On the Interplay of DLIP and LIPSS Upon Ultra-Short Laser Pulse Irradiation

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

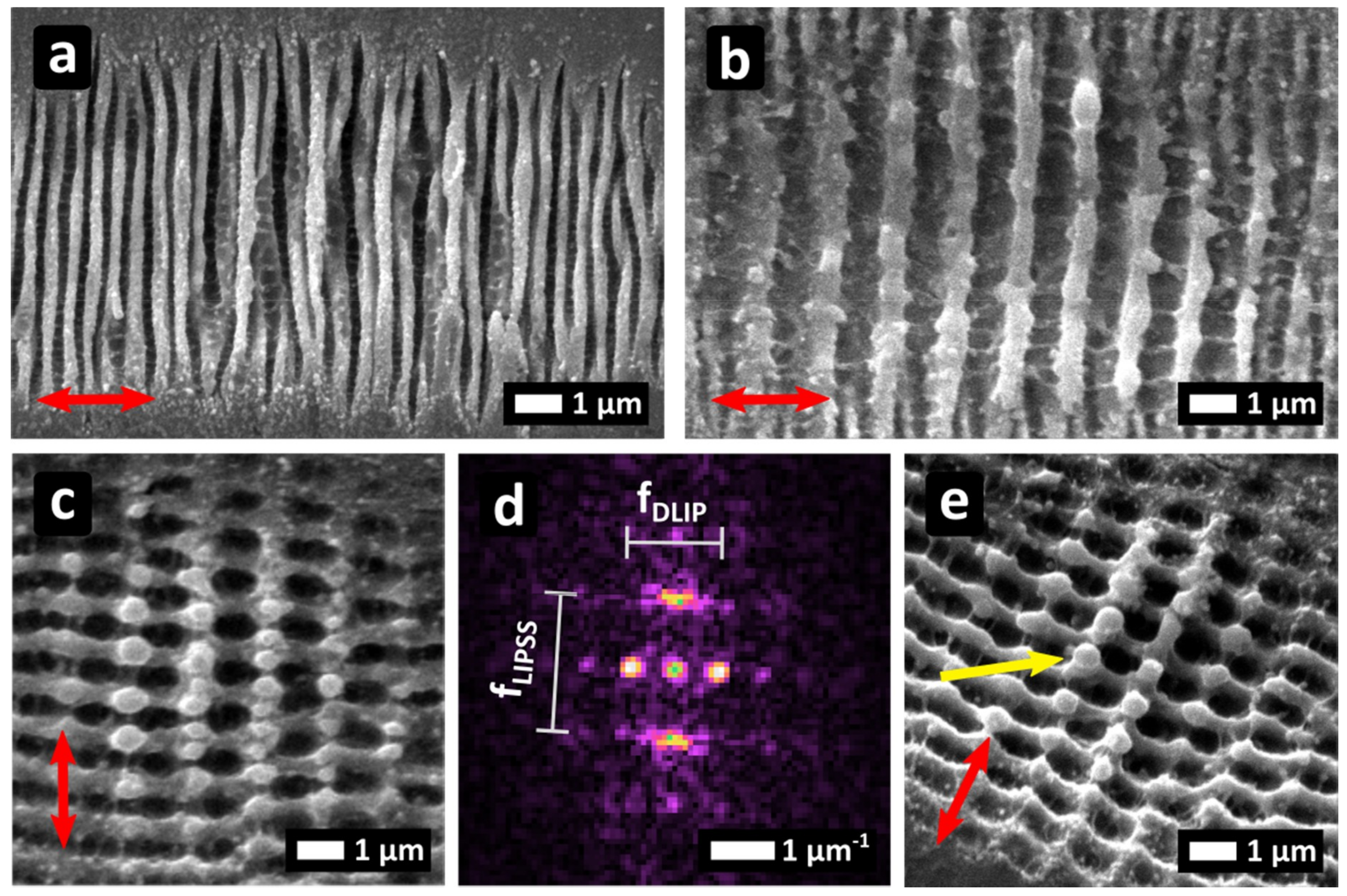

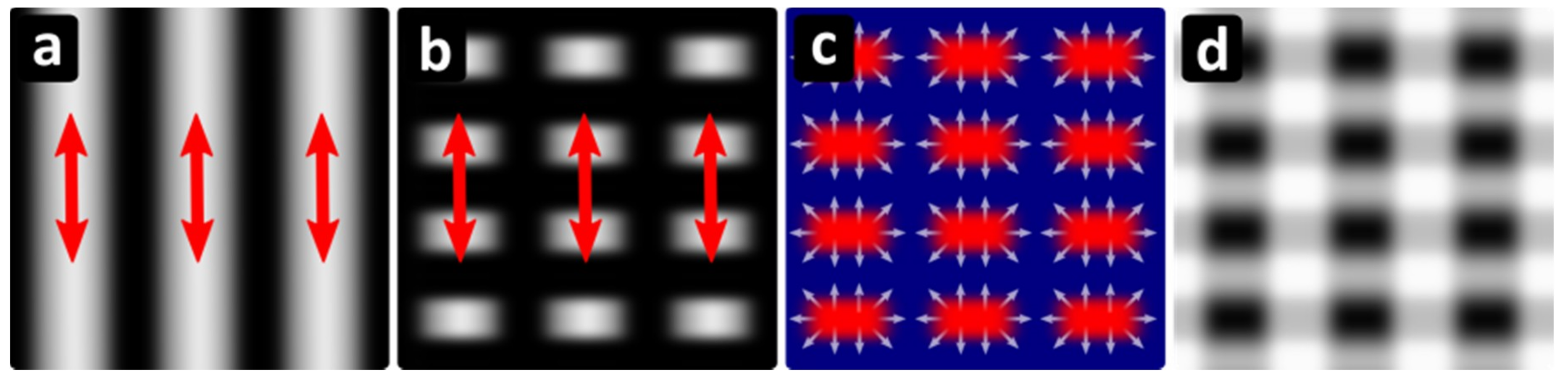

3.1. Stainless Steel

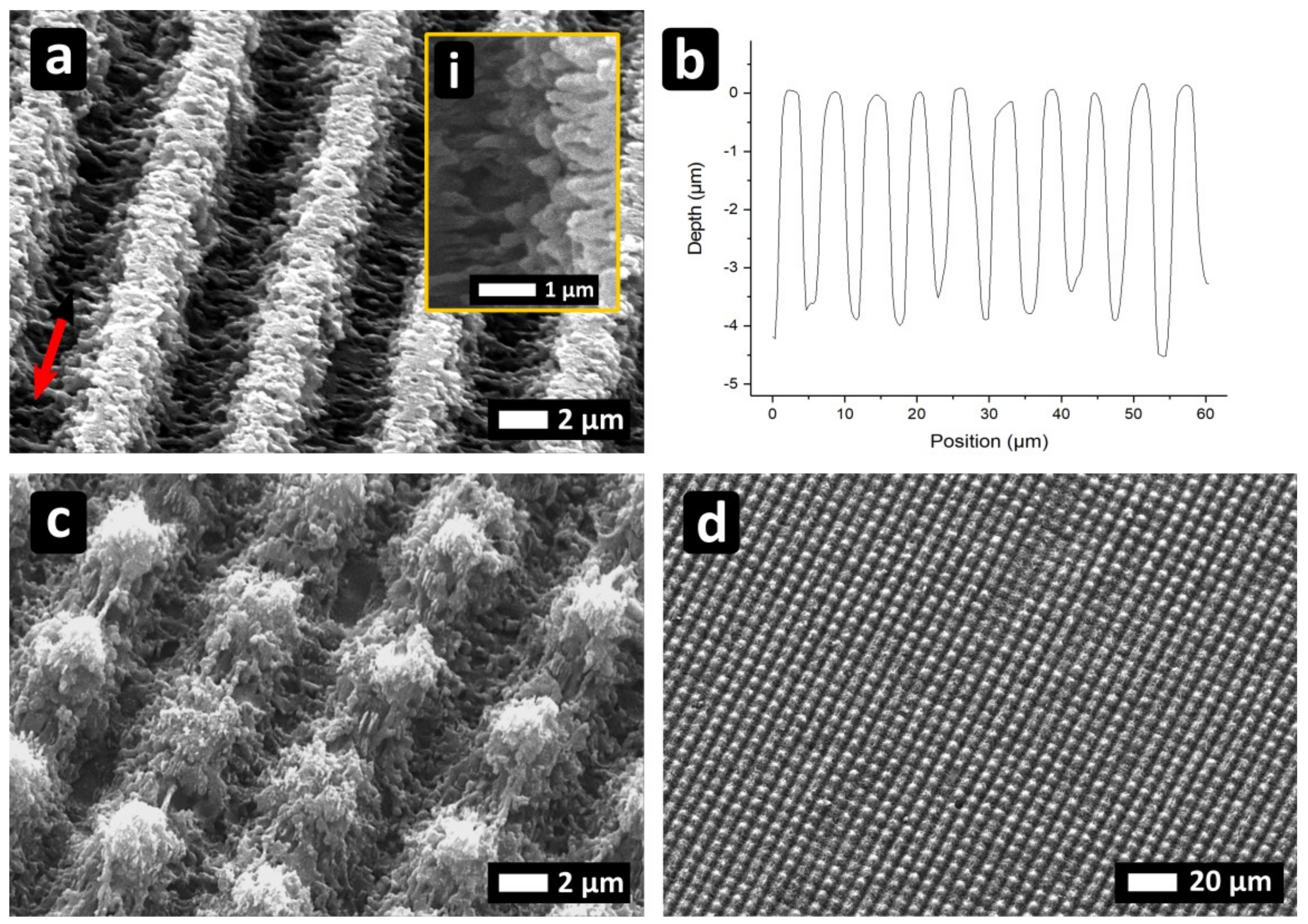

3.2. Polyimide

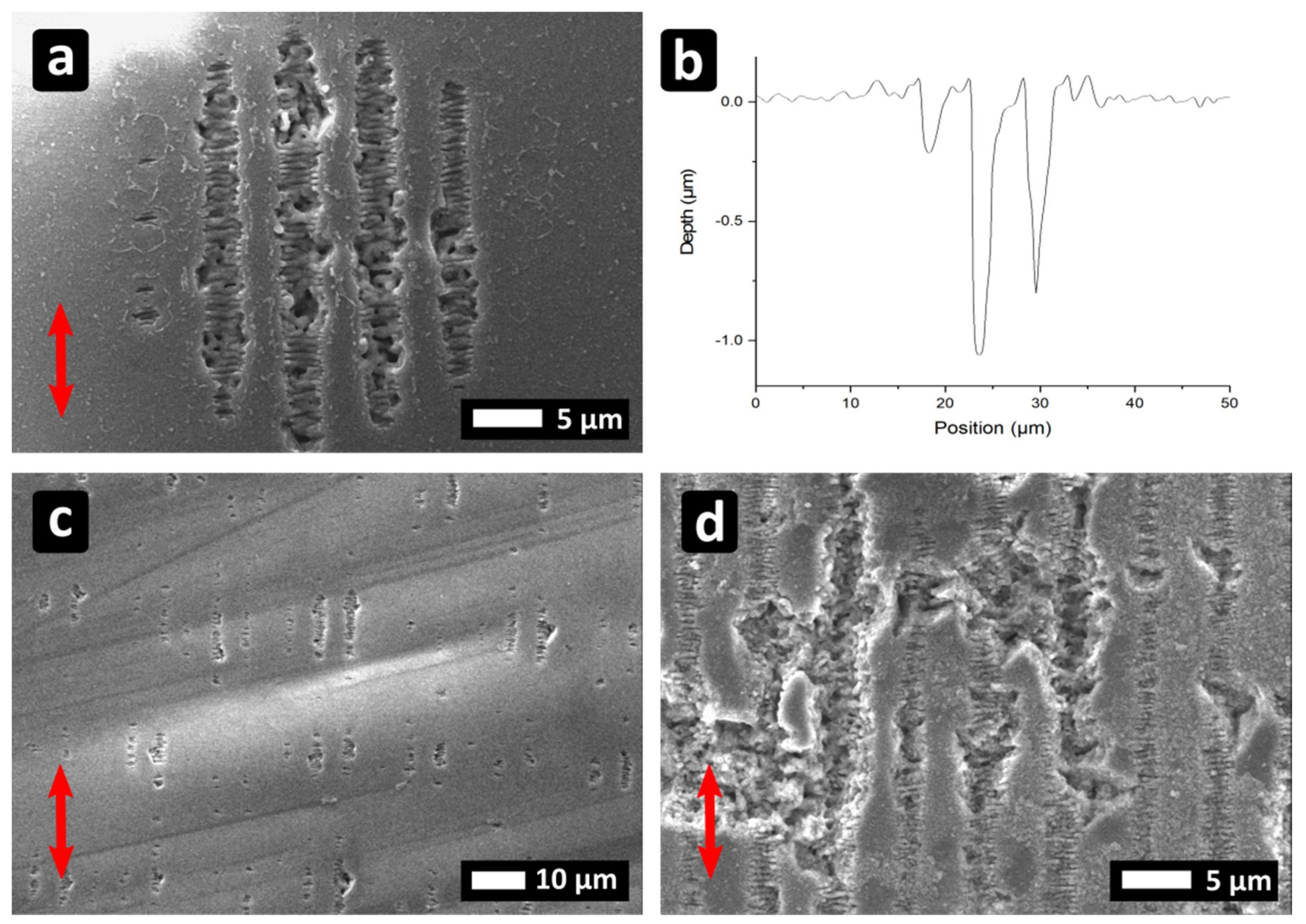

3.3. Sapphire

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gu, B. Ultrafast laser applications in semiconductor industry. In Proceedings of Lasers and Applications in Science and Engineering, San Jose, CA, USA, 25–29 January 2004; Volume 5339. [CrossRef]

- Phillips, K.C.; Gandhi, H.H.; Mazur, E.; Sundaram, S.K. Ultrafast laser processing of materials: A review. Adv. Opt. Photon. 2015, 7, 684–712. [Google Scholar] [CrossRef]

- Yao, J.; Zhang, C.; Liu, H.; Dai, Q.; Wu, L.; Lan, S.; Gopal, A.V.; Trofimov, V.A.; Lysak, T.M. Selective appearance of several laser-induced periodic surface structure patterns on a metal surface using structural colors produced by femtosecond laser pulses. Appl. Surf. Sci. 2012, 258, 7625–7632. [Google Scholar] [CrossRef]

- Guay, J.-M.; Calà Lesina, A.; Côté, G.; Charron, M.; Poitras, D.; Ramunno, L.; Berini, P.; Weck, A. Laser-induced plasmonic colours on metals. Nat. Commun. 2017, 8, 16095. [Google Scholar] [CrossRef]

- Sun, C.; Zhao, X.-W.; Han, Y.-H.; Gu, Z.-Z. Control of water droplet motion by alteration of roughness gradient on silicon wafer by laser surface treatment. Thin Solid Films 2008, 516, 4059–4063. [Google Scholar] [CrossRef]

- Kirner, S.V.; Hermens, U.; Mimidis, A.; Skoulas, E.; Florian, C.; Hischen, F.; Plamadeala, C.; Baumgartner, W.; Winands, K.; Mescheder, H.; et al. Mimicking bug-like surface structures and their fluid transport produced by ultrashort laser pulse irradiation of steel. Appl. Phys. A 2017, 123, 754. [Google Scholar] [CrossRef]

- Zwahr, C.; Günther, D.; Brinkmann, T.; Gulow, N.; Oswald, S.; Grosse Holthaus, M.; Lasagni, A.F. Laser Surface Pattering of Titanium for Improving the Biological Performance of Dental Implants. Adv. Healthc. Mater. 2017, 6, 1600858. [Google Scholar] [CrossRef] [PubMed]

- Lutey, A.H.A.; Gemini, L.; Romoli, L.; Lazzini, G.; Fuso, F.; Faucon, M.; Kling, R. Towards Laser-Textured Antibacterial Surfaces. Sci. Rep. 2018, 8, 10112. [Google Scholar] [CrossRef]

- Bieda, M.; Schmädicke, C.; Roch, T.; Lasagni, A.F. Ultra-low friction on 100Cr6-steel surfaces after direct laser interference patterning. Adv. Eng. Mater. 2015, 17, 102–108. [Google Scholar] [CrossRef]

- Roch, T.; Weihnacht, V.; Scheibe, H.; Roch, A.; Lasagni, A.F. Direct Laser Interference Patterning of tetrahedral amorphous carbon fi lms for tribological applications. Diam. Relat. Mater. 2013, 33, 20–26. [Google Scholar] [CrossRef]

- Scaraggi, M.; Mezzapesa, F.P.; Carbone, G.; Ancona, A.; Sorgente, D.; Lugarà, P.M. Minimize friction of lubricated laser-microtextured-surfaces by tuning microholes depth. Tribol. Int. 2014, 75, 123–127. [Google Scholar] [CrossRef]

- Joshi, G.S.; Putignano, C.; Gaudiuso, C.; Stark, T.; Kiedrowski, T.; Ancona, A.; Carbone, G. Effects of the micro surface texturing in lubricated non-conformal point contacts. Tribol. Int. 2018, 127, 296–301. [Google Scholar] [CrossRef]

- Bonse, J.; Kirner, S. V; Gripentrog, M.; Spaltmann, D.; Krüger, J. Femtosecond Laser Texturing of Surfaces for Tribological Applications. Materials 2018, 11, 801. [Google Scholar] [CrossRef]

- Guo, Z.; Liu, W.; Su, B.L. Superhydrophobic surfaces: From natural to biomimetic to functional. J. Colloid Interface Sci. 2011, 353, 335–355. [Google Scholar] [CrossRef] [PubMed]

- Van Driel, H.M.; Sipe, J.E.; Young, J.F. Laser-induced periodic surface structure on solids: A universal phenomenon. Phys. Rev. Lett. 1982, 49, 1955–1958. [Google Scholar] [CrossRef]

- Bonse, J.; Hohm, S.; Kirner, S.V.; Rosenfeld, A.; Kruger, J. Laser-Induced Periodic Surface Structures—A Scientific Evergreen. IEEE J. Sel. Top. Quantum Electron. 2017, 23, 9000615. [Google Scholar] [CrossRef]

- Reif, J.; Varlamova, O.; Costache, F. Femtosecond laser induced nanostructure formation: Self-organization control parameters. Appl. Phys. A Mater. Sci. Process. 2008, 92, 1019–1024. [Google Scholar] [CrossRef]

- Bonse, J.; Kruger, J.; Höhm, S. Femtosecond laser-induced periodic surface structures. J. Laser Appl. 2012, 24, 42006. [Google Scholar] [CrossRef]

- Nemanich, R.J.; Biegelsen, D.K.; Hawkins, W.G. Aligned, coexisting liquid and solid regions in laser-annealed Si. Phys. Rev. B 1983, 27, 7817–7819. [Google Scholar] [CrossRef]

- Fraggelakis, F.; Mincuzzi, G.; Lopez, J.; Manek-Hönninger, I.; Kling, R. Controlling 2D laser nano structuring over large area with double femtosecond pulses. Appl. Surf. Sci. 2019, 470, 677–686. [Google Scholar] [CrossRef]

- Sipe, J.E.; Young, J.F.; Preston, J.S.; Van Driel, H.M. Laser-induced periodic surface structure. I. Theory. Phys. Rev. B 1983, 27, 1141–1154. [Google Scholar] [CrossRef]

- Aguilar-Morales, A.I.; Alamri, S.; Lasagni, A.F. Micro-Fabrication of High Aspect Ratio Periodic Structures on Stainless Steel by Picosecond Direct Laser Interference Patterning. J. Mater. Process. Technol. 2018, 252, 313–321. [Google Scholar] [CrossRef]

- Lasagni, A.; Mücklich, F. FEM simulation of periodical local heating caused by Laser Interference Metallurgy. J. Mater. Process. Technol. 2009, 209, 202–209. [Google Scholar] [CrossRef]

- Bonse, J.; Rosenfeld, A.; Krüger, J. On the role of surface plasmon polaritons in the formation of laser-induced periodic surface structures upon irradiation of silicon by femtosecond-laser pulses. J. Appl. Phys. 2009, 106, 104910. [Google Scholar] [CrossRef]

- Tsibidis, G.D.; Barberoglou, M.; Loukakos, P.A.; Stratakis, E.; Fotakis, C. Dynamics of ripple formation on silicon surfaces by ultrashort laser pulses in subablation conditions. Phys. Rev. B Condens. Matter Mater. Phys. 2012, 86, 115316. [Google Scholar] [CrossRef]

- Tsibidis, G.D.; Mimidis, A.; Skoulas, E.; Kirner, S. V; Krüger, J.; Bonse, J.; Stratakis, E. Modelling periodic structure formation on 100Cr6 steel after irradiation with femtosecond-pulsed laser beams. Appl. Phys. A 2018, 124, 27. [Google Scholar] [CrossRef]

- Kumagai, H.; Midorikawa, K.; Toyoda, K.; Nakamura, S.; Okamoto, T.; Obara, M. Ablation of polymer films by a femtosecond high-peak-power Ti: Sapphire laser at 798 nm. Appl. Phys. Lett. 1994, 65, 1850–1852. [Google Scholar] [CrossRef]

- Lasagni, A.F.; Roch, T.; Langheinrich, D.; Bieda, M. Large Area Direct Fabrication of periodic Arrays using Interference Patterning. Phys. Procedia 2011, 12, 214–220. [Google Scholar] [CrossRef]

- Langheinrich, D.; Yslas, E.; Broglia, M.; Rivarola, V.; Acevedo, D.; Lasagni, A. Control of cell growth direction by direct fabrication of periodic micro- and submicrometer arrays on polymers. J. Polym. Sci. Part B Polym. Phys. 2012, 50, 415–422. [Google Scholar] [CrossRef]

- Lasagni, A.; Acevedo, D.; Cornejo, M.; Lasagni, F.; Politano, M. Direct Fabrication of Surface Architectures on Polymers and Copolymers Using Laser Interference Patterning. In Proceedings of the SPIE Europe Microtechnologies for the New Millennium, Dresden, Germany, 4–6 May 2009; 7365, pp. 1–10. [Google Scholar] [CrossRef]

- Baudach, S.; Bonse, J.; Kautek, W. Ablation experiments on polyimide with femtosecond laser pulses. Appl. Phys. A Mater. Sci. Process. 1999, 69, 395–398. [Google Scholar] [CrossRef]

- Stoian, R.; Mishchik, K.; Mauclair, C.; Audouard, E.; Cheng, G. Ultrafast laser photoinscription of polarization sensitive devices in bulk silica glass. Opt. Express 2009, 17, 9515. [Google Scholar]

- Stoian, R.; Mishchik, K.; Cheng, G.; Mauclair, C.; D’Amico, C.; Colombier, J.P.; Zamfirescu, M. Investigation and control of ultrafast laser-induced isotropic and anisotropic nanoscale-modulated index patterns in bulk fused silica. Opt. Mater. Express 2013, 3, 1755. [Google Scholar] [CrossRef]

- Mishchik, K.; Cheng, G.; Huo, G.; Burakov, I.M.; Mauclair, C.; Mermillod-Blondin, A.; Rosenfeld, A.; Ouerdane, Y.; Boukenter, A.; Parriaux, O.; et al. Nanosize structural modifications with polarization functions in ultrafast laser irradiated bulk fused silica. Opt. Express 2010, 18, 24809. [Google Scholar] [CrossRef]

- Höhm, S.; Rosenfeld, A.; Krüger, J.; Bonse, J. Femtosecond laser-induced periodic surface structures on silica. J. Appl. Phys. 2012, 112, 14901. [Google Scholar] [CrossRef]

- Tsibidis, G.D.; Skoulas, E.; Papadopoulos, A.; Stratakis, E. Convection roll-driven generation of supra-wavelength periodic surface structures on dielectrics upon irradiation with femtosecond pulsed lasers. Phys. Rev. B 2016, 94, 1–18. [Google Scholar] [CrossRef]

- Athanasiou, C.E.; Hongler, M.O.; Bellouard, Y. Unraveling Brittle-Fracture Statistics from Intermittent Patterns Formed during Femtosecond Laser Exposure. Phys. Rev. Appl. 2017, 8, 054013. [Google Scholar] [CrossRef]

- Stoian, R.; Ashkenasi, D.; Rosenfeld, A.; Campbell, E.E.B. Coulomb explosion in ultrashort pulsed laser ablation of Al2O3. Phys. Rev. B Condens. Matter Mater. Phys. 2000, 62, 13167–13173. [Google Scholar] [CrossRef]

- Sedao, X.; Maurice, C.; Garrelie, F.; Colombier, J.P.; Reynaud, S.; Quey, R.; Pigeon, F. Influence of crystal orientation on the formation of femtosecond laser-induced periodic surface structures and lattice defects accumulation. Appl. Phys. Lett. 2014, 104, 171605. [Google Scholar] [CrossRef]

| Value | Stainless-Steel | Polyimide | Sapphire |

|---|---|---|---|

| Fluence Φ [J] | 0.06–0.28 | 1.34 | 1.80–1.96 |

| Interference Area [µm] | ~100, ~25 | ~100 | ~100 |

| λDLIP [μm] | 6.3, 1.4 | 6.3 | 5.7 |

| N | 20–50 | 5–10 | 5–10 |

| Pulse distance [μm] | 5–100 | 5–20 | 10–100 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alamri, S.; Fraggelakis, F.; Kunze, T.; Krupop, B.; Mincuzzi, G.; Kling, R.; Lasagni, A.F. On the Interplay of DLIP and LIPSS Upon Ultra-Short Laser Pulse Irradiation. Materials 2019, 12, 1018. https://doi.org/10.3390/ma12071018

Alamri S, Fraggelakis F, Kunze T, Krupop B, Mincuzzi G, Kling R, Lasagni AF. On the Interplay of DLIP and LIPSS Upon Ultra-Short Laser Pulse Irradiation. Materials. 2019; 12(7):1018. https://doi.org/10.3390/ma12071018

Chicago/Turabian StyleAlamri, Sabri, Fotis Fraggelakis, Tim Kunze, Benjamin Krupop, Girolamo Mincuzzi, Rainer Kling, and Andrés Fabián Lasagni. 2019. "On the Interplay of DLIP and LIPSS Upon Ultra-Short Laser Pulse Irradiation" Materials 12, no. 7: 1018. https://doi.org/10.3390/ma12071018

APA StyleAlamri, S., Fraggelakis, F., Kunze, T., Krupop, B., Mincuzzi, G., Kling, R., & Lasagni, A. F. (2019). On the Interplay of DLIP and LIPSS Upon Ultra-Short Laser Pulse Irradiation. Materials, 12(7), 1018. https://doi.org/10.3390/ma12071018