Mechanical Behavior of Printed Strain Hardening Cementitious Composites

Abstract

1. Introduction

2. Experimental Methods

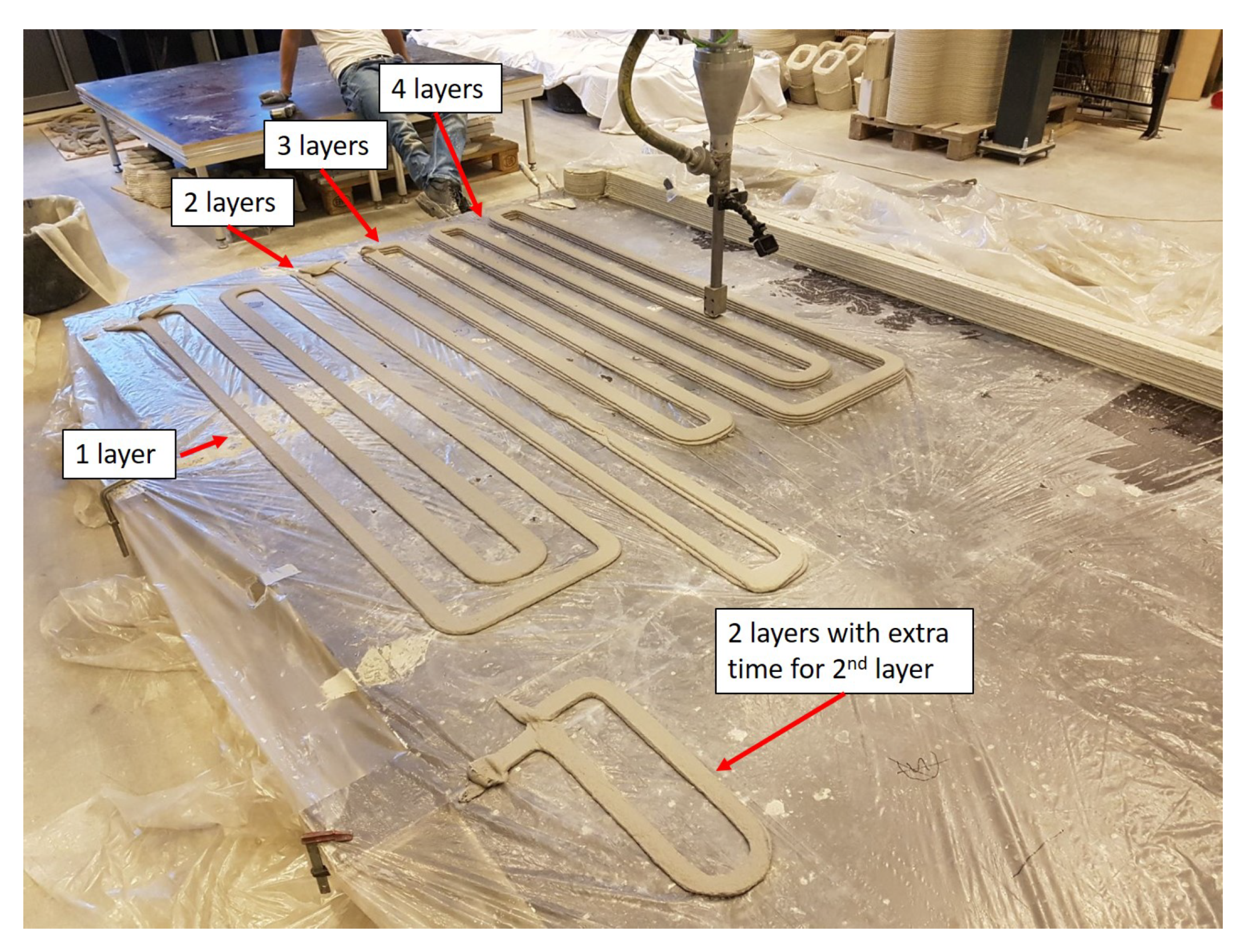

2.1. Materials and Methods

- All dry materials were mixed for two minutes;

- While mixing and within one minute, all the water mixed with superplasticizer was added to the dry mix;

- The last step from the mixing was used to make sure that a homogeneous fresh material was achieved, with no fibre lumps or dry powder left behind.

2.2. Mechanical Characterization

2.2.1. Compressive Strength Test

2.2.2. Fracture Toughness Test

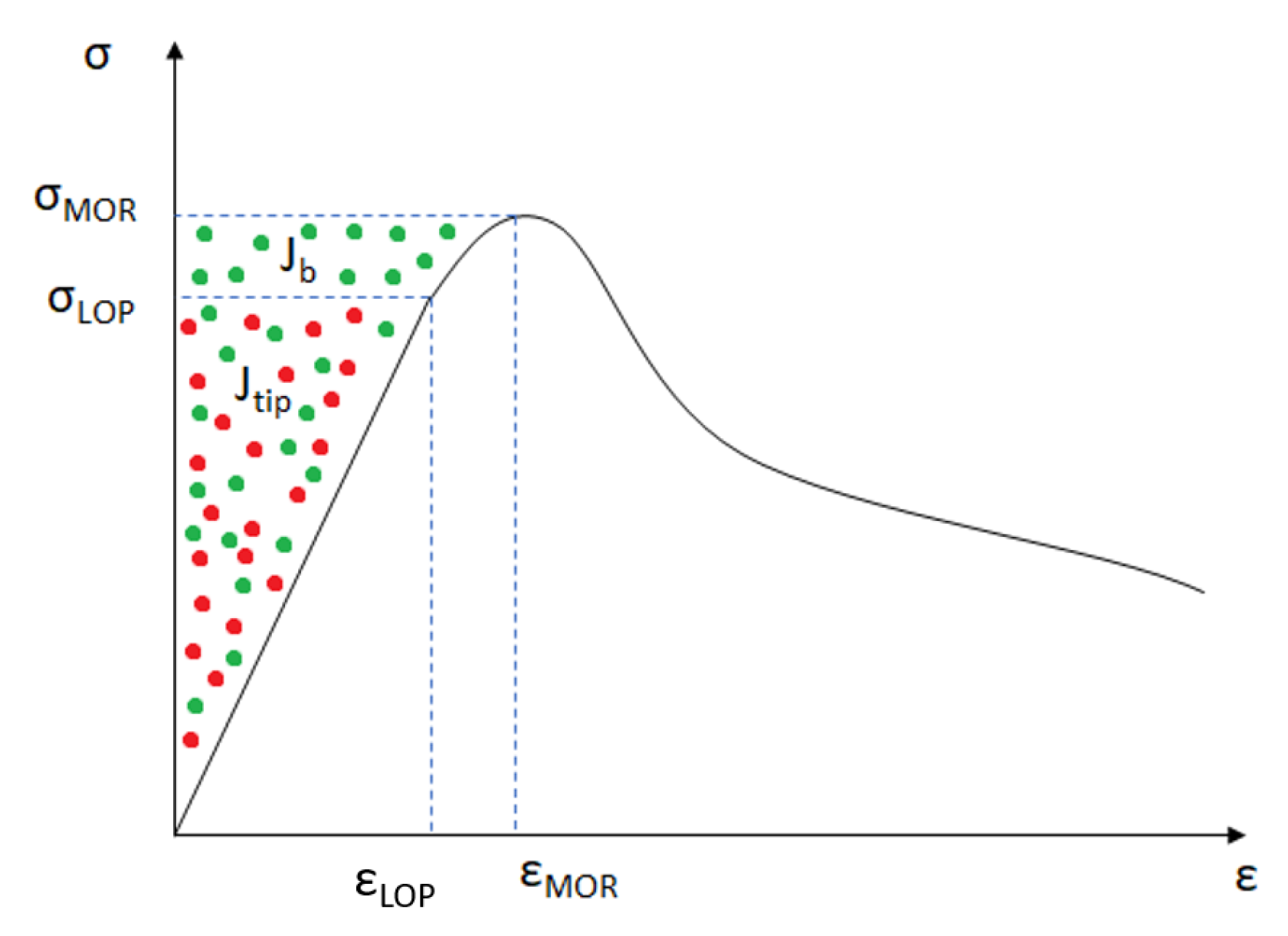

- Limit of proportionality (LOP) and its respective CMOD value: The LOP is the flexural stress obtained from the the first point out of the linear elastic phase;

- Modulus of rupture (MOR) and its respective CMOD value: The MOR is the maximum flexural stress of the composite;

- Matrix crack tip fracture toughness (): This value gives information regarding the matrix of the composite, measuring the amount of energy needed from the material to go over the elastic phase;

- The complementary energy (): This is the complementary energy needed to achieve MOR of the composite. Therefore, this value gives information regarding the amount of energy needed from the fibres being pulled-out from the matrix up to the maximum flexural stress:

2.2.3. Four-Point Bending Test

2.2.4. Uni-Axial Tensile Test

2.2.5. Uni-Axial Tensile Test of Two Printed Layers

2.3. Air Void Content and Fibre Orientation Assessment

3. Results

3.1. Compressive Strength

3.2. Fracture Toughness Test

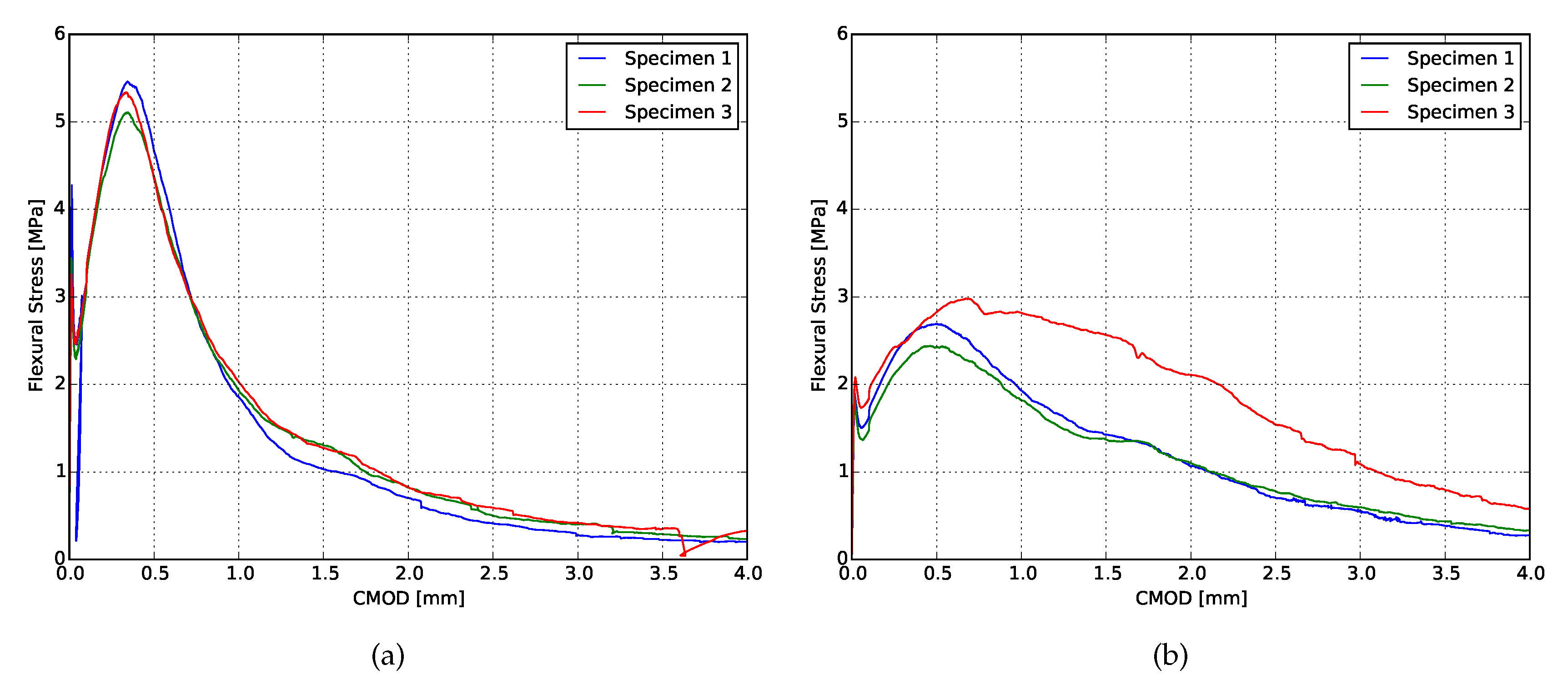

3.3. Four-Point Bending

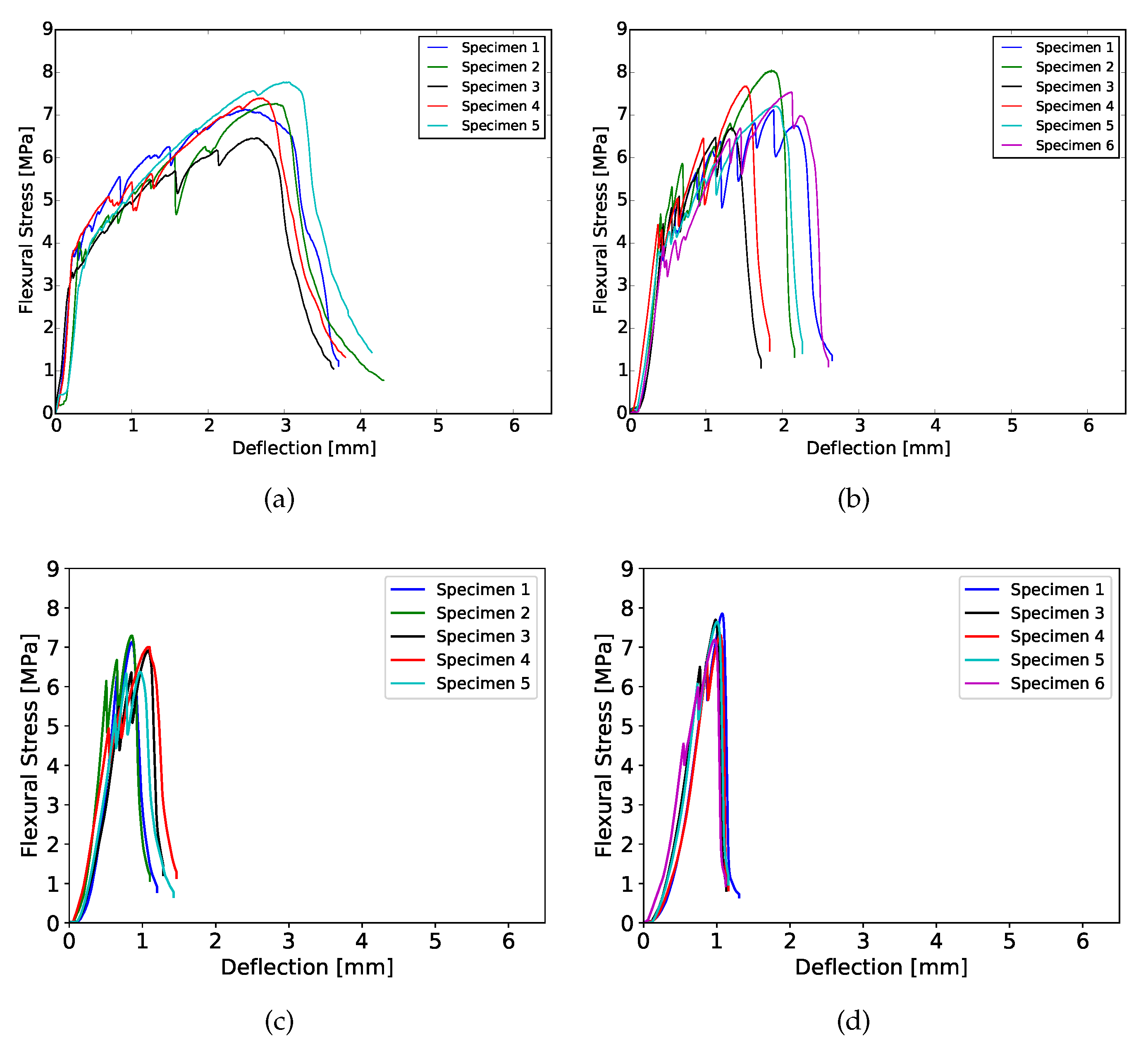

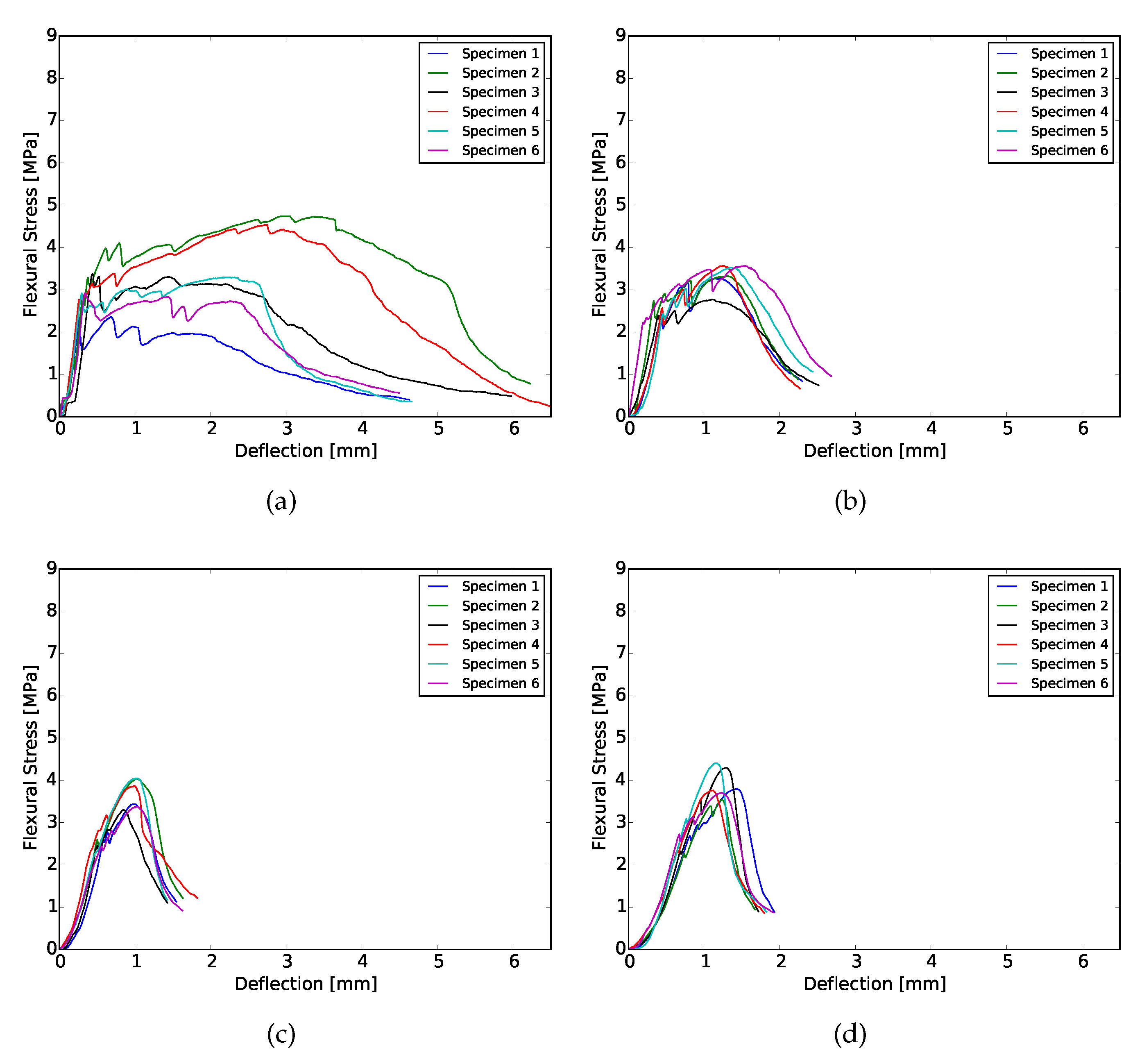

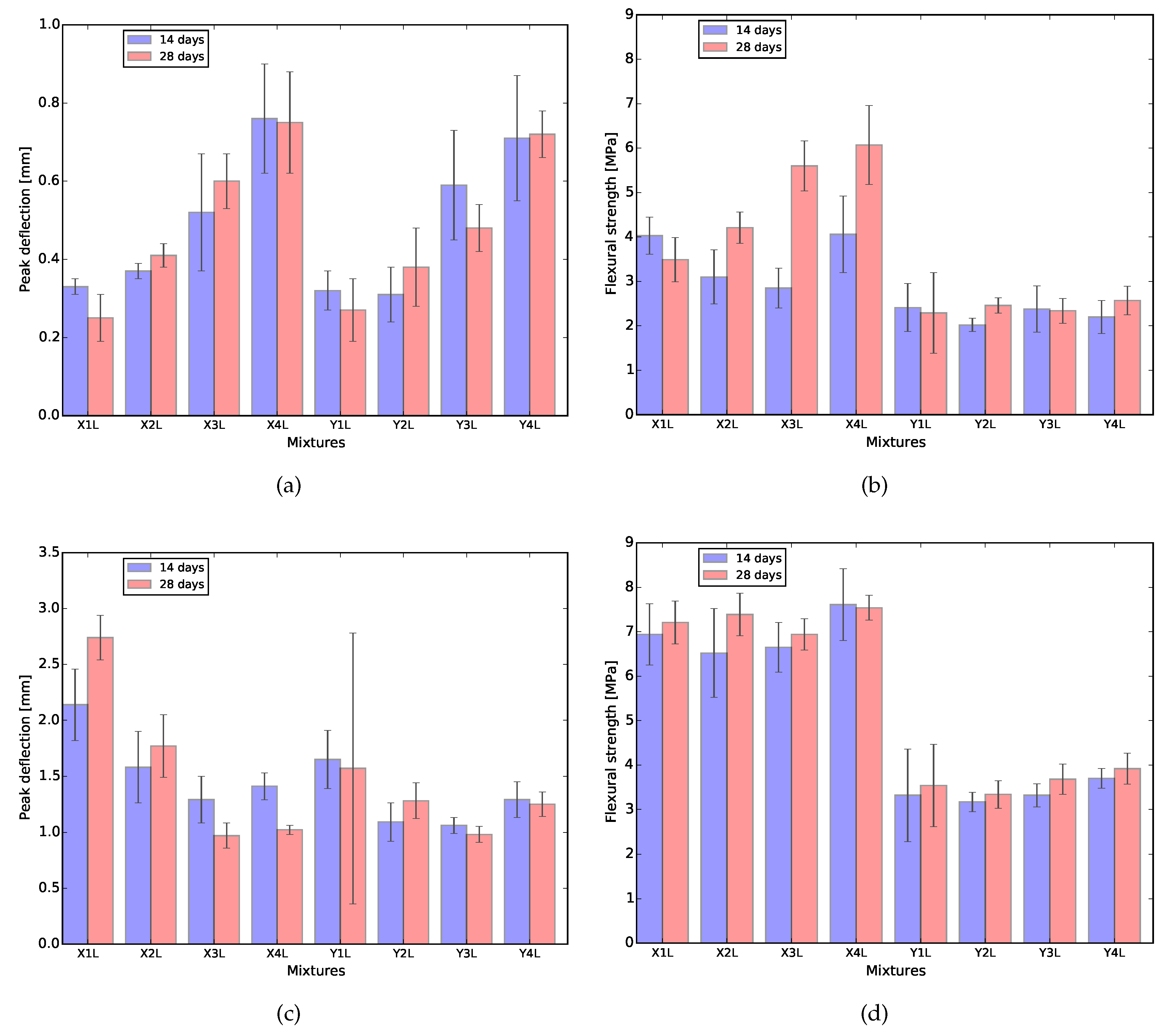

3.4. Uni-Axial Tensile Test

3.4.1. Loading Parallel to the Printing Direction (LPA)

3.4.2. Loading Perpendicular to the Printing Direction (LPE)

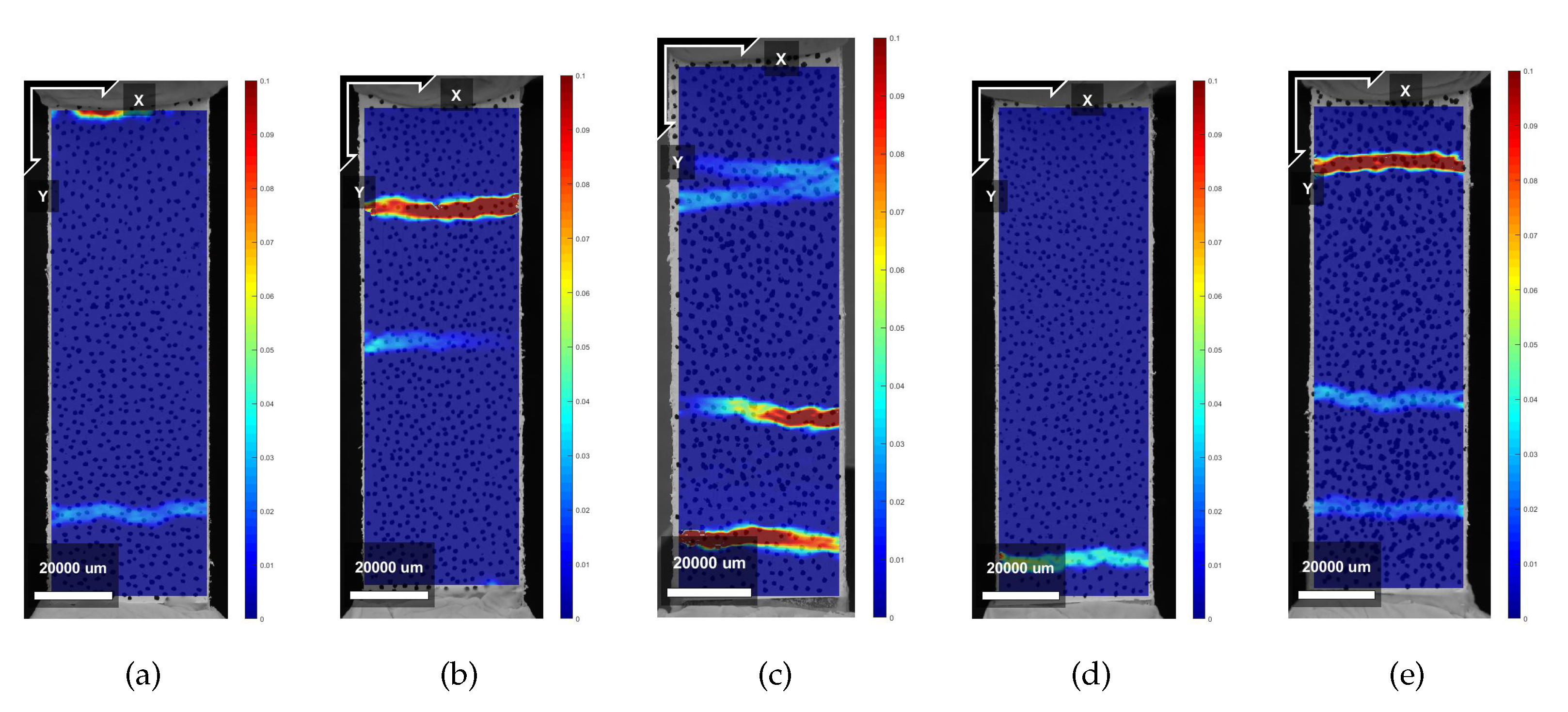

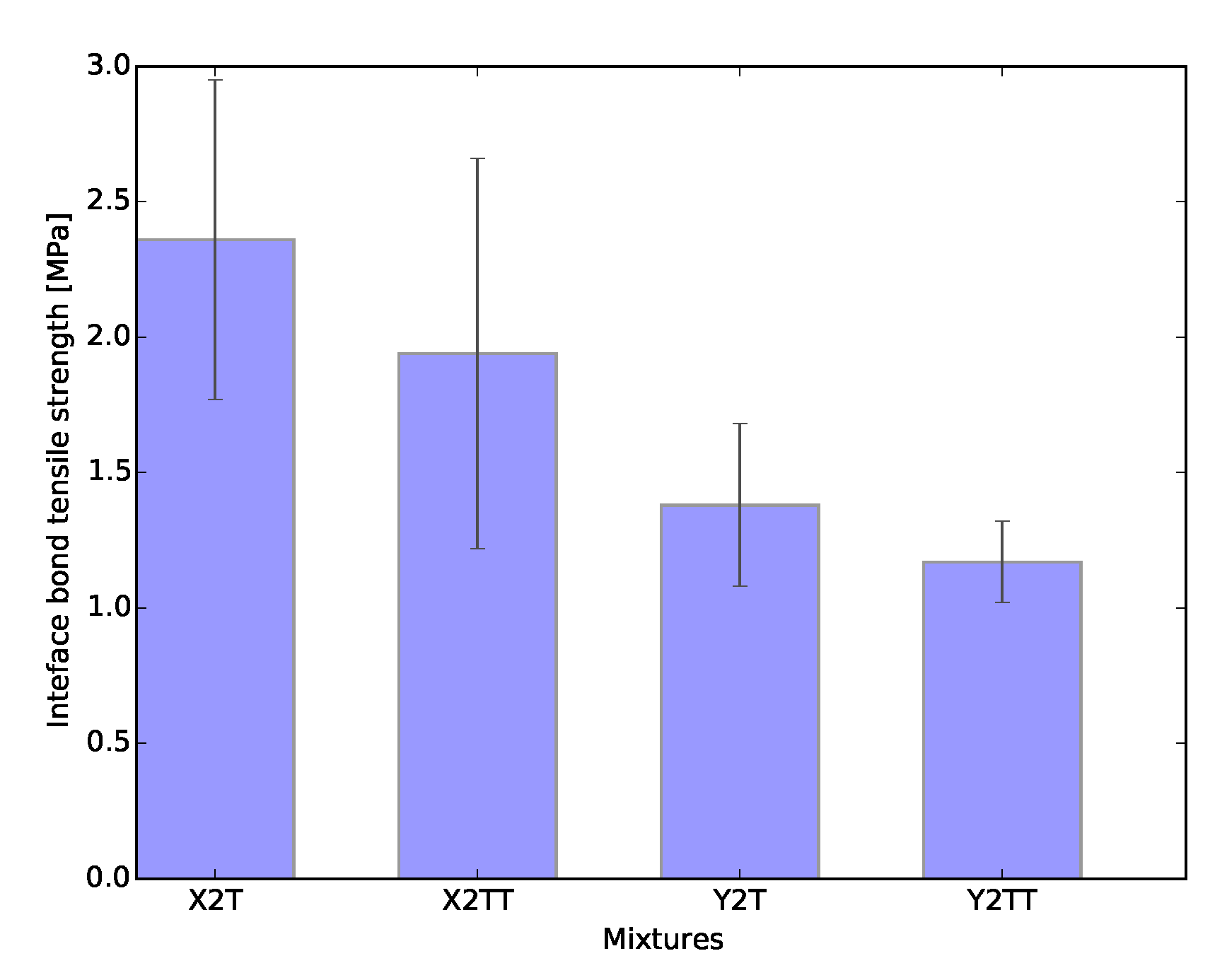

3.5. Tensile Bond Strength of Interface

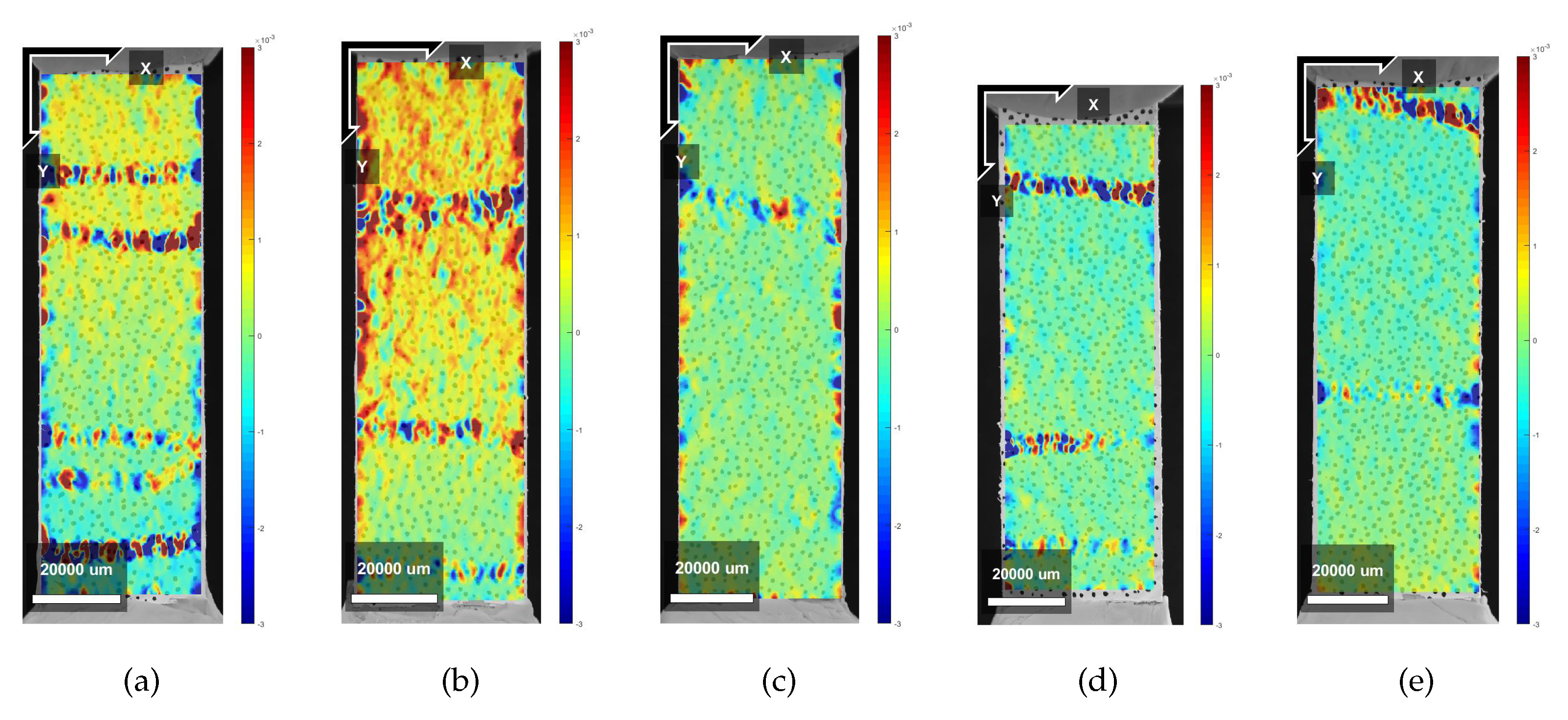

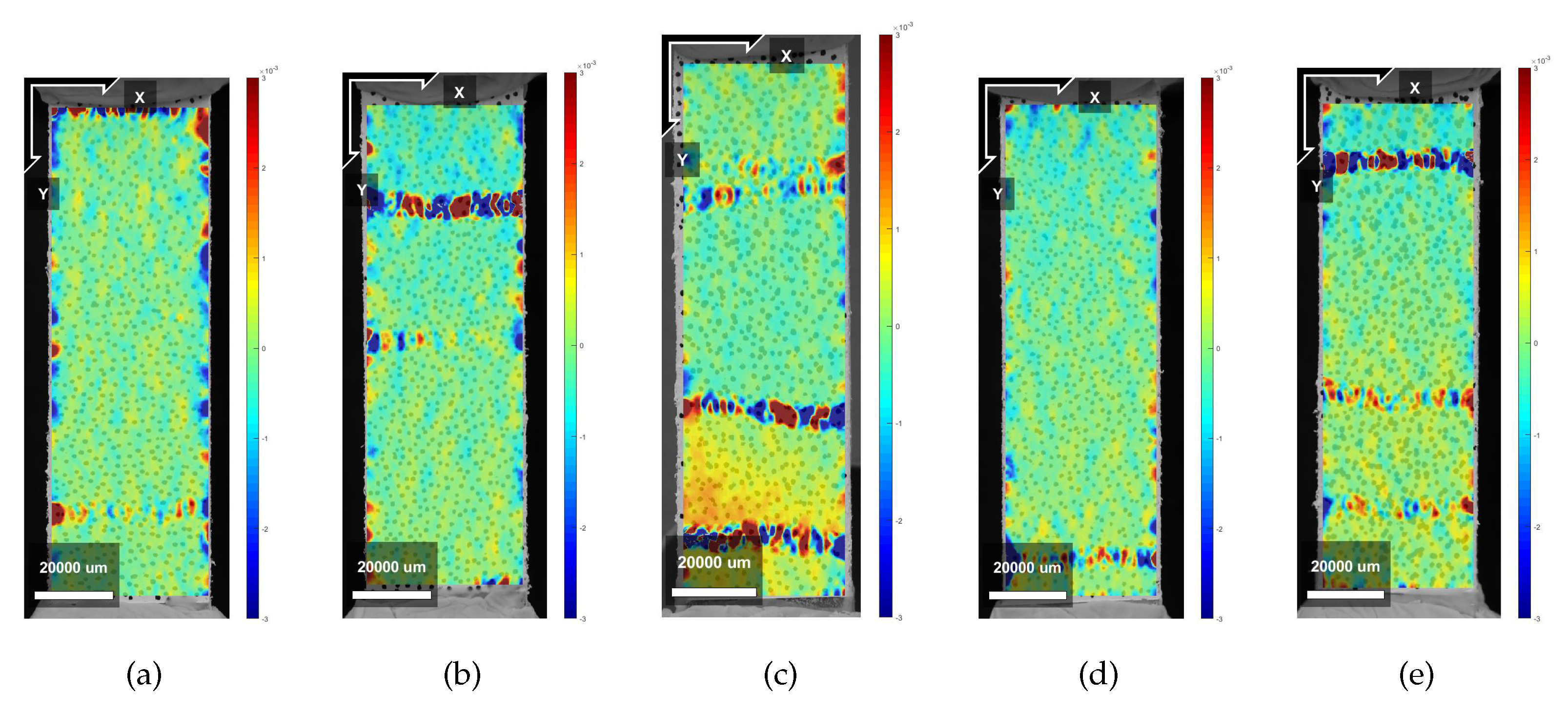

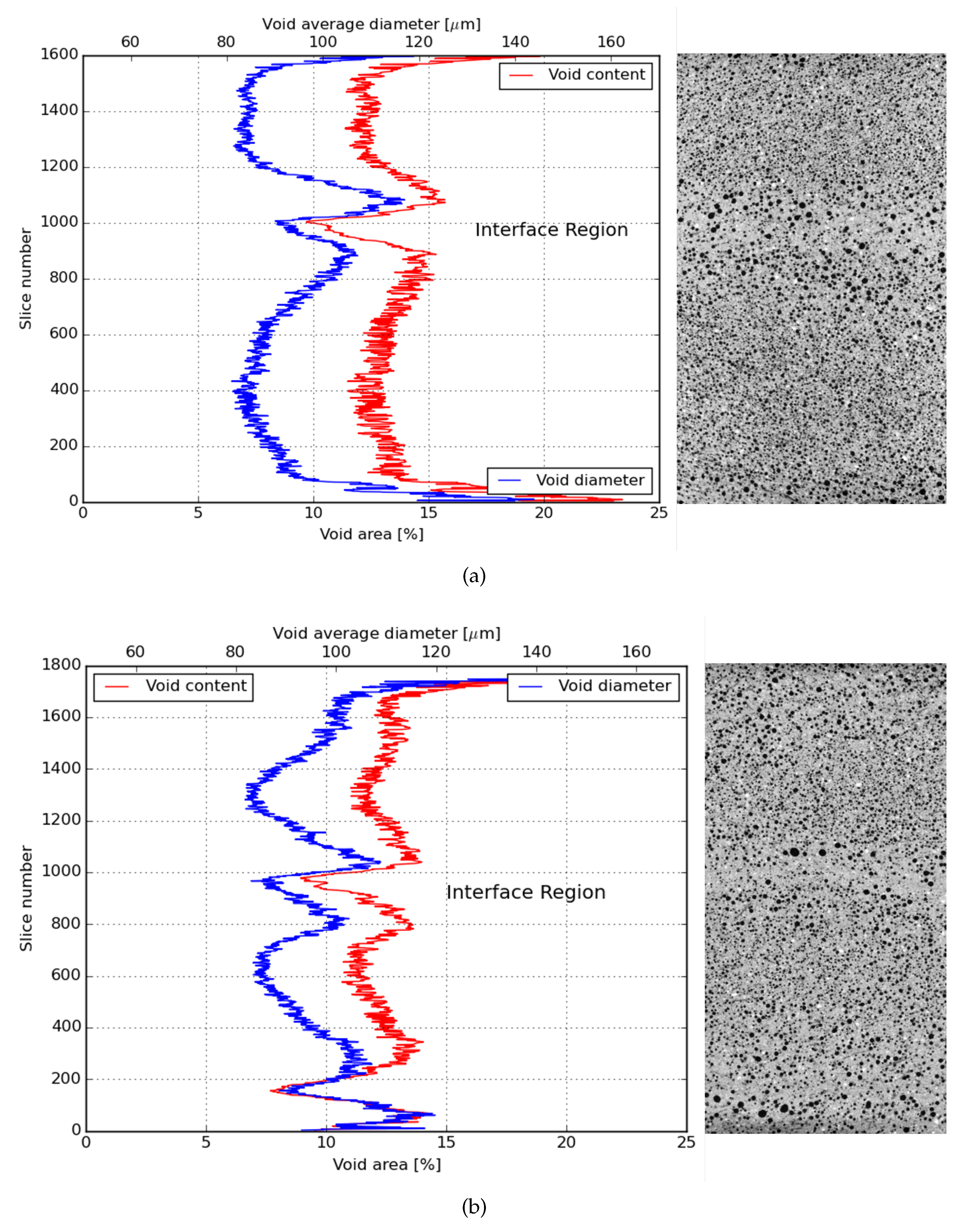

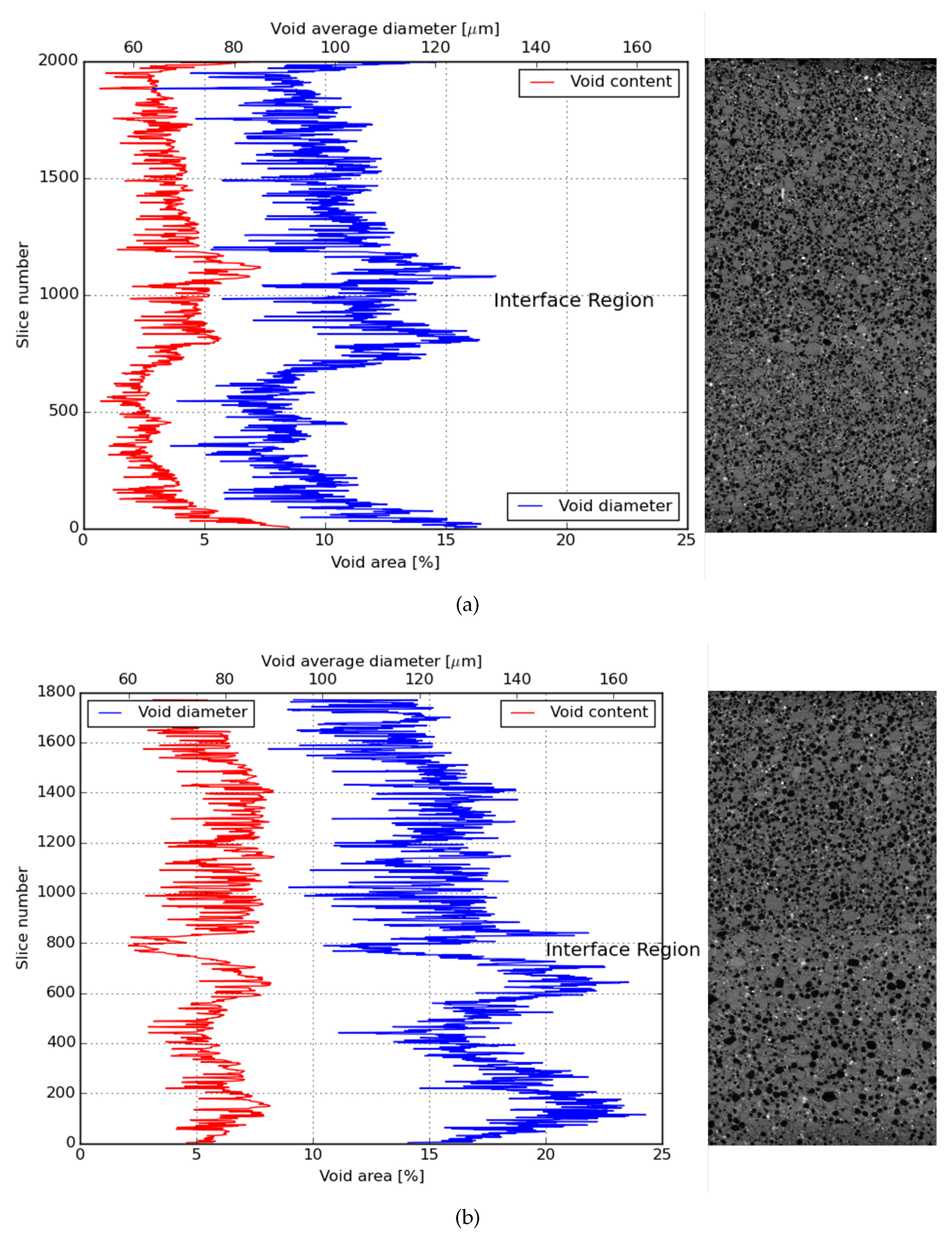

3.6. CT-Scan

4. Conclusions

- Two types of fibre reinforced cementitious composites were successfully printed and characterized. Both demonstrated anisotropic mechanical behavior when tested in direct tensile load with ductility found in two directions loaded parallel and perpendicular to the printing direction (LPA and LPE) and brittleness in the third direction (between two printed layers);

- Both composites showed flexural and strain hardening behavior, as well as multiple cracking, in LPA. Moreover, only the samples with 0.3 wt.% of HPMC and reinforced by 2 vol.% (XVA3PVA20) showed strain hardening in LPE;

- Besides the fact that both mixtures resulted in flexural hardening, 4-point bending tests also showed that thick samples fail to deliver high ductility. This behavior is due to the larger tensile forces in the tension zone. These forces cannot be distributed homogeneously to the fibres when a crack occurs. Consequently, the energy dissipated during the cracking can not be distributed along the specimen to create multiple cracking. Further research is needed to develop ductile composites that could dissipate such high energy;

- Extruding a printed layer against the previous one is a good strategy to enhance its bond strength. As observed in this study, the interface tensile strength of both mixtures were in the same range of values of the first crack when composites were loaded in LPA and LPE. Therefore, this was not a week zone in the composite;

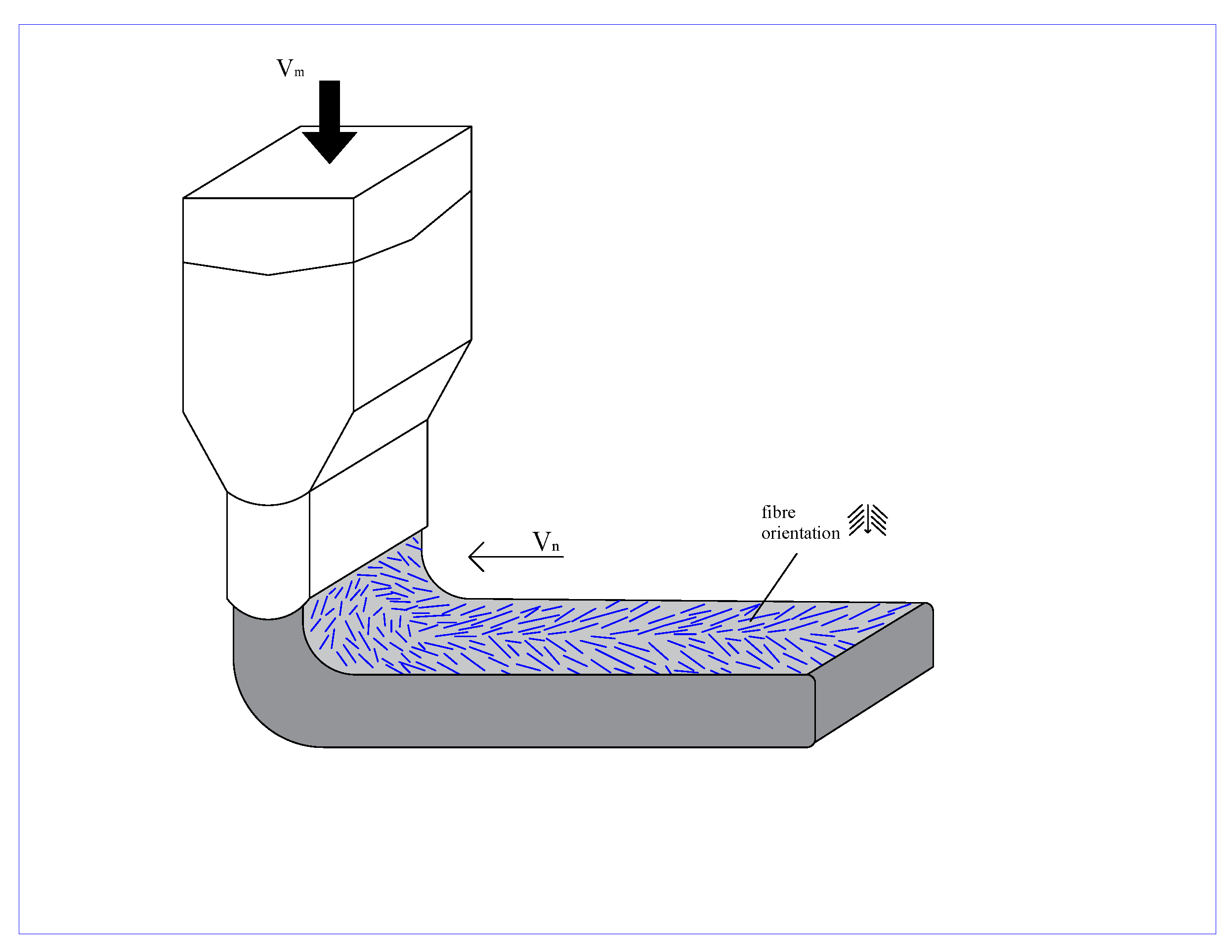

- The same extrusion technique that helped to improve tensile bond strength between printed layers may also have played a role in the fibre orientation, which was observed to be mainly diagonal to the print direction, rather than parallel to it. Flow speed differences in the filament also likely contribute to this fibre orientation.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wangler, T.; Roussel, N.; Bos, F.P.; Salet, T.A.; Flatt, R.J. Digital Concrete: A Review. Cem. Concr. Res. 2019, 123, 105780. [Google Scholar] [CrossRef]

- Bos, F.; Wolfs, R.; Ahmed, Z.; Salet, T. Additive manufacturing of concrete in construction: Potentials and challenges of 3D concrete printing. Virtual Phys. Prototyp. 2016, 11, 209–225. [Google Scholar] [CrossRef]

- Wangler, T.; Lloret, E.; Reiter, L.; Hack, N.; Gramazio, F.; Kohler, M.; Bernhard, M.; Dillenburger, B.; Buchli, J.; Roussel, N.; et al. Digital Concrete: Opportunities and Challenges. RILEM Tech. Lett. 2016, 1, 67–75. [Google Scholar] [CrossRef]

- Schutter, G.D.; Lesage, K.; Mechtcherine, V.; Nerella, V.N.; Habert, G.; Agusti-Juan, I. Vision of 3D printing with concrete—Technical, economic and environmental potentials. Cem. Concr. Res. 2018, 112, 25–36. [Google Scholar] [CrossRef]

- Tay, Y.W.D.; Panda, B.; Paul, S.C.; Mohamed, N.A.N.; Tan, M.J.; Leong, K.F. 3D printing trends in building and construction industry: A review. Virtual Phys. Prototyp. 2017, 12, 261–276. [Google Scholar] [CrossRef]

- Panda, B.; Tan, M.J. Experimental study on mix proportion and fresh properties of fly ash based geopolymer for 3D concrete printing. Ceram. Int. 2018, 44, 10258–10265. [Google Scholar] [CrossRef]

- Soltan, D.G.; Li, V.C. A self-reinforced cementitious composite for building-scale 3D printing. Cem. Concr. Compos. 2018, 90, 1–13. [Google Scholar] [CrossRef]

- Chen, Y.; Li, Z.; Chaves Figueiredo, S.; Çopuroğlu, O.; Veer, F.; Schlangen, E. Limestone and Calcined Clay-Based Sustainable Cementitious Materials for 3D Concrete Printing: A Fundamental Study of Extrudability and Early-Age Strength Development. Appl. Sci. 2019, 9, 1809. [Google Scholar] [CrossRef]

- Chen, Y.; Chaves Figueiredo, S.; Yalçinkaya, C.; Çopuroğlu, O.; Veer, F.; Schlangen, E. The Effect of Viscosity-Modifying Admixture on the Extrudability of Limestone and Calcined Clay-Based Cementitious Material for Extrusion-Based 3D Concrete Printing. Materials 2019, 12, 1374. [Google Scholar] [CrossRef]

- Ma, G.; Li, Z.; Wang, L. Printable properties of cementitious material containing copper tailings for extrusion based 3D printing. Constr. Build. Mater. 2018, 162, 613–627. [Google Scholar] [CrossRef]

- Salet, T.A.M.; Ahmed, Z.Y.; Bos, F.P.; Laagland, H.L.M. Design of a 3D printed concrete bridge by testing. Virtual Phys. Prototyp. 2018, 13, 222–236. [Google Scholar] [CrossRef]

- Buswell, R.; de Silva, W.L.; Jones, S.; Dirrenberger, J. 3D printing using concrete extrusion: A roadmap for research. Cem. Concr. Res. 2018, 112, 37–49. [Google Scholar] [CrossRef]

- Roussel, N. Rheological requirements for printable concretes. Cem. Concr. Res. 2018, 112, 76–85. [Google Scholar] [CrossRef]

- Asprone, D.; Menna, C.; Bos, F.P.; Salet, T.A.; Mata-Falcón, J.; Kaufmann, W. Rethinking reinforcement for digital fabrication with concrete. Cem. Concr. Res. 2018, 112, 111–121. [Google Scholar] [CrossRef]

- Asprone, D.; Auricchio, F.; Menna, C.; Mercuri, V. 3D printing of reinforced concrete elements: Technology and design approach. Constr. Build. Mater. 2018, 165, 218–231. [Google Scholar] [CrossRef]

- Bos, F.P.; Ahmed, Z.Y.; Jutinov, E.R.; Salet, T.A. Experimental exploration of metal cable as reinforcement in 3D printed concrete. Materials 2017, 10, 1314. [Google Scholar] [CrossRef]

- Bos, F.P.; Ahmed, Z.Y.; Wolfs, R.J.M.; Salet, T.A.M. 3D Printing Concrete with Reinforcement. In High Tech Concrete: Where Technology and Engineering Meet; Hordijk, D., Luković, M., Eds.; Springer International Publishing: Berlin, Germany, 2018; pp. 2484–2493. [Google Scholar]

- Ma, G.; Li, Z.; Wang, L.; Bai, G. Micro-cable reinforced geopolymer composite for extrusion-based 3D printing. Mater. Lett. 2019, 235, 144–147. [Google Scholar] [CrossRef]

- Lim, J.H.; Panda, B.; Pham, Q.C. Improving flexural characteristics of 3D printed geopolymer composites with in-process steel cable reinforcement. Constr. Build. Mater. 2018, 178, 32–41. [Google Scholar] [CrossRef]

- Shen, D.; Wang, X.; Cheng, D.; Zhang, J.; Jiang, G. Effect of internal curing with super absorbent polymers on autogenous shrinkage of concrete at early age. Constr. Build. Mater. 2016, 106, 512–522. [Google Scholar] [CrossRef]

- Santos, S.F.; Schmidt, R.; Almeida, A.E.; Tonoli, G.H.; Savastano, H. Supercritical carbonation treatment on extruded fibre–cement reinforced with vegetable fibres. Cem. Concr. Compos. 2015, 56, 84–94. [Google Scholar] [CrossRef]

- Hambach, M.; Rutzen, M.; Volkmer, D. Chapter 5-Properties of 3D-Printed Fiber-Reinforced Portland Cement Paste. In 3D Concrete Printing Technology; Sanjayan, J.G., Nazari, A., Nematollahi, B., Eds.; Butterworth-Heinemann: London, UK, 2019; pp. 73–113. [Google Scholar] [CrossRef]

- Panda, B.; Paul, S.C.; Tan, M.J. Anisotropic mechanical performance of 3D printed fiber reinforced sustainable construction material. Mater. Lett. 2017, 209, 146–149. [Google Scholar] [CrossRef]

- Nematollahi, B.; Vijay, P.; Sanjayan, J.; Nazari, A.; Xia, M.; Naidu Nerella, V.; Mechtcherine, V. Effect of Polypropylene Fibre Addition on Properties of Geopolymers Made by 3D Printing for Digital Construction. Materials 2018, 11, 2352. [Google Scholar] [CrossRef]

- Weng, Y.; Li, M.; Tan, M.J.; Qian, S. Design 3D printing cementitious materials via Fuller Thompson theory and Marson-Percy model. Constr. Build. Mater. 2018, 163, 600–610. [Google Scholar] [CrossRef]

- Zareiyan, B.; Khoshnevis, B. Effects of mixture ingredients on interlayer adhesion of concrete in Contour Crafting. Rapid Prototyp. J. 2018, 24, 584–592. [Google Scholar] [CrossRef]

- Bos, F.P.; Bosco, E.; Salet, T.A.M. Ductility of 3D printed concrete reinforced with short straight steel fibers. Virtual Phys. Prototyp. 2019, 14, 160–174. [Google Scholar] [CrossRef]

- Silva, F.D.A.; Mobasher, B.; Filho, R.D.T. Cracking mechanisms in durable sisal fiber reinforced cement composites. Cem. Concr. Compos. 2009, 31, 721–730. [Google Scholar] [CrossRef]

- Şahmaran, M.; Li, V.C. Durability properties of micro-cracked ECC containing high volumes fly ash. Cem. Concr. Res. 2009, 39, 1033–1043. [Google Scholar] [CrossRef]

- Müller, S.; Mechtcherine, V. Fatigue behavior of strain-hardening cement-based composites (SHCC). Cem. Concr. Res. 2017, 92, 75–83. [Google Scholar] [CrossRef]

- Özbay, E.; Karahan, O.; Lachemi, M.; Hossain, K.M.A.; Atis, C.D. Dual effectiveness of freezing-thawing and sulfate attack on high-volume slag-incorporated ECC. Compos. Part B Eng. 2013, 45, 1384–1390. [Google Scholar] [CrossRef]

- Kamal, A.; Kunieda, M.; Ueda, N.; Nakamura, H. Evaluation of crack opening performance of a repair material with strain hardening behavior. Cem. Concr. Compos. 2008, 30, 863–871. [Google Scholar] [CrossRef]

- Zhou, J.; Qian, S.; Sierra Beltran, M.G.; Ye, G.; Breugel, K.; Li, V.C. Development of engineered cementitious composites with limestone powder and blast furnace slag. Mater. Struct. 2010, 43, 803–814. [Google Scholar] [CrossRef]

- Wang, P.; Wittmann, F.H.; Zhang, P.; Lehmann, E.; Zhao, T. Durability and Service Life of Elements Made With Shcc Under Imposed Strain. In Proceedings of the SHCC3-3rd International RILEM Conference on Strain Hardening Cementitious Composites, Dordrecht, The Netherlands, 3–5 November 2014; pp. 33–41. [Google Scholar]

- Bao, Y.; Xu, M.; Soltan, D.; Xia, T.; Shih, A.; Clack, H.L.; Li, V.C. Three-Dimensional Printing Multifunctional Engineered Cementitious Composites (ECC) for Structural Elements. In Proceedings of the First, RILEM International Conference on Concrete and Digital Fabrication–Digital Concrete, Zurich, Switzerland, 10–12 September 2018; Wangler, T., Flatt, R.J., Eds.; Springer International Publishing: Berlin, Germany, 2019; pp. 115–128. [Google Scholar]

- Zhu, B.; Pan, J.; Nematollahi, B.; Zhou, Z.; Zhang, Y.; Sanjayan, J. Development of 3D printable engineered cementitious composites with ultra-high tensile ductility for digital construction. Mater. Des. 2019, 181, 108088. [Google Scholar] [CrossRef]

- Yu, J.; Leung, C.K.Y. Impact of 3D Printing Direction on Mechanical Performance of Strain-Hardening Cementitious Composite (SHCC). In Proceedings of the First, RILEM International Conference on Concrete and Digital Fabrication–Digital Concrete, Zurich, Switzerland, 15 January 2018; Wangler, T., Flatt, R.J., Eds.; Springer International Publishing: Berlin, Germany, 2019; pp. 255–265. [Google Scholar]

- Ogura, H.; Nerella, V.N.; Mechtcherine, V. Developing and Testing of Strain-Hardening Cement-Based Composites (SHCC) in the Context of 3D-Printing. Materials 2018, 11, 1375. [Google Scholar] [CrossRef]

- Moini, M.; Olek, J.; Youngblood, J.P.; Magee, B.; Zavattieri, P.D. Additive Manufacturing and Performance of Architectured Cement-Based Materials. Adv. Mater. 2018, 30, 1802123. [Google Scholar] [CrossRef]

- Jiang, D.; Hoglund, R.; Smith, D.E. Continuous Fiber Angle Topology Optimization for Polymer Composite Deposition Additive Manufacturing Applications. Fibers 2019, 7, 14. [Google Scholar] [CrossRef]

- Figueiredo, S.C.; Rodríguez, C.R.; Ahmed, Z.Y.; Bos, D.; Xu, Y.; Salet, T.M.; Çopuroğlu, O.; Schlangen, E.; Bos, F.P. An approach to develop printable strain hardening cementitious composites. Mater. Des. 2019, 169, 107651. [Google Scholar] [CrossRef]

- Benbow, J.J.; Jazayeri, S.H.; Bridgwater, J. The flow of pastes through dies of complicated geometry. Powder Technol. 1991, 65, 393–401. [Google Scholar] [CrossRef]

- Wolfs, R.; Bos, F.; Salet, T. Hardened properties of 3D printed concrete: The influence of process parameters on interlayer adhesion. Cem. Concr. Res. 2019, 119, 132–140. [Google Scholar] [CrossRef]

- Blaber, J.; Adair, B.; Antoniou, A. Ncorr: Open-Source 2D Digital Image Correlation Matlab Software. Exp. Mech. 2015, 55, 1105–1122. [Google Scholar] [CrossRef]

- Panda, B.; Paul, S.C.; Mohamed, N.A.N.; Tay, Y.W.D.; Tan, M.J. Measurement of tensile bond strength of 3D printed geopolymer mortar. Measurement 2018, 113, 108–116. [Google Scholar] [CrossRef]

- Nerella, V.N.; Hempel, S.; Mechtcherine, V. Effects of layer-interface properties on mechanical performance of concrete elements produced by extrusion-based 3D-printing. Constr. Build. Mater. 2019, 205, 586–601. [Google Scholar] [CrossRef]

- Luković, M.; Dong, H.; Šavija, B.; Schlangen, E.; Ye, G.; van Breugel, K. Tailoring strain-hardening cementitious composite repair systems through numerical experimentation. Cem. Concr. Compos. 2014, 53, 200–213. [Google Scholar] [CrossRef]

- Luković, M.; Šavija, B.; Dong, H.; Schlangen, E.; Ye, G. Micromechanical Study of the Interface Properties in Concrete Repair Systems. J. Adv. Concr. Technol. 2014, 12, 320–339. [Google Scholar] [CrossRef]

- Zareiyan, B.; Khoshnevis, B. Effects of interlocking on interlayer adhesion and strength of structures in 3D printing of concrete. Autom. Constr. 2017, 83, 212–221. [Google Scholar] [CrossRef]

- Van Der Putten, J.; De Schutter, G.; Van Tittelboom, K. The Effect of Print Parameters on the (Micro)structure of 3D Printed Cementitious Materials. In Proceedings of the First, RILEM International Conference on Concrete and Digital Fabrication–Digital Concrete, Zurich, Switzerland, 15 January 2018; Wangler, T., Flatt, R.J., Eds.; Springer International Publishing: Berlin, Germany, 2019; pp. 234–244. [Google Scholar]

- Schrofl, C.; Nerella, V.N.; Mechtcherine, V. Capillary Water Intake by 3D-Printed Concrete Visualised and Quantified by Neutron Radiography. In Proceedings of the First, RILEM International Conference on Concrete and Digital Fabrication–Digital Concrete, Zurich, Switzerland, 15 January 2018; Wangler, T., Flatt, R.J., Eds.; Springer International Publishing: Berlin, Germany, 2019; pp. 217–224. [Google Scholar]

- Arganda-carreras, I.; Kaynig, V.; Rueden, C.; Eliceiri, K.W.; Schindelin, J.; Cardona, A.; Seung, H.S. Trainable Weka Segmentation: A machine learning tool for microscopy pixel classification. Bioinformatics 2017, 33, 2424–2426. [Google Scholar] [CrossRef]

- Schindelin, J.; Arganda-carreras, I.; Frise, E.; Kaynig, V.; Pietzsch, T.; Preibisch, S.; Rueden, C.; Saalfeld, S.; Schmid, B.; Tinevez, J.Y.; et al. Fiji-an Open Source platform for biological image analysis. Nat. Methods 2012, 9, 676–682. [Google Scholar] [CrossRef]

- Le, T.; Austin, S.; Lim, S.; Buswell, R.; Law, R.; Gibb, A.; Thorpe, T. Hardened properties of high-performance printing concrete. Cem. Concr. Res. 2012, 42, 558–566. [Google Scholar] [CrossRef]

- Feng, P.; Meng, X.; Chen, J.F.; Ye, L. Mechanical properties of structures 3D printed with cementitious powders. Constr. Build. Mater. 2015, 93, 486–497. [Google Scholar] [CrossRef]

- Kanda, T.; Li, V.C. Practical Design Criteria for Saturated Pseudo Strain Hardening Behavior in ECC. J. Adv. Concr. Technol. 2006, 4, 59–72. [Google Scholar] [CrossRef]

- Wang, S.; Li, V.C. Engineered Cementitious Composites with High-Volume Fly Ash. Mater. J. 2007, 104, 233–241. [Google Scholar]

- Sahmaran, M.; Lachemi, M.; Hossain, K.M.; Ranade, R.; Li, V.C. Influence of aggregate type and size on ductility and mechanical properties of engineered cementitious composites. ACI Mater. J. 2009, 106, 308–316. [Google Scholar]

- Manno, R.; Gao, W.; Benedetti, I. Engineering the crack path in lattice cellular materials through bio-inspired micro-structural alterations. Extrem. Mech. Lett. 2019, 26, 8–17. [Google Scholar] [CrossRef]

- Figueiredo, S.C.; Çopuroğlu, O.; Schlangen, E. Effect of viscosity modifier admixture on Portland cement paste hydration and microstructure. Constr. Build. Mater. 2019, 212, 818–840. [Google Scholar] [CrossRef]

| XVA3 PVA20 | YVA4 PVA20-S05 | |

|---|---|---|

| CEM I 42.5 | 259.2 | 480.2 |

| Blast Furnace Slag | 604.9 | 0 |

| Fly ash | 0 | 567.6 |

| Limestone powder | 864.1 | 109.1 |

| Sand (125–250) μm | 0 | 186.3 |

| Sand (250–500) μm | 0 | 294 |

| PVA | 26 | 26 |

| HPMC | 5.1 | 6.5 |

| Superplasticizer | 17.3 | 13 |

| Water | 345.6 | 327.4 |

| Age [days] | XVA3 PVA20 | YVA4 PVA20-S05 | |

|---|---|---|---|

| Printed layers perpendicular to the load | 14 | 37.63 ± 3.8 | 14.57 ± 0.39 |

| 28 | 44.09 ± 4.33 | 17.66 ± 0.24 | |

| Printed layers parallel to the load | 14 | 34.98 ± 1 | 12.03 ± 1.04 |

| 28 | 41.93 ± 1.88 | 15.02 ± 0.52 |

| XVA3PVA20 | YVA4PVA20-S05 | |

|---|---|---|

| LOP [MPa] | 1.10 ± 0.17 | 0.56 ± 0.04 |

| CMOD at LOP [μm] | 10.60 ± 1.29 | 9.49 ± 0.93 |

| MOR [MPa] | 1.84 ± 0.09 | 0.97 ± 0.10 |

| CMOD at MOR [μm] | 341.99 ± 4.00 | 545.06 ± 112.15 |

| Jtip [kJ/m2] | 16.37 ± 4.51 | 7.11 ± 1.51 |

| Jb [kJ/m2] | 430.74 ± 14.62 | 260.94 ± 67.97 |

| Tensile Strength First Crack [MPa] | Deformation at First Crack [%] | |

|---|---|---|

| XLPA | 1.53 ± 0.23 | 0.023 ± 0.006 |

| XLPE | 1.84 ± 0.47 | 0.017 ± 0.003 |

| YLPA | 1.28 ± 0.33 | 0.022 ± 0.017 |

| YLPE | 1.15 ± 0.2 | 0.012 ± 0.003 |

| Maximum Tensile Strength [MPa] | Deformation at Maximum Tensile Strength [%] | |

|---|---|---|

| XLPA | 2.4 ± 0.26 | 0.26 ± 0.08 |

| XLPE | 2.41 ± 0.36 | 0.31 ± 0.26 |

| YLPA | 1.64 ± 0.23 | 0.15 ± 0.12 |

| YLPE | 1.65 ± 0.27 | 0.29 ± 0.26 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chaves Figueiredo, S.; Romero Rodríguez, C.; Y. Ahmed, Z.; Bos, D.H.; Xu, Y.; Salet, T.M.; Çopuroğlu, O.; Schlangen, E.; Bos, F.P. Mechanical Behavior of Printed Strain Hardening Cementitious Composites. Materials 2020, 13, 2253. https://doi.org/10.3390/ma13102253

Chaves Figueiredo S, Romero Rodríguez C, Y. Ahmed Z, Bos DH, Xu Y, Salet TM, Çopuroğlu O, Schlangen E, Bos FP. Mechanical Behavior of Printed Strain Hardening Cementitious Composites. Materials. 2020; 13(10):2253. https://doi.org/10.3390/ma13102253

Chicago/Turabian StyleChaves Figueiredo, Stefan, Claudia Romero Rodríguez, Zeeshan Y. Ahmed, Derk H. Bos, Yading Xu, Theo M. Salet, Oğuzhan Çopuroğlu, Erik Schlangen, and Freek P. Bos. 2020. "Mechanical Behavior of Printed Strain Hardening Cementitious Composites" Materials 13, no. 10: 2253. https://doi.org/10.3390/ma13102253

APA StyleChaves Figueiredo, S., Romero Rodríguez, C., Y. Ahmed, Z., Bos, D. H., Xu, Y., Salet, T. M., Çopuroğlu, O., Schlangen, E., & Bos, F. P. (2020). Mechanical Behavior of Printed Strain Hardening Cementitious Composites. Materials, 13(10), 2253. https://doi.org/10.3390/ma13102253