3.1. Morphology

The morphology of keratin and coconut fibres, APP additive and the composites was studied by Scanning Electron Microscopy (SEM).

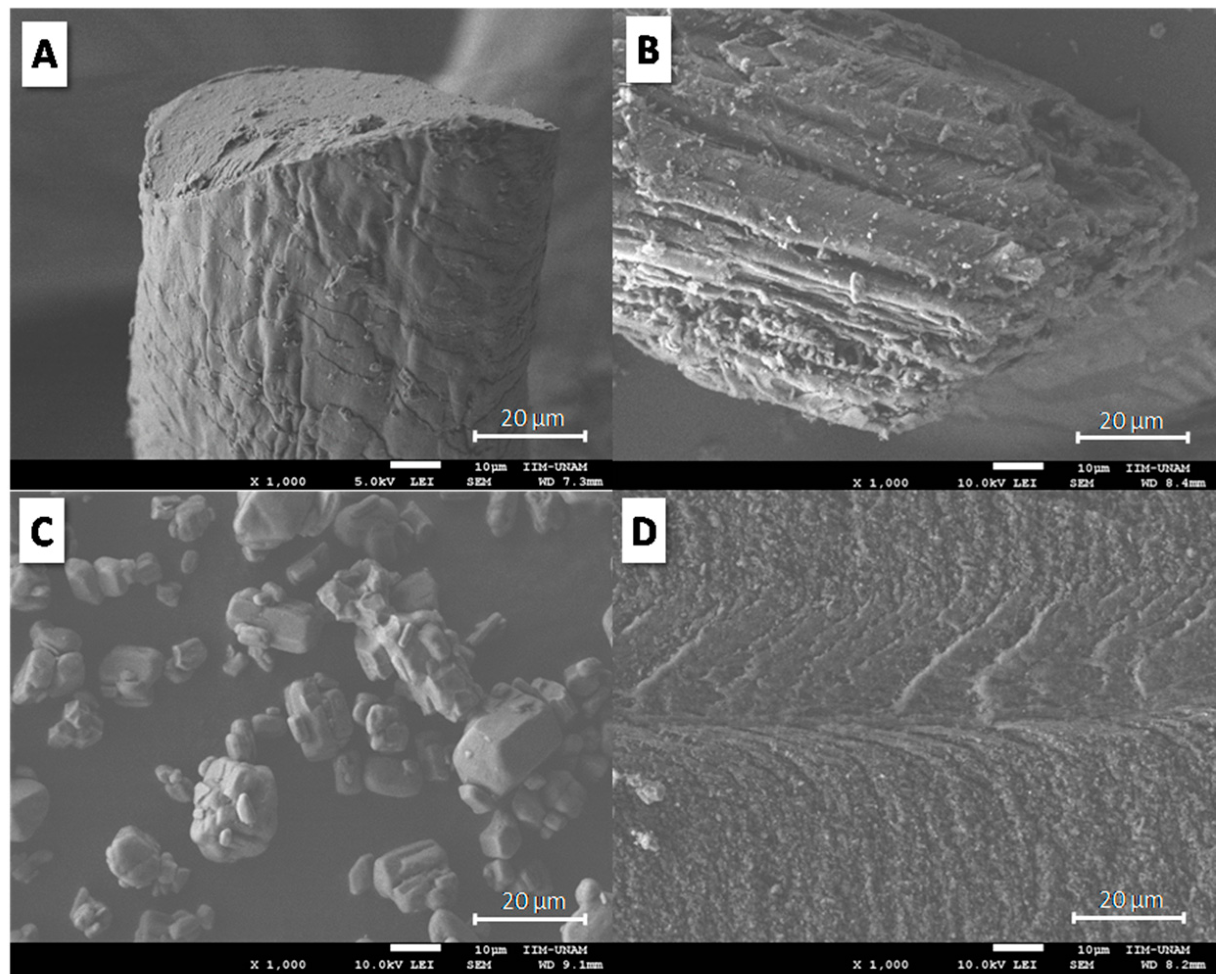

Figure 1 displays the morphology of keratin (

Figure 1A) and coconut (

Figure 1B) fibres, as well as APP (

Figure 1C) and TPS (

Figure 1D). According to

Figure 1A, keratin fibre shows a cylindrical shape, with a diameter of approximately 80 µm; overlapped layers on the keratin fibre surface are clearly observed. Coconut fibre morphology (

Figure 1B) presents a width of approximately 80 µm and consists of microfibres of different widths (approximately 10–15 µm) [

27].

Figure 1C reveals APP morphology. According to the APP micrograph, agglomerates, irregularly shaped particles and different particle sizes (approximately 5–18 µm) are observed.

Figure 1D displays the morphology of the fractured surface of the TPS matrix. The TPS micrograph shows well-defined fractured planes, characterized by thin layers oriented toward the direction of fracture. According to

Figure 1D, TPS morphology exhibits a ductile fracture surface.

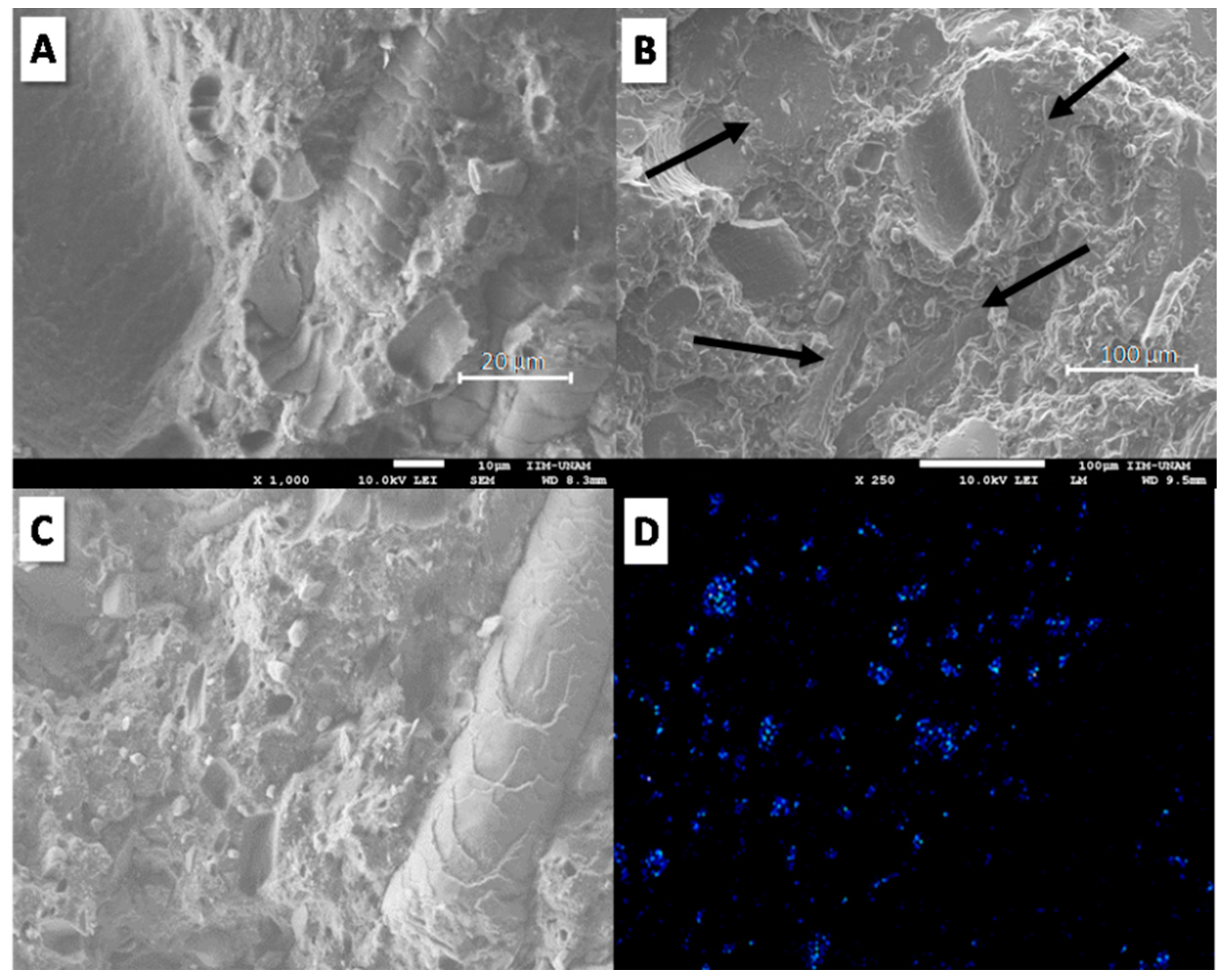

Figure 2 shows the morphology of fractured surfaces for TPP/20KF (

Figure 2A,C) and TPS/20CF (

Figure 2B,D) at two different magnifications. According to the SEM micrograph in

Figure 2A,B, TPS loaded with 20 wt. % KF shows interstices around KF and empty holes caused by fibre extraction. Different fibre sizes were observed, with lengths of around 40–100 µm and diameters of approximately 30–50 µm. A similar morphology was observed for TPS/20CF composite in

Figure 2C,D, where spaces around CF and footprints of fibre extraction are apparent. Coconut fibres showed a width of around 40–85 µm. According to

Figure 2, the morphology of TPS/20KF and TPS/20CF suggests that fibres act as fillers in TPS without any relevant chemical or physical interactions.

Figure 3 shows SEM micrographs of the fractured surface of TPS using 20 wt. % APP. According to

Figure 3A,B, APP additive exhibits poor adhesion with TPS, characterized by empty holes and interstices between the particles and the polymer. However, APP particles showed good dispersion in the polymer matrix; even though large particle sizes (around 20 µm) were observed, no APP agglomerates were visible. This morphology was achieved by the double extrusion process to obtain the well-dispersed TPS composites. In order to confirm the presence and dispersion of APP particles on the fractured surface of TPS, phosphorus elemental analysis was carried out by energy dispersive spectroscopy (EDS) of TPS/20APP composite (

Figure 3C,D). Good dispersion of the phosphorus is shown by EDS analysis of the TPS/20APP fractured surface.

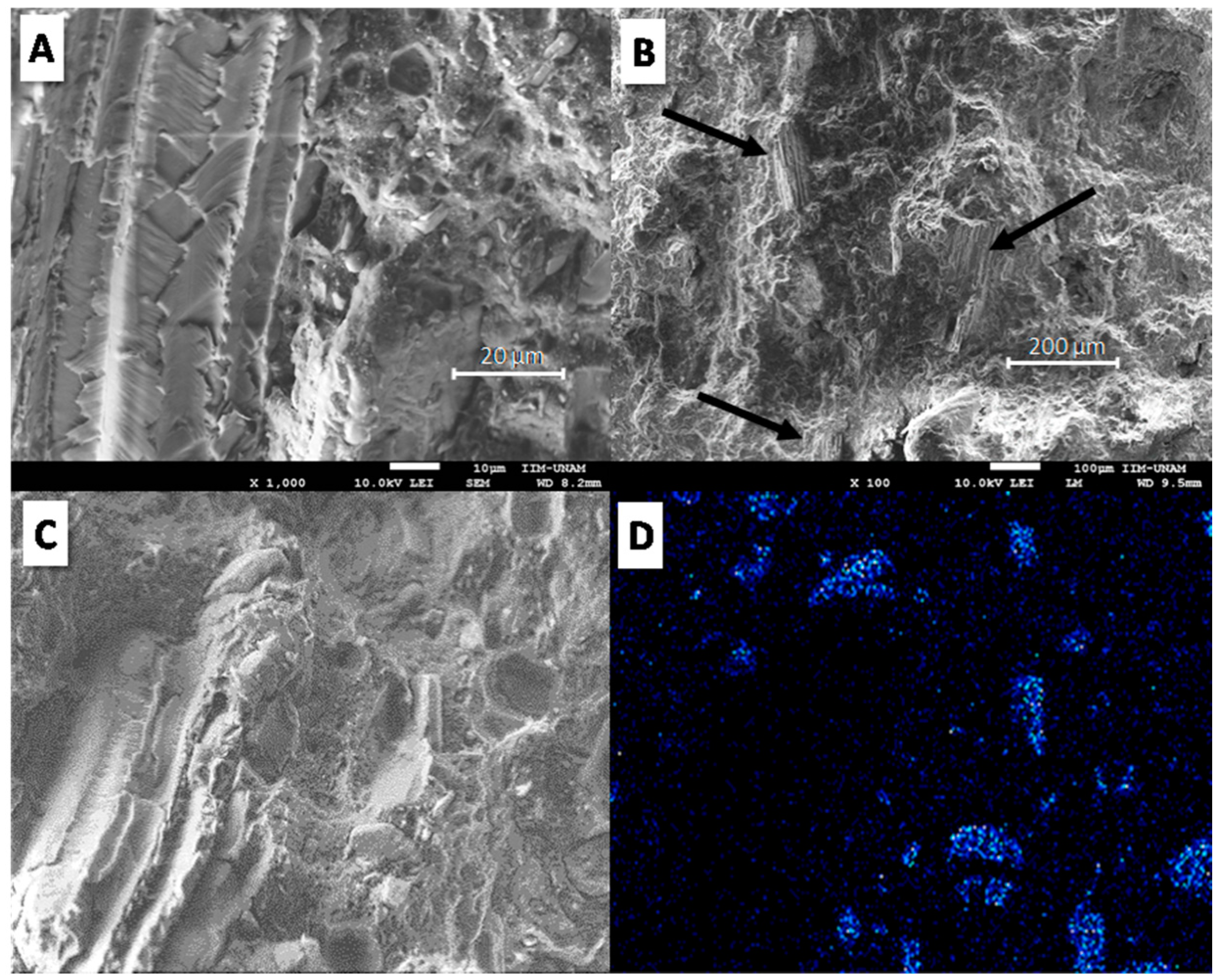

Figure 4 reveals the morphology of the fractured surface at different points and phosphorus elemental analysis of the TPS/20KF/10APP composite. According to

Figure 4A,B, keratin fibres appear well embedded in the polymer matrix (indicated by black arrows); no interstices around the fibres were observed. With respect to APP particles, rather poor adhesion on the fractured surface was still apparent.

Figure 4C,D shows the SEM image and the mapping of phosphorus in TPS/20KF/10APP; the micrographs reveal the presence and dispersion of APP particles.

Figure 5 presents SEM micrographs and phosphorus elemental analysis of the fractured surfaces of the TPS/20CF/10APP composite.

Figure 5A,B reveals dispersed coconut fibre and shows improved mechanical coupling around the fibre.

Figure 5C,D illustrates the presence of APP particles with rather poor adhesion with the polymer matrix. According to morphological analyses of TPS/20KF/10APP and TPS/20CF/10APP composites (

Figure 4 and

Figure 5 respectively), fibres added in combination with APP appeared better embedded on the polymer matrix than the composites without APP additive, probably because the higher load (30 wt. %) produces less polymer contraction in the composites.

3.2. Mechanical Properties

Table 2 presents the mechanical properties of the investigated composites. According to

Table 2, TPS shows ductile behaviour: a low Young’s modulus (128 MPa), along with high strain at break (463%), tenacity (89 MPa) and Izod impact resistance (no break), as expected since this kind of biopolymer has traditionally been used for packaging applications [

28]. Regarding the effect of keratin fibre contents on the mechanical properties of TPS composites,

Table 2 reports that increasing KF content in TPS causes a reduction in strain at break, tenacity and Izod impact resistance. As an example, when KF was added at 15 and 30 wt. % (TPS/15KF and TPS/30KF), the strain at break was reduced from 463% to 190% and 26%, tenacity from 89 MPa to 19 and 2 MPa, Izod impact resistance from no break to 397 and 81 J/m, respectively. The Young’s modulus increased from 128 MPa to 177 and 229 MPa, respectively. Tensile strength exhibited similar results for TPS/15KF and TPS/30KF composites, 11 and 10 MPa, respectively. Comparable mechanical behaviour was observed when CF was added to TPS: high CF content resulted in a high Young’s modulus along with low strain at break, tenacity and Izod impact resistance. Taking a comparison of TPS, TPS/10CF and TPS/30CF as an example, strain at break was reduced from 463% to 207 and 13%, tenacity from 89 MPa to 31 and 2 MPa, Izod impact resistance from no break to 389 and 81 J/m, each in that order. Tensile strength presented the same value, 18 MPa, for both composites (TPS/10CF and TPS/30CF). The Young’s modulus exhibited a remarkable increase, from 128 MPa to 168 and to 474 MPa, respectively, due to the high rigidity of coconut fibre [

29]. According to the results on mechanical properties (

Table 2), the increasing fibre content (KF and CF) in the TPS produced rigid and fragile materials, as already observed in natural fibre polymer composites [

30]. A compatibilizer may be used in the future to obtain better mechanical coupling.

As is well known, the addition of high content of flame retardants to polymer matrix may have a significant effect on mechanical properties [

31]. The addition of 20 and 30 wt. % APP to TPS increased brittleness, as seen in TPS/10APP and TPS/15APP. Similarly, the TPS/20APP composite showed lower tensile strength, strain at break, tenacity and Izod impact resistance than TPS. The Young’s modulus exhibited an increase from 128 to 163 MPa for TPS and TPS/20APP, respectively. The reinforcement achieved by APP is similar to that for CF.

Regarding KF in combination with the APP effect,

Table 2 reports on TPS/15KF/15APP and TPS/20KF/10APP composites with different KF and APP contents but the same total load (30 wt. %), compounded in order to replace part of the APP flame retardant additive (5 or 10 wt. %) using KF. The resulting properties exhibited a similar Young’s modulus, tensile strength and tenacity. Nevertheless, strain at break and Izod impact resistance were somewhat dependent on the composition of TPS/KF/APP: TPS/15KF/15APP exhibited 54% strain at break and 118 J/m Izod impact resistance, while TPS/20KF/10APP showed 45% strain at break and 128 J/m Izod impact resistance. Regarding CF in combination with APP (TPS/10CF/15APP and TPS/20CF/10APP composites), the mechanical properties were influenced by the CF content, as was observed in TPS/CF composites; high CF content reduced strain at break, tenacity and Izod impact resistance, while the Young’s modulus was increased.

Nevertheless, although high KF and CF content, namely 30 wt. %, produces deteriorated mechanical properties, when KF and CF fibres were added at 20 wt. % in combination with 10 wt. % APP (30 wt. % total load), the corresponding mechanical properties were slightly improved over those achieved by adding only KF or CF at 30 wt. % (TPS/30KF and TPS/30CF). The combination of 20 wt. % KF and 10 wt. % APP (TPS/20KF/10APP) produced a less fragile and more ductile material than TPS/30KF. The Young’s modulus, tensile strength, strain at break, tenacity and Izod impact resistance increased from 229 to 243 MPa, 10 to 13 MPa, 26 to 45%, 2 to 5 MPa and 81 to 128 J/m, respectively. This finding was similar to the combination of 20 wt. % CF with 10 wt. % APP (TPS/20CF/10APP) as compared to the TPS/30CF composite; strain at break and Izod impact resistance were slightly improved. In this context, the mechanical improvement in TPS/20KF/10APP and TPS/20CF/10APP composites over TPS/30KF and TPS/30CF indicates better stress transfer due to some physical fibre-polymer interactions [

32], as was observed in morphological analyses (the fibres appeared well embedded in the polymer matrix,

Figure 4 and

Figure 5).

3.3. Rheology

The rheological properties of TPS composites were assessed by oscillatory tests under continuous simple and small amplitude oscillatory shear flow (SAOS).

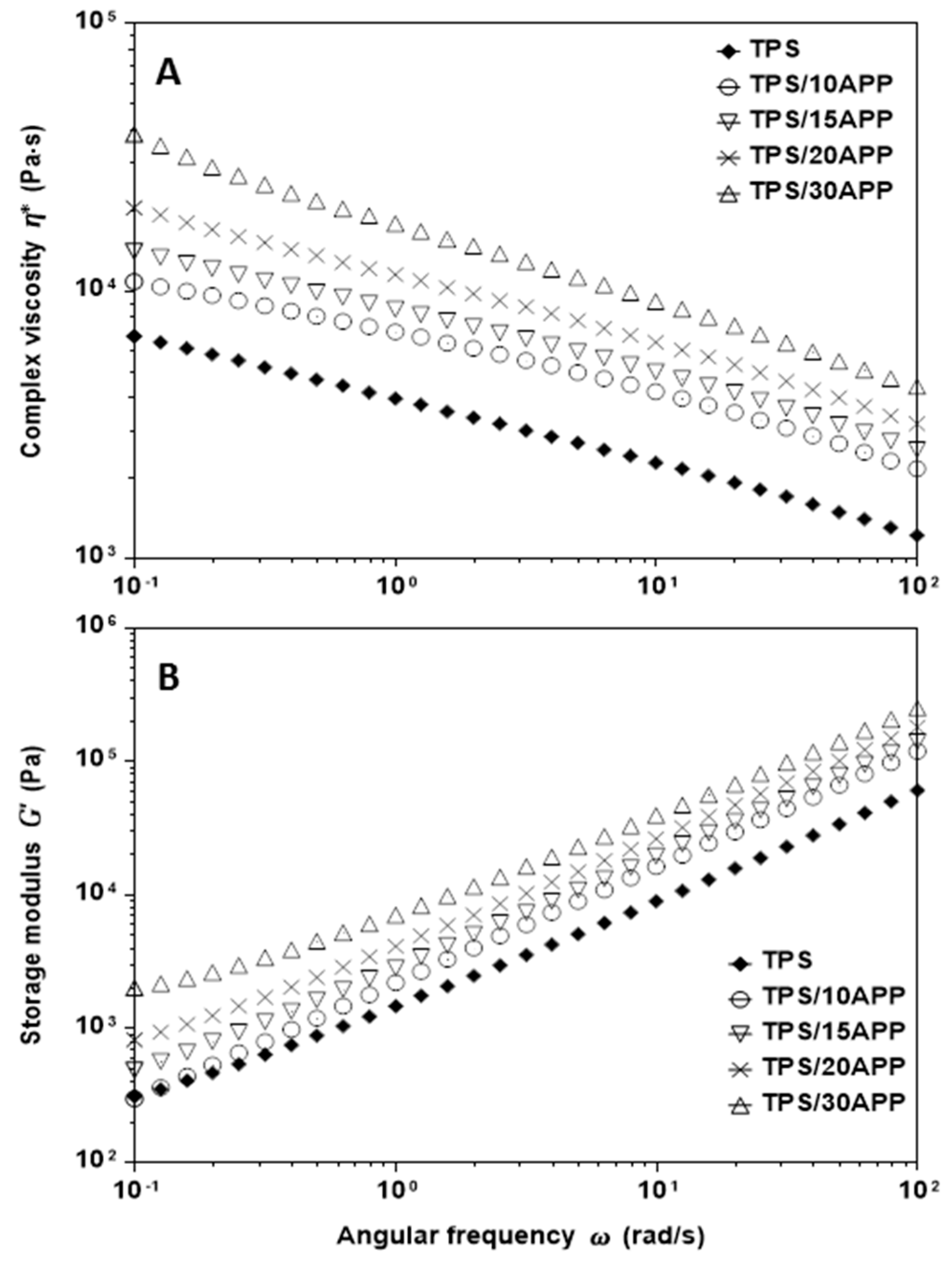

Figure 6 displays complex viscosity (

Figure 6A) and storage modulus (

Figure 6B) as a function of angular frequency for TPS with different contents of 10, 15, 20 and 30 wt. % APP (TPS, TPS/10APP, TPS/15APP, TPS/20APP and TPS/30APP). According to the data plotted in

Figure 6A, the complex viscosity of TPS and TPS/APP composites exhibited remarkable dependency on angular frequency, with complex viscosity decreasing as angular frequency increased. This behaviour is similar to the shear thinning effect observed in shear flow tests (not shown in this work). On the other hand, high APP content (20 and 30 wt. %) exerted an influence on complex viscosity throughout the entire frequency range (0.1–100 rad/s) greater than that for TPS. Regarding elastic properties,

Figure 6B shows the storage modulus as a function of the angular frequency of TPS and TPS/APP composites (at 10, 15, 20 and 30 wt. %): the storage modulus exhibited higher values for samples using 20 and 30 wt. % APP than for TPS over the entire frequency range. The highest content of APP (TPS/30APP) produced the most elastic material, observed in the low frequency range (0.1–1.0 rad/s).

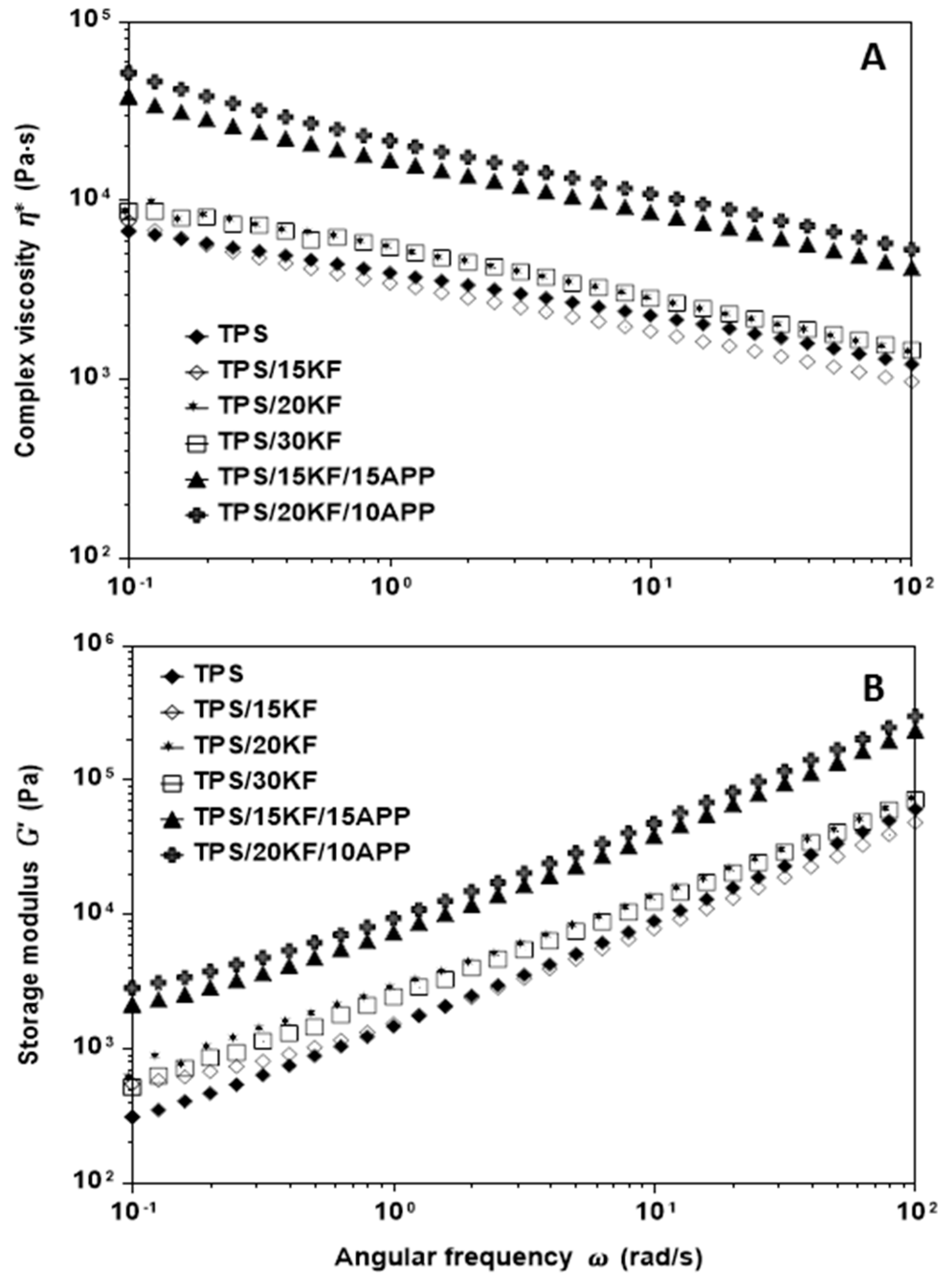

Figure 7 presents the effect of KF content and KF/APP combination on flow behaviour; complex viscosity (

Figure 7A) and storage modulus (

Figure 7B) are plotted as a function of angular frequency. Regarding the effect of KF content,

Figure 7A shows that TPS/KF composites exhibited a rheological pattern similar to TPS; in the low frequency range (0.01–0.1 rad/s) the TPS/15KF composite presented curves overlapping with TPS, whereas in the high frequency range (1.0–100 rad/s), complex viscosity was slightly lower than for TPS. Meanwhile, TPS/20KF and TPS/30KF viscosity was slightly higher than TPS over the entire frequency range. In general, for all TPS/KF composites as well as TPS, complex viscosity showed a dependency on angular frequency similar to shear thinning behaviour in simple shear flow. The shear thinning effect was observed for all TPS/KF composites regardless of KF content. In this regard, it is reasonable to think that keratin fibres are well oriented under flow, which is consistent with similar natural fibre composites [

33,

34].

Figure 7B reveals that TPS/15KF and TPS have a similar storage modulus, with the TPS/15KF and TPS curves overlapping in the 0.1–1.0 rad/s range, while the storage modulus values for TPS/20KF and TPS/30KF were slightly higher than TPS over the entire frequency range. It is interesting to observe that the rheological behaviour of composites using keratin fibres depended mainly on the composition of the materials.

Figure 7 shows that the KF and APP combination has a remarkably stronger effect on the complex viscosity and storage modulus than KF alone. When KF and APP were added to TPS (TPS/15KF/15APP and TPS/20KF/10APP), complex viscosity and storage modulus increased over those of TPS and TPS/KF composites throughout the entire frequency range. However, rheological analyses point out that when KF are added in combination with APP, processing becomes more difficult than for KF without APP.

Figure 8 displays the rheological behaviour of TPS using different contents of CF and the CF/APP combination. As it was observed for TPS, TPS/APP and TPS/KF composites, all composites using coconut fibre (

Figure 8A) showed shear thinning behaviour (complex viscosity was reduced as frequency increased). On the other hand, CF content exhibited an important effect on complex viscosity; high CF content (20 and 30 wt. %) produced much higher complex viscosity than TPS, TPS/10CF, TPS/10CF/15APP and TPS/20CF/10APP, suggesting that CF behaved as a filler without physical or chemical interaction with the polymer matrix. Regarding storage modulus,

Figure 8B shows an increase for TPS/10CF, TPS/10CF/15APP and TPS/20CF/10APP composites with reference to TPS but a storage modulus pattern similar to TPS (similar slopes). TPS/20CF and TPS/30CF composites exhibited much higher elastic properties than TPS/10CF, TPS/10CF/15APP and TPS/20CF/10APP composites. In this regard, it is possible to point out that the combination of coconut fibres with APP appears to favour the processing of these materials.

3.4. Thermal Decomposition

Thermal decomposition under nitrogen was investigated using thermogravimetric analysis. TPS as well as the formulations with CF, KF, APP and their combinations were analysed to make a statement about altered decomposition pathways. Results of the thermogravimetry are displayed in

Table 3. The temperature at 5 wt. % mass loss (Tat 5% Mass Loss) characterizes the beginning of the decomposition, the temperature at the maximum mass loss rates (Tmax) and the mass loss step (Δmass) the decomposition steps.

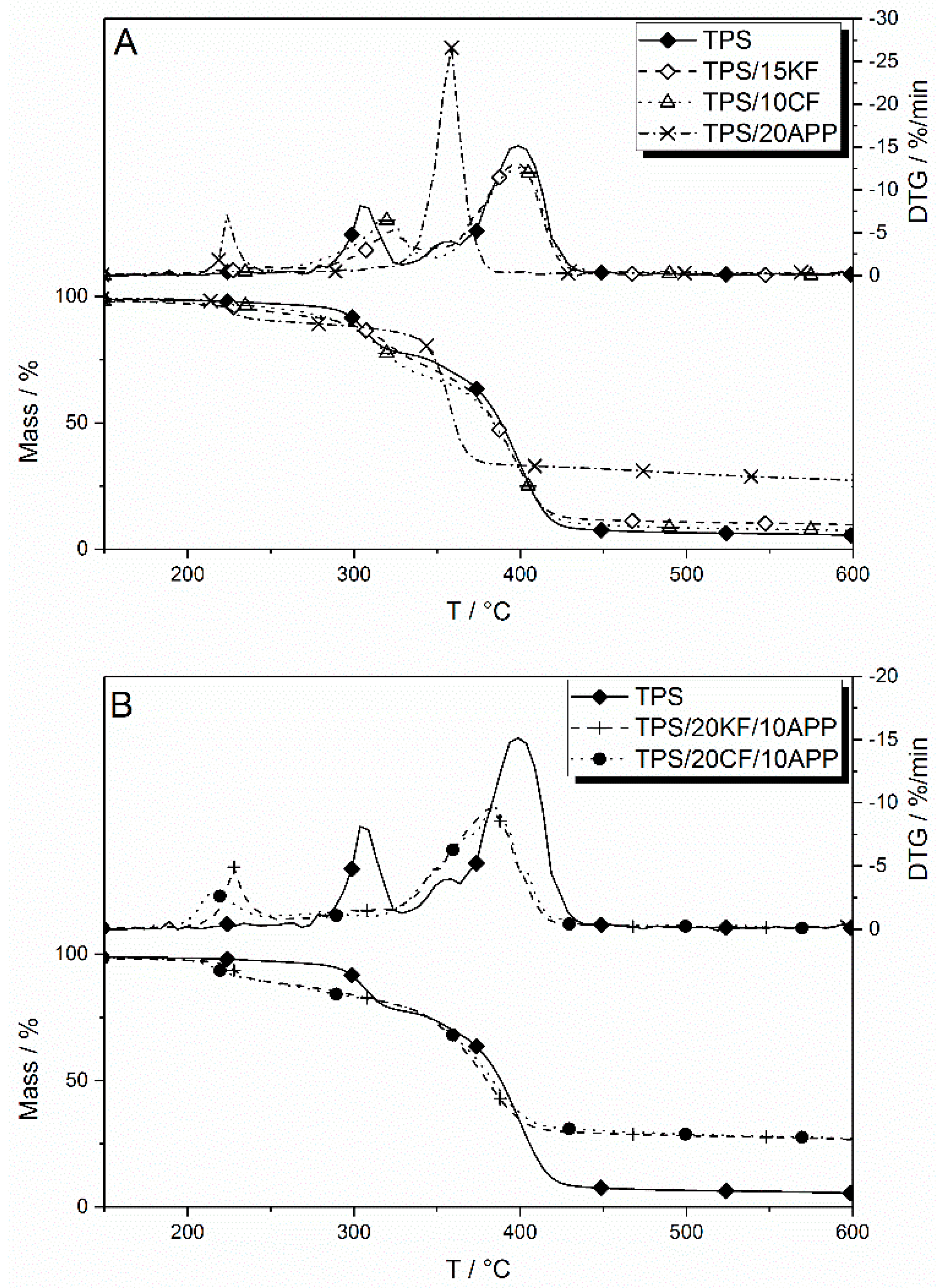

TPS shows two main decomposition steps, which are clearly visible in the mass loss rate (DTG) curve (

Figure 9A). The first peak is attributed to the starch phase, with occurred at a temperature of 304 °C. The second decomposition step, at 402 °C, is associated with the polyester phase of the TPS. In the DTG, a shoulder is visible prior to the second peak, which derived from the additional additives incorporated in the commercial blend [

35].

Both fibres, KF and CF, increased the residue in thermogravimetry in a similar manner with increasing fibre content. The decomposition temperature of the first decomposition step was shifted towards higher temperatures, by 18 °C for 15 wt. % KF and by 22 °C for 10 wt. % CF in TPS, while the temperature for the second decomposition step remained more or less constant. The incorporation of natural fibres led to slightly reduced mass loss in both decomposition steps.

When APP was present in TPS formulations, the pyrolysis and decomposition temperatures changed significantly. With 20 wt. % of APP in TPS, the first decomposition step occurred at around 225 °C and was associated with the release of ammonia. A second decomposition step occurred at 359 °C, a temperature between the first and second steps of the reference TPS. This indicates an interaction between the TPS and the APP additive that led to an altered decomposition pathway during pyrolysis. The amount of residue formed by TPS/20APP is greatly increased, to 19 wt. % more than TPS.

Figure 9B presents mass and mass loss rates (DTG) curves for combinations of natural fibres and APP. They show the same first decomposition step as TPS/20APP, which is attributed to the loss of ammonia. This decomposition step occurred at similar temperatures when KF was incorporated into the APP-TPS blend and was shifted to lower temperatures when CF was used as a natural fibre filler. The second decomposition step was altered as compared to only APP in TPS, in a similar fashion for both fibre fillers. The maximum temperature of the second decomposition step was shifted to temperatures around 20 °C higher. Decomposition also happened at a slower pace and over a broader temperature range compared to only APP in TPS, as seen in a lower but broader peak in the DTG curves. This indicates an interaction between the fibre fillers and APP during thermal degradation. The combination of natural fibres and APP also led to increased residue formation. When comparing the additional residue of TPS/15KF/15APP, the measured residue of 27 wt. % was slightly more than the expected residue of 25 wt. %, suggesting slightly synergistic behaviour, while the formulation TPS/20KF/10APP achieved superposition in residue formation. The expected residue formation of around 24 wt. % for the combination TPS/10CF/15APP was similar to the measured residue amount of 25 wt. %. A good synergistic effect in residue formation is observed in TPS/20CF/10APP, with 24 wt. % compared to an expected amount of only 21 wt. %.

3.5. Flammability

The flammability of TPS biocomposites with the natural fibre fillers KF and CF, APP and the combination of both, were characterized by determining their limiting oxygen index and their classification in the UL 94 vertical test. UL 94 vertical test evaluates the reaction of the plastic materials to a small flame. The classification of this method depends on the flammability characteristics. For example, V0 classification means that the burning stops within 10 s for each individual specimen, after the first or second flame application to the specimen. No flaming drips are allowed. Meanwhile, V2 rating means that the burning stops within 30 s for each individual specimen, after the first or second flame application to the specimen. Flaming drips are allowed. The results of both flammability tests are summarized in

Table 4.

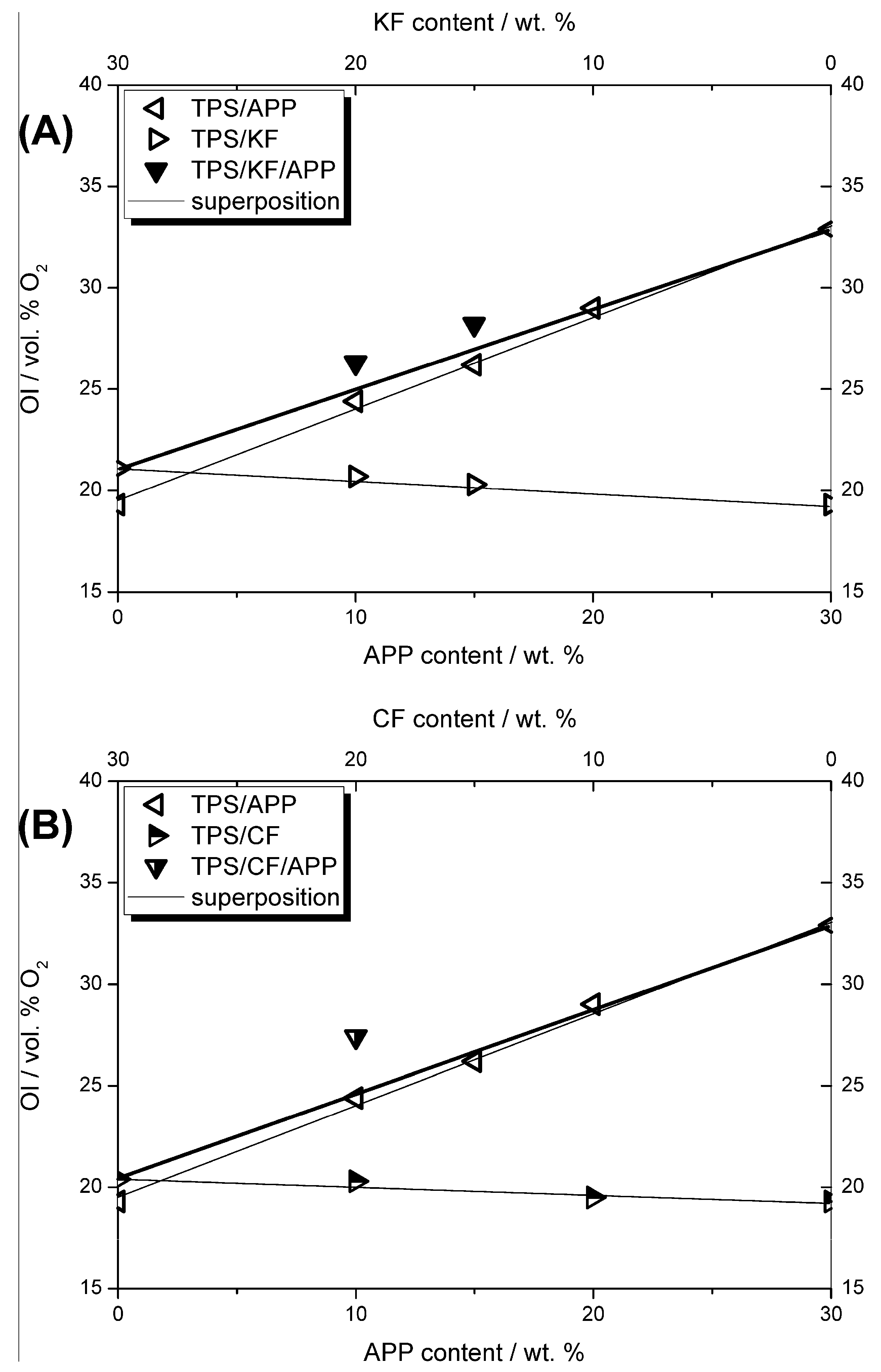

TPS as well as TPS-natural fibre biocomposites did not achieve a rating in the UL 94 vertical test. With increasing fibre content, the OI increased only slightly. However, a loading of 20 wt. % of APP in TPS resulted in an OI of 29 vol. % and was also the lowest concentration measured to achieve a V-0 classification in the UL 94 vertical test. It is remarkable that the minimum APP content to achieve a rating in the vertical test was lowered by the addition of keratin or coconut fibres. Even with 20 wt. % fibre content and only 10 wt. % APP content, a V-2 rating was achieved. OI values for all combinations of fibres and APP were in the range of 27 to 29 vol. %.

Figure 10 displays the change in OI behaviour with increasing additive contents, that is, fibre, APP and combinations of natural fibres and APP. In the graphs, the thin solid lines represent the linear dependency of the OI on the additive content of a respective single component in TPS, while the thick solid line shows the oxygen index behaviour if a combination of both additives, fibres and APP, were to result in a superposition. For the combinations of fibres and APP that amount to an overall additive content of 30 wt. %, namely TPS/15KF/15APP, TPS/20KF/10APP (

Figure 10A) and TPS/20CF/10APP (

Figure 10B), the measured oxygen indices are all located above the superposition line. This illustrates synergistic behaviour in OI. For CF, this synergism between fibres and APP was even more pronounced than for formulations with KF and APP, suggesting a better interaction between CF and APP during burning in terms of flame retardancy. These synergistic effects also explain the improved UL 94 rating for natural fibre-APP combinations.

The synergistic effect index was determined by calculating the theoretical superposition for linear behaviour using Equation (1) [

36,

37]. The OI for TPS/20CF and TPS/10APP increased compared to TPS by 1 vol. % and 5.1 vol. %, respectively. The calculated superpositioned OI increase for the formulation containing 20 wt. % of CF and 10 wt. % amounted to 6.1 vol. %. The oxygen index increase for TPS/20CF/10APP was measured to be 7.6 vol. %. Comparing the calculated superposition and the measured oxygen index increase yielded a synergistic effect index of 1.25.

For TPS/20KF/10APP, the synergistic effect index, calculated in the same manner, amounted to 1.08. Through thorough observation of the OI flammability measurements, the synergistic effect, especially between CF and APP, is attributed to enhanced effectiveness in the condensed phase. This synergistic behaviour would also be expected in forced flaming combustion tests conducted in the cone calorimeter.

3.6. Burning Behaviour under Forced Flaming Combustion

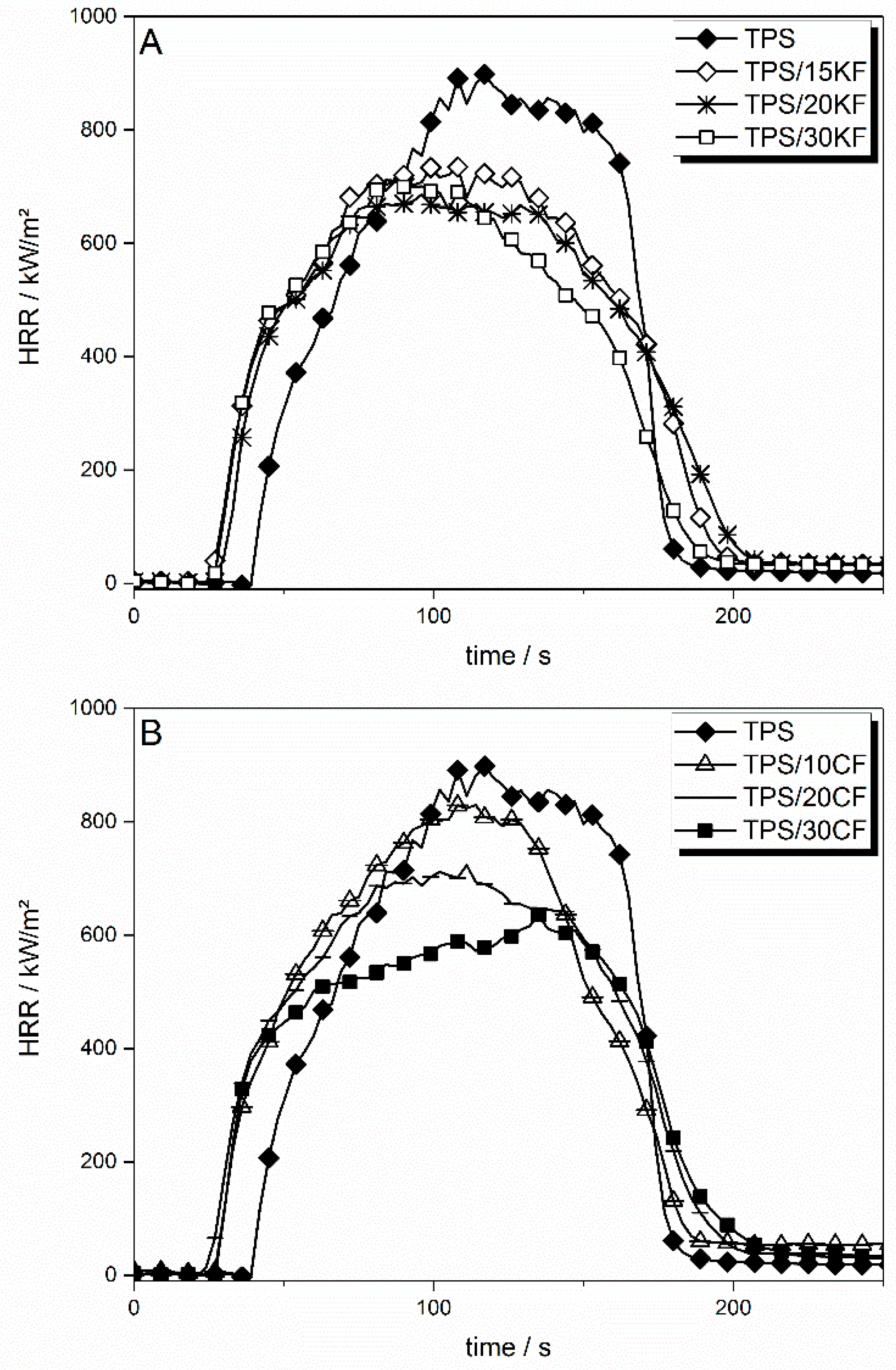

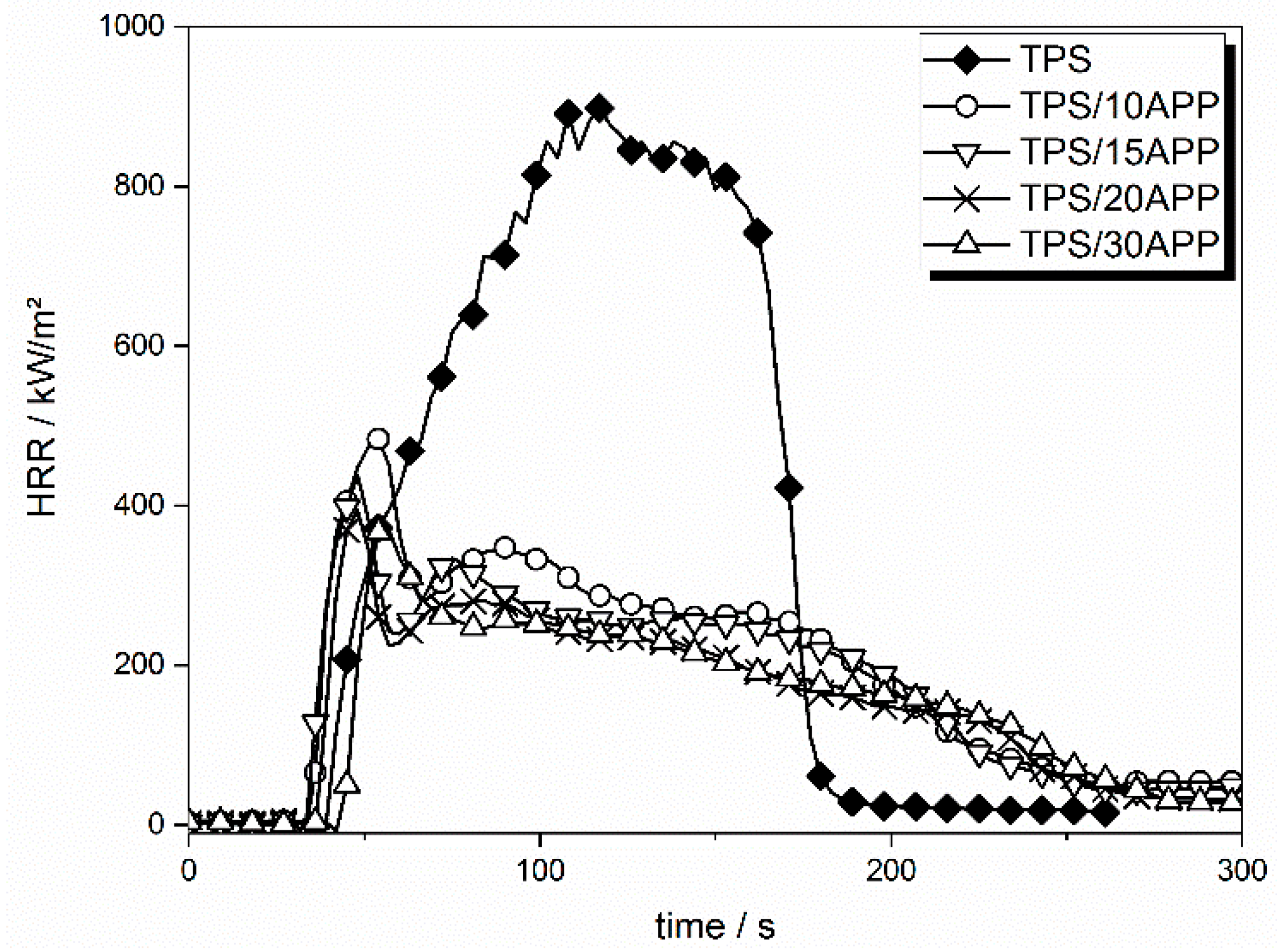

The flame retarding effect of only keratin or coconut fibres in TPS is mainly limited to a PHRR (peak heat release rate) reduction of up to 33% and a THE (total heat evolved) reduction of up to 11%. Cone calorimeter results are shown in

Table 5. The heat release rate (HRR) curves of natural fibres in TPS are shown in

Figure 11.

The incorporation of the natural fibres KF and CF had various effects on the HRR of TPS. For both sorts of fibres, the time to ignition (tig) was shifted to lower temperatures, from 37 s to around 25 s for 30 wt. % of fibres, respectively. Increased viscosity due to the addition of fibres resulted in later liquefaction of the sample surface in the cone calorimeter, reducing the heat exchange and thus cooling via convection. As a consequence, the sample heated up more quickly and ignited earlier. KF (

Figure 11A) at 15 wt. % reduced the PHRR by around 200 kW/m

2. With higher amounts of KF, the reduction in PHRR levelled off. Apart from a slightly slower HRR decay after flameout, the overall burning behaviour was similar to non-flame retarded TPS. The effective heat of combustion, displayed here as total heat evolved (THE) divided by total mass loss (TML), was not influenced by the KF incorporated in TPS. They had an influence neither on the combustion efficiency of released fuel nor on the heat of combustion of the volatiles. When CF was incorporated into TPS, the levelling off of the reduction in PHRR was less pronounced, resulting in a lower PHRR for TPS/30CF (

Figure 11B). The burning behaviour of TPS displayed a more characteristic change in the HRR curve with increasing amounts of CF than with added KF. For TPS/30CF, the PHRR was shifted to later times, just before flameout (tfo) and the fire growth behaviour in the beginning was reduced. This resulted in a decrease in the slope of the HRR curve after the initial rise. This indicates a more pronounced protective layer becoming visible in the HRR curve shape. THE/TML was only insignificantly decreased through the addition of CF. CF also produced a higher amount of residue, with 12.4 wt. % at a loading of 30 wt. % compared to 10.7 wt. % for TPS/30KF, hinting at higher thermal stability of the coconut fibres. In general, residue formation in the cone calorimeter was similar to thermogravimetric residue observation.

The incorporation of APP in TPS resulted in a clear change in HRR curve shape and thus in burning behaviour, as compared to that of a charring material [

38]. The HRR curves of 10, 15, 20 and 30 wt. % APP are displayed in

Figure 12.

HRR changed significantly for formulations with APP as compared to TPS. The initial peak in HRR after ignition, the ensuing local minimum and the slow decay of HRR, point to typical burning behaviour of material forming a protective layer. PHRR was decreased by around 50% with an APP load of just 10 wt. %. A loading of 20 wt. % APP lowered the PHRR by an additional 9%. Even higher APP loadings no longer significantly reduced the PHRR, indicating that the effectiveness of APP levels off. A similar trend is seen in the reduction of fire load (total heat evolved, THE). The THE was reduced by 42% at an APP loading of 10 wt. %. The highest APP load in TPS, which was 30 wt. %, resulted in a THE reduction of 52%. The addition of APP to TPS induced char formation, yielding 23 wt. % of residue at an APP load of 10 wt. %. A levelling off trend was also observed in residue formation with increasing APP load. Considering the initial residue amount of 4 wt. % for TPS, the addition of 10 wt. % APP yielded an additional residue formation of 19 wt. %. Incorporation of 30 wt. % APP in TPS resulted in an additional residue amount of 31 wt. %. APP also led to a reduction of up to 30% in THE/TML. Otherwise released carbonaceous species which act as fuel for the flame were stored in the formed residue, reducing the heat of combustion. Additionally, APP released NH3, which does not contribute to the heat production, diluting the flame and therefore reducing combustion efficiency.

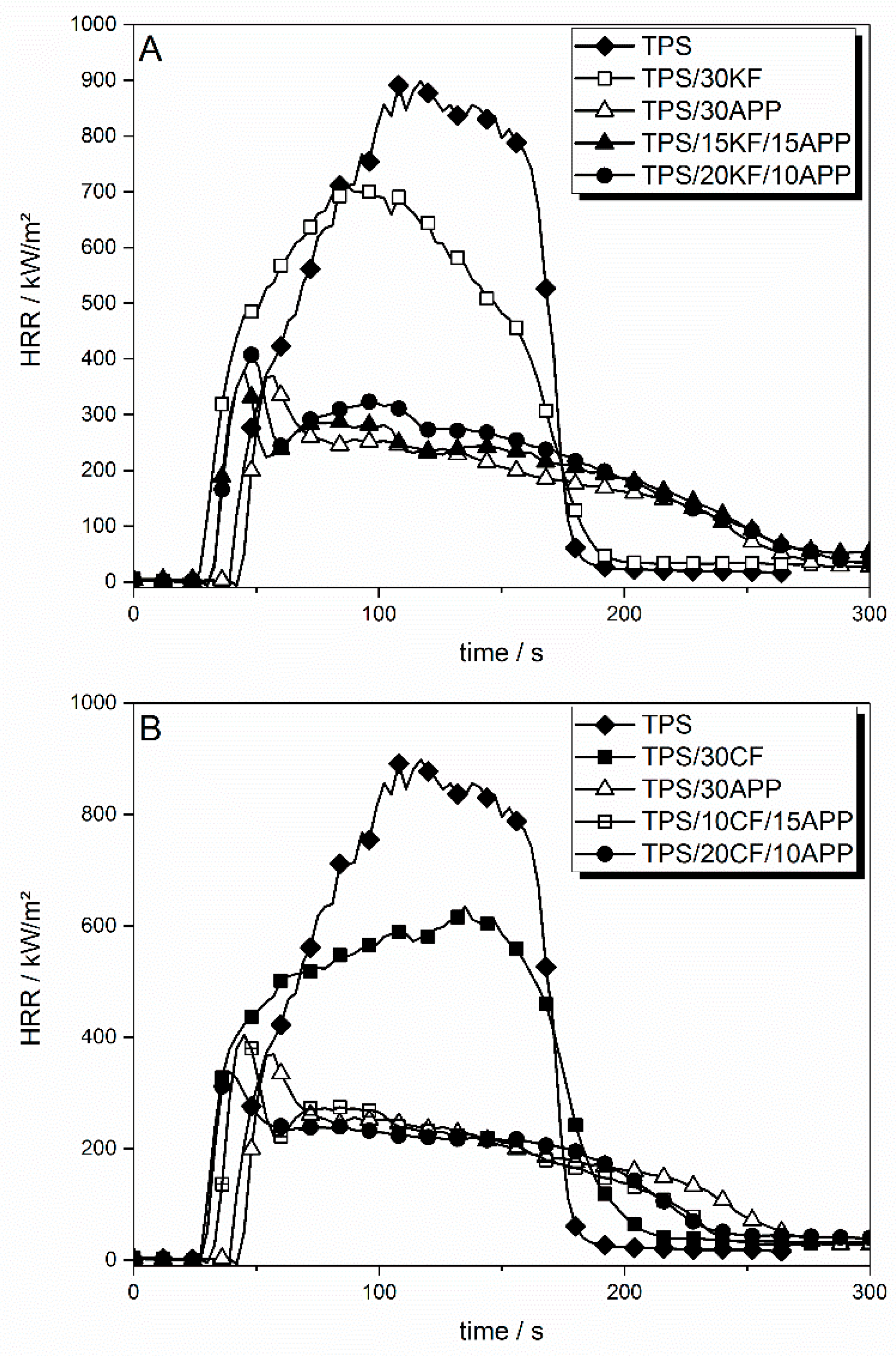

Natural fibre reinforced TPS in combination with APP yielded similar HRR results as TPS formulations with only APP as a flame retardant additive. However, it is possible to replace certain amounts of the flame retardant APP with fibre content to achieve similarly good results as with 20 or 30 wt. % of APP alone. Combinations of natural fibre filler and APP are shown in

Figure 13.

Figure 13A displays the HRR curves derived from cone calorimeter measurements for a total additive amount of 30 wt. % in TPS. The KF-APP combinations TPS/15KF/15APP and TPS/20KF/10APP showed similar HRR results as TPS/30APP. TPS/15KF/15APP exhibited a reduction in PHRR to 379 kW/m

2 and a reduction in THE to 49.9 MJ/m

2, while TPS/20KF/10APP reduced the PHRR to 407 kW/m

2 and the THE to 54.3 MJ/m

2. The HRR was dominated by the addition of APP. The nonlinear levelling off of effectiveness with increasing APP content enabled strong synergy.

Combinations of CF and APP in TPS showed slightly different behaviour (

Figure 13B). While the PHRR of TPS/10CF/15APP was still a bit higher than the PHRR of TPS/30APP, at 407 kW/m

2 compared to 376 kW/m

2, the THE was reduced to 42.2 MJ/m

2 as opposed to 43.4 MJ/m

2. A comparison of TPS/20CF/10APP and TPS/30APP shows that the overall flame retardancy performance may be even better even though a total additive load of 30 wt. % is maintained. The addition of 20 wt. % CF to the mixture of 10 wt. % APP in TPS resulted in a decrease in PHRR, which was not possible by increasing APP content alone. In terms of fire load, the THE of TPS/30APP and TPS/20CF/10APP were similarly low, at around 43.3 to 43.1 MJ/m

2.

For CF, a synergistic effect was observed in both PHRR and THE. In order to obtain the synergistic effect index as a statement for the significance of the synergism, Equation (2) is used [

34], with M being the result derived from cone calorimeter measurement. This approach was chosen over the proportionate approach, in which the total additive load is kept constant, because there was no significant reduction in cone calorimeter results for TPS with 10, 20 or 30 wt. % APP. Since cone calorimeter results like PHRR or THE did not decrease in a linear fashion, the relative synergistic effect index was calculated as a more correct concept.

In TPS/20CF, the PHRR was reduced to 727 kW/m2. APP at a load of 10 wt. % reduced the PHRR of TPS by around 50%. This resulted in an expected PHRR of TPS/20CF/10APP of around 366 kW/m2, assuming no synergistic effect. However, the measured PHRR of TPS/20CF/10APP was 338 kW/m2, yielding a synergistic effect index of 1.08. For THE, the synergism between CF and APP became even clearer. The calculated superposition in THE for TPS/20CF/10APP amounted to 50.9 MJ/m2 and the measured THE was 43.1 MJ/m2. Using Equation (2), this yielded a synergistic effect index of 1.2.

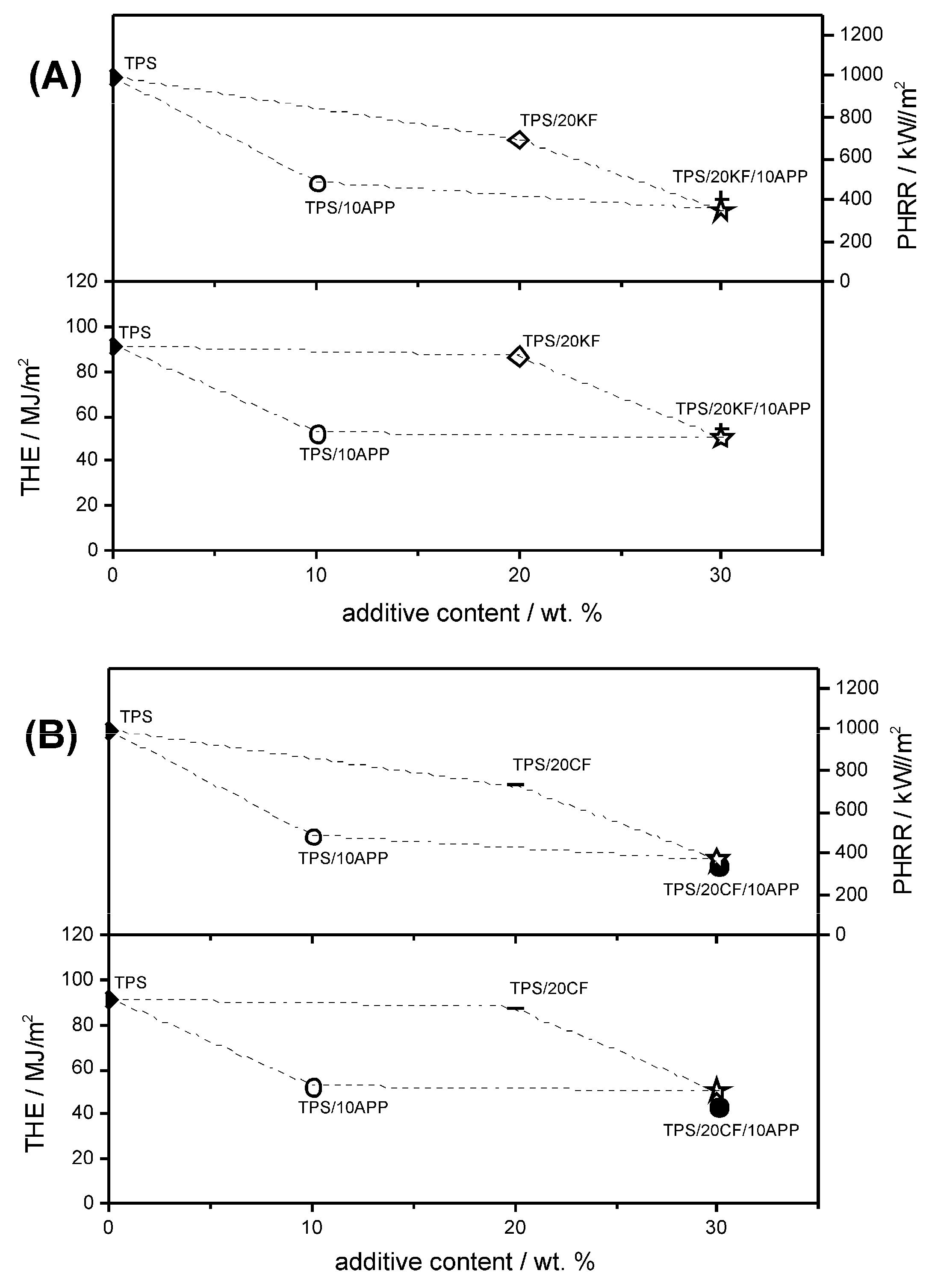

The effect of combining fibres and APP is visualized in

Figure 14. The trapezoid schematics are constructed to illustrate the superposition values for 20 wt. % natural fibre and 10 wt. % APP in TPS. Hollow stars mark the superposition values of THE and PHRR for TPS/20KF/10APP (

Figure 14A) and TPS/20CF/10APP (

Figure 14B). For TPS/20KF/10APP, the measured values for THE and PHRR are located around the hollow star marking the calculated superposition. This illustrates the occurrence of a superposition effect of this combination. On the other hand, TPS/20CF/10APP showed clear synergistic behaviour in PHRR and especially in THE, since the measured values are located below the hollow star superposition.

Since APP and the natural fibre fillers showed their activity as flame retarding additives mostly in the condensed phase, the reason for the synergistic effect of CF in combination with APP is found by analysing the cone calorimeter residues.

Figure 15 shows the character of the cone calorimeter residues of TPS/10APP (

Figure 15A) and the two fibre-APP combinations TPS/20KF/10APP (

Figure 15B) and TPS/20CF/10APP (

Figure 15C). When 10 wt. % of APP were incorporated in the TPS matrix, the formed residue was very light and brittle. The relatively smooth surface was disrupted by small cracks, resulting in a flaky and flocculent residue. Adding 20 wt. % of KF resulted in a more continuous surface but the overall character and nature of the residue was very similar to that of TPS/10APP. When 20 wt. % of CF were combined with 10 wt. % of APP, the char structure of the residue changed completely. Instead of a light and brittle char, the residue was very stable and showed a resemblance to wood char, pervaded by relatively large cracks. The change in char structure becomes clearer in the SEM micrographs of the respective residues.

Comparing the surfaces of TPS/20KF/10APP (

Figure 16B) and TPS/10APP (

Figure 16A) in SEM makes the similarities much clearer. Almost no differences are observed. It must be noted that no residual KF were found on the surface of the investigated TPS/20KF/10APP residue, so they do not contribute to the residue structure. In contrast to this, the residual CF were clearly visible in the TPS/20CF/10APP (

Figure 16C) residue. CF reinforced the APP-induced char, resulting in a completely different char structure. This becomes even clearer at 400x magnification, where interconnection and coating of the CF with residue is apparent. The synergistic effect of CF in combination with APP in TPS is therefore attributed to the physical enhancement of the residue in TPS/20CF/10APP.