Machine Learning Techniques in Concrete Mix Design

Abstract

1. Introduction

2. The Contemporary Concrete Mix Design and Machine Learning Techniques

2.1. Concrete Mix Design in European Corporate Practice

2.2. Machine Learning Techniques

2.2.1. The Overall Concept of Machine Learning

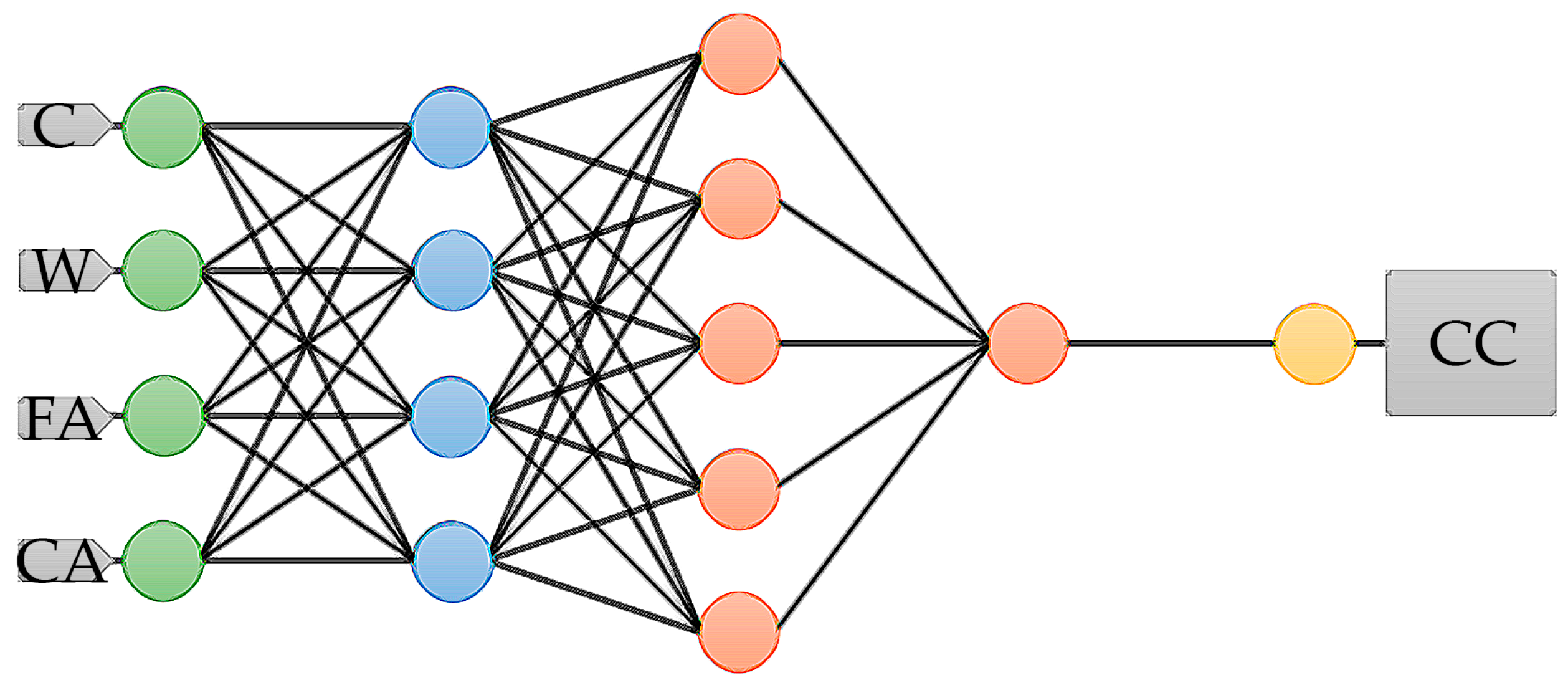

2.2.2. Artificial Neural Networks (ANN)

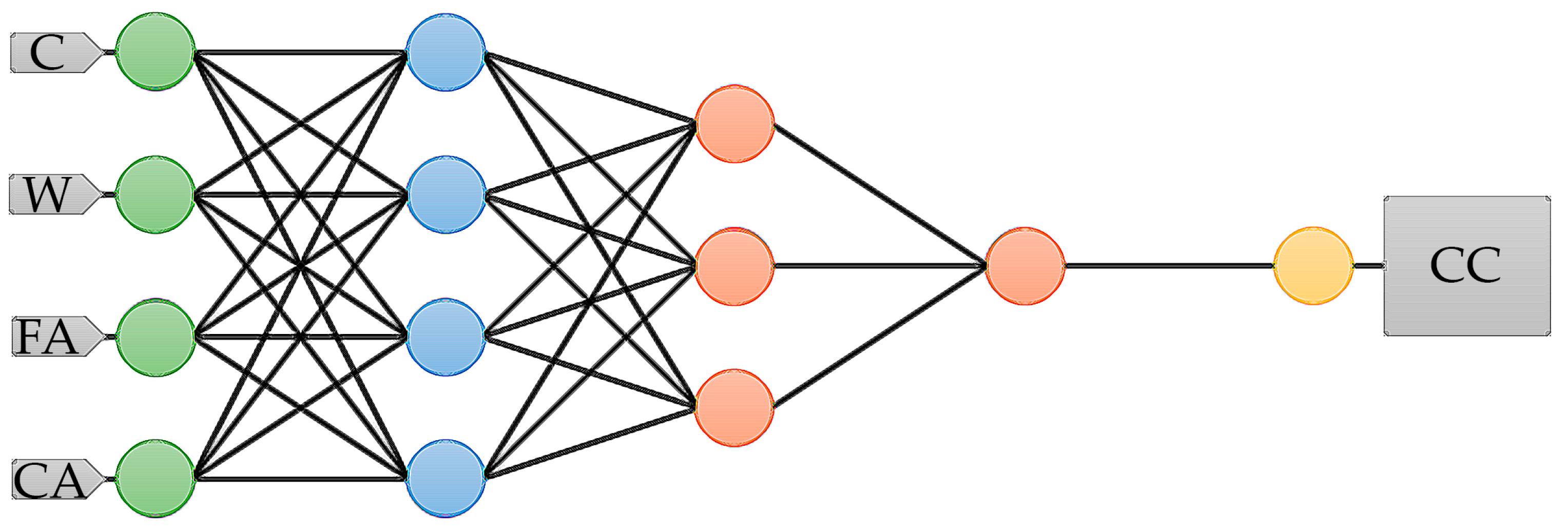

- The input layer;

- The hidden layer;

- The output layer.

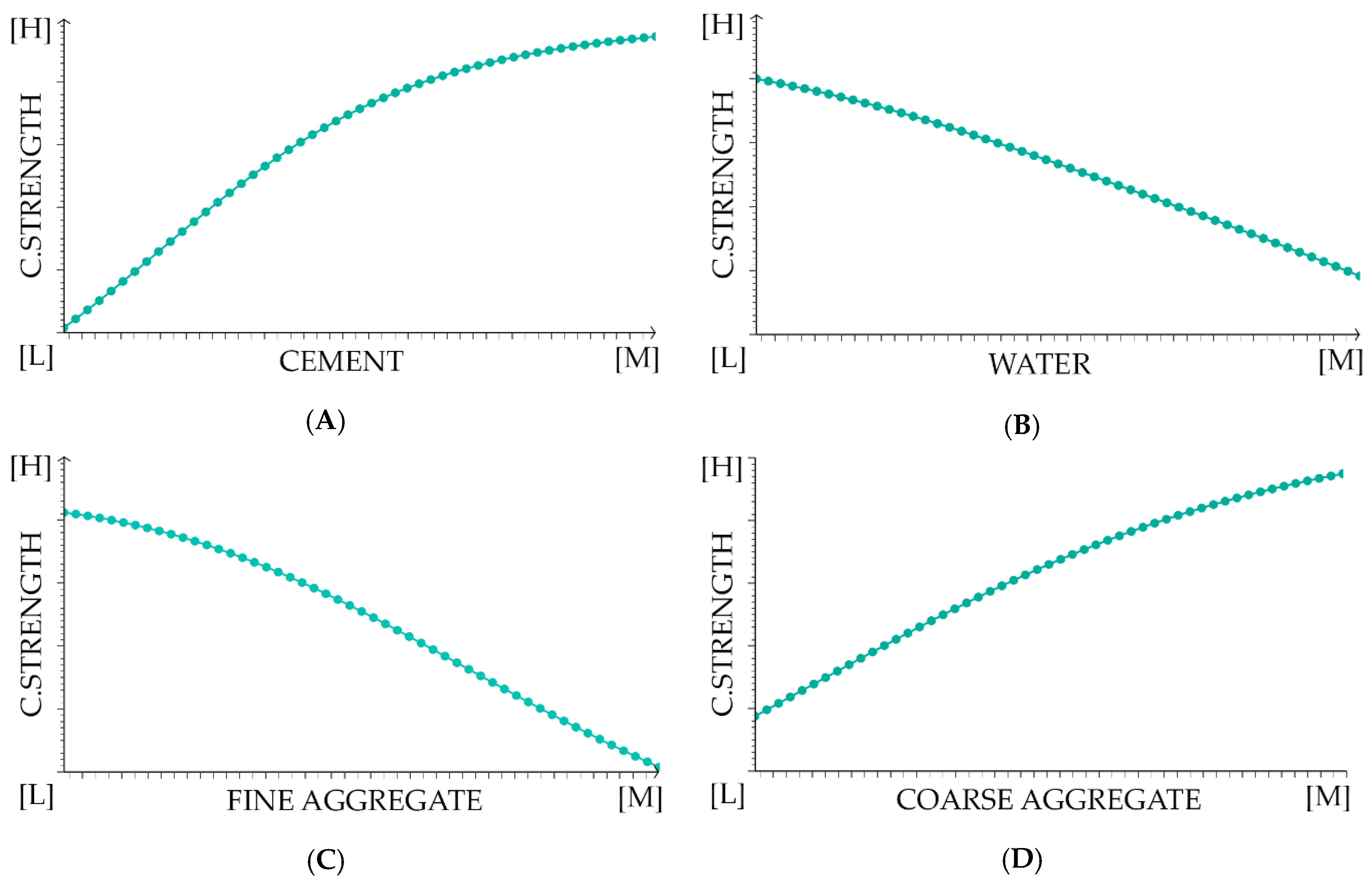

2.3. Use of Machine Learning in Concrete Compressive Strength Prediction

3. Materials and Methods

3.1. Essentials

3.2. The Database of Concrete Mix Recipes

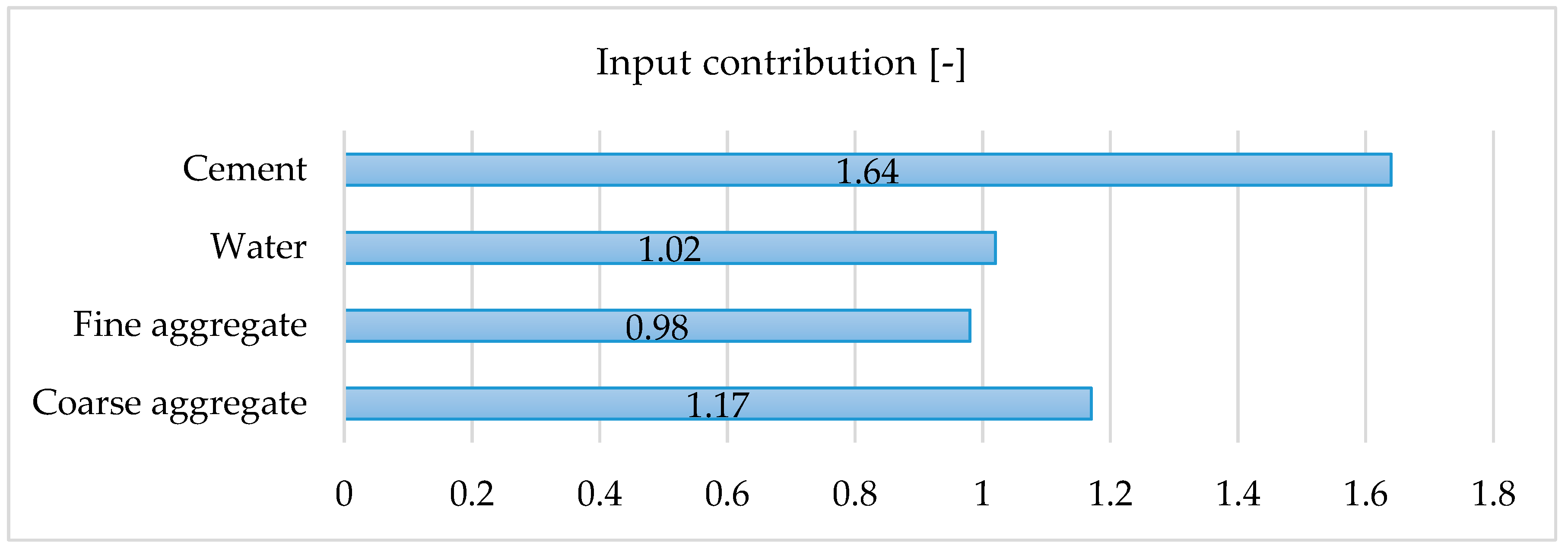

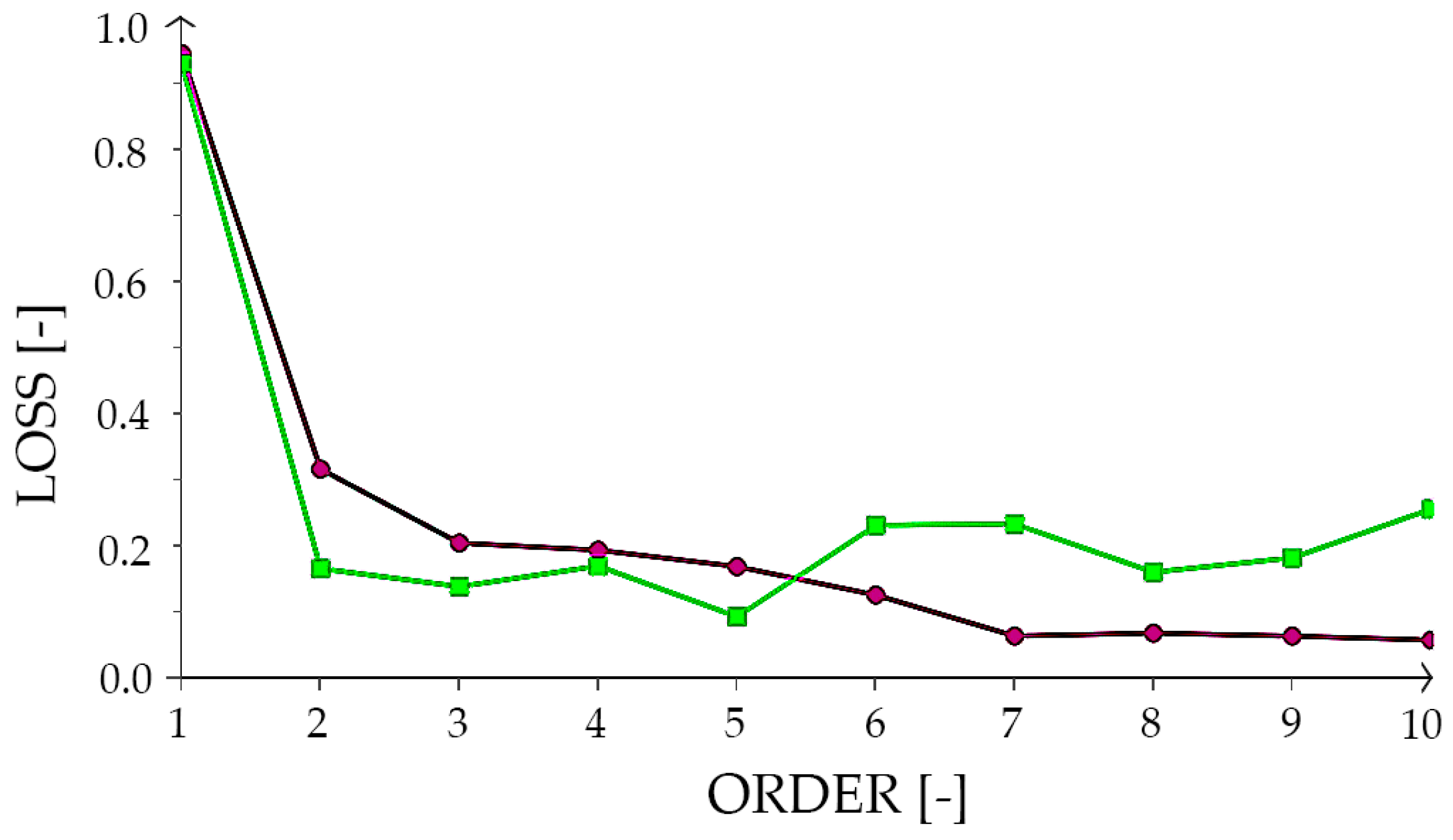

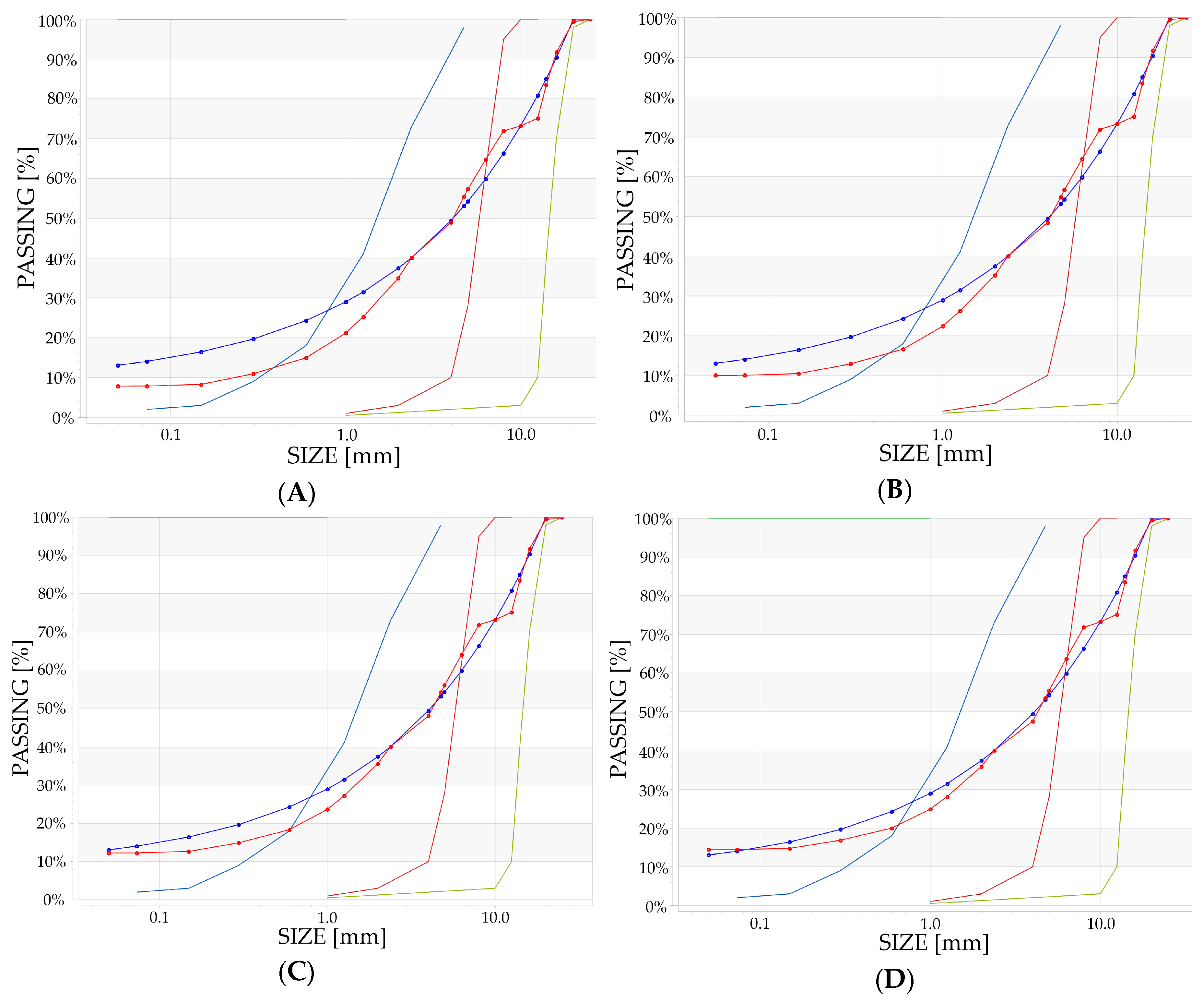

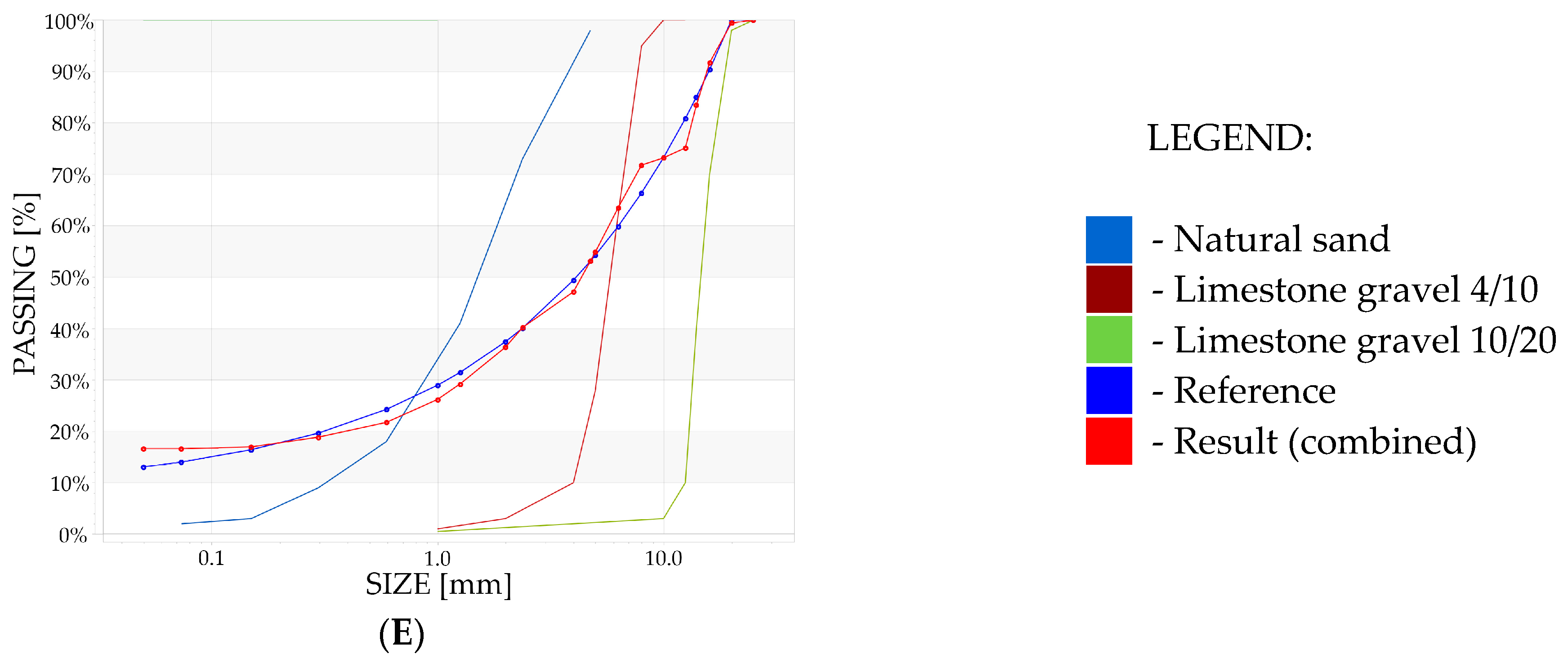

3.3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgements

Conflicts of Interest

References

- Marchon, D.; Flatt, R.J. Mechanisms of cement hydration. In Science and Technology of Concrete Admixtures; Elsevier: Amsterdam, The Netherlands, 2016; pp. 129–145. [Google Scholar]

- Scrivener, K.; Snellings, R.; Lothenbach, B. A Practical Guide to Microstructural Analysis of Cementitious Materials; CRC Press: Boca Raton, FL, USA, 2018; ISBN 1498738672. [Google Scholar]

- Kurdowski, W. Cement and Concrete Chemistry; Springer Science & Business: Berlin, Germany, 2014; ISBN 9400779453. [Google Scholar]

- Young, J.F.; Mindess, S.; Darwin, D. Concrete; Prentice Hall: Upper Saddle River, NJ, USA, 2002; ISBN 0130646326. [Google Scholar]

- Hover, K.C. The influence of water on the performance of concrete. Constr. Build. Mater. 2011, 25, 3003–3013. [Google Scholar] [CrossRef]

- Jensen, O.M.; Hansen, P.F. Water-entrained cement-based materials: I. Principles and theoretical background. Cem. Concr. Res. 2001, 31, 647–654. [Google Scholar] [CrossRef]

- Jensen, O.M.; Hansen, P.F. Water-entrained cement-based materials: II. Experimental observations. Cem. Concr. Res. 2002, 32, 973–978. [Google Scholar] [CrossRef]

- Jiménez Fernández, C.G.; Barra Bizinotto, M.; Valls del Barrio, S.; Aponte Hernández, D.F.; Vázquez Ramonich, E. Durability of recycled aggregate concrete designed with the Equivalent Mortar Volume (EMV) method: Validation under the Spanish context and its adaptation to Bolomey methodology. Mater. Construcción 2014, 64, e006-1–e006-12. [Google Scholar] [CrossRef]

- Abdelgader, H.S. How to design concrete produced by a two-stage concreting method. Cem. Concr. Res. 1999, 29, 331–337. [Google Scholar] [CrossRef]

- Abdelgader, H.S.; Suleiman, R.E.; El-Baden, A.S.; Fahema, A.H.; Angelescu, N. Concrete Mix Proportioning using Three Equations Method (Laboratory Study). In Proceedings of the UKIERI Concrete Congress Innovations in Concrete Construction, Jalandhar, India, 5–8 March 2013. [Google Scholar]

- Cartuxo, F.; De Brito, J.; Evangelista, L.; Jiménez, R.J.; Ledesma, F.E. Increased Durability of Concrete Made with Fine Recycled Concrete Aggregates Using Superplasticizers. Materials 2016, 9, 98. [Google Scholar] [CrossRef] [PubMed]

- Serralheiro, M.I.; de Brito, J.; Silva, A. Methodology for service life prediction of architectural concrete facades. Constr. Build. Mater. 2017, 133, 261–274. [Google Scholar] [CrossRef]

- Plank, J.; Sakai, E.; Miao, C.W.; Yu, C.; Hong, J.X. Chemical admixtures—Chemistry, applications and their impact on concrete microstructure and durability. Cem. Concr. Res. 2015, 78, 81–99. [Google Scholar] [CrossRef]

- Huang, H.; Qian, C.; Zhao, F.; Qu, J.; Guo, J.; Danzinger, M. Improvement on microstructure of concrete by polycarboxylate superplasticizer (PCE) and its influence on durability of concrete. Constr. Build. Mater. 2016, 110, 293–299. [Google Scholar] [CrossRef]

- Arredondo-Rea, S.P.; Corral-Higuera, R.; Gómez-Soberón, J.M.; Gámez-García, D.C.; Bernal-Camacho, J.M.; Rosas-Casarez, C.A.; Ungsson-Nieblas, M.J. Durability parameters of reinforced recycled aggregate concrete: Case study. Appl. Sci. 2019, 9, 617. [Google Scholar] [CrossRef]

- Andrade, C.; Gulikers, J.; Marie-Victoire, E. Service Life and Durability of Reinforced Concrete Structures; Springer: Berlin, Germany, 2018; Volume 17, ISBN 3319902369. [Google Scholar]

- Aïtcin, P.C. The durability characteristics of high performance concrete: A review. Cem. Concr. Compos. 2003, 25, 409–420. [Google Scholar] [CrossRef]

- Ahmad, S. Reinforcement corrosion in concrete structures, its monitoring and service life prediction—A review. Cem. Concr. Compos. 2003, 25, 459–471. [Google Scholar] [CrossRef]

- Schabowicz, K.; Gorzelańczyk, T.; Szymków, M. Identification of the Degree of Degradation of Fibre-Cement Boards Exposed to Fire by Means of the Acoustic Emission Method and Artificial Neural Networks. Materials 2019, 12, 656. [Google Scholar] [CrossRef]

- Godycki-Ćwirko, T.; Nagrodzka-Godycka, K.; Wojdak, R. Reinforced concrete thin-wall dome after eighty years of operation in a marine climate environment. Struct. Concr. 2016, 17, 710–717. [Google Scholar] [CrossRef]

- Schabowicz, K.; Gorzelańczyk, T.; Szymków, M. Identification of the degree of fibre-cement boards degradation under the influence of high temperature. Autom. Constr. 2019, 101, 190–198. [Google Scholar] [CrossRef]

- Argiz, C.; Moragues, A.; Menéndez, E. Use of ground coal bottom ash as cement constituent in concretes exposed to chloride environments. J. Clean. Prod. 2018, 170, 25–33. [Google Scholar] [CrossRef]

- Rajamane, N.P.; Ambily, P.S.; Nataraja, M.C.; Das, L. Discussion: Modified Bolomey equation for strength of lightweight concretes containing fly ash aggregates. Mag. Concr. Res. 2014, 66, 1286–1288. [Google Scholar] [CrossRef]

- Zhang, X.; Deng, S.; Deng, X.; Qin, Y. Experimental research on regression coefficients in recycled concrete Bolomey formula. J. Cent. South Univ. Technol. 2007, 14, 314–317. [Google Scholar] [CrossRef]

- Abdelgader, H.S.; Saud, A.F.; Othman, A.M.; Fahema, A.H.; El-Baden, A.S. Concrete mix design using the double-coating method. Betonw. Fert. Plant Precast Technol. 2014, 80, 66–74. [Google Scholar]

- Rumman, R.; Bose, B.; Emon, M.A.B.; Manzur, T.; Rahman, M.M. An experimental study: Strength prediction model and statistical analysis of concrete mix design. In Proceedings of the International Conference on Advances in Civil Engineering, Istanbul, Turkey, 21–23 September 2016; pp. 21–23. [Google Scholar]

- Pereira, F.C.; Borysov, S.S. Machine Learning Fundamentals. In Pereira Big Data and Transport Analytics; Antoniou, C., Dimitriou, L., Pereira, F., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; Chapter 2; pp. 9–29. ISBN 978-0-12-812970-8. [Google Scholar]

- Shobha, G.; Rangaswamy, S. Machine Learning. In Computational Analysis and Understanding of Natural Languages: Principles, Methods and Applications; Gudivada, V.N., Rao, C.R., Eds.; Elsevier: Amsterdam, The Netherlands, 2018; Volume 38, Chapter 8; pp. 197–228. ISBN 0169-7161. [Google Scholar]

- Yang, Z.R.; Yang, Z. Artificial Neural Networks. In Comprehensive Biomedical Physics; Araghinejad, S., Ed.; Springer: Dordrecht, The Netherlands, 2014; Volume 6, pp. 1–17. ISBN 9780444536327. [Google Scholar]

- Silva, I.N.; Hernane Spatti, D.; Andrade Flauzino, R.; Liboni, L.H.B.; dos Reis Alves, S.F. Artificial Neural Networks; Springer: Berlin, Germany, 2017; ISBN 978-3-319-43161-1. [Google Scholar]

- Brown, C.J. Design of Reinforced Concrete Structures; John Wiley & Sons: New York, NY, USA, 2003; Volume 4, ISBN 9780470279274. [Google Scholar]

- Yeh, I.-C. Modeling of Strength of High-Performance Concrete Using Artificial Neural Networks. Cem. Concr. Res. 1998, 28, 1797–1808. [Google Scholar] [CrossRef]

- Lee, S. Prediction of concrete strength using artificial neural networks. Eng. Struct. 2003, 25, 849–857. [Google Scholar] [CrossRef]

- Gupta, R.; Kewalramani, M.A.; Goel, A. Prediction of Concrete Strength Using Neural-Expert System. J. Mater. Civ. Eng. 2006, 18, 462–466. [Google Scholar] [CrossRef]

- Bui, D.K.; Nguyen, T.; Chou, J.S.; Nguyen-Xuan, H.; Ngo, T.D. A modified firefly algorithm-artificial neural network expert system for predicting compressive and tensile strength of high-performance concrete. Constr. Build. Mater. 2018, 180, 320–333. [Google Scholar] [CrossRef]

- Deng, F.; He, Y.; Zhou, S.; Yu, Y.; Cheng, H.; Wu, X. Compressive strength prediction of recycled concrete based on deep learning. Constr. Build. Mater. 2018, 175, 562–569. [Google Scholar] [CrossRef]

- Naderpour, H.; Rafiean, A.H.; Fakharian, P. Compressive strength prediction of environmentally friendly concrete using artificial neural networks. J. Build. Eng. 2018, 16, 213–219. [Google Scholar] [CrossRef]

- Toniolo, G.; di Prisco, M. Reinforced Concrete Design to Eurocode 2; Springer: Berlin, Germany, 2017; ISBN 978-3-319-52032-2. [Google Scholar]

- Abdi, F.; Shakeri, F. A globally convergent BFGS method for pseudo-monotone variational inequality problems. Optim. Methods Softw. 2017, 34, 25–36. [Google Scholar] [CrossRef]

- Andrei, N. An adaptive scaled BFGS method for unconstrained optimization. Numer. Algorithms 2018, 77, 413–432. [Google Scholar] [CrossRef]

- Battiti, R.; Masulli, F. BFGS optimization for faster and automated supervised learning. In International Neural Network Conference; Springer: Berlin, Germany, 1990; pp. 757–760. [Google Scholar]

- Berahas, A.S.; Nocedal, J.; Takác, M. A multi-batch l-bfgs method for machine learning. In Advances in Neural Information Processing Systems; Curran Associates Inc.: New York, NY, USA, 2016; pp. 1055–1063. [Google Scholar]

- Hagan, M.T.; Menhaj, M.B. Training feedforward networks with the Marquardt algorithm. IEEE Trans. Neural Netw. 1994, 5, 989–993. [Google Scholar] [CrossRef] [PubMed]

- Li, D.-H.; Fukushima, M. A modified BFGS method and its global convergence in nonconvex minimization. J. Comput. Appl. Math. 2001, 129, 15–35. [Google Scholar] [CrossRef]

- Grabowska, K.; Szczuko, P. Ship resistance prediction with Artificial Neural Networks. In Proceedings of the Signal Processing: Algorithms, Architectures, Arrangements, and Applications (SPA), Poznan, Poland, 23–25 September 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 168–173. [Google Scholar]

- Le, D.; Huang, W.; Johnson, E. Neural network modeling of monthly salinity variations in oyster reef in Apalachicola Bay in response to freshwater inflow and winds. Neural Comput. Appl. 2018, 1–11. [Google Scholar] [CrossRef]

- Luenberger, D.G. Introduction to Linear and Nonlinear Programming; Pearson Education, Inc.: London, UK, 1973. [Google Scholar]

- Yildizel, S.A.; Arslan, Y. Flexural strength estimation of basalt fiber reinforced fly-ash added gypsum based composites. J. Eng. Res. Appl. Sci. 2018, 7, 829–834. [Google Scholar]

- Argiz, C.; Menéndez, E.; Sanjuán, M.A. Effect of mixes made of coal bottom ash and fly ash on the mechanical strength and porosity of Portland cement. Mater. Construcción 2013, 63, 49–64. [Google Scholar] [CrossRef]

- Sanjuán, M.Á.; Estévez, E.; Argiz, C.; del Barrio, D. Effect of curing time on granulated blast-furnace slag cement mortars carbonation. Cem. Concr. Compos. 2018, 90, 257–265. [Google Scholar] [CrossRef]

- Kumar Poloju, K. Properties of Concrete as Influenced by Shape and Texture of Fine Aggregate; American Journal of Applied Scientific Research: New York, NY, USA, 2017; Volume 3. [Google Scholar]

- Chinchillas-Chinchillas, M.J.; Corral-Higuera, R.; Gómez-Soberón, J.M.; Arredondo-Rea, S.P.; Jorge, L.; Acuña-Aguero, O.H.; Rosas-Casarez, C.A. Influence of the Shape of the Natural Aggregates, Recycled and Silica Fume on the Mechanical Properties of Pervious Concrete; The Institute of Research Engineers and Doctors (IRED): New York, NY, USA, 2014; Volume 4, ISBN 9781632480064. [Google Scholar]

- Mehnert, A.; Jackway, P. An improved seeded region growing algorithm. Pattern Recognit. Lett. 1997, 18, 1065–1071. [Google Scholar] [CrossRef]

- Huang, G.-B.; Saratchandran, P.; Sundararajan, N. An efficient sequential learning algorithm for growing and pruning RBF (GAP-RBF) networks. IEEE Trans. Syst. Man Cybern. Part B 2004, 34, 2284–2292. [Google Scholar] [CrossRef]

- Arora, P.; Varshney, S. Analysis of k-means and k-medoids algorithm for big data. Procedia Comput. Sci. 2016, 78, 507–512. [Google Scholar] [CrossRef]

- Dariane, A.B.; Azimi, S. Forecasting streamflow by combination of a genetic input selection algorithm and wavelet transforms using ANFIS models. Hydrol. Sci. J. 2016, 61, 585–600. [Google Scholar] [CrossRef]

- Tabakhi, S.; Moradi, P.; Akhlaghian, F. An unsupervised feature selection algorithm based on ant colony optimization. Eng. Appl. Artif. Intell. 2014, 32, 112–123. [Google Scholar] [CrossRef]

- Song, Y.; Liang, J.; Lu, J.; Zhao, X. An efficient instance selection algorithm for k nearest neighbor regression. Neurocomputing 2017, 251, 26–34. [Google Scholar] [CrossRef]

- Yu, H.; Reiner, P.D.; Xie, T.; Bartczak, T.; Wilamowski, B.M. An incremental design of radial basis function networks. IEEE Trans. Neural Netw. Learn. Syst. 2014, 25, 1793–1803. [Google Scholar] [CrossRef]

- Iqbal, S.Z.; Gull, H.; Ahmed, J. Incremental Sorting Algorithm. In Proceedings of the Second International Conference on Computer and Electrical Engineering, Dubai, United Arab Emirates, 28–30 December 2009; pp. 378–381. [Google Scholar]

- Gurbuzbalaban, M.; Ozdaglar, A.; Parrilo, P.A. On the convergence rate of incremental aggregated gradient algorithms. SIAM J. Optim. 2017, 27, 1035–1048. [Google Scholar] [CrossRef]

| Parameter | Compressive Strength after 28 days | Cement | Water | Sand 0–2 mm | Aggregate above 2 mm |

|---|---|---|---|---|---|

| Codename | cs_28 | cement | water | fine_aggregate | coarse_aggregate |

| Type | target | input | input | input | input |

| Description | The compressive strength of concrete 28 days after hydration. Considered as full strength. | The weight of cement added to the mixture | The weight of water added to the mixture | The weight of sand added to the mixture | The weight of aggregate, which have more than 2 mm, added to the mixture |

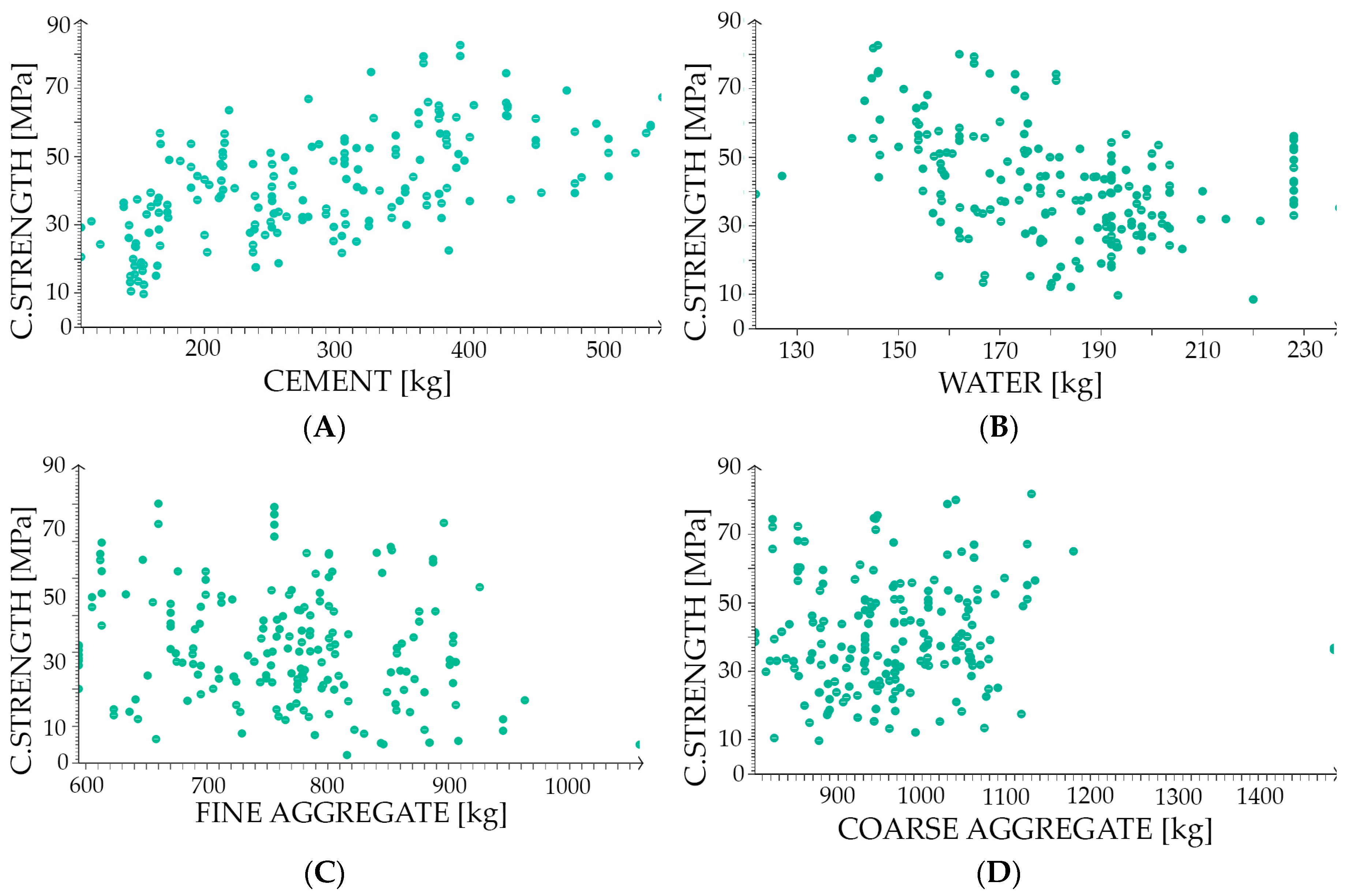

| Input Features | Minimum (kg/m3) | Maximum (kg/m3) | Average (kg/m3) |

|---|---|---|---|

| Cement | 86.00 | 540.00 | 278.00 |

| Water | 121.80 | 247.00 | 182.42 |

| Fine aggregate (sand 0–2 mm) | 372.00 | 1329.00 | 768.55 |

| Coarse aggregate (aggregate above 2 mm) | 597.00 | 1490.00 | 969.08 |

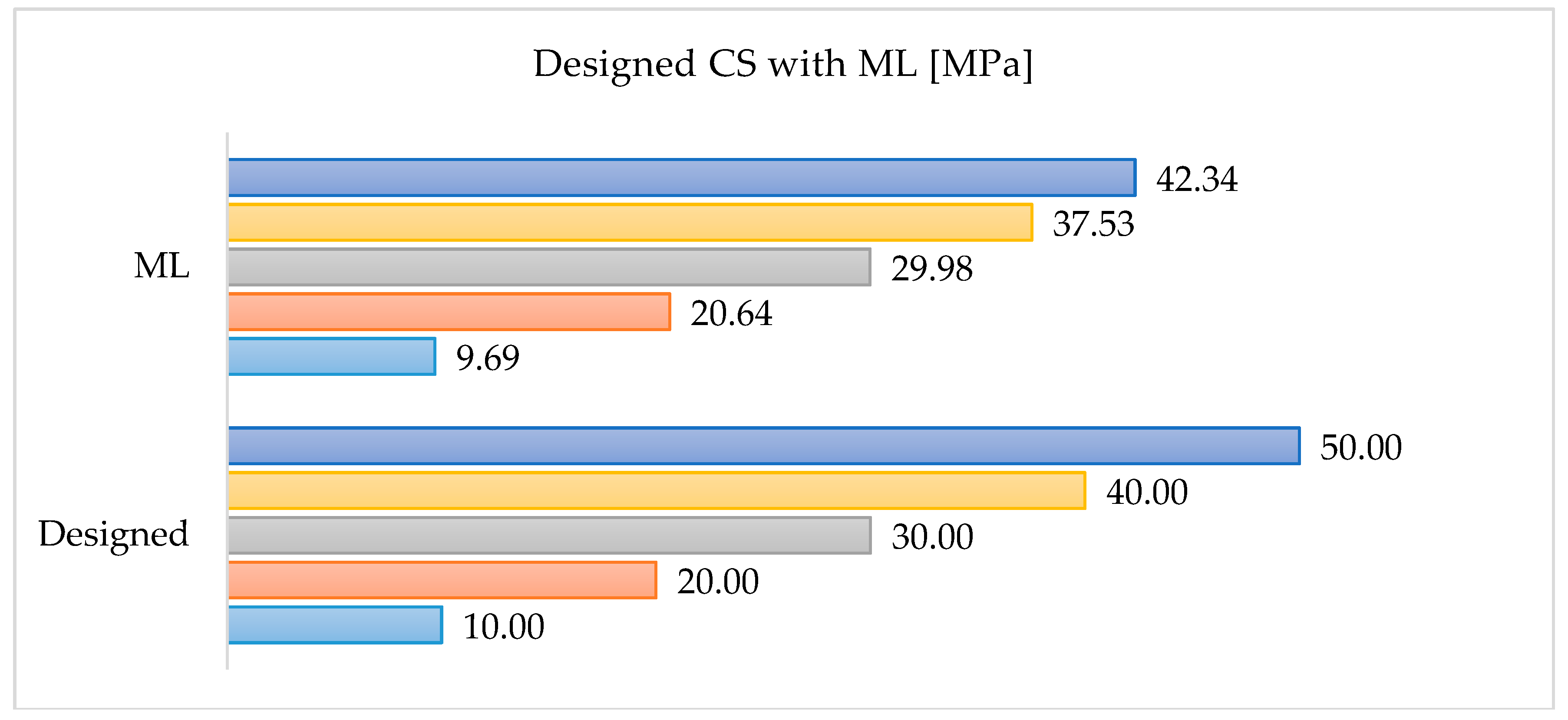

| Designed CC of Concrete Mix | Cement (kg/m3) | Water (L/m3) | Natural Sand (kg/m3) | Limestone Gravel 4/10 (kg/m3) | Limestone Gravel 10/20 (kg/m3) |

|---|---|---|---|---|---|

| 10 | 190.42 | 61.89 | 1089.78 | 531.24 | 676.11 |

| 20 | 249.52 | 81.09 | 991.52 | 541.32 | 661.89 |

| 30 | 308.62 | 94.81 | 901.23 | 554.15 | 651.75 |

| 40 | 367.71 | 101.25 | 821.33 | 570.82 | 646.97 |

| 50 | 426.81 | 107.97 | 745.14 | 583.21 | 641.99 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ziolkowski, P.; Niedostatkiewicz, M. Machine Learning Techniques in Concrete Mix Design. Materials 2019, 12, 1256. https://doi.org/10.3390/ma12081256

Ziolkowski P, Niedostatkiewicz M. Machine Learning Techniques in Concrete Mix Design. Materials. 2019; 12(8):1256. https://doi.org/10.3390/ma12081256

Chicago/Turabian StyleZiolkowski, Patryk, and Maciej Niedostatkiewicz. 2019. "Machine Learning Techniques in Concrete Mix Design" Materials 12, no. 8: 1256. https://doi.org/10.3390/ma12081256

APA StyleZiolkowski, P., & Niedostatkiewicz, M. (2019). Machine Learning Techniques in Concrete Mix Design. Materials, 12(8), 1256. https://doi.org/10.3390/ma12081256