The Correlation of Microstructure and Mechanical Properties of In-Situ Al-Mg2Si Cast Composite Processed by Equal Channel Angular Pressing

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

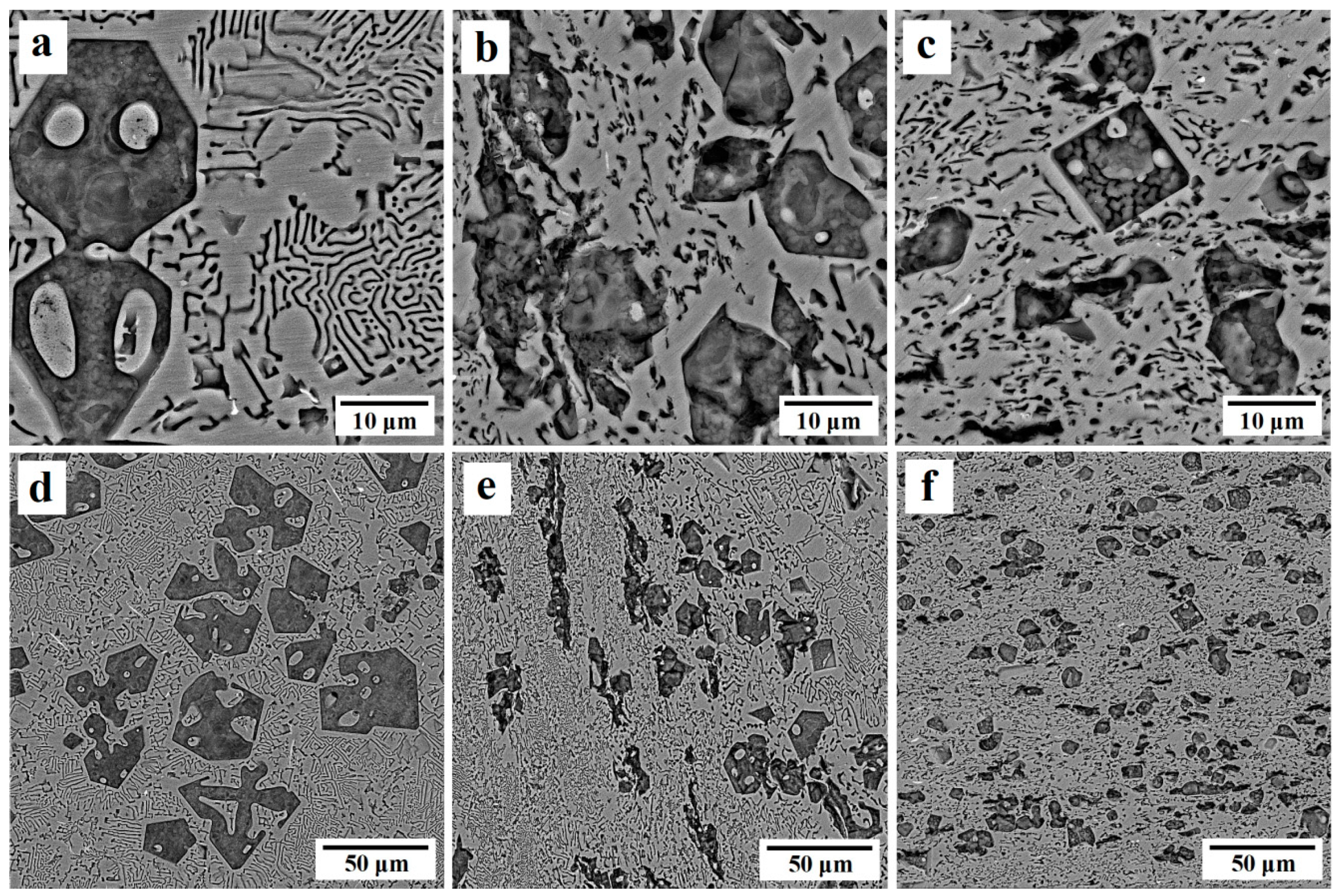

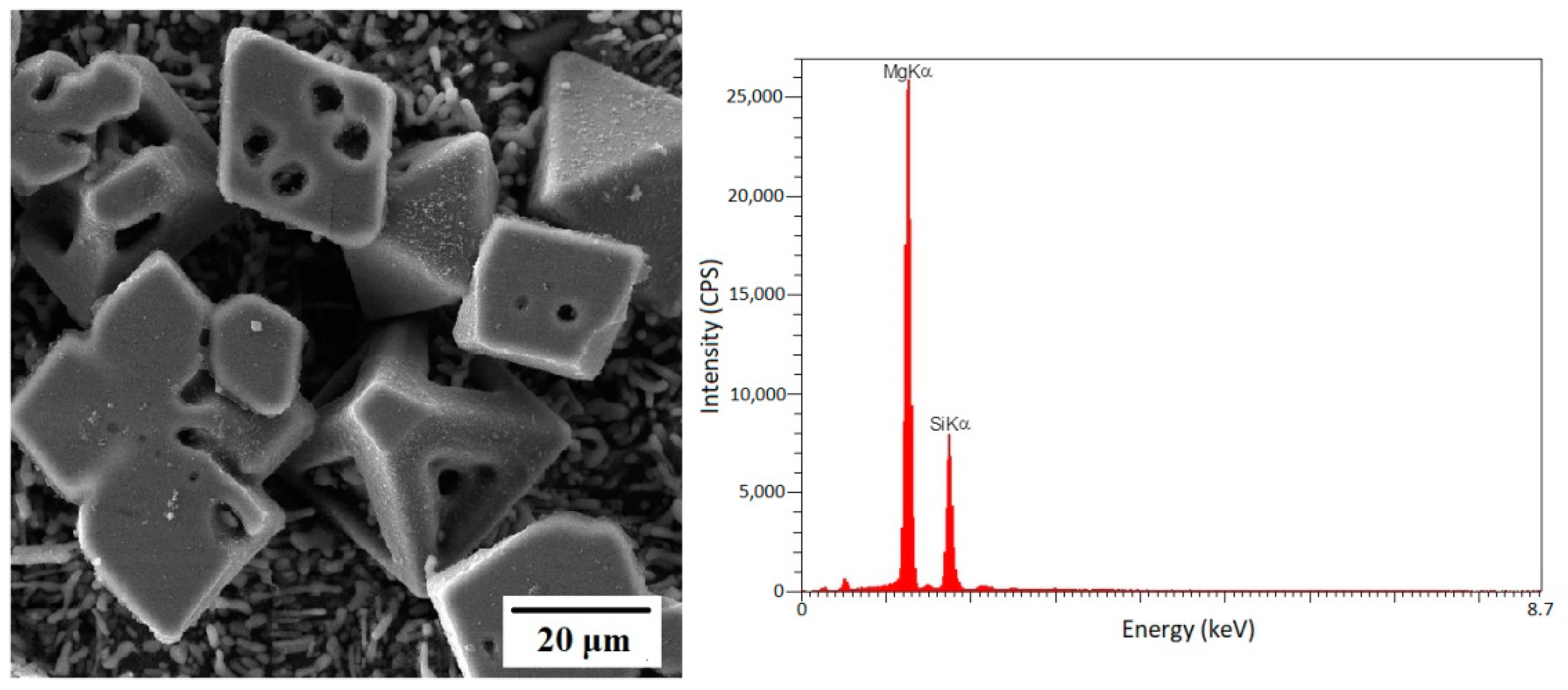

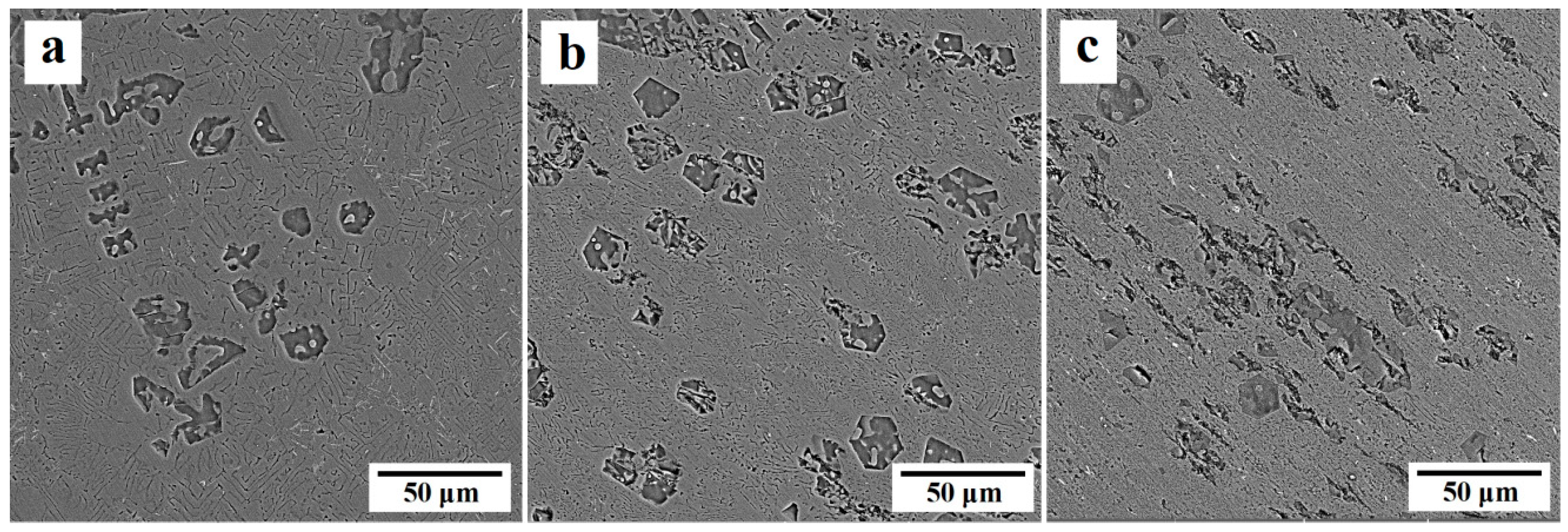

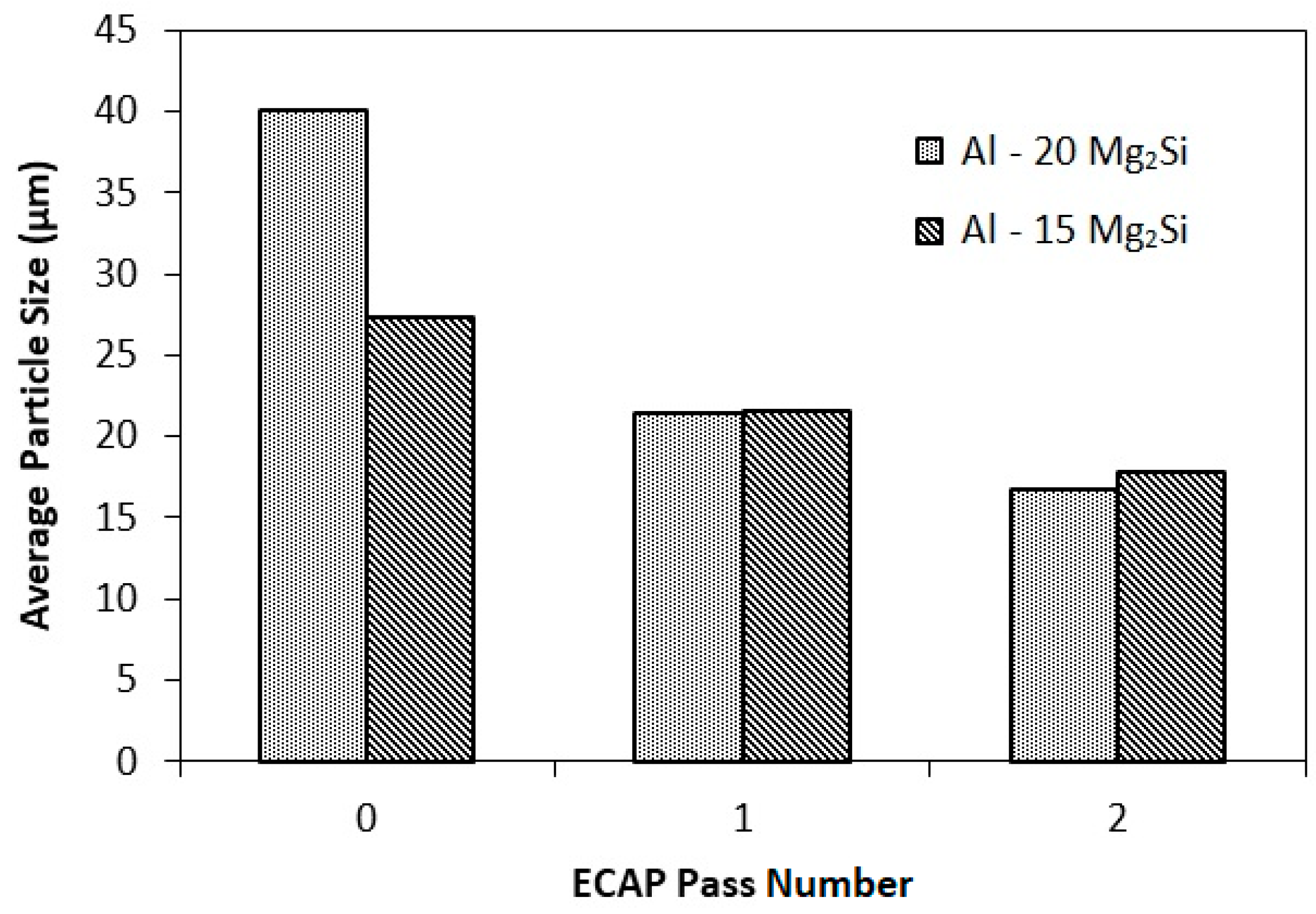

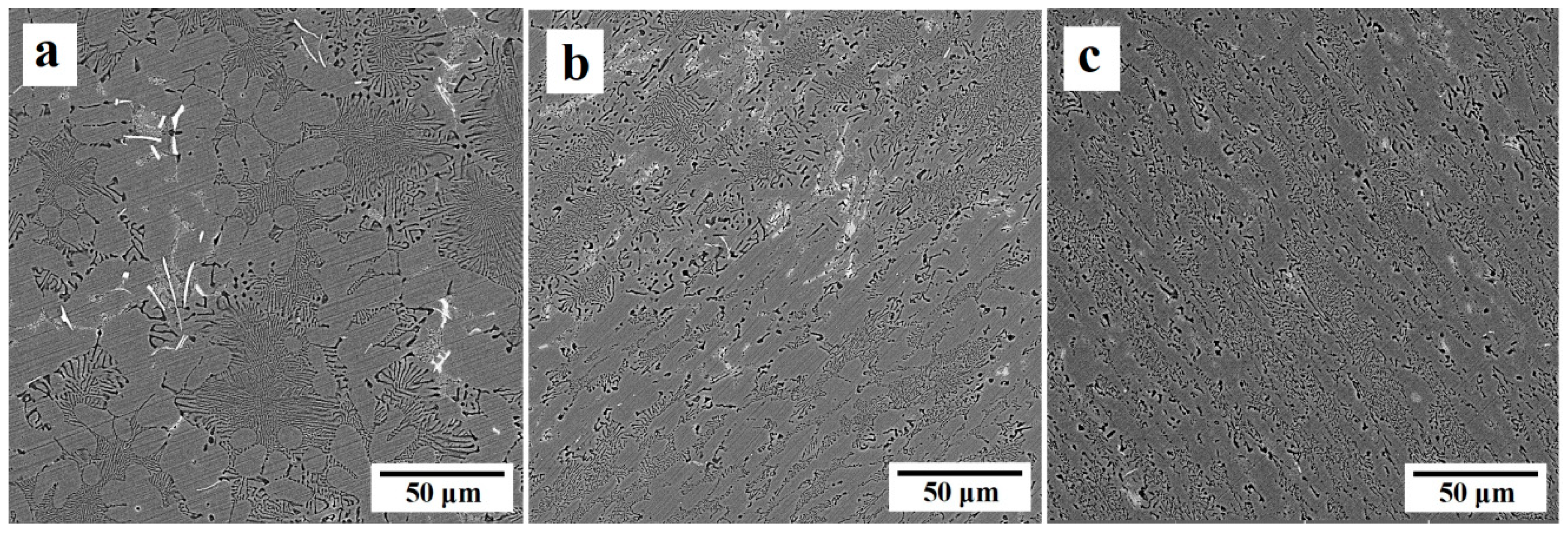

3.1. Microstructure

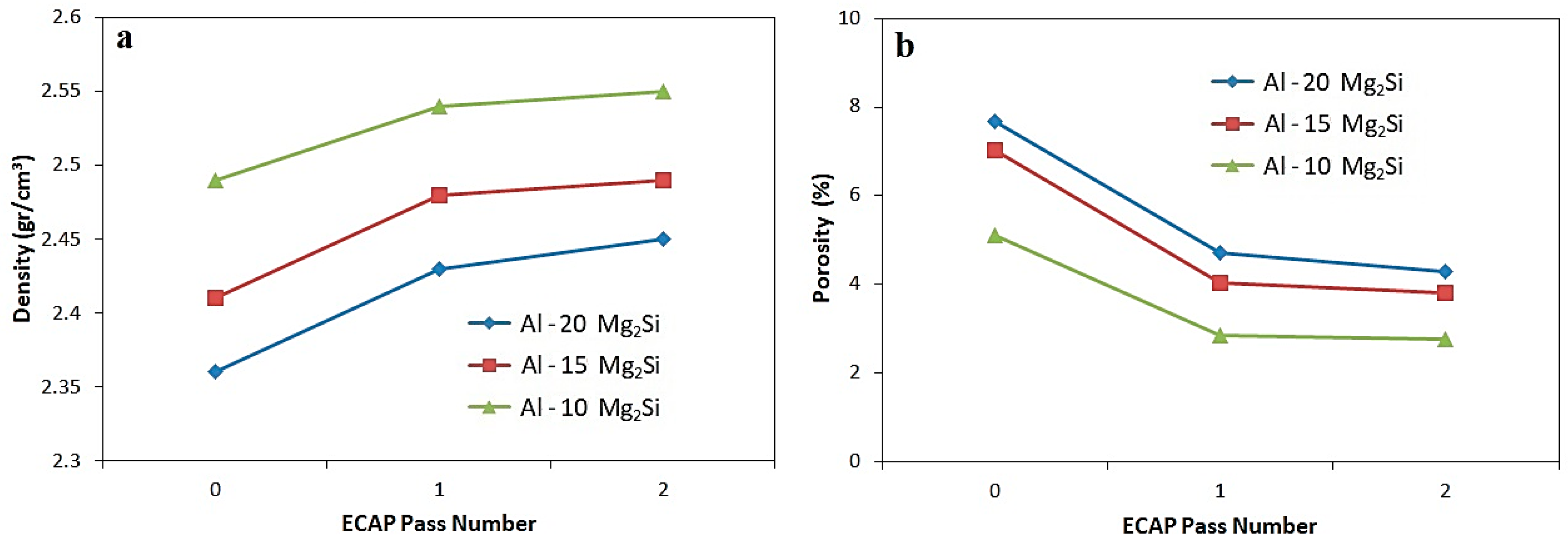

3.2. Density and Porosity Percentage

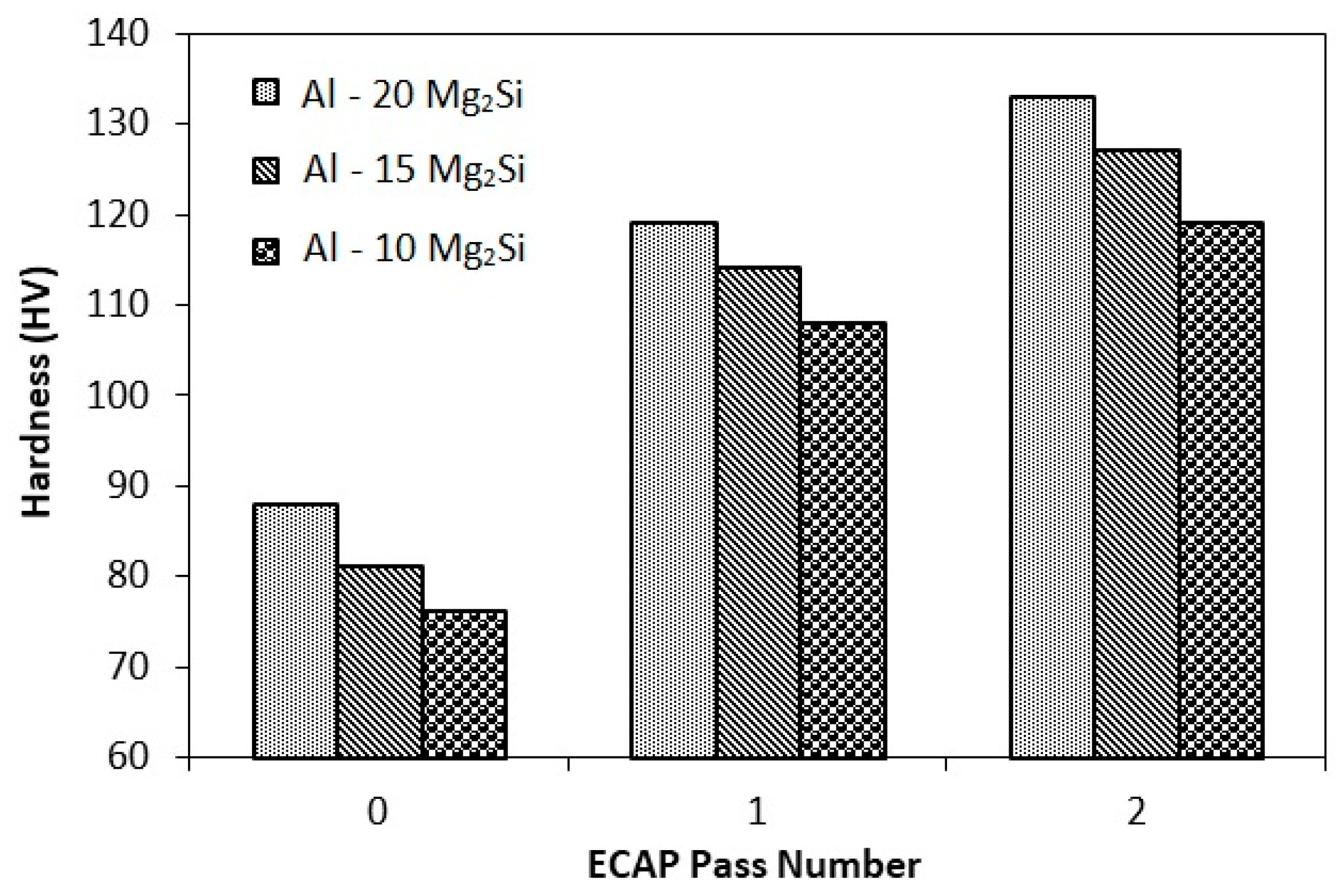

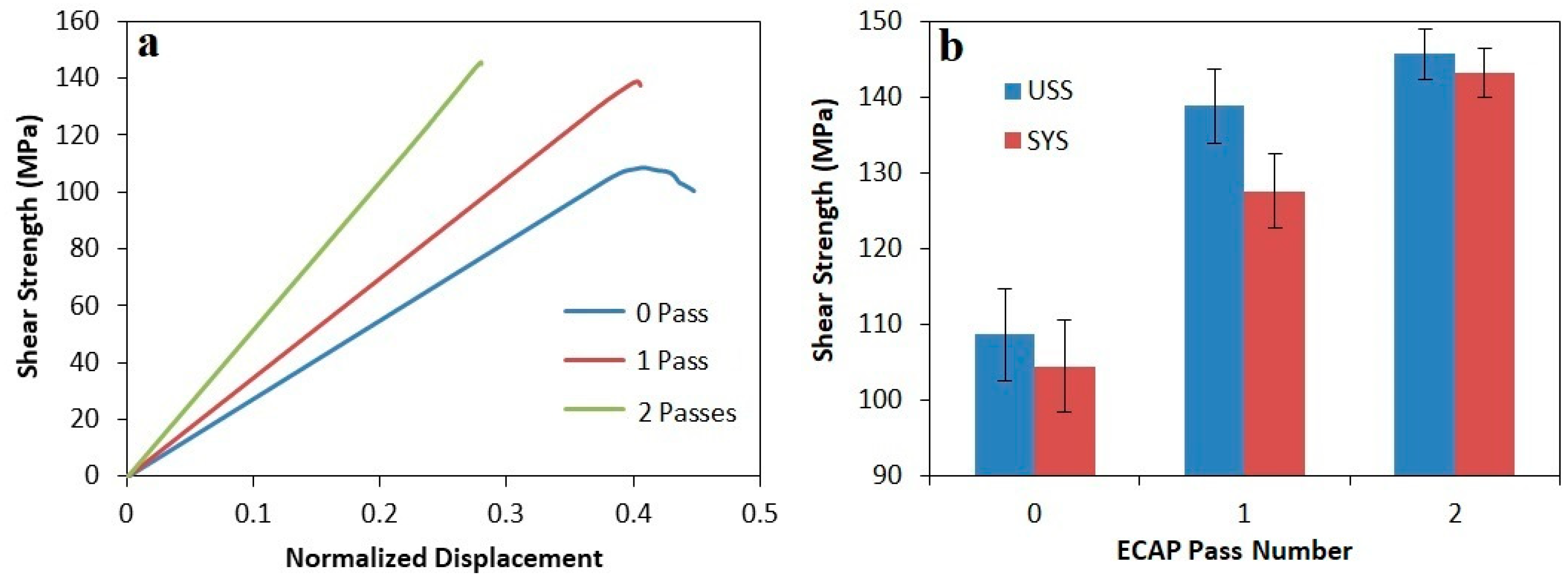

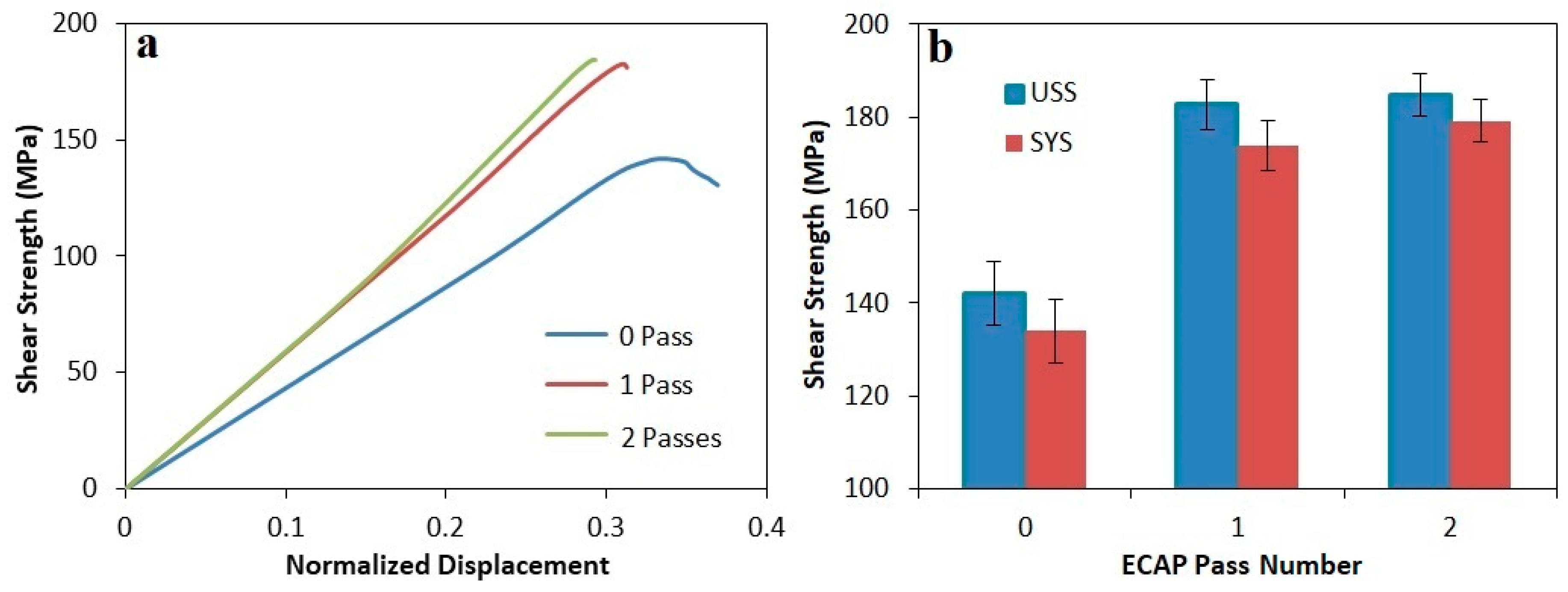

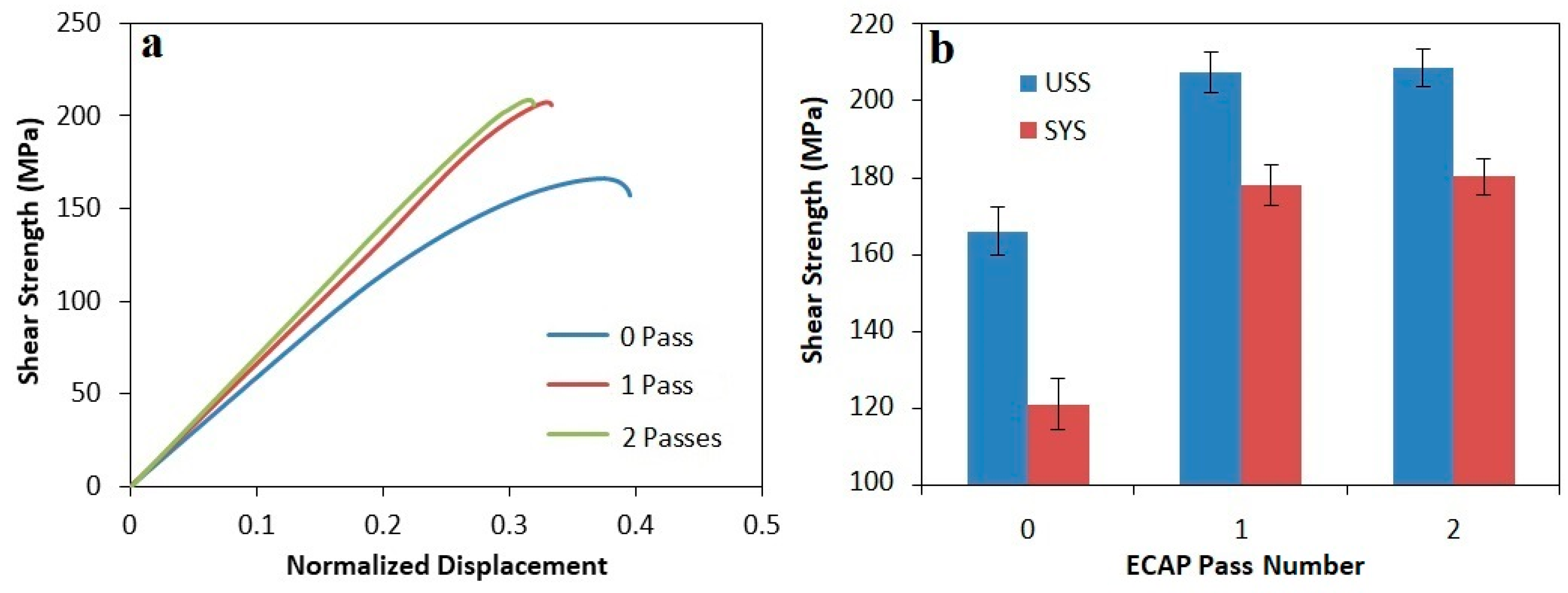

3.3. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Malekan, A.; Emamy, M.; Rassizadehghni, J.; Emami, A.R. The effect of solution temperature on the microstructure and tensile properties of Al-15%Mg2Si composite. Mater. Des. 2011, 325, 2701–2709. [Google Scholar] [CrossRef]

- Soltani, N.; Jafari Nodooshan, H.R.; Bahrami, A.; Pech-Canul, M.I.; Liu, W.; Wu, G. Effect of hot extrusion on wear properties of Al-15 wt.% Mg2Si in situ metal matrix composites. Mater. Des. 2014, 53, 774–781. [Google Scholar] [CrossRef]

- Li, C.; Wu, Y.; Li, H.; Liu, X. Microstructure formation in hypereutectic Al-Mg2Si with extra Si. J. Alloys Compd. 2009, 477, 212–216. [Google Scholar] [CrossRef]

- Emamy, M.; Nemati, N.; Heidarzadeh, A. The influence of Cu rich intermetallic phase on microstructure, hardness and tensile properties of Al-15%Mg2Si composite. Mater. Sci. Eng. A 2010, 527, 2998–3004. [Google Scholar] [CrossRef]

- Li, C.; Wu, Y.; Li, H.; Liu, X. Effect of Ni on eutectic structural evolution in hypereutectic Al-Mg2Si alloys. Mater. Sci. Eng. A 2010, 528, 573–577. [Google Scholar] [CrossRef]

- Qin, Q.D.; Zhao, Y.G.; Liu, C.; Cong, P.J.; Zhou, W. Strontium modification and formation of cubic primary Mg2Si crystals in Mg2Si/Al composite. J. Alloys Compd. 2008, 454, 142–146. [Google Scholar] [CrossRef]

- Khorshidi, R.; Honarbakhsh Raouf, A.; Emamy, M.; Campbell, J. The Study of Li on the microstructure and tensile properties of cast Al-Mg2Si metal matrix composite. J. Alloys Compd. 2011, 509, 9026–9033. [Google Scholar] [CrossRef]

- Li, C.; Liu, X.; Zhang, G. Heterogeneous nucleating role of TiB2 or AlP/TiB2 coupled compounds on primary Mg2Si in Al-Mg-Si alloys. Mater. Sci. Eng. A 2008, 497, 432–437. [Google Scholar] [CrossRef]

- Ghorbani, M.R.; Emamy, M.; Nemati, N. Microstructure and mechanical characterization of Al-15%Mg2Si composite containing chromium. Mater. Des. 2011, 32, 4262–4269. [Google Scholar] [CrossRef]

- Akhlaghi, A.; Noghani, M.; Emamy, M. The effect of La-intermetallic compounds on tensile properties of Al-15%Mg2Si in-situ composite. Procedia Mater. Sci. 2015, 11, 55–60. [Google Scholar] [CrossRef]

- Emamy, M.; Khorshidi, R.; Honarbakhsh Raouf, A. The influence of pure Na on the microstructure and tensile properties of Al-Mg2Si metal matrix composite. Mater. Sci. Eng. A 2011, 528, 4337–4342. [Google Scholar] [CrossRef]

- Zhao, Y.G.; Qin, Q.D.; Zhou, W.; Liang, Y.H. Microstructure of the Ce-modified in situ Mg2Si/Al-Si-Cu composite. J. Alloys Compd. 2005, 389, L1–L4. [Google Scholar] [CrossRef]

- Emamy, M.; Jafari Nodooshan, H.R.; Malekan, A. The microstructure, hardness and tensile properties of Al-15%Mg2Si in situ composite with yttrium addition. Mater. Des. 2011, 32, 4559–4566. [Google Scholar] [CrossRef]

- Zhang, J.; Fan, Z.; Wang, Y.Q.; Zhou, B.L. Equilibrium pseudobinary Al-Mg2Si phase diagram. Mater. Sci. Technol. 2001, 17, 494–496. [Google Scholar] [CrossRef]

- Emamy, M.; Vaziri Yeganeh, S.E.; Razaghian, A.; Tavighi, K. Microstructure and tensile properties of hot-extruded Al matrix composite containing different amount of Mg2Si. Mater. Sci. Eng. A 2013, 586, 190–196. [Google Scholar] [CrossRef]

- Hadian, R.; Emamy, M.; Varahram, N.; Nemati, N. The effect of Li on the tensile properties of cast Al-Mg2Si metal matrix composite. Mater. Sci. Eng. A 2008, 490, 250–257. [Google Scholar] [CrossRef]

- Qin, Q.D.; Zhao, Y.G.; Zhou, W.; Cong, P.J. Effect of phosphorus and growth manner of primary Mg2Si crystal in Mg2Si/Al composite. Mater. Sci. Eng. A 2007, 447, 186–191. [Google Scholar] [CrossRef]

- Soltani, N.; Bahrami, A.; Pech-Canul, M.I. The effect of Ti on mechanical properties of extruded in-situ Al-15 pct Mg2Si composite. Met. Mater. Trans. A 2013, 44, 4366–4373. [Google Scholar] [CrossRef]

- Qin, Q.D.; Zhao, Y.G.; Liu, C.; Cong, P.J.; Zhou, W.; Liang, Y.H. Effect of holding temperature on semisolid microstructure of Mg2Si/Al composite. J. Alloys Compd. 2006, 416, 143–147. [Google Scholar] [CrossRef]

- Nordin, N.A.; Abubakar, T.; Hamzeh, E.; Farahany, S.; Ourdjini, A. Effect of Superheating melt treatment on Mg2Si particulate reinforcement in Al-Mg2Si-Cu in situ composite. Procedia Eng. 2017, 184, 595–603. [Google Scholar] [CrossRef]

- Zhang, J.T.; Zhao, Y.G.; Xu, X.F.; Liu, X.B. Effect of ultrasonic on morphology of primary Mg2Si in in-situ Mg2Si/Al composite. Trans. Nonferrous Met. Soc. China 2013, 23, 2852–2856. [Google Scholar] [CrossRef]

- Lin, J.; Bai, G.; Liu, Z.; Niu, L.; Li, G.; Wen, C. Effect of ultrasonic stirring on the microstructure on the microstructure and mechanical properties of in situ Mg2Si/Al composite. Mater. Chem. Phys. 2016, 178, 112–118. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Islamgaliev, R.K.; Alexandrof, I.V. Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 2000, 45, 103–189. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Langdon, T.G. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Ansarian, I.; Shaeri, M.H. Diffusional bonds in laminated composites produced by ECAP. Trans. Nonferrous Met. Soc. China 2017, 27, 1928–1938. [Google Scholar] [CrossRef]

- Esmaeili, A.; Shaeri, M.H.; Talafi Noghani, M.; Razaghian, A. Fatigue behavior of AA7075 aluminium alloy severely deformed by equal channel angular pressing. J. Alloys Compd. 2018, 757, 324–332. [Google Scholar] [CrossRef]

- Shaeri, M.H.; Shaeri, M.; Salehi, M.T.; Seyyedein, S.H.; Abutalebi, M.R. Effect of equal channel angular pressing on aging treatment of Al-7075 alloy. Prog. Nat. Sci. Mater. Int. 2015, 25, 159–168. [Google Scholar] [CrossRef]

- Shaeri, M.H.; Salehi, M.T.; Seyyedein, S.H.; Abutalebi, M.R.; Park, J.K. Microstructure and mechanical properties of Al-7075 alloy processed by equal channel angular pressing combined with aging treatment. Mater. Des. 2014, 57, 250–257. [Google Scholar] [CrossRef]

- Zhang, S.; Li, M.; Wang, H.; Cheng, W.; Lei, W.; Liu, Y.; Liang, W. Microstructure and tensile properties of ECAPed Mg-9Al-1Si-1SiC composites: The influence of initial microstructures. Materials 2018, 11, 136. [Google Scholar] [CrossRef]

- Chen, J.H.; Shen, Y.C.; Chao, C.G.; Liu, T.F. Wear Behavior and Microstructure of Mg-Sn Alloy Processed by Equal Channel Angular Extrusion. Materials 2017, 10, 1315. [Google Scholar] [CrossRef]

- Ansarian, I.; Shaeri, M.H.; Ebrahimi, M.; Minárik, P.; Bartha, K. Microstructure evolution and mechanical behaviour of severely deformed pure titanium through multi directional forging. J. Alloys Compd. 2018, 776, 83–95. [Google Scholar] [CrossRef]

- Chegini, M.; Shaeri, M.H. Effect of equal channel angular pressing on the mechanical and tribological behavior of Al-Zn-Mg-Cu alloy. Mater. Charact. 2018, 140, 147–161. [Google Scholar] [CrossRef]

- Dashti, A.; Shaeri, M.H.; Taghiabadi, R.; Djavanroodi, F.; Vali Ghazvini, F.; Javadi, H. Microstructure, Texture, Electrical and Mechanical Properties of AA-6063 Processed by Multi Directional Forging. Materials 2018, 11, 2419. [Google Scholar] [CrossRef]

- Chrominski, W.; Olejnik, L.; Rosochowski, A.; Lewandowska, M. Grain refinement in technically pure aluminium plates using incremental ECAP processing. Mater. Sci. Eng. A 2015, 636, 172–180. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Liao, X.Z.; Jin, Z.; Valiev, R.Z.; Zhu, Y.T. Microstructures and mechanical properties of ultrafine grained 7075 Al alloy processed by ECAP and their evolutions during annealing. Acta Mater. 2004, 52, 4589–4599. [Google Scholar] [CrossRef]

- Shaeri, M.H.; Shaeri, M.; Ebrahimi, M.; Salehi, M.; Seyyedein, S. Effect of ECAP temperature on microstructure and mechanical properties of Al-Zn-Mg-Cu alloy. Prog. Nat. Sci. Mater. Int. 2016, 26, 182–191. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Shamsborhan, M. Monotonic and dynamic mechanical properties of PTCAE aluminum. J. Alloys Compd. 2017, 705, 28–37. [Google Scholar] [CrossRef]

- Xu, C.; Furukawa, M.; Horita, Z.; Langdon, T.G. The evolution of homogeneity and grain refinement during equal-channel angular pressing: a grain refinement during equal-channel angular pressing. Mater. Sci. Eng. A 2005, 398, 66–76. [Google Scholar] [CrossRef]

- Bian, L.; Liang, W.; Xie, G.; Zhang, W.; Xue, J. Enhanced ductility in an Al–Mg2Si in situ composite processed by ECAP using a modified BC route. Mater. Sci. Eng. A 2011, 528, 3463–3467. [Google Scholar] [CrossRef]

- Chegini, M.; Shaeri, M.H.; Taghiabadi, R.; Chegini, S. Improving the mechanical properties of heat-treated Al-Mg2Si composites by microstructure modification through equal channel angular pressing. Compos. Part B. under review.

| Material | Mg | Si | Fe | Ni | Zn | Ca | Cu | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| Al-10% Mg2Si | 6.63 | 4.04 | 0.16 | 0.004 | 0.06 | 0.02 | 0.001 | 0.003 | Bal. |

| Al-15% Mg2Si | 9.82 | 5.72 | 0.17 | 0.003 | 0.01 | 0.03 | 0.002 | 0.004 | Bal. |

| Al-15% Mg2Si | 12.8 | 7.7 | 0.19 | 0.005 | 0.01 | 0.04 | 0.003 | 0.006 | Bal. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chegini, M.; Shaeri, M.H.; Taghiabadi, R.; Chegini, S.; Djavanroodi, F. The Correlation of Microstructure and Mechanical Properties of In-Situ Al-Mg2Si Cast Composite Processed by Equal Channel Angular Pressing. Materials 2019, 12, 1553. https://doi.org/10.3390/ma12091553

Chegini M, Shaeri MH, Taghiabadi R, Chegini S, Djavanroodi F. The Correlation of Microstructure and Mechanical Properties of In-Situ Al-Mg2Si Cast Composite Processed by Equal Channel Angular Pressing. Materials. 2019; 12(9):1553. https://doi.org/10.3390/ma12091553

Chicago/Turabian StyleChegini, Mahdi, Mohammad Hossein Shaeri, Reza Taghiabadi, Sajjad Chegini, and Faramarz Djavanroodi. 2019. "The Correlation of Microstructure and Mechanical Properties of In-Situ Al-Mg2Si Cast Composite Processed by Equal Channel Angular Pressing" Materials 12, no. 9: 1553. https://doi.org/10.3390/ma12091553

APA StyleChegini, M., Shaeri, M. H., Taghiabadi, R., Chegini, S., & Djavanroodi, F. (2019). The Correlation of Microstructure and Mechanical Properties of In-Situ Al-Mg2Si Cast Composite Processed by Equal Channel Angular Pressing. Materials, 12(9), 1553. https://doi.org/10.3390/ma12091553