3.1. Effect of DOPO on Epoxy Resin Properties

Glass transition temperature and fracture toughness of DOPO modified epoxy resin systems can be seen in

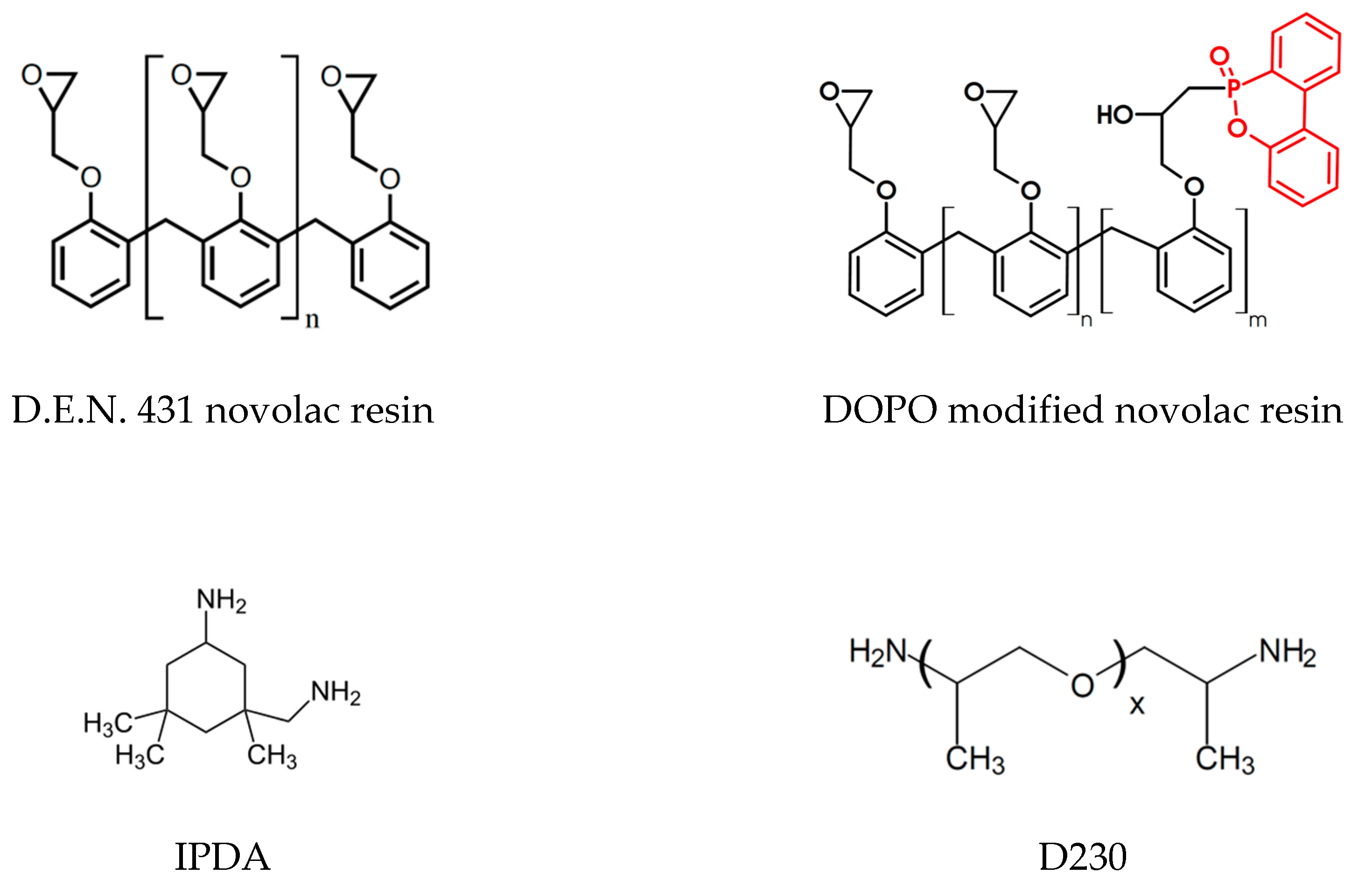

Table 1. The glass transition temperature shows decreasing values for the DOPO-modified system as the Tg decreases from 109.8 °C for neat novolac to 66.5 °C for 3 wt.% phosphorous containing resin. This change is given by the chemical structure of the DOPO-modified system; the DOPO molecule is chemically bound to the epoxy group of the novolac (see

Figure 1) which is consequently not involved in crosslinking and network formation of the cured resin system for that reason [

10,

11]. The fracture toughness of the systems shows a contrary trend as it seems to be increasing for higher amount of DOPO. Neat novolac reference shows a G

Ic-value of 109.2 J/m

2, whereas the highest value (131.8 J/m

2) is measured with 3 wt.% of phosphorous, but considering standard deviation, they are in the same range.

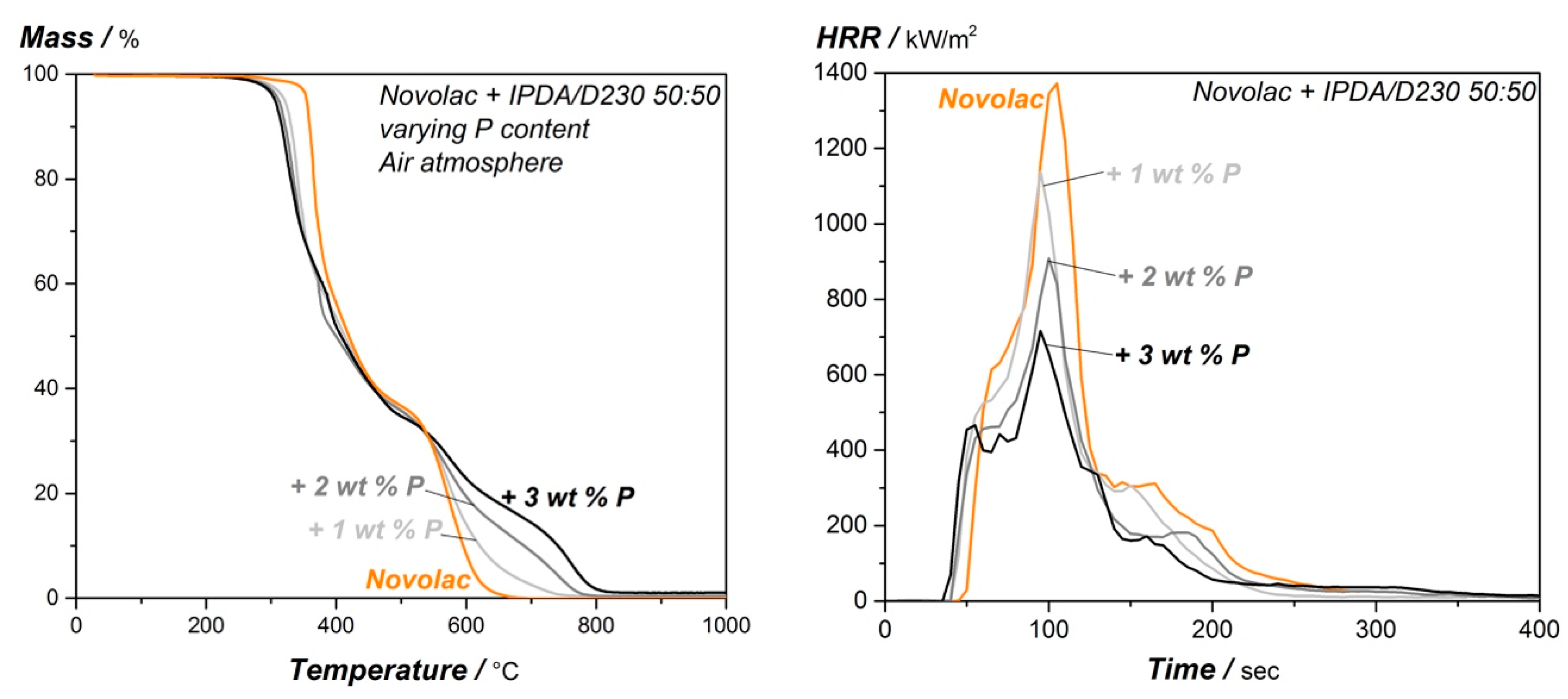

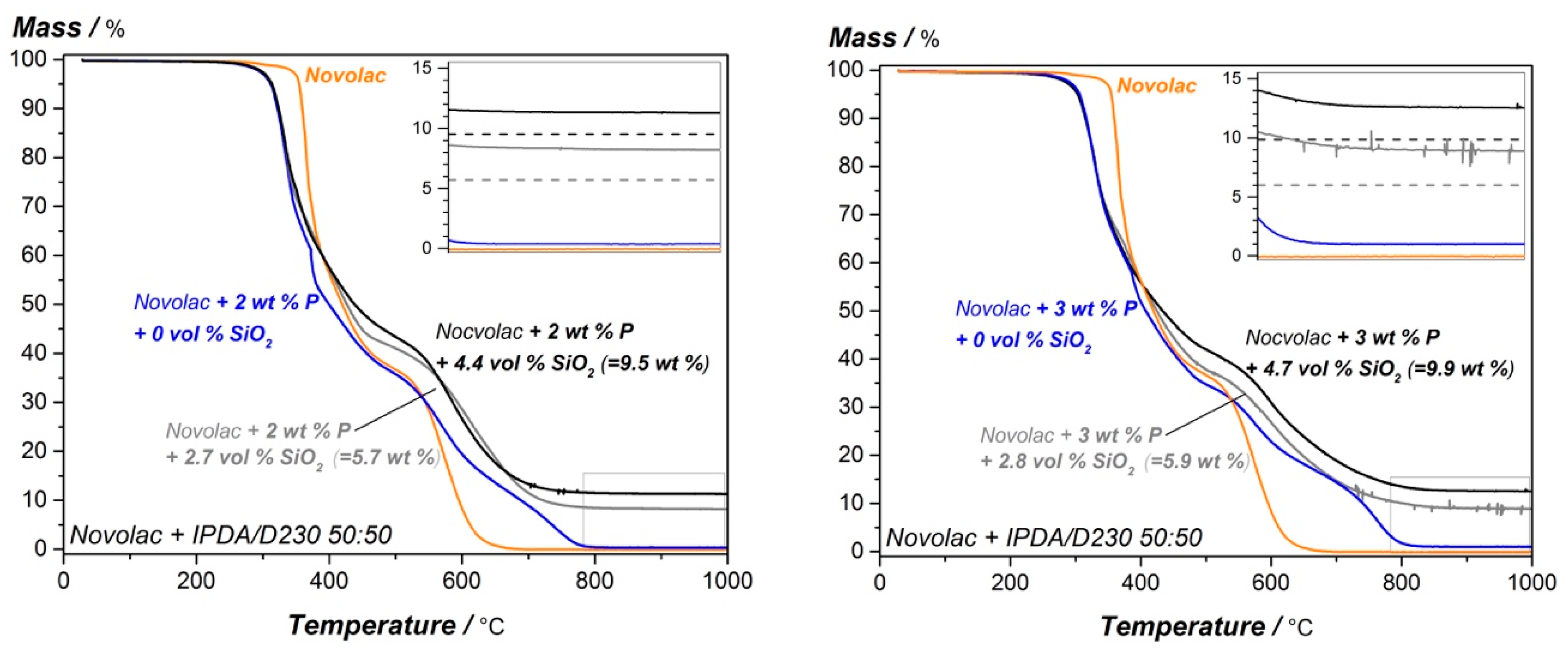

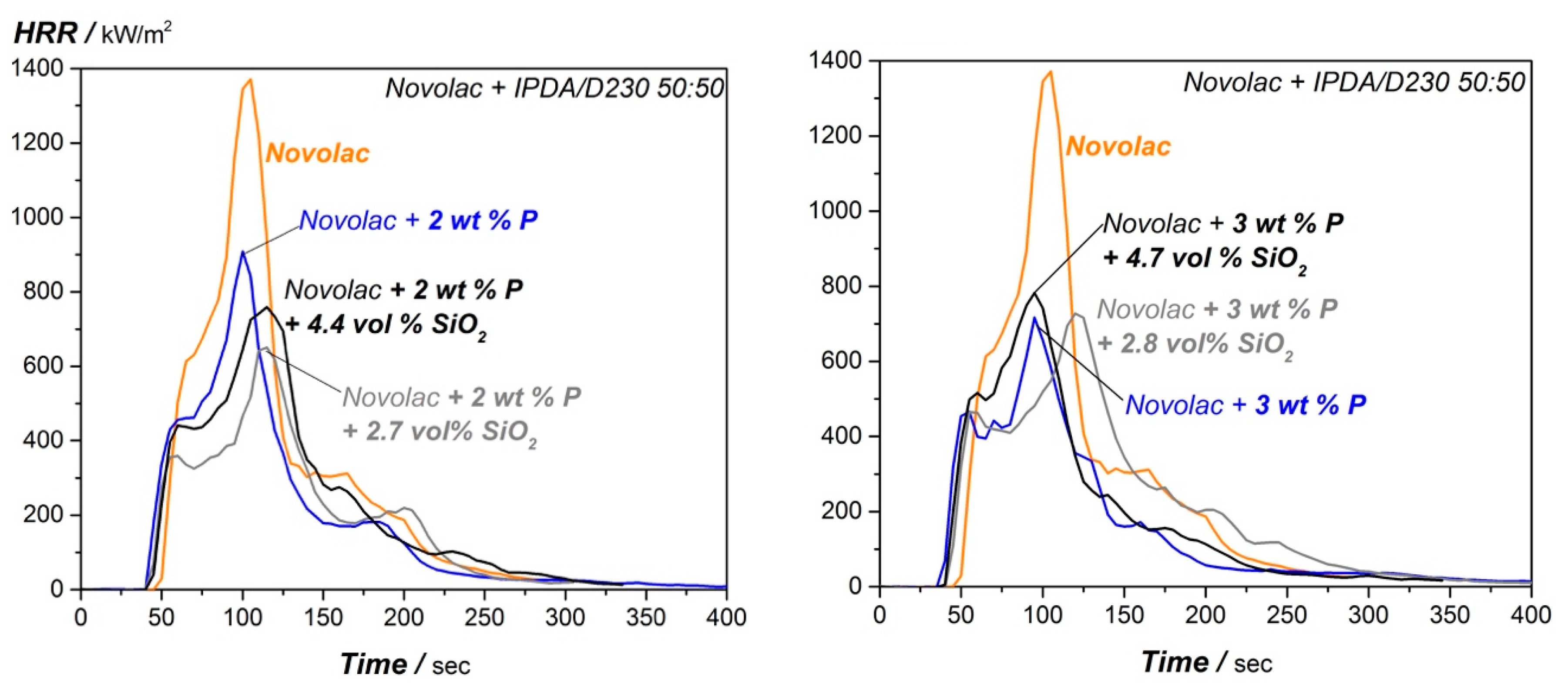

The flame-retardant properties of the DOPO modified epoxy resin systems were evaluated with TGA under air conditions and cone calorimeter experiments to study the decomposition and burning behavior. The mass loss rate from the TGA and the heat release rate from the cone calorimeter measurement of the modified systems is shown in

Figure 2, a summary of the relevant parameters from TGA and cone is given in

Table 2. It is represented in the TGA and cone calorimeter curves that the DOPO additive improve the flame retardancy of the resin system. First, it enhances the char yield at higher temperature, which can be seen in

Figure 2 on the left side and in

Table 2 since it increases with higher phosphorous content (residual mass @700 °C and @900 °C, see

Table 2). The energy release (peak heat release, pHRR and total heat release, THR) is also improved with increasing DOPO content, for highest phosphorous amount, the pHRR and the THR can be reduced from 1373.0 kW/m

2 and 87.7 MJ/m

2 for neat novolac to 689.2 kW/m

2 and 57.4 MJ/m

2. The reduction in heat release is referred to the gas phase since phosphorous containing flame retardants decompose and release phosphorous-oxide radicals to reduce overall heat release. However, the systems start to decompose earlier for higher phosphorous content, as the T

d5%-value (the temperature when 5% of the systems is degraded) as well as the time to ignition (tti) are reduced. It is estimated that the resin absorbs energy and starts to decompose earlier, as the glass transition temperature and network density is reduced with a higher amount of phosphorous.

3.2. Effect of Nano-SiO2 on Epoxy Resin Properties

The influence of silica particles on glass transition and fracture toughness is summarized in

Table 3. It is shown that the Tg is increased for the nano-SiO

2 modified novolac resin which is referred to the surface modification of the silica particles. It is expected that the surface modified particles show high interaction with the epoxy resin which results in an ordered structure of the epoxy resin matrix around the particles. The ordered particle-matrix interphase needs higher thermal energy to start the polymer chain vibration. The compatibility of the commercial NANOPOX product with epoxy resin systems is already discussed in the literature and demonstrated by increasing Tg [

12]. In addition, the fracture toughness is also improved for higher silica content from 109.2 J/m

2 for neat novolac to 207.6 J/m

2 for 3.9 vol.% SiO

2 particles. The toughening mechanism for nano silica particles is discussed in the literature already and basically referred to the shear yielding mechanism, a deeper evaluation of toughening effect for the systems given here will be discussed in

Section 3.3.

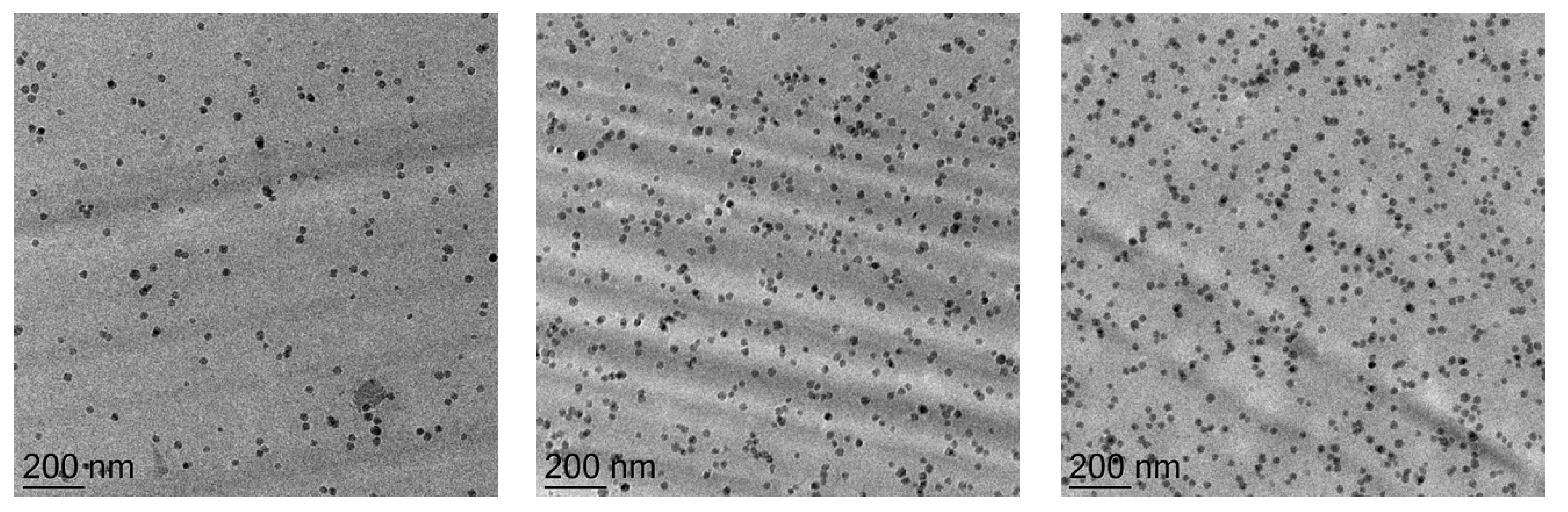

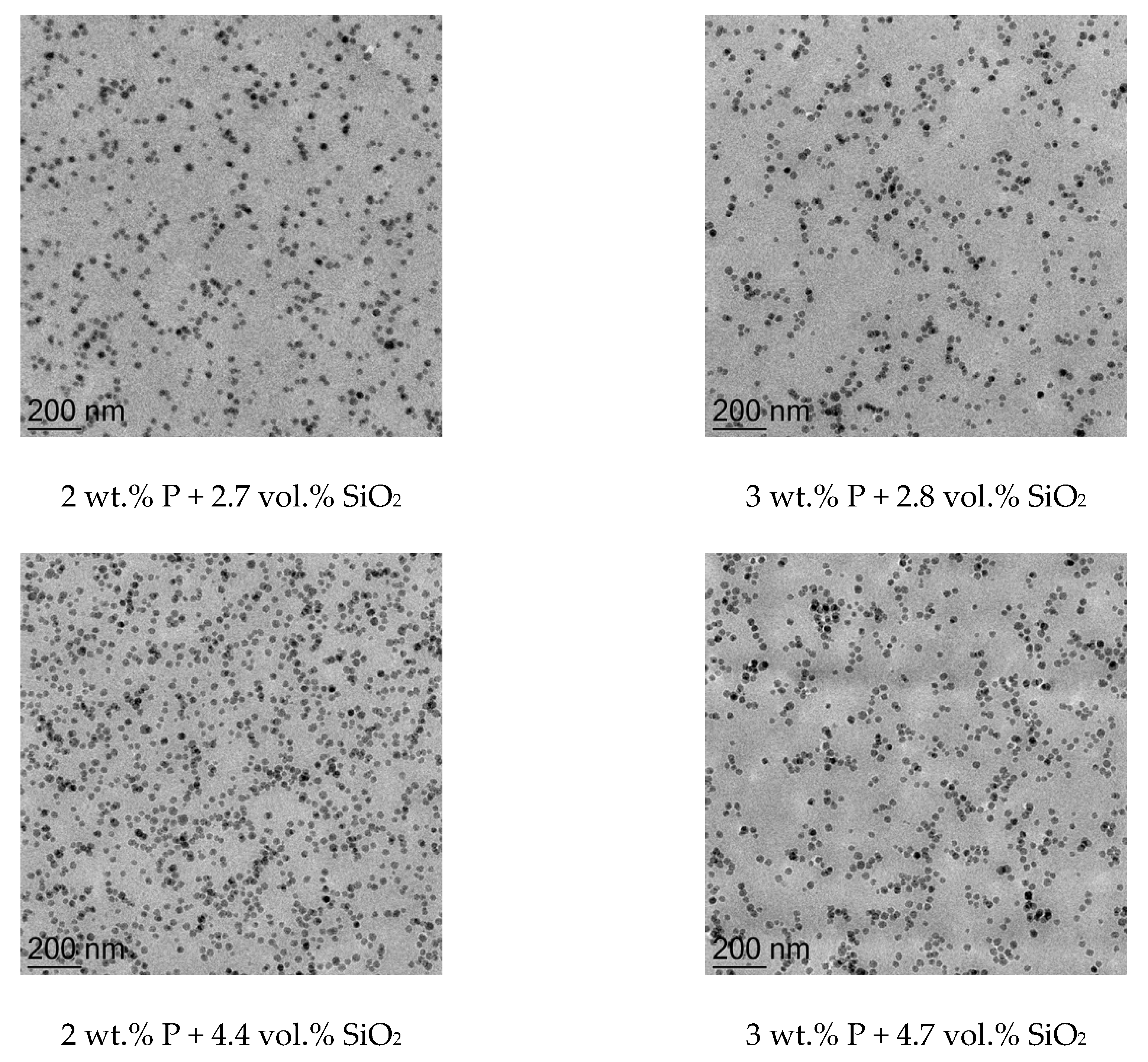

TEM images are taken to evaluate the dispersion quality of the silica nano-particles and to ensure that cured epoxy resins only show slight amount of small agglomerates. The TEM images are represented in

Figure 3 for lowest and highest nano-SiO

2 content and 2.3 vol.% SiO

2. It can be summarized that the particles are homogeneously distributed, and no agglomerates are formed even at higher content.

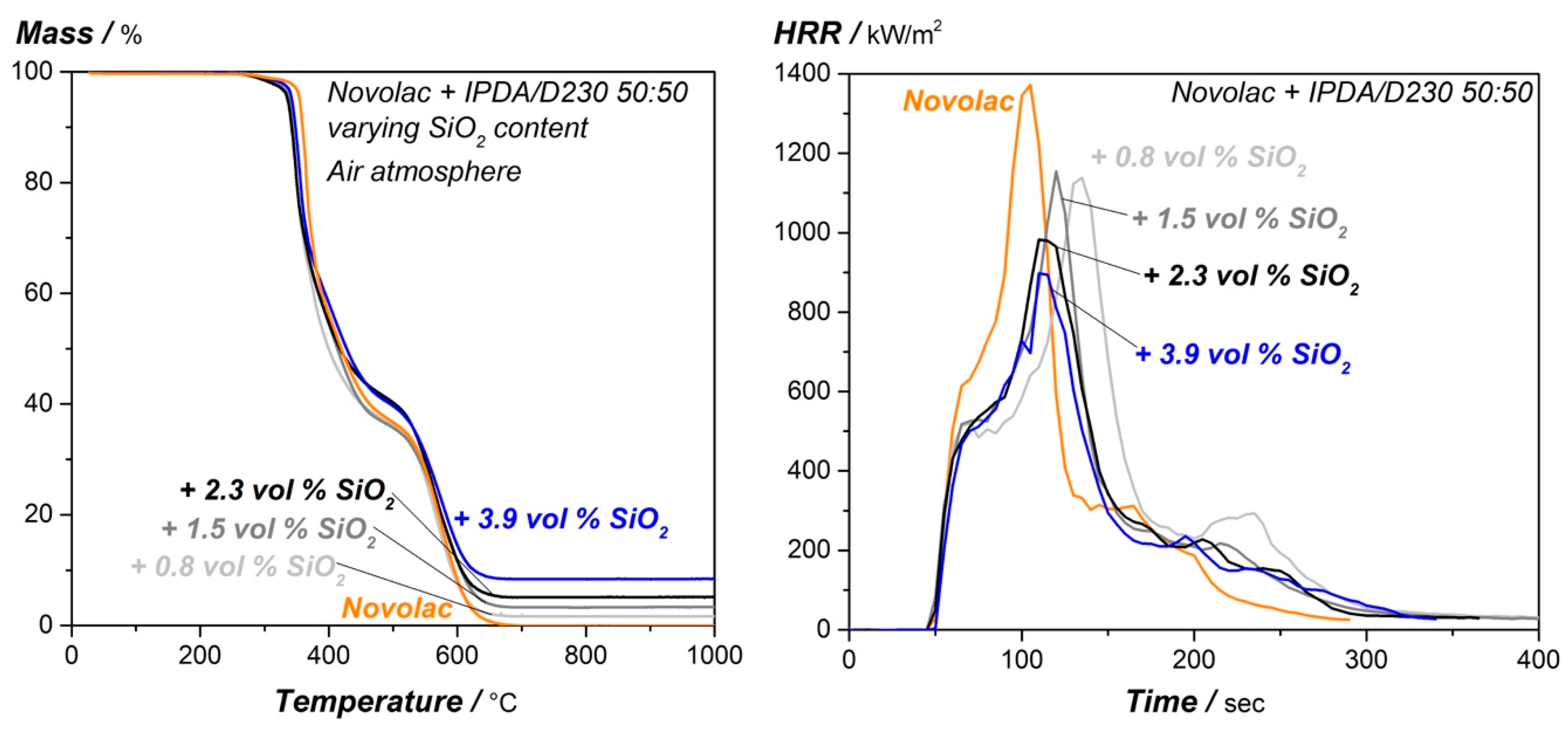

Decomposition and burning behavior of nano-silica modified epoxy resin is shown in

Figure 4 and summarized in

Table 4. The decomposition behavior on the left side of

Figure 4 is only influenced by the silica particles, the residual mass at higher temperature is basically represented by the adjusted silica amount, the T

d5%-value is reduced for the silica nanocomposites to 338.5 °C and 343.2 °C as highest and lowest value respectively, however the effect is only marginal. Silica amount shows only slight impact on the heat release values and time to ignition from the cone calorimeter experiments. Whereas the peak heat release rate is continuously decreasing from 1373.0 kW/m

2 for the neat resin to 910.9 kW/m

2 for a resin containing 3.9 vol.% SiO

2, the total heat release is decreased for highest silica content. However, the THR increases for lower nano SiO

2 amount which can be explained by a supportive effect of the particles as they raise the effective surface for the flame. The reduction in THR and especially pHRR can be explained by the amount of non-flammable silica particles. The time to ignition is unaffected for the tested nanocomposites considering standard deviation. It can be summarized that nano-SiO

2 shows only a slight impact on the flame-retardant properties of the epoxy resin, especially for lower particle loading, compared to the DOPO modified systems for instance.

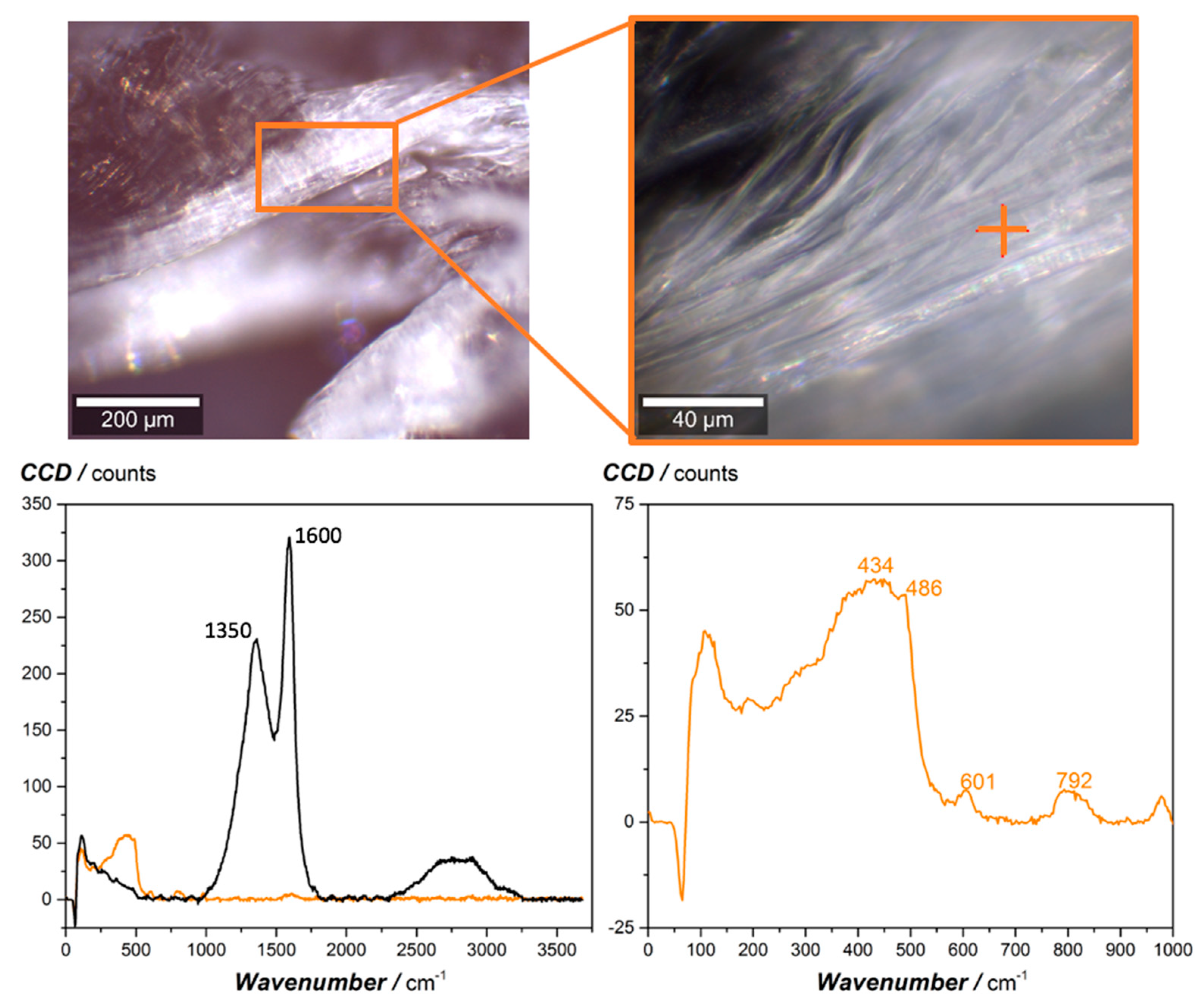

The residual cone calorimeter char layer was investigated with Raman spectroscopy to evaluate the flame-retardant effect of the silicon-oxide particles. The optical microscopy images (10× and 50× magnification) taken at the burning zone and the Raman spectra of the sample with 2.3 vol.% SiO

2 are presented in

Figure 5. The orange cross indicates the position, where the Raman spectrum was recorded. The microscopy images reveal that the nano-SiO

2 particles generate a white appearing, dense and closed glass layer, which results during the burning process of the matrix material. The layer is composed of silicon oxide basically, since the Raman spectrum shows the typical SiO

2 peaks discussed in the literature [

13]. In contrast to this, the black Raman spectrum, which was recorded at the inside (the opposite side to the burning zone) of the cone calorimeter sample, indicates the peaks resulting from carbon black, according to Pawlyta et al. [

14]. The different Raman spectra from the inside and the outside (burning zone side) of the nano-SiO

2 modified sample show that silicon oxide accumulates at the burning side of the sample and generates a dense and closed layer.

3.3. Additive Combination: Effect on Glass Transition Temperature, Dispersion Quality and Fracture Toughness Modelling of Modified Systems

So far, both additives are investigated and evaluated separately; next, the influence on the properties of the combination of both additives will be discussed. The impact on glass transition temperature and fracture toughness is represented in

Table 5 and compared to the appropriate system without silica particles. The combination shows a reduction in Tg for 2 wt.% and 3 wt.% phosphorous with higher silica amount. For 2 wt.% and 3 wt.% phosphorous, the glass transition is reduced from 81.9 °C to 75.6 °C by adding 4.4 vol.% SiO

2 for 2 wt.% P and from 66.5 °C to 62.2 °C for 3 wt.% phosphorous and 4.7 vole% silica. It is represented in the TEM microscopy images in

Figure 6 that the dispersion quality of the nano-silica particles is deteriorated for material systems with higher DOPO amount as there are some particle agglomerates visible in the micrographs. Due to agglomeration of silica particles, the particle-matrix interphase is weakened, resulting in continuously decreasing T

g for higher SiO

2-content. The reason for lower dispersion quality is estimated to occur due to the shift of the chemical potential of the liquid resin due to the DOPO modified novolac which is not optimized for the commercial silica particle modification. The particle-particle interaction is estimated to be higher leading to increased agglomerate number.

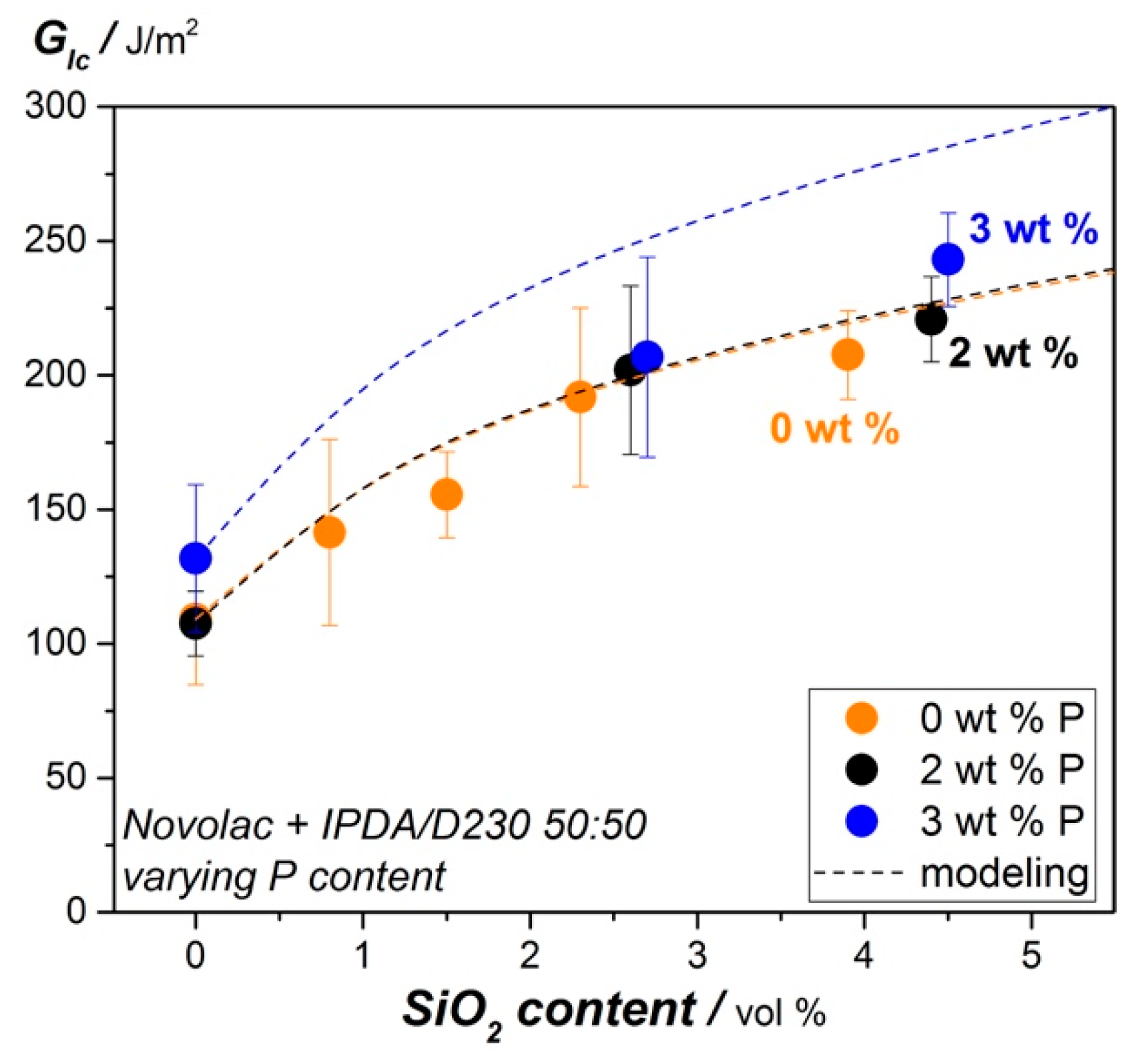

The G

Ic-value from

Table 5 for the combined systems is plotted in

Figure 6 for varying silica content. It can be seen that the nano silica particles show high impact on fracture toughness of modified epoxy resin, increasing from 107.3 J/m

2 and 131.8 J/m

2 for 2 wt.% and 3 wt.% P up to 220.8 J/m

2 (2 wt.% P) and 243.1 J/m

2 (3 wt.% P) for 4.4 vol.% and 4.7 vol.% SiO

2 respectively. In addition, the dotted lines in

Figure 7 represent a model of the toughening effect of the shear yielding mechanism for nano-sized particles in epoxy resin systems proposed by Hsieh et al. and Johnsen et. al. [

15,

16]. A particle size of 20 nm is assumed for the calculation according to the datasheet of the supplier of silica particles. It is shown that the modelling fits to the measured values for 0 wt.% phosphorous and the 2 wt.% phosphorous epoxy resin system. This confirms that the dominating toughening mechanisms is shear yielding of 20 nm sized SiO

2-particles. However, the toughening contribution from shear yielding induced by nano-SiO

2 particles is overestimated with the modelling for the epoxy resin with 3 wt.% phosphorous. As it is shown in the TEM micrographs in

Figure 6, the DOPO modification seems to support particle agglomeration. The overall average particle size is increased for this reason and consequently the shear yielding mechanisms is deteriorated as higher particle sizes lead to lower fracture toughness for this model.

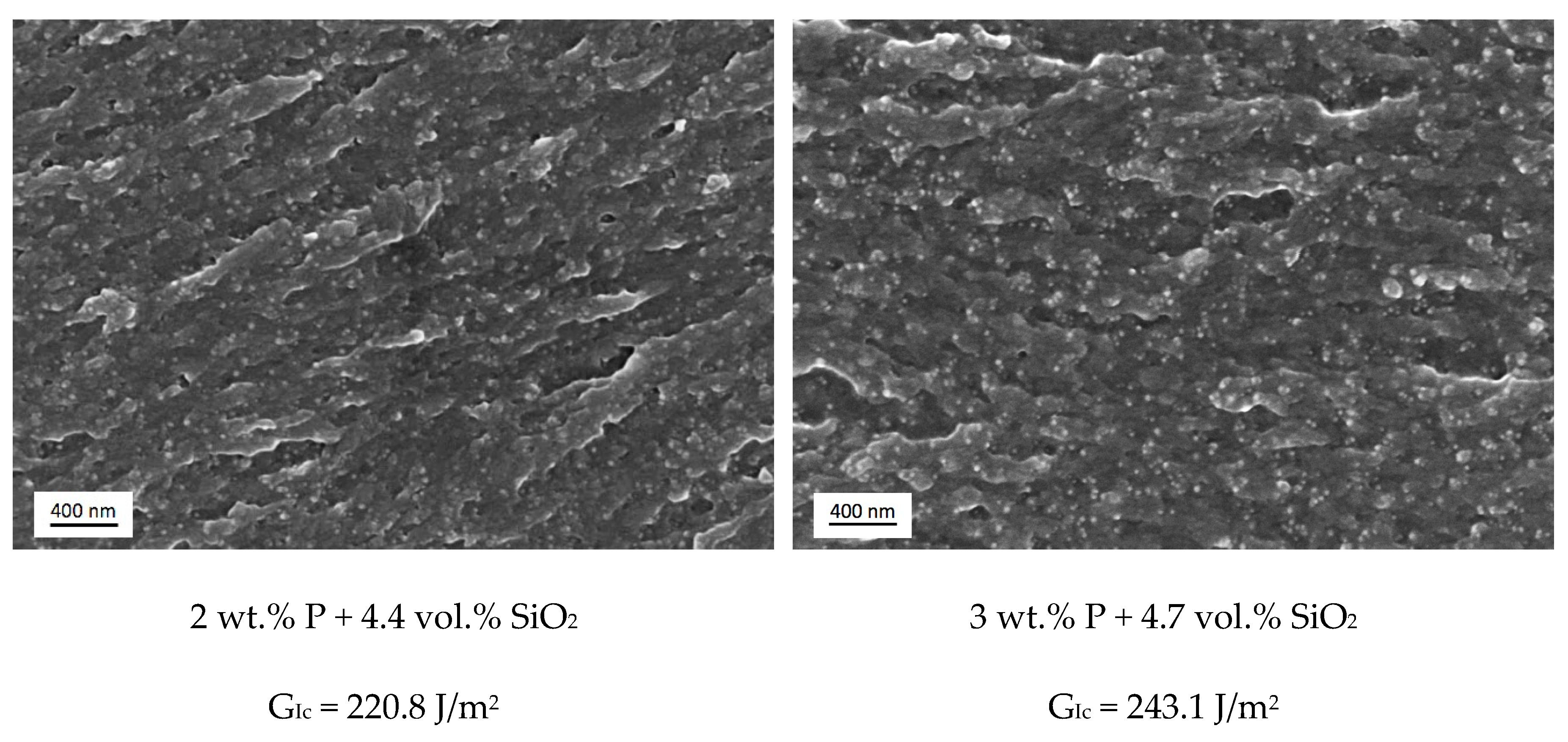

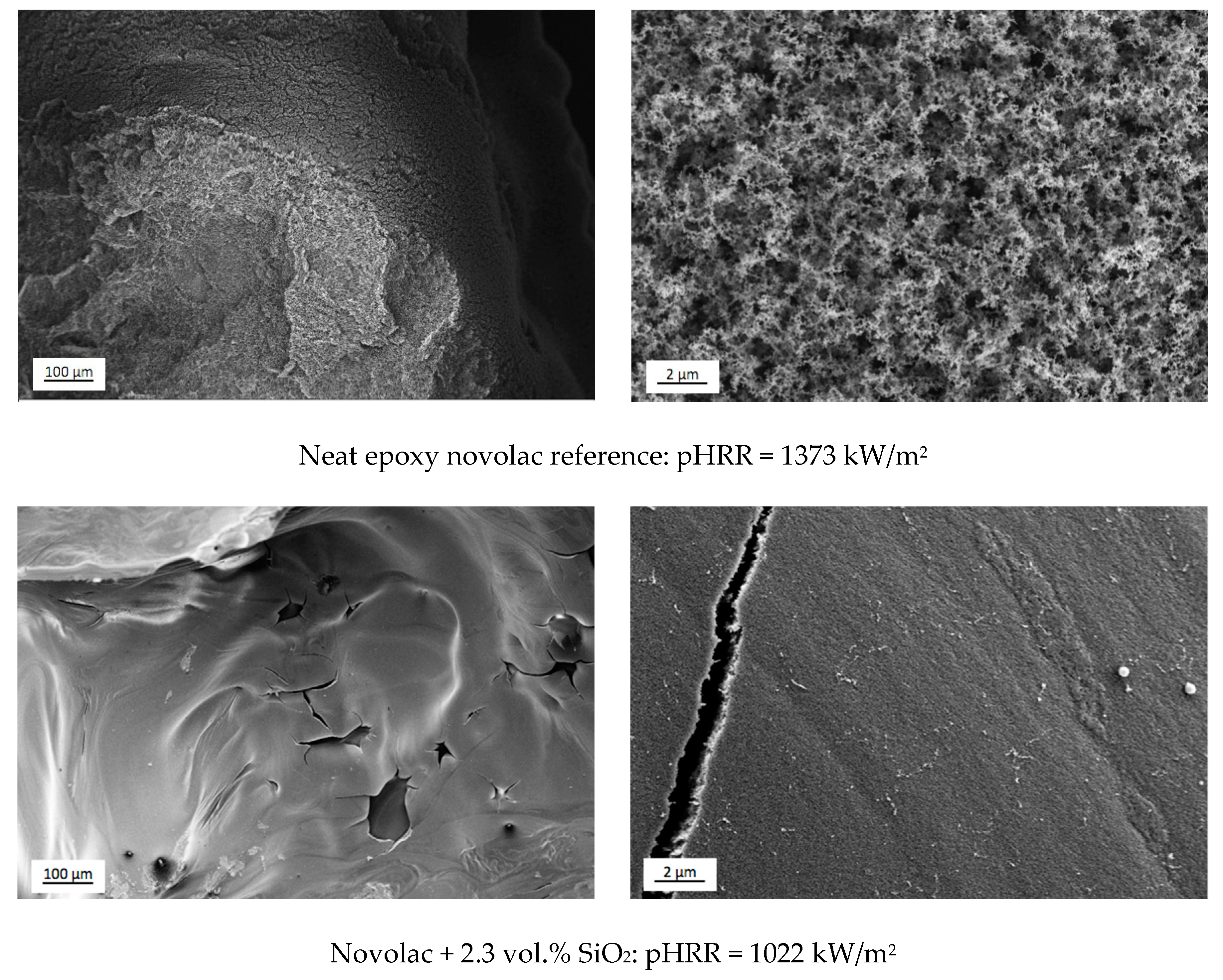

To get deeper information of the fracture and toughening mechanism, the fracture surface is studied with SEM (see

Figure 7). For comparison, the fracture surface of neat novolac resin and the fracture surface of only silica modified epoxy resin with comparable nano-SiO

2 content is represented. For the neat novolac reference a flat and smooth fracture surface is developing during crack propagation which indicates the brittle character of the unmodified system and the low G

Ic-value of only 109.2 J/m

2. However, there are also some river lines visible on the fracture surface of the epoxy resin, indicating plastic deformation and shear yielding mechanism.

For rigid nano silica epoxy resin, different toughening mechanism are already discussed in the literature [

17,

18,

19], these are, in general: shear yielding and particle pull-out and plastic void growth of the matrix [

17,

18,

19]. In

Figure 8, for the only silica modified system, the different toughening effects are demonstrated on the fracture surface. However, the particle pull-out toughening mechanism could hardly be verified for the presented systems. Shear yielding seems to be the dominating toughening mechanisms for the system presented here. The river like structure on the fracture surface of silica modified systems in

Figure 8 is reflected to the shear yielding mechanism and plastic deformation of the matrix which is more dominant and effective for the SiO

2 modified epoxy resin compared to neat novolac resin. For the DOPO modified epoxy resins, the river like structure is still pronounced on the surface, especially for the 2 wt.% phosphorous. However, the tendency of silica particles to agglomerate for higher phosphorous content seems to reduce plastic deformation and shear yielding mechanism as the river like structure is less dominant compared to lower phosphorous content. The deteriorating effect has already been discussed previously for the modelling studies (see

Figure 7).

3.4. Additive Combination: Flame Retardancy of DOPO and Silica Modified Novolac Resin

To evaluate the degradation behavior and flame retarding effects of the DOPO and silica modified system, TGA (air atmosphere) and cone calorimeter measurements are performed. The resulting TGA mass loss curves for the reference system without DOPO, with 2 wt.% and 3 wt.% phosphorous and varying silica content are given in

Figure 9, the summary (T

d5%, residual mass @700 °C and @900 °C) is given in

Table 6.

The silica content does not show any influence on the decomposition behavior of the novolac epoxy resin at lower temperatures for the DOPO modified systems. The T

d5% is nearly unaffected, compared to the appropriate only DOPO modified system. Compared to this, the residual mass at higher temperature (900 °C) is affected by the combination of DOPO and silica. To quantify this in detail, the deviation in between the adjusted silica content and the measured residual mass of the systems at 900 °C (∆m

900°C) is calculated with the following equation.

Equation (2) includes the char yield of the appropriate only DOPO modified epoxy resin at 900 °C (m

DOPO900°C from

Table 6), the adjusted silica content (m

SiO2 from

Table 6) and the measured residual mass of the nano-silica and phosphorous modified novolac resin (m

DOPO+SiO2900°C: char yield at 900 °C for DOPO and silica modified system from

Table 6).

The deviation is graphically represented in

Figure 9 as mismatch between the measured TGA-curve and the adjusted SiO

2 content (dotted lines) for the combined systems. If the flame retardants would not interact with each other, the deviation should be 0.0% which means that the residual mass is equal to the adjusted silica content. However, as there is a higher deviation observed, it is estimated that a residual char product is generated being composed of both flame-retardant additive types (phosphorous and silica) having high temperature stability as it is stable in the measured area up to 1000 °C. The high temperature stability of the residual product also shows that it is highly oxidized as there is no further degradation and mass loss in air atmosphere. The deviation is in the range of 14–15% for higher and up to 30% and 36% for lower silica content, the biggest difference is given for the 2 wt.% phosphorous and 2.7 vol.% SiO

2 modified system.

To get deeper information about the flammability and decomposition behavior of the material, cone calorimeter tests are performed. The resulting HRR curves are shown in

Figure 10 and summarized in

Table 7. It is shown that the combination of additives continuously increases the pHRR for the epoxy novolac resin with 3 wt.% phosphorous from 689.2 kW/m

2 to 814.2 kW/m

2, further the total heat release is not improved for these systems. However, the time to ignition is nearly unaffected by the combination of DOPO and silica. For the novolac resin with 2 wt.% phosphorous and different silica content, the p-HRR shows lowest value (646.6 kW/m

2) for 2 wt.% phosphorous and 2.7 vol.% SiO

2. For higher silica content, the HRR increases again, this tendency is also reflected for the THR. The time to ignition is in addition elevated for the systems with higher silica content and 2 wt.% P.

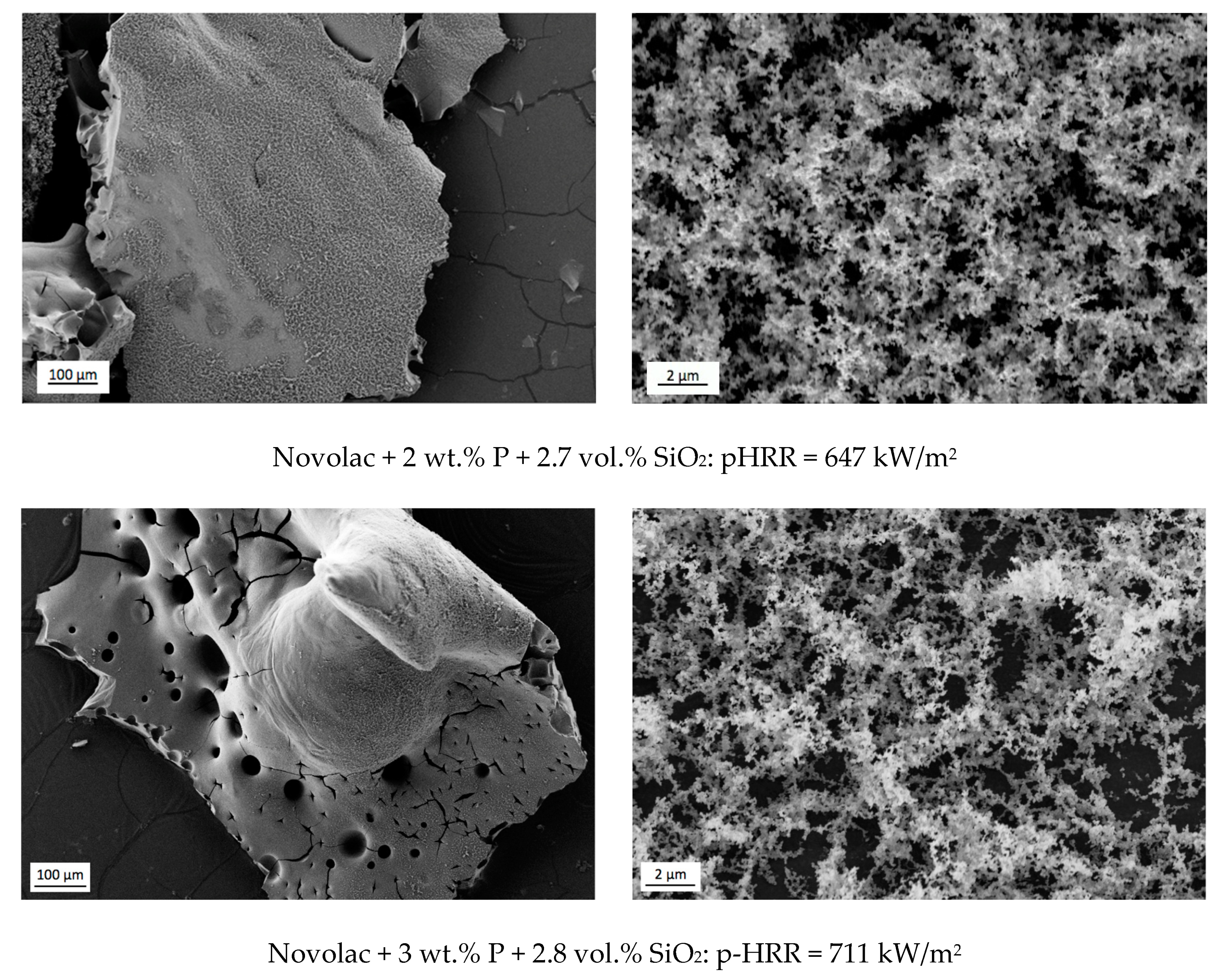

For deeper evaluation and understanding of the flame retarding effect of the silica and/or DOPO modified epoxy novolac systems, SEM studies of the char morphology of cone calorimeter samples are performed. The images for neat novolac, 2.3 vol.% SiO

2, 2 wt.% phosphorous + 2.7 vol.% SiO

2 and 3 wt.% phosphorous + 2.8 vol.% SiO

2 modified epoxy resin are represented in

Figure 11 with different magnifications. The neat novolac char morphology shows rough and uneven surface (see

Figure 11, upper image), and a typical carbon black like char residue structure is represented in the image with higher magnification. The morphology shows no flame retarding structure like stable char layer for instance which is also indicated in the HRR-curve in

Figure 10 as the curve rises up to the maximum when the majority of the material is already decomposed and afterwards slowly declines again. DOPO modified epoxy resin shows the same char morphology as neat novolac, the flame-retardant effect is verified by the gas phase. However, the 2.3 vol.% silica modified epoxy resin shows smooth char layer with a lower number of leaks. It is estimated that silica particles induce the formation of a char layer which traps the evaporating material up to the point when the inner pressure is reaching the strength of the layer and the combustible gases escape from the generated leaks in the layer. The stable and dense SiO

2-layer is already proven with the Raman measurement.

The char morphology of cone calorimeter samples with both flame-retardant additives also show the carbon black like structure at higher magnification (see

Figure 11), indeed there is a dense layer visible below this morphology which is shown in the image with lower magnification. However, the 3 wt.% phosphorous and 2.8 vol.% SiO

2 modified novolac resin also shows a high number of leaks in the char layer resulting in decreased flame-retardant properties. In contrast to this, 2 wt.% phosphorous and 2.7 vol.% SiO

2 modified novolac resin, the char layer seems to be more stable as there are less leaks generated by the combusting gases shown in the SEM micrograph. The stable char layer is also indicated by the pronounced shoulder formation in the HRR-curve (see

Figure 10) as it delays the release of combustible gases to the burning zone and therefore reduces the energy release of the fire. Considering the results from the TGA measurements, the resin system with 2 wt.% P + 2.7 vol.% SiO

2 shows highest deviation from the adjusted silica content (36.1%, see

Table 6) which consequently demonstrates that the highest phosphorous amount is incorporated in the char layer and the thickest layer is generated. The combinational effect of the DOPO- and silica modified systems is referred to a stable and dense char layer which develops during the burning process of the material. The layer can clearly be seen in the SEM micrographs in

Figure 11. Due to its high temperature stability (stable up to 1000 °C, see

Figure 9), it is estimated that the residual product is highly oxidized and composed of silicone- and phosphorous-oxides, basically. Once the protective effect of the char layer reaches its limits as the gas pressure increases up to a critical value, the gas is released by the formation of slight leaks and the burning process is supported. However, it can be seen from the SEM images and the HRR-curve that protective effect of the char layer of the 2.7 vol.% nano-SiO

2 and 2 wt.% phosphorous modified resin is the most effective one.