, M.; Naranjo, F.B. In-rich AlxIn1−xN grown by RF-sputtering on sapphire: From closely-packed columnar to high-surface quality compact layers. J. Phys. D Appl. Phys. 2017, 50, 65101. [Google Scholar] [CrossRef]

- Núñez-Cascajero, A.; Valdueza-Felip, S.; Blasco, R.; Mata, M.; Molina, S.I.; González-Herráez, M.; Monroy, E.; Naranjo, F.B. Quality improvement of AlInN/p-Si heterojunctions with AlN buffer layer deposited by RF-sputtering. J. Alloys Compd. 2018, 769, 824. [Google Scholar] [CrossRef]

- Núñez-Cascajero, A.; Monteagudo-Lerma, L.; Valdueza-Felip, S.; Navío, C.; Monroy, E.; Gonzalez-Herráez, M.; Naranjo, F.B. Study of high In-content AlInN deposition on p-Si(111) by RF-sputtering. Jpn. J. Appl. Phys. 2016, 55, 05FB07. [Google Scholar] [CrossRef]

- Lannoo, M. The role of dangling bonds in the properties of surfaces and interfaces of semiconductors. Rev. Phys. Appl. 1990, 25, 887. [Google Scholar] [CrossRef]

- Yodo, T.; Ando, H.; Nosei, D.; Harada, Y. Growth and characterization of InN heteroepitaxial layers grown on Si substrates by ECR-Assisted MBE. Phys. Status Solidi B 2001, 228, 21. [Google Scholar] [CrossRef]

- Chen, W.C.; Wu, Y.H.; Peng, C.Y.; Hsiao, C.N.; Chang, L. Effect of In/Al ratios on structural and optical properties of InAlN films grown on Si (100) by RF-MOMBE. Nanoscale Res. Lett. 2014, 9, 204. [Google Scholar] [CrossRef][Green Version]

- He, H.; Yongge, C.; Renli, F.; Hai, W.; Jiquan, H.; Changgang, H.; Wang, M.; Zhonghua, D. Structure and optical properties of InN and InAlN films grown by rf magnetron sputtering. J. Mater. Sci. Mater. 2010, 21, 676. [Google Scholar] [CrossRef]

- Afzal, N.; Devarajan, M.; Subramani, S.; Ibrahim, K. Structural and surface analysis of AlInN thin films synthesized by elemental stacks annealing. Mater. Res. Express 2014, 1, 026403. [Google Scholar] [CrossRef]

- Liu, H.F.; Tan, C.C.; Dalapati, G.K.; Chi, D.Z. Magnetron-sputter deposition of high-indium-content n-AlInN thin film on p-Si (001) substrate for photovoltaic applications. J. Appl. Phys. 2012, 112, 063114. [Google Scholar] [CrossRef]

- Valdueza-Felip, S.; Núñez-Cascajero, A.; Blasco, R.; Montero, D.; Grenet, L.; Mata, M.; Fernández, S.; Marcos, L.R.; Molina, S.I.; Olea, J.; et al. Influence of the AlN interlayer thickness on the photovoltaic properties of in-rich AlInN on Si heterojunctions deposited by RF sputtering. Aip Adv. 2018, 8, 115315. [Google Scholar] [CrossRef]

- Blasco, R. Development of solar cells based on AlInN on Si heterojunctions grown by RF-sputtering. Ph.D. Thesis, University of Alcalá, Alcalá de Henares, Spain, March 2020. [Google Scholar]

- Blasco, R.; Núñez-Cascajero, A.; Jiménez-Rodríguez, M.; Montero, D.; Grenet, L.; Olea, J.; Naranjo, F.B.; Valdueza-Felip, S. Influence of the AlInN thickness on the photovoltaic characteristics of AlInN on Si solar cells deposited by RF sputtering. Phys. Status Solidi A 2018, 216, 1800494. [Google Scholar] [CrossRef]

- Blasco, R.; Naranjo, F.B.; Valdueza-Felip, S. Design of AlInN on silicon heterojunctions grown by sputtering for solar devices. Curr. Appl. Phys. under review.

- Blasco, R.; Valdueza-Felip, S.; Montero, D.; Olea, J.; Naranjo, F.B. Low-to-mid Al content (x~0-0.56) AlxIn1-xN layers deposited on Si (100) by RF sputtering. Phys. Status Solidi B 2020, 257, 1900575. [Google Scholar] [CrossRef]

- Final Advanced Materials. Aluminium Nitride Substrate. Available online: www.final-materials.com/gb/383-aluminium-nitride-substrate (accessed on 2 May 2020).

- Darakchieva, V.; Barradas, N.P.; Xie, M.Y.; Lorenz, K.; Alves, E.; Schubert, M.; Persson, P.O.; Giuliani, F.; Munnik, F.; Hsiao, C.L.; et al. Role of impurities and dislocations for the unintentional n-type conductivity in InN. Physica B 2009, 404, 4476. [Google Scholar] [CrossRef]

- Darakchieva, V.; Lorenz, K.; Barradas, N.P.; Alves, E.; Monemar, B.; Schubert, M.; Franco, N.; Hsiao, C.L.; Chen, L.C.; Schaff, W.J.; et al. Hydrogen in InN: A ubiquitous phenomenon in molecular beam epitaxy grown material. Appl. Phys. Lett. 2010, 96, 081907. [Google Scholar] [CrossRef]

- Wu, J. When group-III nitrides go infrared: New properties and perspectives. J. Appl. Phys. 2009, 106, 11101. [Google Scholar] [CrossRef]

- Núñez-Cascajero, A. Development of Nitrides Based on InN for Sensor Applications. Ph.D. Thesis, University of Alcalá, Alcalá de Henares, Spain, June 2017. [Google Scholar]

- PC1D—Software for modelling a solar cell. Available online: www.engineering.unsw.edu.au/energy-engineering/research/software-data-links/pc1d-software-for-modelling-a-solar-cell (accessed on 2 May 2020).

| Sample | PAl (W) | x | Eg of Thin Samples (eV) | Eg of Thick Samples (eV) |

|---|---|---|---|---|

| D1 | 0 | 0 | 1.74 | 1.73 |

| D2 | 100 | 0.20 | 1.87 | - |

| D3 | 125 | 0.28 | 2.03 | 1.79 |

| D4 | 150 | 0.35 | 2.08 | 2.13 |

| D5 | 175 | 0.45 | 2.24 | - |

| D6 | 200 | 0.49 | 2.38 | 2.27 |

| D7 | 225 | 0.56 | 2.57 | 2.56 |

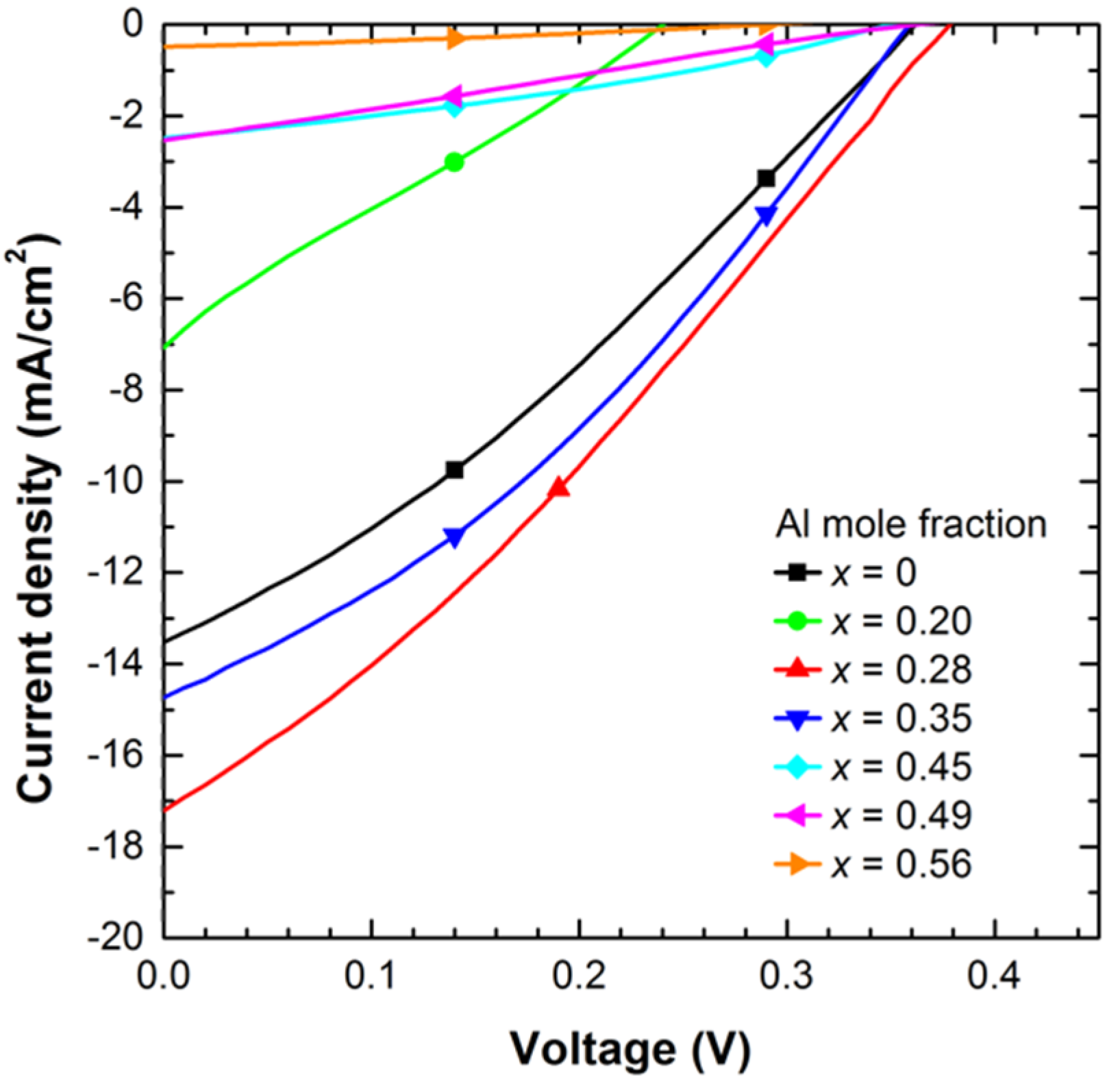

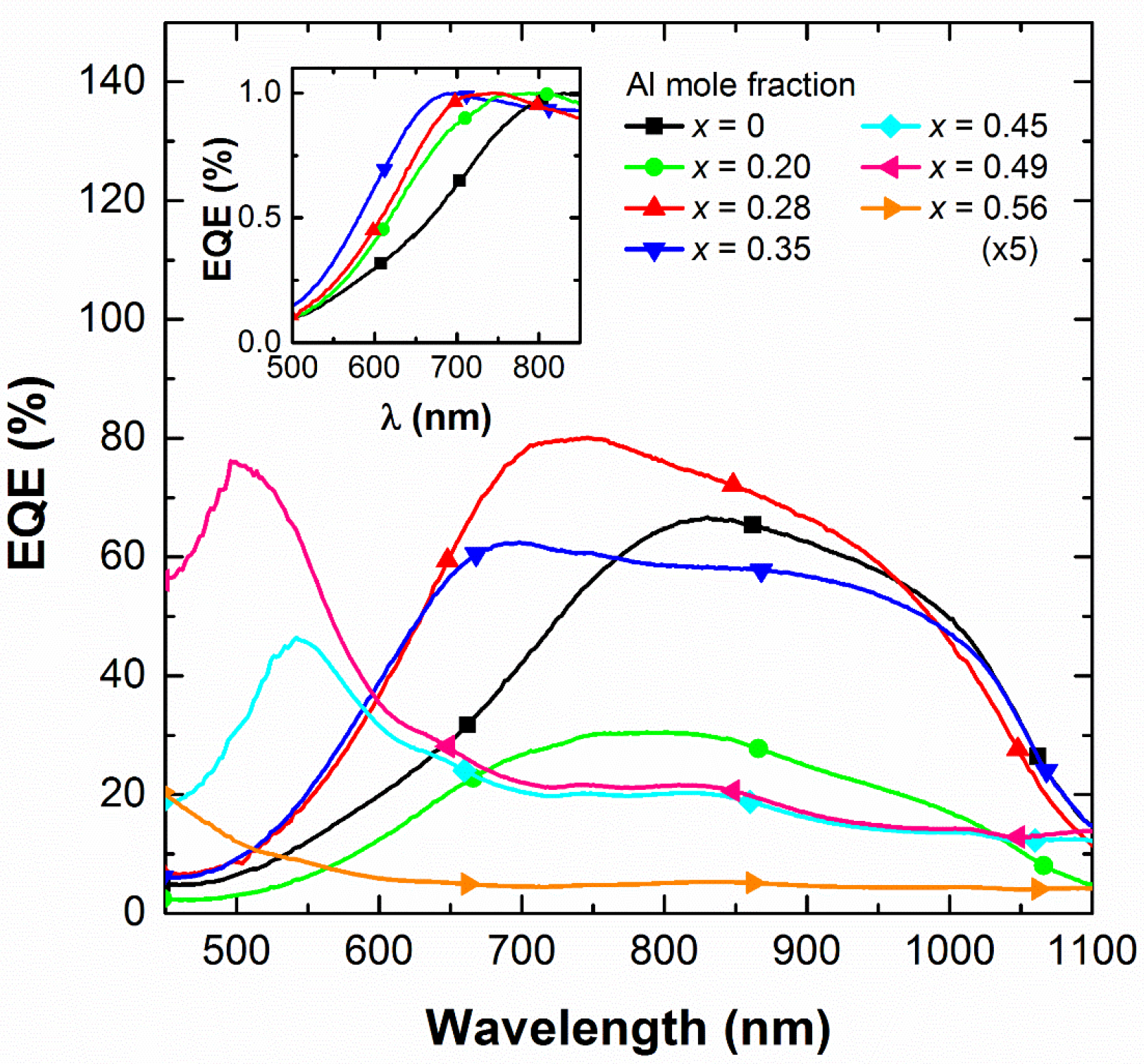

| Sample | x | Area (cm2) | Rs (Ω·cm2) | Rsh (kΩ·cm2) | J0 @-1V (µA/cm2) | η | VOC (V) | JSC (mA/ cm2) | FF (%) | Eff. (%) | EQE at 860 nm (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|

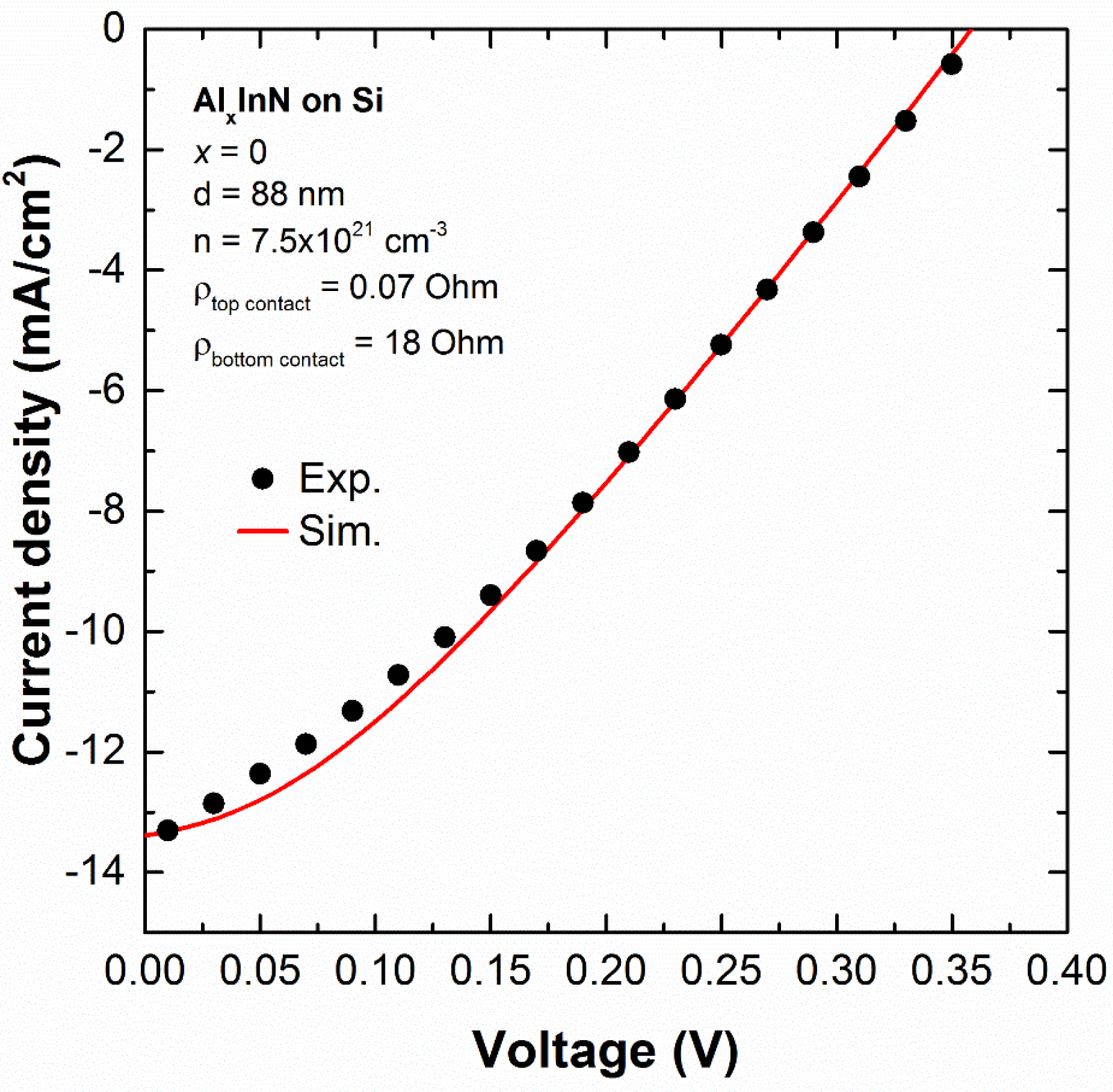

| D1 | 0 | 0.67 | 4.7 | 12 | 3.60 | 2.8 | 0.36 | 13.4 | 30.7 | 1.49 | 66.7 |

| D2 | 0.20 | 0.60 | 58.9 | 980 | 0.04 | 3.8 | 0.25 | 7.3 | 21.6 | 0.40 | 29.9 |

| D3 | 0.28 | 0.62 | 2.1 | 180 | 0.41 | 6.0 | 0.39 | 17.1 | 31.4 | 2.12 | 73.8 |

| D4 | 0.35 | 0.70 | 12.3 | 21 | 4.40 | 4.7 | 0.36 | 14.6 | 33.8 | 1.77 | 58.3 |

| D5 | 0.45 | 0.60 | 14.1 | 180 | 0.31 | 4.2 | 0.35 | 2.5 | 32.8 | 0.28 | 20.1 |

| D6 | 0.49 | 0.48 | 18.0 | 320 | 0.23 | 3.4 | 0.36 | 2.5 | 25.2 | 0.23 | 21.4 |

| D7 | 0.56 | 0.65 | 60.3 | 3100 | 0.15 | 3.0 | 0.29 | 0.47 | 31.0 | 0.05 | 1.1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valdueza-Felip, S.; Blasco, R.; Olea, J.; Díaz-Lobo, A.; Braña, A.F.; Naranjo, F.B. AlxIn1−xN on Si (100) Solar Cells (x = 0–0.56) Deposited by RF Sputtering. Materials 2020, 13, 2336. https://doi.org/10.3390/ma13102336

Valdueza-Felip S, Blasco R, Olea J, Díaz-Lobo A, Braña AF, Naranjo FB. AlxIn1−xN on Si (100) Solar Cells (x = 0–0.56) Deposited by RF Sputtering. Materials. 2020; 13(10):2336. https://doi.org/10.3390/ma13102336

Chicago/Turabian StyleValdueza-Felip, Sirona, Rodrigo Blasco, Javier Olea, Alba Díaz-Lobo, Alejandro F. Braña, and Fernando B. Naranjo. 2020. "AlxIn1−xN on Si (100) Solar Cells (x = 0–0.56) Deposited by RF Sputtering" Materials 13, no. 10: 2336. https://doi.org/10.3390/ma13102336

APA StyleValdueza-Felip, S., Blasco, R., Olea, J., Díaz-Lobo, A., Braña, A. F., & Naranjo, F. B. (2020). AlxIn1−xN on Si (100) Solar Cells (x = 0–0.56) Deposited by RF Sputtering. Materials, 13(10), 2336. https://doi.org/10.3390/ma13102336