Mineral Materials Coated with and Consisting of MnOx—Characteristics and Application of Filter Media for Groundwater Treatment: A Review

Abstract

1. Introduction

2. Properties of Mineral Filter Media Commonly Used for Ground Water Treatment

2.1. Juxtaposition of Properties

2.2. Quartz Sand and Gravel

2.3. Chalcedonite

2.4. Diatomite

2.5. Glauconite

2.6. Zeolite

2.7. Anthracite

3. Manganese Oxides Coated Filter Media for Groundwater Treatment

3.1. Chemically Coated Filter Media

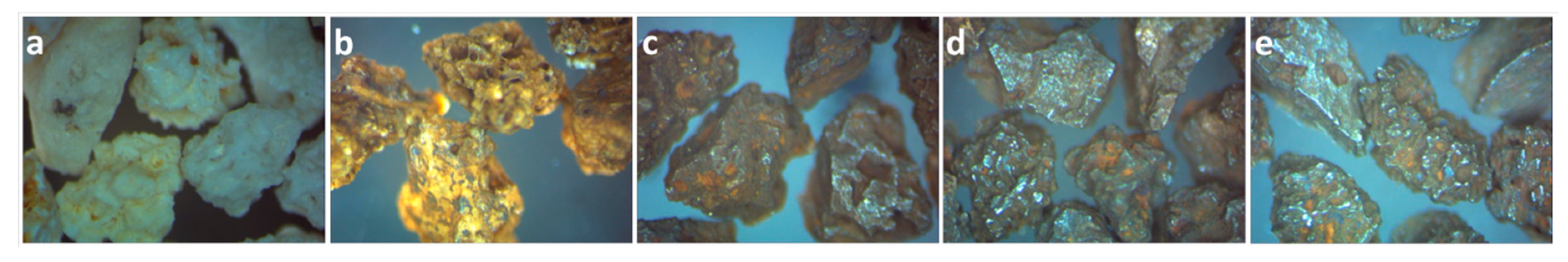

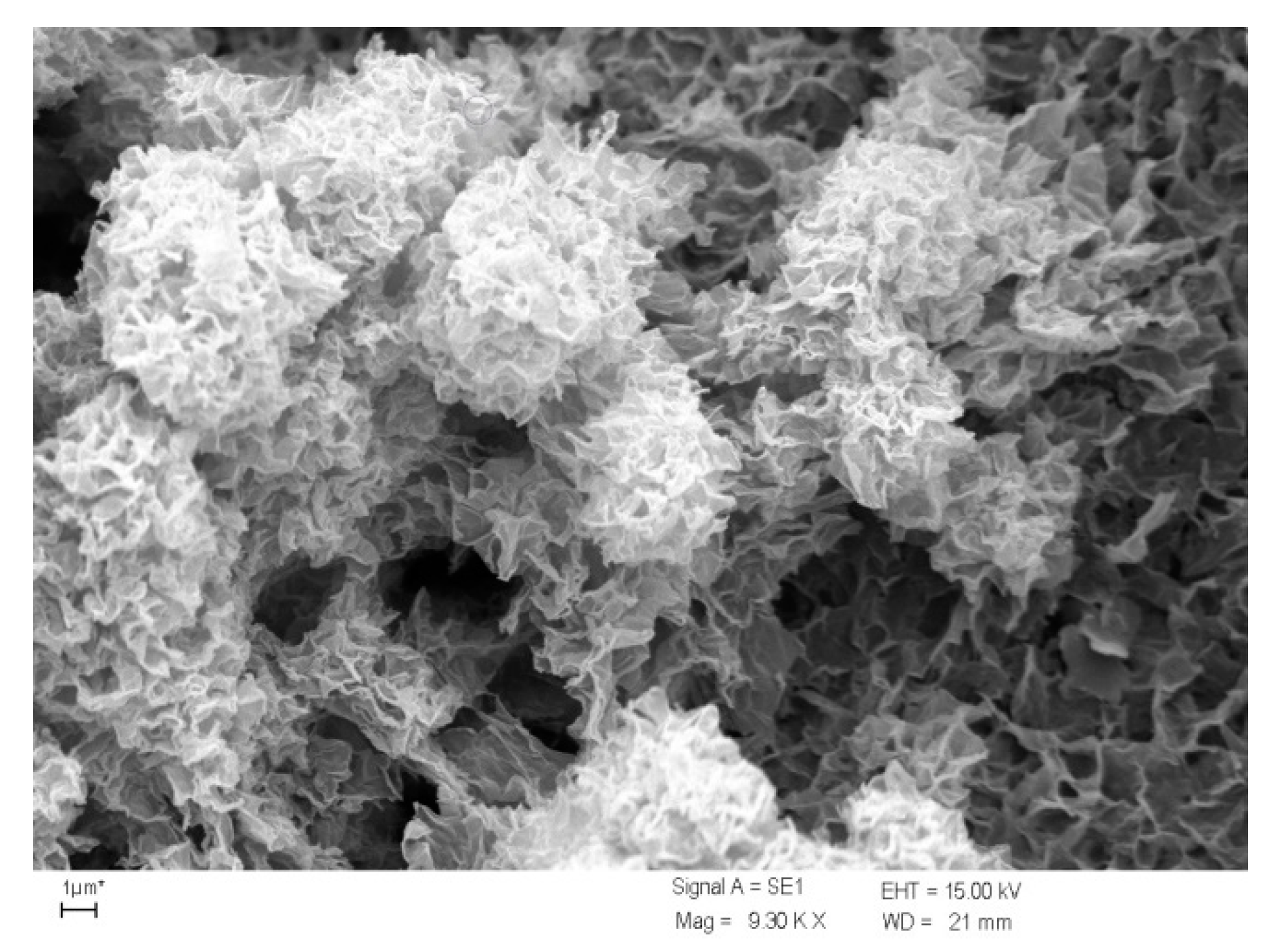

3.1.1. Coatings Characteristic

3.1.2. Adsorption Properties

3.1.3. Commercial Media Characteristic

3.1.4. Operating Conditions and Examples

3.2. Naturally Coated Filter Media

3.2.1. Coating Formation

3.2.2. Coatings Characteristic

4. Manganese Oxides Consisted of Filter Media for Groundwater Treatment

4.1. Manganese Ores Properties

4.2. Commercial Media Characteristic

4.3. Operating Conditions

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sen Gupta, S.; Bhattacharyya, K.G. Kinetics of adsorption of metal ions on inorganic materials: A review. Adv. Colloid Interface Sci. 2011, 162, 39–58. [Google Scholar] [CrossRef] [PubMed]

- Hua, M.; Zhang, S.; Pan, B.; Zhang, W.; Lv, L.; Zhang, Q. Heavy metal removal from water/wastewater by nanosized metal oxides: A review. J. Hazard. Mater. 2012, 211–212, 317–331. [Google Scholar] [CrossRef] [PubMed]

- Adeyemo, A.A.; Adeoye, I.O.; Bello, O.S. Adsorption of dyes using different types of clay: A review. Appl. Water Sci. 2017, 7, 543–568. [Google Scholar] [CrossRef]

- Jiang, N.; Shang, R.; Heijman, S.G.J.; Rietveld, L.C. High-silica zeolites for adsorption of organic micro-pollutants in water treatment: A review. Water Res. 2018, 144, 145–161. [Google Scholar] [CrossRef]

- Weidner, E.; Ciesielczyk, F. Removal of Hazardous Oxyanions from the Environment Using Metal-Oxide-Based Materials. Materials 2019, 12, 927. [Google Scholar] [CrossRef]

- Letterman, R.D.; American Water Works Association (Eds.) Water Quality and Treatment: A Handbook of Community Water Supplies, 5th ed.; McGraw-Hill: New York, NY, USA, 1999; ISBN 978-0-07-001659-0. [Google Scholar]

- Hendricks, D. Fundamentals of Water Treatment Unit Processes: Physical, Chemical, and Biological; IWA Publishing, CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2011; ISBN 978-1-4200-6192-5. [Google Scholar]

- Withers, A. Options for recarbonation, remineralisation and disinfection for desalination plants. Desalination 2005, 179, 11–24. [Google Scholar] [CrossRef]

- Greiserman, M.; Hasson, D.; Semiat, R.; Shemer, H. Kinetics of dolomite dissolution in a packed bed by acidified desalinated water. Desalination 2016, 396, 39–47. [Google Scholar] [CrossRef]

- Dong, J.; Xu, Z.; Yang, S.; Murad, S.; Hinkle, K.R. Zeolite membranes for ion separations from aqueous solutions. Curr. Opin. Chem. Eng. 2015, 8, 15–20. [Google Scholar] [CrossRef]

- Kayvani Fard, A.; McKay, G.; Buekenhoudt, A.; Al Sulaiti, H.; Motmans, F.; Khraisheh, M.; Atieh, M. Inorganic membranes: Preparation and application for water treatment and desalination. Materials 2018, 11, 74. [Google Scholar] [CrossRef]

- Goh, P.S.; Ismail, A.F. A review on inorganic membranes for desalination and wastewater treatment. Desalination 2018, 434, 60–80. [Google Scholar] [CrossRef]

- Bandura, L.; Woszuk, A.; Kołodyńska, D.; Franus, W. Application of Mineral Sorbents for Removal of Petroleum Substances: A Review. Minerals 2017, 7, 37. [Google Scholar] [CrossRef]

- Guidelines for Drinking-Water Quality: Fourth Edition Incorporating the First Addendum; World Health Organization: Geneva, Switzerland, 2017; ISBN 978-92-4-154995-0.

- Burri, N.M.; Weatherl, R.; Moeck, C.; Schirmer, M. A review of threats to groundwater quality in the anthropocene. Sci. Total Environ. 2019, 684, 136–154. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, A.Y.; Al-Ghouti, M.A. Approaches to achieve sustainable use and management of groundwater resources in Qatar: A review. Groundw. Sustain. Dev. 2020, 11, 100367. [Google Scholar] [CrossRef]

- Coyte, R.M.; Singh, A.; Furst, K.E.; Mitch, W.A.; Vengosh, A. Co-occurrence of geogenic and anthropogenic contaminants in groundwater from Rajasthan, India. Sci. Total Environ. 2019, 688, 1216–1227. [Google Scholar] [CrossRef]

- Vatandoost, M.; Naghipour, D.; Omidi, S.; Ashrafi, S.D. Survey and mapping of heavy metals in groundwater resources around the region of the Anzali International Wetland; a dataset. Data Brief 2018, 18, 463–469. [Google Scholar] [CrossRef]

- Li, F.; Qiu, Z.; Zhang, J.; Liu, W.; Liu, C.; Zeng, G. Investigation, pollution mapping and simulative leakage health risk assessment for heavy metals and metalloids in groundwater from a typical brownfield, Middle China. Int. J. Environ. Res. Public. Health 2017, 14, 768. [Google Scholar] [CrossRef]

- Liang, C.-P.; Jang, C.-S.; Liang, C.-W.; Chen, J.-S. Groundwater Vulnerability Assessment of the pingtung plain in Southern Taiwan. Int. J. Environ. Res. Public. Health 2016, 13, 1167. [Google Scholar] [CrossRef]

- Li, J.; He, Z.; Du, J.; Zhao, L.; Chen, L.; Zhu, X.; Lin, P.; Fang, S.; Zhao, M.; Tian, Q. Regional variability of agriculturally-derived nitrate-nitrogen in shallow groundwater in China, 2004–2014. Sustainability 2018, 10, 1393. [Google Scholar] [CrossRef]

- Guo, Q.; Zhou, Z.; Huang, G.; Dou, Z. Variations of groundwater quality in the multi-layered aquifer system near the Luanhe River, China. Sustainability 2019, 11, 994. [Google Scholar] [CrossRef]

- Lapworth, D.J.; Baran, N.; Stuart, M.E.; Ward, R.S. Emerging organic contaminants in groundwater: A review of sources, fate and occurrence. Environ. Pollut. 2012, 163, 287–303. [Google Scholar] [CrossRef]

- Koda, E.; Sieczka, A.; Miszkowska, A.; Osiński, P. Groundwater Contamination by Organic Compounds: A Case Study of Łubna Landfill Site in Warsaw, Poland. In Environmental Geotechnology; Agnihotri, A.K., Reddy, K.R., Bansal, A., Eds.; Lecture Notes in Civil Engineering; Springer Singapore: Singapore, 2019; Volume 31, pp. 307–317. ISBN 9789811370090. [Google Scholar]

- Jia, H.; Qian, H.; Qu, W.; Zheng, L.; Feng, W.; Ren, W. Fluoride occurrence and human health risk in drinking water wells from southern edge of Chinese Loess Plateau. Int. J. Environ. Res. Public. Health 2019, 16, 1683. [Google Scholar] [CrossRef] [PubMed]

- Verlicchi, P.; Grillini, V. Surface water and groundwater quality in South Africa and mozambique—Analysis of the Most critical pollutants for drinking purposes and challenges in water treatment selection. Water 2020, 12, 305. [Google Scholar] [CrossRef]

- Filtration Materials for Groundwater: A Guide to Good Practice; Kozyatnyk, I., Ed.; IWA Publishing: London, UK, 2016; ISBN 978-1-78040-699-2. [Google Scholar]

- van Beek, C.G.E.M.; Hiemstra, T.; Hofs, B.; Nederlof, M.M.; van Paassen, J.A.M.; Reijnen, G.K. Homogeneous, heterogeneous and biological oxidation of iron(II) in rapid sand filtration. J. Water Supply Res. Technol. Aqua 2012, 61, 1–13. [Google Scholar] [CrossRef]

- Vries, D.; Bertelkamp, C.; Schoonenberg Kegel, F.; Hofs, B.; Dusseldorp, J.; Bruins, J.H.; de Vet, W.; van den Akker, B. Iron and manganese removal: Recent advances in modelling treatment efficiency by rapid sand filtration. Water Res. 2017, 109, 35–45. [Google Scholar] [CrossRef]

- Park, B.; Dempsey, B.A. Heterogeneous Oxidation of Fe(II) on Ferric Oxide at Neutral pH and a Low Partial Pressure of O 2 †. Environ. Sci. Technol. 2005, 39, 6494–6500. [Google Scholar] [CrossRef]

- Tekerlekopoulou, A.G.; Pavlou, S.; Vayenas, D.V. Removal of ammonium, iron and manganese from potable water in biofiltration units: A review: Removal of ammonium, iron and manganese from potable water. J. Chem. Technol. Biotechnol. 2013, 88, 751–773. [Google Scholar] [CrossRef]

- Wirth, M. The magic of manganese dioxide: What it is and why you should care. Water Cond. Purif. Mag. 2013. [Google Scholar]

- European Food Safety Authority (EFSA). Safety in use of the treatments for the removal of manganese, iron and arsenic from natural mineral waters by oxyhydroxide media—Scientific Opinion of the Panel on Food additives, Flavourings, Processing aids and Materials in Contact with Food (AFC). EFSA J. 2008, 6, 784. [Google Scholar] [CrossRef]

- Kaleta, J.; Puszkarewicz, A.; Papciak, D. Removal of iron, manganese and nitrogen compounds from underground waters with diverse physical and chemical characteristics. Environ. Prot. Eng. 2007, 33, 5–13. [Google Scholar]

- Tobiason, J.E.; Bazilio, A.; Goodwill, J.; Mai, X.; Nguyen, C. Manganese removal from drinking water sources. Curr. Pollut. Rep. 2016, 2, 168–177. [Google Scholar] [CrossRef]

- Bielański, A. Podstawy Chemii Nieorganicznej. 1 1; Wydawnictwo Naukowe PWN: Warszawa, Poland, 2012; ISBN 978-83-01-16281-8. [Google Scholar]

- Fritsch, S.; Post, J.E.; Navrotsky, A. Energetics of low-temperature polymorphs of manganese dioxide and oxyhydroxide. Geochim. Cosmochim. Acta 1997, 61, 2613–2616. [Google Scholar] [CrossRef]

- Feng, Q.; Kanoh, H.; Ooi, K. Manganese oxide porous crystals. J. Mater. Chem. 1999, 9, 319–333. [Google Scholar] [CrossRef]

- Murray, J.W. The surface chemistry of hydrous manganese dioxide. J. Colloid Interface Sci. 1974, 46, 357–371. [Google Scholar] [CrossRef]

- Lee, C.; Yang, W.; Hsieh, C. Removal of copper (II) by manganese-coated sand in a liquid fluidized-bed reactor. J. Hazard. Mater. 2004, 114, 45–51. [Google Scholar] [CrossRef] [PubMed]

- Taffarel, S.R.; Rubio, J. Removal of Mn2+ from aqueous solution by manganese oxide coated zeolite. Miner. Eng. 2010, 23, 1131–1138. [Google Scholar] [CrossRef]

- Huang, X.; Chen, T.; Zou, X.; Zhu, M.; Chen, D.; Pan, M. The adsorption of Cd(II) on manganese oxide investigated by batch and modeling techniques. Int. J. Environ. Res. Public. Health 2017, 14, 1145. [Google Scholar] [CrossRef]

- Islam, M.A.; Morton, D.W.; Johnson, B.B.; Mainali, B.; Angove, M.J. Manganese oxides and their application to metal ion and contaminant removal from wastewater. J. Water Process Eng. 2018, 26, 264–280. [Google Scholar] [CrossRef]

- Slavik, I.; Jehmlich, A.; Uhl, W. Impact of backwashing procedures on deep bed filtration productivity in drinking water treatment. Water Res. 2013, 47, 6348–6357. [Google Scholar] [CrossRef]

- Siwiec, T. The sphericity of grains of filtration beds applied for water treatment on examples of selected minerals. Electron. J. Pol. Agric. Univ. 2007, 10, 1–30. [Google Scholar]

- Beňo, J.; Mikšovský, F.; Jelínek, P.; Konečná, K.; Smysl, P. Alternative Evaluation of the Properties of the Silica Sands. Arch. Metall. Mater. 2014, 59, 735–738. [Google Scholar] [CrossRef]

- Anthony, J.W.; Bideaux, R.A.; Bladh, K.W.; Nichols, M.C. (Eds.) Handbook of Mineralogy; Mineralogical Society of America: Chantilly, VA, USA; Available online: http://www.handbookofmineralogy.org/ (accessed on 22 March 2020).

- Naziemiec, Z.; Pichniarczyk, P.; Saramak, D. Methods of improvement chalcedonite processing effectiveness with the use of density separation. Gospod. Surowcami Miner. 2017, 33, 163–178. [Google Scholar] [CrossRef][Green Version]

- Michel, M.M. Charakterystyka chalcedonitu ze złoża Teofilów pod kątem możliwości wykorzystania w technologii uzdatniania wody i oczyszczania ścieków. Gospod. Surowcami Miner. 2011, 27, 49–67. [Google Scholar]

- Radziemska, M.; Koda, E.; Bilgin, A.; Vaverková, M. Concept of aided phytostabilization of contaminated soils in postindustrial areas. Int. J. Environ. Res. Public. Health 2017, 15, 24. [Google Scholar] [CrossRef] [PubMed]

- Roniewicz, P. Przewodnik do Ćwiczeń z Geologii Dynamicznej: Praca Zbiorowa; Polska Agencja Ekologiczna: Warszawa, Poland, 1999; ISBN 978-83-85636-16-8. [Google Scholar]

- Inglethorpe, S.D.J. Industrial Minerals Laboratory Manual: Diatomite: British Geological Survey, Mineralogy & Petrology Series, Technical Report WG/92/39; British Geological Survey: Nottingham, UK, 1993. [Google Scholar]

- Flores-Cano, J.V.; Leyva-Ramos, R.; Padilla-Ortega, E.; Mendoza-Barron, J. Adsorption of Heavy Metals on Diatomite: Mechanism and Effect of Operating Variables. Adsorpt. Sci. Technol. 2013, 31, 275–291. [Google Scholar] [CrossRef]

- Manecki, A.; Muszyński, M.; Czerny, J. Przewodnik do Petrografii: Praca Zbiorowa; AGH Uczelniane Wydawnictwa Naukowo-Dydaktyczne: Kraków, Poland, 2008; ISBN 978-83-7464-110-4. [Google Scholar]

- Benkacem, T.; Hamdi, B.; Chamayou, A.; Balard, H.; Calvet, R. Physicochemical characterization of a diatomaceous upon an acid treatment: A focus on surface properties by inverse gas chromatography. Powder Technol. 2016, 294, 498–507. [Google Scholar] [CrossRef]

- Figarska-Warchoł, B.; Stańczak, G.; Rembiś, M.; Toboła, T. Diatomaceous rocks of the Jawornik deposit (the Polish Outer Carpathians)—Petrophysical and petrographical evaluatio. Geol. Geophys. Environ. 2015, 41, 311. [Google Scholar] [CrossRef]

- Hernández-Ávila, J.; Salinas-Rodríguez, E.; Cerecedo-Sáenz, E.; Reyes-Valderrama, M.; Arenas-Flores, A.; Román-Gutiérrez, A.; Rodríguez-Lugo, V. Diatoms and their capability for heavy metal removal by cationic exchange. Metals 2017, 7, 169. [Google Scholar] [CrossRef]

- Belousov, P.; Semenkova, A.; Egorova, T.; Romanchuk, A.; Zakusin, S.; Dorzhieva, O.; Tyupina, E.; Izosimova, Y.; Tolpeshta, I.; Chernov, M.; et al. Cesium sorption and desorption on glauconite, bentonite, zeolite and diatomite. Minerals 2019, 9, 625. [Google Scholar] [CrossRef]

- Geptner, A.R.; Ivanovskaya, T.A. Glauconite from lower cretaceous marine terrigenous rocks of England: A concept of biochemogenic origin. Lithol. Miner. Resour. 2000, 35, 434–444. [Google Scholar] [CrossRef]

- Franus, M.; Bandura, L.; Madej, J. Mono and poly-cationic adsorption of heavy metals using natural glauconite. Minerals 2019, 9, 470. [Google Scholar] [CrossRef]

- Franus, M. Zastosowanie Glaukonitu do Usuwania Śladowych Ilości Metali Ciężkich: Application of Glauconite for Removal of Traces Heavy Metals; Monografie / Politechnika Lubelska; Politechnika Lubelska: Lublin, Poland, 2010; ISBN 978-83-62596-06-5. [Google Scholar]

- Ivanovskaya, T.A.; Geptner, A.R. Glauconite at Different Stages of Lithogenesis in Lower Cambrian Rocks of Western Lithuania. Lithol. Miner. Resour. 2004, 39, 191–202. [Google Scholar] [CrossRef]

- Barlokova, D.; Ilavsky, J. Removal of iron and manganese from water using filtration by natural materials. Pol. J. Environ. Study 2010, 19, 1117–1122. [Google Scholar]

- European Standard EN 16070:2014. Products Used for Treatment of Water Intended for Human Consumption—Natural Zeolite; European Committee for Standarization: Brussels, Belgium, 2014. [Google Scholar]

- Nazarenko, O.; Zarubina, R. Application of Sakhaptinsk zeolite for improving the quality of ground water. Energy Environ. Eng. 2013, 1, 68–73. [Google Scholar] [CrossRef]

- Doula, M.K. Removal of Mn2+ ions from drinking water by using Clinoptilolite and a Clinoptilolite–Fe oxide system. Water Res. 2006, 40, 3167–3176. [Google Scholar] [CrossRef]

- Ibrahim, K.; Khoury, H.; Tuffaha, R. Mo and Ni removal from drinking water using zeolitic tuff from Jordan. Minerals 2016, 6, 116. [Google Scholar] [CrossRef]

- Isaias, N.P. Experience in reverse osmosis pretreatment. Desalination 2001, 139, 57–64. [Google Scholar] [CrossRef]

- Mitrouli, S.T.; Karabelas, A.J.; Yiantsios, S.G.; Kjølseth, P.A. New granular materials for dual-media filtration of seawater: Pilot testing. Sep. Purif. Technol. 2009, 65, 147–155. [Google Scholar] [CrossRef]

- Magasinski, A.; Furdin, G.; Marêché, J.F.; Medjahdi, G.; Albiniak, A.; Broniek, E.; Jasienko-Halat, M. Graphitization, intercalation, and exfoliation of cokes and anthracites: A comparative study. Fuel Process. Technol. 2002, 79, 259–264. [Google Scholar] [CrossRef]

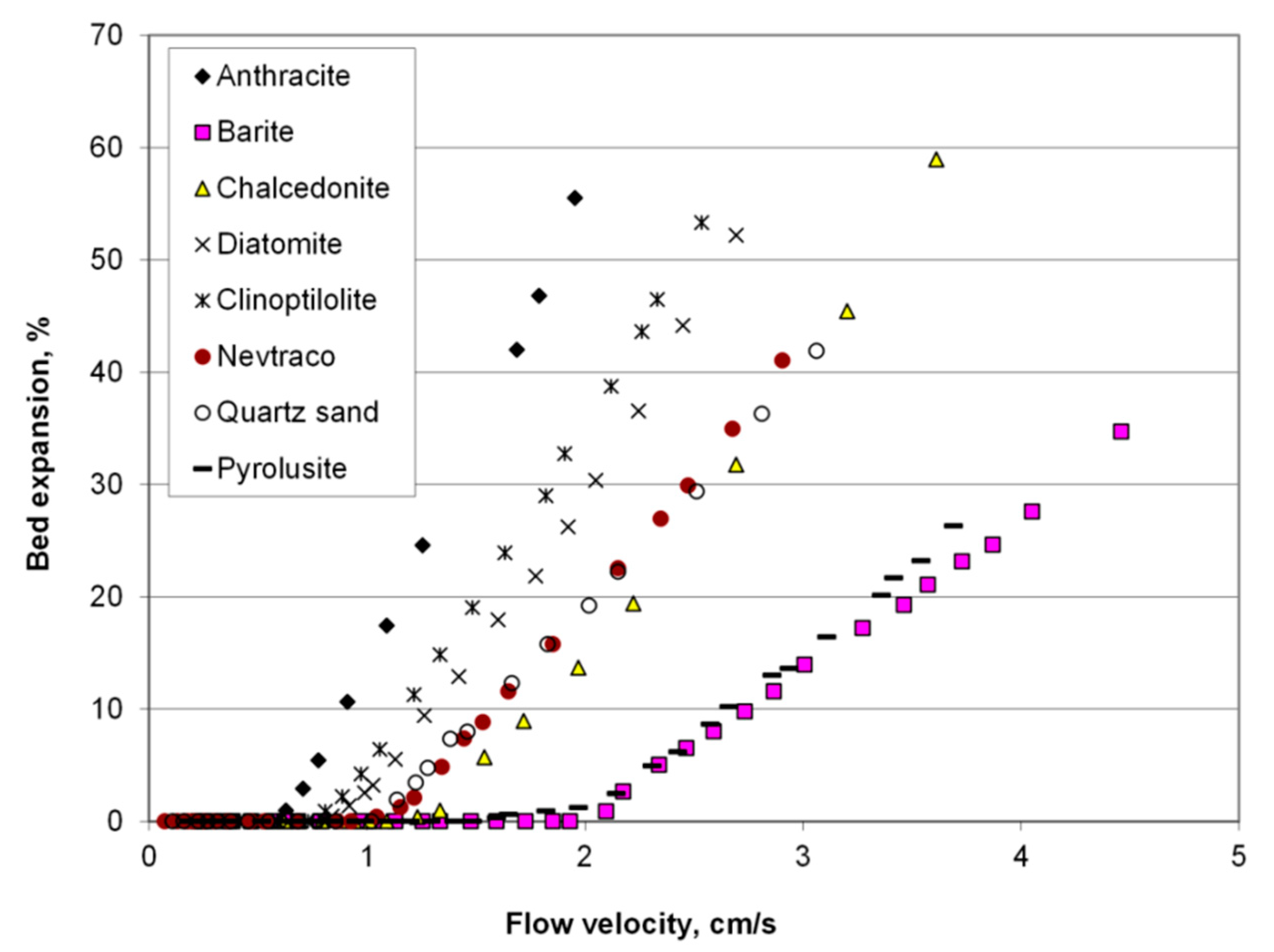

- Siwiec, T. The experimental verification of Richardson-Zaki law on example of selected beds used in water treatment. Electron. J. Pol. Agric. Univ. 2007, 10, 1–5. [Google Scholar]

- European Standard EN 12904:2005. Products Used for Treatment of Water Intended for Human Consumption—Silica Sand and Silica Gravel; European Committee for Standarization: Brussels, Belgium, 2005. [Google Scholar]

- Kaluđerović Radoičić, T.; Đuriš, M.; Garić-Grulović, R.; Arsenijević, Z.; Grbavčić, Ž. Particle characterization of polydisperse quartz filtration sand. Powder Technol. 2014, 254, 63–71. [Google Scholar] [CrossRef]

- Morawiecki, A. O chalcedonicie spongiolitowym znad Pilicy. Arch. Mineral. 1955, 19, 89–129. [Google Scholar]

- Haldar, S.K. Introduction to Mineralogy and Petrology; Elsevier: Amsterdam, The Netherland, 2014; ISBN 978-0-12-408133-8. [Google Scholar]

- Ratajczak, T.; Wyszomirski, P. Charakterystyka mineralogiczno-surowcowa chalcedonitów spongiolitowych z Teofilowa nad Pilicą. Gospod. Surowcami Miner. 1991, 7, 65–84. [Google Scholar]

- Hygienic Certificate BK/W/0076/01/2018 of Chalcedonite. 2018.

- Chalcedonite Manufacturer’s Website. Available online: http://crusil.pl/zestawienie-miejsc-z-chalcedonitem/ (accessed on 14 February 2020).

- Ryka, W.; Maliszewska, A. Słownik Petrograficzny; Wyd. 2., popr. i uzup.; Wydawnictwa Geologiczne: Warszawa, Poland, 1991; ISBN 978-83-220-0406-7. [Google Scholar]

- Puszkarewicz, A.; Kaleta, J. Adsorption of chromium (VI) on raw and modified carpathian diatomite. J. Ecol. Eng. 2019, 20, 11–17. [Google Scholar] [CrossRef]

- Galal Mors, H.E. Diatomite: Its characterization, modifications and applications. Asian J. Mater. Sci. 2010, 2, 121–136. [Google Scholar] [CrossRef]

- Zhao, Y.; Tian, G.; Duan, X.; Liang, X.; Meng, J.; Liang, J. Environmental applications of diatomite minerals in removing heavy metals from water. Ind. Eng. Chem. Res. 2019, 58, 11638–11652. [Google Scholar] [CrossRef]

- Kaleta, J.; Papciak, D.; Puszkarewicz, A. Klinoptylolity i diatomity w aspekcie przydatności w uzdatnianiu wody i oczyszczaniu ścieków. Gospod. Surowcami Miner. 2007, 23, 21–34. [Google Scholar]

- Ediz, N.; Bentli, İ.; Tatar, İ. Improvement in filtration characteristics of diatomite by calcination. Int. J. Miner. Process. 2010, 94, 129–134. [Google Scholar] [CrossRef]

- Ibrahim, S.S.; Selim, A.Q. Heat treatment of natural diatomite. Physicochem. Probl. Miner. Process. 2012, 48, 413–424. [Google Scholar]

- European Standard EN 12913:2012. Products Used for Treatment of Water Intended for Human Consumption—Powdered Diatomaceous Earth; European Committee for Standarization: Brussels, Belgium, 2012. [Google Scholar]

- Triplehorn, D.M. Morphology, internal structure, and origin of glauconite pellets. Sedimentology 1966, 6, 247–266. [Google Scholar] [CrossRef]

- Kłapyta, Z.; Żabiński, W.; Bajda, T. Sorbenty Mineralne Polski: Praca Zbiorowa; AGH Uczelniane Wydawnictwa Naukowo-Dydaktyczne: Kraków, Poland, 2008; ISBN 978-83-7464-107-4. [Google Scholar]

- McRae, S.G.; Lambert, J.L.M. A study of some glauconites from cretaceous and tertiary formations in South-East England. Clay Miner. 1968, 7, 431–440. [Google Scholar] [CrossRef]

- Vigdorovich, V.I.; Tsygankova, L.E.; Esina, M.N.; Uryadnikov, A.A.; Shel, N.V. Calculation of the dynamic sorbent capacity in the presence of two sorbates. J. Water Process Eng. 2017, 20, 180–186. [Google Scholar] [CrossRef]

- Voronina, A.V.; Kulyaeva, I.O.; Gupta, D.K. Determination of the parameters of selective 137Cs sorption onto natural and ferrocyanide-modified glauconite and clinoptilolite. Radiochemistry 2018, 60, 35–41. [Google Scholar] [CrossRef]

- Ali, O.; Osman, H.H.; Sayed, S.A.; Shalabi, M.E.H. The removal of uranium and thorium from their aqueous solutions via glauconite. Desalination Water Treat. 2015, 53, 760–767. [Google Scholar] [CrossRef]

- European Standard EN 12911:2013. Products Used for Treatment of Water Intended for Human Consumption—Manganese Greensand; European Committee for Standarization: Brussels, Belgium, 2013. [Google Scholar]

- Mansouri, N.; Rikhtegar, N.; Panahi, H.A.; Atabi, F.; Shahaki, B.K. Porosity, characterization and structural properties of natural zeolite-clinoptilolite—As a sorbent. Environ. Prot. Eng. 2013, 39, 139–152. [Google Scholar]

- Rhodes, C.J. Properties and applications of Zeolites. Sci. Prog. 2010, 93, 223–284. [Google Scholar] [CrossRef]

- Fuoco, D. A new method for characterization of natural zeolites and organic nanostructure using atomic force microscopy. Nanomaterials 2012, 2, 79–91. [Google Scholar] [CrossRef]

- Zeolites in Industrial Separation and Catalysis; Kulprathipanja, S., Ed.; Wiley-VCH: Weinheim, France, 2010; ISBN 978-3-527-32505-4. [Google Scholar]

- Wang, S.; Peng, Y. Natural zeolites as effective adsorbents in water and wastewater treatment. Chem. Eng. J. 2010, 156, 11–24. [Google Scholar] [CrossRef]

- Sharma, S.; Bhattacharya, A. Drinking water contamination and treatment techniques. Appl. Water Sci. 2017, 7, 1043–1067. [Google Scholar] [CrossRef]

- Vistuba, J.P.; Coral, L.A.; Pizzolatti, B.S.; Vitali, L.; Nagel-Hassemer, M.E.; Lapolli, F.R.; Lobo-Recio, M.Á. Adsorption behaviour of the zeolite, Controll M.F. 574® in removing iron and manganese from natural water. Desalination Water Treat. 2015, 55, 1523–1533. [Google Scholar] [CrossRef]

- Agents classified by the IARC Monographs, Volumes 1–125, on the identification of carcinogenic hazards to humans. Available online: https://monographs.iarc.fr/agents-classified-by-the-iarc/ (accessed on 17 February 2020).

- Bolewski, A.; Parachoniak, W. Petrografia; II.; Wydawnictwa Geologiczne: Warsaw, Poland, 1982. [Google Scholar]

- Park, N.-S.; Kim, S.-S.; Park, D.-H.; Park, S.; Choi, S.-I. The optimal composition of the filter-media for coping with daily flow-rate fluctuation. Korean J. Chem. Eng. 2010, 27, 1492–1496. [Google Scholar] [CrossRef]

- Zouboulis, A.; Traskas, G.; Samaras, P. Comparison of single and dual media filtration in a full-scale drinking water treatment plant. Desalination 2007, 213, 334–342. [Google Scholar] [CrossRef]

- Chien, C.C.; Kao, C.M.; Dong, C.D.; Chen, T.Y.; Chen, J.Y. Effectiveness of AOC removal by advanced water treatment systems: A case study. Desalination 2007, 202, 318–325. [Google Scholar] [CrossRef]

- Chien, C.C.; Kao, C.M.; Chen, C.W.; Dong, C.D.; Wu, C.Y. Application of biofiltration system on AOC removal: Column and field studies. Chemosphere 2008, 71, 1786–1793. [Google Scholar] [CrossRef] [PubMed]

- Yang, B.M.; Liu, J.K.; Chien, C.C.; Surampalli, R.Y.; Kao, C.M. Variations in AOC and microbial diversity in an advanced water treatment plant. J. Hydrol. 2011, 409, 225–235. [Google Scholar] [CrossRef]

- European Standard EN 12909:2012. Products Used for Treatment of Water Intended for Human Consumption—Anthracite; European Committee for Standarization: Brussels, Belgium, 2012. [Google Scholar]

- Dashtban Kenari, S.L.; Barbeau, B. Pyrolucite fluidized-bed reactor (PFBR): A robust and compact process for removing manganese from groundwater. Water Res. 2014, 49, 475–483. [Google Scholar] [CrossRef] [PubMed]

- Dashtban Kenari, S.L.; Barbeau, B. Integrated pyrolucite fluidized bed-membrane hybrid process for improved iron and manganese control in drinking water. Water Res. 2017, 113, 50–61. [Google Scholar] [CrossRef] [PubMed]

- Kim, G.; Sim, K.; Kim, S.; Komarneni, S.; Cho, Y. Selective sorption of strontium using two different types of nanostructured manganese oxides. J. Porous Mater. 2018, 25, 321–328. [Google Scholar] [CrossRef]

- Sánchez-España, J.; Yusta, I. Coprecipitation of Co2+, Ni2+ and Zn2+ with Mn(III/IV) oxides formed in metal-rich mine waters. Minerals 2019, 9, 226. [Google Scholar] [CrossRef]

- Feng, X.H.; Zhai, L.M.; Tan, W.F.; Liu, F.; He, J.Z. Adsorption and redox reactions of heavy metals on synthesized Mn oxide minerals. Environ. Pollut. 2007, 147, 366–373. [Google Scholar] [CrossRef]

- Michel, M.M.; Kiedryńska, L.; Tyszko, E. Badania skuteczności odmanganiania wody podziemnej na modyfikowanym chalcedonicie i masie katalitycznej Purolite MZ-10. Ochr. Śr. 2008, 30, 15–20. [Google Scholar]

- Michel, M.M. Odmanganianie wody podziemnej na modyfikowanym chalcedonicie. Gaz Woda Tech. Sanit. 2009, 22–26. [Google Scholar]

- Mu, J.; Gu, Z.; Sun, H.; Wei, Q. Low temperature synthesis of Mn3O4 nanoparticles using starch as capping agent. J. Dispers. Sci. Technol. 2006, 27, 307–309. [Google Scholar] [CrossRef]

- Georgiadis, A.; Rennert, T. A simple method to produce birnessite-coated quartz sand. J. Plant Nutr. Soil Sci. 2017, 180, 491–495. [Google Scholar] [CrossRef]

- Cheney, M.A.; Jose, R.; Banerjee, A.; Bhowmik, P.K.; Qian, S.; Okoh, J.M. Synthesis and characterization of birnessite and cryptomelane nanostructures in presence of hoffmeister anions. J. Nanomater. 2009, 2009, 1–8. [Google Scholar] [CrossRef]

- Korablev, V.V.; Chechevichkin, A.V.; Boricheva, I.K.; Samonin, V.V. Structure and morphological properties of clinoptilolite modified by manganese dioxide. St Petersburg Polytech. Univ. J. Phys. Math. 2017, 3, 63–70. [Google Scholar] [CrossRef]

- Michel, M. A study of application of chalcedonite as a manganese dioxide carrier. Ann. Wars. Univ. Life Sci. SGGW Land Reclam. 2012, 44, 63–73. [Google Scholar] [CrossRef]

- Hu, P.-Y.; Hsieh, Y.-H.; Chen, J.-C.; Chang, C.-Y. Characteristics of manganese-coated sand using SEM and EDAX analysis. J. Colloid Interface Sci. 2004, 272, 308–313. [Google Scholar] [CrossRef]

- Han, R.; Zou, W.; Zhang, Z.; Shi, J.; Yang, J. Removal of copper(II) and lead(II) from aqueous solution by manganese oxide coated sand: I. Characterization and kinetic study. J. Hazard. Mater. 2006, 137, 384–395. [Google Scholar] [CrossRef]

- Han, R.; Lu, Z.; Zou, W.; Daotong, W.; Shi, J.; Jiujun, Y. Removal of copper(II) and lead(II) from aqueous solution by manganese oxide coated sand: II. Equilibrium study and competitive adsorption. J. Hazard. Mater. 2006, 137, 480–488. [Google Scholar] [CrossRef]

- Michel, M.; Kiedryńska, L. Modelling equilibrium data for manganese(II) sorption onto manganese dioxide modified chalcedonite using the non-linear regression method. Ann. Wars. Univ. Life Sci. SGGW Land Reclam. 2011, 43. [Google Scholar] [CrossRef]

- Reczek, L.; Michel, M.M.; Siwiec, T. Sorption of Pb(II) ions onto some filter materials used in water treatment technology. Przemysl Chem. 2014, 1978–1982. [Google Scholar] [CrossRef]

- Al-Degs, Y. Sorption of lead ions on diatomite and manganese oxides modified diatomite. Water Res. 2001, 35, 3724–3728. [Google Scholar] [CrossRef]

- Li, S.; Li, D.; Su, F.; Ren, Y.; Qin, G. Uniform surface modification of diatomaceous earth with amorphous manganese oxide and its adsorption characteristics for lead ions. Appl. Surf. Sci. 2014, 317, 724–729. [Google Scholar] [CrossRef]

- Michel, M.M. Kruszywa Melafirowe Jako Złoża Filtrów Odmanganiających; Wydawnictwo SGGW: Warszawa, Poland, 2019; ISBN 978-83-7583-844-2. [Google Scholar]

- Cheney, M.A.; Bhowmik, P.K.; Moriuchi, S.; Villalobos, M.; Qian, S.; Joo, S.W. The effect of stirring on the morphology of birnessite nanoparticles. J. Nanomater. 2008, 2008, 1–9. [Google Scholar] [CrossRef]

- Michel, M.M. Usuwanie Jonów Manganu(ii) z Roztworów Wodnych na Chalcedonicie Naturalnym i Modyfikowanym. Removal of Manganese(ii) from Aqueos Solution by Natural and Modified Chalcedonite; Polskie Zrzeszenie Inżynierów i Techników Sanitarnych Oddział Wielkopolski: Poznań, Poland, 2008; Volume 1, pp. 557–569. [Google Scholar]

- Merkle, P.B.; Knocke, W.; Gallagher, D.; Junta-Rosso, J.; Solberg, T. Characterizing filter media mineral coatings. J. Am. Water Works Assoc. 1996, 88, 62–73. [Google Scholar] [CrossRef]

- Du, Y.; Zheng, G.; Wang, J.; Wang, L.; Wu, J.; Dai, H. MnO2 nanowires in situ grown on diatomite: Highly efficient absorbents for the removal of Cr(VI) and As(V). Microporous Mesoporous Mater. 2014, 200, 27–34. [Google Scholar] [CrossRef]

- Michel, M.M.; Tytkowska, M. A Study of Chalcedonite Coated with Manganese Dioxide. In Pitna Voda, Proceedings of 15th International Conference Pitna Voda, Trenčianske Teplice, Slovakia, 8–10 October 2013; Buchlovičová, J., Ed.; VodaTim Publishing: Bratislava, Slovakia, 2013; pp. 143–150. [Google Scholar]

- Caliskan, N.; Kul, A.R.; Alkan, S.; Sogut, E.G.; Alacabey, İ. Adsorption of Zinc(II) on diatomite and manganese-oxide-modified diatomite: A kinetic and equilibrium study. J. Hazard. Mater. 2011, 193, 27–36. [Google Scholar] [CrossRef]

- Rachmawati, S.; Tizaoui, C.; Hilal, N. Manganese coated sand for copper (ii) removal from water in batch mode. Water 2013, 5, 1487–1501. [Google Scholar] [CrossRef]

- Irannajad, M.; Haghighi, H.K. Removal of Co2+, Ni2+, and Pb2+ by manganese oxide-coated zeolite: Equilibrium, thermodynamics, and kinetics studies. Clays Clay Miner. 2017, 65, 52–62. [Google Scholar] [CrossRef]

- Michel, M.M.; Kiedryńska, L. Usuwanie manganu(II) na chalcedonicie modyfikowanym tlenkiem manganu(IV). Przem. Chem. 2012, 91, 1416–1419. [Google Scholar]

- Anielak, A.M. Właściwości fizykochemiczne klinoptylolitu modyfikowanego ditlenkiem manganu. Przem. Ćhemiczny 2006, 85, 487–491. [Google Scholar]

- Pitteloud, C.; Nagao, M.; Itoh, K.; Kanno, R. The structure of manganese dioxide and position of proton studied by neutron diffraction with isotopic substitution. J. Solid State Chem. 2008, 181, 467–472. [Google Scholar] [CrossRef]

- Kanungo, S.B.; Tripathy, S.S.; Mishra, S.K.; Sahoo, B. Rajeev Adsorption of Co2+, Ni2+, Cu2+, and Zn2+ onto amorphous hydrous manganese dioxide from simple (1–1) electrolyte solutions. J. Colloid Interface Sci. 2004, 269, 11–21. [Google Scholar] [CrossRef] [PubMed]

- Mende, M.; Schwarz, D.; Steinbach, C.; Boldt, R.; Schwarz, S. The influence of salt anions on heavy metal ion adsorption on the example of nickel. Materials 2018, 11, 373. [Google Scholar] [CrossRef] [PubMed]

- European Standard EN 13752:2012. Products Used for Treatment of Water Intended for Human Consumption—Manganese Dioxide; European Committee for Standarization: Brussels, Belgium, 2012. [Google Scholar]

- Tobiason, J.E.; Knocke, W.R.; Goodwill, J.; Hargette, P.; Bouchard, R.; Zuravnsky, L. Characterization and Performance of Filter Media for Manganese Control; AWWA Research Foundation: Denver, CO, USA, 2008; ISBN 978-1-60573-014-1. [Google Scholar]

- Tytkowska, M.; Michel, M.M.; Reczek, L.; Siwiec, T. Sorption of Ni(II) on surface of bed grains used in iron and manganese removal filters. Water Supply 2019, 19, 815–822. [Google Scholar] [CrossRef]

- Bruins, J.H.; Petrusevski, B.; Slokar, Y.M.; Huysman, K.; Joris, K.; Kruithof, J.C.; Kennedy, M.D. Reduction of ripening time of full-scale manganese removal filters with manganese oxide-coated media. J. Water Supply Res. Technol. Aqua 2015, 64, 434–441. [Google Scholar] [CrossRef]

- Manganese Greensand and Its Substitute. Available online: https://www.inversand.com/files/Zabel-AAD%20article.pdf (accessed on 6 March 2020).

- Manganese Greensand Commercial Data Sheet. Available online: https://www.lenntech.com/Data-sheets/Clack-manganesegreensand-L.pdf (accessed on 6 March 2020).

- Manganese Greensand Material Safety Data Sheet. Available online: http://superiormechanical.us/pdf/msds/Inversand%20Co%20Manganese%20Greensand.pdf (accessed on 6 March 2020).

- GreensandPlusTM Commercial Data Sheet. Available online: https://www.inversand.com/files/Inversand_GSP_POE_POU.pdf (accessed on 6 March 2020).

- GreensandPlusTM Material Safety Data Sheet. Available online: http://www.clackcorp.com/downloads/msds/Active%20Online%20Filter%20Medias/A8042%20GreensandPlus%20SDS%208-20-2015.pdf (accessed on 6 March 2020).

- MTM® Commercial Data Sheet. Available online: http://www.clackcorp.com/downloads/ion_exchange_resin_and_filter_media/mtm_2353.pdf (accessed on 6 March 2020).

- MTM® Material Safety Data Sheet. Available online: http://www.clackcorp.com/downloads/msds/Active%20Online%20Filter%20Medias/MTM-EU.pdf (accessed on 6 March 2020).

- BIRM® Commercial Data Sheet. Available online: http://www.clackcorp.com/downloads/ion_exchange_resin_and_filter_media/birm_2350.pdf (accessed on 6 March 2020).

- BIRM® Material Safety Data Sheet. Available online: http://www.clackcorp.com/downloads/msds/Active%20Online%20Filter%20Medias/BIRM-EU.pdf (accessed on 6 March 2020).

- Outram, J.G.; Couperthwaite, S.J.; Millar, G.J. Comparitve analysis of the physical, chemical and structural characteristics and performance of manganese greensands. J. Water Process Eng. 2016, 13, 16–26. [Google Scholar] [CrossRef]

- Granops, M. Wysokosprawne metody usuwania żelaza i manganu z wody w stacjach wodociągowych na obszarach niezurbanizowanych. Sci. Rev. Eng. Environ. Sci. 2005, 32, 153–160. [Google Scholar]

- Kaleta, J.; Papciak, D.; Puszkarewicz, A. Naturalne i modyfikowane minerały w uzdatnianiu wód podziemnych—Natural and modified minerals in remediation of groundwaters. Gospod. Surowcami Miner. 2009, 25, 51–63. [Google Scholar]

- Barlokova, D. Natural zeolites in the water treatment process. Slovak J. Civ. Eng. 2008, 8–12. [Google Scholar]

- Barloková, D.; Ilavský, J. Modified clinoptilolite in the removal of iron and manganese from water. Slovak J. Civ. Eng. 2012, 20, 1–8. [Google Scholar] [CrossRef][Green Version]

- Barlokova, D.; Ilavsky, J.; Sokač, M. Modified zeolites in ground water treatment. Geosci. Eng. 2015, 61, 10–17. [Google Scholar] [CrossRef][Green Version]

- Michel, M.M. A study of application the modified chalcedonite for underground water treatment. Ann. Wars. Univ. Life Sci. SGGW Land Reclam. 2012, 44. [Google Scholar] [CrossRef]

- Štembal, T.; Markić, M.; Ribičić, N.; Briški, F.; Sipos, L. Removal of ammonia, iron and manganese from groundwaters of northern Croatia—Pilot plant studies. Process Biochem. 2005, 40, 327–335. [Google Scholar] [CrossRef]

- Bruins, J.H.; Vries, D.; Petrusevski, B.; Slokar, Y.M.; Kennedy, M.D. Assessment of manganese removal from over 100 groundwater treatment plants. J. Water Supply Res. Technol. Aqua 2014, 63, 268–280. [Google Scholar] [CrossRef]

- Zeng, H.; Yin, C.; Zhang, J.; Li, D. Start-Up of a Biofilter in a Full-Scale Groundwater Treatment Plant for Iron and Manganese Removal. Int. J. Environ. Res. Public. Health 2019, 16, 698. [Google Scholar] [CrossRef] [PubMed]

- Bai, Y.; Chang, Y.; Liang, J.; Chen, C.; Qu, J. Treatment of groundwater containing Mn(II), Fe(II), As(III) and Sb(III) by bioaugmented quartz-sand filters. Water Res. 2016, 106, 126–134. [Google Scholar] [CrossRef]

- Nitzsche, K.S.; Weigold, P.; Lösekann-Behrens, T.; Kappler, A.; Behrens, S. Microbial community composition of a household sand filter used for arsenic, iron, and manganese removal from groundwater in Vietnam. Chemosphere 2015, 138, 47–59. [Google Scholar] [CrossRef]

- Sahabi, D.M.; Takeda, M.; Suzuki, I.; Koizumi, J. Removal of Mn2+ from water by “aged” biofilter media: The role of catalytic oxides layers. J. Biosci. Bioeng. 2009, 107, 151–157. [Google Scholar] [CrossRef]

- Voegelin, A.; Kaegi, R.; Berg, M.; Nitzsche, K.S.; Kappler, A.; Lan, V.M.; Trang, P.T.K.; Göttlicher, J.; Steininger, R. Solid-phase characterisation of an effective household sand filter for As, Fe and Mn removal from groundwater in Vietnam. Environ. Chem. 2014, 11, 566. [Google Scholar] [CrossRef]

- Marsidi, N.; Abu Hasan, H.; Sheikh Abdullah, S.R. A review of biological aerated filters for iron and manganese ions removal in water treatment. J. Water Process Eng. 2018, 23, 1–12. [Google Scholar] [CrossRef]

- Qin, S.; Ma, F.; Huang, P.; Yang, J. Fe (II) and Mn (II) removal from drilled well water: A case study from a biological treatment unit in Harbin. Desalination 2009, 245, 183–193. [Google Scholar] [CrossRef]

- Tekerlekopoulou, A.G.; Vayenas, D.V. Ammonia, iron and manganese removal from potable water using trickling filters. Desalination 2007, 210, 225–235. [Google Scholar] [CrossRef]

- Tekerlekopoulou, A.G.; Papazafiris, P.G.D.; Vayenas, D.V. A full-scale trickling filter for the simultaneous removal of ammonium, iron and manganese from potable water. J. Chem. Technol. Biotechnol. 2010, 85, 1023–1026. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, R.; Zhou, A.; Zhang, J.; Luan, Y.; Jia, J.; Yue, X.; Zhang, J. Microbial community response reveals underlying mechanism of industrial-scale manganese sand biofilters used for the simultaneous removal of iron, manganese and ammonia from groundwater. AMB Express 2018, 8, 2. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Q.; Nengzi, L.; Bao, L.; Huang, Y.; Liu, S.; Cheng, X.; Li, B.; Zhang, J. Distribution and genetic diversity of microbial populations in the pilot-scale biofilter for simultaneous removal of ammonia, iron and manganese from real groundwater. Chemosphere 2017, 182, 450–457. [Google Scholar] [CrossRef] [PubMed]

- Han, M.; Zhao, Z.; Gao, W.; Cui, F. Study on the factors affecting simultaneous removal of ammonia and manganese by pilot-scale biological aerated filter (BAF) for drinking water pre-treatment. Bioresour. Technol. 2013, 145, 17–24. [Google Scholar] [CrossRef] [PubMed]

- Bruins, J.H.; Petrusevski, B.; Slokar, Y.M.; Huysman, K.; Joris, K.; Kruithof, J.C.; Kennedy, M.D. Biological and physico-chemical formation of Birnessite during the ripening of manganese removal filters. Water Res. 2015, 69, 154–161. [Google Scholar] [CrossRef]

- Burger, M.S.; Mercer, S.S.; Shupe, G.D.; Gagnon, G.A. Manganese removal during bench-scale biofiltration. Water Res. 2008, 42, 4733–4742. [Google Scholar] [CrossRef]

- Guo, Y.; Huang, T.; Wen, G.; Cao, X. The simultaneous removal of ammonium and manganese from groundwater by iron-manganese co-oxide filter film: The role of chemical catalytic oxidation for ammonium removal. Chem. Eng. J. 2017, 308, 322–329. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhang, S.; Huang, T.; Li, Y. Arsenite removal from groundwater by iron–manganese oxides filter media: Behavior and mechanism. Water Environ. Res. 2019, 91, 536–545. [Google Scholar] [CrossRef] [PubMed]

- Gude, J.C.J.; Rietveld, L.C.; van Halem, D. As(III) oxidation by MnO2 during groundwater treatment. Water Res. 2017, 111, 41–51. [Google Scholar] [CrossRef] [PubMed]

- Voegelin, A.; Senn, A.-C.; Kaegi, R.; Hug, S.J.; Mangold, S. Dynamic Fe-precipitate formation induced by Fe(II) oxidation in aerated phosphate-containing water. Geochim. Cosmochim. Acta 2013, 117, 216–231. [Google Scholar] [CrossRef]

- Cheng, Y.; Huang, T.; Cheng, L.; Wu, J. Study on the factors affecting the start-up of iron-manganese co-oxide filters for ammonium and manganese removal from groundwater. Int. J. Environ. Res. Public. Health 2018, 15, 1822. [Google Scholar] [CrossRef] [PubMed]

- Bruins, J.H.; Petrusevski, B.; Slokar, Y.M.; Kruithof, J.C.; Kennedy, M.D. Manganese removal from groundwater: Characterization of filter media coating. Desalination Water Treat. 2015, 55, 1851–1863. [Google Scholar] [CrossRef]

- Olańczuk-Neyman, K.; Częścik, P.; Łasińska, E.; Bray, R. Evaluation of the effectivity of selected filter beds for iron and manganese removal. Water Sci. Technol. Water Supply 2001, 1, 159–165. [Google Scholar] [CrossRef]

- Han, M.; Zhao, Z.; Cui, F.; Gao, W.; Liu, J.; Zeng, Z. Pretreatment of contaminated raw water by a novel double-layer biological aerated filter for drinking water treatment. Desalination Water Treat. 2012, 37, 308–314. [Google Scholar] [CrossRef]

- Jeż-Walkowiak, J. Badania autoaktywacji materiałów filtracyjnych dwutlenkiem manganu na przykładzie chalcedonitu. Ochr. Śr. 2013, 35, 23–26. [Google Scholar]

- Papciak, D.; Domoń, A.; Puszkarewicz, A.; Kaleta, J. The use of chalcedonite as a biosorption bed in the treatment of groundwater. Appl. Sci. 2019, 9, 751. [Google Scholar] [CrossRef]

- Tekerlekopoulou, A.G.; Vasiliadou, I.A.; Vayenas, D.V. Biological manganese removal from potable water using trickling filters. Biochem. Eng. J. 2008, 38, 292–301. [Google Scholar] [CrossRef]

- Bruins, J.H.; Petrusevski, B.; Slokar, Y.M.; Huysman, K.; Joris, K.; Kruithof, J.C.; Kennedy, M.D. Factors controlling the ripening of manganese removal filters in conventional aeration-filtration groundwater treatment. Desalination Water Treat. 2017, 72, 22–29. [Google Scholar] [CrossRef]

- Weber, Ł.; Szambelańczyk, K. Badania technologiczne nad uzdatnianiem wody podziemnej na złożach chalcedonitowych na Stacji Uzdatniania Wody—Nowy Folwark. Forum Eksploatatora 2006, 22, 31–33. [Google Scholar]

- Weber, Ł. Problemy z wpracowaniem złóż antracytowo-kwarcowych do usuwania manganu na Stacji Uzdatniania Wody we Wrześni. Forum Eksploatatora 2006, 23, 10–12. [Google Scholar]

- Bray, R.; Olańczuk-Neyman, K. The influence of changes in groundwater composition on the efficiency of manganese and ammonia nitrogen removal on mature quartz sand filtering beds. Water Sci. Technol. Water Supply 2001, 1, 91–98. [Google Scholar] [CrossRef]

- Jeż-Walkowiak, J. Odmanganianie wód podziemnych w filtrach pospiesznych ze złożami oksydacyjnymi Manganese removal from ground water on oxidative filters. Przem. Chem. 2008, 87, 470–472. [Google Scholar]

- Jeż-Walkowiak, J.; Dymaczewski, Z.; Szuster-Janiaczyk, A.; Nowicka, A.; Szybowicz, M. Efficiency of Mn removal of different filtration materials for groundwater treatment linking chemical and physical properties. Water 2017, 9, 498. [Google Scholar] [CrossRef]

- Jones, A.; Murayama, M.; Knocke, W.R. Incorporating aluminum species in MnO x (s) coatings on water filtration media. AWWA Water Sci. 2019, 1, e1114. [Google Scholar] [CrossRef]

- Jones, A.; Knocke, W.R. Evaluating the role of soluble aluminum in manganese removal via MnOx(s)-coated filtration media in drinking water treatment. Water Res. 2017, 111, 59–65. [Google Scholar] [CrossRef]

- Katsoyiannis, I.A.; Zouboulis, A.I. Biological treatment of Mn(II) and Fe(II) containing groundwater: Kinetic considerations and product characterization. Water Res. 2004, 38, 1922–1932. [Google Scholar] [CrossRef]

- Zhou, D.; Kim, D.-G.; Ko, S.-O. Heavy metal adsorption with biogenic manganese oxides generated by Pseudomonas putida strain MnB1. J. Ind. Eng. Chem. 2015, 24, 132–139. [Google Scholar] [CrossRef]

- Cui, H.; Qiu, G.; Feng, X.; Tan, W.; Liu, F. Birnessites with different average manganese oxidation states synthesized, characterized, and transformed to todorokite at atmospheric pressure. Clays Clay Miner. 2009, 57, 715–724. [Google Scholar] [CrossRef]

- Kuleshov, V. Isotope Geochemistry: The Origin and Formation of Manganese Rocks and Ores; Maynard, J.B., Ed.; Elsevier: Amsterdam, The Netherlands; Boston, MA, USA; Heidelberg, Germany; London, UK; New York, NY, USA; Oxford, UK; Paris, France; San Diego, CA, USA; San Francisco, CA, USA; Singapore; Sydney, Australia; Tokyo, Japan, 2016; ISBN 978-0-12-803165-0. [Google Scholar]

- Sorensen, B.; Gaal, S.; Ringdalen, E.; Tangstad, M.; Kononov, R.; Ostrovski, O. Phase compositions of manganese ores and their change in the process of calcination. Int. J. Miner. Process. 2010, 94, 101–110. [Google Scholar] [CrossRef]

- Kusumaningrum, R.; Rahmani, S.A.; Widayatno, W.B.; Wismogroho, A.S.; Nugroho, D.W.; Maulana, S.; Rochman, N.T.; Amal, M.I. Characterization of Sumbawa Manganese Ore and Recovery of Manganese Sulfate as Leaching Products. In Metallurgy and Advanced Material Technology for Sustainable Development, Proceedings of the International Seminar on Metallurgy and Materials (ISMM2017), Jakarta, Indonesia, 24–25 October 2017; Amal, M.I., Herbirowo, S., Hasbi, M.Y., Lestari, Y., Annur, D., Malau, D.P., Eds.; AIP conference proceedings; AIP Publishing: Melville, NY, USA, 2018; p. 020042. ISBN 978-0-7354-1669-7. [Google Scholar]

- Manganese Ore G1 Filter Media—Commercial Data Sheet. Available online: https://gc2000.pl/wp-content/uploads/docs/G1.pdf (accessed on 21 March 2020).

- Jeż-Walkowiak, J.; Komorowska-Kaufman, M.; Dymaczewski, Z.; Sozański, M.M.; Zakrzewski, P. Properties of catalyst for iron and manganese oxidation in filter materials. E3S Web Conf. 2018, 59, 00014. [Google Scholar] [CrossRef]

- Manganese Ore Metalease Filter Media—Commercial Data Sheet. Available online: https://www.swtwater.com/catalog/pdf/1093%20-%20MetalEase.pdf (accessed on 21 March 2020).

- Schaefer, M.V.; Handler, R.M.; Scherer, M.M. Fe(II) reduction of pyrolusite (β-MnO2) and secondary mineral evolution. Geochem. Trans. 2017, 18, 7. [Google Scholar] [CrossRef] [PubMed]

- Manganese Ore Defeman Filter Media—Commercial Data Sheet. Available online: https://gc2000.pl/wp-content/uploads/docs/DEFEMAN.pdf (accessed on 21 March 2020).

- Manganese Ore Multiman 3M Filter Media—Commercial Data Sheet. Available online: http://www.dynamikfiltr.pl/df_files/files/pl_74_pl_9_ZLOZE_FILTRACYJNE_MULTIMAN_3M.pdf (accessed on 21 March 2020).

- Manganese Ore Pyrolox Filter Media—Commercial Data Sheet. Available online: http://www.clackcorp.com/downloads/ion_exchange_resin_and_filter_media/pyrolox_2356.pdf (accessed on 21 March 2020).

- Manganese Ore Filox-R Filter Media—Commercial Data Sheet. Available online: https://www.watts.com/dfsmedia/0533dbba17714b1ab581ab07a4cbb521/29526-source/options/download/c-wq-purewatercommercial (accessed on 21 March 2020).

| Material | Density (kg/m3) | Bulk Density (kg/m3) | Specific Surface Area (m2/g) | Mohs Hardness (-) |

|---|---|---|---|---|

| Quartz sand | 2650 [44] | 1520–1568 [45] | 0.05–1.8 [46] | 7 [47] |

| 2650–2667 [45] | ||||

| Chalcedonite | 2390–2500 [48] | 1237–1403 [45] | 6.13 [49], 7.44 [50] | 6–6.5 [51] |

| 2488–2682 [45] | ||||

| Diatomite | 2000–2100 * [52] | 200–400 * [52] | 14.6 [53], | 5–6.5 [54] |

| 2244 ** [55] | 1280–1780 ** [56] | 22 [57], 42 [58] | ||

| Glauconite | 2450–2600 [59] | 1380 [60] | 48 [58], 58 [61], 78 [60] | 2 [47] |

| 2650–2750 [62] | ||||

| Zeolite | 2339–2407 (clinoptilolite) [45] 2390 (clinoptilolite) [63] | 800–1000 (clinoptilolite) 700–850 (chabazite) 1000–1100 (phillipsite-analcime) [64] | 14 (clinoptilolite 71.8 wt. %) [57] 19.2 (clinoptilolite 45–50 wt. %) [65] 30.98 (clinoptilolite >90 wt. % ) [66] 60.32 (phillipsite and chabazite 55 wt.% ) [67] | 3.5–4 (clinoptilolite) 4–5 (chabazite) 4–4.5 (phillipsite) 5–5.5 (analcime) [47] |

| Anthracite | 1400–1450 [68,69] 1743–1801 [45] | 730 [69] 732–900 [45] | 2.2, 6.4 [70] | 2–4 [54] |

| Carrier | Coating Components | Coating Method * | Specific Surface Area before/after Coating of | Amount of Coating on the Carrier | Maximum Adsorption Capacity of Coated Material | Ref. |

|---|---|---|---|---|---|---|

| Quartz sand | Pyrolusite (MnO2), γ-Mn2O3, Mn(OH)4 | Reduction method: prepared under moderate temperature and acidic conditions by impregnation processes with igneous rock and KMnO4 | –/1.99 m2/g | 0.396 mg Mn/g | 0.3805 mg Mn/g batch conditions, 25 °C | [121] |

| Quartz sand | Amorphous manganese dioxide | Reduction method: acid-digested sand placed in KMnO4 boiling solution, MnOx precipitated by dropwise 37.5% HCl addition, 1 h contact time with agitation | 0.674/0.712 m2/g | 5.46 mg Mn/g | 0.00591 mmol Cu/g (0.375 mg Cu/g) 0.00771 mmol Pb/g (1.60 mg Pb/g)batch conditions, 15 °C and 22 °C resp. | [122,123] |

| Chalcedonite | Amorphous manganese dioxide | Redox method: chalcedonite soaked in 20% MnSO4, next soaked in 5% KMnO4 to MnOx precipitate | 6.13/9.88 m2/g | – | 1.07 mg Mn/g 10.3 mg Pb/g batch conditions, 10 °C 0.76 g Mn/L (0.62 mg Mn/g) ** flow conditions | [49,115,124,125] |

| Chalcedonite | Birnessite type manganese oxide | Oxidation method: chalcedonite soaked in 6 M NaOH (2 h, T 80–90 °C), next soaked in 2.5 M MnCl2 (pH 1–2, 10 h, room T), soaked in 6 M NaOH (10 h, room T) and finally oxidized in air | 6.13/10.25 m2/g | – | 2.63 g/L (2.16 mg Mn/g) ** flow conditions | [49,114] |

| Diatomite | Birnessite type manganese oxide | Oxidation method: chalcedonite soaked in 6 M NaOH (2 h, T 80–90 °C), next soaked in 2.5 M MnCl2 (pH 1–2, 10 h, room T), soaked in 6 M NaOH (10 h, room T) and finally oxidized in air | 33/80 m2/g | 0.38 g MnOx/g | 99 mg Pb/g batch conditions, 23 ± 1 °C | [126] |

| Diatomite | Amorphous manganese dioxide | Reduction method: carbon covered diatomaceous earth dispersed into KMnO4 solution, next microwave heated (10 min, 700 W) and cooled | 23.3/24.1 m2/g | – | 56.843 mg Pb/g batch conditions, 30 °C | [127] |

| Zeolite: clinoptilolite 36%, mordenite 33%, quartz 26%, montmorillonite 5% | Vernadite (δ-MnO2) | Reduction method: Na-zeolite placed in KMnO4 solution (T 90 °C), manganese oxide precipitated by dropwise 37.5% HCl addition, contact time 1 h with agitation | – | – | 1.123 meq Mn/g (30.85 mg Mn/g) batch conditions, 25 °C | [41] |

| Zeolite: 58–75% of clinoptilolite | Cryptomelane (α-MnO2) | Redox method: Mn2+-clinoptilolite treated with KMnO4 solution (T 20 °C) | – | MnO2 0.30–0.49% (1.9–3.1 mg Mn/g) | 6.9–21.6 mg Mn/g batch conditions, 20 ± 1 °C | [119] |

| Specified Parameter with Unit | Adsorption Capacity or Uptake Capacity (mg Mn/mg of Media) | Oxidation Capacity (mg Mn/L of Media) | Oxidation Capacity (L of Treated Water/L of Media) |

|---|---|---|---|

| Test type | column | column | column |

| Type of media | MnOx-coated media exploited in filters enhanced with chemical oxidants | MnOx-coated glauconite (Manganese Greensand) | manganese ore (pyrolusite) |

| Flow velocity (m/h) | 24.5 | 10 | 10 |

| Concentration of manganese in test water (mg Mn/L) | 0.3–0.5 | 10 | 1 |

| Composition of test water | pH 6.3 ± 0.1 MnSO4, NaHCO3 and CaCl2 (alkalinity 25 mg CaCO3/L, calcium 10 mg/L) | pH 6–7 MnSO4 (27.5 mg/L), NaHCO3 (100 mg/L) | pH 7.0 ± 0.5 MnSO4 (2.75 mg/L), NaHCO3 (20 mg/L) |

| Amount of test sample | 2–10 g | 300 mL | 20 g |

| Additional sample treatment | sieving, washing, regeneration with chlorine solution (20 mg/L, pH 6.3) | washing, regeneration with KMnO4 (3.0 g/L) | sieving, washing, regeneration with chlorine solution (1200 mg/L) |

| References | [143] | [93] | [142] |

| Features | Trade Name | |||

|---|---|---|---|---|

| Manganese Greensand | GreensandPlusTM | MTM® | BIRM® | |

| Carrier compounds (wt.%) | glauconite 96–97 | quartz 90.4–93.6 | silicon dioxide >75 | quartz 40–60 |

| Quartz <10 | ||||

| cristobalite <0.1 | ||||

| Coating compounds (wt.%) | manganese oxide 3–4 | manganese dioxide 3.2–4.8 | manganese dioxide <1 | manganese dioxide 10–20 |

| Regenerative agent | potassium permanganate | chlorine | potassium permanganate or chlorine | does not require |

| Dissolved components possible to remove from water | Iron Manganese hydrogen sulphide | Iron Manganese hydrogen sulphide arsenic, radium | Iron Manganese hydrogen sulphide | Iron manganese |

| Removal capacities (g/L of media) | Fe: 1.34 | Fe: 1.34 | Fe: 1.34 | not specified |

| Fe+Mn: 0.94 | Mn: 0.67 | Mn: 0.67 | ||

| H2S: 0.40 | H2S: 0.27 | H2S: 0.27 | ||

| Max. concentration of components in water (mg/L) | Fe: 15 | not specified | Fe: 15 | H2S absence |

| Mn: 15 | Mn: 5 | TOC 4–5 | ||

| H2S: 2 | H2S: 2 | Cl2 0.5 | ||

| Preferred water pH | 6.2–8.5 | 6.2–8.8 | 6.2–8.5 | 6.8–9.0 |

| Density (kg/m3) | 2400–2900 | 2400 | 2000 | 2000 |

| Bulk density (kg/m3) | 1382 | 1410 | 720–800 | 580–610 |

| Effective size d10 (mm) | 0.3–0.35 | 0.3–0.35 | 0.43 | 0.48 |

| Uniformity coefficient | 1.6 | 1.6 | 2.0 | 2.7 |

| Flow velocity (m/h) | 9–15 | 5–12 | 6–15 | 10.5–15 |

| Min. bed depth (m): single layer double layer | 0.76 | 0.76 | 0.90 | 0.90 |

| – | 0.40–0.45 | 0.60 | 0.75 | |

| Manufacturer | Inversand Co. | Inversand Co. | Clack Corp. | Clack Corp. |

| References | [147,148] | [149,150] | [151,152] | [153,154] |

| Time of Start-up | Type of Media and Grain Size | Technological Conditions | Chemistry of Raw Water | Ref. |

|---|---|---|---|---|

| 20 days | Quartz sand and gravel 2–5 mm | Empty bed contact time: 10 min bed depth: 0.2 m backwashing with water inoculation with manganese oxidized bacteria | pH 7.0–7.2 | [165] |

| Mn: 1.5–2 mg/L | ||||

| Fe: 5–6 mg/L | ||||

| O2: 3.5 mg/L | ||||

| 20 days | Chalcedonite 0.5–2.0 mm | Flow velocity: 5.5 m/h empty bed contact time: 8 min bed depth: 0.75 m backwashing with treated water | pH 7.2 ± 0.03 | [128] |

| Eh +210 ± 29 mV | ||||

| Mn: 0.241 ± 0.024 mg/L | ||||

| Fe: 0.03 ± 0.01 mg/L | ||||

| NH4+: 0.07 ± 0.04 mg/L | ||||

| O2: 3.39 ± 0.73 mg/L | ||||

| 21 days | Quartz sand 0.5–1.8 mm | Flow velocity: 5.5 m/h empty bed contact time: 8 min bed depth: 0.75 m backwashing with treated water | pH 7.2 ± 0.03 | [128] |

| Eh +210 ± 29 mV | ||||

| Mn: 0.241 ± 0.024 mg/L | ||||

| Fe: 0.03 ± 0.01 mg/L | ||||

| NH4+: 0.07 ± 0.04 mg/L | ||||

| O2: 3.39 ± 0.73 mg/L | ||||

| 25 days | Quartz sand 0.7–1.25 mm | Flow velocity: 5.1 m/h empty bed contact time: 3.5 min bed depth: 0.3 m backwashing with water | pH 7.5–7.9 | [176] |

| Eh +200–+290 | ||||

| Mn: 0.10–0.15 mg/L | ||||

| Fe: 0.03–0.1 mg/L | ||||

| NH4+: max 0.2 mg/L | ||||

| O2: 8.0–9.5 mg/L | ||||

| 26 days | Quartz sand 1.0 mm | Flow velocity: 7.0 m/h empty bed contact time: 8.6 min bed depth: 1.0 m backwashing with water and air KMnO4 dosage | pH 8.0 ± 0.1 | [178] |

| Mn: 0.99 ± 0.12 mg/L | ||||

| Fe: 1.06 ± 0.2 mg/L | ||||

| NH4+: 1.39 ± 0.1 mg/L | ||||

| O2: 6.5–7.0 mg/L | ||||

| 40 days | Chalcedonite d10 0.8–1.0 mm UC 1.4–1.6 | Flow velocity: 6–12 m/h bed depth: 1.8 m | pH 6.9–7.5 | [186] |

| Mn: 0.1–0.9 mg/L | ||||

| Fe: 0.4–5.0 mg/L | ||||

| NH4+: 0.2–0.9 mg/L | ||||

| O2: 5.5–11.0 mg/L | ||||

| 70–80 days | Chalcedonite 0.8–2.4 mm | Flow velocity: 11–14 m/h bed depth: 0.8 m backwashing with water and air | Mn: 0.22–0.27 mg/L | [190] |

| NH4+: 0.7–0.8 mg/L | ||||

| 7 months | Sand 0.5–1.2 mm | Flow velocity: 1.5 m/h empty bed contact time: 40 min bed depth: 1.00 m inoculation with indigenous bacteria backwashing with treated, chlorinated water | pH 6.7–6.9 | [164] |

| Mn: 0.8–2.0 mg/L | ||||

| Fe: 0.15–0.20 mg/L | ||||

| O2: present | ||||

| 350 days | Anthracite and quartz sand | Flow velocity: 6–8 m/h bed depth: 1.0 m anthracite and 0.6 m quartz sand backwashing with air and treated, chlorinated water | pH 6.9–7.3 | [191] |

| Mn: 0.21–0.30 mg/L | ||||

| Fe: 0.55–1.63 mg/L | ||||

| NH4+: 0.65–0.90 mg/L |

| Location of Water Treatment Plant | De Punt, The Netherlands | Onnen, The Netherlands | Wierden, The Netherlands | Poznań, Poland | Poznań, Poland | Joyo, Japan | Joyo, Japan |

|---|---|---|---|---|---|---|---|

| Operating time of filter | 15 years | 40 years | 18 years | 10 years | 10 years | 3 years | 15 years |

| Place of origin | from 1.4–1.5 m depth of manganese removal zone | from the top of manganese removal postfilter | from the top of manganese removal postfilter | from filter iron removal zone | from filter manganese removal zone | from the top of iron and manganese removal filter | from the top of iron and manganese removal filter |

| Carrier | quartz sand | quartz sand | quartz sand | quartz sand | quartz sand | anthracite | anthracite |

| Content of major elements, wt.% | |||||||

| Fe | n.a. | n.a. | n.a. | 29.5 | 15.6 | 9.21 | 23.13 |

| Mn | n.a. | n.a. | n.a. | 18.5 | 21.5 | 12.87 | 11.58 |

| O | n.a. | n.a. | n.a. | 46.0 | 55.0 | 29.72 | 26.56 |

| C | n.a. | n.a. | n.a. | n.a. | n.a. | 36.06 | 24.84 |

| Content of side elements, wt.% | |||||||

| Ca | 2.3 | 7.2 | 7.7 | 3.00 | 2.90 | 10.06 | 9.71 |

| Si | 5.9 | 2.6 | 0.9 | 1.05 | 0.90 | 0.69 | 1.87 |

| Al | <0.1 | 0.6 | <0.1 | 0.70 | 3.51 | 0.19 | n.d. |

| Mg | <0.1 | 0.4 | 0.3 | n.a. | n.a. | n.a. | n.a. |

| Na | <0.1 | 0.2 | <0.1 | n.a. | n.a. | n.a. | n.a. |

| K | <0.1 | <0.1 | <0.1 | n.d. | n.d. | 0.15 | n.d. |

| S | n.a. | n.a. | n.a. | 0.09 | n.d. | 0.50 | 0.66 |

| p | n.a. | n.a. | n.a. | 0.40 | 0.21 | 0.56 | 1.63 |

| Analysis technique | - | - | - | SEM/EDX | SEM/EDX | WDXS | WDXS |

| Ref. | [183] | [183] | [183] | [194] | [194] | [167] | [167] |

| Features | Trade Name | |||||

|---|---|---|---|---|---|---|

| G1 | Defeman | Multiman 3M | Pyrolox | Filox-R | MetalEase | |

| MnO2 content (wt.%) | ≥82 | 84 | min. 80 | – | 75–85 | 75–85 |

| Preferred water pH | ≥7 | 7.0–8.5 | >7.4 | 6.5–9.0 | 6.5–9.0 | 5.0–9.0 |

| Max. concentration of components in water (mg/L) | for Fe, Mn, (values not given) | Fe: 20 Mn: 1.5 | Fe: 15 Mn: 1.5 | for Fe, Mn, H2S (values not given) | Fe: 10 Mn: 5 H2S: 3 | Fe: 10 Mn: 3 H2S: 5 |

| Flow velocity (m/h) | 10–20 | to 20 | 7–15 | 12 | 15 | 10–12 |

| Min. depth of bed (cm) | 35–45 | – | – | 46 | 51 | 61 |

| Typical grain size (mm) | 1–3 | 0.5–0.8 0.8–3.0 3.0–10.0 | 0.8–2.5 1.0–3.0 | 0.42–0.84 0.84–2.38 | 0.42–1.68 | 0.42–1.68 |

| Density Bulk density (kg/m3) | 4100–4300 | – | 4000–4200 | 3800 | – | – |

| 1800–2000 | 1900 | 2000 | 1920 | 1760 | 1824 | |

| Manufacturer | Global Concepts 2000 Polska Sp. z o.o. | Global Concepts 2000 Polska Sp. z o.o. | Dynamik Filtr s. j. | Prince Minerals Inc. | Watts Water Technologies EMEA B.V. | Safe Water Technologies Inc. |

| References | [203] | [207] | [208] | [209] | [210] | [205] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Michel, M.M.; Reczek, L.; Papciak, D.; Włodarczyk-Makuła, M.; Siwiec, T.; Trach, Y. Mineral Materials Coated with and Consisting of MnOx—Characteristics and Application of Filter Media for Groundwater Treatment: A Review. Materials 2020, 13, 2232. https://doi.org/10.3390/ma13102232

Michel MM, Reczek L, Papciak D, Włodarczyk-Makuła M, Siwiec T, Trach Y. Mineral Materials Coated with and Consisting of MnOx—Characteristics and Application of Filter Media for Groundwater Treatment: A Review. Materials. 2020; 13(10):2232. https://doi.org/10.3390/ma13102232

Chicago/Turabian StyleMichel, Magdalena M., Lidia Reczek, Dorota Papciak, Maria Włodarczyk-Makuła, Tadeusz Siwiec, and Yuliia Trach. 2020. "Mineral Materials Coated with and Consisting of MnOx—Characteristics and Application of Filter Media for Groundwater Treatment: A Review" Materials 13, no. 10: 2232. https://doi.org/10.3390/ma13102232

APA StyleMichel, M. M., Reczek, L., Papciak, D., Włodarczyk-Makuła, M., Siwiec, T., & Trach, Y. (2020). Mineral Materials Coated with and Consisting of MnOx—Characteristics and Application of Filter Media for Groundwater Treatment: A Review. Materials, 13(10), 2232. https://doi.org/10.3390/ma13102232