Cavitation Wear of Basalt-Based Glass Ceramic

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

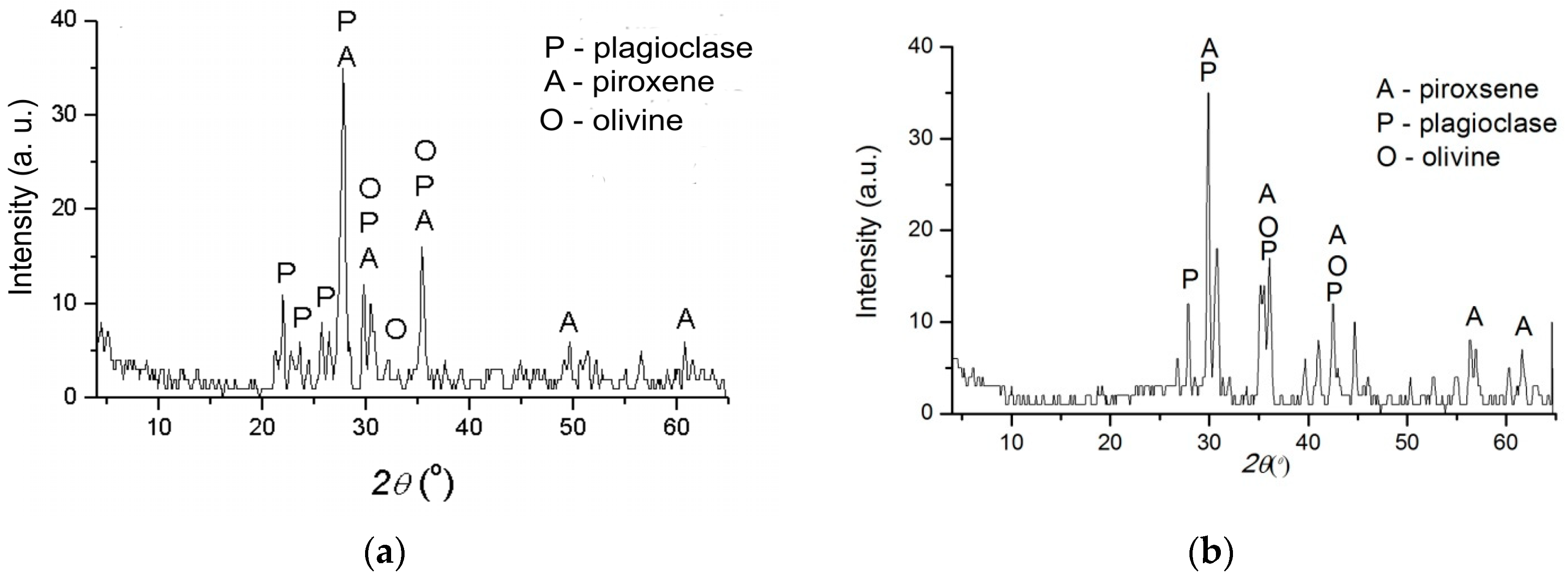

3.1. Phase Composition of Basalts Samples

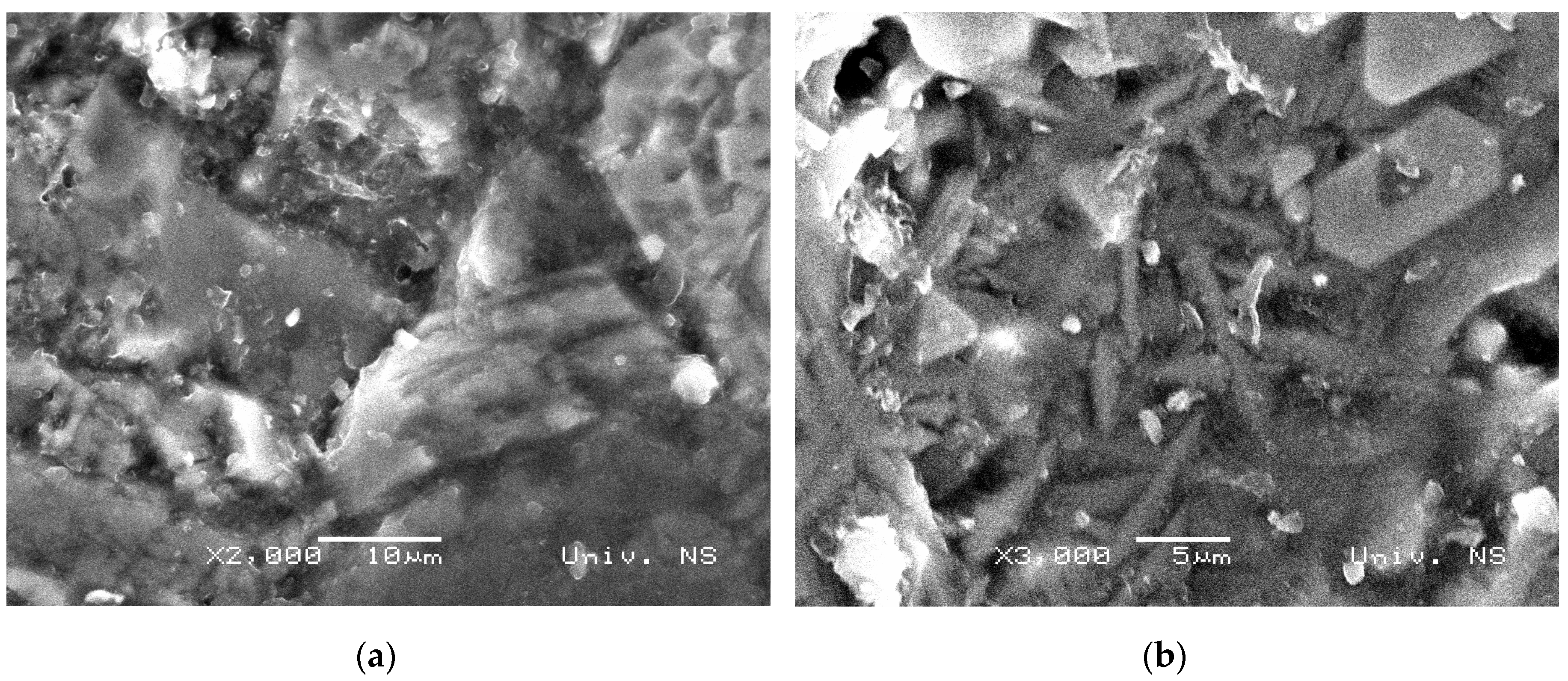

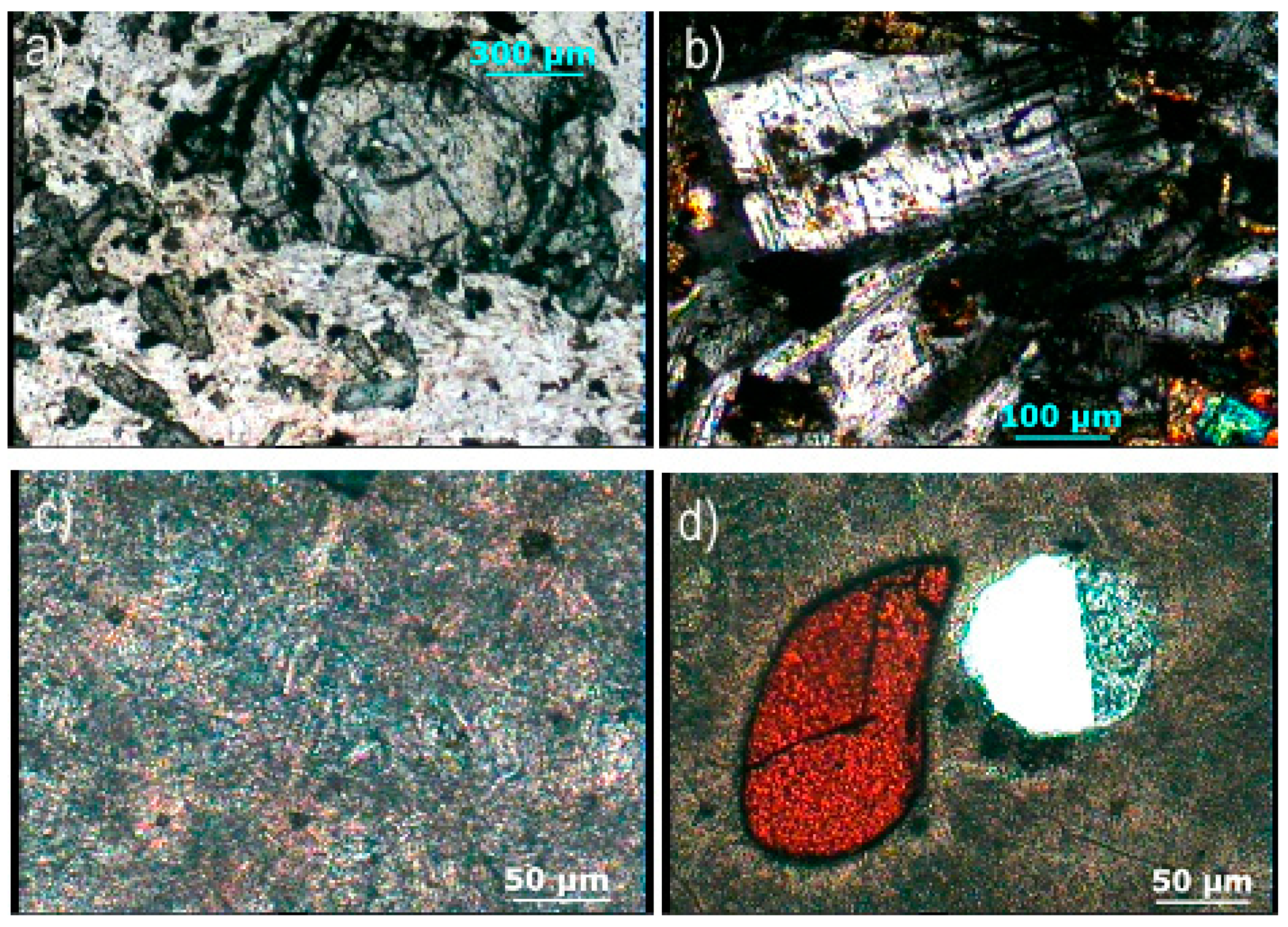

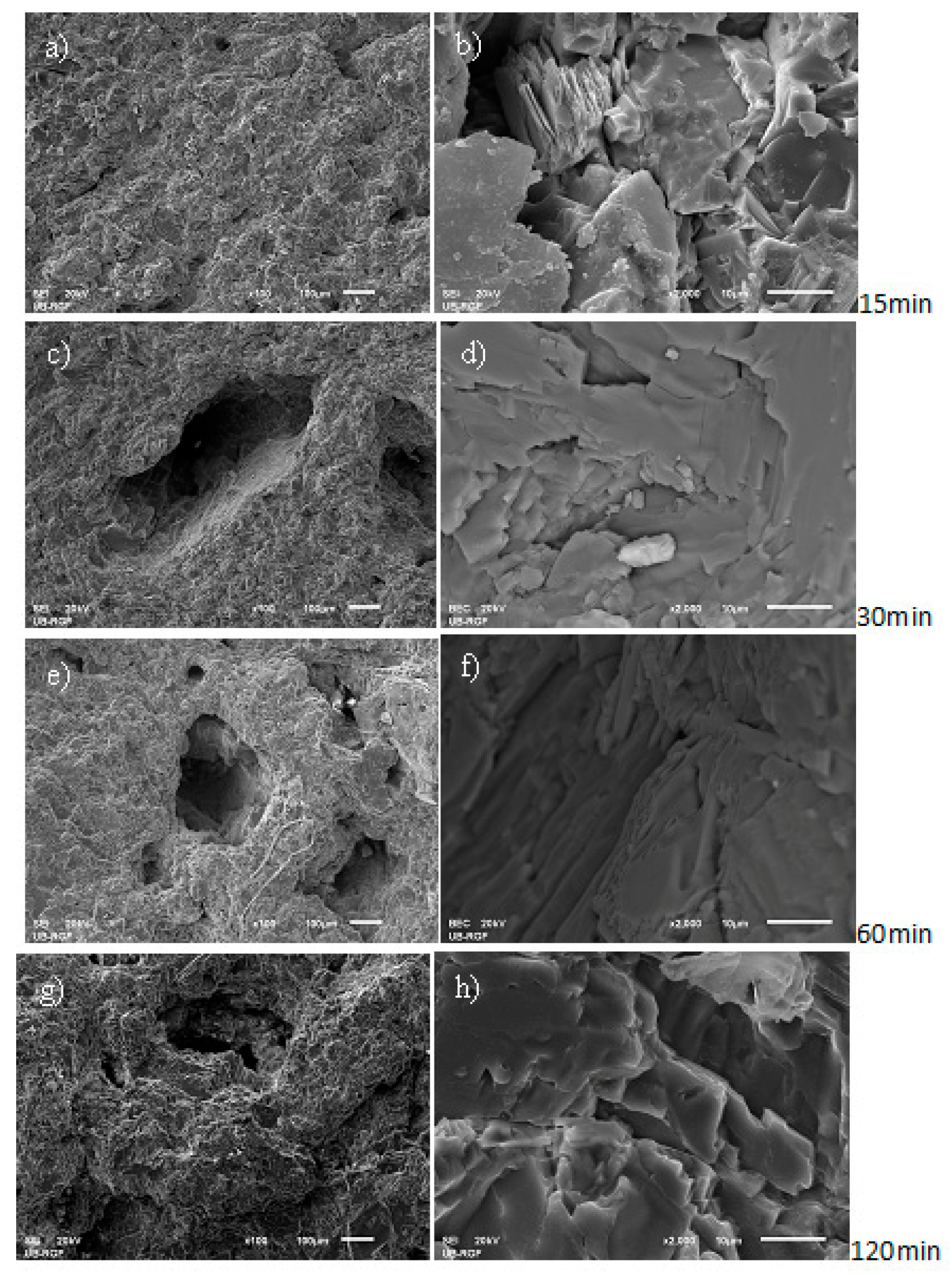

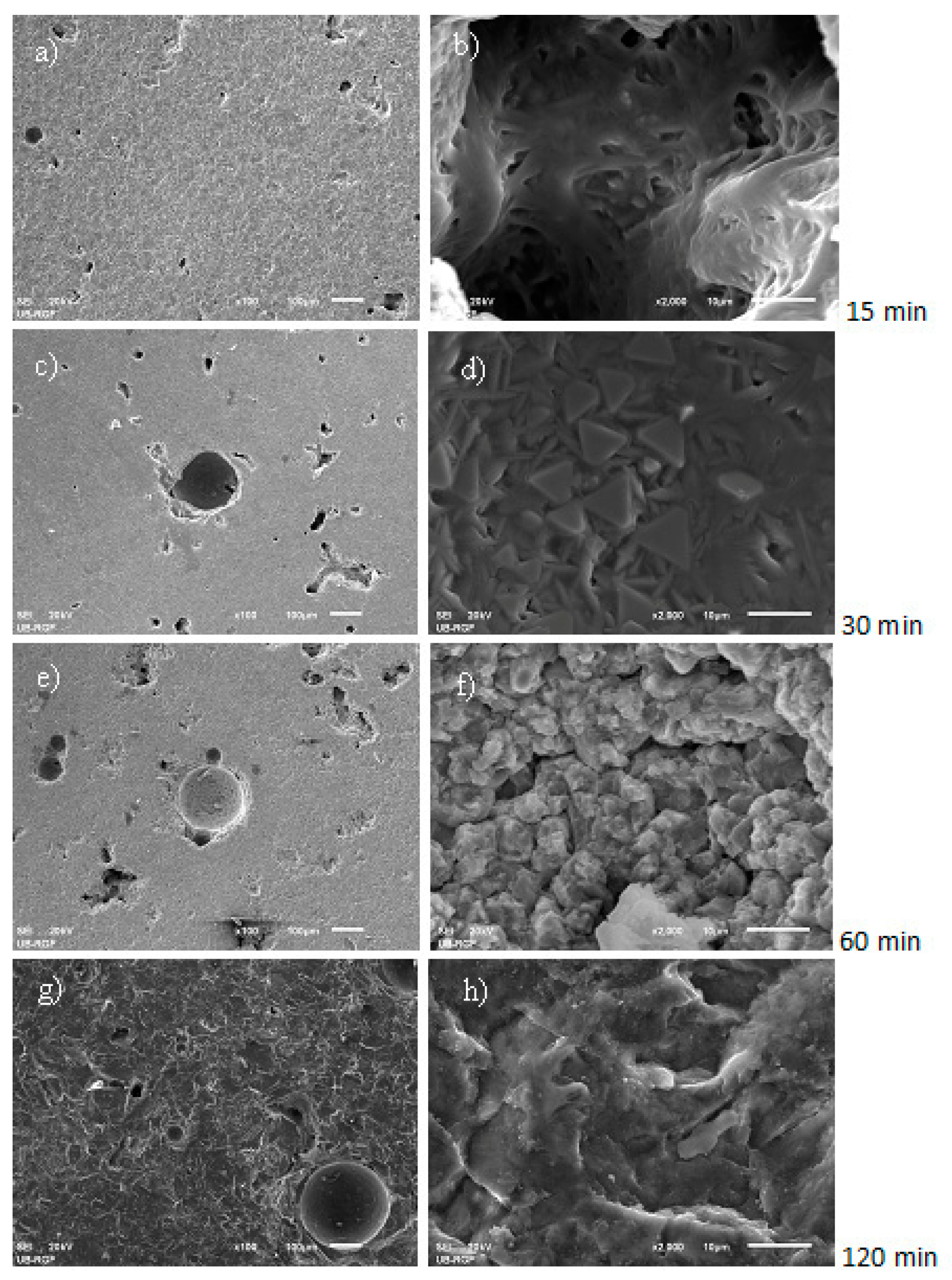

3.2. Micro-Structural Analysis of Basalt Samples

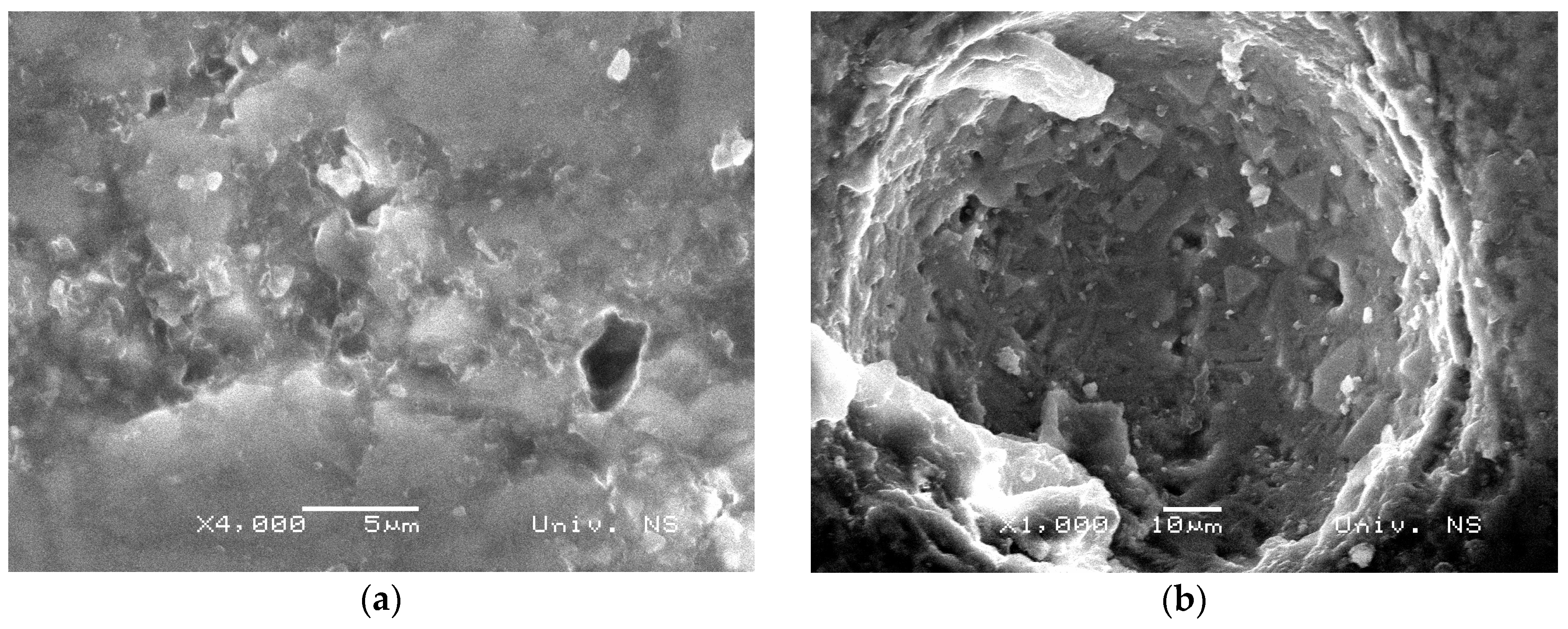

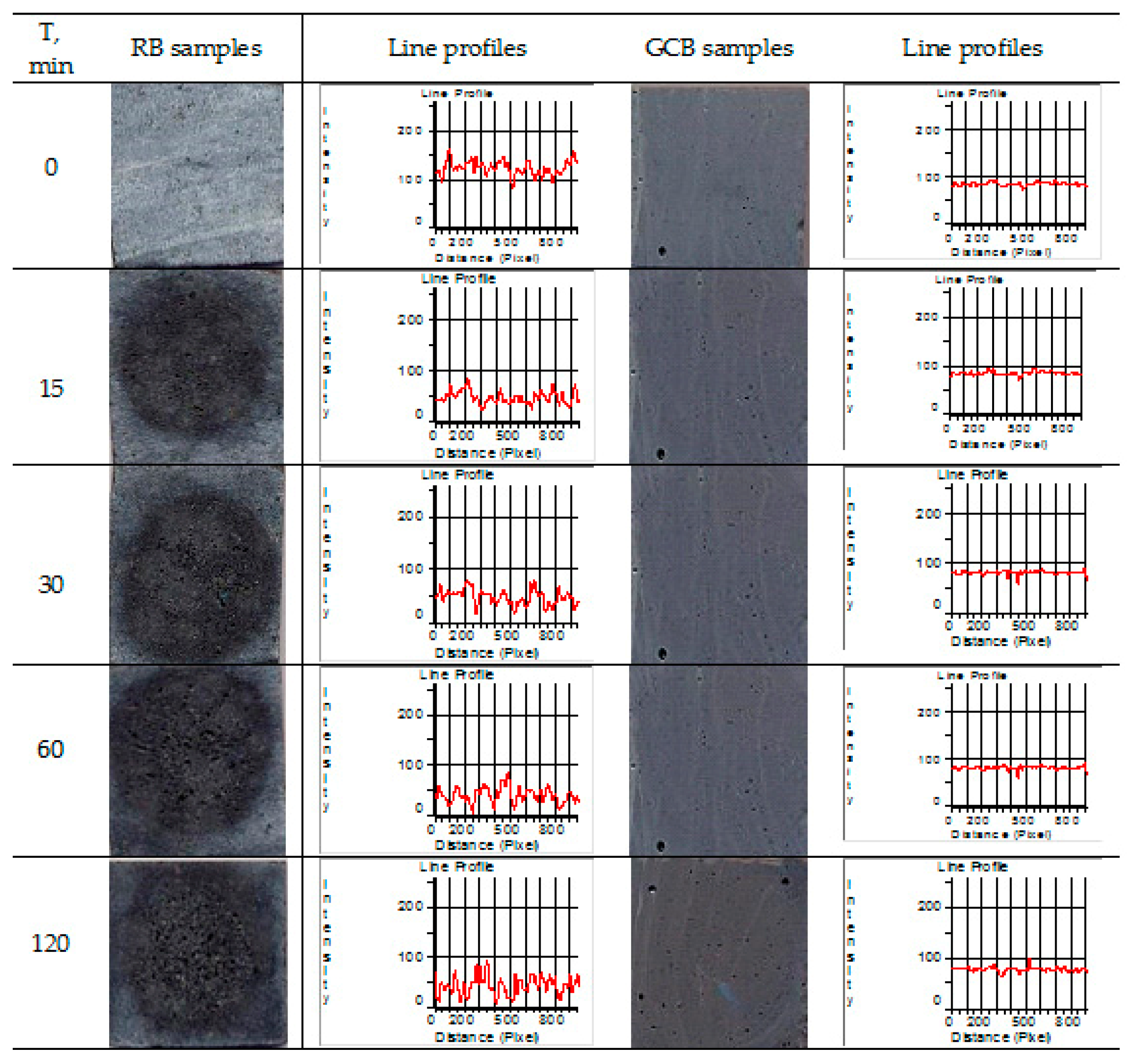

3.3. Implementation of Image Analysis on Comparison of Cavitation Erosion Degradation of Basalt Samples

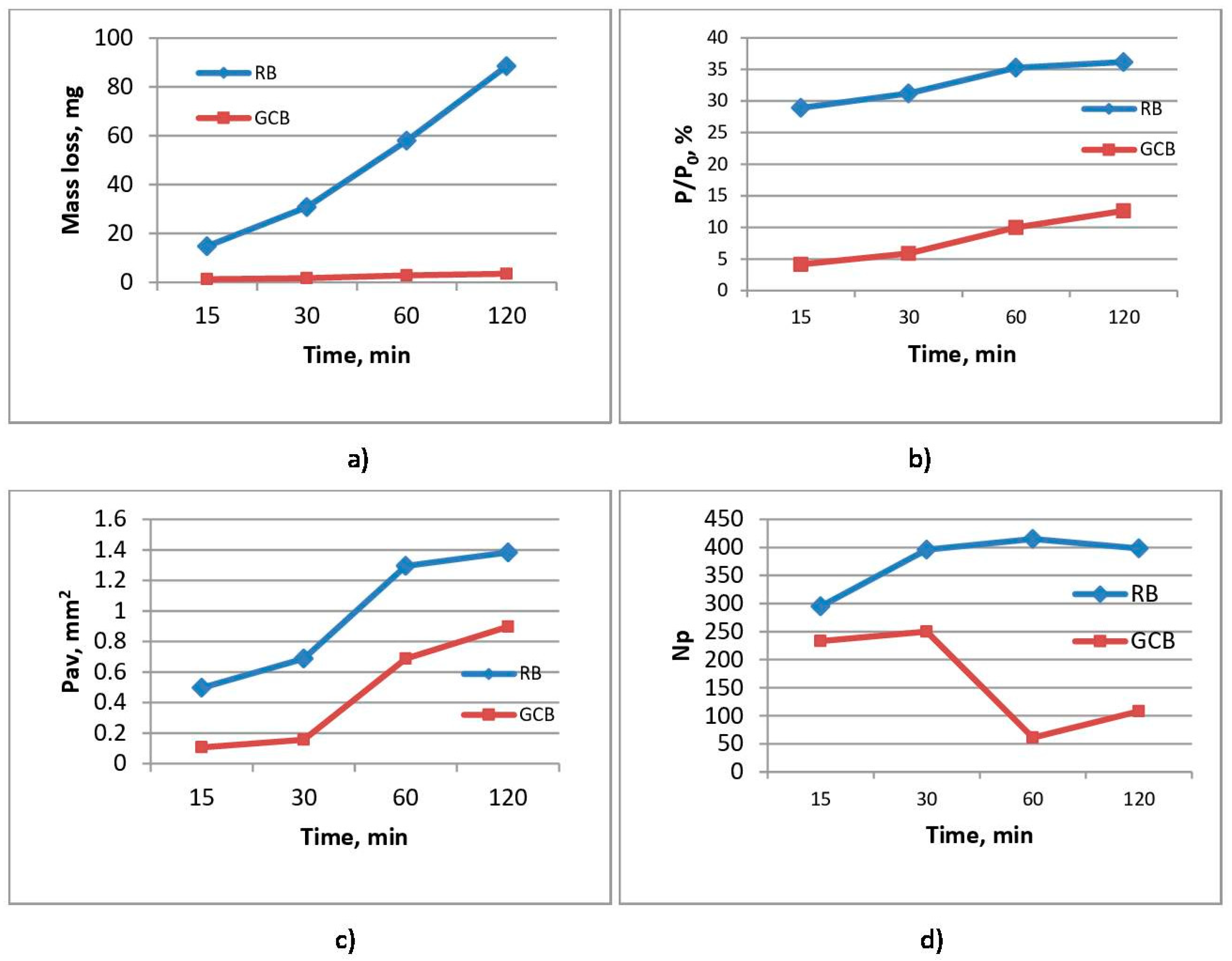

3.4. Mass Change

3.5. Image Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Cocić, M.; Logar, M.; Matović, B.; Poharac-Logar, V. Glass-Ceramics Obtained by the Cristallyzation of Basalt. Sci. Sinter. 2010, 42, 383–388. [Google Scholar] [CrossRef]

- Barth, T.F.W. Theoretical Petrology, 3rd ed.; John Wiley and Sons Inc.: New York, NY, USA, 1952; pp. 120–150. [Google Scholar]

- Matović, B.; Bošković, S.; Logar, M. Preparation of basalt -based glass ceramics. J. Serb. Chem. Soc. 2003, 68, 505–510. [Google Scholar] [CrossRef]

- Čikara, D.; Todić, A.; Čikara-Anić, D. Posibilitiesod Production of Wear Resistant Construction Elements by Processing of Serbian Basalt. FME Trans. 2010, 38, 203–207. [Google Scholar]

- Kostić–Gvozdenović, L.; Ninković, R. Inorganic Chemical Technology; Faculty of Technology and Metallurgy: Belgrade, Serbia, 1997. [Google Scholar]

- Pavlović, M.; Grujić, S.; Terzić, A.; Andrić, L. Synthesis of the Glass-Ceramics Based on Basalt. In Proceedings of Serbian Ceramic Society Conference—Advanced Ceramic and Application II—New Frontiers in Multifunctional Material Science and Procession, Book of Abstracts; Serbian Ceramic Society: Belgrade, Serbia, 2013; p. 36. ISBN 978-86-915627-1-7. [Google Scholar]

- Pavlović, M.; Sarvan, M.; Klisura, F.; Aćimović, Z. Basalt- Raw Material for Production of Aggregate for Modern Road and Rail Shourd. In Proceedings of the 4th Conference Maintenace, Zenica, B&H, 2–4 June 2016; pp. 175–183. [Google Scholar]

- Pavlović, M.; Đuričić, M.; Mumđić, A. Basalt Application Prospects for Touristic Facilities Furnishing. In Proceedings of the Conference SED, Uzice, Serbia, 2–3 October 2015; pp. 53–60. [Google Scholar]

- Prstić, A.; Aćimović, Z.; Pavlović, L.; Andrić, L.; Terzić, A. The application of basalt in the manufacturing of ceramic glazes. J. Min. Metall. Sect. A 2007, 43, 53–60. [Google Scholar]

- Andrić, L.; Aćimović, Z.; Trumić, M.; Prstić, A.; Tanasković, Z. Specific characteristic of coating glazes based on basalt. Mater. Des. 2012, 33, 9–13. [Google Scholar] [CrossRef]

- Yılmaz, S.; Bayrak, G.; Sen, S.; Sen, U. Structural characterization of basalt-based glass-ceamic coatings. Mater. Des. 2006, 27, 1092–1096. [Google Scholar] [CrossRef]

- Ercenk, E.; Ugur, S.; Yilmaz, S. Structural characterization of plasma sprayed basalt-SiC glass-ceramic coatings. Ceram. Int. 2011, 37, 883–889. [Google Scholar] [CrossRef]

- Karamanov, A.; Ergul, S.; Afyildiz, M.; Pelino, M. Sinter -crystallization of a glass obtained from basaltic tuffs. J. Non-Cryst. Solids 2008, 354, 290–295. [Google Scholar] [CrossRef]

- Fiore, V.; Di Bella, G.; Valenza, A. Glass-basalt/epoxy hybrid composites for marine applications. Mater. Des. 2011, 32, 2091–2099. [Google Scholar] [CrossRef]

- Dehkordi, M.T.; Nosraty, H.; Shokrieh, M.M.; Minak, G.; Ghelli, D. Low velocity impact properties of intra-ply hybrid composites based on basalt and nylon woven fabrics. Mater. Des. 2010, 31, 3835–3844. [Google Scholar] [CrossRef]

- Todic, A.; Nedeljkovic, B.; Cikara, D.; Ristovic, I. Particulate basalt–polymer composites characteristics investigation. Mater. Des. 2011, 32, 1677–1683. [Google Scholar] [CrossRef]

- Franc, J.P.; Michel, J.M. Fundamentals of Cavitation; Series Fluid Mechanics and Its Applications (Book 76); Kluwer Academic Publishers: New York, NY, USA, 2004. [Google Scholar]

- Hammitt, F.G. Cavitation and Multiphase Flow Phenomena; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Hattori, S.; Mori, H.; Okada, T. Quantitative evaluation of cavitation erosion. J. Fluids Eng.-Trans ASME 1998, 1201, 179–185. [Google Scholar] [CrossRef]

- Pola, A.; Montesano, L.; Tocci, M.; La Vecchia, G.M. Influence of Ultrasound Treatment on Cavitation Erosion Resistance of AlSi7 Alloy. Materials 2017, 10, 256–268. [Google Scholar] [CrossRef]

- Feng, C.; Shuyun, J. Cavitation erosion of diamond-like carbon coating on stainless steel. Appl. Surf. Sci. 2014, 292, 16. [Google Scholar] [CrossRef]

- Dular, M.; Stoffel, B.; Sirok, B. Development of cavitation erosion model. Wear 2006, 261, 642–655. [Google Scholar] [CrossRef]

- Dular, M.; Osterman, A. Pit clustering in cavitation erosion. Wear 2008, 265, 811–820. [Google Scholar] [CrossRef]

- Dojčinović, M. Rougness measurement as an alternative method in evaluation of cavitation resistance of steel. Chem. Ind. 2013, 67, 323–330. [Google Scholar] [CrossRef]

- Aleksić, V.; Dojčinović, M.; Milović, L.; Samardžić, I. Cavitation damages morphology of high-strength low-alloy steel. Metalurgija 2016, 55, 423–425. [Google Scholar]

- Laguna-Camacho, J.R.; Lewis, R.; Vite-Torres, M.; Mendez-Mendez, J.V. A study of cavitation erosion on engineering materials. Wear 2013, 301, 467–476. [Google Scholar] [CrossRef]

- Qiu, N.; Wang, L.; Wu, S.; Likhachev, D.S. Research on cavitation erosion and wear resistance performance of coatings. Eng. Fail. Anal. 2015, 55, 208–223. [Google Scholar] [CrossRef]

- Niebuhr, D. Cavitation erosion behavior of ceramic in aqueous solution. Wear 2007, 263, 295–300. [Google Scholar] [CrossRef]

- Tomlinson, W.J.; Matthews, S.J. Cavitation erosion of structural ceramics. Ceram. Int. 1994, 20, 201–209. [Google Scholar] [CrossRef]

- Jasionwski, R.; Pedzich, Z.; Zasada, D.; Przetakiewicz, W. Cavitation Erosion Resistance of FeAlIntermetalics Alloys and Al2O3–based Ceramics. Arch. Metall. Mater. 2015, 60, 671–675. [Google Scholar] [CrossRef]

- Pavlović, M.; Dojčinović, M.; Andrić, L.; Stojanović, J.; Radulović, D.; Petrov, M.; Blagojev, M. Influence of the basalt structure and properties on development the cavitation damage. In Proceedings of the 50th International October Conference on Mining and Metallurgy (IOC 2018), Bor Lake, Serbia, 30 September–3 October 2018; pp. 155–158. [Google Scholar]

- Dojcinovic, M. Comparative cavitation erosion test on steels produced by ESR and AOD refining. Mater. Sci. Poland 2011, 29, 216–222. [Google Scholar] [CrossRef]

- García-Atance Fatjó, G.; Hadfield, M.; Tabeshfar, K. Early stage cavitation erosion within ceramics—An experimental investigation. Ceram. Int. 2011, 37, 1919. [Google Scholar] [CrossRef]

- Standard Method of Vibratory Cavitation Erosion Test, G32-92. Annual Book of ASTM Standards; ASTM: Philadelphia, PA, USA, 1992; Volume 03.02. [Google Scholar]

- Image Pro Plus, The Proven Solution for Image Analysis; Media Cybernetics: Rockville, MD, USA, 1993.

| Sample | SiO2 | Al2O3 | Fe2O3 | FeO | MgO | CaO | Na2O | K2O | TiO2 |

|---|---|---|---|---|---|---|---|---|---|

| Raw basalt | 56.21 | 18.61 | 1.15 | 2.97 | 3.40 | 7.78 | 4.73 | 3.37 | 1.11 |

| Basalt-based glass ceramic | 52.78 | 16.97 | 1.87 | 7.52 | 7.56 | 8.94 | 1.79 | 0.89 | 1.26 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pavlovic, M.; Dojcinovic, M.; Prokic-Cvetkovic, R.; Andric, L.; Ceganjac, Z.; Trumbulovic, L. Cavitation Wear of Basalt-Based Glass Ceramic. Materials 2019, 12, 1552. https://doi.org/10.3390/ma12091552

Pavlovic M, Dojcinovic M, Prokic-Cvetkovic R, Andric L, Ceganjac Z, Trumbulovic L. Cavitation Wear of Basalt-Based Glass Ceramic. Materials. 2019; 12(9):1552. https://doi.org/10.3390/ma12091552

Chicago/Turabian StylePavlovic, Marko, Marina Dojcinovic, Radica Prokic-Cvetkovic, Ljubisa Andric, Zoran Ceganjac, and Ljiljana Trumbulovic. 2019. "Cavitation Wear of Basalt-Based Glass Ceramic" Materials 12, no. 9: 1552. https://doi.org/10.3390/ma12091552

APA StylePavlovic, M., Dojcinovic, M., Prokic-Cvetkovic, R., Andric, L., Ceganjac, Z., & Trumbulovic, L. (2019). Cavitation Wear of Basalt-Based Glass Ceramic. Materials, 12(9), 1552. https://doi.org/10.3390/ma12091552