Densification Mechanism of Soft Magnetic Composites Using Ultrasonic Compaction for Motors in EV Platforms

Abstract

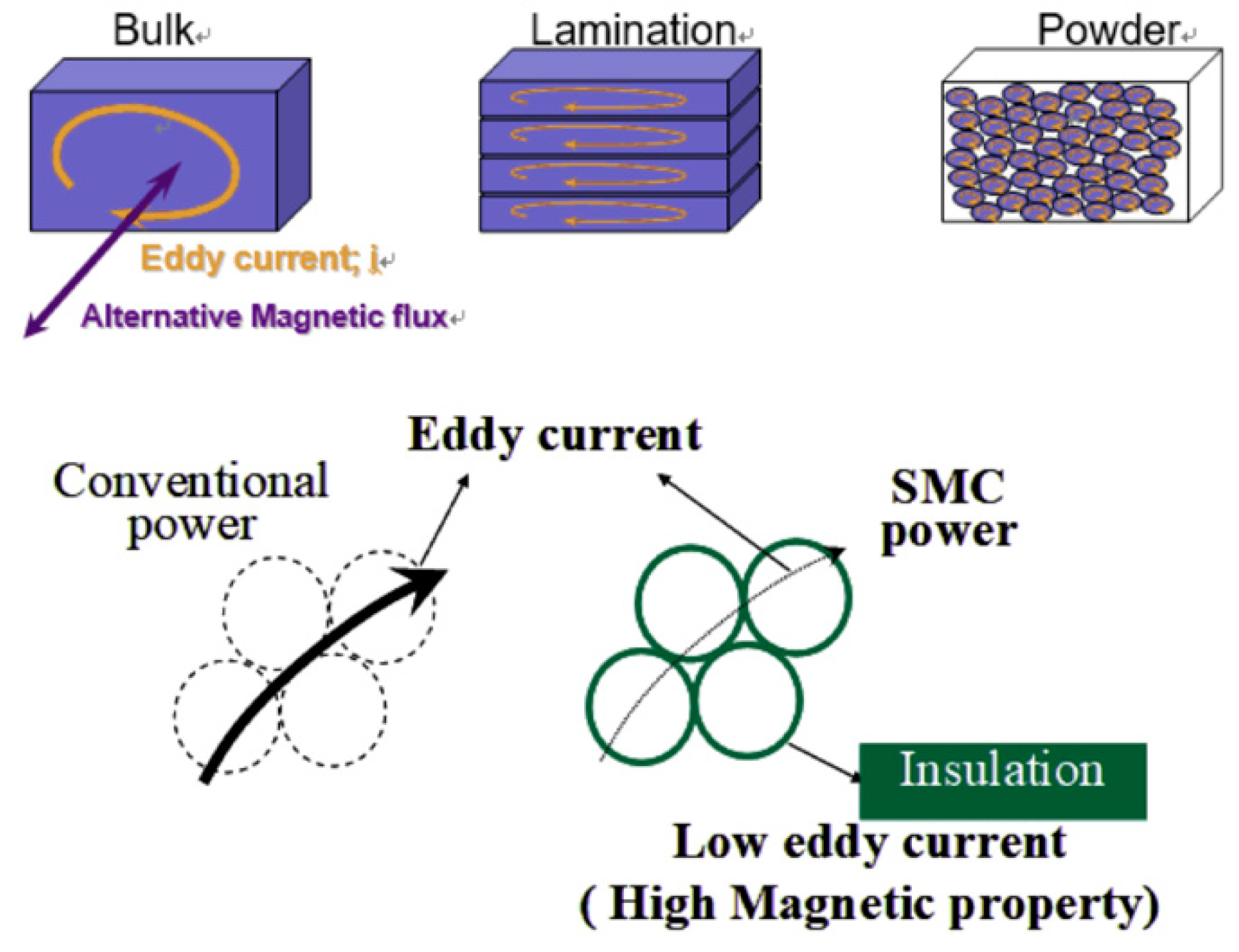

1. Introduction

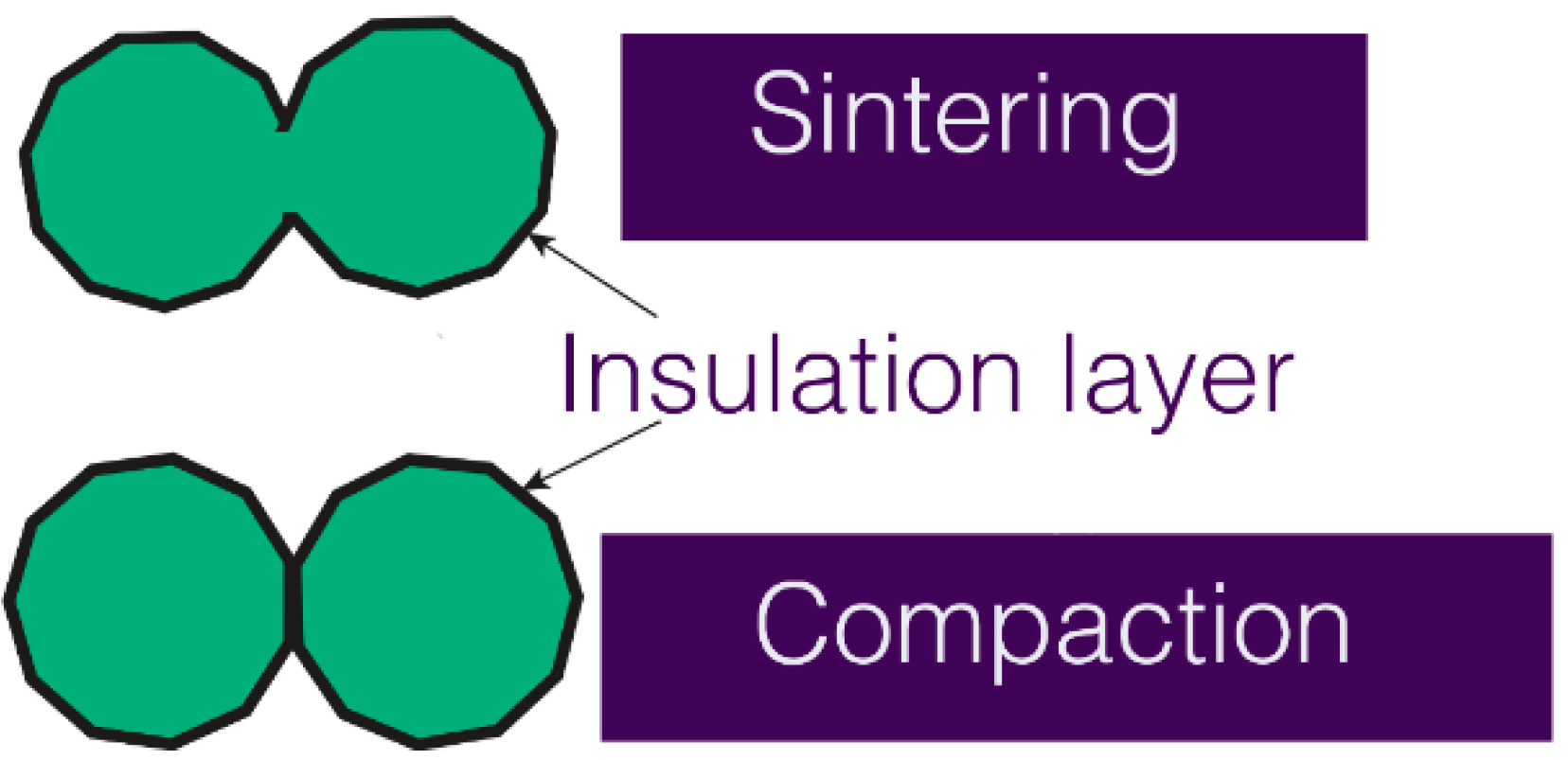

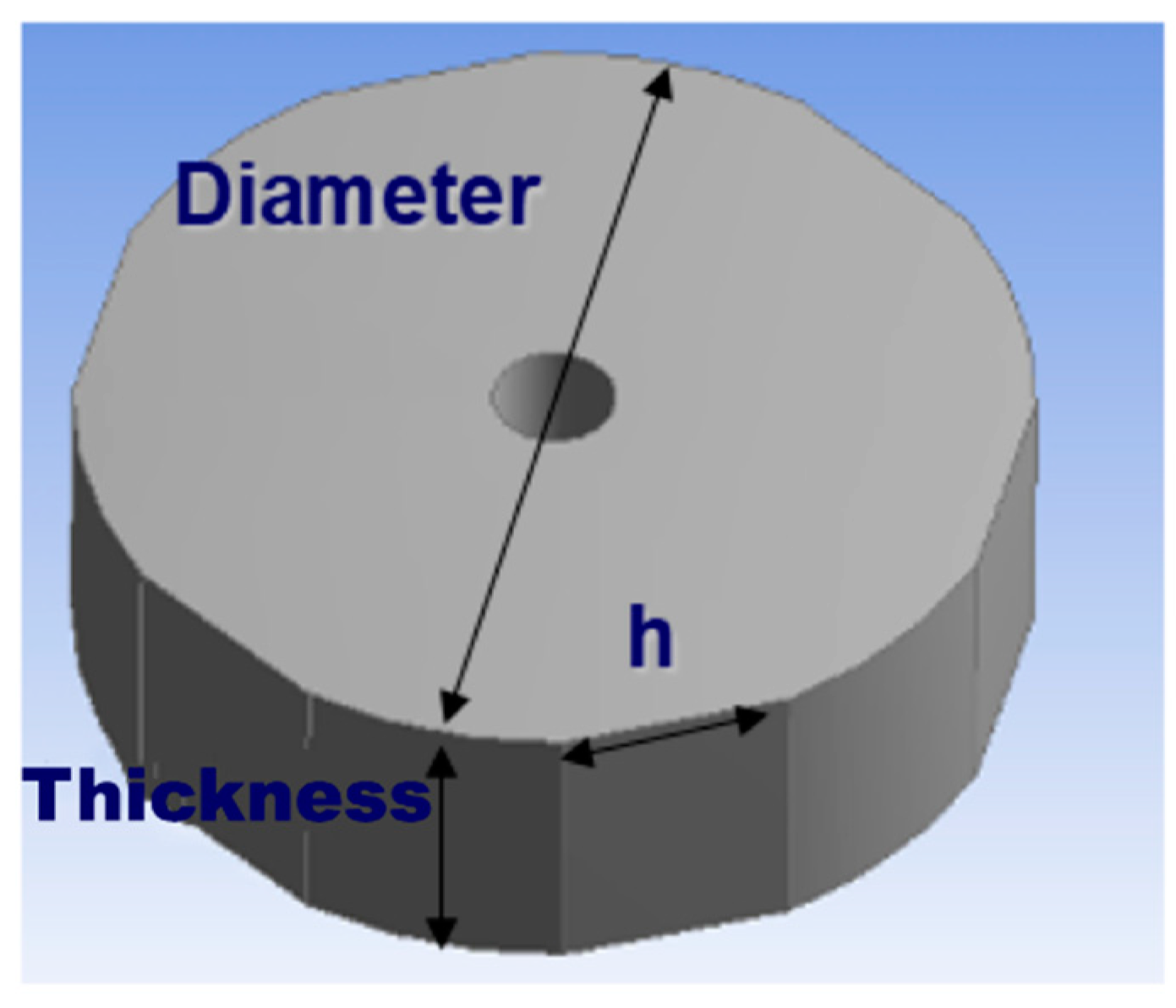

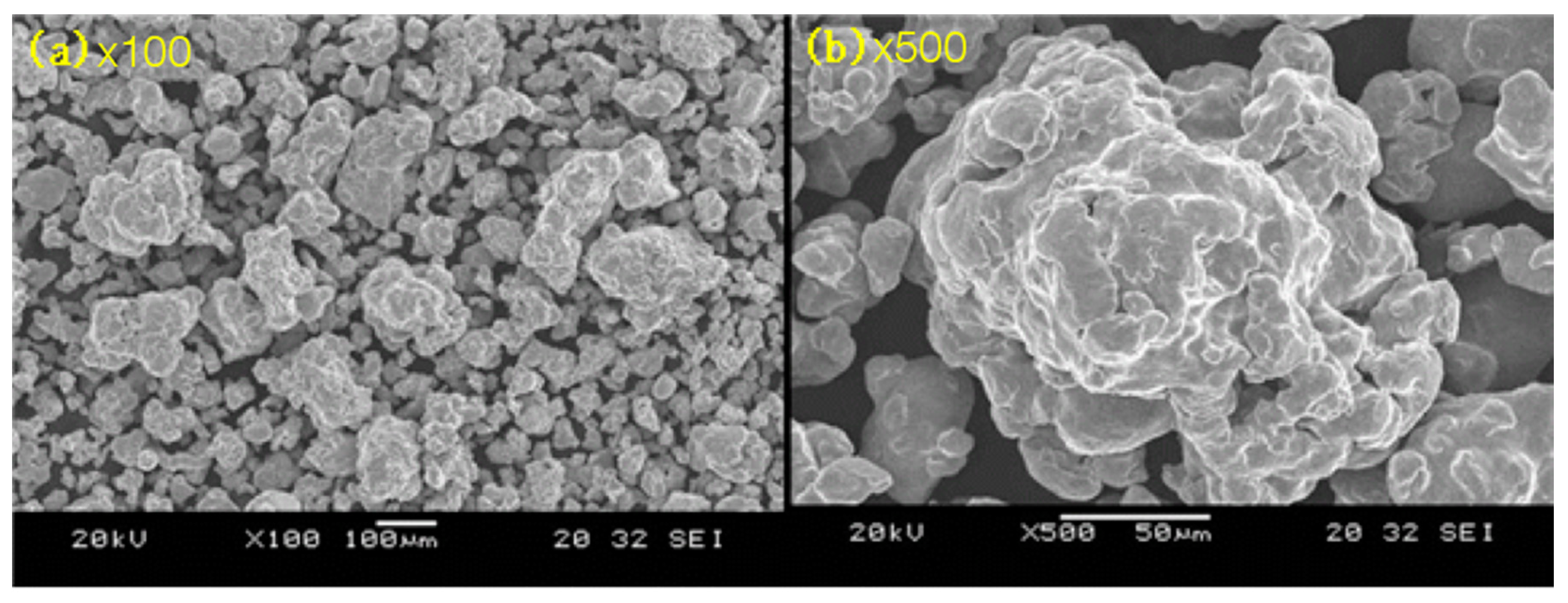

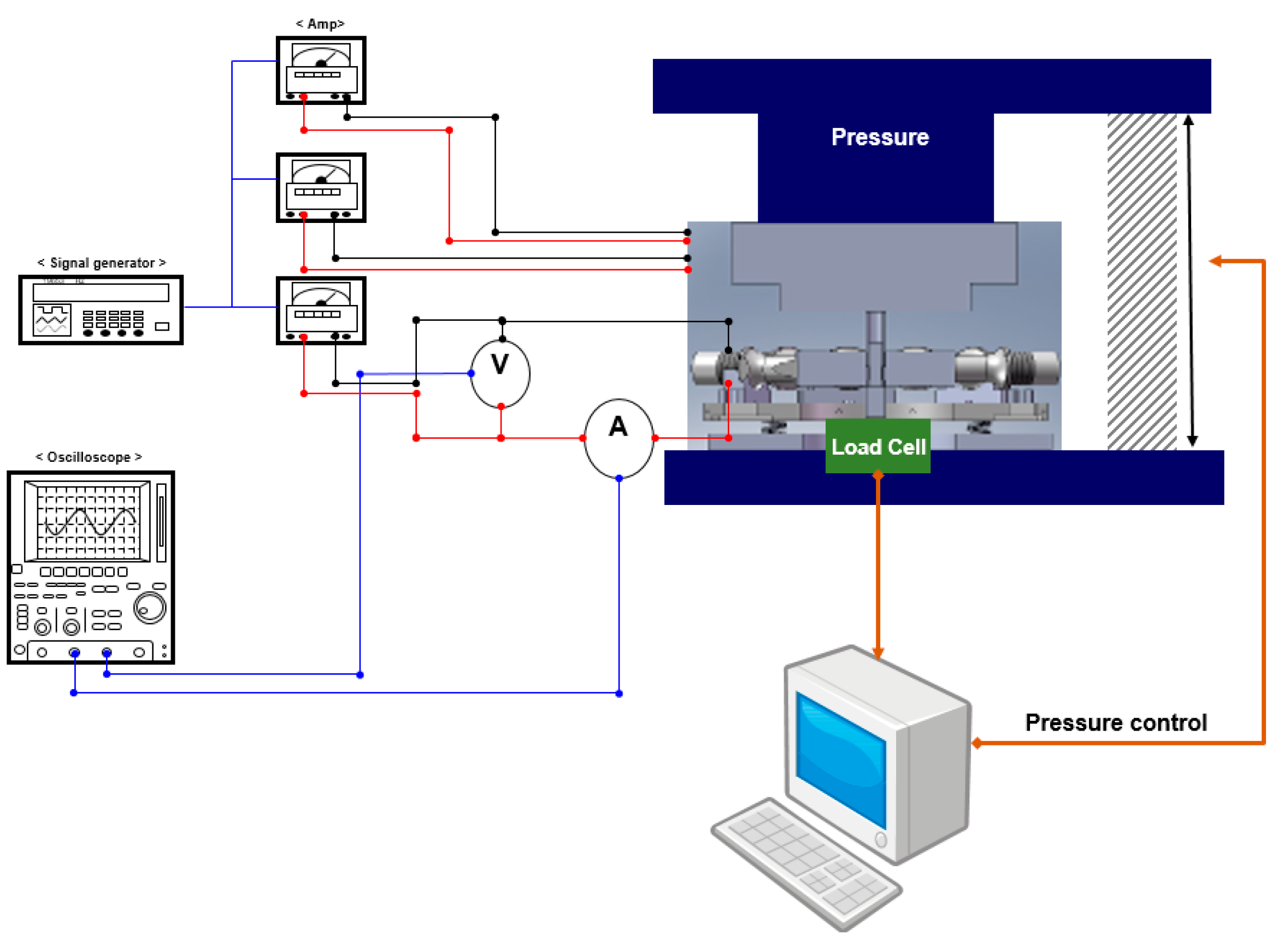

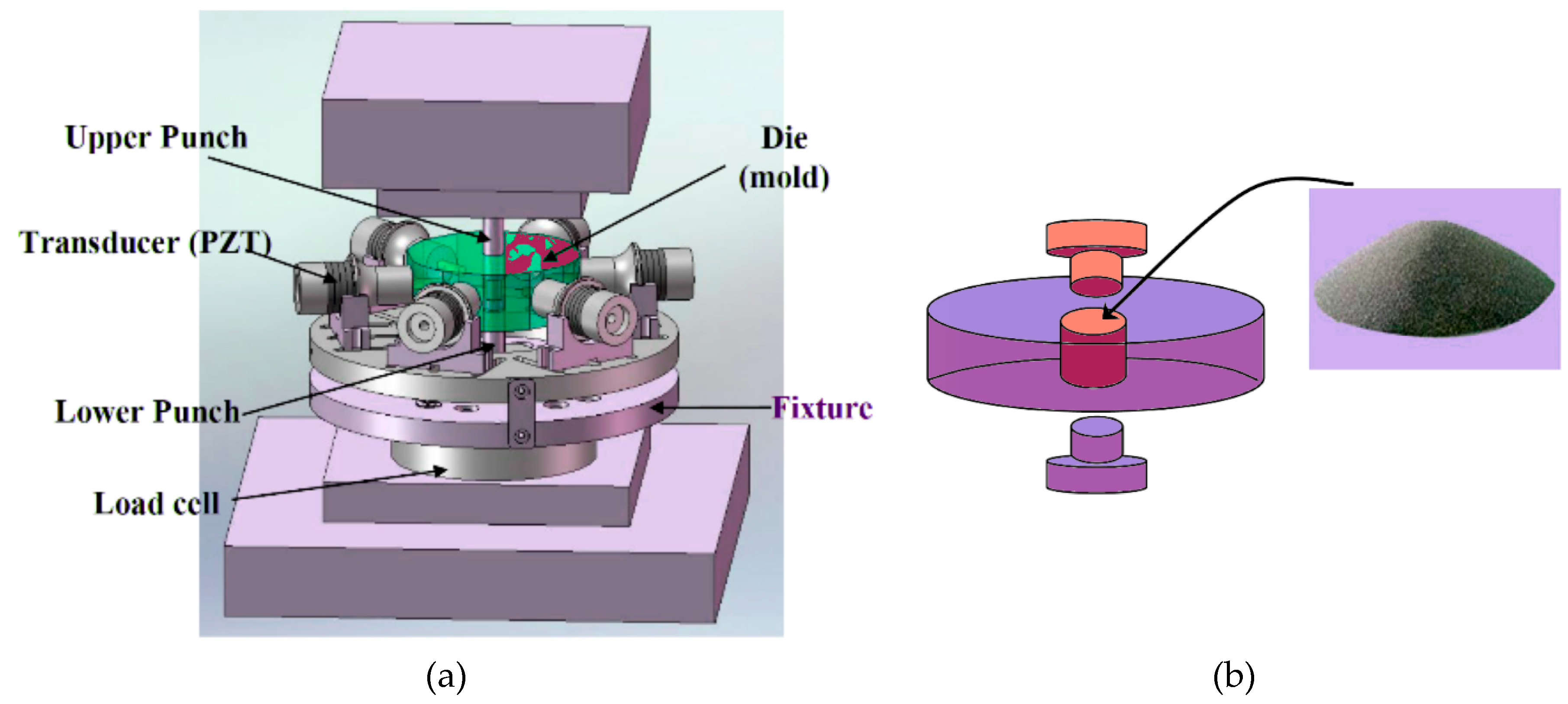

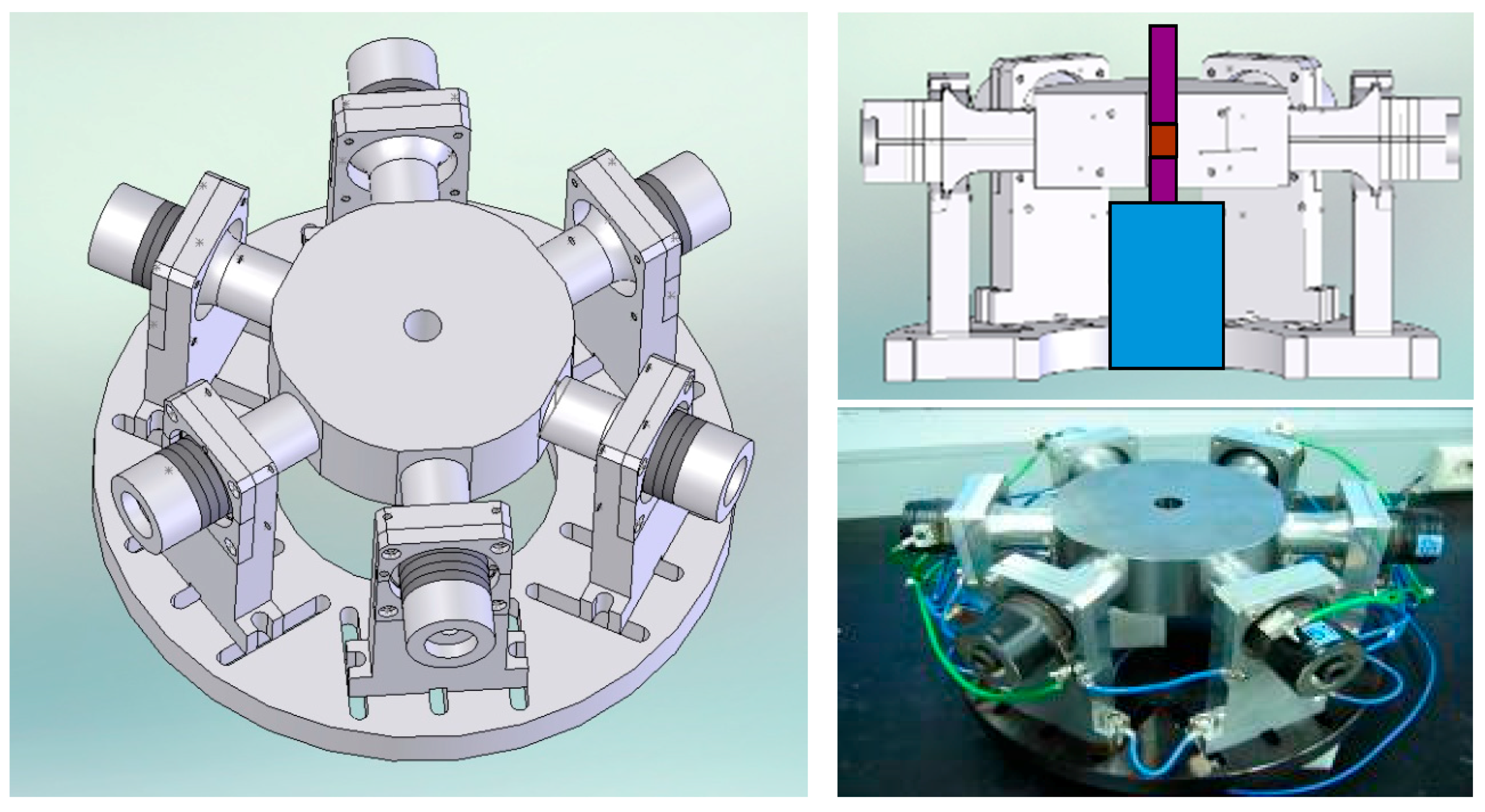

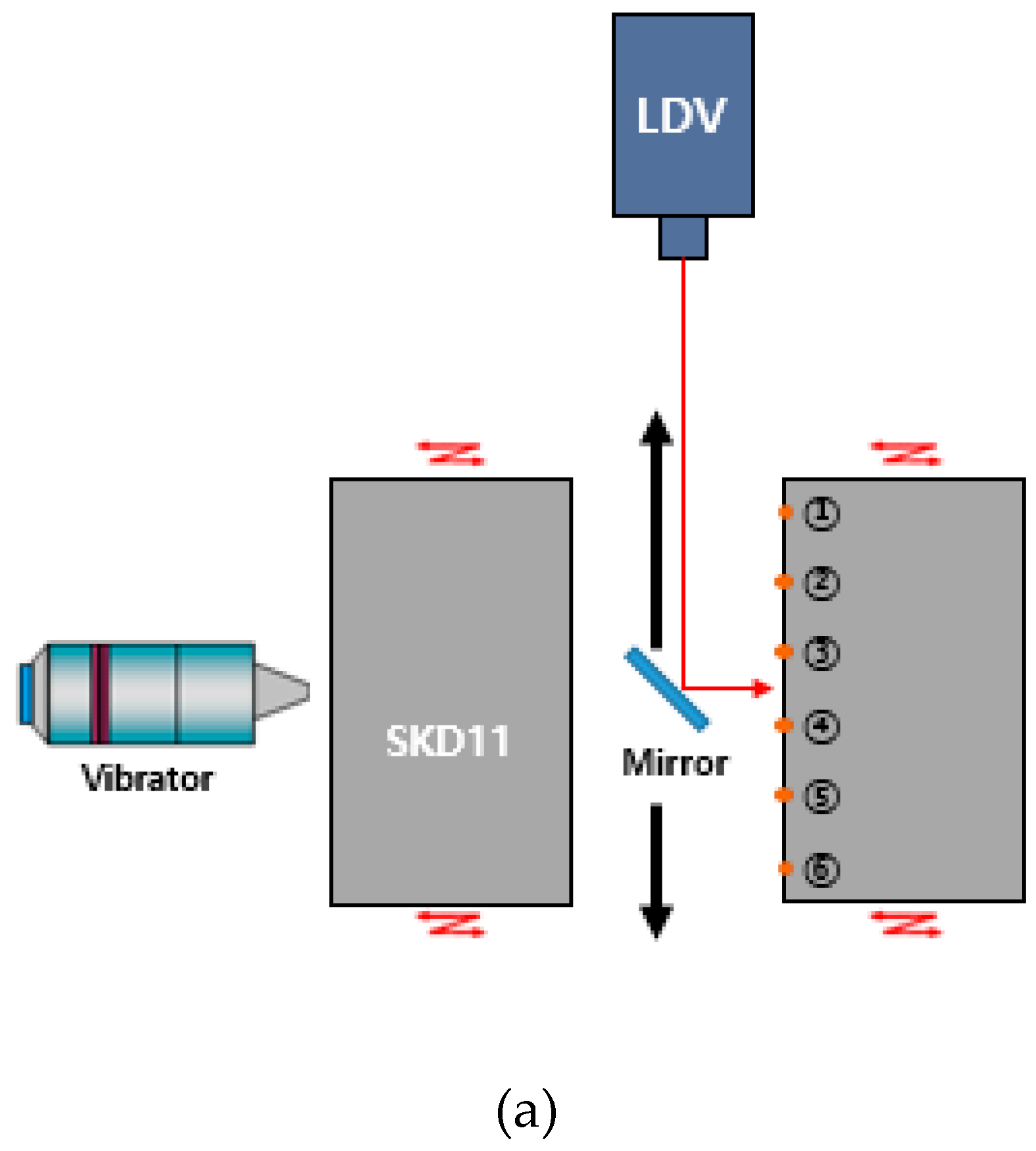

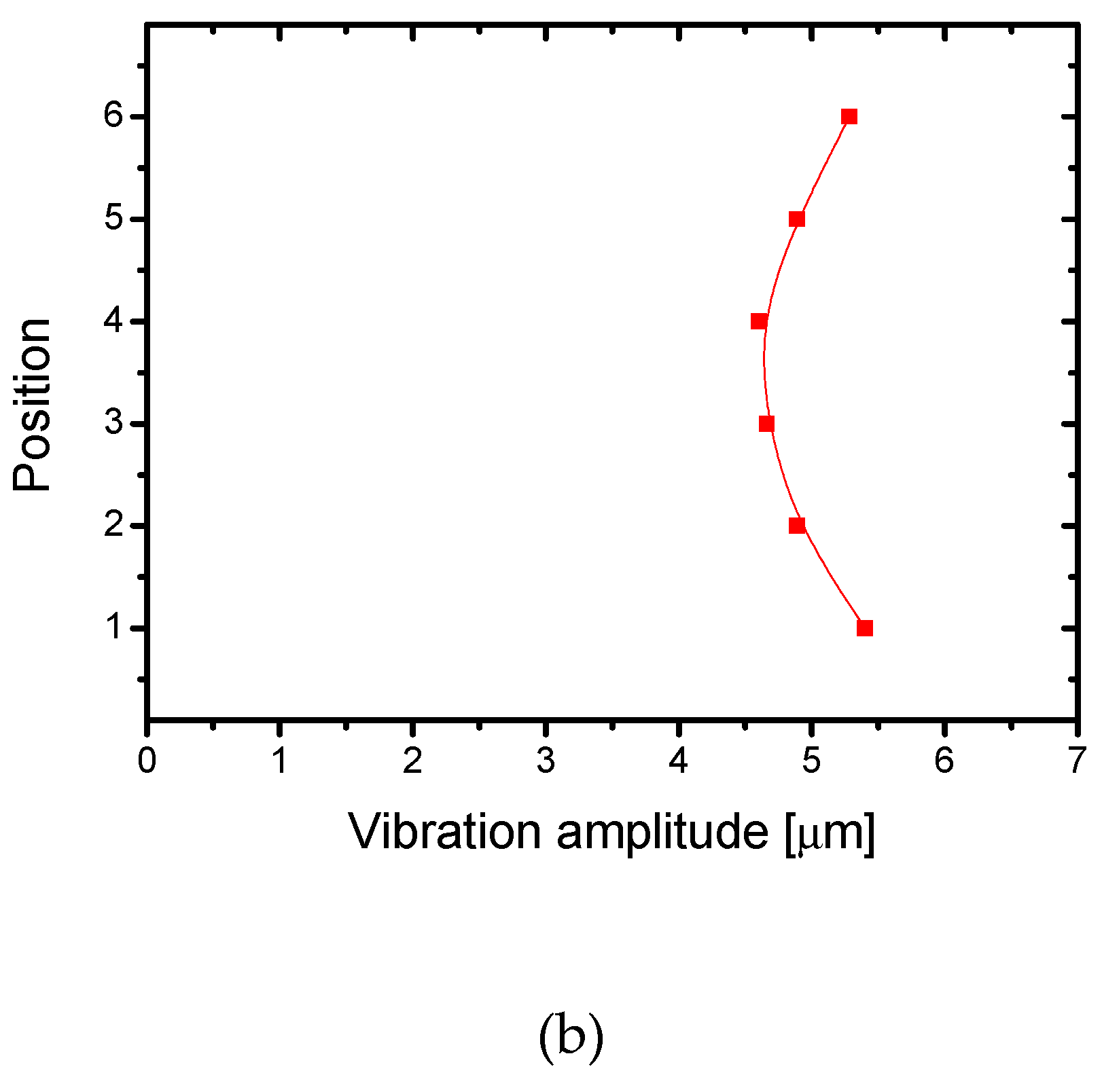

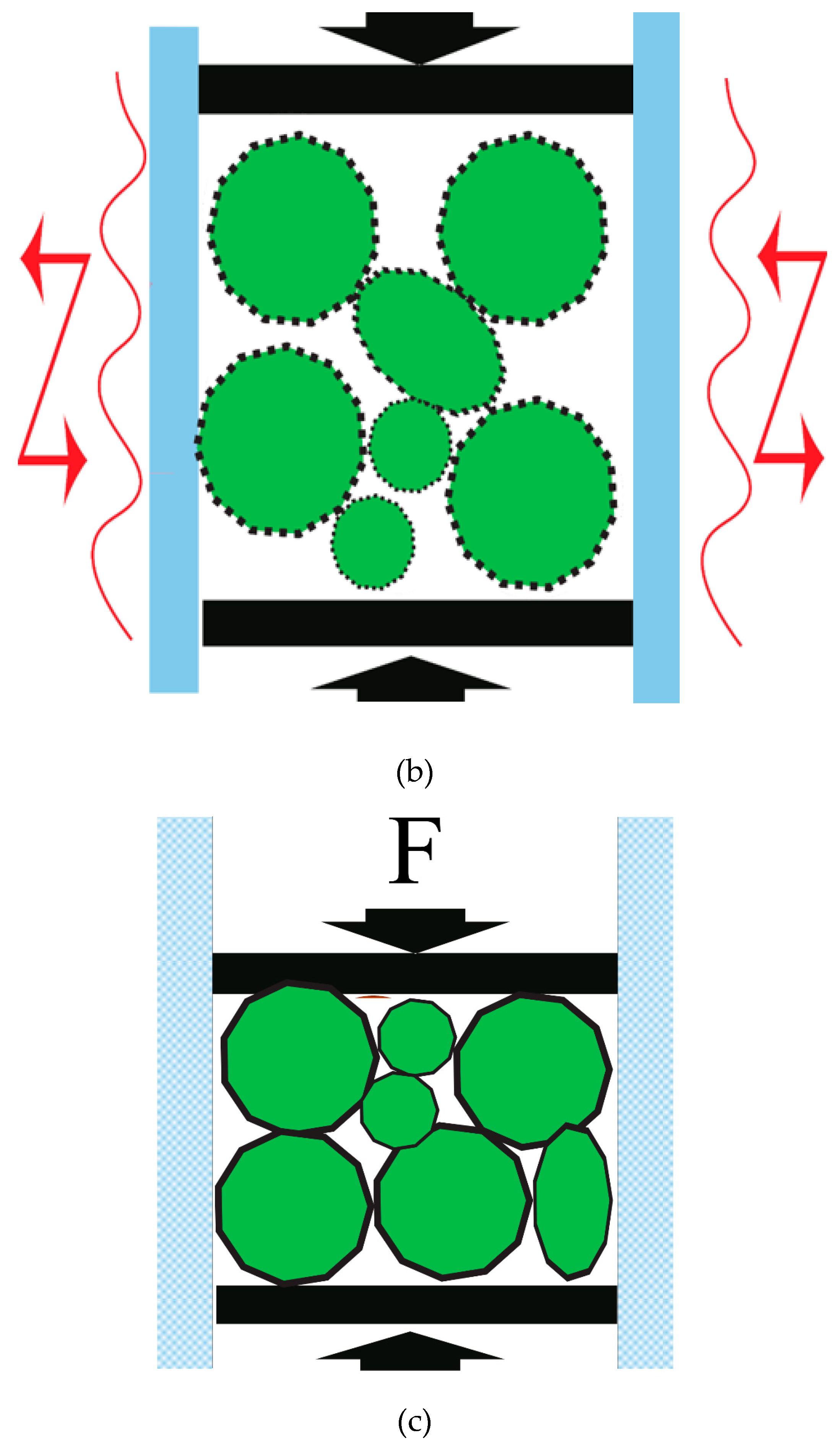

2. Materials and Methods

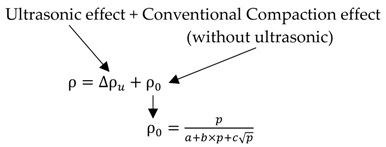

3. Analysis of Densification Mechanism under Ultrasonic Compaction

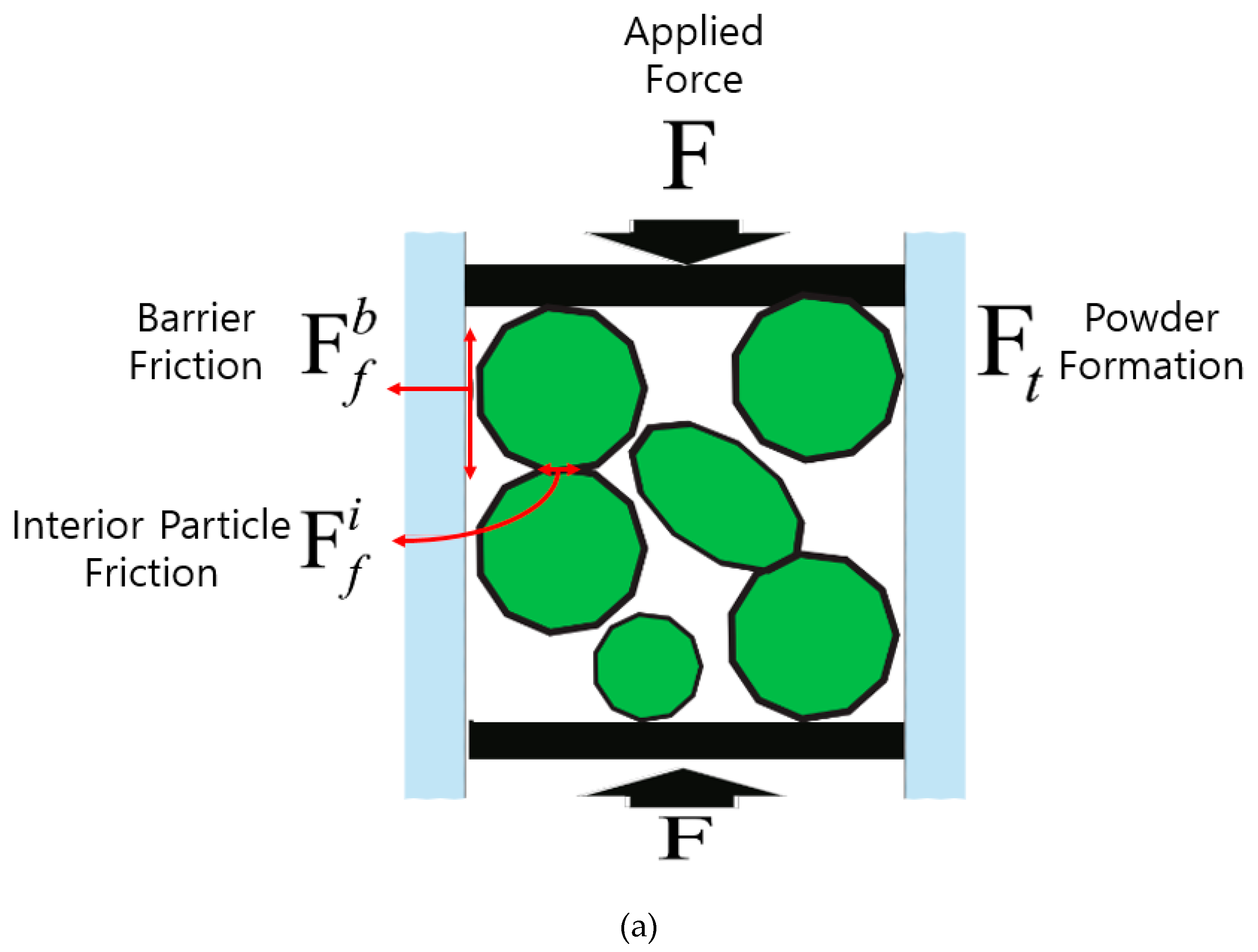

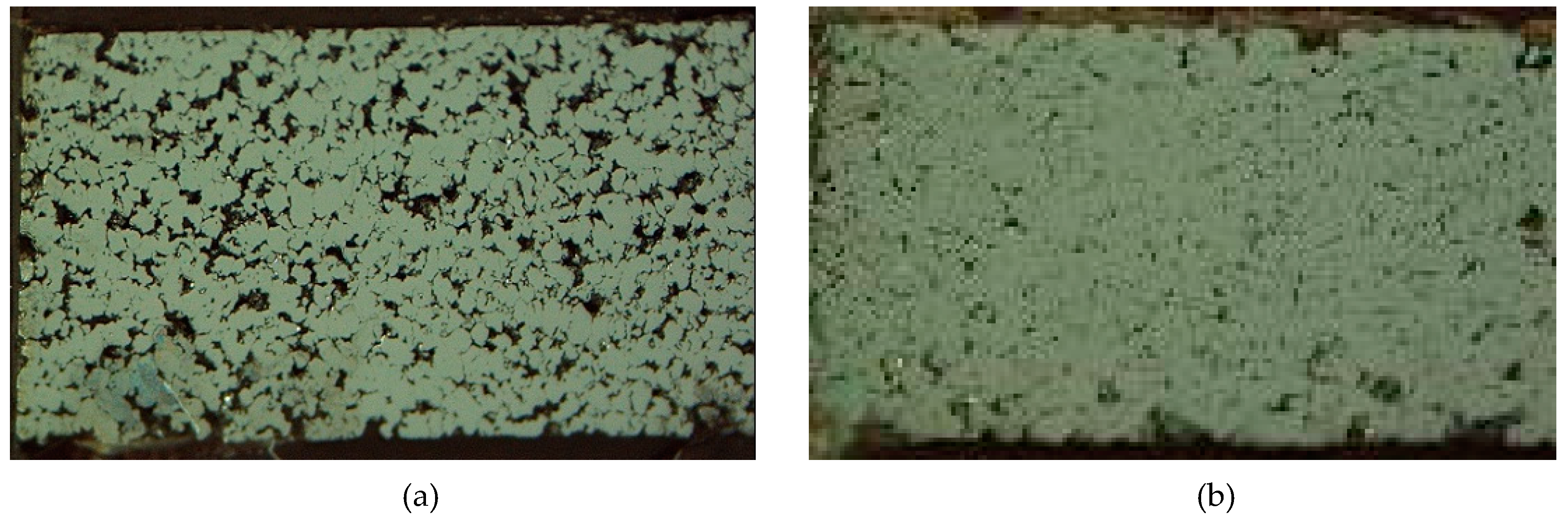

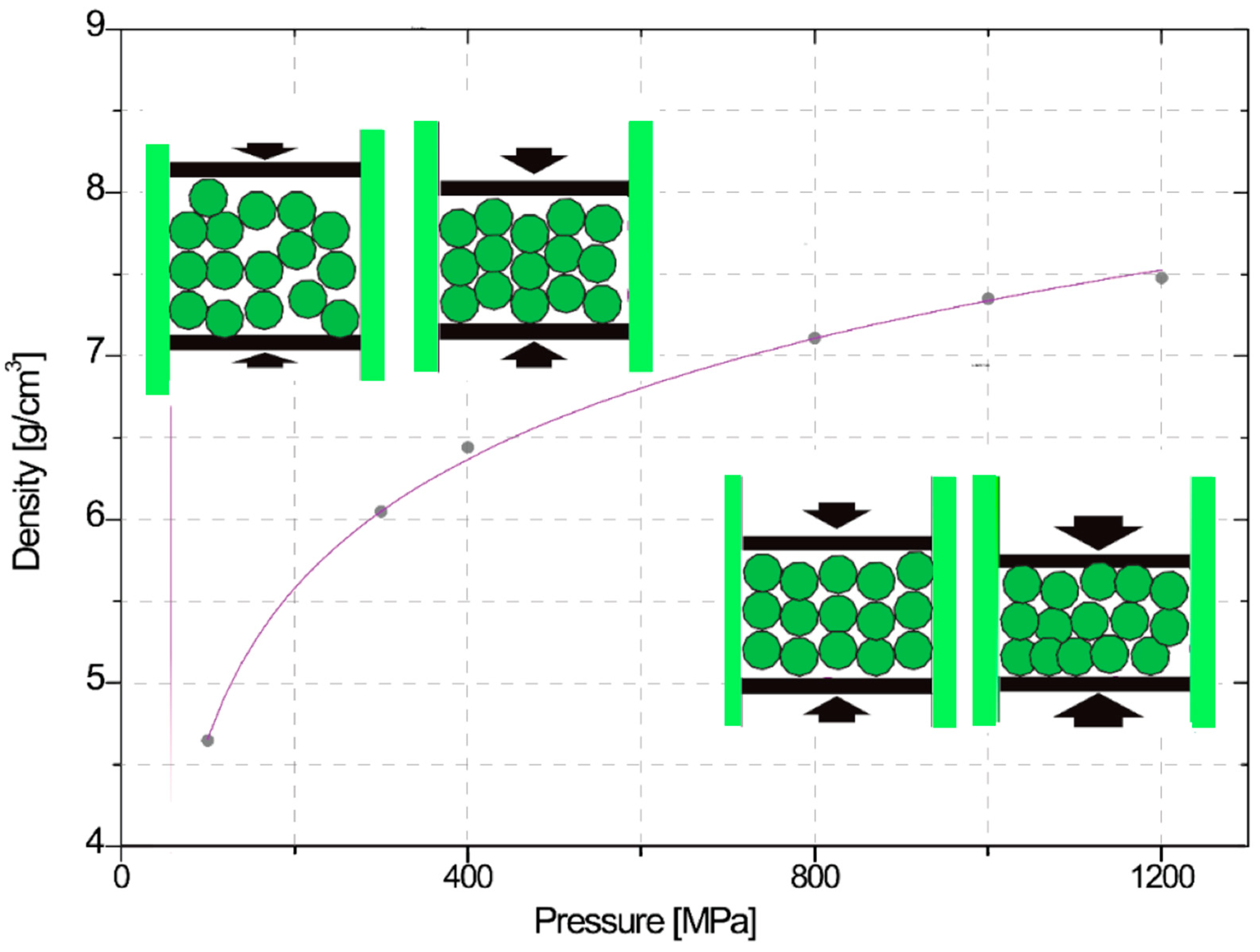

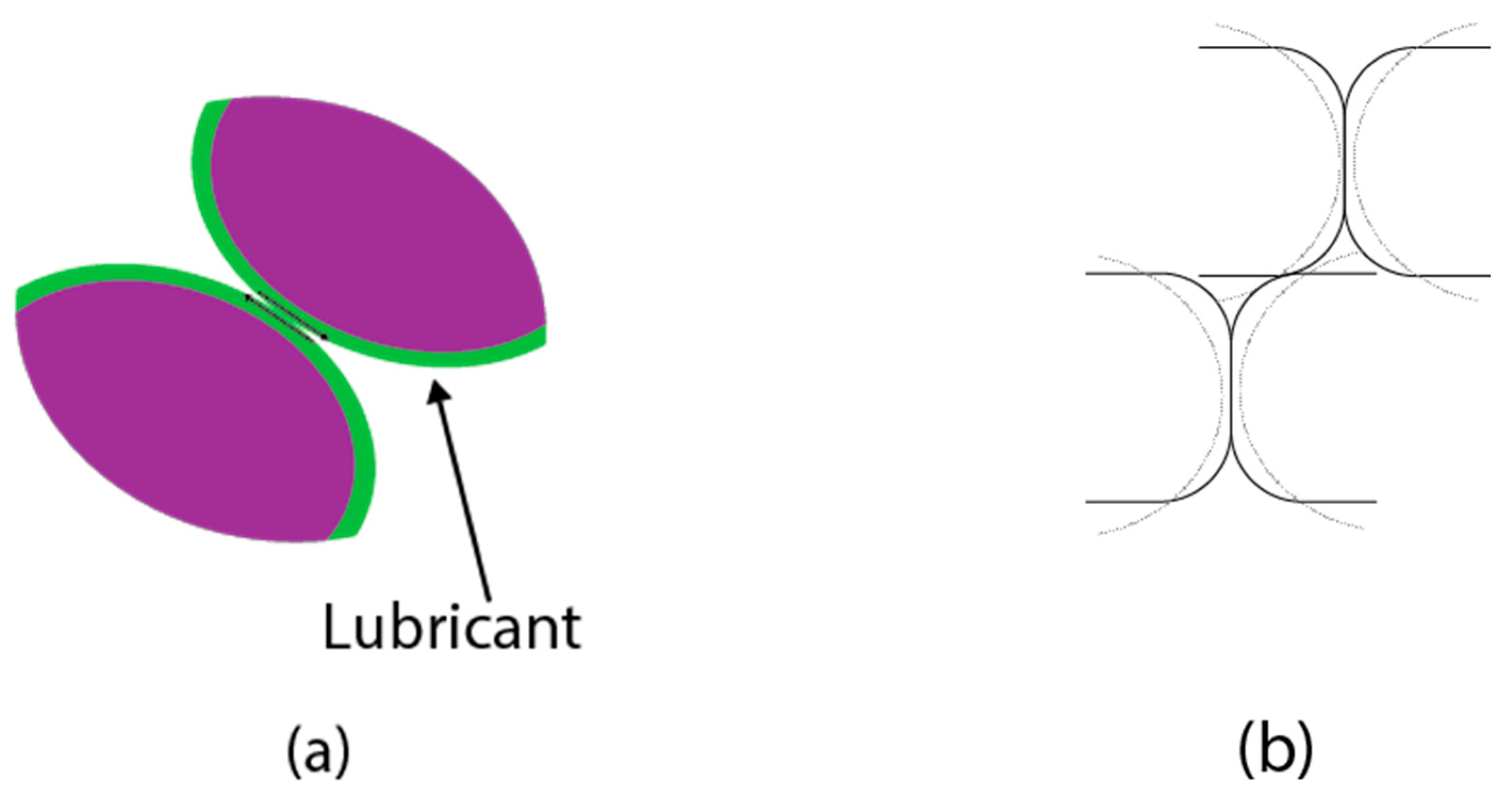

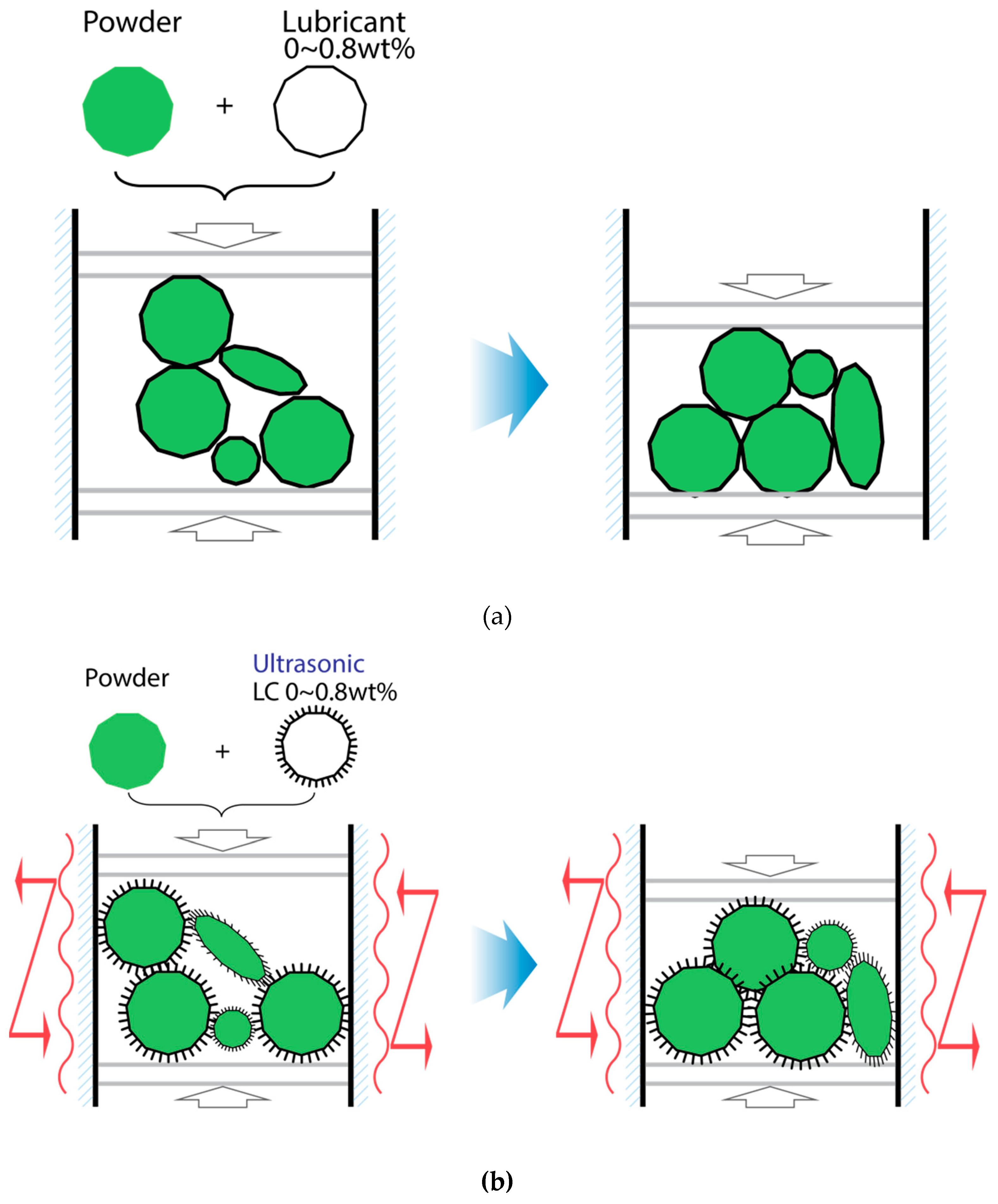

3.1. Conventional Compaction Mechanism

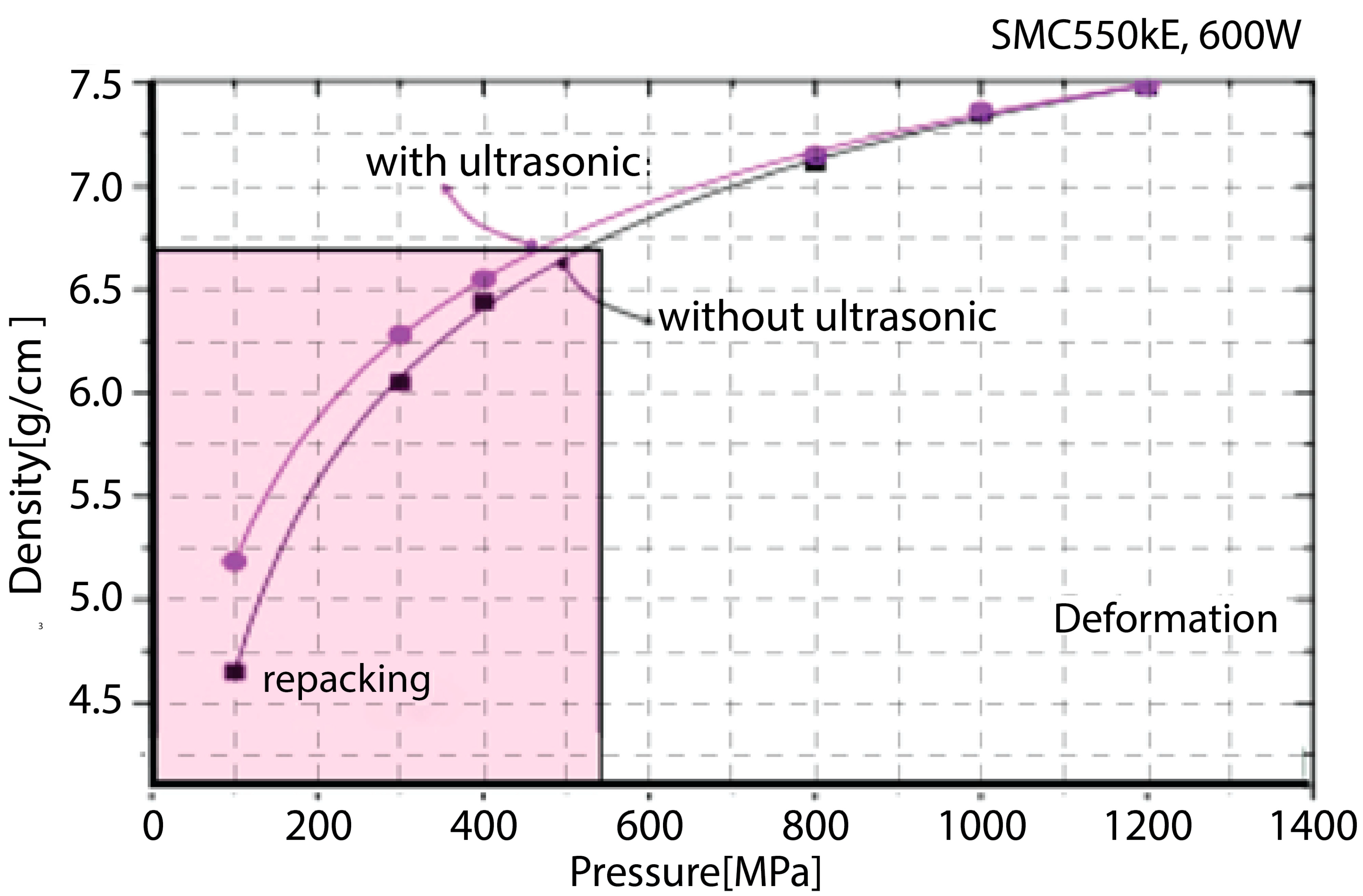

3.2. Density Comparison with Ultrasonic and Non-Ultrasonic Effects under Different Compacting Pressures

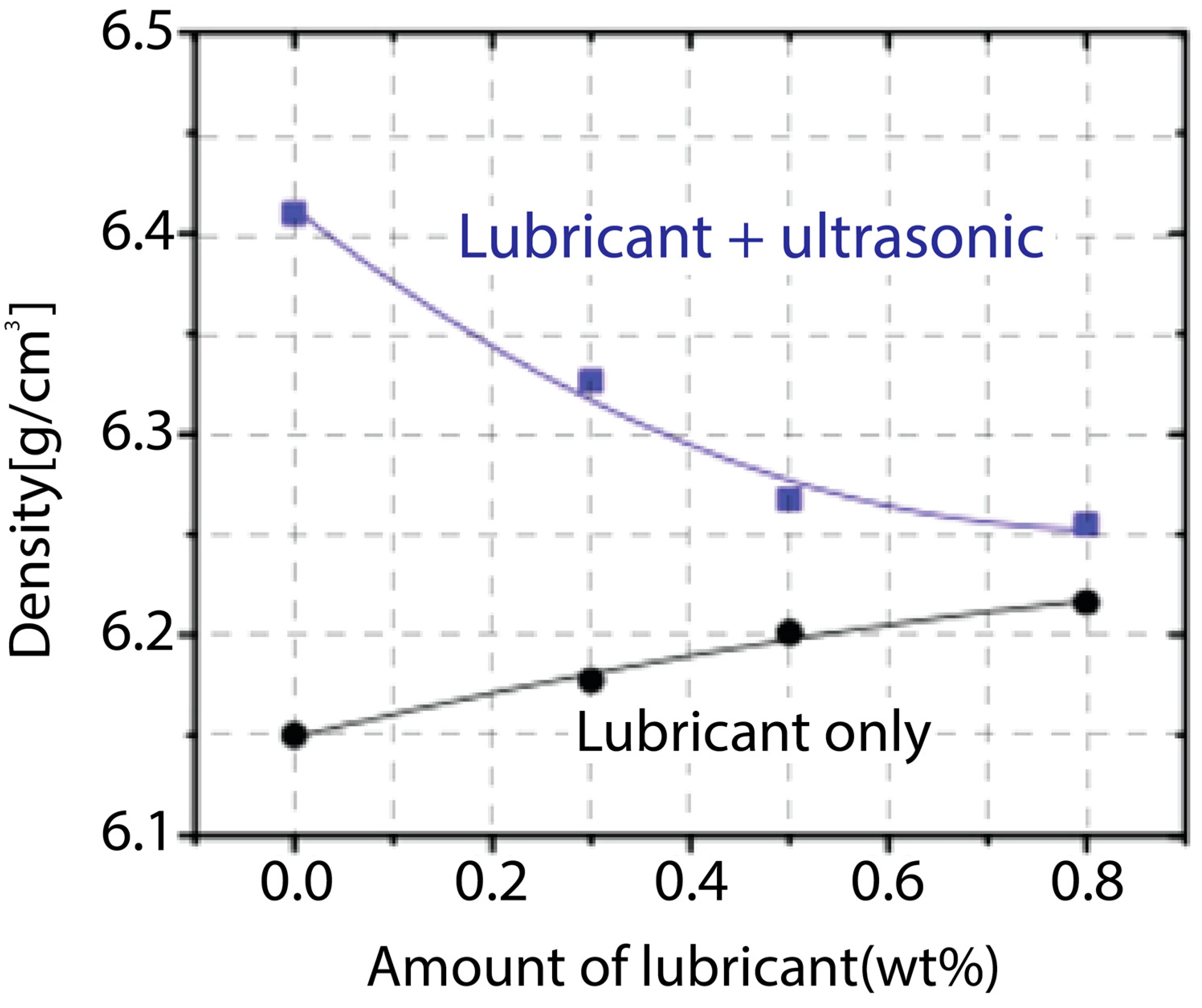

3.3. Analysis of Repacking Effect on the SMC Density

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Polinder, H.; Hoeijmakers, M.J. Eddy-current losses in the segmented surface-mounted magnets of a PM machine. IEE Proc.-Electr. Power Appl. 1999, 146, 261–266. [Google Scholar] [CrossRef]

- Shokrollahi, H.; Janghorban, K. Soft magnetic composite materials (SMCs). J. Mater. Process. Technol. 2007, 189, 1–12. [Google Scholar] [CrossRef]

- Guo, Y. Measurement and modeling of core losses of soft magnetic composites under 3-D magnetic excitations in rotating motors. IEEE Trans. Magn. 2005, 41, 3925–3927. [Google Scholar]

- Guo, Y. Development of a PM transverse flux motor with soft magnetic composite cores. IEEE Trans. Energy Convers. 2006, 21, 426–434. [Google Scholar] [CrossRef]

- Kondoh, M.; Takashi, S.; Hiroyuki, T. Green Compact and Process for Compacting the Same, Metallic Sintered Body and Process for Producing the Same, Worked Component Part and Method of Working. U.S. Patent Application No. 10/615,939, 22 January 2004. [Google Scholar]

- Li, Y.Y. Effect of die wall lubrication on warm compaction powder metallurgy. J. Mater. Process. Technol. 2002, 129, 354–358. [Google Scholar] [CrossRef]

- Hasegawa, T.; Koyama, D.; Nakamura, K.; Ueha, S. Modeling and performance evaluation of an ultrasonic suction pump. JJAP 2008, 47, 4248–4252. [Google Scholar] [CrossRef]

- Kumar, V.C.; Hutchings, I.M. Reduction of the sliding friction of metals by the application of longitudinal or transverse ultrasonic vibration. Tribol. Int. 2004, 37, 833–840. [Google Scholar] [CrossRef]

- Pohlman, R.; Lehfeldt, E. Influence of ultrasonic vibration on metallic friction. Ultrasonics 1966, 4, 178–185. [Google Scholar] [CrossRef]

- Tsujino, J.; Suzuki, H. Ultrasonic vibration press of powder using 20 kHz upper and lower vibration punches and a vacuum compacting die. Jpn. J. Appl. Phys. 1992, 31, 290–293. [Google Scholar] [CrossRef]

- Tsujino, J.; Ueoka, T.; Aoyama, T.; Karatsu, R.; Kyuzen, T. 27 kHz Ultrasonic Complex Vibration Source Using (1, 1) Mode Transverse Vibration Disk with Multiple Transducers of 40 mm Diameter. JJAP 2007, 46, 4945–4947. [Google Scholar] [CrossRef]

- Khasanov, O.L.; Dvilis, E.S.; Sokolov, V.M.; Pokholkov, Y.P. Investigation of structural hierarchy of nanoceramics compacted by dry pressing under powerful ultrasound action. Key Eng. Mater. 2004, 268, 73–76. [Google Scholar] [CrossRef]

- Khasanov, O.L.; Edgar, S.D. Net shaping nanopowders with powerful ultrasonic action and methods of density distribution control. Adv. Appl. Ceram. 2008, 107, 135–141. [Google Scholar] [CrossRef]

- Khasanov, O.L. Effect of ultrasonic compaction of nanopowder on structure and fracture character of zirconia nanoceramics. In Fracture Mechanics of Ceramics; Springer: Boston, MA, USA, 2002; pp. 503–512. [Google Scholar]

- German, R.M. Powder Metallurgy & particulate materials processing. In Metal Powder Industries Federation; Metal Powder Industry: Princeton, NJ, USA, 2005; ISBN 0-9762057-1-8. [Google Scholar]

- Cha, H.R.; Lee, S.H.; Jeon, S.K.; Cho, J.I.; Kikuch, S.; Nakamura, K. Motor Core Fabrication through Ultrasonic Vibration Compaction of Soft Magnetic Composite. JJAP 2009, 48, 07GM18-1–07GM18-7. [Google Scholar] [CrossRef]

- York, P. Particle slippage and rearrangement during compression of pharmaceutical powders. J. Pharm. Pharmacol. 1978, 30, 6–10. [Google Scholar] [CrossRef] [PubMed]

- Mallick, S. Study of particle rearrangement, compression behavior and dissolution properties after melt dispersion of ibuprofen, Avicel and Aerosil. Results Pharma Sci. 2011, 1, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Zhu, J.; Dorrell, D.G. Design and analysis of a claw pole permanent magnet motor with molded soft magnetic composite core. IEEE Trans. Magn. 2009, 45, 4582–4585. [Google Scholar]

- Morimoto, M. Performance improvement of induction motor made of three dimensional shaped SMC core. In Proceedings of the 2011 IEEE Ninth International Conference on Power Electronics and Drive Systems (PEDS), Singapore, 5–8 December 2011. [Google Scholar]

| Parameter | Function | Parameter | Function |

|---|---|---|---|

| u | Vibration amplitude (~20 μm) | po | Compacted position |

| F | Force | mo | Modal shape |

| A | Ultrasonic applied area | St | Strength of material |

| P | Pressure | Si | Size of material |

| t | Operating time (~3 s) | lu | Effect of lubricant |

| f | Frequency (15, 20, 38 Khz) | Sh | Shape of material |

| fr | Friction |

| a | b | c | |

|---|---|---|---|

| SMC550KE * | 1.933 | 0.106 | 0.894 |

| SMC550 * | −4.830 | 0.084 | 1.819 |

| SMC500KE * | 3.283 | 0.125 | 0.364 |

| SMC500 * | 1.266 | 0.118 | 0.682 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hwang, M.-H.; Lee, H.-S.; Han, J.-H.; Kim, D.-H.; Cha, H.-R. Densification Mechanism of Soft Magnetic Composites Using Ultrasonic Compaction for Motors in EV Platforms. Materials 2019, 12, 824. https://doi.org/10.3390/ma12050824

Hwang M-H, Lee H-S, Han J-H, Kim D-H, Cha H-R. Densification Mechanism of Soft Magnetic Composites Using Ultrasonic Compaction for Motors in EV Platforms. Materials. 2019; 12(5):824. https://doi.org/10.3390/ma12050824

Chicago/Turabian StyleHwang, Myeong-Hwan, Hae-Sol Lee, Jong-Ho Han, Dong-Hyun Kim, and Hyun-Rok Cha. 2019. "Densification Mechanism of Soft Magnetic Composites Using Ultrasonic Compaction for Motors in EV Platforms" Materials 12, no. 5: 824. https://doi.org/10.3390/ma12050824

APA StyleHwang, M.-H., Lee, H.-S., Han, J.-H., Kim, D.-H., & Cha, H.-R. (2019). Densification Mechanism of Soft Magnetic Composites Using Ultrasonic Compaction for Motors in EV Platforms. Materials, 12(5), 824. https://doi.org/10.3390/ma12050824