Effect of Heat Treatment on the Compressive Behavior of Zinc Alloy ZA27 Syntactic Foam

Abstract

:1. Introduction

2. Materials and Methods

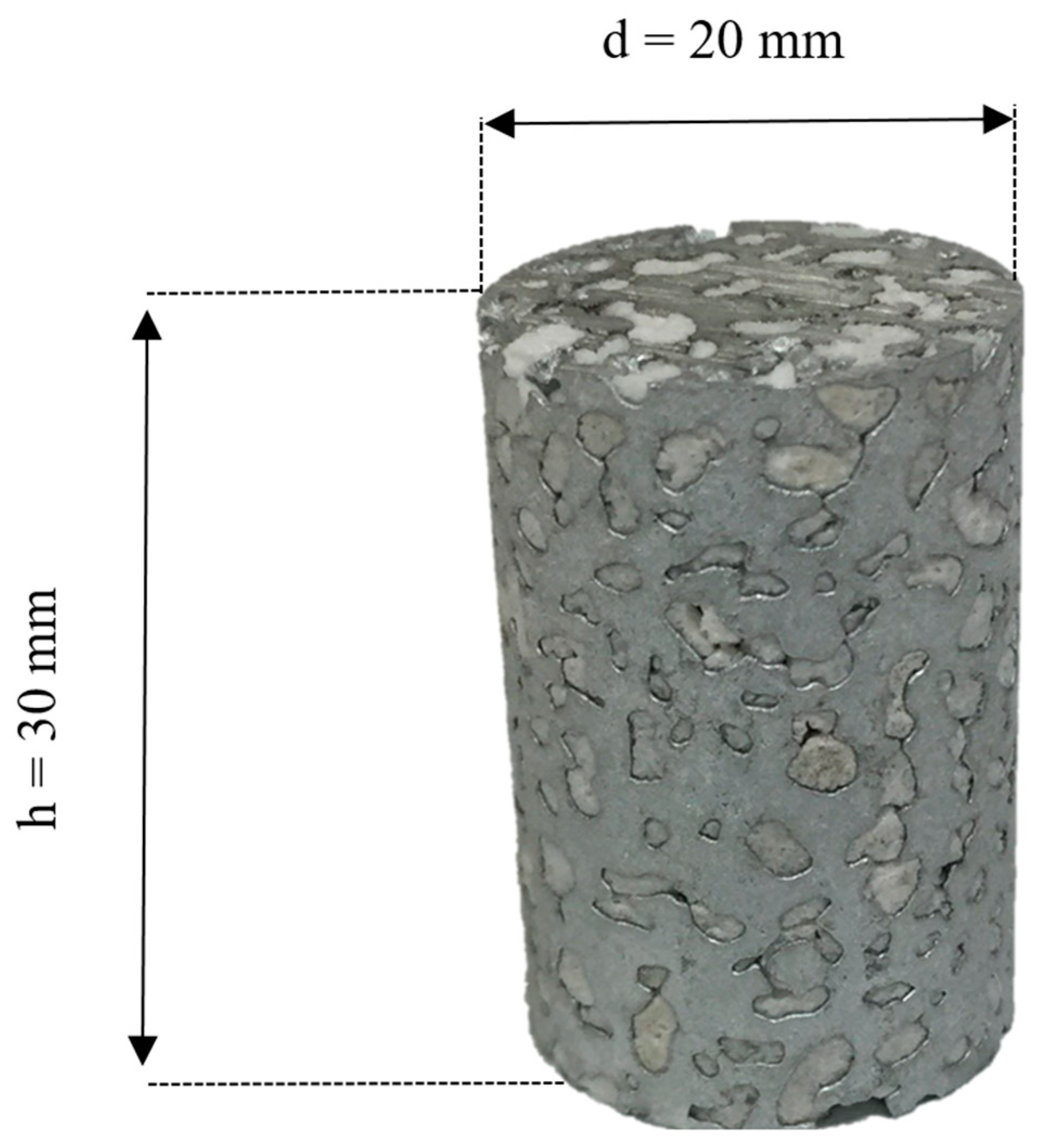

2.1. Sample Preparation

2.2. Sample Characterization

3. Results and Discussion

3.1. Physical Properties

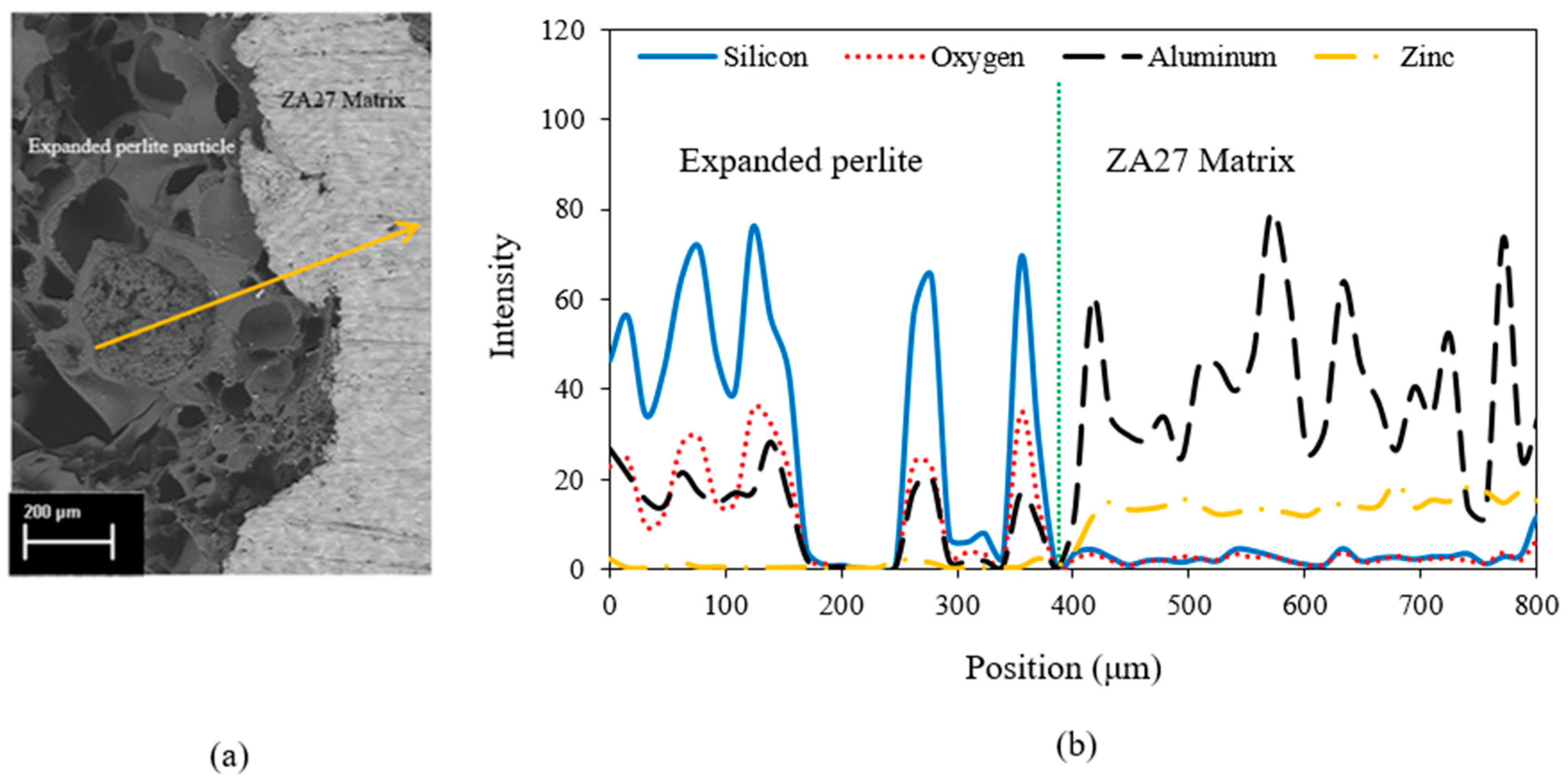

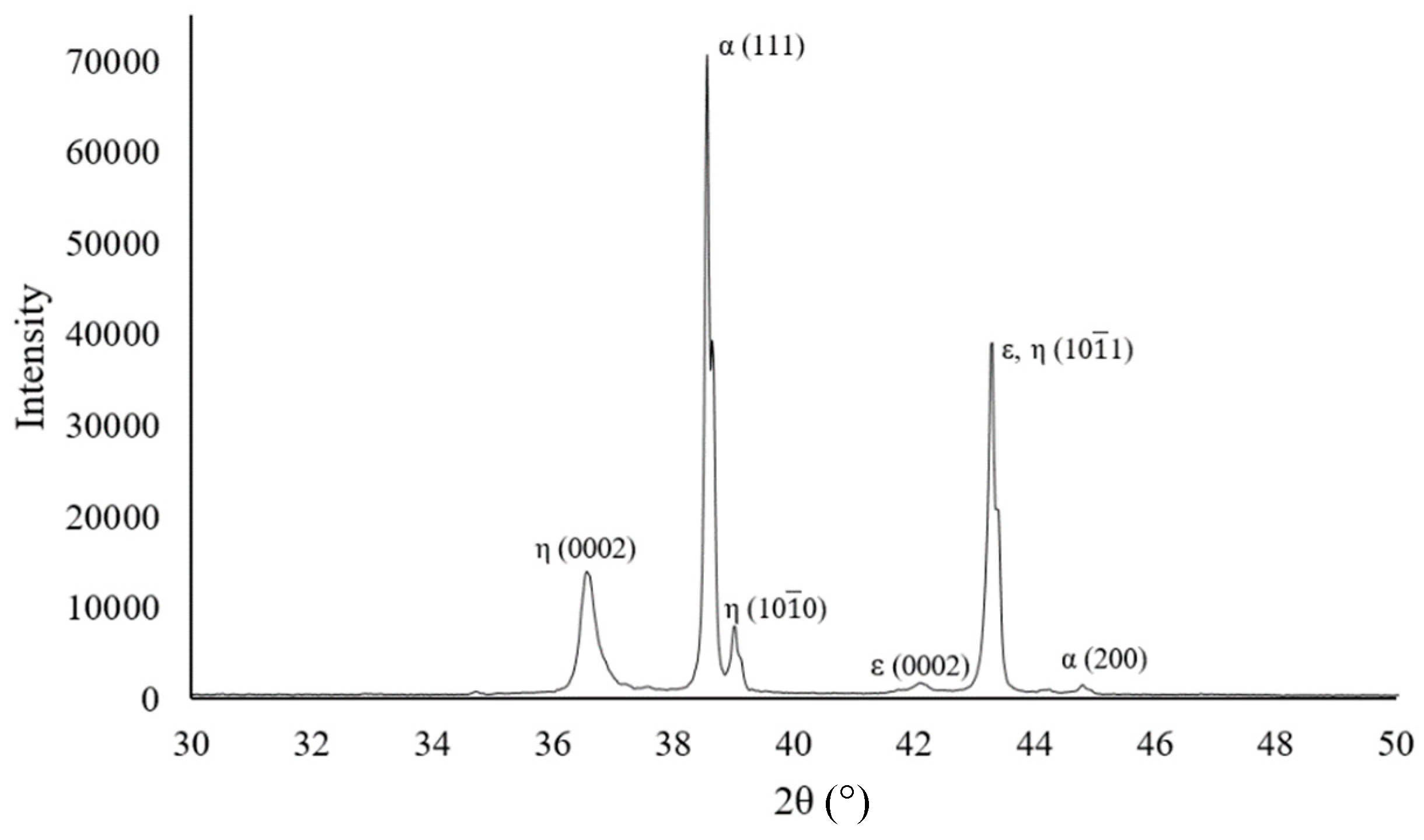

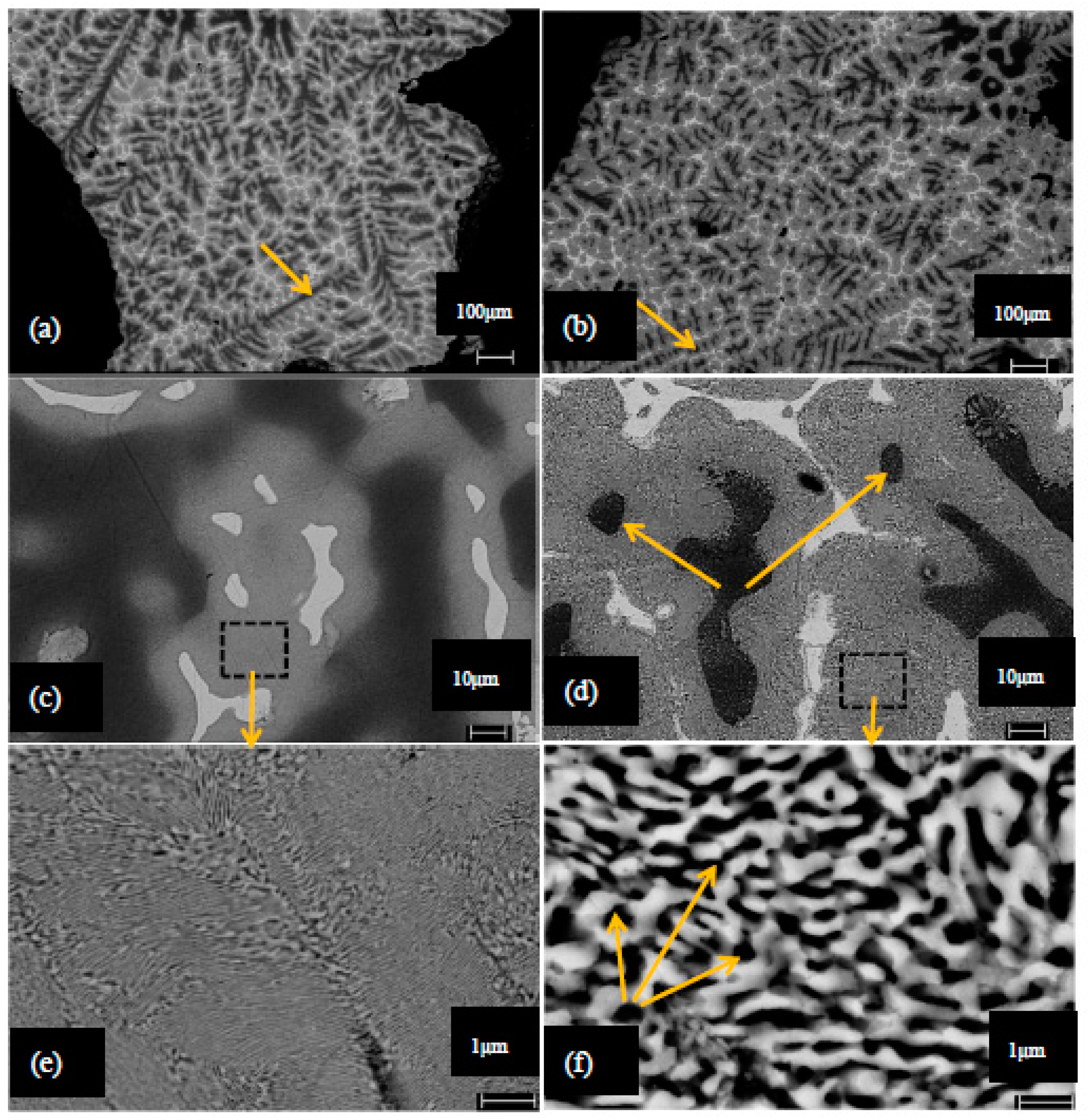

3.2. Microstructural Observations

3.3. Mechanical Properties of Constituents

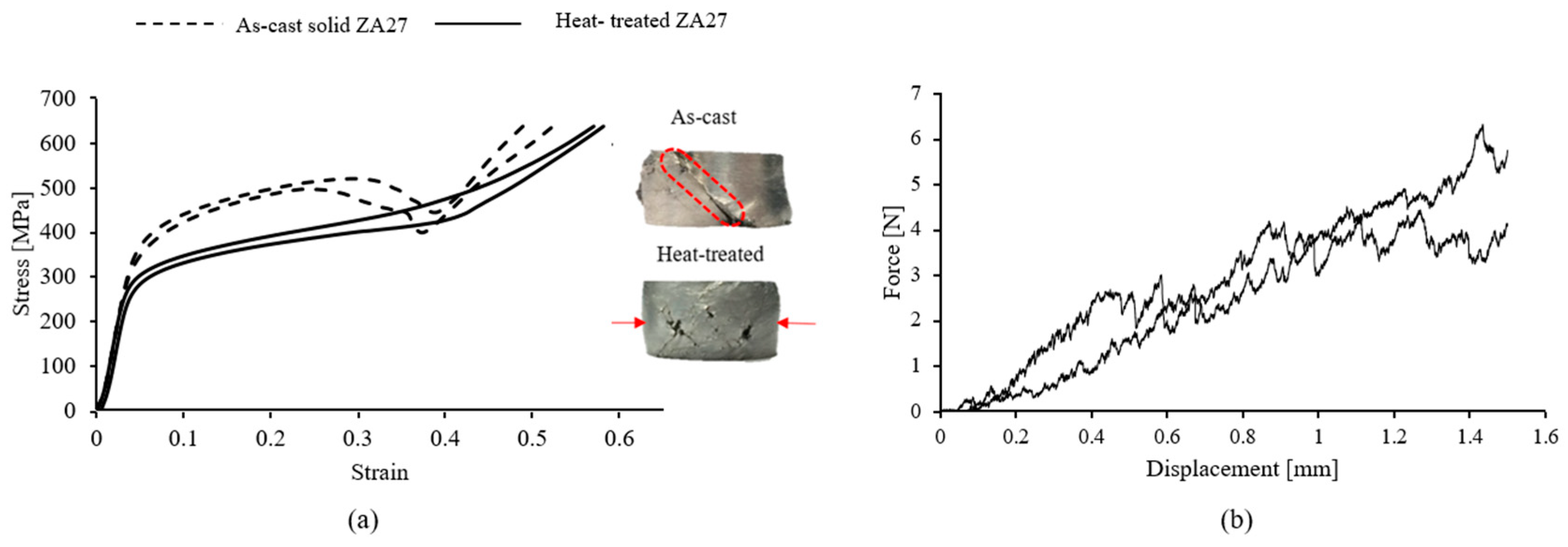

3.3.1. Mechanical Properties of Solid ZA27 Samples

3.3.2. Mechanical Properties of the EP Particles

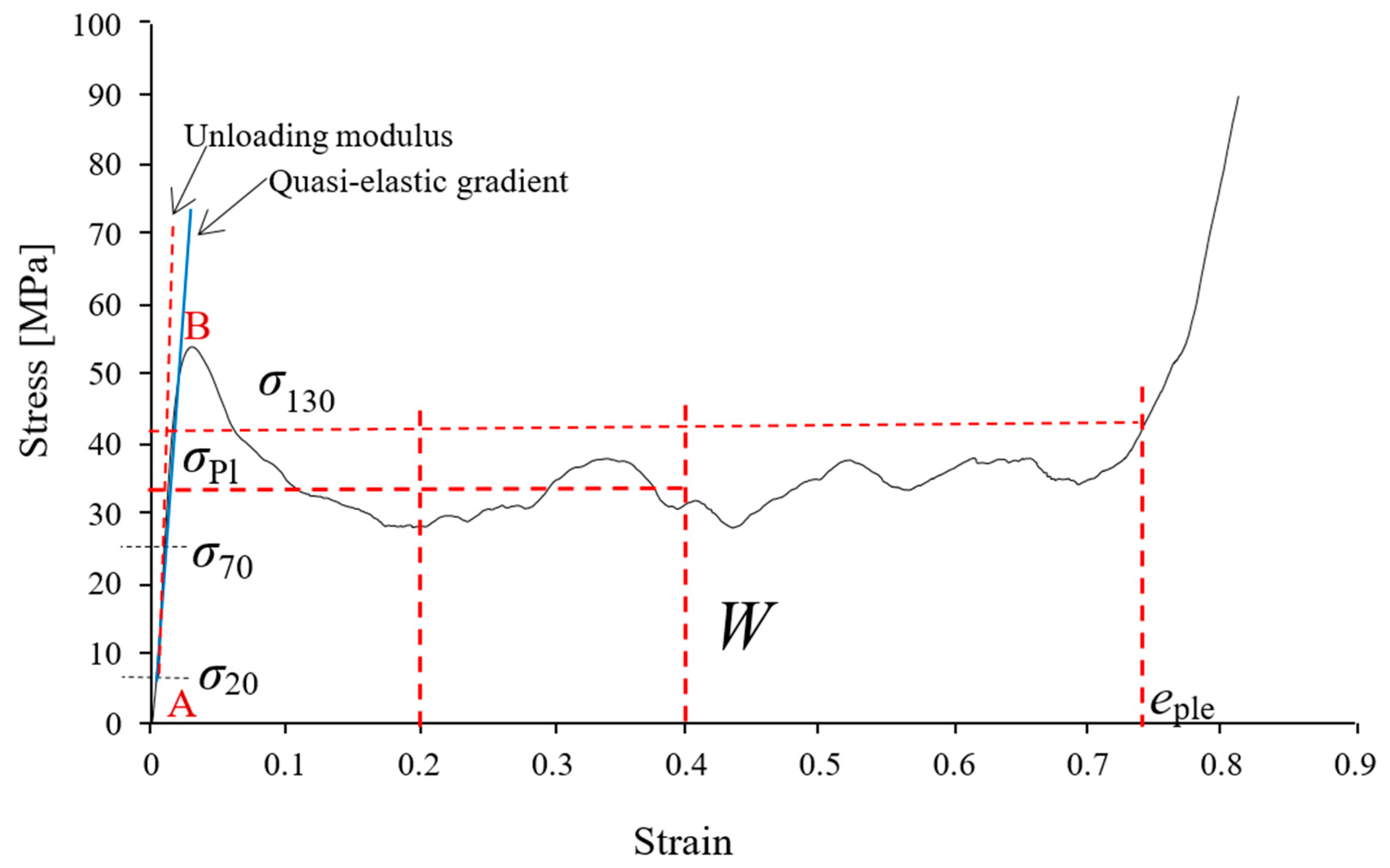

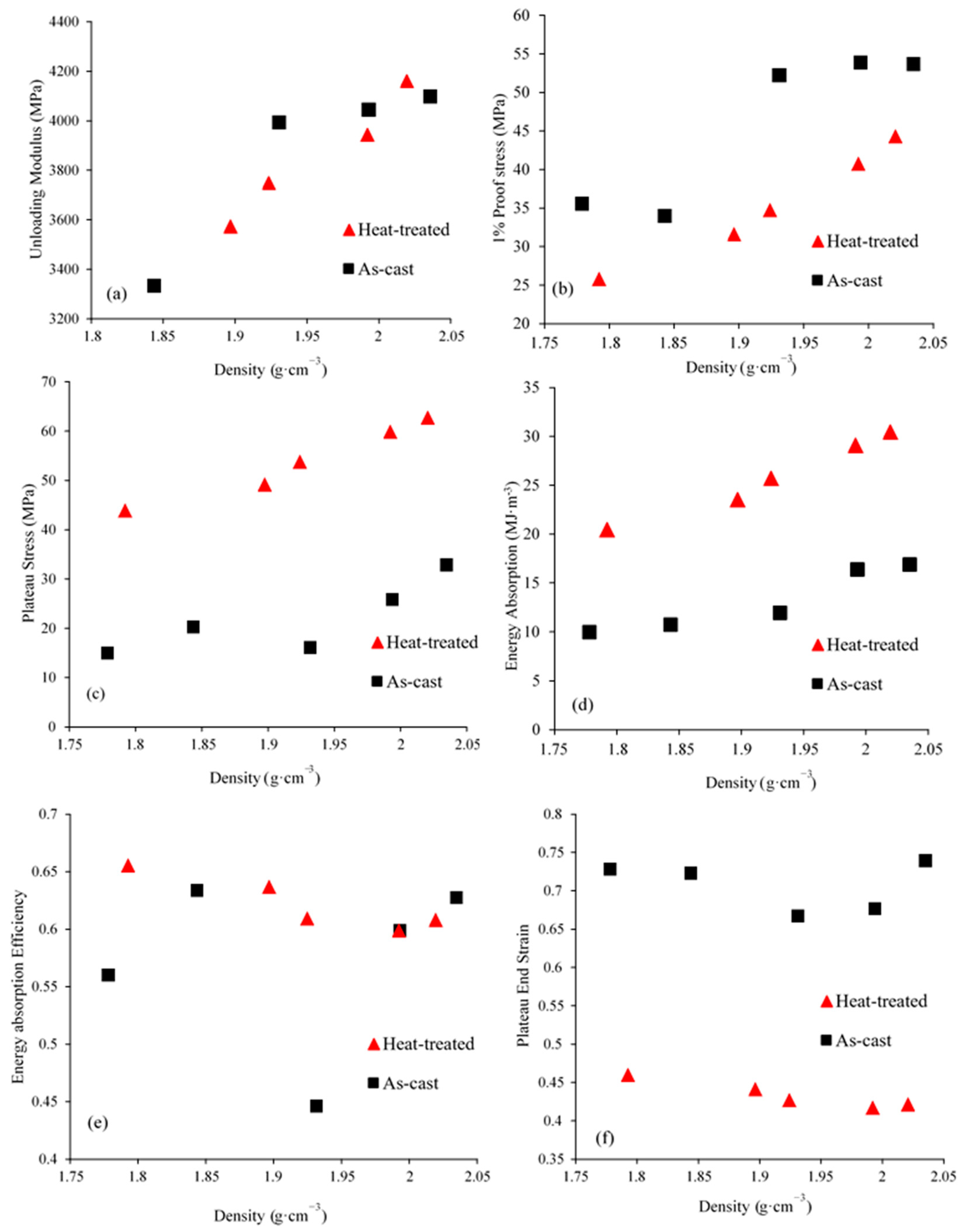

3.4. Mechanical Properties of ZA27 Syntactic Foam Samples

3.5. Failure Mechanisms

4. Conclusions

- (1)

- ZA27 syntactic foam samples with low densities (1.78–2.03 g·cm−3) can be manufactured.

- (2)

- (3)

- As previously observed in [17], the change of the microstructure increases the ductility of solid ZA27 alloy.

- (4)

- The increased matrix ductility changes the deformation mechanism of ZA27 syntactic foams from brittle fracture and macroscopic shear band formation to ductile deformation and layer-by-layer collapse.

- (5)

- The compressive stress-strain curves of as-cast ZA27 syntactic foam show distinct stress oscillations. This is linked to the propagation of macroscopic shear bands.

- (6)

- Heat-treated ZA27 syntactic foam exhibits a smooth stress plateau with gradually increasing stress. This is attributed to the ongoing plastic deformation and work hardening of foam struts.

- (7)

- Heat-treatment improves the specific energy absorption, plateau stress, and energy absorption efficiency of ZA 27 syntactic foam.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Degischer, H.P.; Kriszt, B. Handbook of Cellular Metals Production, Processing, Application, 1st ed.; WILEY-VCH Verlag GmbH: Weinheim, Germany, 2002. [Google Scholar]

- Ashby, M.F.; Evans, A.; Fleck, N.A.; Gibson, L.J.; Hutchinson, J.W.; Wadley, H.N.G.; Delale, F. Metal Foams: A Design Guide; Butterworth-Heinemann: Oxford, UK, 2000. [Google Scholar]

- Gibson, L.J.; Ashby, M.F. Cellular Solids: Structure and Properties, 2nd ed.; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar]

- Banhart, J. Manufacture, characterisation and application of cellular metals and metal foams. Prog. Mater Sci. 2001, 46, 559–632. [Google Scholar] [CrossRef]

- Gupta, N.; Rohatgi, P.K. Metal Matrix Syntactic Foams, Processing, Microstructure, Properties and Applications; DEStech Publication: Lancaster, PA, USA, 2015. [Google Scholar]

- Szlancsik, A.; Katona, B.; Bobor, K.; Májlinger, K.; Orbulov, I.N. Compressive behavior of aluminium matrix syntactic foams reinforced by iron hollow spheres. Mater. Des. 2015, 83, 230–237. [Google Scholar] [CrossRef]

- Daoud, A. Effect of fly ash addition on the structure and compressive properties of 4032–fly ash particle composite foams. J. Alloys Compd. 2009, 487, 618–625. [Google Scholar] [CrossRef]

- Braszczyńska-Malik, K.N.; Kamieniak, J. Analysis of interface between components in AZ91 magnesium alloy foam composite with Ni-P coated fly ash cenospheres. J. Alloys Compd. 2017, 720, 352–359. [Google Scholar] [CrossRef]

- Taherishargh, M.; Belova, I.V.; Murch, G.E.; Fiedler, T. Low-density expanded perlite–aluminium syntactic foam. Mater. Sci. Eng. A 2014, 604, 127–134. [Google Scholar] [CrossRef]

- Mondal, D.P.; Das, S.; Ramakrishnan, N.; Bhasker, K.U. Cenosphere filled aluminum syntactic foam made through stir-casting technique. Compos. Part A 2009, 40, 279–288. [Google Scholar] [CrossRef]

- Taherishargh, M.; Belova, I.V.; Murch, G.E.; Fiedler, T. The effect of particle shape on mechanical properties of perlite/metal syntactic foam. J. Alloys Compd. 2017, 693, 55–60. [Google Scholar] [CrossRef]

- Apelian, D.; Paliwal, M.; Herrschaft, D.C. Casting with Zinc alloys. JOM 1981, 33, 12–20. [Google Scholar] [CrossRef]

- Ares, A.E.; Schvezov, C.E. The effect of structure on tensile properties of directionally solidified Zn-based alloys. J. Cryst. Growth 2011, 318, 59–65. [Google Scholar] [CrossRef]

- Porter, F.C. Corrosion Resistance of Zinc and Zinc Alloys; Marcel Dekker: New York, NY, USA, 1994. [Google Scholar]

- Liu, Z.; Li, R.; Jiang, R.; Li, X.; Zhang, M. Effects of Al addition on the structure and mechanical properties of Zn alloys. J. Alloys Compd. 2016, 687, 885–892. [Google Scholar] [CrossRef]

- Venkatappa, S.; Sharma, K.V. Influence of heat treatment on microstructure and mechanical properties of some zinc based alloys. IJoMS 2011, 6, 57–64. [Google Scholar]

- Liu, Y.; Li, H.Y.; Jiang, H.F.; Lu, X.C. Effects of heat treatment on microstructure and mechanical properties of ZA27 alloy. Trans. Nonferrous Met. Soc. China 2013, 23, 642–649. [Google Scholar] [CrossRef]

- Astaraie, A.H.; Shahverdi, H.R.; Elahi, S.H. Compressive behavior of Zn-22Al closed-cell foams under uniaxial quasi-static loading. Trans. Nonferrous Met. Soc. China 2015, 25, 162–169. [Google Scholar] [CrossRef]

- Mondal, D.P.; Goel, M.D.; Bagde, N.; Jha, N.; Sahu, S.; Barnwal, A.K. Closed cell ZA27–SiC foam made through stir-casting technique. Mater. Des. 2014, 57, 315–324. [Google Scholar] [CrossRef]

- Liu, J.; Yu, S.; Zhu, X.; Wei, M.; Luo, Y.; Liu, Y. Correlation between ceramic additions and compressive properties of Zn–22Al matrix composite foams. J. Alloys Compd. 2009, 476, 220–225. [Google Scholar] [CrossRef]

- Kitazono, K.; Takiguchi, Y. Strain rate sensitivity and energy absorption of Zn–22Al foams. Scr. Mater. 2006, 55, 501–504. [Google Scholar] [CrossRef]

- Daoud, A. Synthesis and characterization of novel ZnAl22 syntactic foam composites via casting. Mater. Sci. Eng. A 2008, 488, 281–295. [Google Scholar] [CrossRef]

- Roulia, M.; Chassapis, K.; Fotinopoulos, C.; Savvidis, T.; Katakis, D. Dispersion and Sorption of Oil Spills by Emulsifier-Modified Expanded Perlite. Spill Sci. Technol. Bull. 2003, 8, 425–431. [Google Scholar] [CrossRef]

- Singh, M.; Garg, M. Perlite-based building materials—A review of current applications. Constr. Build. Mater. 1991, 5, 75–81. [Google Scholar] [CrossRef]

- ASTM. Standard Specification for Zinc and Zinc-Aluminum (ZA) Alloy Foundry and Die Castings; B86-13; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Chakarbarti, A.K. Casting Technology and Cast Alloys; Prentice-Hall: New Delhi, India, 2005. [Google Scholar]

- Arifuzzaman, M.; Kim, H.S. Novel mechanical behavior of perlite/sodium silicate composites. Constr. Build. Mater. 2015, 93, 230–240. [Google Scholar] [CrossRef]

- Huo, D.W.; Yang, J.; Zhou, X.Y.; Wang, H.; Zhang, T.K. Preparation of open-celled aluminum foams by counter-gravity infiltration casting. Trans. Nonferrous Met. Soc. China 2012, 22, 85–89. [Google Scholar] [CrossRef]

- Al-Sahlani, K.; Taherishargh, M.; Kisi, E.; Fiedler, T. Controlled shrinkage of expanded glass particles in metal syntactic foams. Materials 2017, 10, 1073. [Google Scholar] [CrossRef] [PubMed]

- ISO 13314. Mechanical Testing of Metals—Ductility Testing—Compression Test for Porous and Cellular Metals; International Organization for Standardization: Geneva, Switzerland, 2011. [Google Scholar]

- Braszczyńska-Malik, K.N.; Kamieniak, J. AZ91 magnesium matrix foam composites with fly ash cenospheres fabricated by negative pressure infiltration technique. Mater. Charact. 2017, 128, 209–216. [Google Scholar] [CrossRef]

- Taherishargh, M.; Sulong, M.A.; Belova, I.V.; Murch, G.E.; Fiedler, T. On the particle size effect in expanded perlite aluminium syntactic foam. Mater. Des. 2015, 66, 294–303. [Google Scholar] [CrossRef]

- Orbulov, I.N. Compressive properties of aluminium matrix syntactic foams. Mater. Sci. Eng. A 2012, 555, 52–56. [Google Scholar] [CrossRef]

| Sample No* | SF Density (g·cm−3) | |||

|---|---|---|---|---|

| AC-1 | 1.78 | 33.75 | 56.88 | 9.37 |

| AC-2 | 1.84 | 35.03 | 56.88 | 8.09 |

| AC-3 | 1.93 | 36.80 | 56.88 | 6.32 |

| AC-4 | 1.99 | 38.06 | 56.88 | 5.06 |

| AC-5 | 2.03 | 38.89 | 56.88 | 4.23 |

| HT-1 | 1.79 | 34.03 | 56.88 | 9.09 |

| HT-2 | 1.89 | 36.12 | 56.88 | 7.00 |

| HT-3 | 1.92 | 36.66 | 56.88 | 6.46 |

| HT-4 | 1.99 | 38.04 | 56.88 | 5.08 |

| HT-5 | 2.02 | 38.58 | 56.88 | 4.54 |

| Phase | Zn (wt.%) | Al (wt.%) | Cu (wt.%) |

|---|---|---|---|

| α | 44.07 | 55.15 | 0.78 |

| ϵ | 94.49 | 1.81 | 3.70 |

| η | 90.66 | 6.84 | 2.50 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Movahedi, N.; Murch, G.E.; Belova, I.V.; Fiedler, T. Effect of Heat Treatment on the Compressive Behavior of Zinc Alloy ZA27 Syntactic Foam. Materials 2019, 12, 792. https://doi.org/10.3390/ma12050792

Movahedi N, Murch GE, Belova IV, Fiedler T. Effect of Heat Treatment on the Compressive Behavior of Zinc Alloy ZA27 Syntactic Foam. Materials. 2019; 12(5):792. https://doi.org/10.3390/ma12050792

Chicago/Turabian StyleMovahedi, Nima, Graeme E. Murch, Irina V. Belova, and Thomas Fiedler. 2019. "Effect of Heat Treatment on the Compressive Behavior of Zinc Alloy ZA27 Syntactic Foam" Materials 12, no. 5: 792. https://doi.org/10.3390/ma12050792

APA StyleMovahedi, N., Murch, G. E., Belova, I. V., & Fiedler, T. (2019). Effect of Heat Treatment on the Compressive Behavior of Zinc Alloy ZA27 Syntactic Foam. Materials, 12(5), 792. https://doi.org/10.3390/ma12050792