Performances of Cement Mortar Incorporating Superabsorbent Polymer (SAP) Using Different Dosing Methods

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

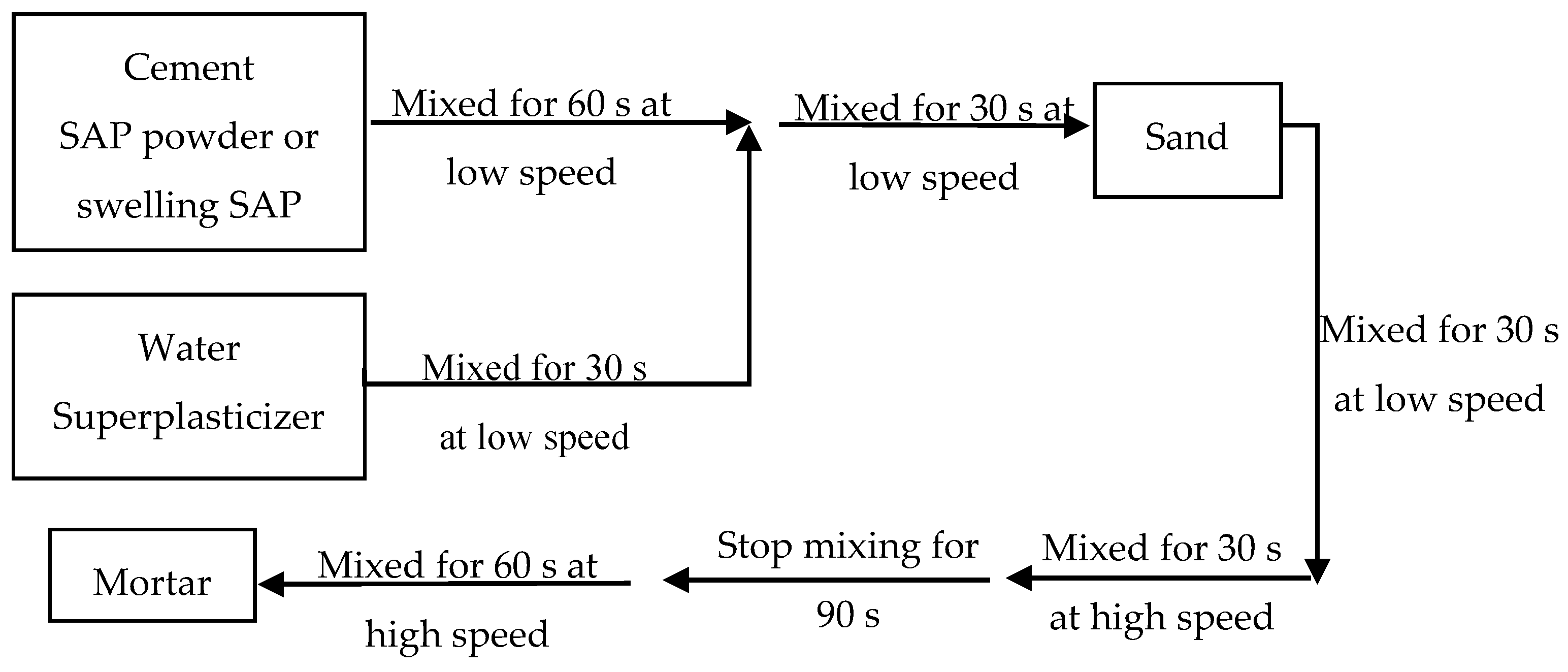

2.2. Mixture Preparation and Testing Methods

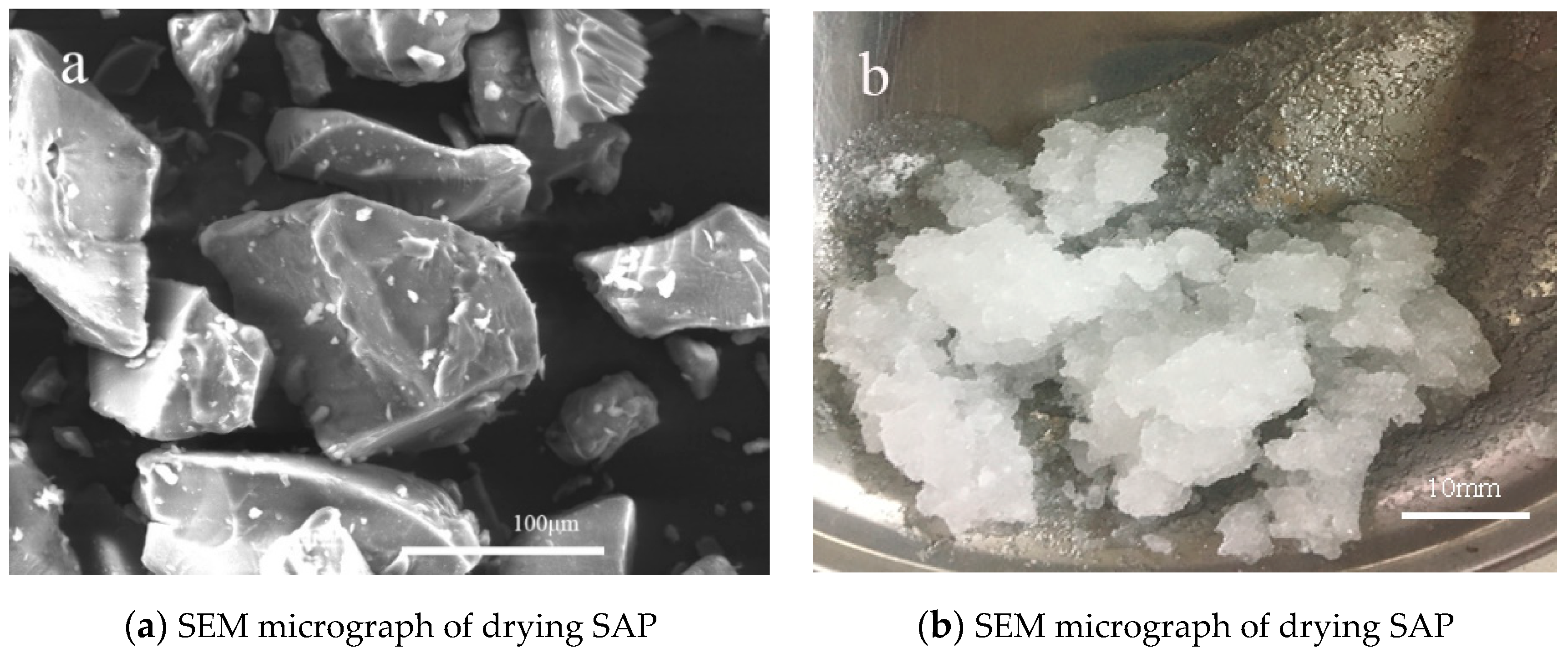

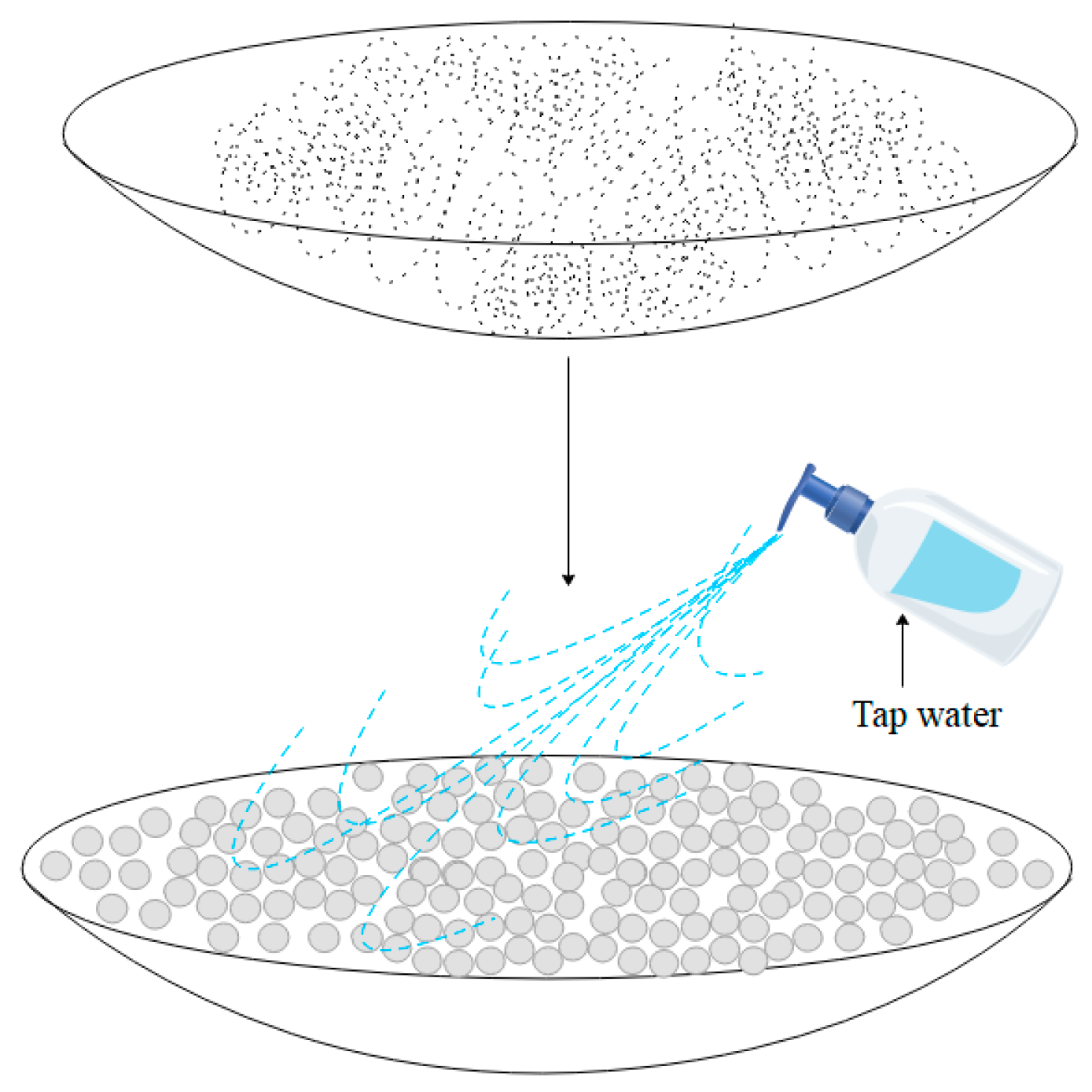

2.2.1. Two Adding Methods of Superabsorbent Polymer (SAP)

2.2.2. Preparation and Testing of Internal Curing Mortar

- ①

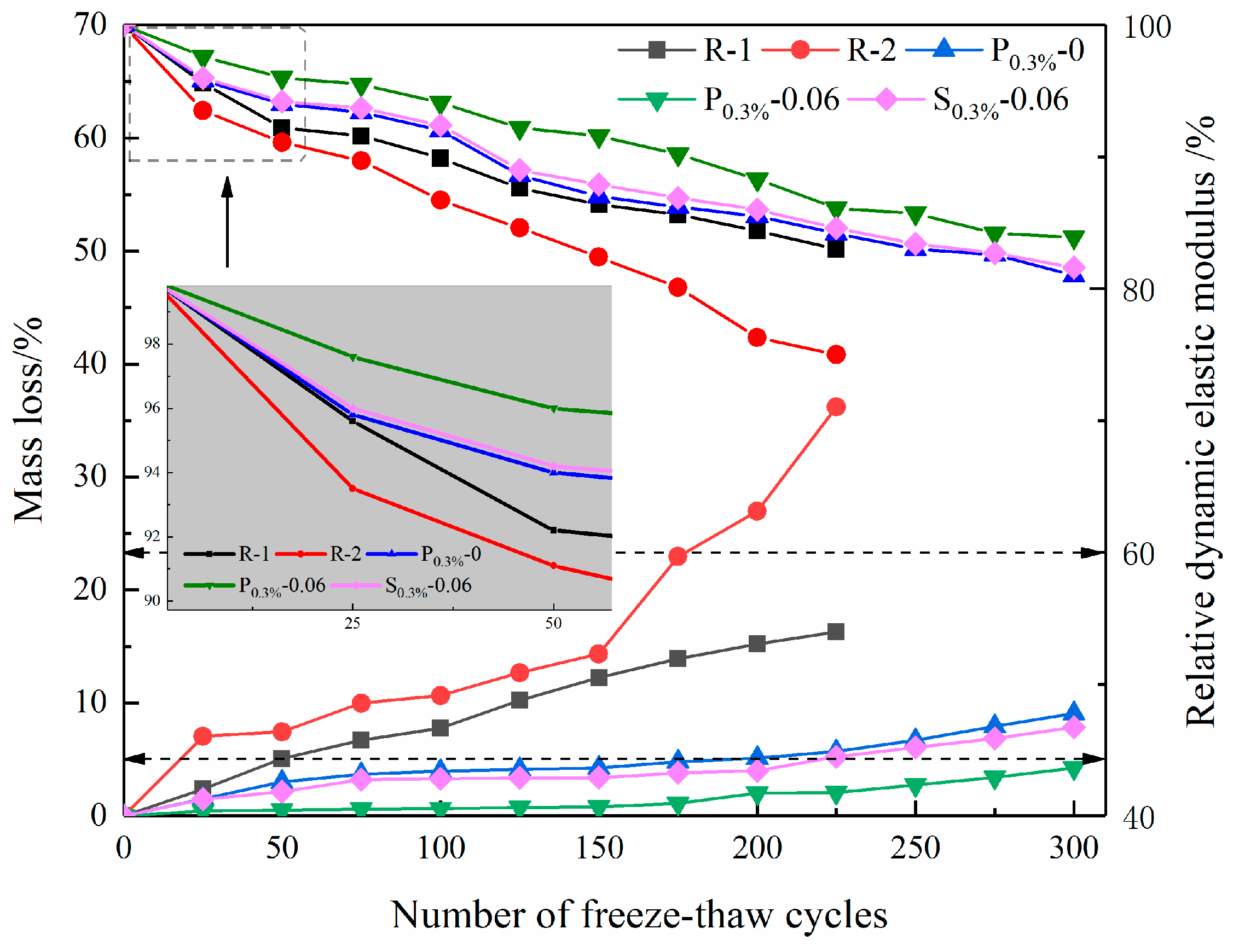

- The number of freeze–thaw cycles reaches 300;

- ②

- The relative dynamic elastic modulus of the specimen is less than 60% of the initial value;

- ③

- The rate of mass loss of the specimen is more than 5%.

3. Results and Discussion

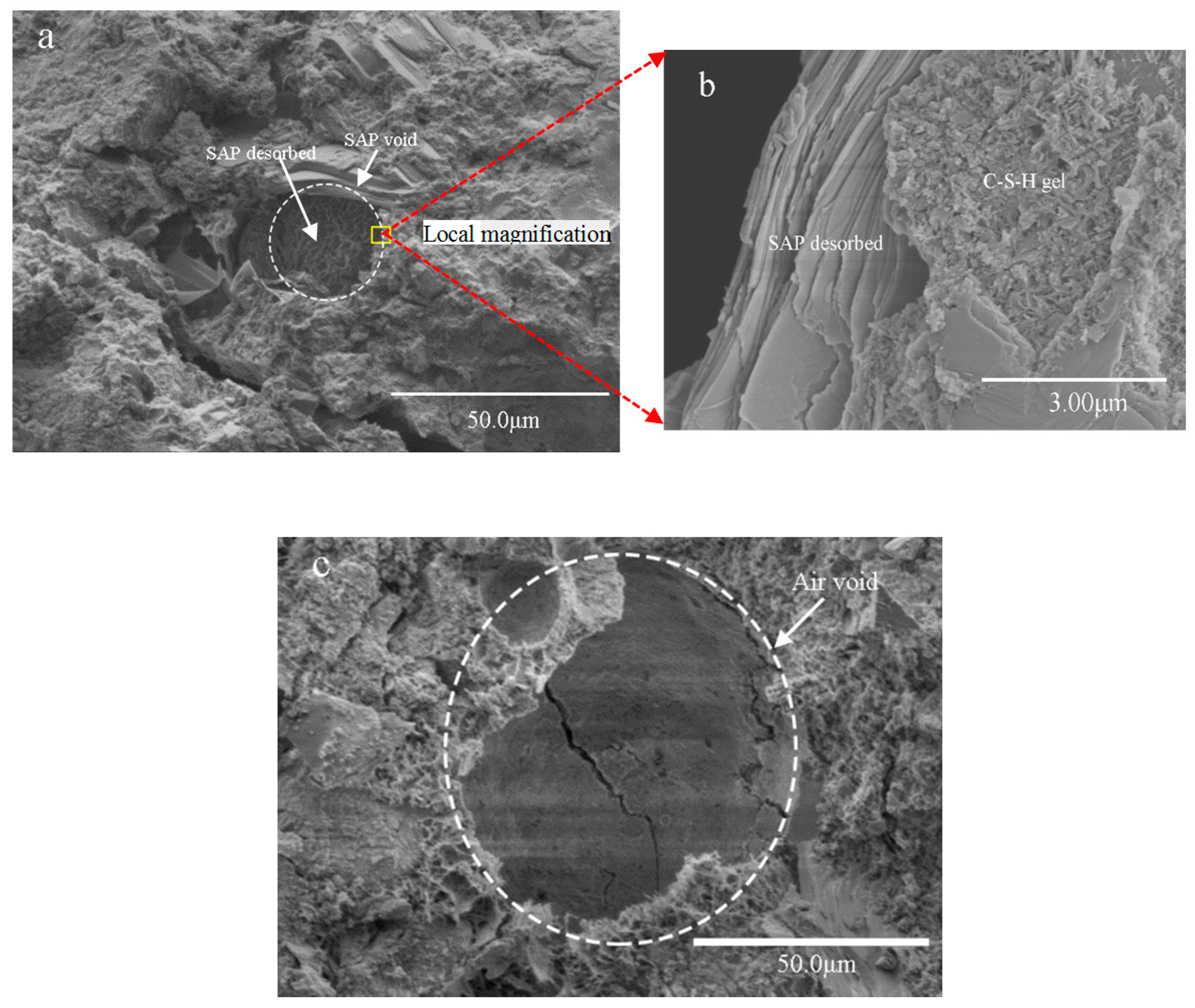

3.1. The Microstructure around SAP Voids

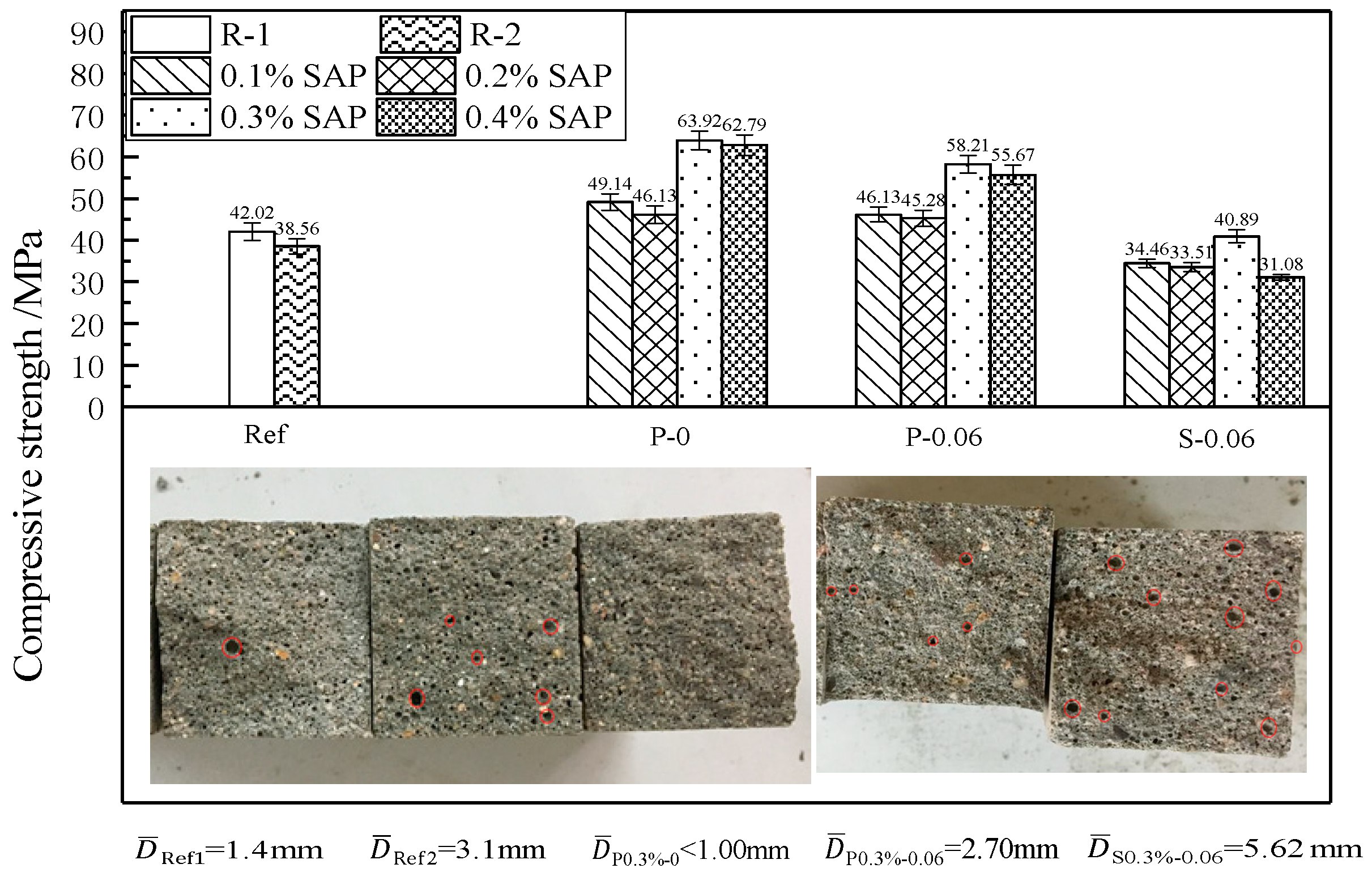

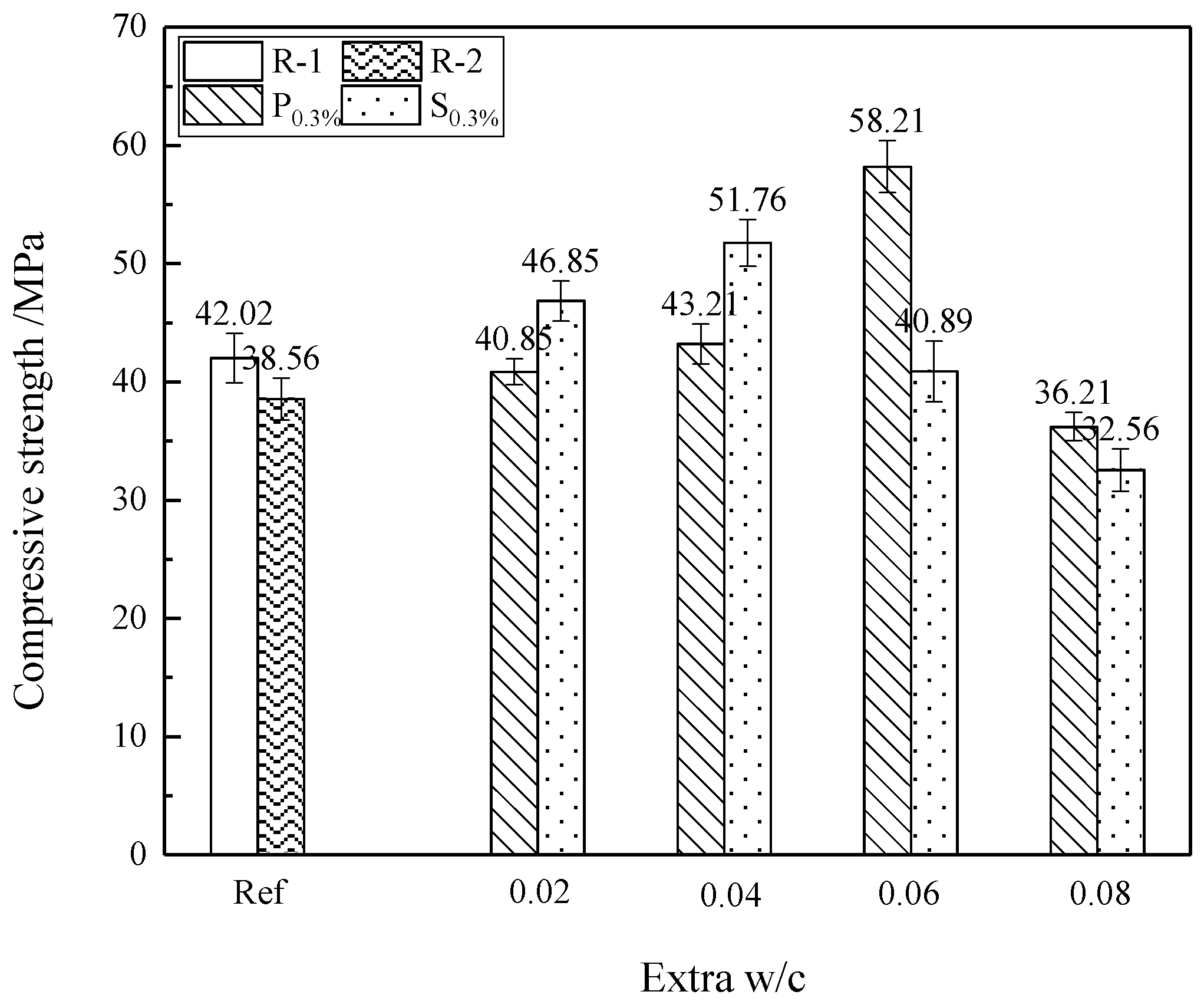

3.2. Mechanical Properties

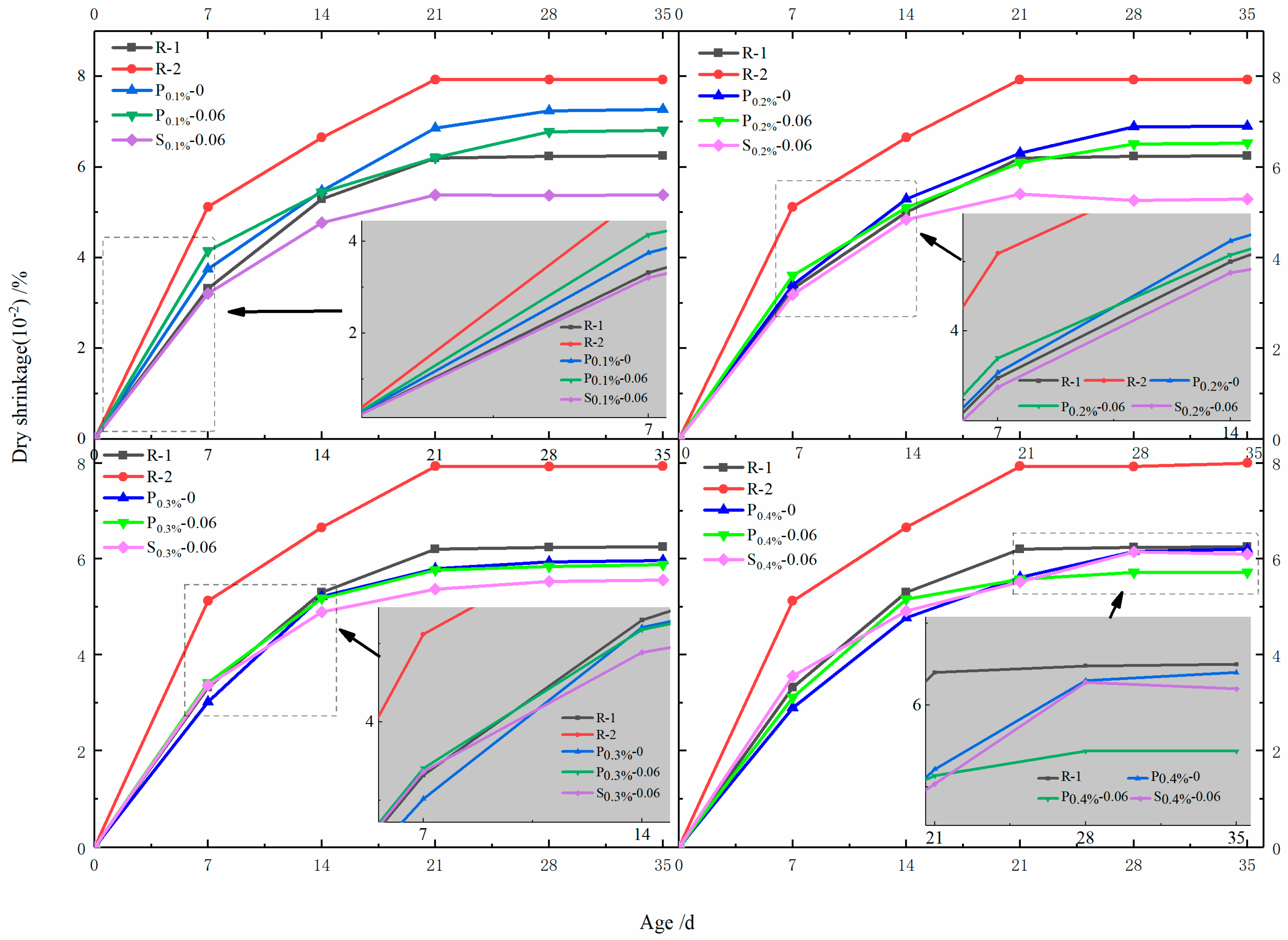

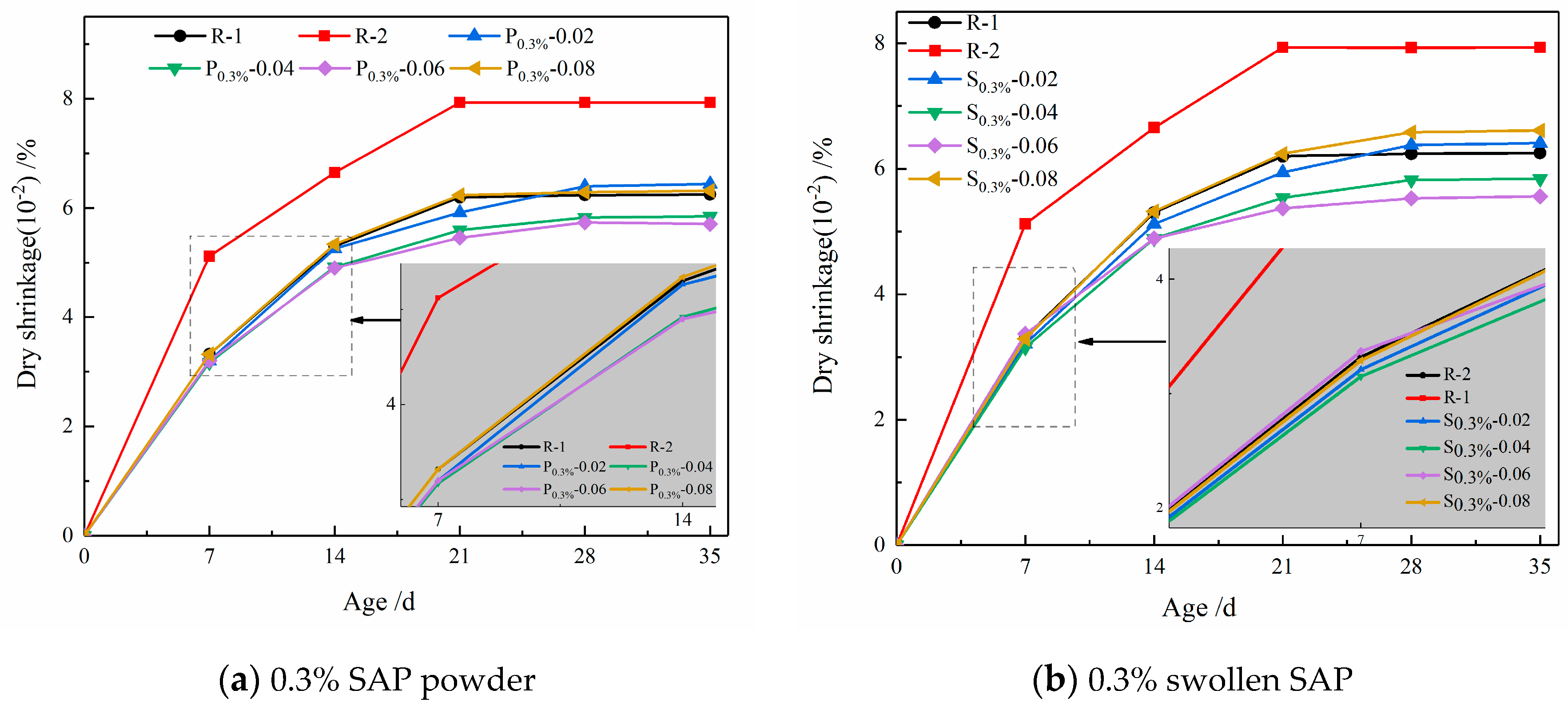

3.3. Drying Shrinkage

3.4. Freeze–Thaw Resistance

4. Conclusions

- (1)

- SAP voids in mortar are completely different from normal air voids and SAP particles can be easily curled and agglomerated to form an agglomerative accumulation after the desorption of water in the mortar. There are abundant hydration products around SAP voids, especially C-S-H gels;

- (2)

- Compared with the reference mortars (R-1 and R-2), the incorporation of the powdery SAP increases the 28 d compressive strength of the mortars by about 10% to 50%, while for the incorporation of swelled SAP, the 28 d compressive strength of the mortar can be increased by about −26% to 6%;

- (3)

- At a dosage of 0.1% SAP and an entrained water–cement ratio of 0.06, the powdery SAP and the swelled SAP can reduce the mortar shrinkage rate by about 32.2% and 14.5%, respectively. When the entrained w/c is within the range of 0.02 to 0.06, the drying shrinkage decreased with the increase of entrained w/c for the two adding methods of SAP;

- (4)

- The addition of SAP can improve the freeze–thaw resistance of the mortar, especially for the mortar with the powdery SAP and an entrained water-to-cement ratio of 0.06, and the mass loss rate after 300 cycles is still lower than 5%.

Author Contributions

Funding

Conflicts of Interest

References

- Wehbe, Y.; Ghahremaninezhad, A. Combined effect of shrinkage reducing admixtures (SRA) and superabsorbent polymers (SAP) on the autogenous shrinkage, hydration and properties of cementitious materials. Constr. Build. Mater. 2017, 138, 151–162. [Google Scholar] [CrossRef]

- Ramazani-Harandi, M.J.; Zohuriaan-Mehr, M.J.; Yousefi, A.A. Rheological determination of the swollen gel strength of superabsorbent polymer hydrogels. Polym. Test. 2006, 25, 470–474. [Google Scholar] [CrossRef]

- Wang, F.; Yang, J.; Cheng, H.; Wu, J.; Liang, X. Study on mechanism of desorption behavior of saturated superabsorbent polymers in concrete. ACI Mater. 2015, 112, 463–470. [Google Scholar] [CrossRef]

- Yu, F.Q.; Sun, N.; Deng, C. The Effect of Super-Absorbent Polymer as a Self-Curing Admixture on the Performance of Mortars. Adv. Mater. Res. 2011, 6, 287–290. [Google Scholar] [CrossRef]

- Bentz, D.P.; Snyder, K.A. Protected paste volume in concrete: Extension to internal curing using saturated lightweight fine aggregate. Cem. Concr. Res. 1999, 29, 1863–1867. [Google Scholar] [CrossRef]

- Hajibabaee, A.; Ley, M.T. The impact of wet curing on curling in concrete caused by drying shrinkage. Mater. Struct. 2016, 49, 1629–1639. [Google Scholar] [CrossRef]

- Shen, D.; Jiang, J.; Jiao, Y. Early-age tensile creep and cracking potential of concrete internally cured with pre-wetted lightweight aggregate. Constr. Build. Mater. 2017, 135, 420–429. [Google Scholar] [CrossRef]

- Islam, M.R.; Xue, X.; Li, S. Effectiveness of Water-Saving Superabsorbent Polymer in Soil Water Conservation for Oat Based on Ecophysiological Parameters. Commun. Soil Sci. Plan Anal. 2011, 42, 2322–2333. [Google Scholar] [CrossRef]

- Liu, T.; Qian, L.; Li, B. Homogeneous synthesis of chitin-based acrylate superabsorbents in NaOH/urea solution. Carbohydr. Polym. 2013, 94, 261–271. [Google Scholar] [CrossRef]

- Hussien, R.A.; Donia, A.M.; Atia, A.A. Studying some hydro-physical properties of two soils amended with kaolinite-modified cross-linked poly-acrylamides. Catena 2012, 92, 172–178. [Google Scholar] [CrossRef]

- Jensen, O.M.; Hansen, P.F. Water-entrained cement-based materials: I. Principles and theoretical background. Cem. Concr. Res. 2001, 31, 647–654. [Google Scholar] [CrossRef]

- Bentz, D.P.; Jensen, O.M. Mitigation strategies for autogenous shrinkage cracking. Cem. Concr. Compos. 2004, 26, 677–685. [Google Scholar] [CrossRef]

- Viejo, I.; Esteves, L.P.; Laspalas, M. Numerical modelling of porous cement-based materials by superabsorbent polymers. Cem. Concr. Res. 2016, 90, 184–193. [Google Scholar] [CrossRef]

- Lee, H.X.D.; Wong, H.S.; Buenfeld, N.R. The potential of superabsorbent polymer for self-sealing cracks in concrete. Adv. App. Ceram. 2010, 109, 296–302. [Google Scholar] [CrossRef]

- Lee, H.X.D.; Wong, H.S.; Buenfeld, N.R. Self-sealing of cracks in concrete using superabsorbent polymers. Cem. Concr. Res. 2016, 79, 194–208. [Google Scholar] [CrossRef]

- Snoeck, D.; Pel, L.; De, N.B. The water kinetics of superabsorbent polymers during cement hydration and internal curing visualized and studied by NMR. Sci. Rep. 2017, 7, 9514. [Google Scholar] [CrossRef] [PubMed]

- Craeye, B.; Geirnaert, M.; Schutter, G.D. Super absorbing polymers as an internal curing agent for mitigation of early-age cracking of high-performance concrete bridge decks. Constr. Build. Mater. 2011, 25, 1–13. [Google Scholar] [CrossRef]

- Senff, L.; Modolo, R.C.E.; Ascensão, G. Development of mortars containing superabsorbent polymer. Constr. Build. Mater. 2015, 95, 575–584. [Google Scholar] [CrossRef]

- Liu, H.; Bu, Y.; Sanjayan, J.G. Suitability of polyacrylamide superabsorbent polymers as the internal curing agent of well cement. Constr. Build. Mater. 2016, 112, 253–260. [Google Scholar] [CrossRef]

- Jensen, O.M.; Hansen, P.F. Water-entrained cement-based materials. Cem. Concr. Res. 2002, 32, 973–978. [Google Scholar] [CrossRef]

- Wang, W.B.; Liu, J.P.; Tian, Q. Effects of Water Absorption and Size of Superabsorbent Polymers on Internal Curing of Cement Paste. Mater. Sci. Forum 2013, 5, 743–744. [Google Scholar] [CrossRef]

- Mechtcherine, V. Effect of Internal Curing by Using Superabsorbent Polymers (SAP) on Autogenous Shrinkage and Other Properties of a High-performance Fine-grained Concrete: Results of a RILEM Round-robin Test, TC 225-SAP. Mater. Struct. 2014, 47, 541–562. [Google Scholar] [CrossRef]

- Snoeck, D.; Jensen, O.M.; Belie, N.D. The influence of superabsorbent polymers on the autogenous shrinkage properties of cement pastes with supplementary cementitious materials. Cem. Concr. Res. 2015, 74, 59–67. [Google Scholar] [CrossRef]

- Craeye, B.; Cockaerts, G.; De Maeijer, P.K. Improving freeze-thaw resistance of concrete road infrastructure by means of superabsorbent polymers. Infrastructures 2018, 3, 4. [Google Scholar] [CrossRef]

- Laustsen, S.; Hasholt, M.T.; Jensen, O.M. Void structure of concrete with superabsorbent polymers and its relation to frost resistance of concrete. Mater. Struct. 2015, 48, 357–368. [Google Scholar] [CrossRef]

- Farzanian, K.; Pimenta Teixeira, K. The mechanical strength, degree of hydration, and electrical resistivity of cement pastes modified with superabsorbent polymers. Constr. Build. Mater. 2016, 109, 156–165. [Google Scholar] [CrossRef]

- Woyciechowski, P.P.; Kalinowski, M. The Influence of Dosing Method and Material Characteristics of Superabsorbent Polymers (SAP) on the Effectiveness of the Concrete Internal Curing. Materials 2018, 11, 1600. [Google Scholar] [CrossRef]

- Schröefl, C.; Mechtcherine, V.; Vontobel, P. Sorption kinetics of superabsorbent polymers (SAPs) in fresh Portland cement-based pastes visualized and quantified by neutron radiography and correlated to the progress of cement hydration. Cem. Concr. Res. 2015, 75, 1–13. [Google Scholar] [CrossRef]

- Klemm, A.J.; Sikora, K.S. The effect of Superabsorbent Polymers (SAP) on microstructure and mechanical properties of fly ash cementitious mortars. Constr. Build. Mater. 2013, 49, 134–143. [Google Scholar] [CrossRef]

- Lee, H.X.D.; Wong, H.S.; Buenfeld, N.R. Effect of alkalinity and calcium concentration of pore solution on the swelling and ionic exchange of superabsorbent polymers in cement paste. Cem. Concr. Compos. 2018, 88, 150–164. [Google Scholar] [CrossRef]

- Goncalves, H.; Goncalves, B.; Silva, L. The influence of porogene additives on the properties of mortars used to control the ambient moisture. Energy Build. 2014, 74, 61–68. [Google Scholar] [CrossRef]

- Ma, X.; Liu, J.; Wu, Z. Effects of SAP on the properties and pore structure of high performance cement-based materials. Constr. Build. Mater. 2017, 131, 476–484. [Google Scholar] [CrossRef]

- Azarijafari, H.; Kazemian, A.; Rahimi, M. Effects of pre-soaked super absorbent polymers on fresh and hardened properties of self-consolidating lightweight concrete. Constr. Build. Mater. 2016, 113, 215–220. [Google Scholar] [CrossRef]

- Snoeck, D. The effects of superabsorbent polymers on the microstructure of cementitious materials studied by means of sorption experiments. Cem. Concr. Res. 2015, 77, 26–35. [Google Scholar] [CrossRef]

- Snoeck, D.; Schaubroeck, D.; Dubruel, P. Effect of high amounts of superabsorbent polymers and additional water on the workability, microstructure and strength of mortars with a water-to-cement ratio of 0.50. Constr. Build. Mater. 2014, 72, 148–157. [Google Scholar] [CrossRef]

- Soliman, A.M.; Nehdi, M.L. Effect of partially hydrated cementitious materials and superabsorbent polymer on early-age shrinkage of UHPC. Constr. Build. Mater. 2013, 41, 270–275. [Google Scholar] [CrossRef]

- Beushausen, H.; Gillmer, M.; Alexander, M. The influence of superabsorbent polymers on strength and durability properties of blended cement mortars. Cem. Concr. Compos. 2014, 52, 73–80. [Google Scholar] [CrossRef]

- Valcuende, M.; Marco, E.; Parra, C. Influence of limestone filler and viscosity-modifying admixture on the shrinkage of self-compacting concrete. Cem. Concr. Res. 2012, 42, 583–592. [Google Scholar] [CrossRef]

- Schröfl, C.; Mechtcherine, V.; Gorges, M. Relation between the molecular structure and the efficiency of superabsorbent polymers (SAP) as concrete admixture to mitigate autogenous shrinkage. Cem. Concr. Res. 2012, 42, 865–873. [Google Scholar] [CrossRef]

- Kong, X.M.; Zhang, Z.L.; Lu, Z.C. Effect of pre-soaked superabsorbent polymer on shrinkage of high-strength concrete. Mater. Struct. 2015, 48, 2741–2758. [Google Scholar] [CrossRef]

- Mo, J.C.; Ou, Z.W. Influence of superabsorbent polymer on shrinkage properties of reactive powder concrete blended with granulated blast furnace slag. Constr. Build. Mater. 2017, 146, 283–296. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Secrieru, E. Effect of superabsorbent polymers (SAPs) on rheological properties of fresh cement-based mortars—Development of yield stress and plastic viscosity over time. Cem. Concr. Res. 2015, 67, 52–65. [Google Scholar] [CrossRef]

| Chemical Compositions | CaO | SiO2 | A12O3 | Fe2O3 | MgO | Na2O | SO3 |

|---|---|---|---|---|---|---|---|

| Mass percentage (%) | 65.36 | 22.15 | 4.51 | 3.39 | 2.31 | 0.49 | 0.46 |

| Mineral compositions | C3S | C2S | C2A | C4AF | |||

| Mass percentage (%) | 56.54 | 20.87 | 6.22 | 10.31 |

| Code | Cement/g | Sand/g | Effective w/c | Entrained w/c | Total w/c | SAP |

|---|---|---|---|---|---|---|

| R-1 | 495 | 990 | 0.42 | 0 | 0.42 | 0 |

| R-2 | 495 | 990 | 0.48 | 0 | 0.48 | 0 |

| P0.1%-0 | 495 | 990 | 0.42 | 0 | 0.42 | 0.10% |

| P0.2%-0 | 495 | 990 | 0.42 | 0 | 0.42 | 0.20% |

| P0.3%-0 | 495 | 990 | 0.42 | 0 | 0.42 | 0.30% |

| P0.4%-0 | 495 | 990 | 0.42 | 0 | 0.42 | 0.40% |

| P0.1%-0.06 | 495 | 990 | 0.42 | 0.06 | 0.48 | 0.10% |

| P0.2%-0.06 | 495 | 990 | 0.42 | 0.06 | 0.48 | 0.20% |

| P0.3%-0.06 | 495 | 990 | 0.42 | 0.06 | 0.48 | 0.30% |

| P0.4%-0.06 | 495 | 990 | 0.42 | 0.06 | 0.48 | 0.40% |

| S0.1%-0.06 | 495 | 990 | 0.42 | 0.06 | 0.48 | 0.10% |

| S0.2%-0.06 | 495 | 990 | 0.42 | 0.06 | 0.48 | 0.20% |

| S0.3%-0.06 | 495 | 990 | 0.42 | 0.06 | 0.48 | 0.30% |

| S0.4%-0.06 | 495 | 990 | 0.42 | 0.06 | 0.48 | 0.40% |

| P0.3%-0.02 | 495 | 990 | 0.42 | 0.02 | 0.44 | 0.30% |

| P0.3%-0.04 | 495 | 990 | 0.42 | 0.04 | 0.46 | 0.30% |

| P0.3%-0.08 | 495 | 990 | 0.42 | 0.08 | 0.50 | 0.30% |

| S0.3%-0.02 | 495 | 990 | 0.42 | 0.02 | 0.44 | 0.30% |

| S0.3%-0.04 | 495 | 990 | 0.42 | 0.04 | 0.46 | 0.30% |

| S0.3%-0.08 | 495 | 990 | 0.42 | 0.08 | 0.50 | 0.30% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, Y.; Chen, H.; Wang, Z.; Xue, C.; He, R. Performances of Cement Mortar Incorporating Superabsorbent Polymer (SAP) Using Different Dosing Methods. Materials 2019, 12, 1619. https://doi.org/10.3390/ma12101619

Tan Y, Chen H, Wang Z, Xue C, He R. Performances of Cement Mortar Incorporating Superabsorbent Polymer (SAP) Using Different Dosing Methods. Materials. 2019; 12(10):1619. https://doi.org/10.3390/ma12101619

Chicago/Turabian StyleTan, Yawen, Huaxin Chen, Zhendi Wang, Cheng Xue, and Rui He. 2019. "Performances of Cement Mortar Incorporating Superabsorbent Polymer (SAP) Using Different Dosing Methods" Materials 12, no. 10: 1619. https://doi.org/10.3390/ma12101619

APA StyleTan, Y., Chen, H., Wang, Z., Xue, C., & He, R. (2019). Performances of Cement Mortar Incorporating Superabsorbent Polymer (SAP) Using Different Dosing Methods. Materials, 12(10), 1619. https://doi.org/10.3390/ma12101619