Evaluating the Effects of High RAP Content and Rejuvenating Agents on Fatigue Performance of Fine Aggregate Matrix through DMA Flexural Bending Test

Abstract

:1. Introduction

- Assess the LAS test method for beam FAM specimens under flexural bending mode which serves as an alternative approach for the torsional LAS test with DSR.

- Define a reasonable failure criterion of FAM mixes for LAS test under flexural bending mode.

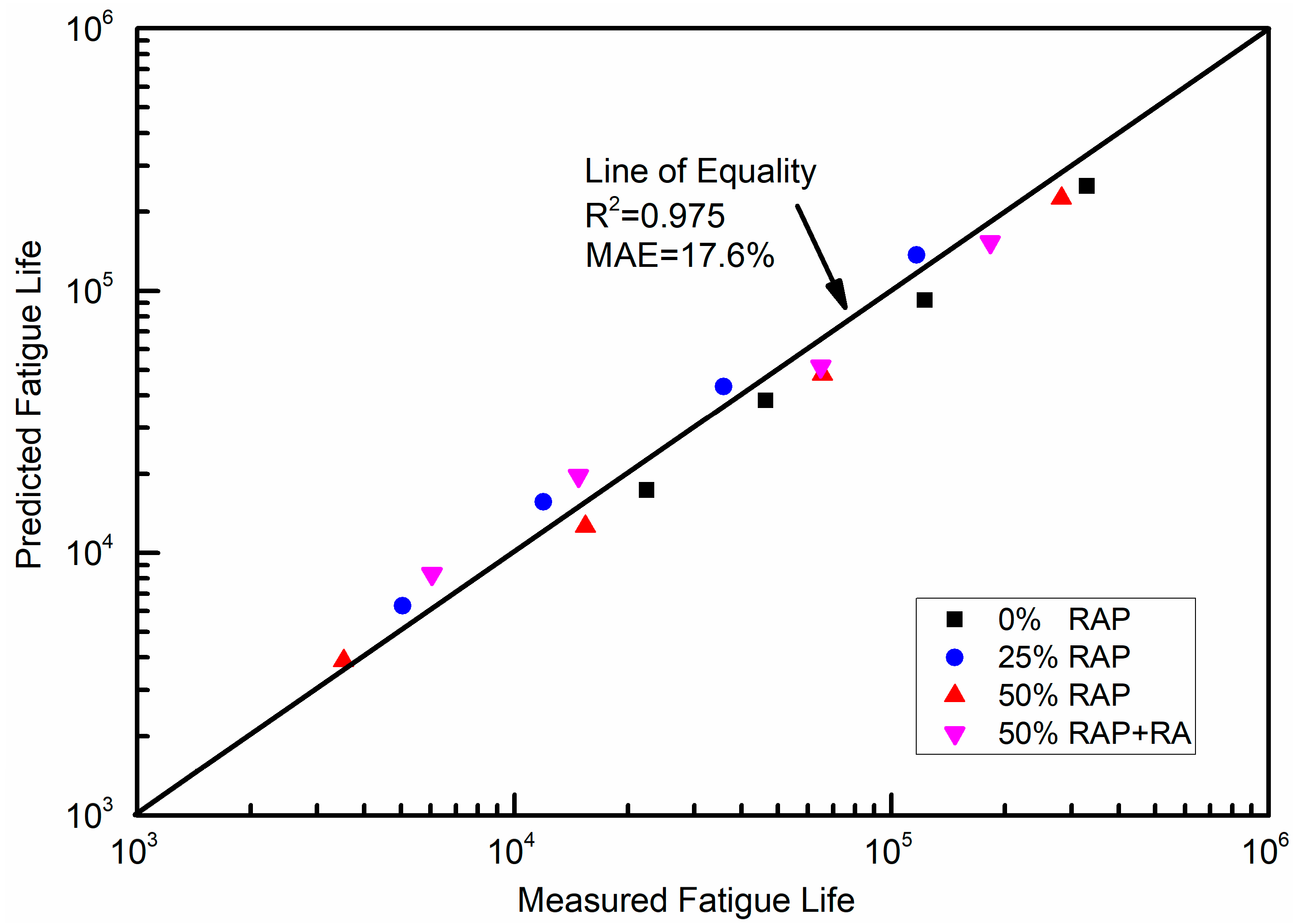

- Establish fatigue life prediction models based on VECD analysis according to LAS tests, and validate the models with measured data from time sweep (TS) tests.

- Study the influence of high RAP content (over 25%) on the fatigue lives of FAMs and evaluate the effectiveness of rejuvenating agent.

2. Materials and Test Procedures

2.1. Materials

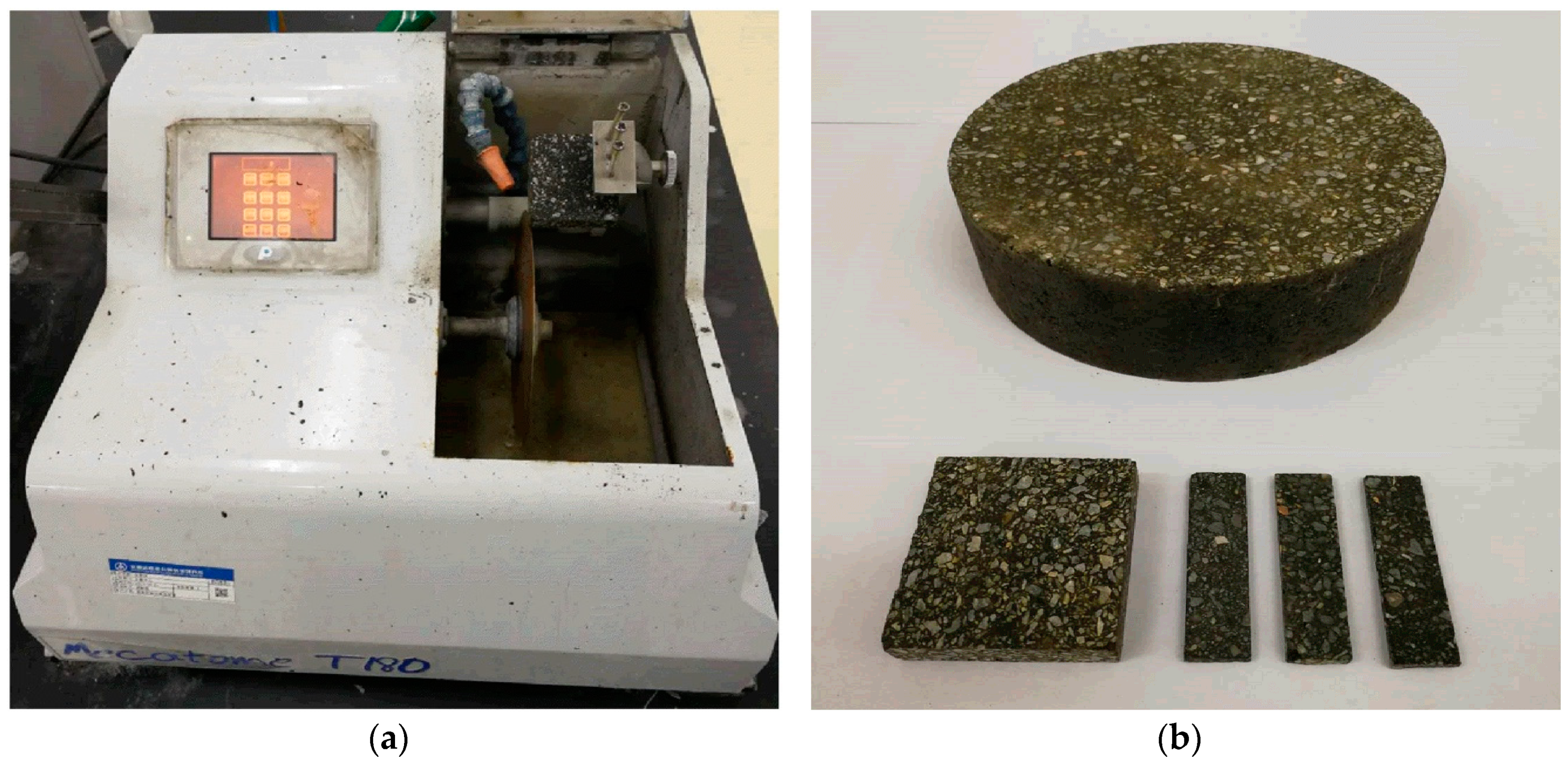

2.2. FAM Specimen Preparation

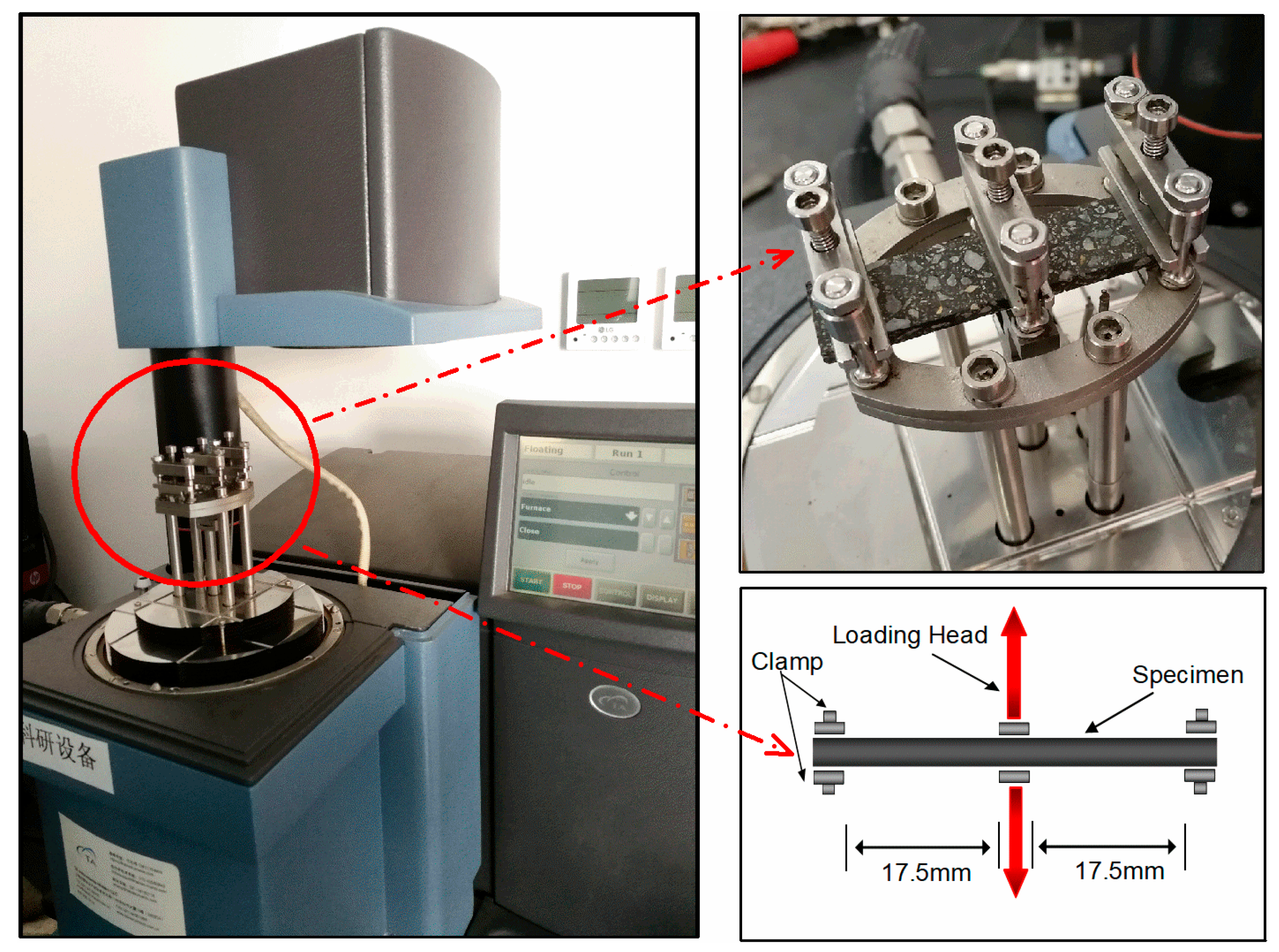

2.3. Test Setup and Procedures

2.3.1. Frequency Sweep Test

2.3.2. Linear Amplitude Sweep Test

2.3.3. Time Sweep Test

3. Results and Discussion

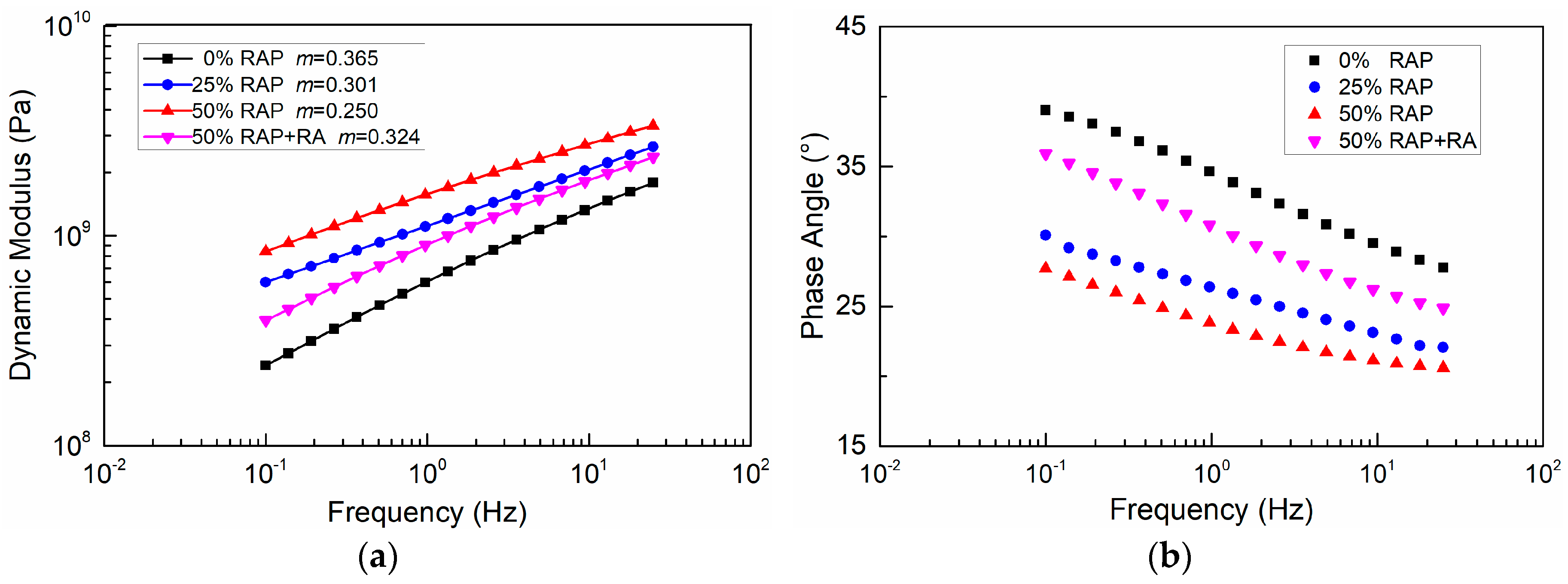

3.1. Frequency Sweep Test

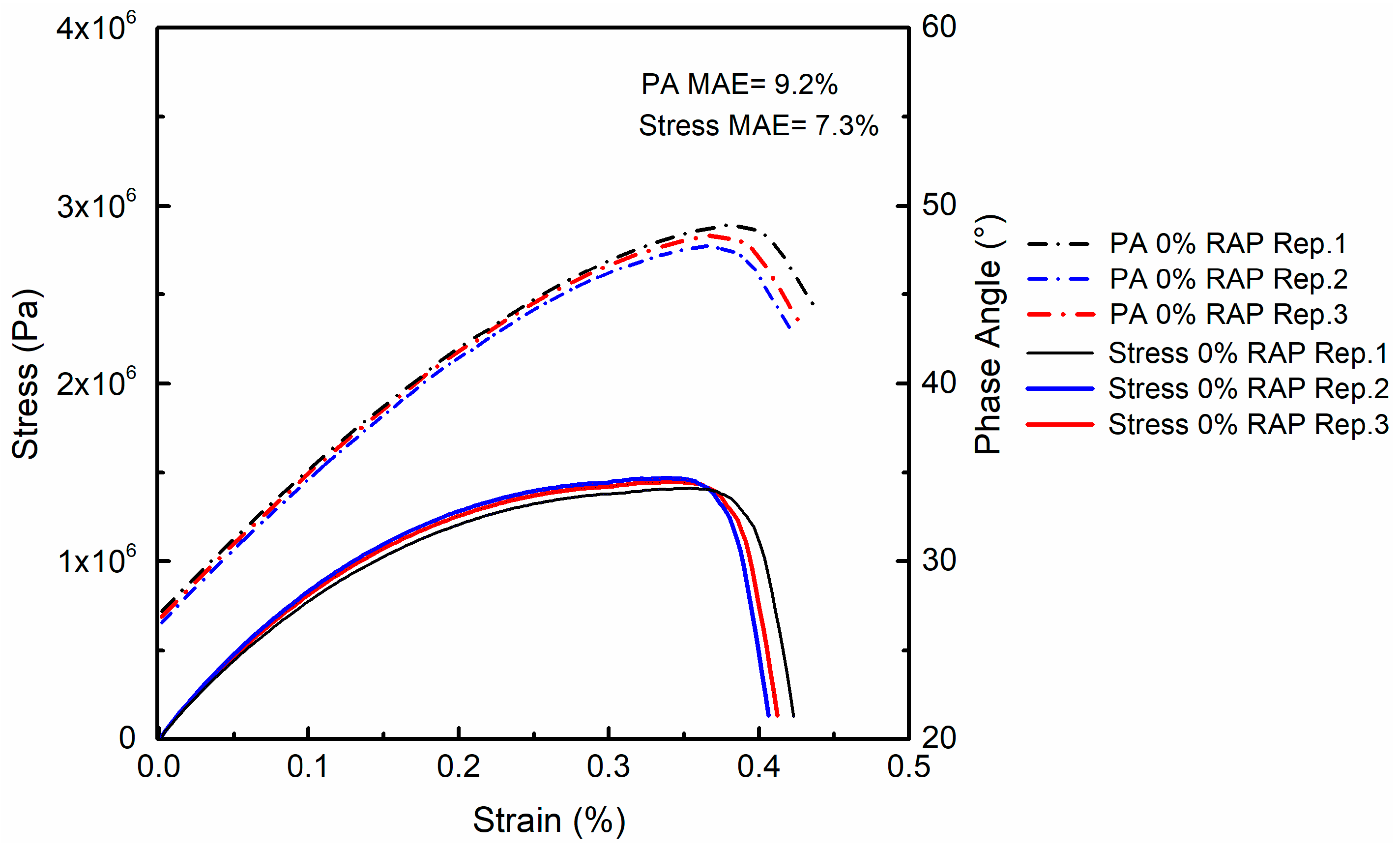

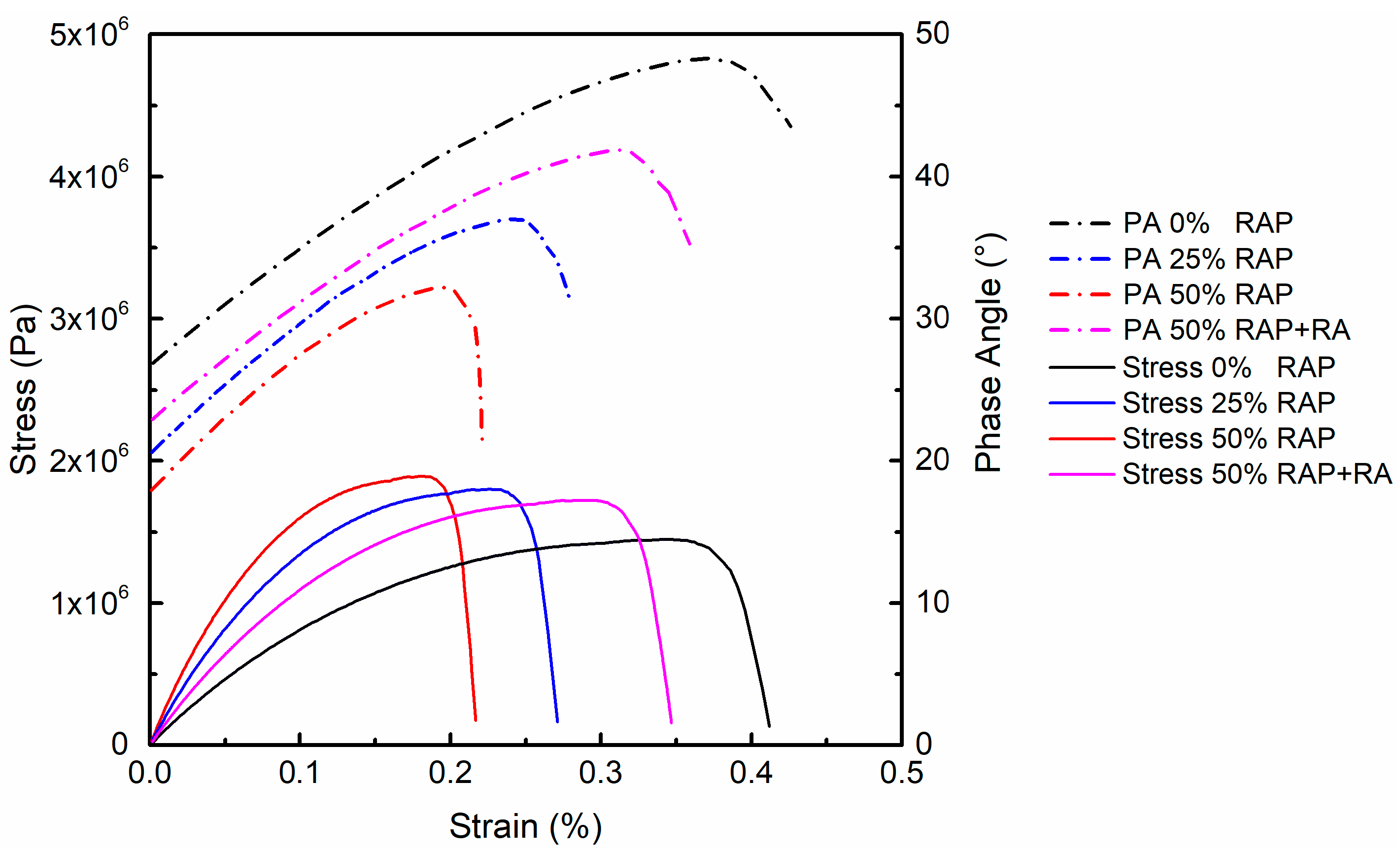

3.2. Failure Criterion Definition of LAS and TS Test

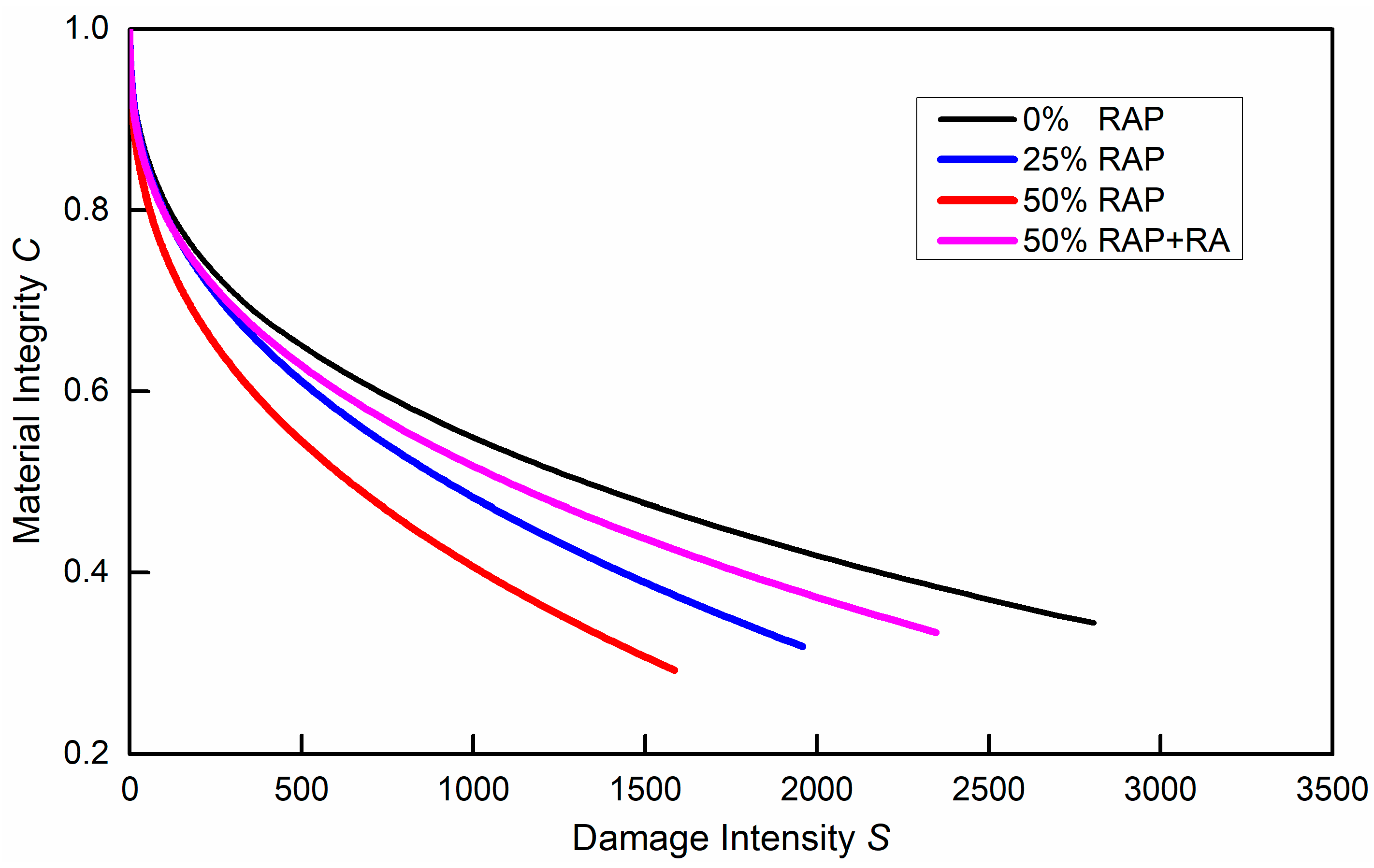

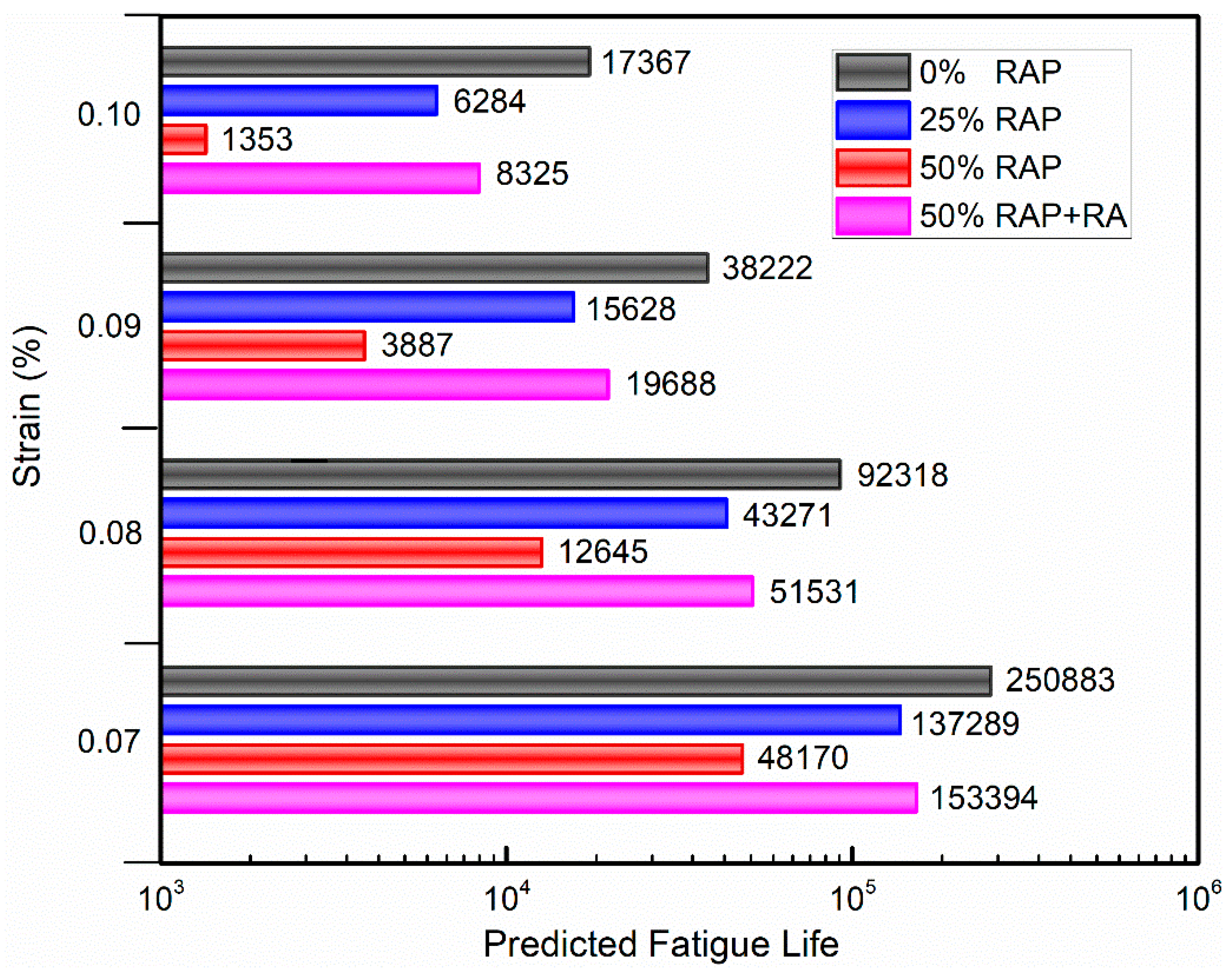

3.3. Fatigue Prediction Model Based on VECD Analysis

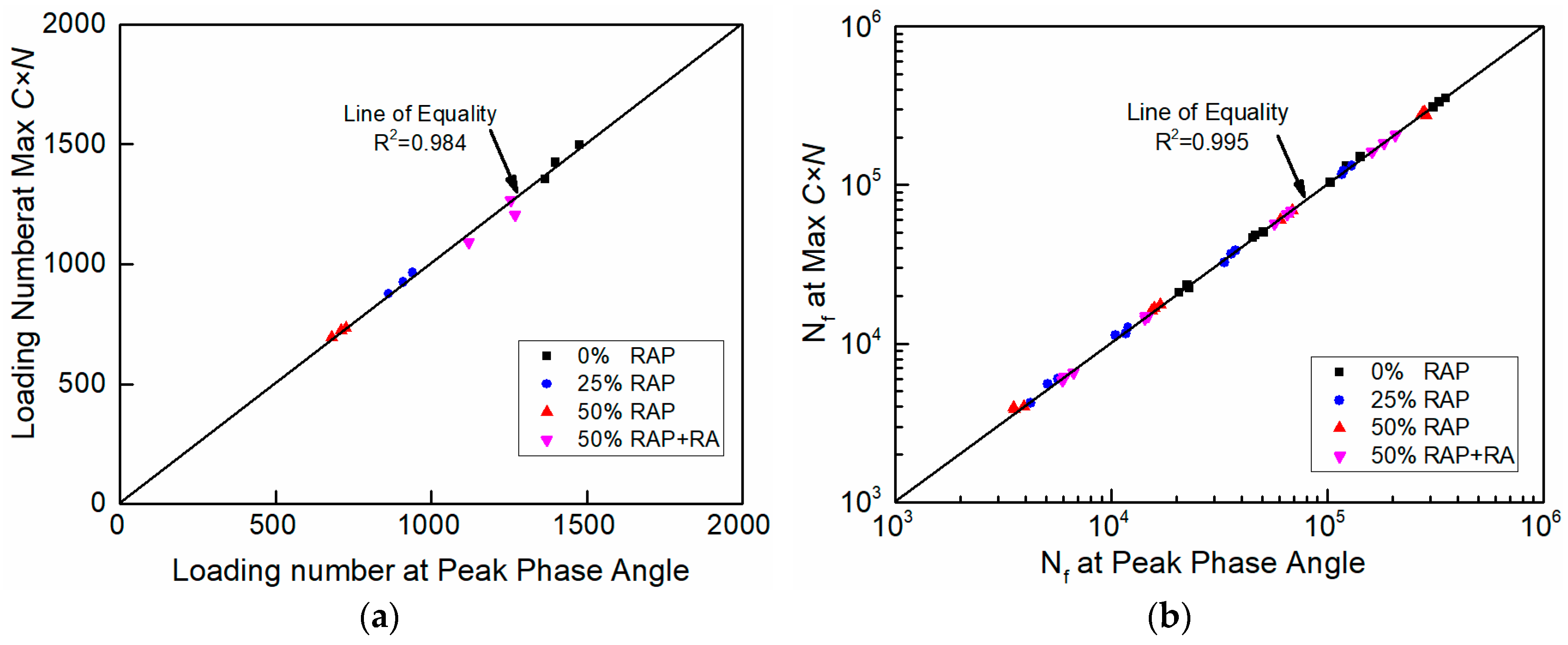

3.4. Validation of Fatigue Prediction Model from TS Test

4. Conclusions

- As an alternative test method for torsion bar test with a DSR, the LAS test of FAM mixes under flexural bending mode can provide acceptable data with good repeatability.

- The phase angle peak and the maximum appeared simultaneously in both LAS tests and strain-controlled TS tests. In this study, the maximum was selected as a reasonable parameter for defining fatigue failure criterions.

- Based on the maximum failure criterion and VECD analysis, fatigue life prediction models can effectively capture the fatigue resistance of different FAMs. The predicted fatigue lives were well-consistent with the measured results of TS tests.

- Higher RAP content will considerably increase the stiffness of FAM mixes, resulting in a decrease in phase angle and fatigue resistance. The presence of petroleum-based rejuvenating agents will soften FAMs, resulting in a significant recovery of the lost fatigue resistance.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Copeland, A. Reclaimed Asphalt Pavement in Asphalt Mixtures: State of the Practice; FHWA-HRT-11-021; Turner-Fairbank Highway Research Center: McLean, VA, USA, 2011; pp. 1–5.

- McDaniel, R.S.; Shah, A.; Huber, G.A.; Copeland, A. Effects of reclaimed asphalt pavement content and virgin binder grade on properties of plant produced mixtures. Road Mater. Pavement 2012, 13, 161–182. [Google Scholar] [CrossRef]

- Yang, R.; Kang, S.; Ozer, H.; Al-Qadi, I.L. Environmental and economic analyses of recycled asphalt concrete mixtures based on material production and potential performance. Resour. Conserv. Recycl. 2015, 104, 141–151. [Google Scholar] [CrossRef]

- Williams, B.A.; Copeland, A.; Ross, T.C. Asphalt Pavement Industry Survey on Recycled Materials and Warm-Mix Asphalt Usage: 2017, 8th ed.; National Asphalt Pavement Association (NAPA): Lanham, MD, USA, 2018; pp. 1–11. [Google Scholar]

- EAPA. EAPA’s Position Statement on the Use of Secondary Materials, by-Products and Waste in Asphalt Mixtures; European Asphalt Pavement Association: Brussels, Belgium, 2017; pp. 4–9. [Google Scholar]

- Lin, J.; Hong, J.; Xiao, Y. Dynamic characteristics of 100% cold recycled asphalt mixture using asphalt emulsion and cement. J. Clean. Prod. 2017, 156, 337–344. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B. Review of very high-content reclaimed asphalt use in plant produced-pavements: State of the art. Int. J. Pavement Eng. 2015, 16, 39–55. [Google Scholar] [CrossRef]

- Tang, S.; Williams, R.C.; Cascione, A.A. Reconsideration of the fatigue tests for asphalt mixtures and binders containing high percentage RAP. Int. J. Pavement Eng. 2017, 18, 443–449. [Google Scholar] [CrossRef]

- Moghaddam, T.B.; Baaj, H. The use of rejuvenating agents in production of recycled hot mix asphalt: A systematic review. Constr. Build. Mater. 2016, 114, 805–816. [Google Scholar] [CrossRef]

- You, Z.; Mills-Beale, J.; Fini, E.; Goh, S.W.; Colbert, B. Evaluation of low-temperature binder properties of warm-mix asphalt, extracted and recovered RAP and RAS, and Bioasphalt. J. Mater. Civil Eng. 2011, 23, 1569–1574. [Google Scholar] [CrossRef]

- Ma, T.; Mahmoud, E.; Bahia, U.H. Development of testing procedure for the estimation of rap binder low temperature properties without extraction. Transport. Res. Rec. 2010, 2179, 58–65. [Google Scholar] [CrossRef]

- Peterson, R.; Soleymani, H.; Anderson, R.; McDaniel, R. Recovery and testing of RAP binders from recycled asphalt pavements. J. Assoc. Asph. Paving Technol. 2000, 69, 72–91. [Google Scholar]

- Kim, Y.; Lee, H.J.; Little, D.N.; Kim, Y.R. A simple testing method to evaluate fatigue fracture and damage performance of asphalt mixtures. J. Assoc. Asph. Paving Technol. 2006, 75, 755–788. [Google Scholar]

- Suresha, S.N.; Ningappa, A. Recent trends and laboratory performance studies on FAM mixtures: A state of the art review. Constr. Build. Mater. 2018, 174, 496–506. [Google Scholar] [CrossRef]

- Kim, Y.R.; Little, D.N.; Lytton, R.L. Use of dynamic mechanical analysis (DMA) to evaluate the fatigue and healing potential of asphalt binders in sand asphalt mixtures. J. Assoc. Asph. Paving Technol. 2002, 71, 176–206. [Google Scholar]

- Lee, H.; Kim, Y.R.; Lee, S. Prediction of asphalt mix fatigue life with viscoelastic material properties. Transport. Res. Rec. 2003, 1832, 139–147. [Google Scholar] [CrossRef]

- Zhu, J.; Alavi, M.Z.; Harvey, J.; Sun, L.; He, Y. Evaluating fatigue performance of fine aggregate matrix of asphalt mix containing recycled asphalt shingles. Constr. Build. Mater. 2017, 139, 203–211. [Google Scholar] [CrossRef]

- Gudipudi, P.P.; Underwood, B.S. Use of fine aggregate matrix experimental data in improving reliability of fatigue life prediction of asphalt concrete: Sensitivity of this approach to variation in input parameters. Transport. Res. Rec. 2017, 2631, 65–73. [Google Scholar] [CrossRef]

- Shanmugasundaram, N.; Rajendran, I.; Ramkumar, T. Static, dynamic mechanical and thermal properties of untreated and alkali treated mulberry fiber reinforced polyester composites. Polym. Compos. 2018, 39, 1908–1919. [Google Scholar] [CrossRef]

- He, Y.; Alavi, M.Z.; Jones, D.; Harvey, J. Proposing a solvent-free approach to evaluate the properties of blended binders in asphalt mixes containing high quantities of reclaimed asphalt pavement and recycled asphalt shingles. Constr. Build. Mater. 2016, 114, 172–180. [Google Scholar] [CrossRef]

- Kutay, M.E.; Gibson, N.; Youtcheff, J. Conventional and viscoelastic continuum damage (VECD)-based fatigue analysis of polymer modified asphalt pavements. J. Assoc. Asph. Paving Technol. 2008, 77, 395–434. [Google Scholar]

- Schapery, R.A. Correspondence principles and a generalized J integral for large deformation and fracture analysis of viscoelastic media. Int. J. Fract. 1984, 25, 195–223. [Google Scholar] [CrossRef]

- Masad, E.; Castelo Branco, V.T.F.; Little, D.N.; Lytton, R. A unified method for the analysis of controlled-strain and controlled-stress fatigue testing. Int. J. Pavement Eng. 2008, 9, 233–246. [Google Scholar] [CrossRef]

- Kim, Y.R.; Lee, Y.C.; Lee, H.J. Correspondence principle for characterization of asphalt concrete. J. Mater. Civ. Eng. 1995, 7, 59–68. [Google Scholar] [CrossRef]

- Park, S.W.; Richard Kim, Y.; Schapery, R.A. A viscoelastic continuum damage model and its application to uniaxial behavior of asphalt concrete. Mech. Mater. 1996, 24, 241–255. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, J.X. Characterization on fatigue failure definition and failure criterion of asphalt binder. J. B. Univ. Technol. 2015, 41, 1574–1583. [Google Scholar]

- Zhang, J.; Sabouri, M.; Guddati, M.N.; Kim, Y.R. Development of a failure criterion for asphalt mixtures under fatigue loading. J. Assoc. Asph. Paving Technol. 2013, 82, 1–22. [Google Scholar] [CrossRef]

- Safaei, F.; Lee, J.; Nascimento, L.A.H.D.; Hintz, C.; Kim, Y.R. Implications of warm-mix asphalt on long-term oxidative ageing and fatigue performance of asphalt binders and mixtures. Road Mater. Pavement 2014, 15, 45–61. [Google Scholar] [CrossRef]

| Technical Index | Unit | Value |

|---|---|---|

| Penetration | 0.1 mm (25 °C) | 68 |

| Softening point | °C | 49 |

| Ductility | cm (5 cm/min, 5 °C) | 27.8 |

| Viscosity | Pa•s (60 °C) | 0.51 |

| Flash point | °C | 271 |

| Wax content | % | 1.1 |

| Density | g/cm3 (15 °C) | 1.027 |

| Mix | Target Binder Content (%) | Binder Replacement Rate (%) | Binder Replacement Content (%) | Virgin Binder Content (%) | RAP Content (%) | RA Content * (%) |

|---|---|---|---|---|---|---|

| 0% RAP | 9.0 | 0 | 0.0 | 9.0 | 0.0 | - |

| 25% RAP | 25 | 2.2 | 6.8 | 29.7 | - | |

| 50% RAP | 50 | 4.5 | 4.5 | 61.6 | - | |

| 50% RAP + RA | 50 | 4.5 | 4.5 | 61.6 | 10 |

| Mix | VECD-Based Fatigue Model Parameters | |||||||

|---|---|---|---|---|---|---|---|---|

| 0% RAP | 1361 | 0.365 | 3.743 | 2735 | 3.95 × 10−2 | 0.358 | 5.66 × 10−4 | 7.487 |

| 25% RAP | 2060 | 0.301 | 4.322 | 1940 | 1.51 × 10−2 | 0.365 | 1.42 × 10−5 | 8.647 |

| 50% RAP | 2705 | 0.250 | 5.008 | 1550 | 6.11 × 10−2 | 0.413 | 1.30 × 10−7 | 10.016 |

| 50% RAP+RA | 1812 | 0.324 | 4.085 | 2225 | 3.37 × 10−2 | 0.318 | 5.64 × 10−5 | 8.169 |

| Mix | Strain level (%) | Fatigue Life Nf | Standard Deviation | Coefficient of Variation (%) | Fatigue Performance Ranking | |

|---|---|---|---|---|---|---|

| Measured | Predicted | |||||

| 0% RAP | 0.10 | 22,432 | 1664 | 7.4 | 1 | 1 |

| 0.09 | 46,310 | 3801 | 8.2 | |||

| 0.08 | 122,571 | 19,473 | 15.9 | |||

| 0.07 | 329,224 | 21,940 | 6.7 | |||

| 25% RAP | 0.10 | 5062 | 740 | 14.6 | 3 | 3 |

| 0.09 | 11,932 | 1626 | 13.6 | |||

| 0.08 | 35,858 | 2142 | 6.0 | |||

| 0.07 | 116,548 | 14,384 | 12.3 | |||

| 50% RAP | 0.10 | 3524 | 440 | 12.5 | 4 | 4 |

| 0.09 | 15,425 | 1630 | 10.6 | |||

| 0.08 | 65,568 | 4608 | 7.0 | |||

| 0.07 | 282,052 | 6405 | 2.3 | |||

| 50% RAP + RA | 0.10 | 6049 | 575 | 9.5 | 2 | 2 |

| 0.09 | 14,782 | 736 | 5.0 | |||

| 0.08 | 64,868 | 7005 | 10.8 | |||

| 0.07 | 182,665 | 22,795 | 12.5 | |||

| Test Method | Number of FAM Specimens Required for Each Mix | Average Total Testing Time for Each FAM Mix (h) |

|---|---|---|

| Time sweep | 12 | 27 |

| Linear amplitude sweep | 3 | 3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Ren, Q.; Qian, Z.; Wang, X. Evaluating the Effects of High RAP Content and Rejuvenating Agents on Fatigue Performance of Fine Aggregate Matrix through DMA Flexural Bending Test. Materials 2019, 12, 1508. https://doi.org/10.3390/ma12091508

Zhang C, Ren Q, Qian Z, Wang X. Evaluating the Effects of High RAP Content and Rejuvenating Agents on Fatigue Performance of Fine Aggregate Matrix through DMA Flexural Bending Test. Materials. 2019; 12(9):1508. https://doi.org/10.3390/ma12091508

Chicago/Turabian StyleZhang, Chenchen, Qi Ren, Zhendong Qian, and Xudong Wang. 2019. "Evaluating the Effects of High RAP Content and Rejuvenating Agents on Fatigue Performance of Fine Aggregate Matrix through DMA Flexural Bending Test" Materials 12, no. 9: 1508. https://doi.org/10.3390/ma12091508

APA StyleZhang, C., Ren, Q., Qian, Z., & Wang, X. (2019). Evaluating the Effects of High RAP Content and Rejuvenating Agents on Fatigue Performance of Fine Aggregate Matrix through DMA Flexural Bending Test. Materials, 12(9), 1508. https://doi.org/10.3390/ma12091508