Characterization of Geometrical Changes of Spherical Advanced Pore Morphology (APM) Foam Elements during Compressive Deformation

Abstract

1. Introduction

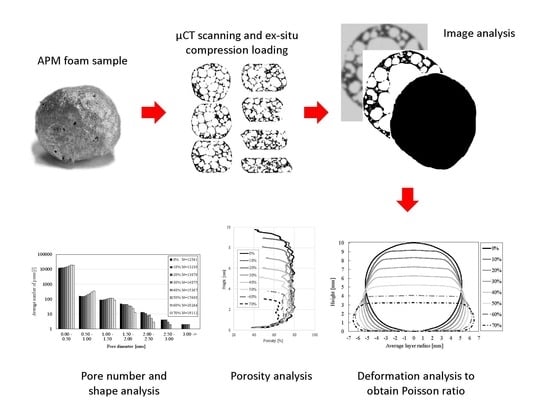

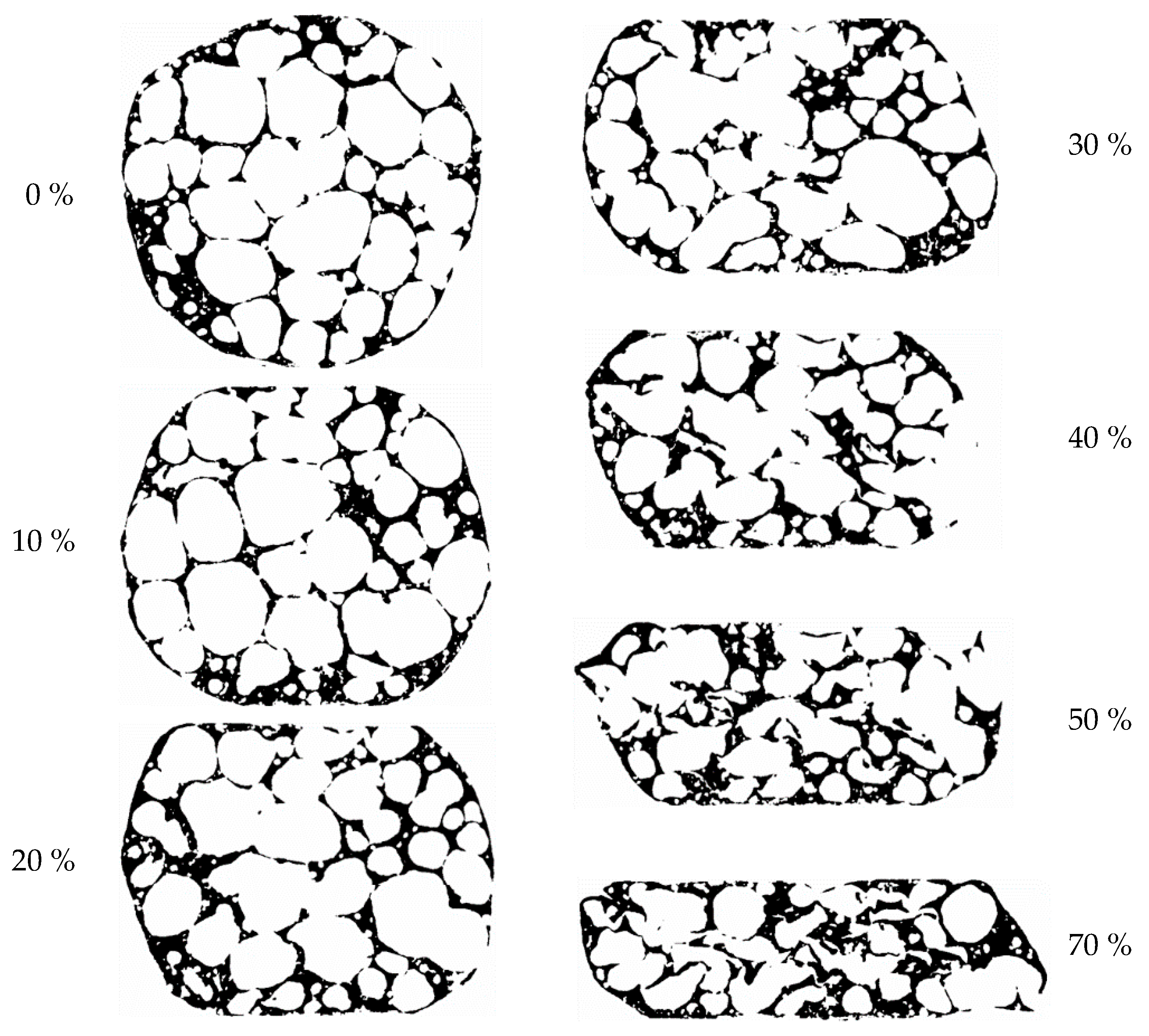

2. Methods

2.1. Micro-Computed Tomography and Ex-Situ Compression

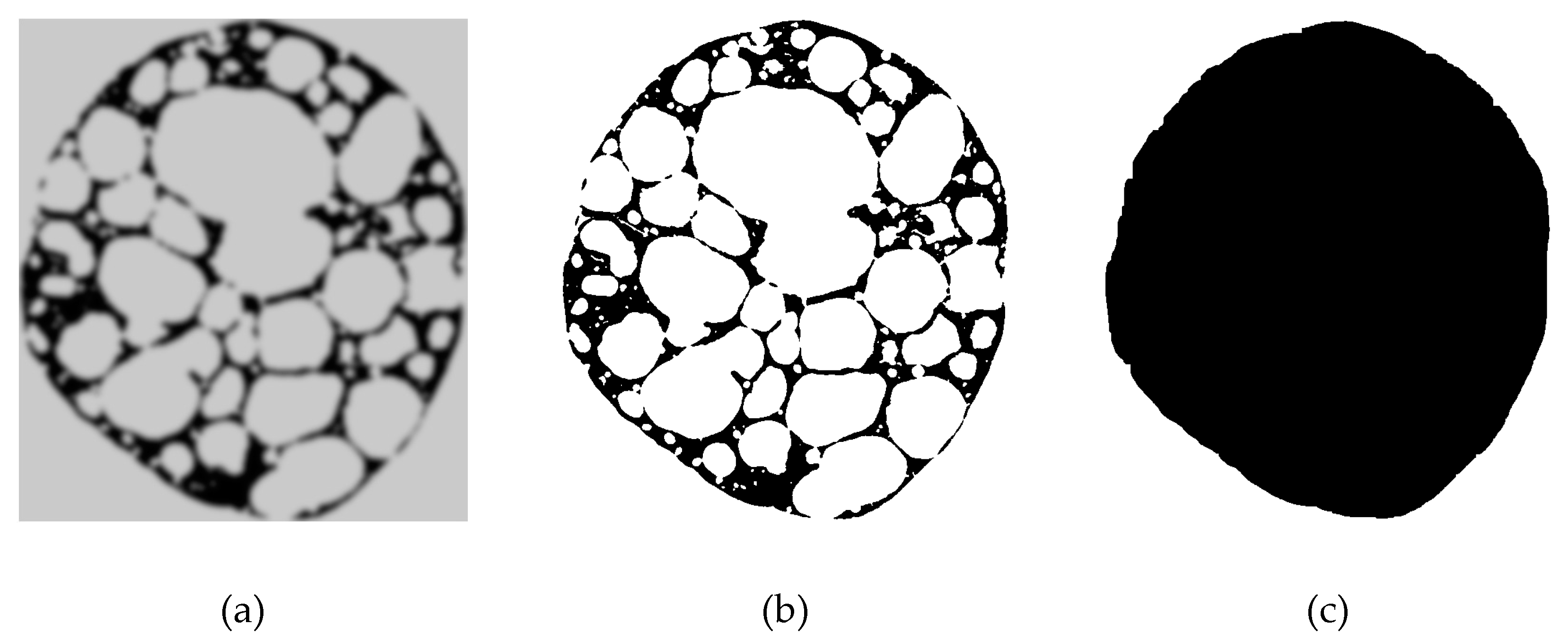

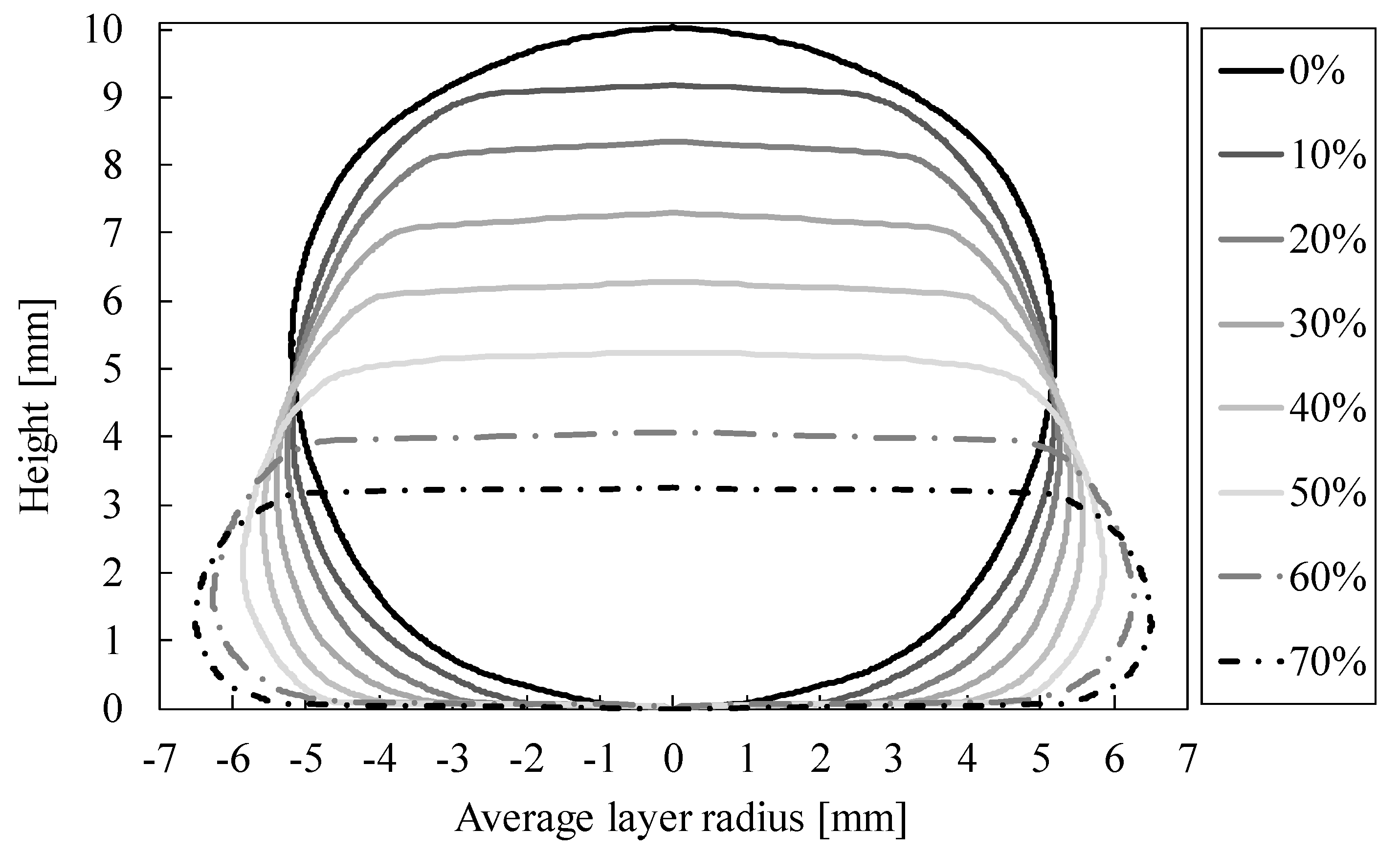

2.2. Geometrical Characterization

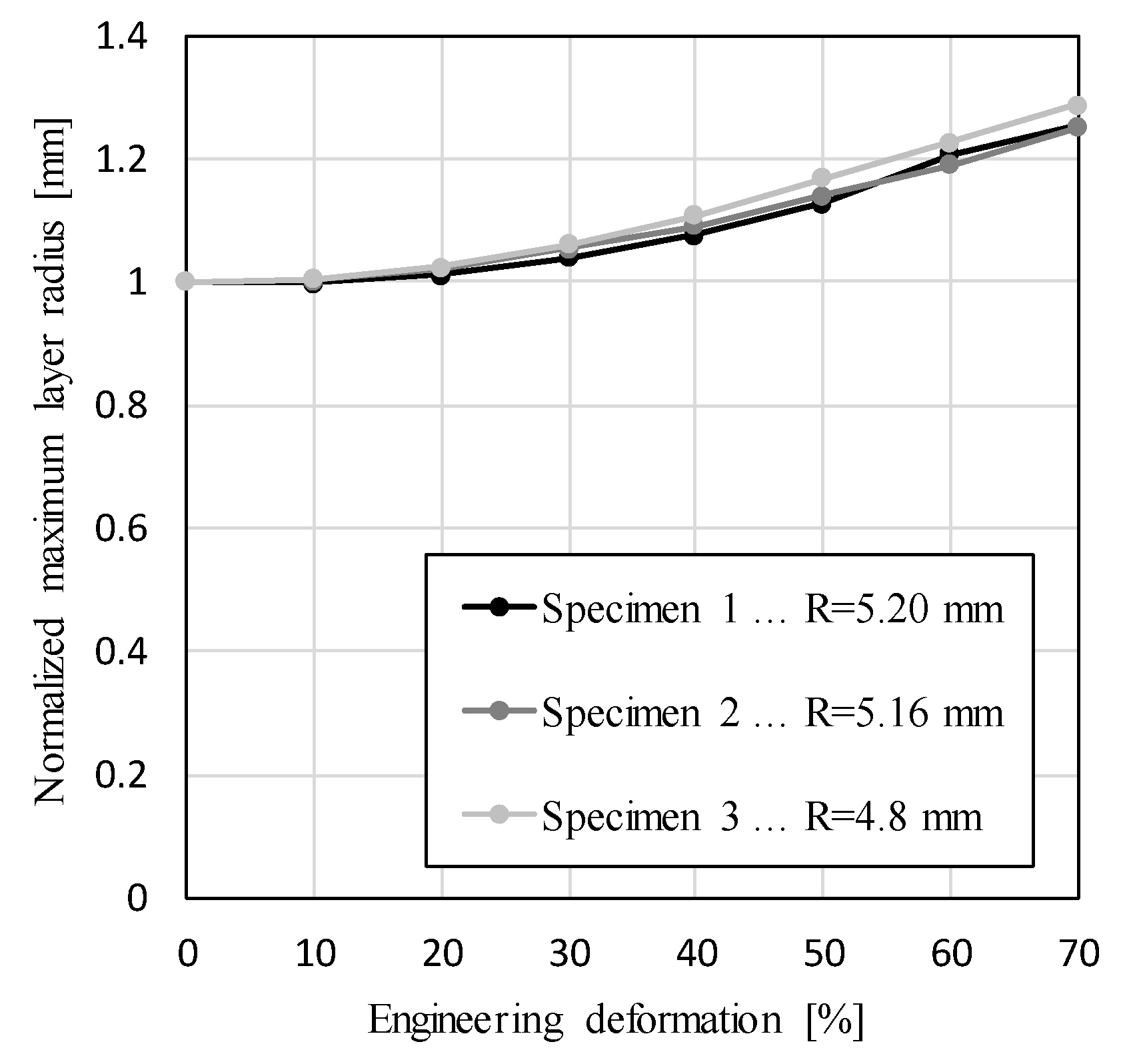

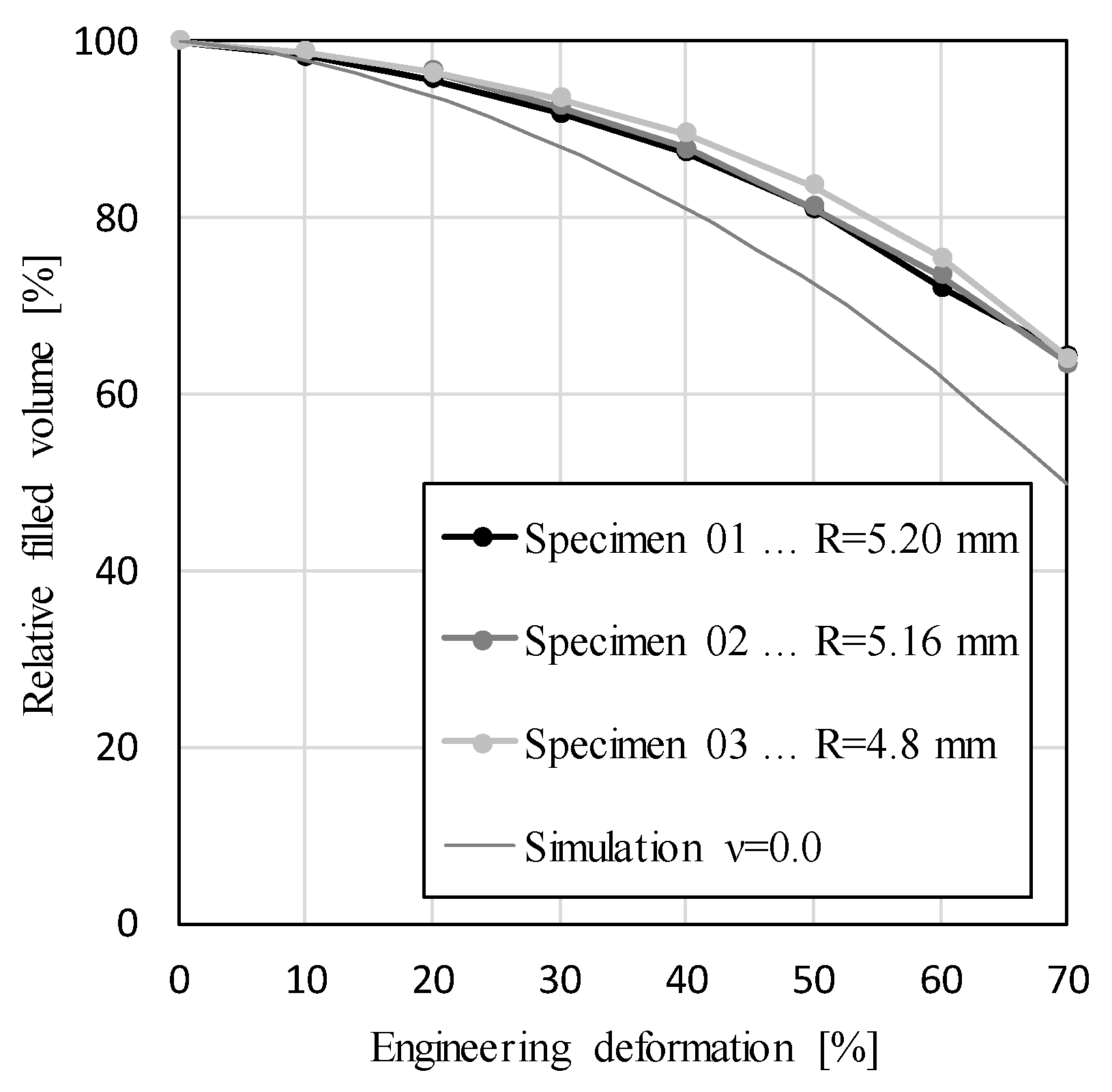

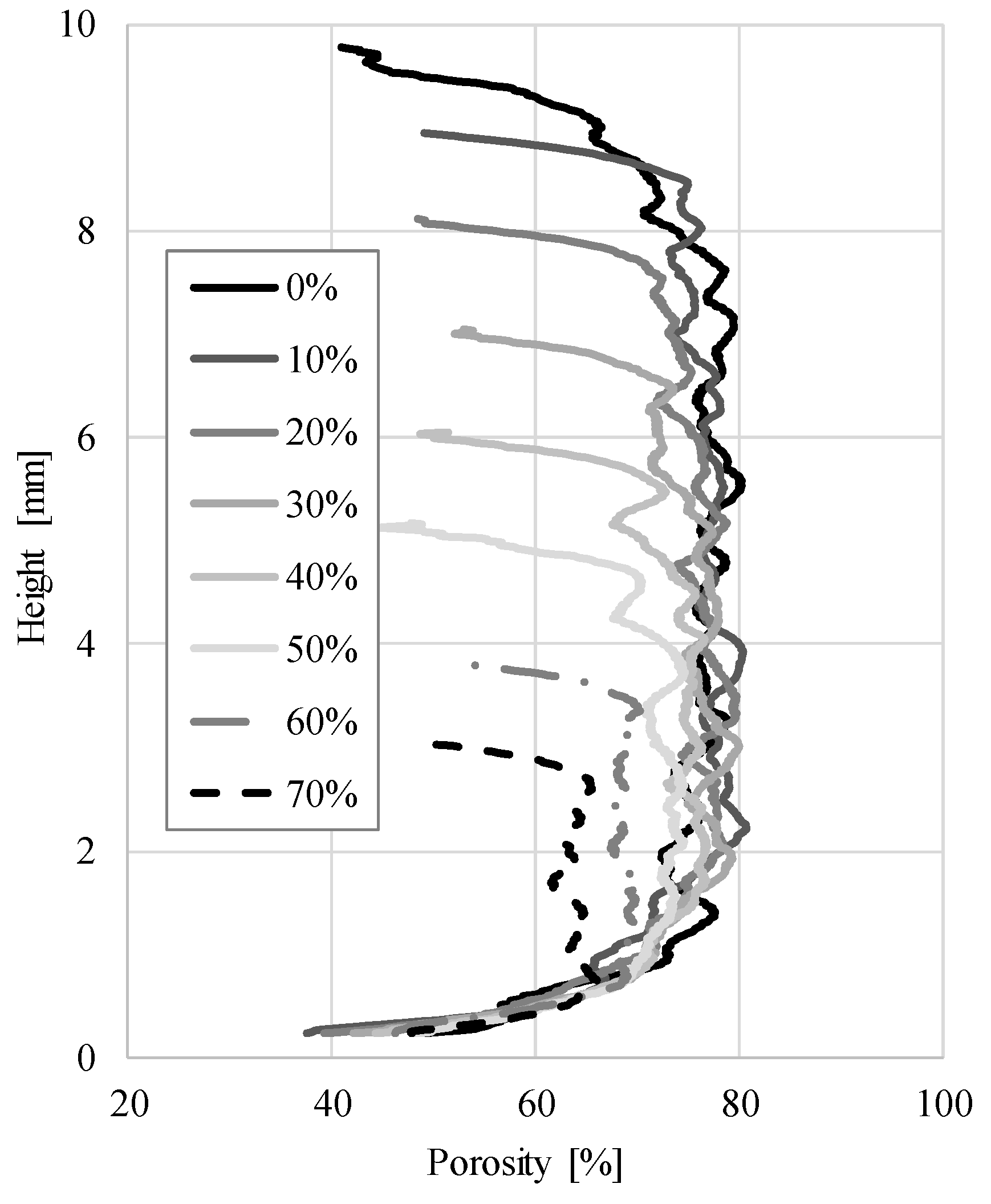

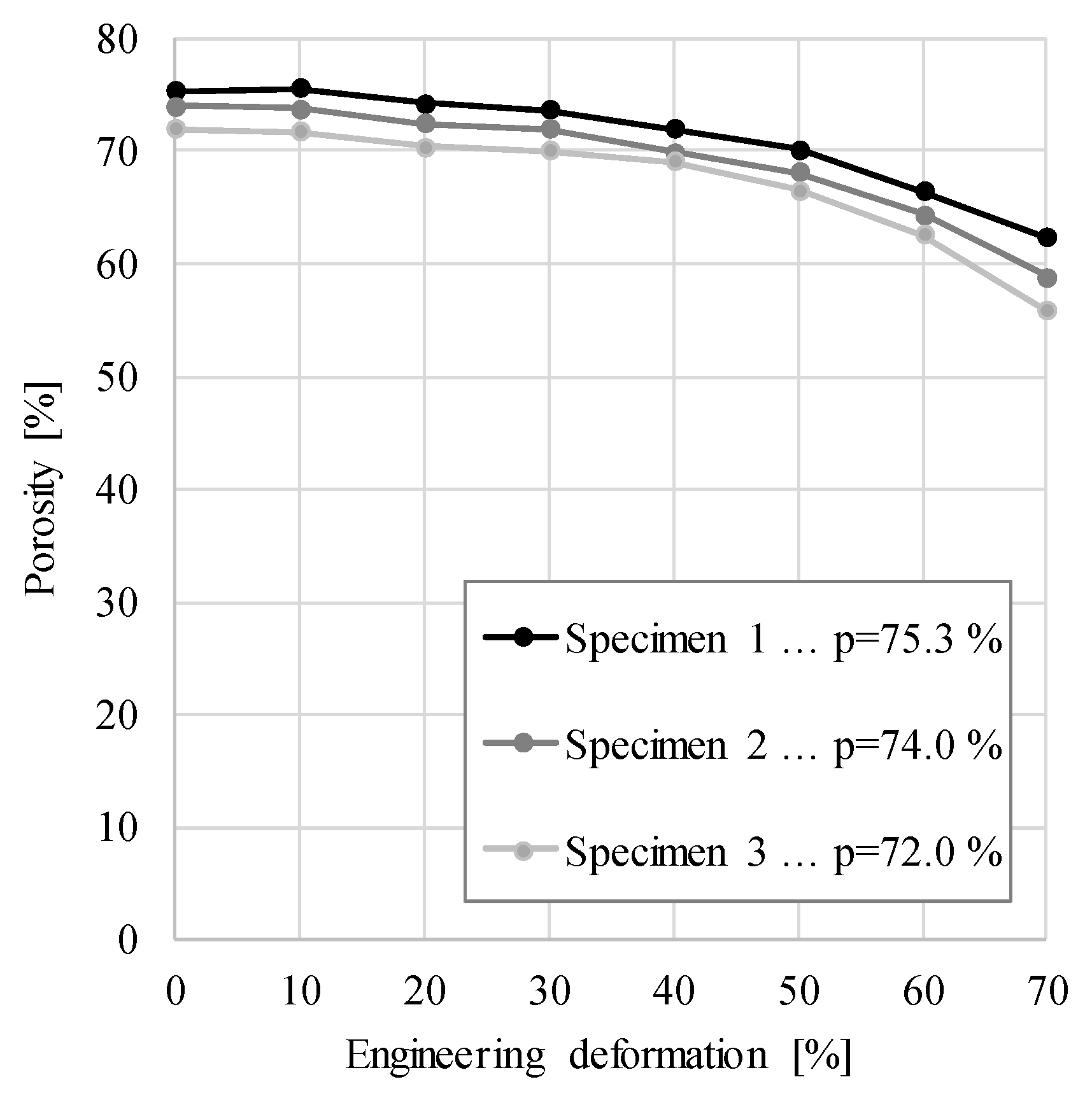

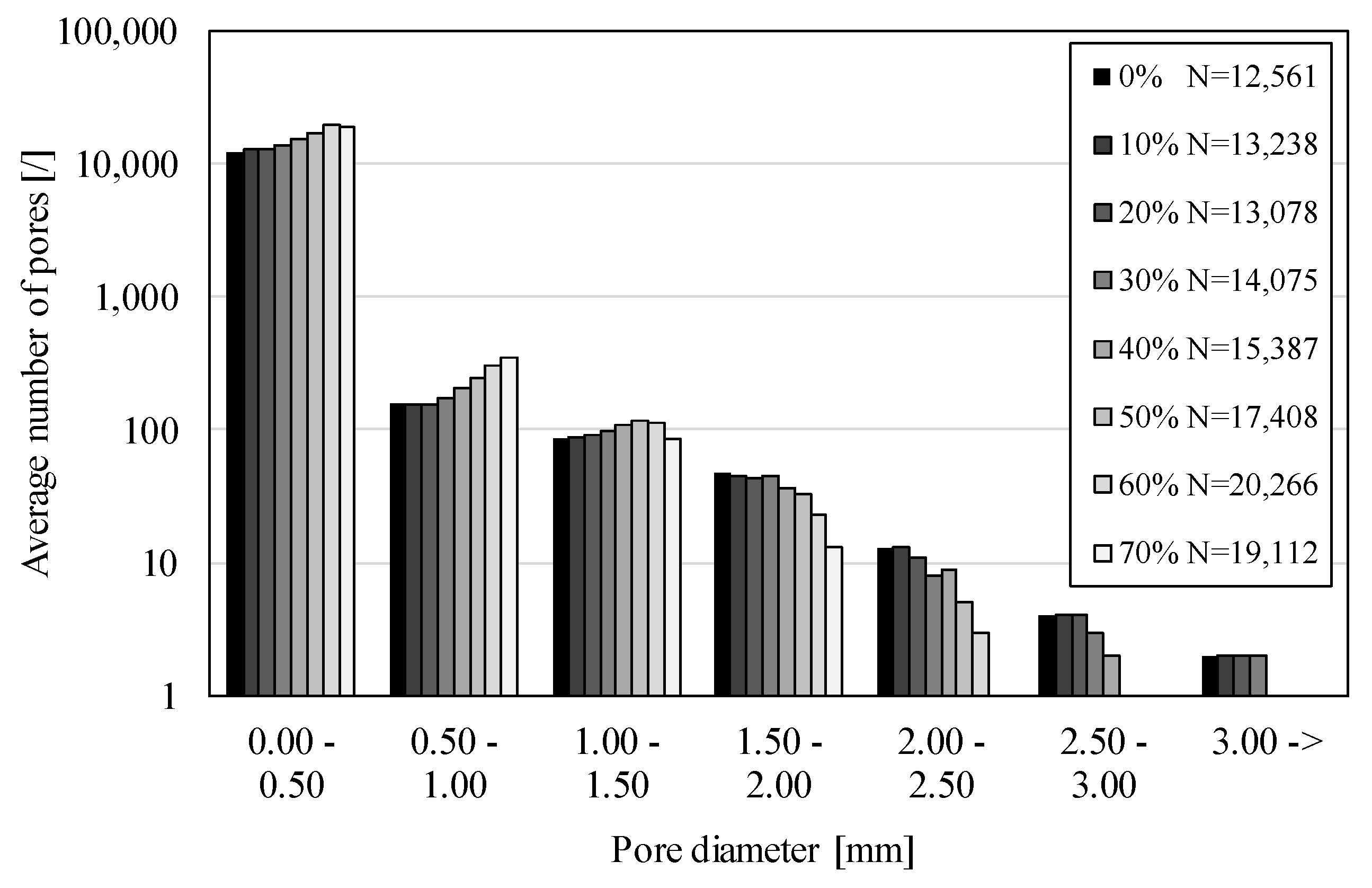

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Busse, M.; Rausch, G.; Stöbener, K.; Baumeister, J. Advanced pore morphology (APM) metal foams. In High Temperature Materials and Processes; Fraunhofer Institut Fertigungstechnik Materialforschung (IFAM): Bremen, Germany, 2007; pp. 231–238. [Google Scholar]

- Stöbener, K. Advanced Pore Morphology (APM)–Aluminiumschaum; University of Bremen: Bremen, Germany, 2007; pp. 31–54. [Google Scholar]

- Vesenjak, M.; Borovinšek, M.; Fiedler, T.; Higa, Y.; Ren, Z. Structural characterisation of advanced pore morphology (APM) foam elements. Mater. Lett. 2013, 110, 201–203. [Google Scholar] [CrossRef]

- Sulong, M.A.; Vesenjak, M.; Belova, I.V.; Murch, G.E.; Fiedler, T. Compressive properties of advanced pore morphology (APM) foam elements. Mater. Sci. Eng. A 2014, 607, 498–504. [Google Scholar] [CrossRef]

- Stöbener, K.; Lehmhus, D.; Avalle, M.; Peroni, L.; Busse, M. Aluminum foam-polymer hybrid structures (APM aluminum foam) in compression testing. Int. J. Solids Struct. 2008, 45, 5627–5641. [Google Scholar] [CrossRef]

- Baumeister, J.; Monno, M.; Goletti, M.; Mussi, V.; Weise, J. Dynamic behavior of hybrid APM (advanced pore morphology foam) and aluminum foam filled structures. Metals 2012, 2, 211–218. [Google Scholar] [CrossRef]

- Lehmhus, D.; Baumeister, J.; Stutz, L.; Schneider, E.; Stöbener, K.; Avalle, M.; Peroni, L.; Peroni, M. Mechanical characterization of particulate aluminum foams—Strain-rate, density and matrix alloy versus adhesive effects. Adv. Eng. Mater. 2010, 12, 596–603. [Google Scholar] [CrossRef]

- Stöbener, K.; Baumeister, J.; Rausch, G.; Rausch, M. Forming metal foams by simpler methods for cheaper solutions. Met. Powder Rep. 2005, 60, 12–16. [Google Scholar] [CrossRef]

- Weise, J.; Queiroz Barbosa, A.F.; Yezerska, O.; Lehmhus, D.; Baumeister, J. Mechanical behavior of particulate aluminium-epoxy hybrid foams based on cold-setting polymers. Adv. Eng. Mater. 2017, 19, 1–7. [Google Scholar] [CrossRef]

- Lehmhus, D.; Weise, J.; Baumeister, J. Cellular metals—from aluminium foams to iron/steel matrix syntactic foams. In Iron Matrix Syntactic Foams; DEStech Publications, Inc.: Lancester, Pennsylvania, 2017; pp. 201–245. ISBN 9783527327874. [Google Scholar]

- Rohatgi, P.K.; Gupta, N.; Schultz, B.F.; Luong, D.D. The synthesis, compressive properties, and applications of metal matrix syntactic foams. Jom 2011, 63, 36–42. [Google Scholar] [CrossRef]

- Rabiei, A.; Garcia-Avila, M. Effect of various parameters on properties of composite steel foams under variety of loading rates. Mater. Sci. Eng. A 2013, 564, 539–547. [Google Scholar] [CrossRef]

- Taherishargh, M.; Belova, I.V.; Murch, G.E.; Fiedler, T. Low-density expanded perlite–aluminium syntactic foam. Mater. Sci. Eng. A 2014, 604, 127–134. [Google Scholar] [CrossRef]

- Májlinger, K.; Orbulov, I.N. Characteristic compressive properties of hybrid metal matrix syntactic foams. Mater. Sci. Eng. A 2014, 606, 248–256. [Google Scholar] [CrossRef]

- Vesenjak, M.; Gačnik, F.; Krstulović-Opara, L.; Ren, Z. Mechanical properties of advanced pore morphology foam elements. Mech. Adv. Mater. Struct. 2014, 22, 359–366. [Google Scholar] [CrossRef]

- Duarte, I.; Vesenjak, M.; Krstulović-Opara, L.; Ren, Z. Compressive performance evaluation of APM (advanced pore morphology) foam filled tubes. Compos. Struct. 2015, 134, 409–420. [Google Scholar] [CrossRef]

- Vesenjak, M.; Gacnik, F.; Krstulovic-Opara, L.; Ren, Z. Behavior of composite advanced pore morphology foam. J. Compos. Mater. 2011, 45, 2823–2831. [Google Scholar] [CrossRef]

- Fiedler, T.; Sulong, M.A.; Vesenjak, M.; Higa, Y.; Belova, I.V.; Öchsner, A.; Murch, G.E. Determination of the thermal conductivity of periodic APM foam models. Int. J. Heat Mass Transf. 2014, 73, 826–833. [Google Scholar] [CrossRef]

- Hohe, J.; Hardenacke, V.; Fascio, V.; Girard, Y.; Baumeister, J.; Stöbener, K.; Weise, J.; Lehmhus, D.; Pattofatto, S.; Zeng, H.; et al. Numerical and experimental design of graded cellular sandwich cores for multi-functional aerospace applications. Mater. Des. 2012, 39, 20–32. [Google Scholar] [CrossRef]

- Lehmhus, D.; Vesenjak, M.; de Schampheleire, S.; Fiedler, T. From stochastic foam to designed structure: Balancing cost and performance of cellular metals. Materials 2017, 10, 922. [Google Scholar] [CrossRef] [PubMed]

- Vesenjak, M.; Krstulović-Opara, L.; Ren, Z.; Öchsner, A.; Domazet, Ž. Experimental study of open-cell cellular structures with elastic filler material. Exp. Mech. 2009, 49, 501–509. [Google Scholar] [CrossRef]

- Kader, M.A.; Islam, M.A.; Saadatfar, M.; Hazell, P.J.; Brown, A.D.; Ahmed, S.; Escobedo, J.P. Macro and micro collapse mechanisms of closed-cell aluminium foams during quasi-static compression. Mater. Des. 2017, 118, 11–21. [Google Scholar] [CrossRef]

- Campana, F.; Mancini, E.; Pilone, D.; Sasso, M. Strain rate and density-dependent strength of AlSi7 alloy foams. Mater. Sci. Eng. A 2016, 651, 657–667. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, X.; Shao, Z.; Li, Q.M. Image-based correlation between the meso-scale structure and deformation of closed-cell foam. Mater. Sci. Eng. A 2017, 688, 27–39. [Google Scholar] [CrossRef]

- Kovačič, A.; Ren, Z. On the porosity of advanced pore morphology structures. Compos. Struct. 2016, 158, 235–244. [Google Scholar] [CrossRef]

- Ulbin, M.; Borovinšek, M.; Higa, Y.; Shimojima, K.; Vesenjak, M.; Ren, Z. Internal structure characterization of AlSi7 and AlSi10 advanced pore morphology (APM) foam elements. Mater. Lett. 2014, 136, 416–419. [Google Scholar] [CrossRef]

- Felzenszwalb, P.F.; Huttenlocher, D.P. Distance transforms of sampled functions. Theory Comput. 2012, 8, 415–428. [Google Scholar] [CrossRef]

- Stephen, W. New Kind of Science, 1st ed.; Wolfram Media: Champaign, IL, USA, 2002. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Borovinšek, M.; Vesenjak, M.; Higa, Y.; Shimojima, K.; Ren, Z. Characterization of Geometrical Changes of Spherical Advanced Pore Morphology (APM) Foam Elements during Compressive Deformation. Materials 2019, 12, 1088. https://doi.org/10.3390/ma12071088

Borovinšek M, Vesenjak M, Higa Y, Shimojima K, Ren Z. Characterization of Geometrical Changes of Spherical Advanced Pore Morphology (APM) Foam Elements during Compressive Deformation. Materials. 2019; 12(7):1088. https://doi.org/10.3390/ma12071088

Chicago/Turabian StyleBorovinšek, Matej, Matej Vesenjak, Yoshikazu Higa, Ken Shimojima, and Zoran Ren. 2019. "Characterization of Geometrical Changes of Spherical Advanced Pore Morphology (APM) Foam Elements during Compressive Deformation" Materials 12, no. 7: 1088. https://doi.org/10.3390/ma12071088

APA StyleBorovinšek, M., Vesenjak, M., Higa, Y., Shimojima, K., & Ren, Z. (2019). Characterization of Geometrical Changes of Spherical Advanced Pore Morphology (APM) Foam Elements during Compressive Deformation. Materials, 12(7), 1088. https://doi.org/10.3390/ma12071088