The Potential of Ladle Slag and Electric Arc Furnace Slag use in Synthesizing Alkali Activated Materials; the Influence of Curing on Mechanical Properties

Abstract

:1. Introduction

2. Experimental Methods

2.1. Characterization of Materials

2.2. Sample Preparation

3. Results and Discussion

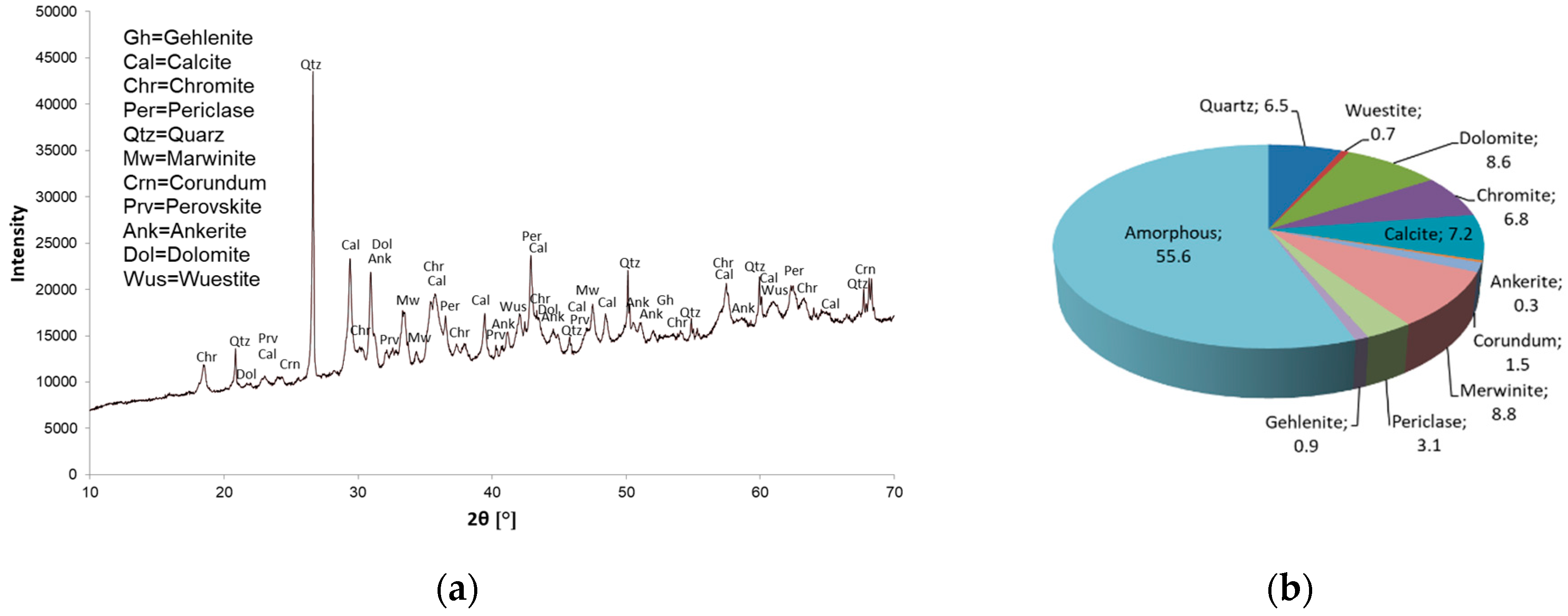

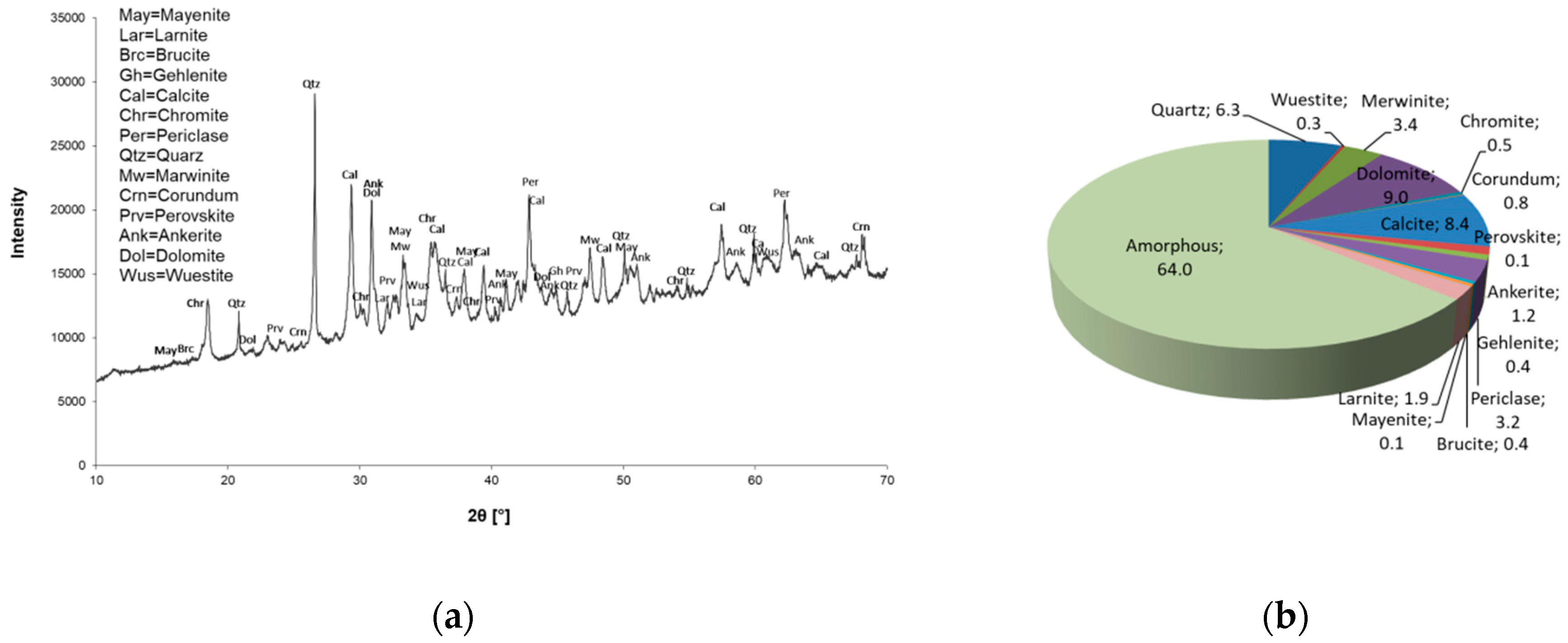

3.1. Analysis of Raw Materials

3.2. Analysis of AAM

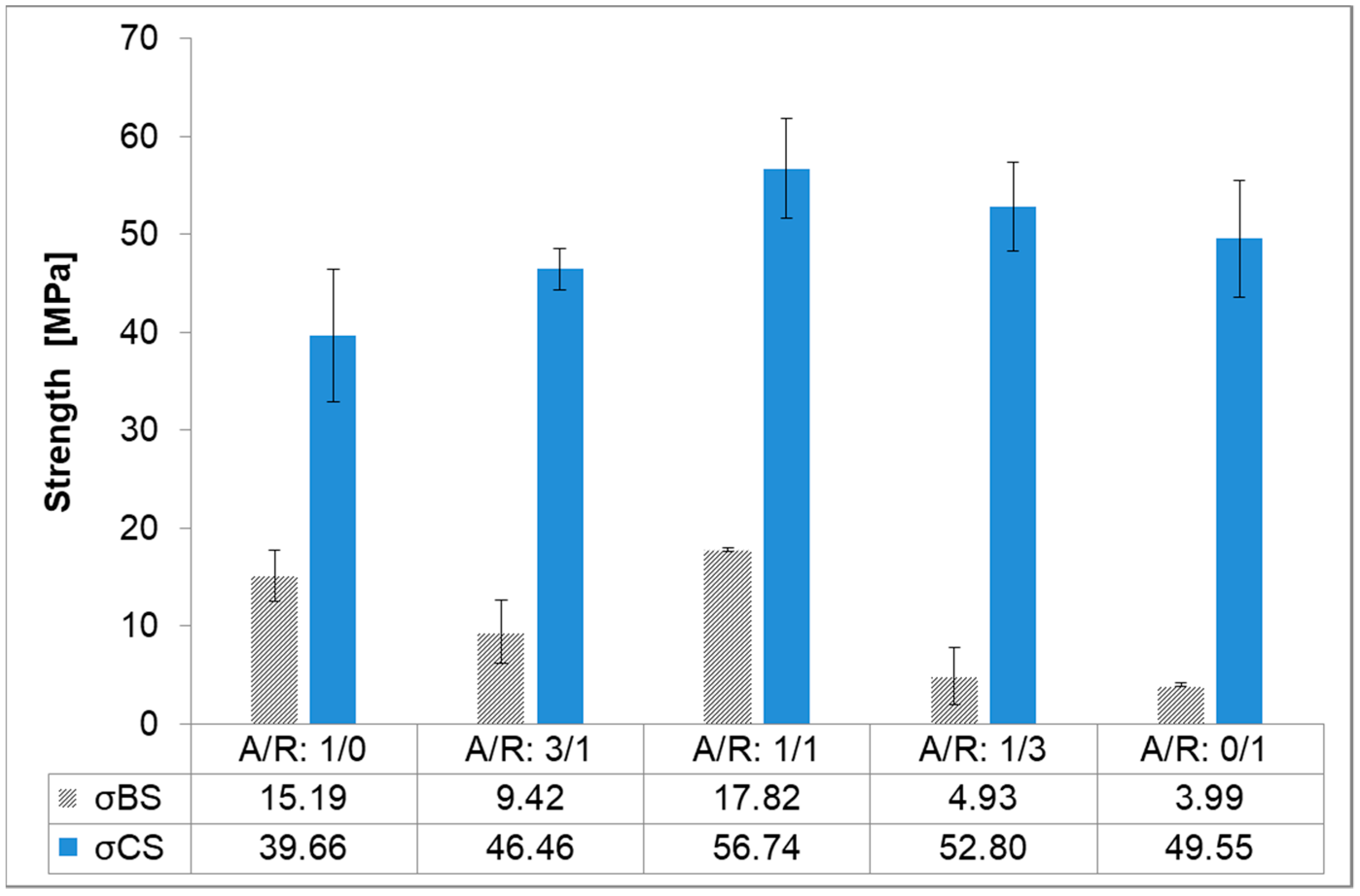

3.2.1. Influence of the Slag A/Slag R Ratio on Mechanical Properties

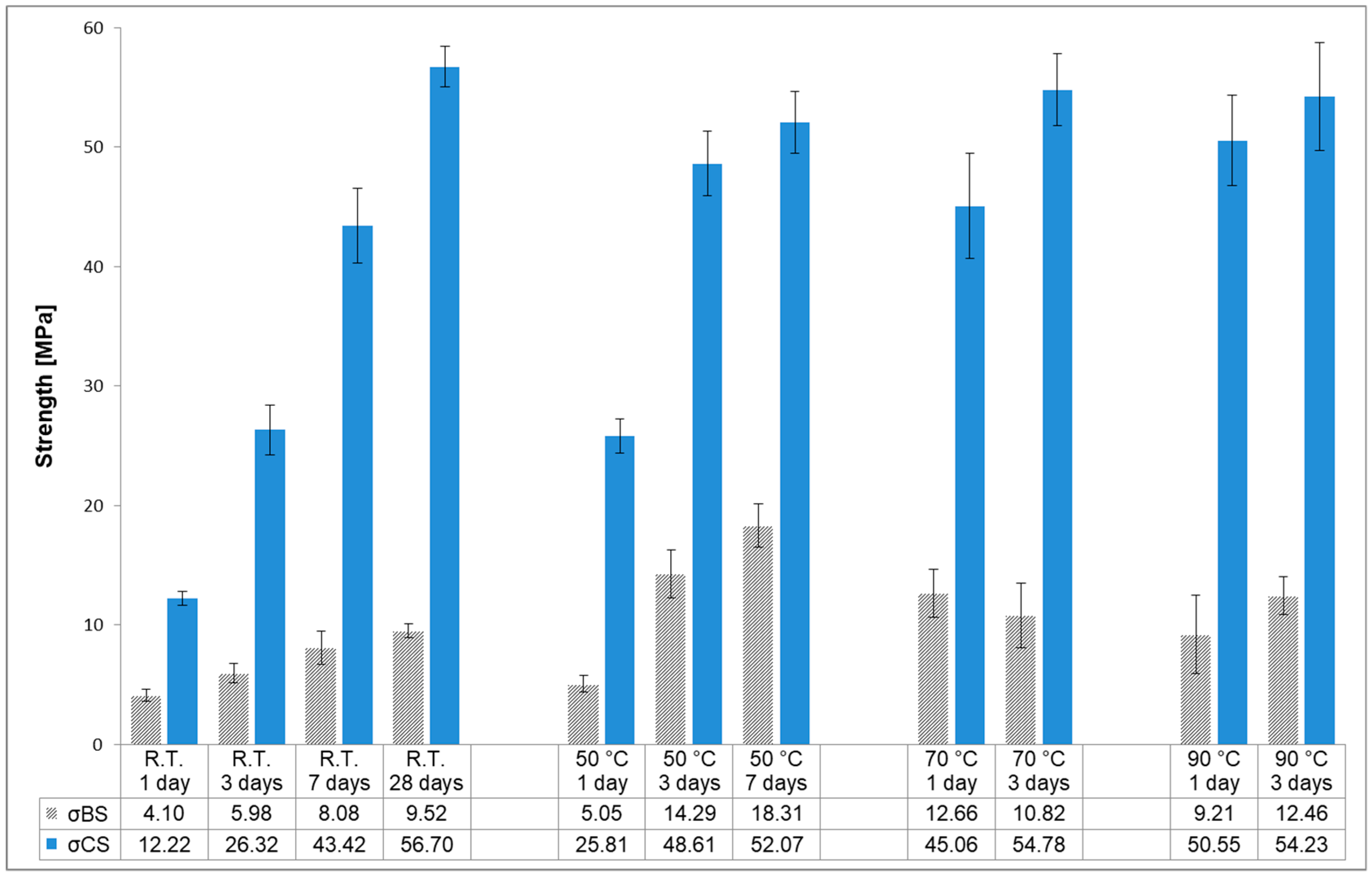

3.2.2. The Influence of Curing Temperature and Time on Mechanical Properties

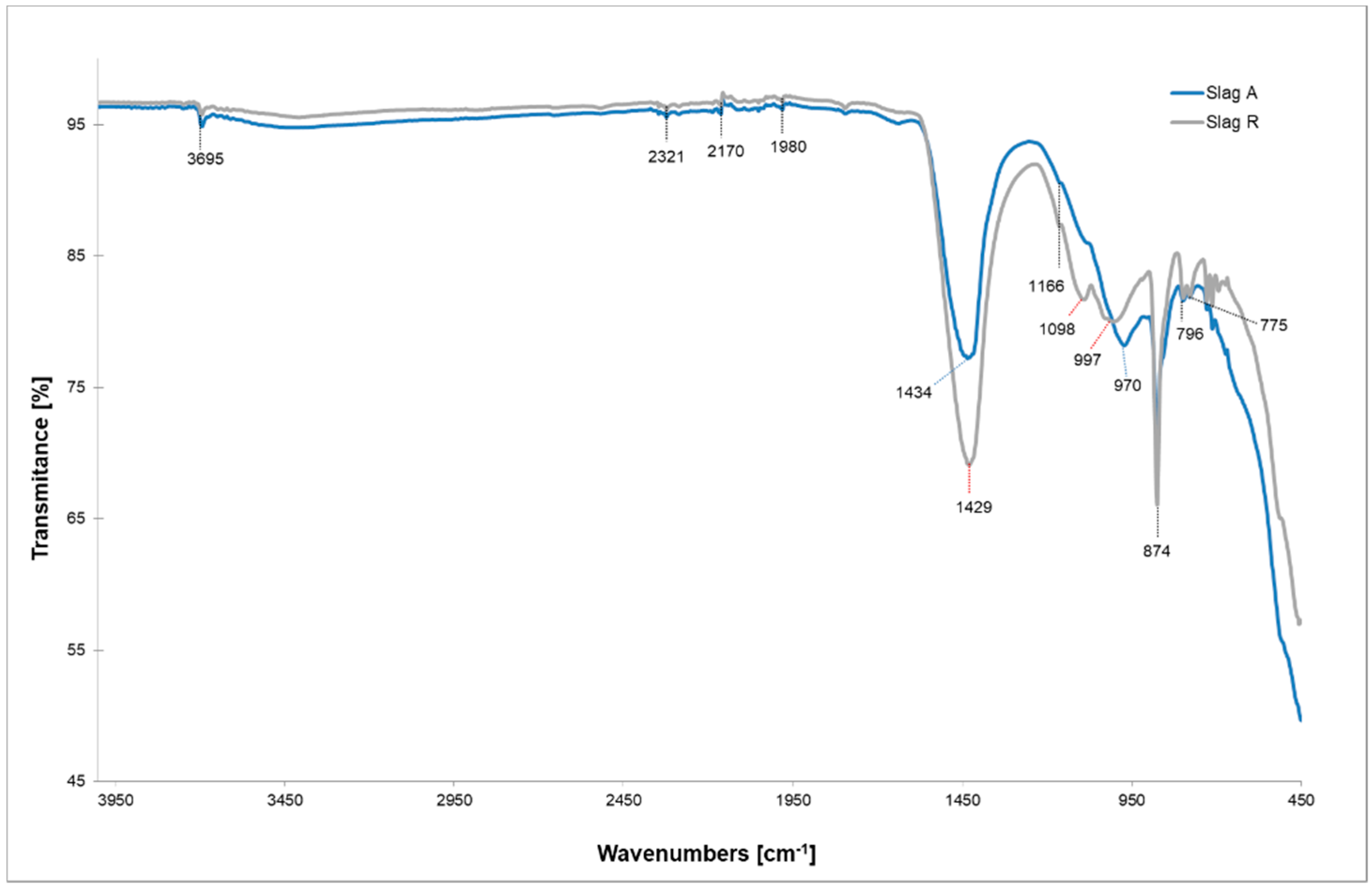

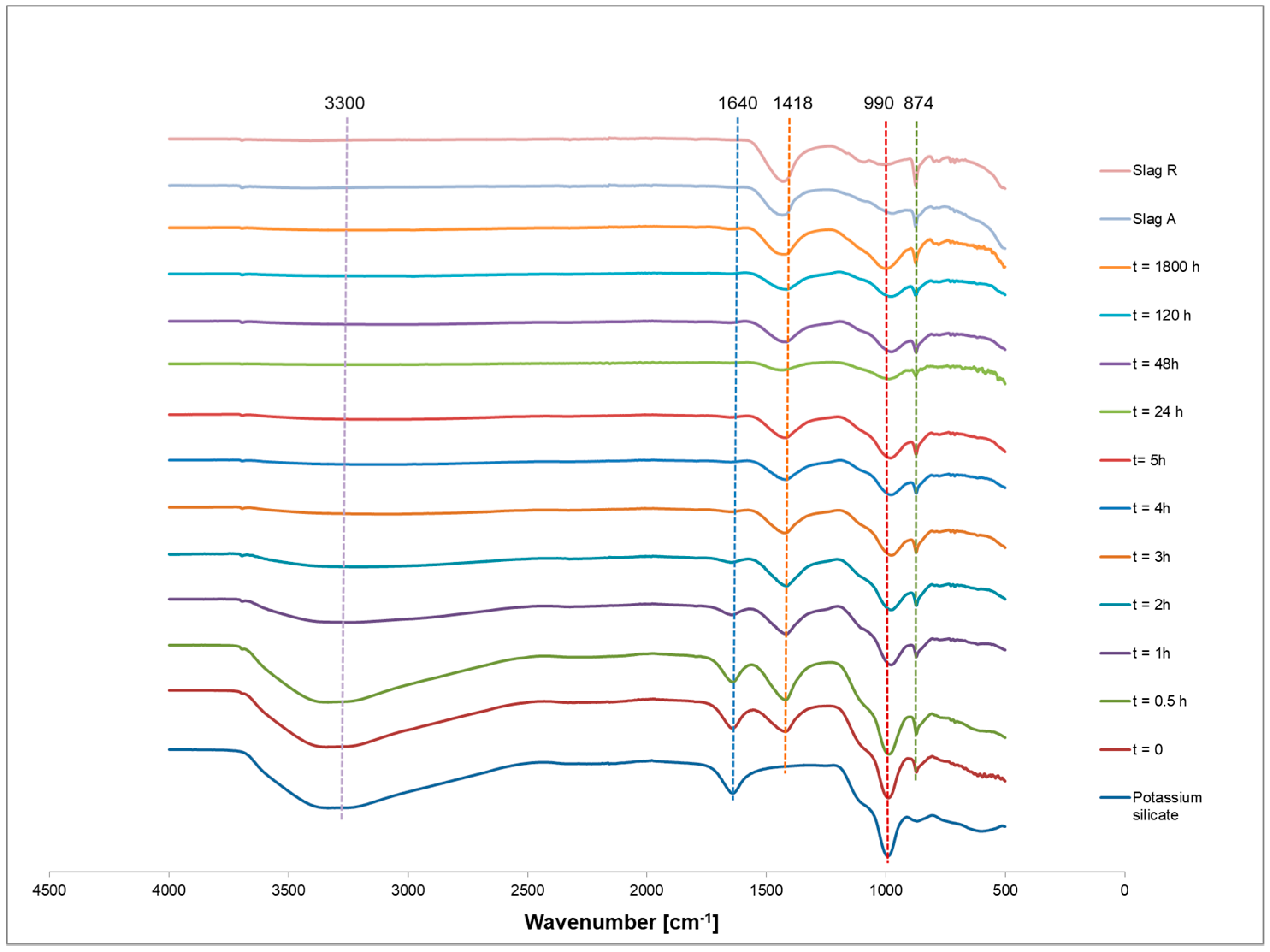

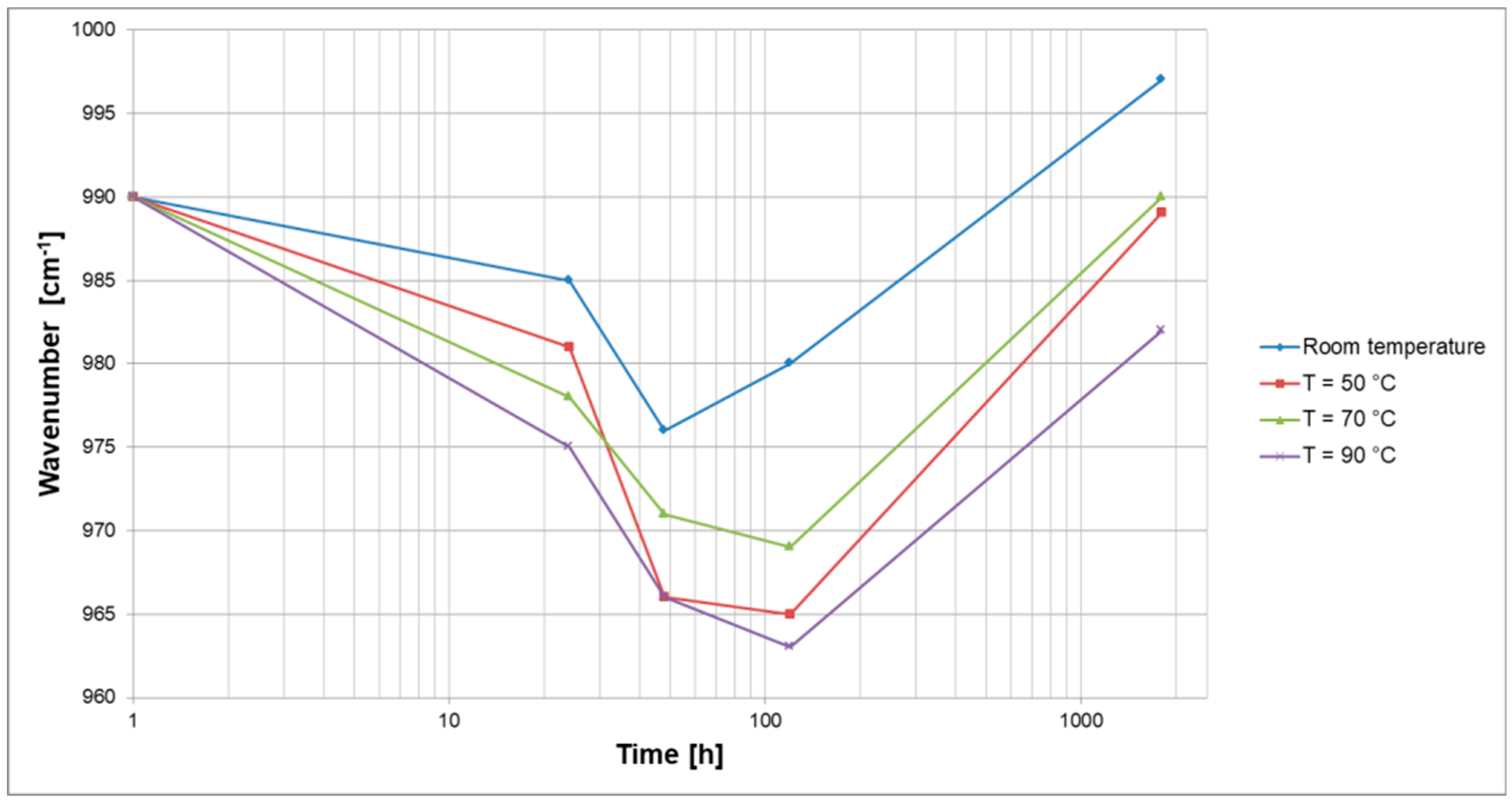

3.2.3. FTIR Evaluation

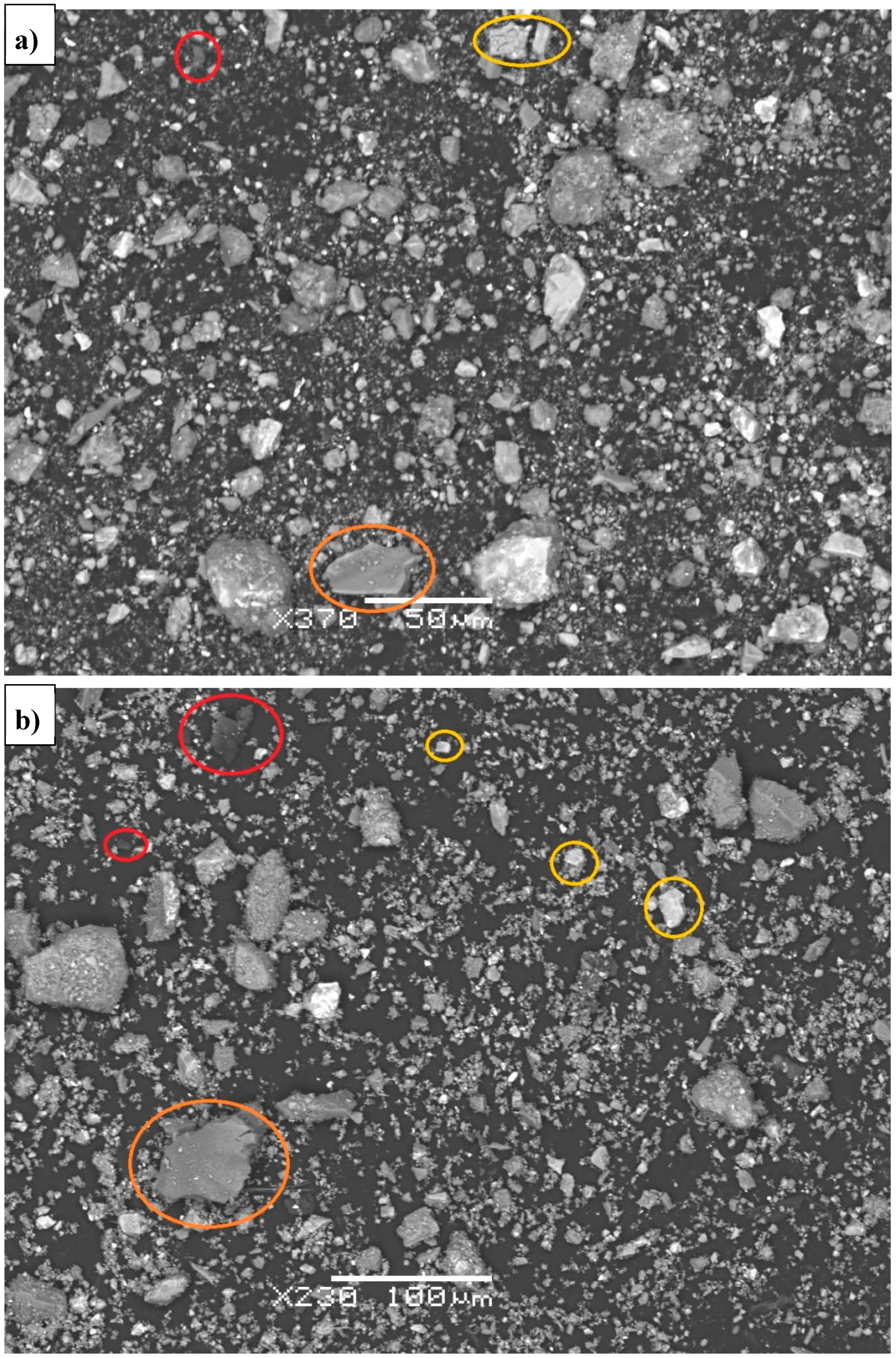

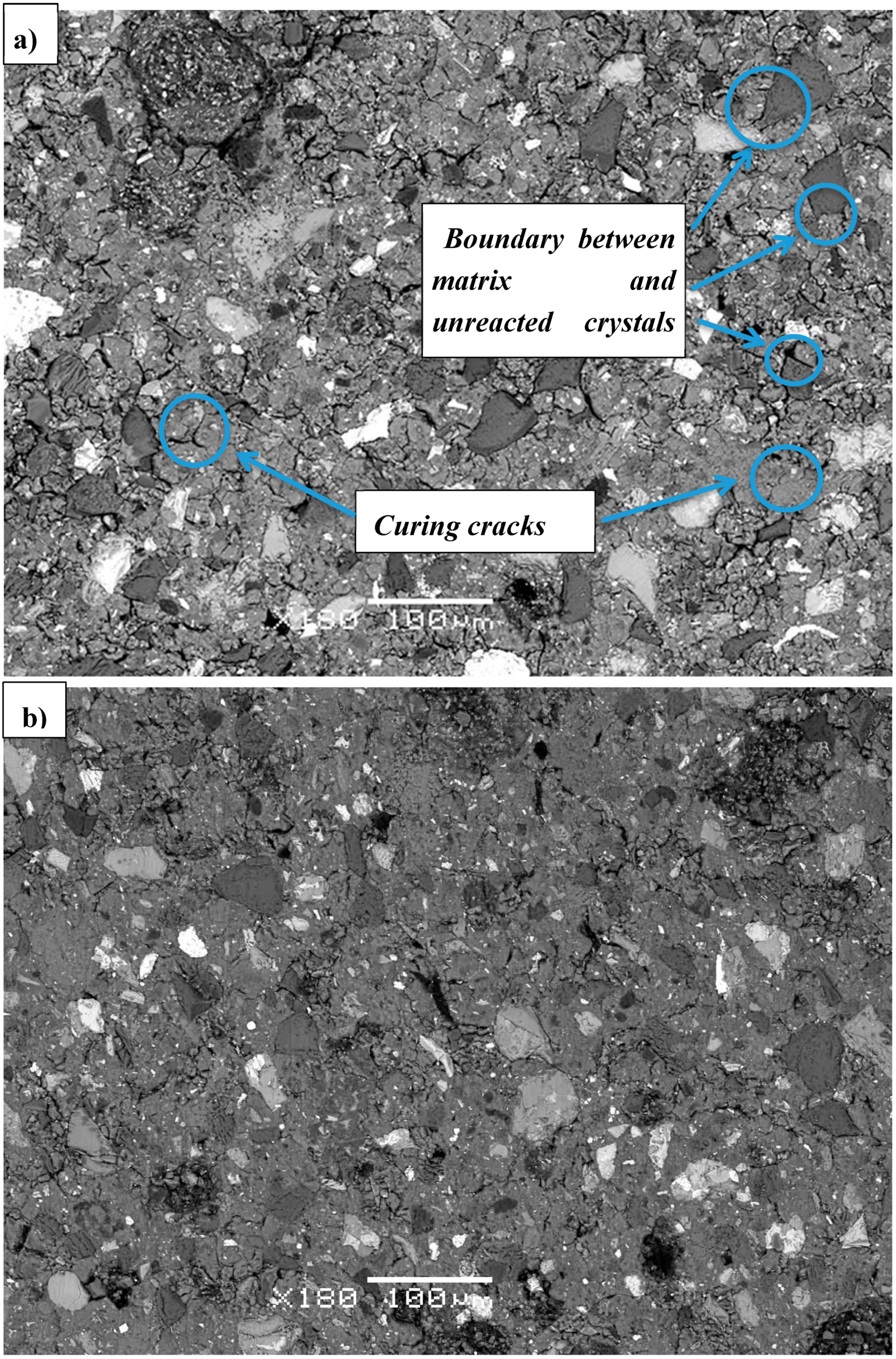

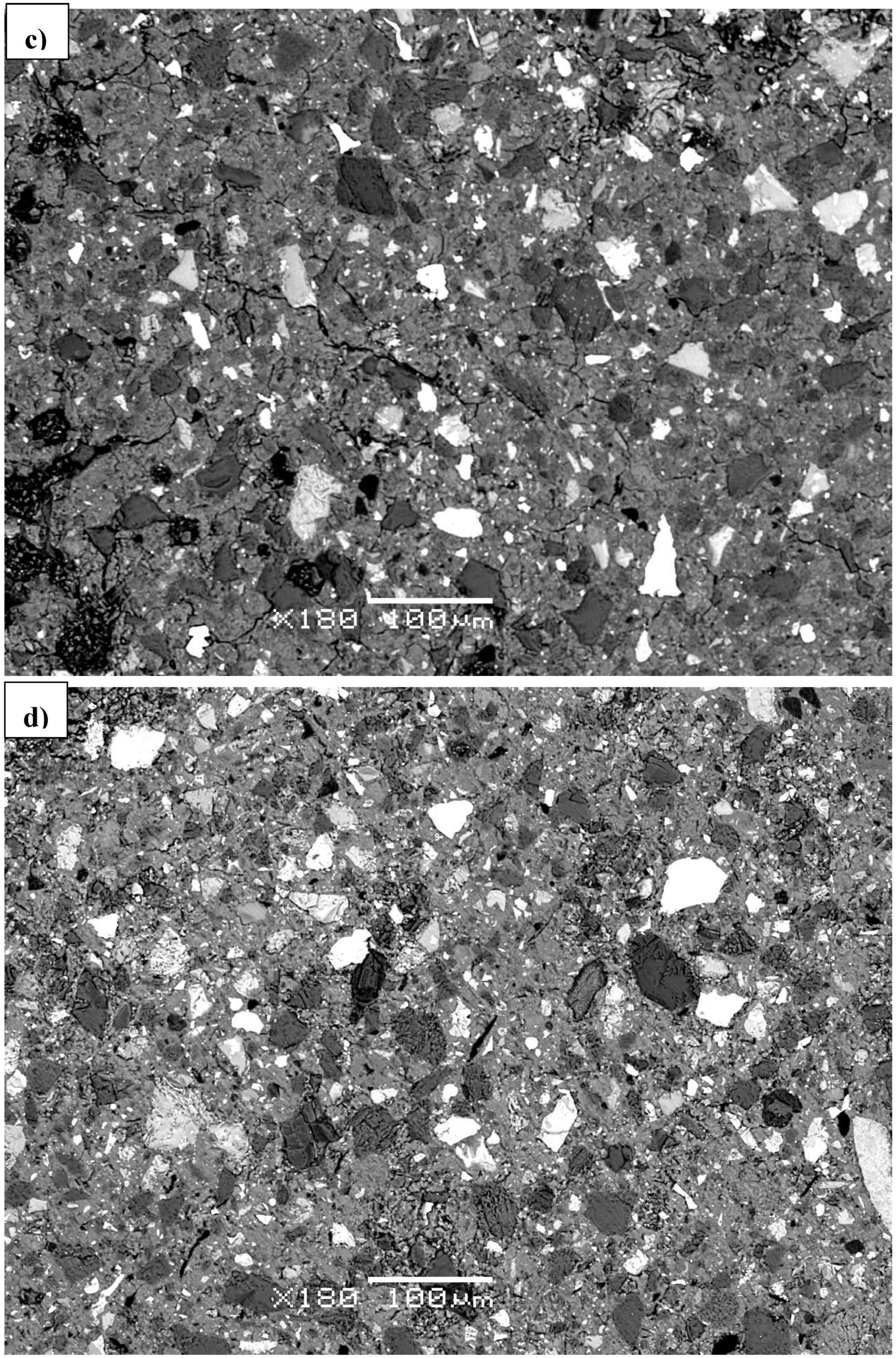

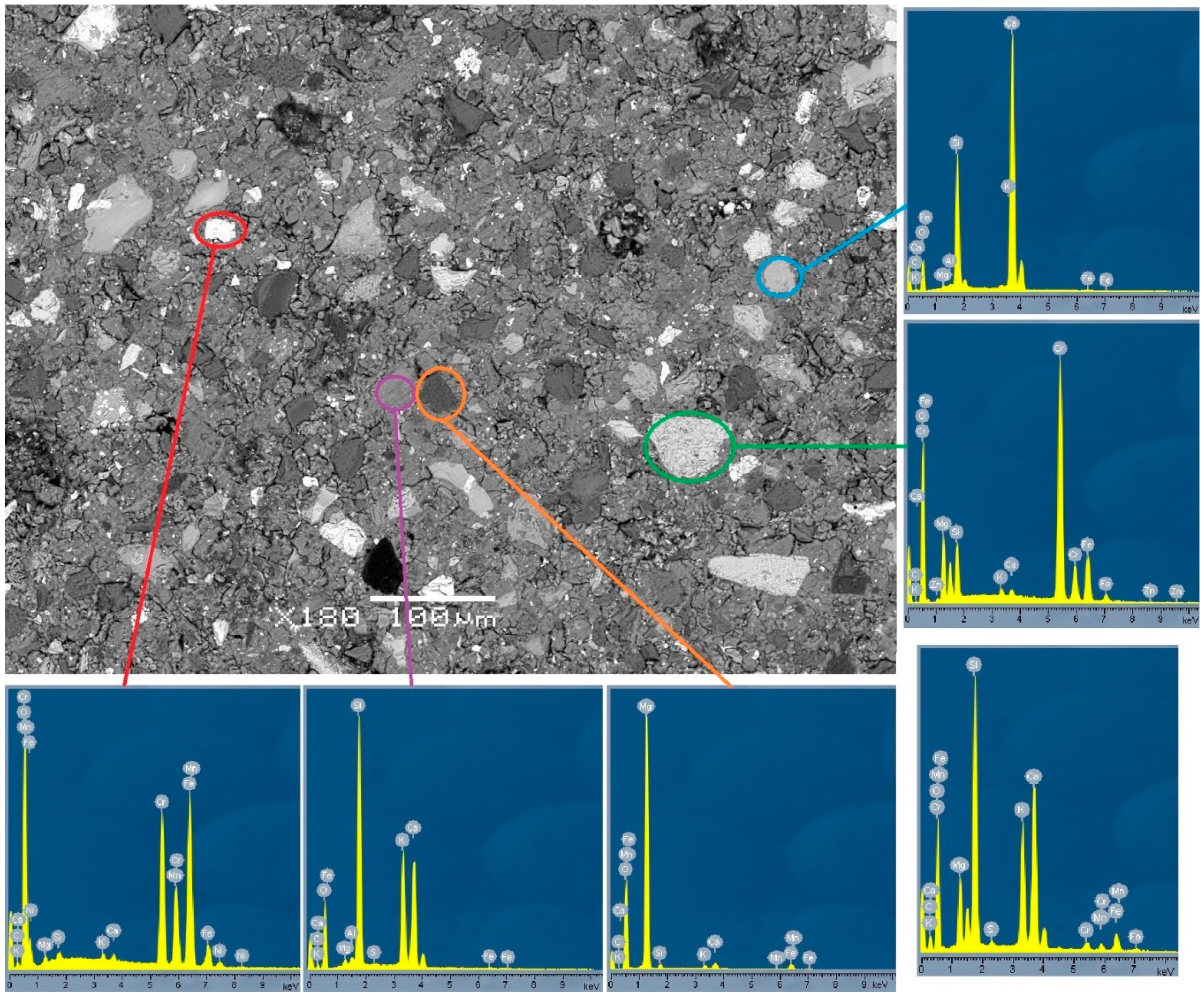

3.2.4. Microstructural Evaluation

4. Conclusions

- with the in-situ FTIR measurements two phenomena are observed: (i) a decrease in the intensity of the H2O bands consumed by reaction and/or evaporation (at about 3300 cm−1 and 1639 cm−1) and (ii) a condensation reaction, evidenced by the displacement of the main peak around 980 cm−1, as the time and temperature of curing increased.

- MIP analysis showed a reduction in porosity when curing occurred at an elevated temperature, primarily due to a reduction in the proportion of pores with a diameter of less than 1 µm.

- SEM analysis confirmed the presence of micro cracks which are present in the samples cured under 70 °C for one day. Above this temperature and time exposure cracks are not detected any more.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jun, Y.; Yoon, S.; Oh, J.E. A comparison Study for Chloride-Binding Capacity between Alkali-Activated Fly Ash and Slag in the Use of Seawater. Appl. Sci. 2017, 7, 971. [Google Scholar] [CrossRef]

- Cosa, J.; Soriano, L.; Borrachero, M.V.; Reig, L.; Paya, J.; Monzo, J.M. The compressive Strength and Microstructure of alkali-Activated Binary Cements Developed by Combining Ceramic Sanitaryware with Fly Ash or Blast Furnace Slag. Minerals 2018, 8, 337. [Google Scholar] [CrossRef]

- Metalkah, F.; Salem, T.; Shaafey, M.; Soroushian, P. Drying shrinkage of alkali binders cured at room temperature. Constr. Build. Mater. 2019, 201, 563–570. [Google Scholar] [CrossRef]

- Nasr, D.; Pakshir, A.H.; Ghayour, H. The influence of curing conditions and alkaline activator concentration on elevated temperature behavior of alkali activated slag (AAS) mortars. Constr. Build. Mater. 2018, 190, 108–119. [Google Scholar] [CrossRef]

- Ozturk, M.; Bankir, M.B.; Bolukbasi, O.S.; Sevim, U.K. Alkali activation of electric arc furnace slag: Mechanical properties and micro analyzes. J. Build. Eng. 2019, 21, 97–105. [Google Scholar] [CrossRef]

- Chen, T.A.; Chen, J.H.; Huang, J.S. Effects of activator and aging process on the compressive strengths of alkali-activated glass inorganic binders. Cem. Concr. Compos. 2017, 76, 1–12. [Google Scholar] [CrossRef]

- Bernal, S.A.; Provis, J.L. Durability of Alkali-Activated Materials; Progress and Perspectives. J. Am. Ceram. Soc. 2014, 97, 997–1008. [Google Scholar] [CrossRef]

- Euroslag. Available online: http://www.euroslag.com/products/eaf/ (accessed on 5 April 2019).

- Provis, J.L.; Palomo, A.; Shi, C. Advances in understanding alkali-activated materials. Cem. Concr. Res. 2015, 78, 110–125. [Google Scholar] [CrossRef]

- Shi, C.; Qian, J. High performance cementing materials from industrial slag—A review. Resour. Conserv. Recycl. 2000, 29, 195–207. [Google Scholar] [CrossRef]

- Ismail, I.; Bernal, S.A.; Provis, J.L.; San Nicolas, R.; Hamadan, S.; van Deventer, J.S.J. Modification of phase evolution in alkali-activated blast furnace slag by incorporation of fly ash. Cem. Concr. Compos. 2014, 45, 125–135. [Google Scholar] [CrossRef]

- Natali Murri, A.; Rickard, W.D.A.; Bignozzi, M.C.; van Riessen, A. High temperature behavior of ambient cured alkali-activated materials based on ladle slag. Cem. Concr. Res. 2013, 43, 51–61. [Google Scholar] [CrossRef]

- Aminorroaya, S.; Edris, H.; Tohidi, A.; Parsi, J.; Zamani, B. Recycling of ladle furnace slags. In Proceedings of the 2nd International Conference on Process Development in Iron and Steelmaking (SCANMET II), Luleå, Sweden, 6–9 June 2004; pp. 379–384. [Google Scholar]

- Muhmood, L.; Vitta, S.; Ventkateswaran, D. Cementious and pozzolanic behavior of electric arc furnace steel slags. Cem. Concr. Res. 2009, 39, 102–109. [Google Scholar] [CrossRef]

- Amin, M.N.; Khan, K.; Saleem, M.U.; Khurram, N.; Niazi, M.U.K. Influence of Mechanically Activated Electric Arc Furnace Slag in Compressive Strength of Mortars Incorporating Curing Moisture and Temperature Effects. Sustainabillity 2017, 9, 1178. [Google Scholar] [CrossRef]

- Rađenović, A.; Malina, J.; Sofilić, T. Characterization of Ladle Furnace Slag from Carbon Steel Production as a Potential Adsorbent. Adv. Mater. Sci. Eng. 2013, 1–6. [Google Scholar] [CrossRef]

- Yi, H.; Xu, G.; Cheng, H.; Wang, J.; Wan, Y.; Chen, H. An overview of utilization of steel slag. Procedia Environ. Sci. 2012, 16, 791–801. [Google Scholar] [CrossRef]

- Dippenaar, R. Industrial uses of slag (the use and re-use of iron and steelmaking slags). Ironmak. Steelmak. 2005, 32, 35–46. [Google Scholar] [CrossRef]

- Khale, D.; Chaudhary, R. Mechanism of Geopolymerization and Factors Influencing Its Development: A review. J. Mater. Sci. 2007, 42, 729–746. [Google Scholar] [CrossRef]

- Fernandez-Jimenez, A.; Puertas, F. Effect of activator mix on hydration and strength behaviour of alkali-activated slag cements. Adv. Cem. Res. 2003, 15, 129. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Castro-Gomes, J.; Jalali, S. Alkali-Activated Binders: A Review. Part 2. About Materials and Binders Manufacture. Constr. Build. Mater. 2008, 22, 1315–1322. [Google Scholar] [CrossRef]

- Yip, C.K.; Deventer, J.S.J. Microanalysis of calcium silicate hydrate gel formed within a geopolymer binder. J. Mater. Sci. 2003, 38, 3851–3860. [Google Scholar] [CrossRef]

- Altan, E.; Erdogan, S.T. Alakli activation of slag at ambient and elevated temperatures. Cem. Concr. Compos. 2012, 34, 131–139. [Google Scholar] [CrossRef]

- Petermann, J.C.; Saeed, A.; Hammons, M.I. Alkali-activated geopolymers: A literature review. Air force research laboratory, 2012, pp. 1–99. Available online: https://apps.dtic.mil/docs/citations/ADA559113/ (accessed on 5 April 2019).

- Fernández-Jimenez, A.; García-Lodeiro, I.; Palomo, A. Development of New Cementitious Materials by Alkaline Activating Industrial by-Products. Mater. Sci. Eng. 2005, 96, 1–10. [Google Scholar]

- Rudić, O.; Ducman, V.; Malešev, M.; Radonjanin, V.; Draganić, S.; Šupić, S.; Radeka, M. Aggregates Obtained by Alkali Activation of Fly Ash: The Effect of Granulation, Pelletization Methods and Curing Regimes. Materials 2019, 12, 776. [Google Scholar] [CrossRef]

- Duxson, P.; Provis, J.L.; Lukey, G.C.; Mallicoat, S.W.; Kriven, W.M.; van Deventer, J.S.J. Understanding the relationship between geopolymer composition, microstructure and mechanical properties. Coll. Surf. Physicochem. Eng. Asp. 2005, 269, 47–58. [Google Scholar] [CrossRef]

- Türker, H.T.; Balcikanli, M.; Durmus, I.H.; Özbay, E.; Erdemir, M. Microstructural alteration of alkali activated slag mortars depend on exposed high temperature level. Constr. Build. Mater. 2016, 104, 169–180. [Google Scholar] [CrossRef]

- Cwirzen, A.; Engblom, R.; Punkki, J.; Habermehl-Cvirzen, K. Effects of curing: Comparison of optimized alkali-activated PC-FA-BFS and PC concretes. Mag. Concr. Res. 2014, 66, 315–325. [Google Scholar] [CrossRef]

- Gao, X. Reaction kinetics, gel character and strength of ambient temperature cured alkali activated slag-fly ash blends. Constr. Build. Mater. 2015, 80, 105–115. [Google Scholar] [CrossRef]

- Komnitsas, K. Effect of synthesis parameters on the quality of construction and demolition wastes (CDW) geopolymers. Adv. Powder Technol. 2014, 26, 368–376. [Google Scholar] [CrossRef]

- Khater, H.M. Characterization of alkali activated geopolymer mortar doped with MWCNT. Constr. Build. Mater. 2016, 102, 329–337. [Google Scholar] [CrossRef]

- Adesanya, E. Alkali Activation of Ladle Slag from Steel-Making Process. J. Sustain. Metal. 2017, 3, 300–310. [Google Scholar] [CrossRef]

- Fernandez-Jimenez, A. Structure of Calcium Silicate Hydrates Formed in Alkaline-Activated Slag: Influence of the Type of Alkaline Activator. J. Am. Ceram. Soc. 2003, 86, 1389–1394. [Google Scholar] [CrossRef]

- Hong, S.-Y. Alkali Sorption by C-S-H and C-A-S-H gels: Part II. Role of Alumina. Cem. Concr. Res. 2002, 32, 1101–1111. [Google Scholar] [CrossRef]

- Fernandez-Jimenez, A.; de la Torre, A.G.; Palomo, A.; Lopez-Olmo, G.; Alonso, M.M.; Aranda, M.A.G. Quantitative determination of phases in the alkali activation of fly ash. Part I. Potential ash reactivity. Fuel 2006, 85, 625–634. [Google Scholar] [CrossRef]

- Brough, A.R.; Atkinson, A. Sodium Silicate-Based, Alkali-Activated Slag Mortars: Part I. Strength, Hydration and Microstructure. Cem. Concr. Res. 2002, 32, 865–879. [Google Scholar] [CrossRef]

- Sedira, N.; Castro-Gomes, J.; Magrinho, M. Red clay brick and tungsten mining waste-based alkali-activated binder: Microstructural and mechanical properties. Constr. Build. Mater. 2018, 190, 1034–1048. [Google Scholar] [CrossRef]

- Ma, Y.; Ye, G. The shrinkage of Alkali activated fly ash. Cem. Concr. Res. 2015, 68, 75–82. [Google Scholar] [CrossRef]

- Mastali, M.; Kinnunen, P.; Dalvand, A.; Mohammadi Firouz, R.; Illikainen, M. Drying shrinkage in alkali-activated binders—A critical review. Const. Build. Mater. 2018, 190, 533–550. [Google Scholar] [CrossRef]

| Precursor | C 10 (µm) | C 50 (µm) | C 90 (µm) | Surface Area—BET (m2/g) |

|---|---|---|---|---|

| Slag A | 0.80 | 5.94 | 28.71 | 7.61 |

| Slag R | 0.83 | 5.45 | 24.75 | 3.52 |

| Sample Designation | Slag A [wt %] | Slag R [wt %] | K2SiO3 [wt %] | Ratio of (Na+K)/Al/Si in Precursors | Ratio of (Na+K)/Al/Si in Prepared Mixture |

|---|---|---|---|---|---|

| A/R: 1/0 | 66.6 | / | 33.3 | 0.08:1:1 | 1.4:1:3.33 |

| A/R: 3/1 | 49.9 | 16.7 | 33.3 | 0.09:1:1.4 | 1.52:1:3.21 |

| A/R: 1/1 | 33.3 | 33.3 | 33.3 | 0.11:1:1.09 | 1.67:1:3.07 |

| A/R: 1/3 | 16.7 | 49.9 | 33.3 | 0.13:1:0.72 | 1.84:1:2.9 |

| A/R: 0/1 | / | 66.6 | 33.3 | 0.15:1:0.23 | 2.05:1:2.69 |

| Elements (wt %) | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | Na2O | K2O | Cr2O3 | MnO | LOI | OTH |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Slag A | 21.05 | 8.54 | 11.37 | 20.87 | 14.87 | 0.13 | 0.17 | 3.76 | 2.24 | 14.15 | 2.80 |

| Slag R | 13.69 | 5.20 | 4.64 | 27.85 | 23.25 | 0.28 | 0.14 | 0.18 | 0.62 | 20.47 | 4.43 |

| R.T. | 50/1 | 50/3 | 70/1 | 70/3 | 90/1 | 90/3 | |

|---|---|---|---|---|---|---|---|

| Total pore area [m2/g] | 2.12 | 2.06 | 2.11 | 2.03 | 2.61 | 2.19 | 2.17 |

| Porosity [%] | 19.51 | 20.10 | 18.71 | 22.92 | 17.02 | 15.88 | 15.41 |

| Median Pore Diameter (Volume) [µm] | 0.91 | 1.02 | 1.02 | 1.20 | 1.33 | 1.31 | 1.13 |

| Median Pore Diameter (Area) [µm] | 0.017 | 0.008 | 0.006 | 0.008 | 0.151 | 0.004 | 0.113 |

| Average Pore Diameter (4V/A) [µm] | 0.23 | 0.05 | 0.04 | 0.07 | 0.50 | 0.14 | 0.39 |

| Apparent (skeletal) Density [g/mL] | 2.63 | 2.59 | 2.59 | 2.63 | 2.61 | 2.60 | 2.57 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Češnovar, M.; Traven, K.; Horvat, B.; Ducman, V. The Potential of Ladle Slag and Electric Arc Furnace Slag use in Synthesizing Alkali Activated Materials; the Influence of Curing on Mechanical Properties. Materials 2019, 12, 1173. https://doi.org/10.3390/ma12071173

Češnovar M, Traven K, Horvat B, Ducman V. The Potential of Ladle Slag and Electric Arc Furnace Slag use in Synthesizing Alkali Activated Materials; the Influence of Curing on Mechanical Properties. Materials. 2019; 12(7):1173. https://doi.org/10.3390/ma12071173

Chicago/Turabian StyleČešnovar, Mark, Katja Traven, Barbara Horvat, and Vilma Ducman. 2019. "The Potential of Ladle Slag and Electric Arc Furnace Slag use in Synthesizing Alkali Activated Materials; the Influence of Curing on Mechanical Properties" Materials 12, no. 7: 1173. https://doi.org/10.3390/ma12071173

APA StyleČešnovar, M., Traven, K., Horvat, B., & Ducman, V. (2019). The Potential of Ladle Slag and Electric Arc Furnace Slag use in Synthesizing Alkali Activated Materials; the Influence of Curing on Mechanical Properties. Materials, 12(7), 1173. https://doi.org/10.3390/ma12071173