Influence of Ammonium Polyphosphate/Lignin Ratio on Thermal and Fire Behavior of Biobased Thermoplastic: The Case of Polyamide 11

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Processing

2.2. Blends Preparation

2.3. Thermal Decomposition

2.4. Fire Reaction

3. Results and Discussion

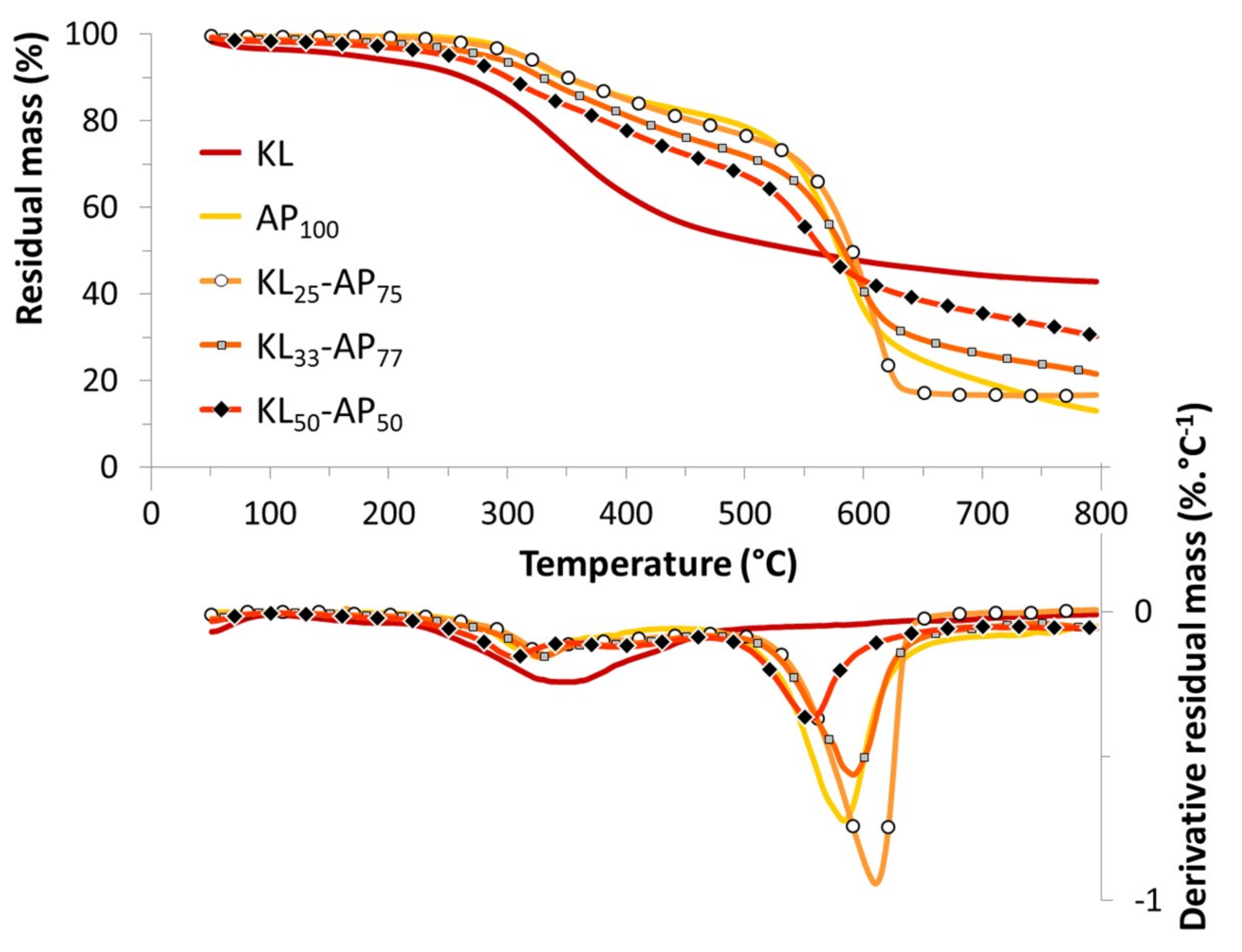

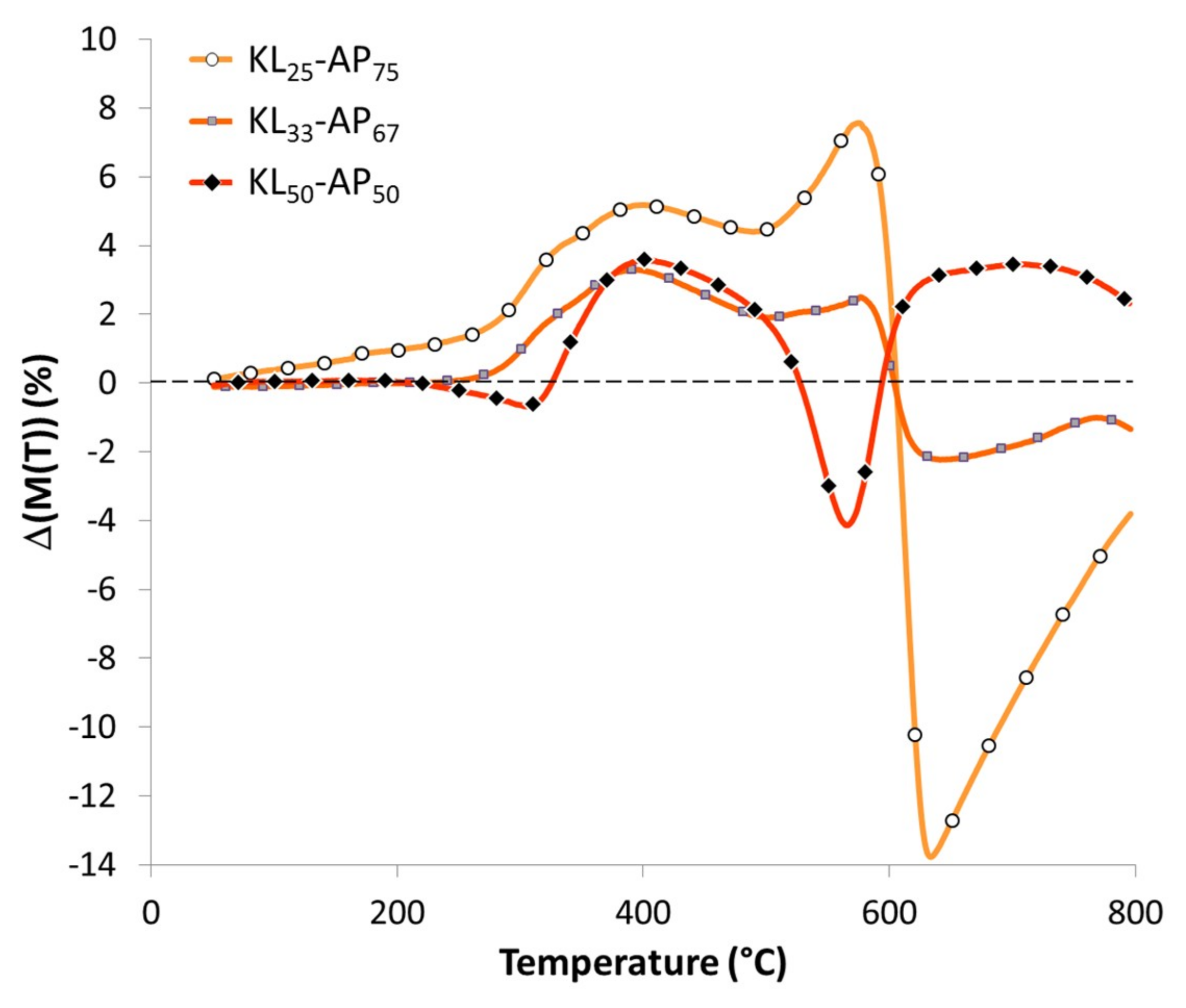

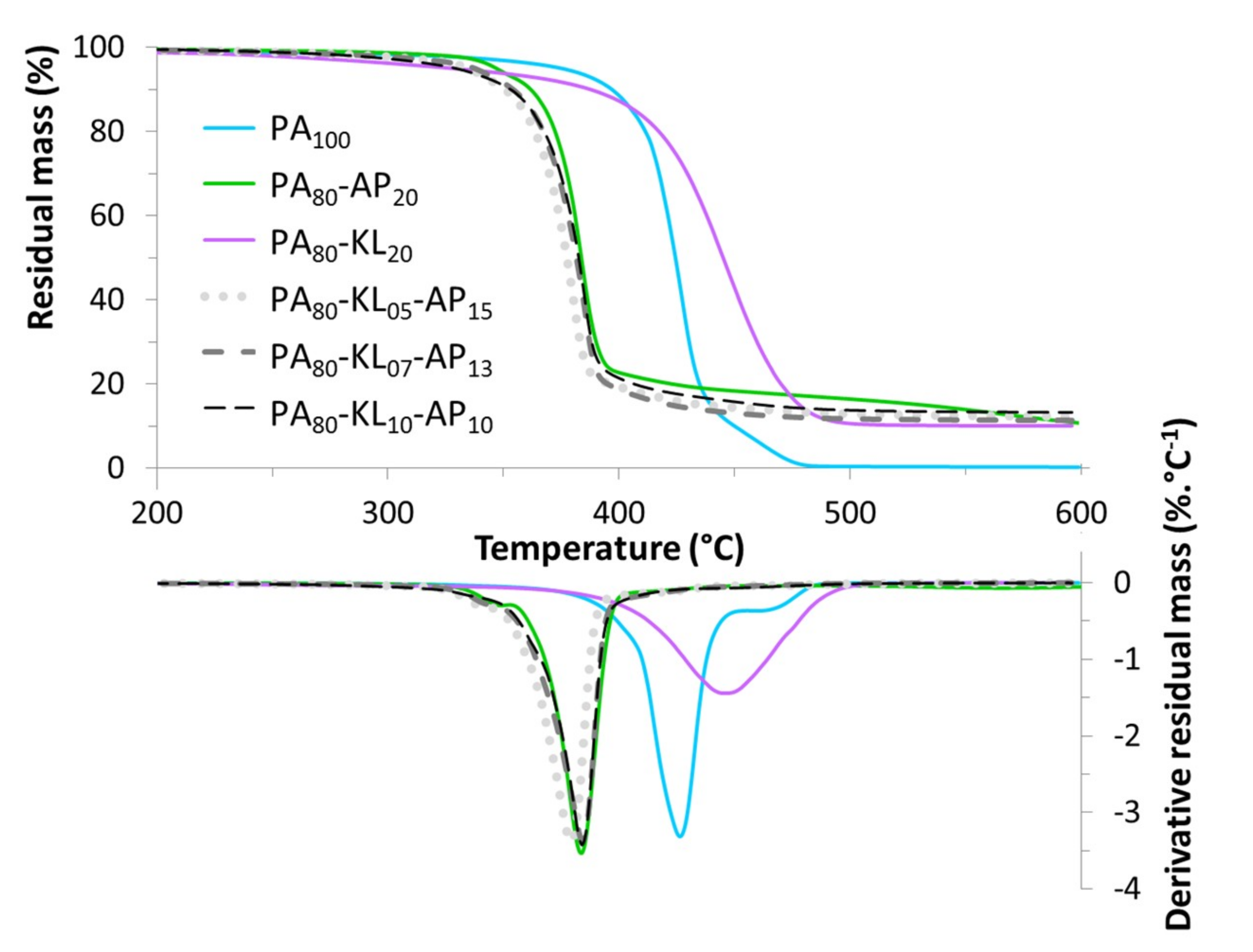

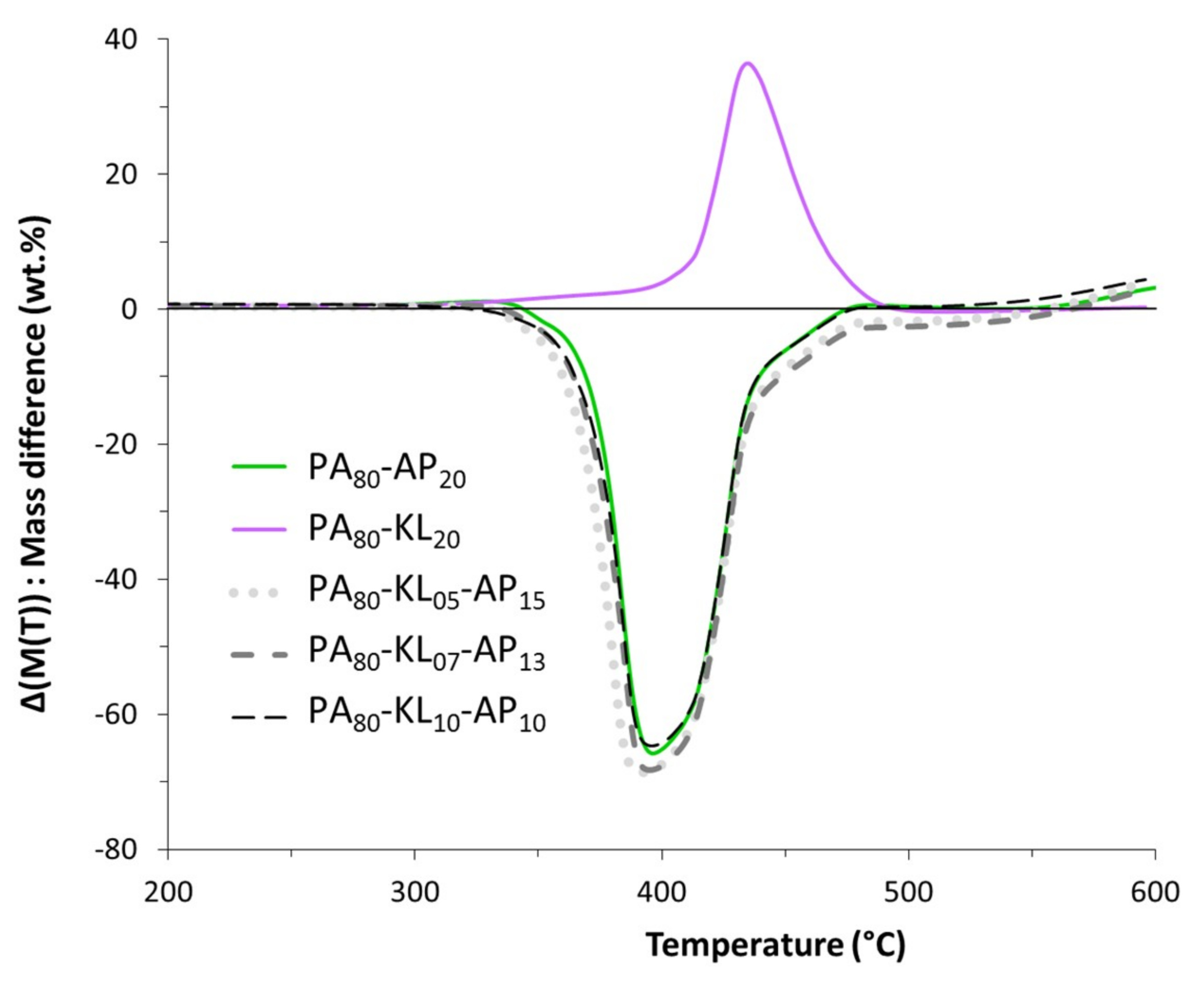

3.1. Thermal Degradation

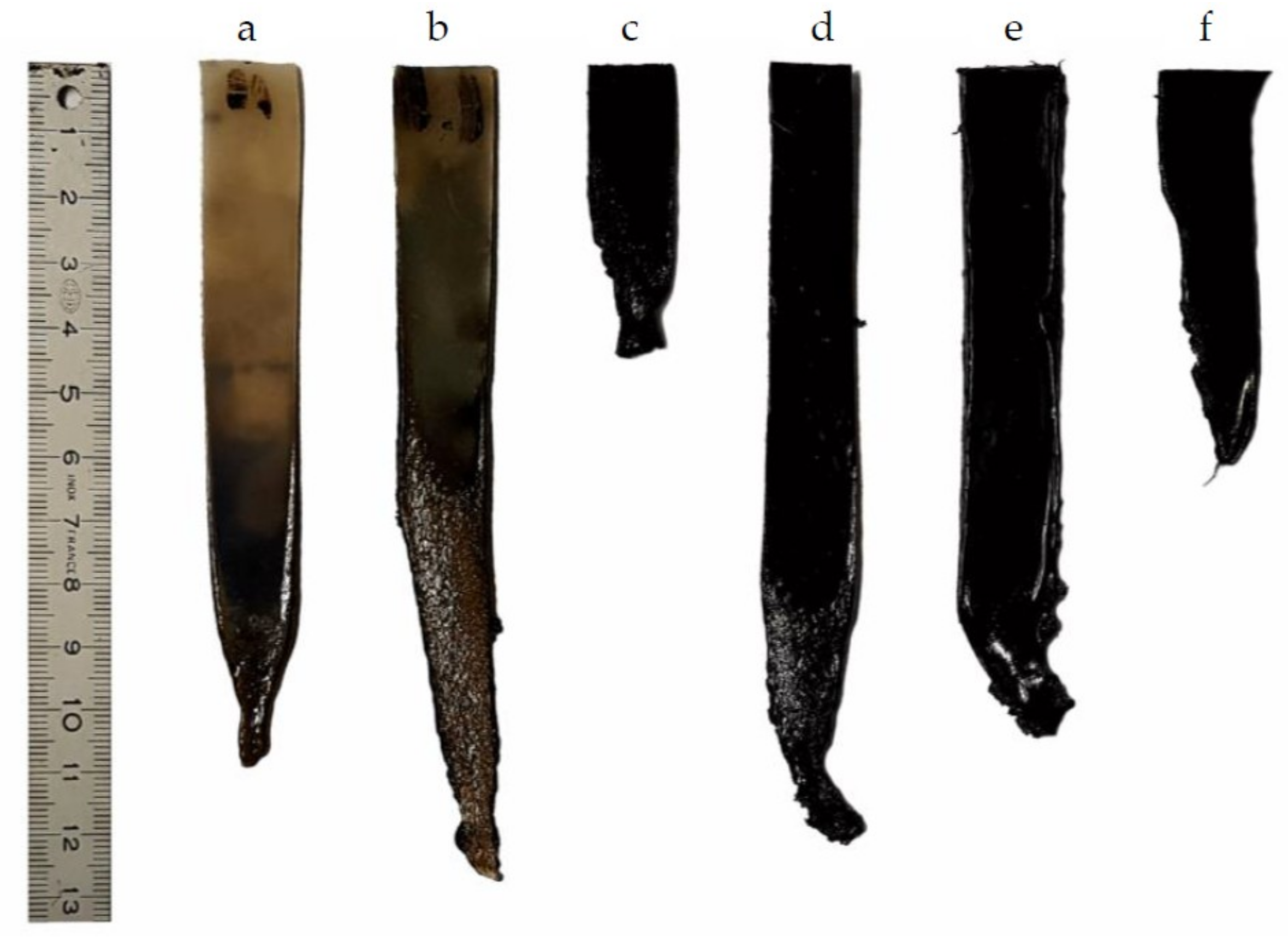

3.2. Flammability Behavior

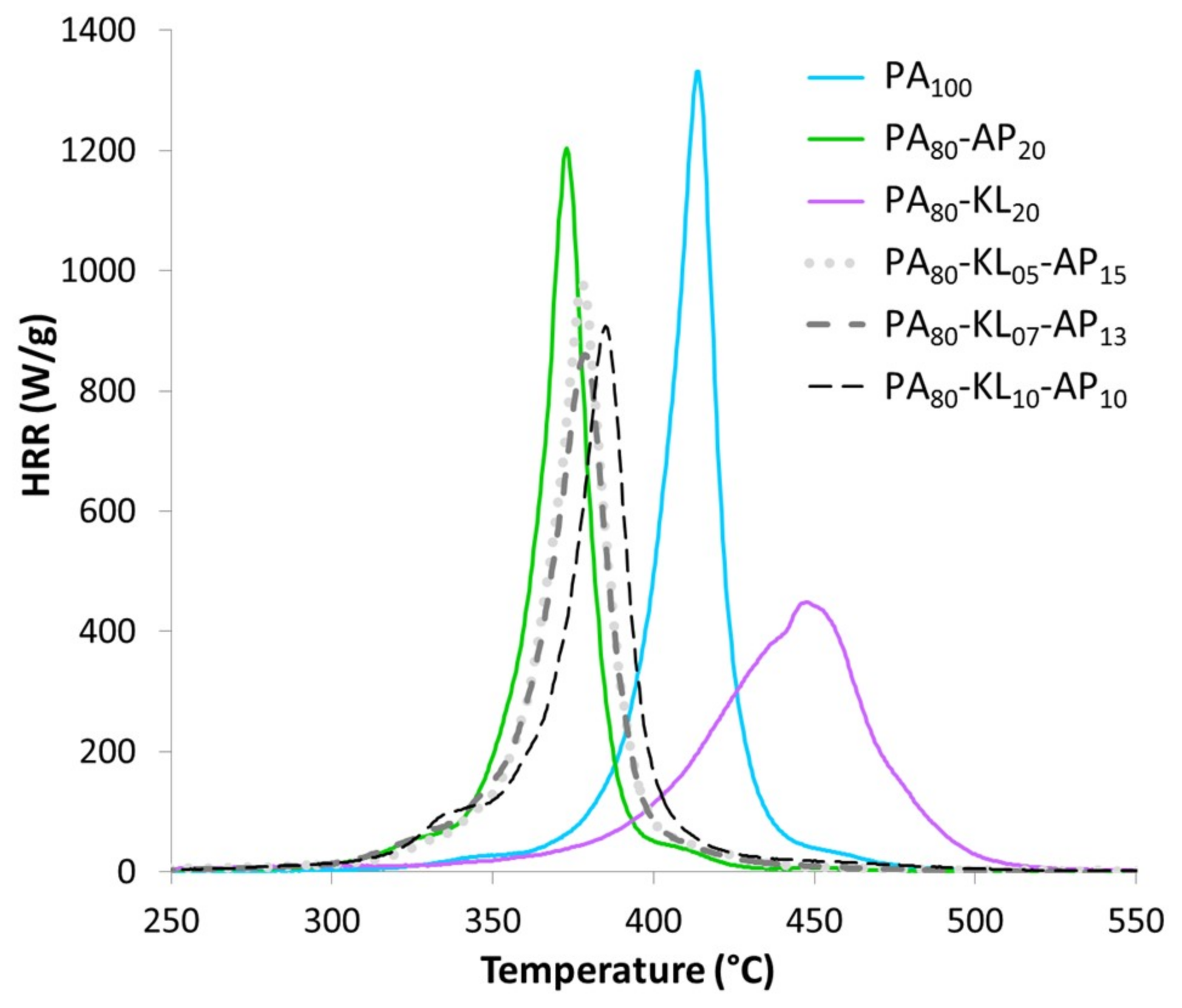

3.3. Combustion Behavior

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hobbs, C.E. Recent advances in bio-based flame retardant additives for synthetic polymeric materials. Polymers 2019, 11, 224. [Google Scholar] [CrossRef]

- Réti, C.; Casetta, M.; Duquesne, S.; Bourbigot, S.; Delobel, R. Flammability properties of intumescent PLA including starch and lignin. Polym. Adv. Technol. 2008, 19, 628–635. [Google Scholar] [CrossRef]

- Wang, X.; Hu, Y.; Song, L.; Xuan, S.; Xing, W.; Bai, Z.; Lu, H. Flame retardancy and thermal degradation of intumescent flame retardant poly(lactic acid)/starch Biocomposites. Ind. Eng. Chem. Res. 2011, 50, 713–720. [Google Scholar] [CrossRef]

- Maqsood, M.; Seide, G. Investigation of the flammability and thermal stability of halogen-free intumescent system in biopolymer composites containing biobased carbonization agent and mechanism of their char formation. Polymers 2018, 11, 48. [Google Scholar] [CrossRef]

- Feng, J.-X.; Su, S.-P.; Zhu, J. An intumescent flame retardant system using β-cyclodextrin as a carbon source in polylactic acid (PLA). Polym. Adv. Technol. 2011, 22, 1115–1122. [Google Scholar] [CrossRef]

- Wang, X.; Xing, W.; Wang, B.; Wen, P.; Song, L.; Hu, Y.; Zhang, P. Comparative Study on the Effect of Beta-Cyclodextrin and Polypseudorotaxane As Carbon Sources on the Thermal Stability and Flame Retardance of Polylactic Acid. Ind. Eng. Chem. Res. 2013, 52, 3287–3294. [Google Scholar] [CrossRef]

- Vahabi, H.; Shabanian, M.; Aryanasab, F.; Laoutid, F.; Benali, S.; Saeb, M.R.; Seidi, F.; Kandola, B.K. Three in one: β-cyclodextrin, nanohydroxyapatite, and a nitrogen-rich polymer integrated into a new flame retardant for poly (lactic acid). Fire Mater. 2018, 42, 593–602. [Google Scholar] [CrossRef]

- Chen, C.; Gu, X.; Jin, X.; Sun, J.; Zhang, S. The effect of chitosan on the flammability and thermal stability of polylactic acid/ammonium polyphosphate biocomposites. Carbohydr. Polym. 2017, 157, 1586–1593. [Google Scholar] [CrossRef]

- Costes, L.; Laoutid, F.; Brohez, S.; Dubois, P. Bio-based flame retardants: When nature meets fire protection. Mater. Sci. Eng. R Reports 2017, 117, 1–25. [Google Scholar] [CrossRef]

- Ferry, L.; Dorez, G.; Taguet, A.; Otazaghine, B.; Lopez-Cuesta, J.M. Chemical modification of lignin by phosphorus molecules to improve the fire behavior of polybutylene succinate. Polym. Degrad. Stab. 2015, 113, 135–143. [Google Scholar] [CrossRef]

- Wu, W.; He, H.; Liu, T.; Wei, R.; Cao, X.; Sun, Q.; Venkatesh, S.; Yuen, R.K.K.; Roy, V.A.L.; Li, R.K.Y. Synergetic enhancement on flame retardancy by melamine phosphate modified lignin in rice husk ash filled P34HB biocomposites. Compos. Sci. Technol. 2018, 168, 246–254. [Google Scholar] [CrossRef]

- Zhang, R.; Xiao, X.; Tai, Q.; Huang, H.; Hu, Y. Modification of lignin and its application as char agent in intumescent flame-retardant poly(lactic acid). Polym. Eng. Sci. 2012, 52, 2620–2626. [Google Scholar] [CrossRef]

- Zhang, R.; Xiao, X.; Tai, Q.; Huang, H.; Yang, J.; Hu, Y. Preparation of lignin–silica hybrids and its application in intumescent flame-retardant poly(lactic acid) system. High Perform. Polym. 2012, 24, 738–746. [Google Scholar] [CrossRef]

- Zhang, R.; Xiao, X.; Tai, Q.; Huang, H.; Yang, J.; Hu, Y. The effect of different organic modified montmorillonites (OMMTs) on the thermal properties and flammability of PLA/MCAPP/lignin systems. J. Appl. Polym. Sci. 2013, 127, 4967–4973. [Google Scholar] [CrossRef]

- Cayla, A.; Rault, F.; Giraud, S.; Salaün, F.; Fierro, V.; Celzard, A. PLA with intumescent system containing lignin and ammonium polyphosphate for flame retardant textile. Polymers 2016, 8, 331. [Google Scholar] [CrossRef]

- Costes, L.; Laoutid, F.; Brohez, S.; Delvosalle, C.; Dubois, P. Phytic acid–lignin combination: A simple and efficient route for enhancing thermal and flame retardant properties of polylactide. Eur. Polym. J. 2017, 94, 270–285. [Google Scholar] [CrossRef]

- Song, Y.; Zong, X.; Wang, N.; Yan, N.; Shan, X.; Li, J. Preparation of γ-Divinyl-3-Aminopropyltriethoxysilane modified lignin and its application in flame retardant poly(lactic acid). Materials 2018, 11, 1505. [Google Scholar] [CrossRef]

- Mandlekar, N.; Cayla, A.; Rault, F.; Giraud, S.; Salaün, F.; Malucelli, G.; Guan, J. Thermal stability and fire retardant properties of Polyamide 11 microcomposites containing different lignins. Ind. Eng. Chem. Res. 2017, 56. [Google Scholar] [CrossRef]

- Mandlekar, N.; Malucelli, G.; Cayla, A.; Rault, F.; Giraud, S.; Salaün, F.; Guan, J. Fire retardant action of zinc phosphinate and polyamide 11 blend containing lignin as a carbon source. Polym. Degrad. Stab. 2018, 153, 63–74. [Google Scholar] [CrossRef]

- Mandlekar, N.; Cayla, A.; Rault, F.; Giraud, S.; Salaün, F.; Guan, J. Valorization of industrial lignin as biobased carbon source in fire retardant system for Polyamide 11 blends. Polymers 2019, 11, 180. [Google Scholar] [CrossRef]

- Levchik, S.V.; Costa, L.; Camino, G. Effect of the fire-retardant, ammonium polyphosphate, on the thermal decomposition of aliphatic polyamides. I. Polyamides 11 and 12. Polym. Degrad. Stab. 1992, 36, 31–41. [Google Scholar] [CrossRef]

- Troitzsch, J. Plastics Flammability Handbook: Principles, Regulations, Testing, and Approval, 3rd ed.; Carl Hanser Verlag: Munich, Germany, 2004; pp. 514–516. [Google Scholar]

- Lyon, R.E.; Walters, R.N. Pyrolysis combustion flow calorimetry. J. Anal. Appl. Pyrolysis 2004, 71, 27–46. [Google Scholar] [CrossRef]

- Brebu, M.; Vasile, C. Thermal Degradation of Lignin—A review. Cellul. Chem. Technol. 2010, 44, 353–363. [Google Scholar]

- Rodrigues, J.; Graça, J.; Pereira, H. Influence of tree eccentric growth on syringyl/guaiacyl ratio in Eucalyptus globulus wood lignin assessed by analytical pyrolysis. J. Anal. Appl. Pyrolysis 2001, 58–59, 481–489. [Google Scholar] [CrossRef]

- Wittkowski, R.; Ruther, J.; Drinda, H.; Rafiei-Taghanaki, F. Formation of smoke flavor compounds by thermal lignin degradation. In Proceedings of the ACS Symposium Series; American Chemical Society (ACS): Washington, DC, USA, 1992; Volume 490, pp. 232–243. [Google Scholar]

- Kandola, B.K.; Horrocks, A.R. Complex char formation in flame-retarded fibre-intumescent combinations—II. Thermal analytical studies. Polym. Degrad. Stab. 1996, 54, 289–303. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, F.; Chen, X.; Jin, Y.; Zhang, J. Burning and dripping behaviors of polymers under the UL94 verticla burning test conditions. Fire Mater. 2010, 34, 203–215. [Google Scholar] [CrossRef]

- 29 Joseph, P.; Tretsiakova-McNally, S. Melt-flow behaviours of thermoplastic materials under fire conditions: Recent experimental studies and some theoretical approaches. Materials 2015, 8, 8793–8803. [Google Scholar] [CrossRef]

- Dorez, G.; Ferry, L.; Sonnier, R.; Taguet, A.; Lopez-Cuesta, J.-M. Effect of cellulose, hemicellulose and lignin contents on pyrolysis and combustion of natural fibers. J. Anal. Appl. Pyrolysis 2014, 107, 323–331. [Google Scholar] [CrossRef]

| Sample | PA (wt. %) | KL (wt. %) | AP (wt. %) |

|---|---|---|---|

| KL25-AP75 | - | 25 | 75 |

| KL33-AP67 | - | 33 | 67 |

| KL50-AP50 | - | 50 | 50 |

| PA100 | 100 | - | - |

| PA80-KL20 | 80 | 20 | - |

| PA80-AP20 | 80 | - | 20 |

| PA80-KL05-AP15 | 80 | 5 | 15 |

| PA80-KL07-AP13 | 80 | 7 | 13 |

| PA80-KL10-AP10 | 80 | 10 | 10 |

| Samples | T5% (°C) | T50% (°C) | Tmax (°C) & Rmax (%·°C−1) | Residue (%)1 | ||

|---|---|---|---|---|---|---|

| Step I | Step II | Step III | 800 °C | |||

| KL | 185 | 551 | 355 0.2433 | - | - | 43.0 |

| AP | 311 | 586 | 327 0.1345 | 583 0.7235 | - | 13.0 |

| KL50-AP50 | 260 | 570 | 305 0.1571 | 386 0.1210 | 557 0.3696 | 33.0 (28.0) |

| KL33-AP67 | 280 | 578 | 328 0.1557 | 593 0.5613 | - | 23.7 (23.0) |

| KL25-AP75 | 314 | 590 | 333 0.1487 | 611 0.9401 | - | 16.5 (20.5) |

| Samples | T5% (°C) | T50% (°C) | Tmax (°C) & Rmax (%·°C−1) | Residue (%)1 | ||

|---|---|---|---|---|---|---|

| Step I | Step II | Step III | 600 °C | |||

| PA100 | 375 | 424 | 426 3.320 | 463 0.361 | - | 0.2 |

| PA80-AP20 | 347 | 383 | 384 3.485 | - | - | 10.7 (7.3) |

| PA80-KL20 | 325 | 445 | 445 1.443 | - | - | 10.0 (9.5) |

| PA80-KL05-AP15 | 335 | 377 | 379 3.888 | - | - | 12.3 (8.4) |

| PA80-KL07-AP13 | 336 | 381 | 384 3.381 | - | - | 11.3 (8.1) |

| PA80-KL10-AP10 | 329 | 382 | 384 3.431 | - | - | 13.3 (8.6) |

| Samples | 1st Flame t1 (s) | 2nd Flame t2 (s) | Combustion Time (t1+t2) | Cotton Ignition | Rating | Mass Loss (%) |

|---|---|---|---|---|---|---|

| PA100 | 1.6 ± 0.4 | 2.4 ± 0.6 | 4.0 ± 1.0 | Yes | V2 | 33.7 ± 10.9 |

| PA80-AP20 | 8.9 ± 5.9 | 4.8 ± 1.6 | 13.7 ± 5.7 | Yes | V2 | 34.7 ± 4.9 |

| PA80-KL20 | 1.1 ± 0.1 | 14.4 ± 11.3 | 15.5 ± 11.5 | Yes | V2 | 64.1 ± 3.3 |

| PA80-KL05-AP15 | 1.9 ± 0.9 | 2.7 ± 1.4 | 4.6 ± 1.9 | Yes | V2 | 21.4 ± 3.3 |

| PA80-KL07-AP13 | 3.0 ± 2.2 | 7.0 ± 1.9 | 10.0 ± 1.2 | Yes | V2 | 19.1 ± 4.5 |

| PA80-KL10-AP10 | 6.6 ± 0.7 | 22.8 ± 5.9 | 29.4 ± 6.5 | Yes | V2 | 81.5 ± 16.6 |

| Samples | pHRR (W/g) | pHRR Reduction (%) | pHRR Temperature (°C) | THR (KJ/g) | THR Reduction (%) | Residue (%) | Δh (KJ/g) |

|---|---|---|---|---|---|---|---|

| PA100 | 1293 ± 39 | - | 413 ± 2 | 32.4 ± 0.1 | - | 3.2 ± 0.3 | 33.6 ± 0.4 |

| PA80-AP20 | 1108 ± 92 | 14 | 382 ± 3 | 29.3 ± 0.4 | 10 | 11.4 ± 0.0 | 33.0 ± 0.4 |

| PA80-KL20 | 442 ± 5 | 66 | 451 ± 2 | 28.3 ± 0.1 | 13 | 11.0 ± 0.2 | 31.7 ± 0.1 |

| PA80-KL05-AP15 | 993 ± 30 | 23 | 380 ± 1 | 27.9 ± 0.2 | 14 | 14.4 ± 0.4 | 32.6 ± 0.4 |

| PA80-KL07-AP13 | 908 ± 47 | 30 | 379 ± 0 | 26.8 ± 0.5 | 17 | 13.9 ± 0.1 | 31.1 ± 0.6 |

| PA80-KL10-AP10 | 924 ± 19 | 29 | 383 ± 2 | 26.9 ± 0.9 | 17 | 12.1 ± 0.3 | 30.5 ± 0.4 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cayla, A.; Rault, F.; Giraud, S.; Salaün, F.; Sonnier, R.; Dumazert, L. Influence of Ammonium Polyphosphate/Lignin Ratio on Thermal and Fire Behavior of Biobased Thermoplastic: The Case of Polyamide 11. Materials 2019, 12, 1146. https://doi.org/10.3390/ma12071146

Cayla A, Rault F, Giraud S, Salaün F, Sonnier R, Dumazert L. Influence of Ammonium Polyphosphate/Lignin Ratio on Thermal and Fire Behavior of Biobased Thermoplastic: The Case of Polyamide 11. Materials. 2019; 12(7):1146. https://doi.org/10.3390/ma12071146

Chicago/Turabian StyleCayla, Aurélie, François Rault, Stéphane Giraud, Fabien Salaün, Rodolphe Sonnier, and Loïc Dumazert. 2019. "Influence of Ammonium Polyphosphate/Lignin Ratio on Thermal and Fire Behavior of Biobased Thermoplastic: The Case of Polyamide 11" Materials 12, no. 7: 1146. https://doi.org/10.3390/ma12071146

APA StyleCayla, A., Rault, F., Giraud, S., Salaün, F., Sonnier, R., & Dumazert, L. (2019). Influence of Ammonium Polyphosphate/Lignin Ratio on Thermal and Fire Behavior of Biobased Thermoplastic: The Case of Polyamide 11. Materials, 12(7), 1146. https://doi.org/10.3390/ma12071146