Mechanical Characterization of Different Aluminium Foams at High Strain Rates

Abstract

1. Introduction

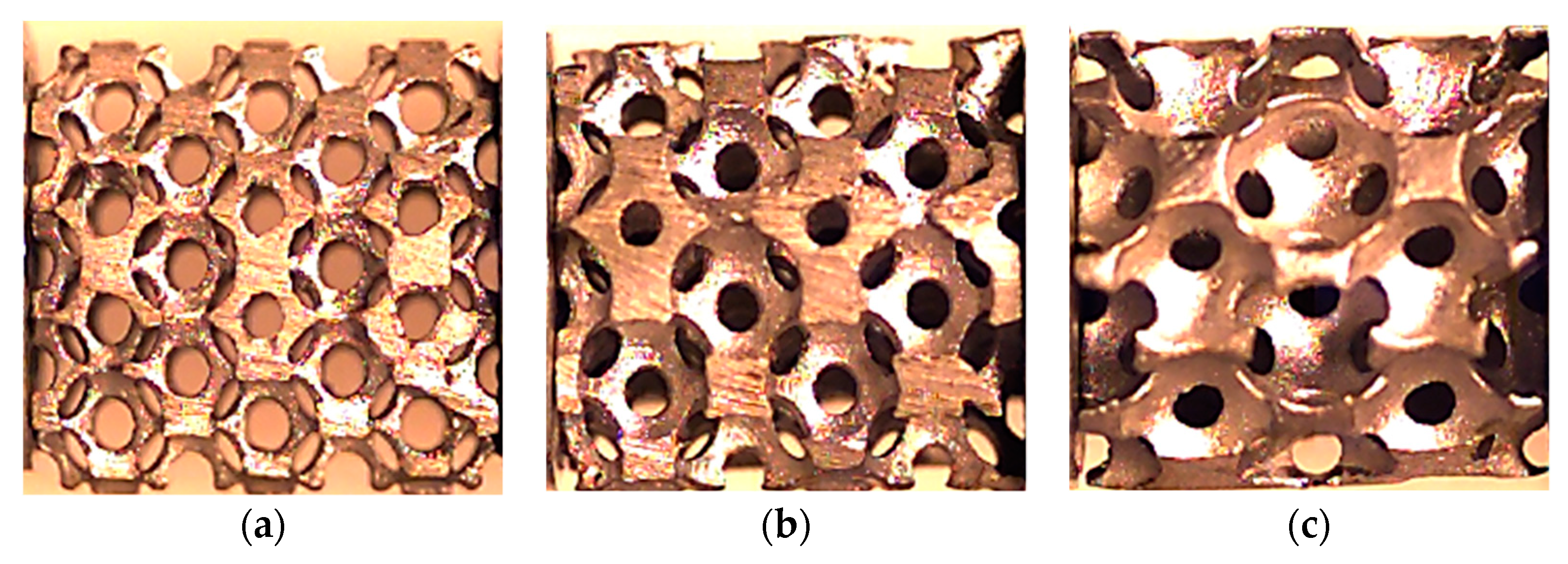

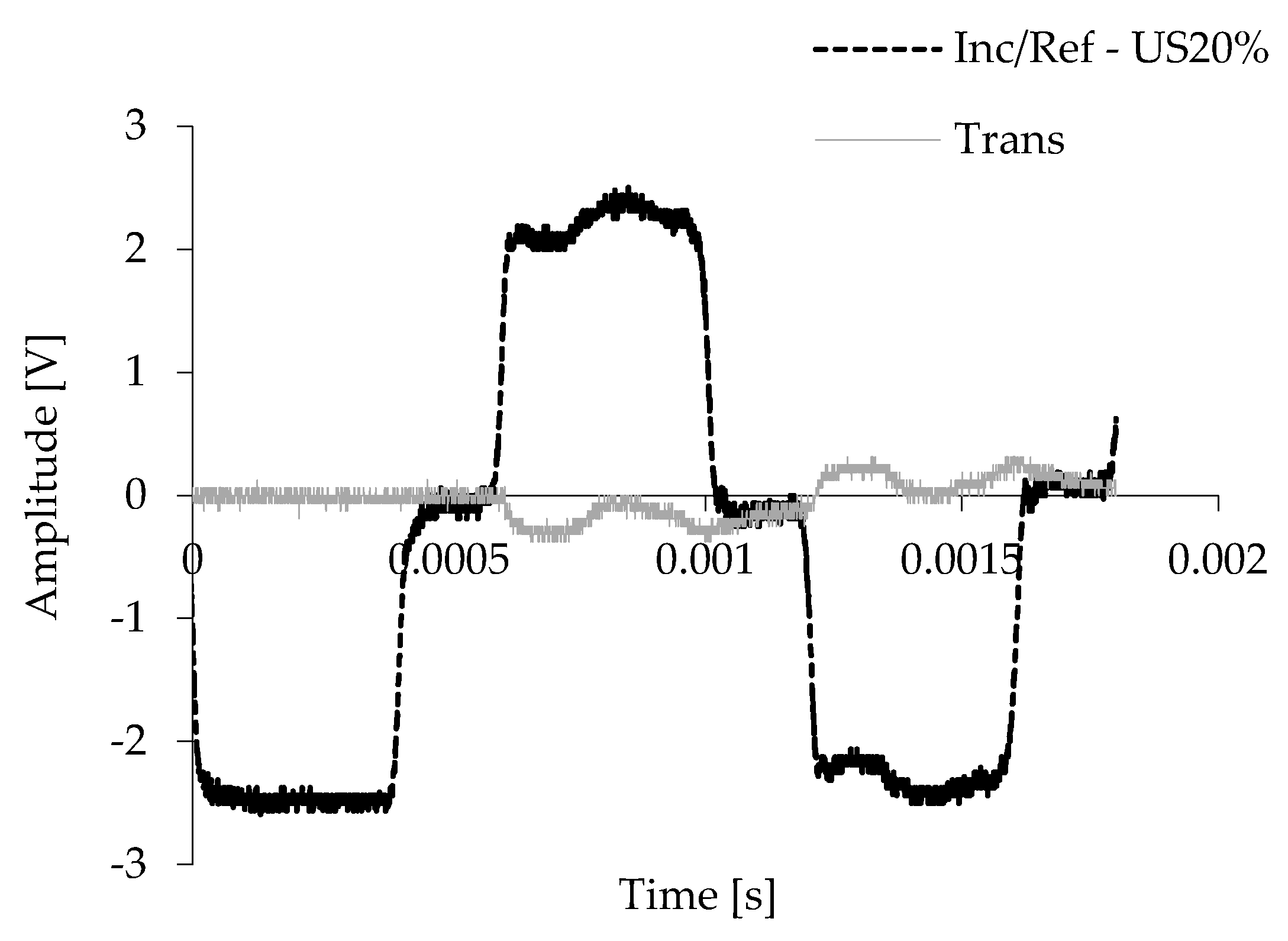

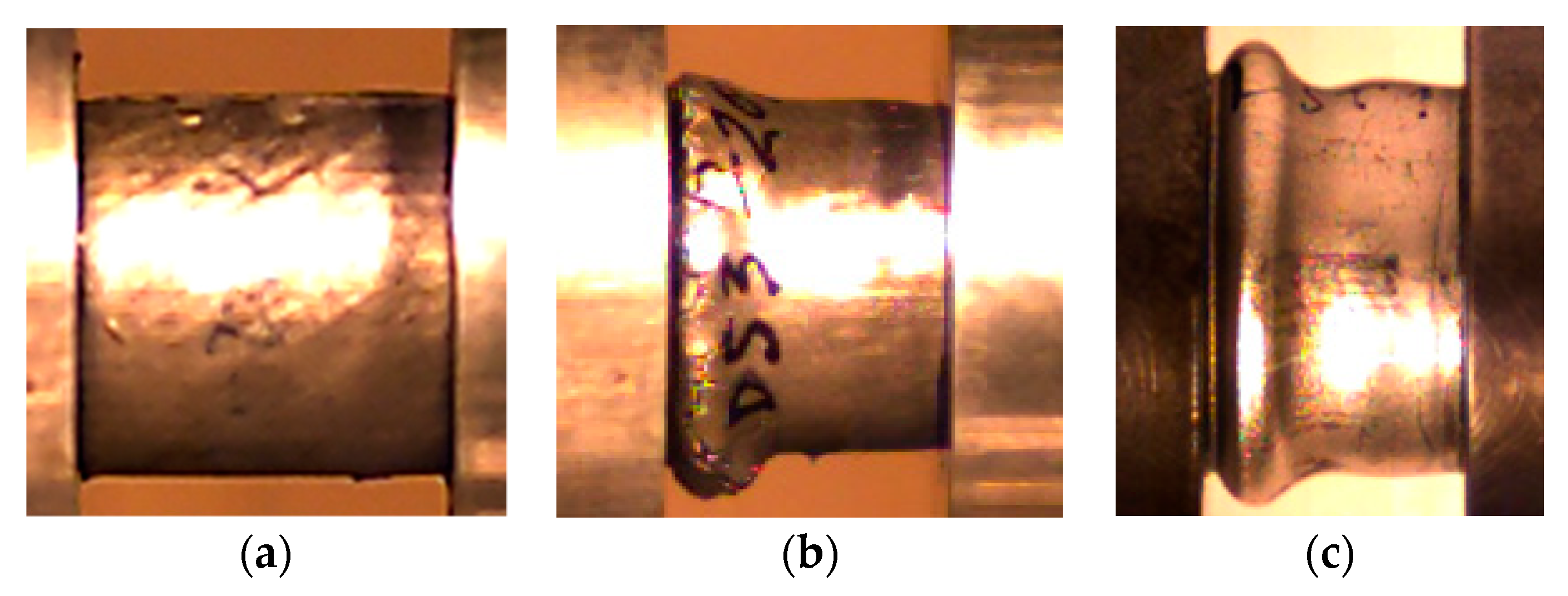

2. Materials and Methods

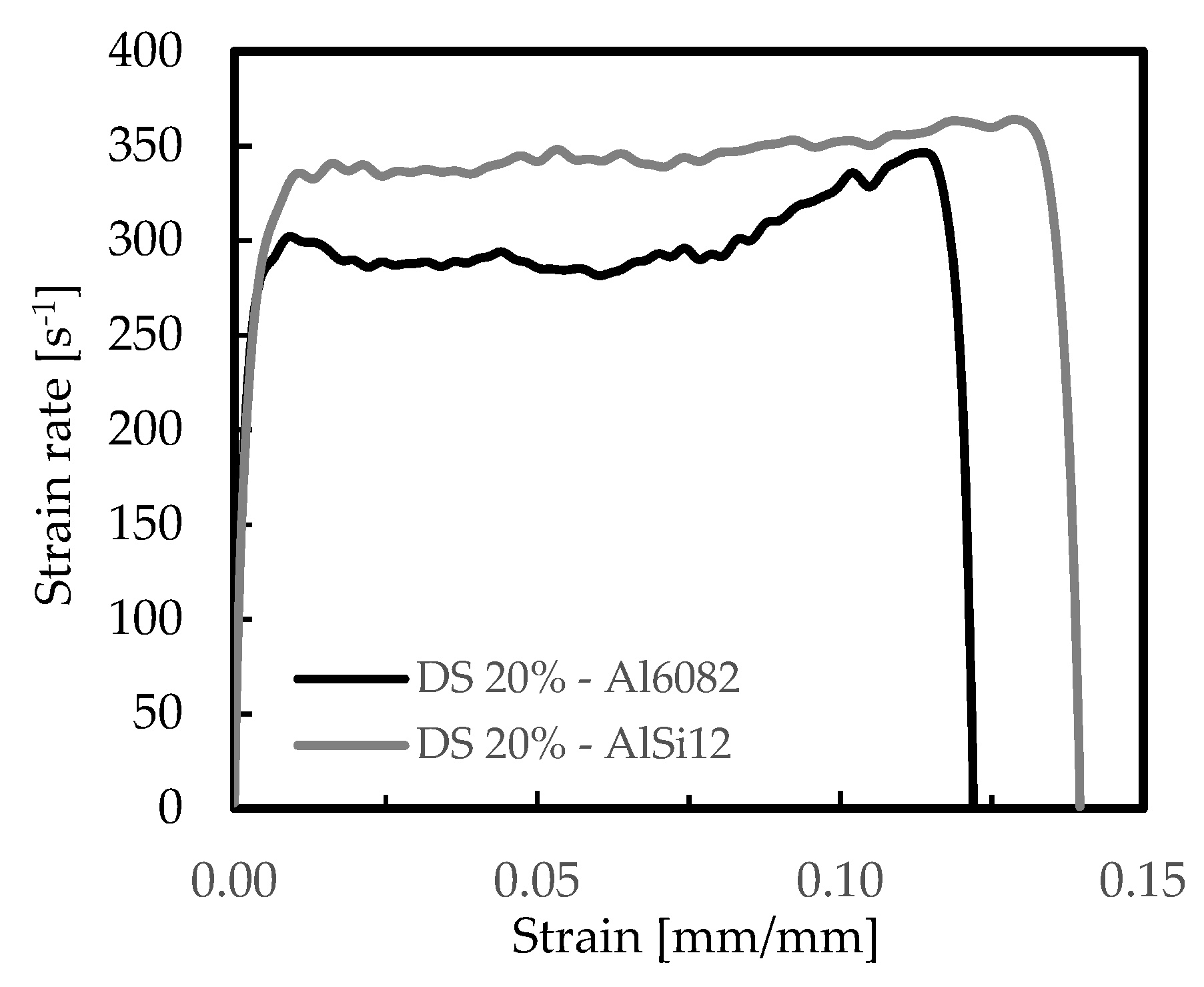

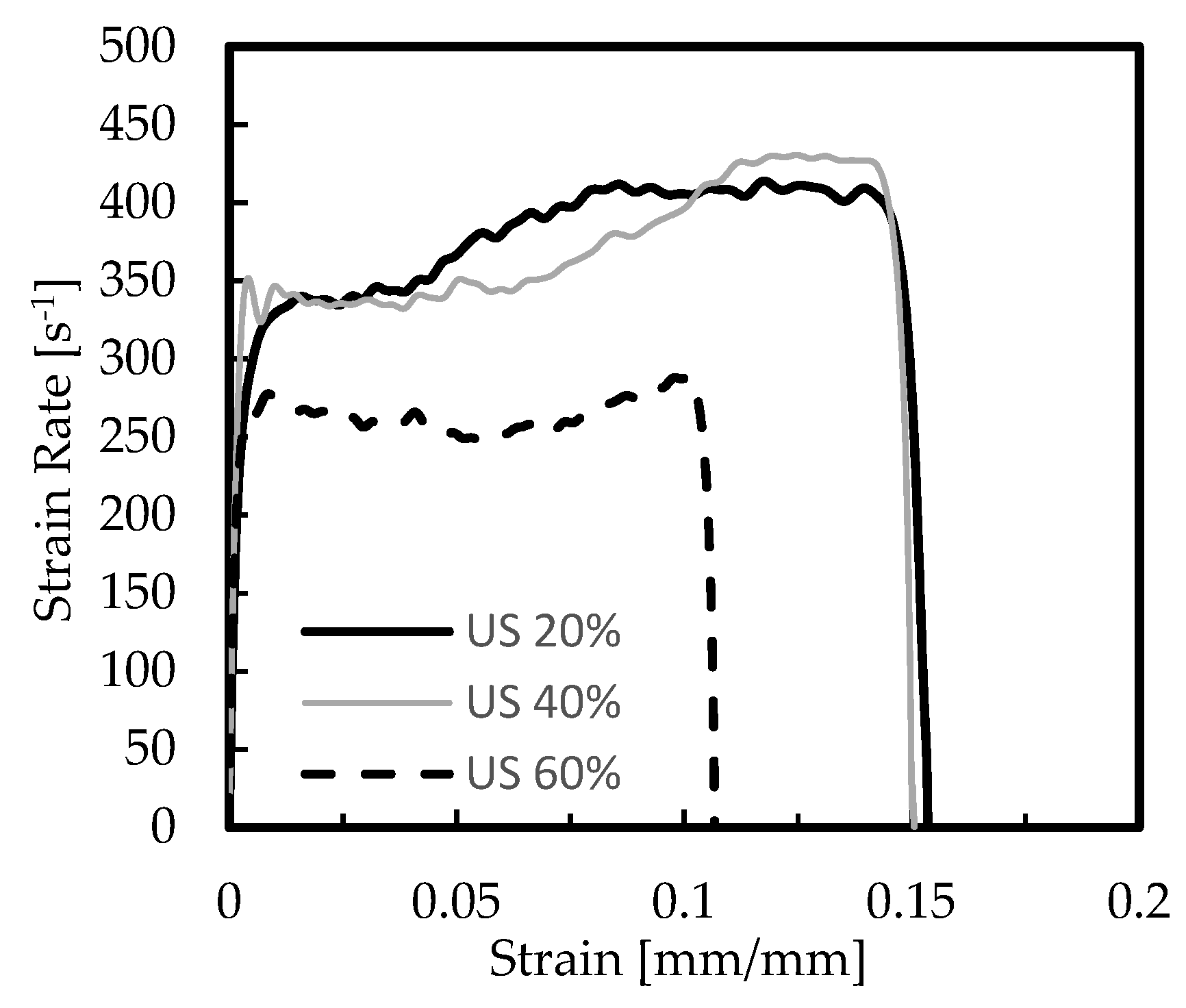

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zanjani, N.A.; Wang, W.; Kalyanasundaram, S. The Effect of Fiber Orientation on the Formability and Failure Behavior of a Woven Self-Reinforced Composite. J. Manuf. Sci. Eng. 2015, 137, 051012. [Google Scholar] [CrossRef]

- Marsavina, L.; Kovácik, J.; Linu, E. Experimental validation of micromechanical models for brittle aluminium alloy foam. Theor. Appl. Fract. Mech. 2016, 83, 11–18. [Google Scholar] [CrossRef]

- Banhart, J. Manufacture, characterisation and application of cellular metals and metal foams. Prog. Mater. Sci. 2001, 46, 559–632. [Google Scholar] [CrossRef]

- Kang, Y.A.; Zhang, J.-Y.; Tan, J.-C. Compressive behavior of aluminum foams at low and high strain rates. J. Cent. South Univ. Technol. 2007, 14, 301–305. [Google Scholar] [CrossRef]

- Pinto, P.; Peixinho, N.; Silva, F.; Soares, D. Compressive properties and energy absorption of aluminum foams with modified cellular geometry. J. Mater. Process. Technol. 2014, 214, 571–577. [Google Scholar] [CrossRef]

- Banhart, J.; Baumeister, J. Deformation characteristics of metal foams. J. Mater. Sci. 1998, 33, 1431–1440. [Google Scholar] [CrossRef]

- Nieh, T.G.; Higashi, K.; Wadsworth, J. Effect of cell morphology on the compressive properties of open-cell aluminum foams. Mat. Sci. Eng. A Struct. Mater. 2000, 283, 105–110. [Google Scholar] [CrossRef]

- Korner, C.; Singer, R.F. Processing of Metal Foams–Challenges and Opportunities. Adv. Eng. Mater. 2000, 2, 159–165. [Google Scholar] [CrossRef]

- Li, J.R.; Cheng, H.F.; Yu, J.L.; Han, F.S. Effect of dual-size cell mix on the stiffness and strength of open-cell aluminum foams. Mat. Sci. Eng. A Struct. Mater. 2003, 362, 240–248. [Google Scholar] [CrossRef]

- Lee, S.; Barthelat, N.; Moldovan, H.; Espinosa, H.D.; Wadley, H.N.G. Deformation rate effects on failure modes of open-cell Al foams and textile cellular materials. Int. J. Solids Struct. 2006, 43, 53–73. [Google Scholar] [CrossRef]

- Deqing, W.; Weiwei, X.; Xiangjun, M.; Ziyuan, S. Cell structure and compressive behavior of an aluminum foam. J. Mater. Sci. 2005, 40, 3475–3480. [Google Scholar] [CrossRef]

- Cady, C.M.; Gray III, G.T.; Liu, C.; Lovato, M.L.; Mukai, T. Compressive properties of a closed-cell aluminum foam as a function of strain rate and temperature. Mat. Sci. Eng. A Struct. Mater. 2009, 525, 1–6. [Google Scholar] [CrossRef]

- Cheng, Y.; Li, Y.; Chen, X.; Zhou, X.; Wang, N. Compressive Properties and Energy Absorption of Aluminum Foams with a Wide Range of Relative Densities. J. Mater Eng. Perform. 2018, 27, 4016–4024. [Google Scholar] [CrossRef]

- Shunmugasamy, V.C.; Mansoor, B. Compressive behavior of a rolled open-cell aluminum foam. Mater. Sci. Eng. A Struct. Mater. 2018, 715, 281–294. [Google Scholar] [CrossRef]

- Wang, S.; Ding, Y.; Wang, C.; Zheng, Z.; Yu, J. Dynamic material parameters of closed-cell foams under high-velocity impact. Int. J. Impact Eng. 2017, 99, 111–121. [Google Scholar] [CrossRef]

- Su, B.-Y.; Huang, C.-M.; Sheng, H.; Jang, W.-Y. The effect of cell-size dispersity on the mechanical properties of closed-cell aluminum foam. Mater. Charact. 2018, 135, 203–213. [Google Scholar] [CrossRef]

- Deshpande, V.S.; Fleck, N.A. High strain rate compressive behavior of aluminum alloy foams. Int. J. Impact Eng. 2000, 24, 277–298. [Google Scholar] [CrossRef]

- Paul, A.; Ramamurty, U. Strain rate sensitivity of a closed-cell aluminum foam. Mater. Sci. Eng. A Struct. Mater. 2000, 281, 1–7. [Google Scholar] [CrossRef]

- Kou, D.P.; Li, J.R.; Yu, J.L.; Cheng, H.F. Mechanical behavior of open-cell metallic foams with dual-size cellular structure. Scr. Mater. 2008, 59, 483–486. [Google Scholar] [CrossRef]

- Alexander, J.M. An approximate analysis of the collapse of thin cylindrical shells under axial loading. Q. J. Mech. Appl. Math. 1960, 13, 10–15. [Google Scholar] [CrossRef]

- Reid, S.R.; Reddy, T.Y.; Gray, M.D. Static and dynamic crushing of foam-filled sheet metal tubes. Int. J. Mech. Sci. 1986, 28, 295–322. [Google Scholar] [CrossRef]

- Reddy, T.Y.; Wall, R.J. Axial compression of foam-filled thin-walled circular tubes. Int. J. Impact Eng. 1998, 7, 151–166. [Google Scholar] [CrossRef]

- Abramowicz, W.; Wierzbicki, T. Axial crushing of foam-filled columns. Int. J. Mech. Sci. 1988, 30, 263–271. [Google Scholar] [CrossRef]

- Seitzberger, M.; Rammerstorfer, F.G.; Degischer, H.P.; Gradinger, R. Crushing of axially compressed steel tubes filled with aluminium foam. Acta Mech. 1997, 125, 93–105. [Google Scholar] [CrossRef]

- Hanssen, A.G.; Langseth, M.; Hopperstad, O.S. Static crushing of square aluminium extrusions with aluminium foam filler. Int. J. Mech. Sci. 1999, 41, 967–993. [Google Scholar] [CrossRef]

- Langseth, M.; Hopperstad, O.S.; Hanssen, A.G. Crash behaviour of thin-walled aluminium members. Thin Wall. Struct. 1998, 32, 127–150. [Google Scholar] [CrossRef]

- Fiedler, T.; Taherishargh, M.; Krstulović-Opara, L.; Vesenjak, M. Dynamic compressive loading of expanded perlite/aluminum syntactic foam. Mater. Sci. Eng. A Struct. Mater. 2015, 626, 296–304. [Google Scholar] [CrossRef]

- Pan, L.; Yang, Y.; Ahsan, M.U.; Luong, D.D.; Gupta, N.; Kumar, A.; Rohatgi, P.K. Zn-matrix syntactic foams: Effect of heat treatment on microstructure and compressive properties. Mater. Sci. Eng. A Struct. Mater. 2018, 731, 413–422. [Google Scholar] [CrossRef]

- Orbulov, I.N.; Szlancvsik, A. On the Mechanical Properties of Aluminum Matrix Syntactic Foams. Adv. Eng. Mater. 2018, 20, 1700980. [Google Scholar] [CrossRef]

- Szlancsik, A.; Katona, B.; Májlinger, K.; Orbulov, I.N. Compressive behavior and microstructural characteristics of iron hollow sphere filled aluminum matrix syntactic foams. Materials 2015, 8, 7926–7937. [Google Scholar] [CrossRef]

- Szlancsik, A.; Katona, B.; Bobor, K.; Májlinger, K.; Orbulov, I.N. Compressive behaviour of aluminium matrix syntactic foams reinforced by iron hollow spheres. Mater. Des. 2015, 83, 230–237. [Google Scholar] [CrossRef]

- Omar, M.Y.; Xiang, C.; Gupta, N.; Strbik, O.M.; Cho, K. Data characterizing compressive properties of Al/Al2O3 syntactic foam core metal matrix sandwich. Data Br. 2015, 5, 522–527. [Google Scholar] [CrossRef] [PubMed]

- Omar, M.Y.; Xiang, C.; Gupta, N.; Strbik, O.M.; Cho, K. Data characterizing flexural properties of Al/Al2O3 syntactic foam core metal matrix sandwich. Data Br. 2015, 5, 564–571. [Google Scholar] [CrossRef]

- Balch, D.K.; Dunand, D.C. Load partitioning in aluminum syntactic foams containing ceramic microspheres. Acta Mater. 2006, 54, 1501–1511. [Google Scholar] [CrossRef]

- Peroni, L.; Scapin, M.; Avalle, M.; Weise, J.; Lehmhus, D. Dynamic mechanical behavior of syntactic iron foams with glass microspheres. Mater. Sci. Eng. A Struct. Mater. 2012, 552, 364–375. [Google Scholar] [CrossRef]

- Szlancsik, A.; Katona, B.; Károly, D.; Orbulov, I.N. Notch (In)Sensitivity of Aluminum Matrix Syntactic Foams. Materials 2019, 12, 574. [Google Scholar] [CrossRef] [PubMed]

- Goel, M.D.; Peroni, M.; Solomos, G.; Mondal, D.P.; Matsagar, V.A.; Gupta, A.K.; Larcher, M.; Marburg, S. Dynamic compression behavior of cenosphere aluminum alloy syntactic foam. Mater. Des. 2012, 42, 418–423. [Google Scholar] [CrossRef]

- Mondal, D.P.; Goel, M.D.; Das, S. Effect of strain rate and relative density on compressive deformation behaviour of closed cell aluminum–fly ash composite foam. Mater. Des. 2009, 30, 1268–1274. [Google Scholar] [CrossRef]

- Goel, M.D.; Mondal, D.P.; Yadav, M.S.; Gupta, S.K. Effect of strain rate and relative density on compressive deformation behavior of aluminum cenosphere syntactic foam. Mater. Sci. Eng. A Struct. Mater. 2014, 590, 406–415. [Google Scholar] [CrossRef]

- Song, H.-W.; He, Q.-J.; Xie, J.-J.; Tobota, A. Fracture mechanisms and size effects of brittle metallic foams: In situ compression tests inside SEM. Compos. Sci. Technol. 2008, 68, 2441–2450. [Google Scholar] [CrossRef]

- Wang, P.; Xu, S.; Li, Z.; Yang, J.; Zhang, C.; Zheng, H.; Hu, S. Experimental investigation on the strain-rate effect and inertia effect of closed-cell aluminum foam subjected to dynamic loading. Mater. Sci. Eng. A Struct. Mater. 2015, 620, 253–261. [Google Scholar] [CrossRef]

- Marais, S.T.; Tait, R.B.; Cloete, T.J.; Nurick, G.N. Material testing at high strain rate using the split hopkinson pressure bar. Latin Amer. J. Solids Struct. 2004, 1, 319–339. [Google Scholar]

- Church, P.; Cornish, R.; Cullis, I.; Gould, P.; Lewtas, I. Using the split Hopkinson pressure bar to validate material models. Phil. Trans. R. Soc. A 2014, 372, 20130294. [Google Scholar] [CrossRef]

- Amaro, A.M.; Neto, M.A.; Reis, P.N.B. Mechanical characterization of AlSi12 foams at high strain rates. Mater. Des. Process. Commun. 2019, e55. [Google Scholar] [CrossRef]

- Reis, P.N.B.; Amaro, A.M.; Neto, M.A.; Cirne, J.S. Effect of Hostile Solutions on Composites Laminates Subjected to Low and High Velocity Impact Loads. Fiber. Polym. 2019, 20, 158–164. [Google Scholar] [CrossRef]

- Weinberg, K.; Khosravani, M.R.; Thimm, B.; Reppel, T.; Bogunia, L.; Aghayan, S.; Nötzel, R. Hopkinson bar experiments as a method to determine impact properties of brittle and ductile materials. GAMM-Mitteilungen 2018, 41, 1–15. [Google Scholar] [CrossRef]

- Luong, D.D.; Strbik III, O.M.; Hammond, V.H.; Gupta, N.; Cho, K. Development of high performance lightweight aluminum alloy/SiC hollow sphere syntactic foams and compressive characterization at quasi-static and high strain rates. J. Alloys Compd. 2013, 550, 412–422. [Google Scholar] [CrossRef]

- Florek, R.; Simančík, F.; Nosko, M.; Harnúšková, J. Compression test evaluation method for aluminium foam parts of different alloys and densities. Powder Metall. Prog. 2010, 10, 207–212. [Google Scholar]

- Marchi, C.S.; Despois, J.F.; Mortensen, A. Uniaxial deformation of open-cell aluminum foam: the role of internal damage. Acta Mater. 2004, 52, 2895–2902. [Google Scholar] [CrossRef]

- Gherasim, G.; Thalmaier, G.; Sechel, N.; Cziple, F.; Petrescu, V.; Vida-Simiti, I. Open cell Al-Si foams by a sintering and dissolution process. Solid State Phenomena 2014, 216, 249–254. [Google Scholar] [CrossRef]

- Kováčik, J.; Orovčík, Ľ.; Jerz, J. High-temperature compression of closed cell aluminium foams. Kovove Mater. 2016, 54, 429–440. [Google Scholar]

- Shi, X.; Liu, S.; Nie, H.; Lu, G.; Li, Y. Study of cell irregularity effects on the compression of closed-cell foams. Int. J. Mech. Sci. 2018, 135, 215–225. [Google Scholar] [CrossRef]

- Zhou, Z.; Wang, Z.; Zhao, L.; Shu, X. Uniaxial and biaxial failure behaviors of aluminum alloy foams. Compos. B Eng. 2014, 61, 340–349. [Google Scholar] [CrossRef]

- Wang, N.; Maire, E.; Chen, X.; Adrien, J.; Li, Y.; Amani, Y.; Hu, L.; Cheng, Y. Compressive performance and deformation mechanism of the dynamic gas injection aluminum foams. Mater. Charact. 2019, 147, 11–20. [Google Scholar] [CrossRef]

- Koza, E.; Leonowicz, M.; Wojciechowski, S.; Simancik, F. Compressive strength of aluminium foams. Mater. Lett. 2003, 58, 132–135. [Google Scholar] [CrossRef]

- Sun, Y.; Burgueño, R.; Vanderklok, A.J.; Tekalur, S.A.; Wang, W.; Lee, I. Compressive behavior of aluminum/copper hybrid foams under high strain rate loading. Mater. Sci. Eng. A Struct. Mater. 2014, 592, 111–120. [Google Scholar] [CrossRef]

- Bastawros, A.F.; Bart-Smith, H.; Evans, A.G. Experimental analysis of deformation mechanisms in a closed-cell aluminum alloy foam. J. Mech. Phys. Solid. 2000, 48, 301–322. [Google Scholar] [CrossRef]

- Beals, J.T.; Thompson, M.S. Density gradient effects on aluminium foam compression behaviour. J. Mater. Sci. 1997, 32, 3595–3600. [Google Scholar] [CrossRef]

- Yamada, Y.; Banno, T.; Xie, Z.; Wen, C. Energy Absorption and Crushing Behaviour of Foam-Filled Aluminium Tubes. Mater. Trans. 2005, 46, 2633–2636. [Google Scholar] [CrossRef][Green Version]

- Yan, W.; Durif, Y.; Yamada, Y.; Wen, C. Crushing Simulation of Foam-Filled Aluminium Tubes. Mater. Trans. 2007, 48, 1901–1906. [Google Scholar] [CrossRef]

- Zarei, H.R.; Kroger, M. Optimization of the foam-filled aluminum tubes for crush box application. Thin-Walled Struct. 2008, 46, 214–221. [Google Scholar] [CrossRef]

- Li, Z.; Chen, R.; Lu, F. Comparative analysis of crashworthiness of empty and foam-filled thin-walled tubes. Thin-Walled Struct. 2018, 124, 343–349. [Google Scholar] [CrossRef]

- Guillow, S.R.; Lu, G.; Grzebieta, R.H. Quasi-static axial compression of thin-walled circular aluminium tubes. Int. J. Mech. Sci. 2001, 43, 2103–2123. [Google Scholar] [CrossRef]

- Hangai, Y.; Saito, M.; Utsunomiya, T.; Kitahara, S.; Kuwazuru, O.; Yoshikawa, N. Fabrication of aluminum foam-filled thin-wall steel tube by friction welding and its compression properties. Materials 2014, 7, 6796–6810. [Google Scholar] [CrossRef] [PubMed]

| Chemical Elements | Si | Cu | Fe | Mg | Mn | Zn | Ni | Al |

|---|---|---|---|---|---|---|---|---|

| wt. (%) | 11.0–13.0 | 1.00 | 1.00 | 0.10 | 0.35 | 0.40 | 0.50 | Balance |

| Chemical Elements | Si | Cu | Fe | Mg | Mn | Cr | Zn | Al |

|---|---|---|---|---|---|---|---|---|

| wt. (%) | 0.70–1.30 | 0.10 | 0.50 | 0.60–1.20 | 0.40–1.00 | 0.25 | 0.20 | Balance |

| Materials | Sample | Projectile Velocity (m/s) | Mass (g) | Diameter (mm) | Length (mm) |

|---|---|---|---|---|---|

| Al foams | AlSi12/US/20% | 6.33 ± 0.44 | 1.41 ± 0.11 | 15.3 ± 0.3 | 16.1 ± 0.4 |

| AlSi12/US/40% | 6.65 ± 0.03 | 1.75 ± 0.19 | 14.9 ± 0.4 | 15.6 ± 0.6 | |

| AlSi12/US/60% | 6.66 ± 0.62 | 2.10 ± 0.13 | 15.7 ± 0.1 | 15.9 ± 0.5 | |

| AlSi12/DS/20% | 6.15 ± 0.04 | 1.39 ± 0.12 | 15.6 ± 0.4 | 15.7 ± 0.4 | |

| Al6082-T4/US/20% | 6.33 ± 0.41 | 1.52 ± 0.18 | 15.0 ± 0.4 | 15.6 ± 0.2 | |

| Al6082-T4/US/60% | 6.34 ± 0.01 | 1.74 ± 0.06 | 15.0 ± 0.1 | 15.2 ± 0.1 | |

| Al6082-T4/DS/20% | 6.49 ± 0.29 | 1.16 ± 0.12 | 15.0 ± 0.1 | 15.3 ± 0.2 | |

| Al foam-filled tubes | AlSi12/US/20% | 6.34 ± 0.07 | 2.98 ± 0.31 | 16.3 ± 0.1 | 15.8 ± 0.1 |

| AlSi12/US/20% | 11.8 ± 0.27 | 2.86 ± 0.21 | 16.4 ± 0.1 | 16.2 ± 0.1 | |

| AlSi12/DS/20% | 6.28 ± 0.62 | 2.74 ± 0.25 | 16.4 ± 0.3 | 14.3 ± 0.2 | |

| AlSi12/DS/20% | 2.32 ± 0.12 | 3.03 ± 0.19 | 16.5 ± 0.3 | 14.7 ± 0.3 | |

| Al6082-T4 /US/20% | 7.69 ± 0.06 | 4.76 ± 0.26 | 19.1 ± 0.1 | 17.1 ± 0.1 | |

| Al6082-T4 /DS/20% | 7.53 ± 0.06 | 4.37 ± 0.17 | 19.1 ± 0.1 | 17.3 ± 0.2 |

| Sample | ε = 0.05 mm/mm | ε = 0.1 mm/mm | ||||

|---|---|---|---|---|---|---|

| Strain Rate (s−1) | Stress (MPa) | Absorbed Energy (J/m3) | Strain Rate (s−1) | Stress (MPa) | Absorbed Energy (J/m3) | |

| AlSi12 US 20% | 376 ± 22.5 | 3.88 ± 0.12 | 2.8 × 105 ± 1.2 × 103 | 406 ± 35.4 | 1.52 ± 0.09 | 3.2 × 105 ± 1.5 × 103 |

| AlSi12 DS 20% | 342 ± 12.5 | 9.71 ± 0.21 | 3.8 × 105 ± 1.6 × 103 | 353 ± 25.4 | 6.50 ± 0.19 | 7.2 × 105 ± 3.6 × 103 |

| Al6082-T4 US 20% | 341 ± 18.6 | 7.40 ± 0.15 | 4.0 × 105 ± 2.1 × 103 | 399 ± 27.8 | 4.67 ± 0.21 | 4.8 × 105 ± 2.2 × 103 |

| Al6082-T4 DS 20% | 286 ± 21.2 | 10.30 ± 0.29 | 4.2 × 105 ± 1.8 × 103 | 330 ± 28.2 | 9.30 ± 0.31 | 8.2 × 105 ± 3.9 × 103 |

| Sample | ε = 0.05 mm/mm | ||

|---|---|---|---|

| Strain Rate (s−1) | Stress (MPa) | Absorbed Energy (J/m3) | |

| AlSi12 US 20% | 376 ± 22.5 | 3.88 ± 0.12 | 2.8 × 105 ± 1.2 × 103 |

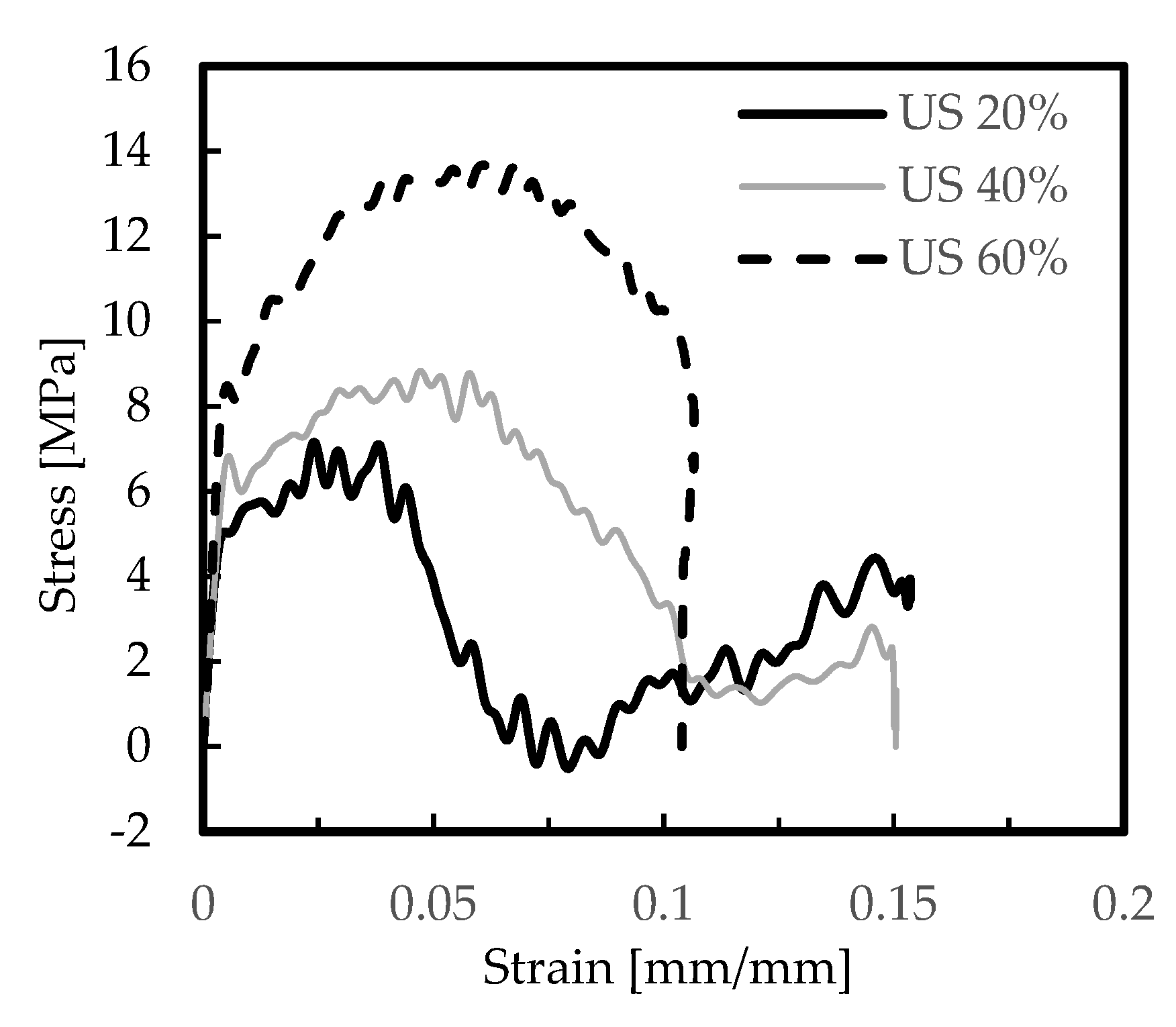

| AlSi12 US 40% | 350 ± 17.5 | 8.51 ± 0.31 | 3.1 × 105 ± 1.7 × 103 |

| AlSi12 US 60% | 255 ± 11.8 | 13.3 ± 0.19 | 5.2 × 105 ± 3.4 × 103 |

| Sample | ε = 0.05 mm/mm | ε = 0.1 mm/mm | ||||

|---|---|---|---|---|---|---|

| Strain Rate (s−1) | Stress (MPa) | Absorbed Energy (J/m3) | Strain Rate (s−1) | Stress (MPa) | Absorbed Energy (J/m3) | |

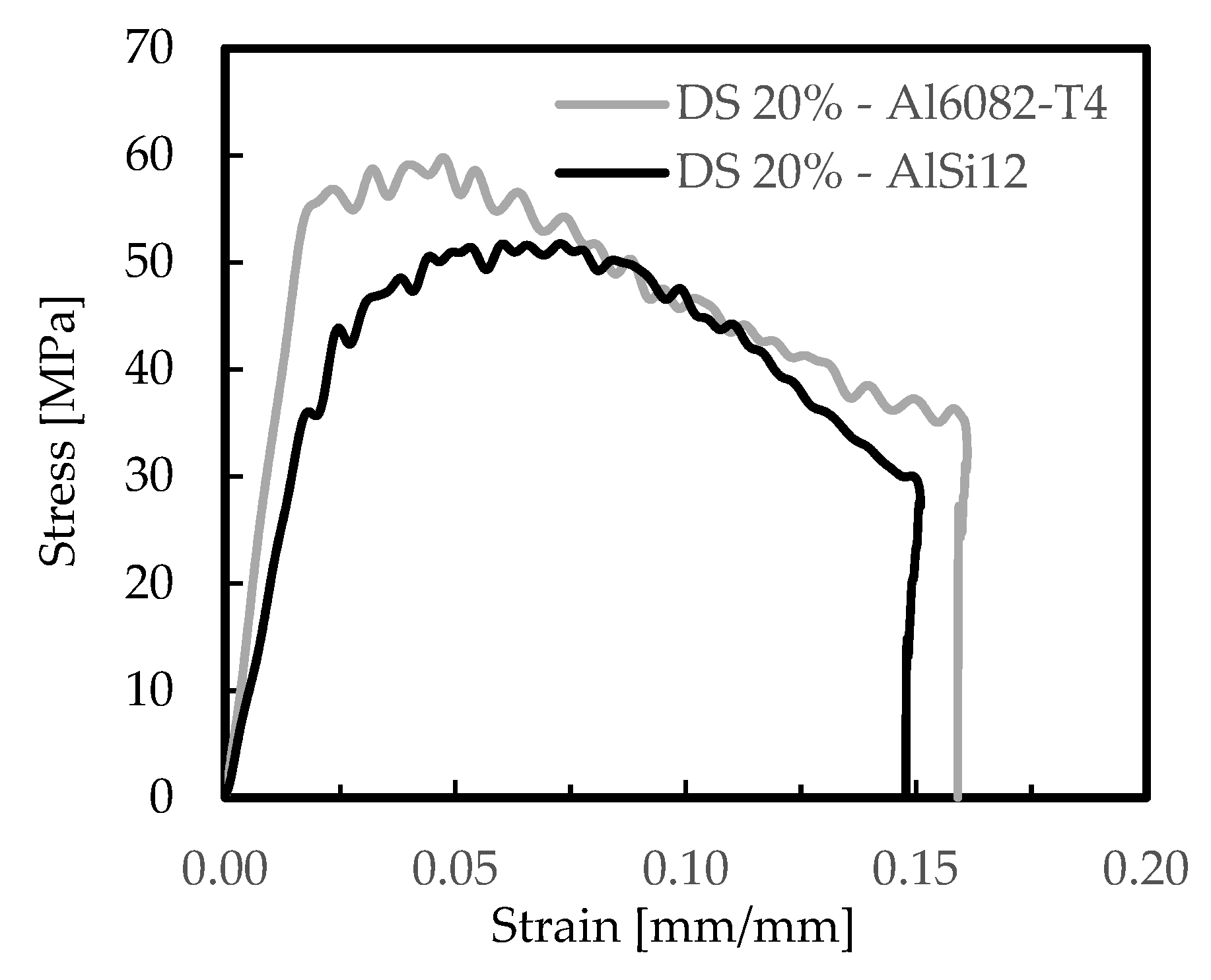

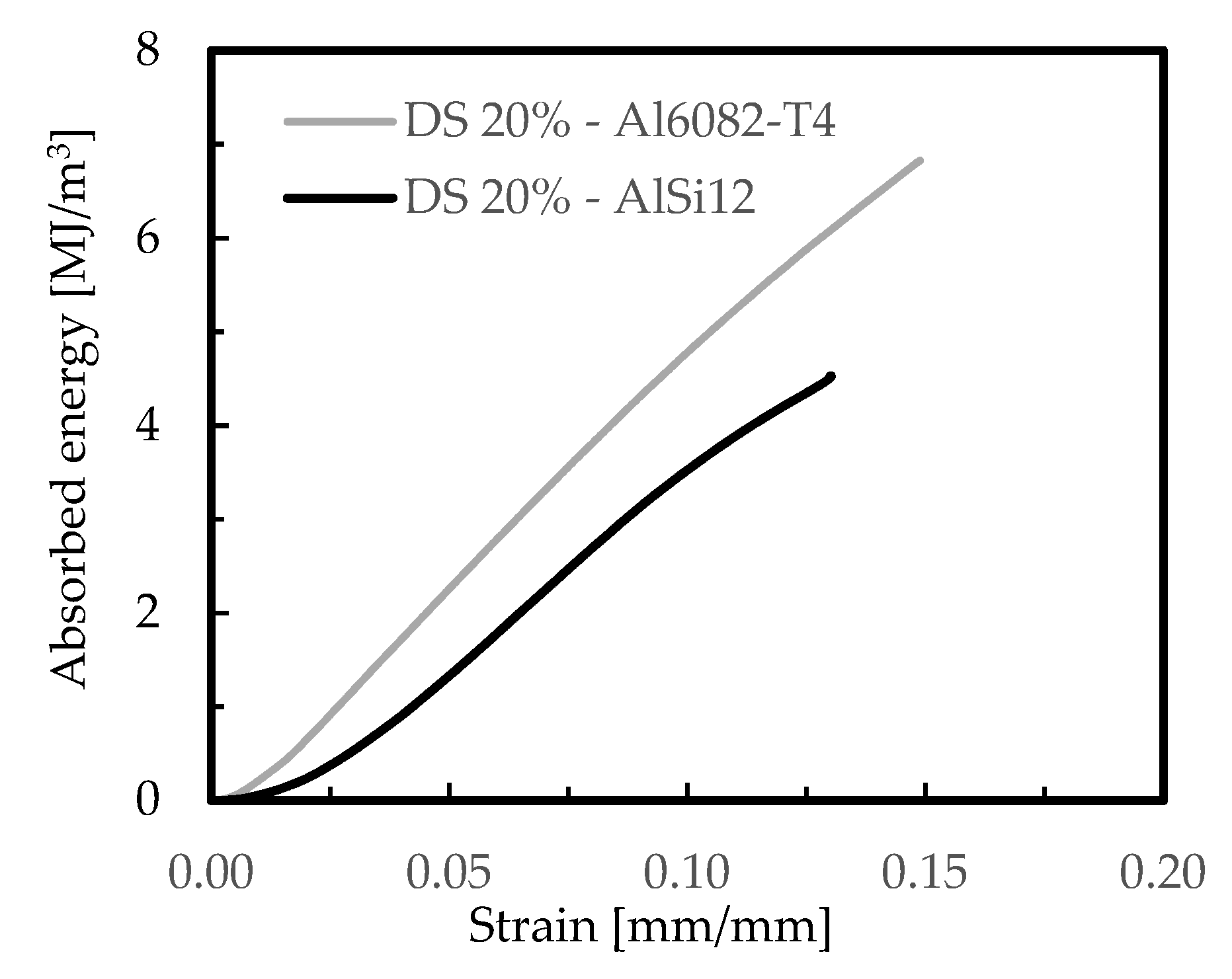

| AlSi12 DS 20% | 314 ± 18.6 | 51.0 ± 9.51 | 1.5 × 106 ± 1.2 × 104 | 311 ± 15.9 | 46.1 ± 7.18 | 3.5 × 106 ± 1.9 × 104 |

| Al6082-T4 DS 20% | 393 ± 31.2 | 57.1 ± 9.59 | 2.3 × 106 ± 1.5 × 104 | 421 ± 26.8 | 47.0 ± 9.85 | 4.8 × 106 ± 2.4 × 104 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amaro, A.M.; Neto, M.A.; Cirne, J.S.; Reis, P.N.B. Mechanical Characterization of Different Aluminium Foams at High Strain Rates. Materials 2019, 12, 1428. https://doi.org/10.3390/ma12091428

Amaro AM, Neto MA, Cirne JS, Reis PNB. Mechanical Characterization of Different Aluminium Foams at High Strain Rates. Materials. 2019; 12(9):1428. https://doi.org/10.3390/ma12091428

Chicago/Turabian StyleAmaro, Ana M., Maria A. Neto, José S. Cirne, and Paulo N.B. Reis. 2019. "Mechanical Characterization of Different Aluminium Foams at High Strain Rates" Materials 12, no. 9: 1428. https://doi.org/10.3390/ma12091428

APA StyleAmaro, A. M., Neto, M. A., Cirne, J. S., & Reis, P. N. B. (2019). Mechanical Characterization of Different Aluminium Foams at High Strain Rates. Materials, 12(9), 1428. https://doi.org/10.3390/ma12091428