Thermo–Mechanical Behavior and Constitutive Modeling of In Situ TiB2/7050 Al Metal Matrix Composites Over Wide Temperature and Strain Rate Ranges

Abstract

1. Introduction

2. Experimental Materials and Procedures

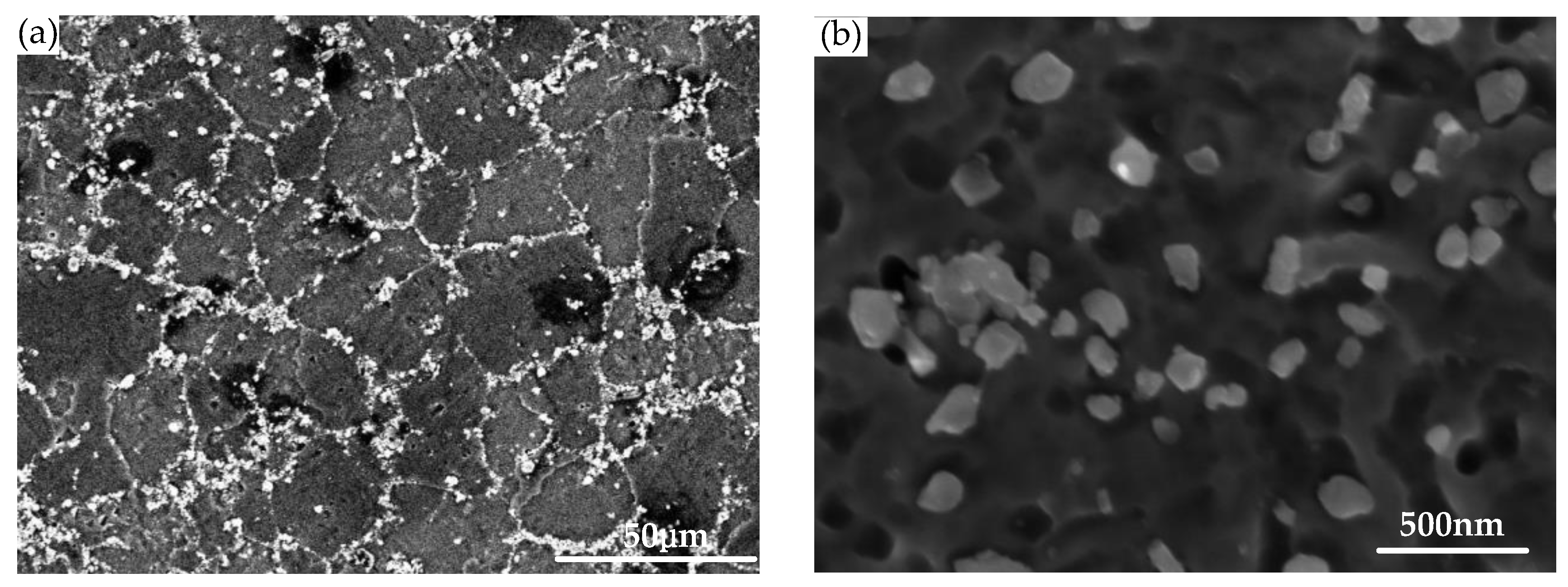

2.1. Materials

2.2. Quasi-Static Uniaxial Compression Experiments

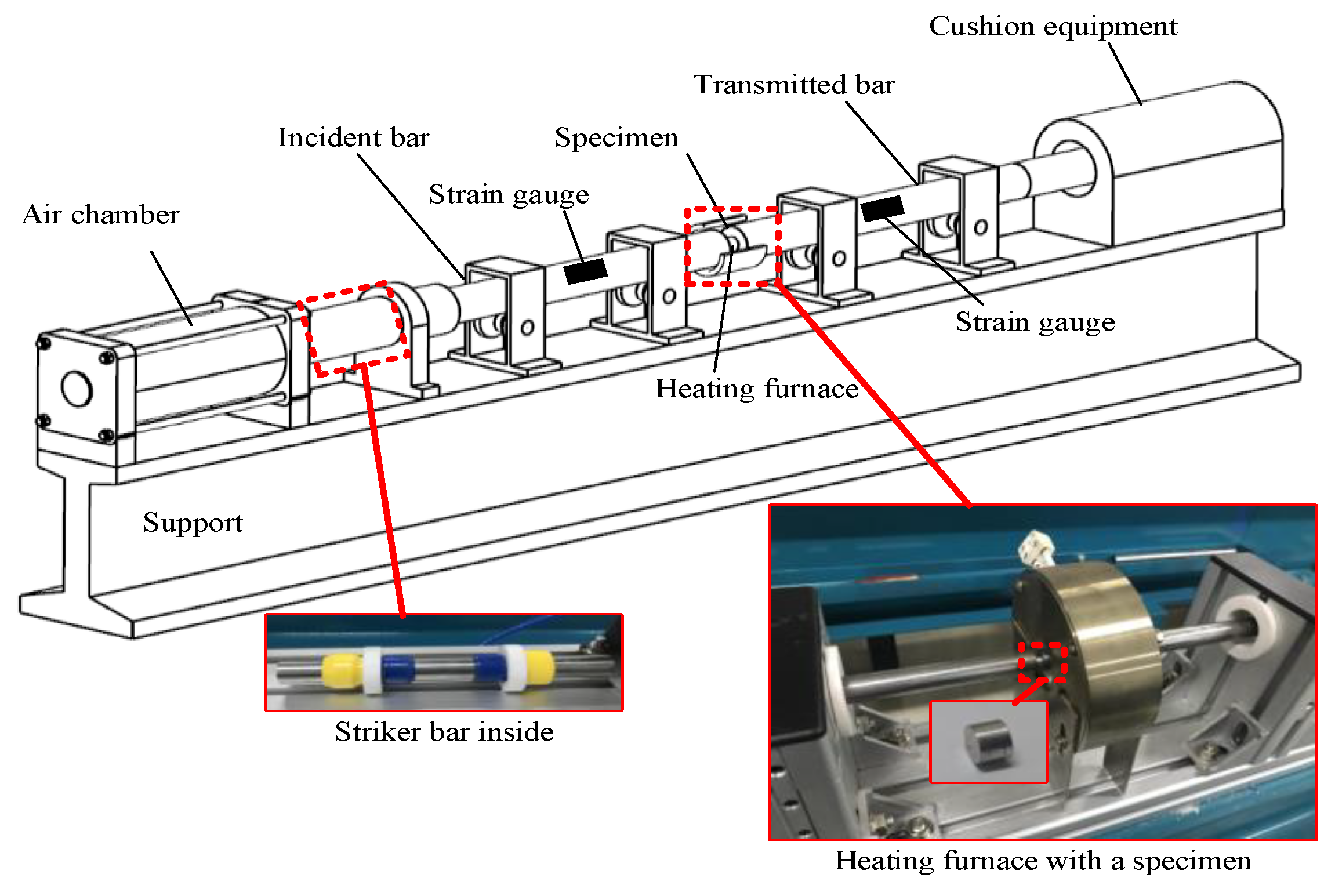

2.3. Dynamic Compressive Experiments

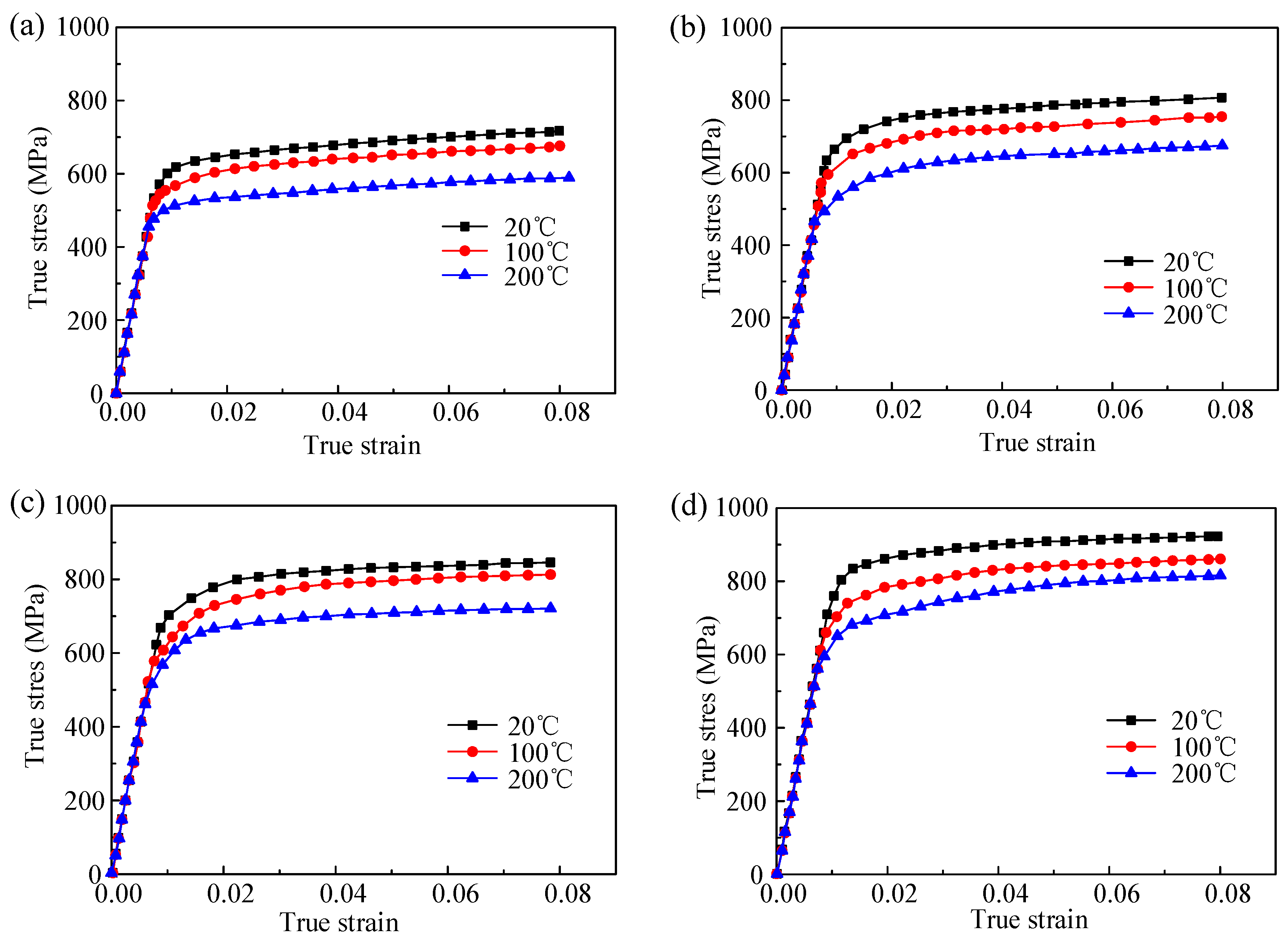

3. Experiment Results

4. Constitutive Modeling

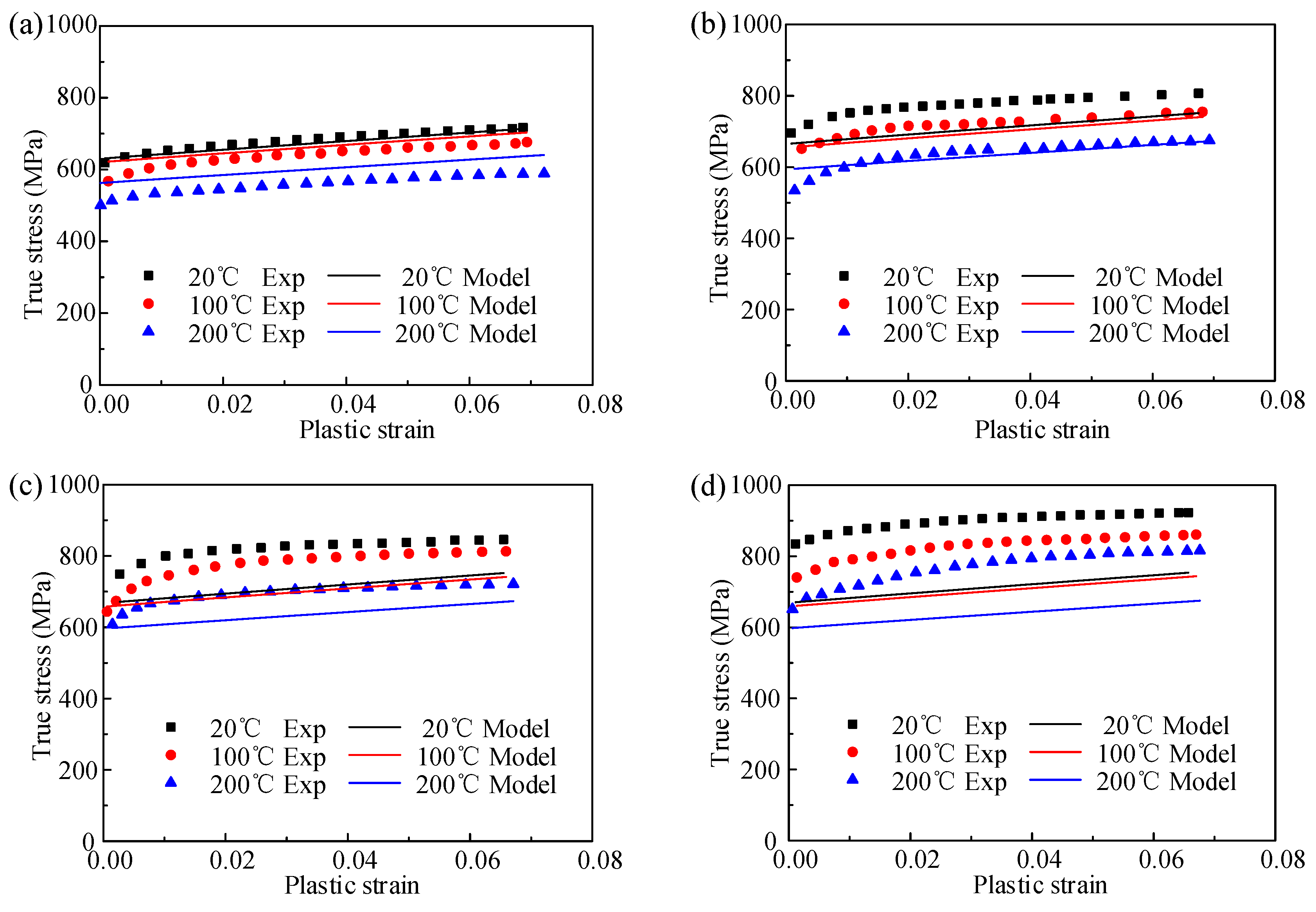

4.1. Johnson–Cook Constitutive Model

- (1)

- By using the experiment result at reference strain rate and temperature, Equation (1) reduces to:The material constant A can be got from the yield stress when plastic strain ε = 0. By the stress data at different plastic strains, B and n can be determined from the intercept and slope of the ln(σ-A) versus lnε fitting line respectively.

- (2)

- At the reference temperature, the third bracket in Equation (1) become unity and the Equation (1) reduces to:By selecting a series of plastic strain at different strain rates, the material constant C can be determined from the above relationship in Equation (7).

- (3)

- At the reference strain rate, the second bracket in Equation (3) become unity and the Equation (3) becomes:By selecting a series of plastic strain at different temperatures, the material constant m can be determined from the above relationship.

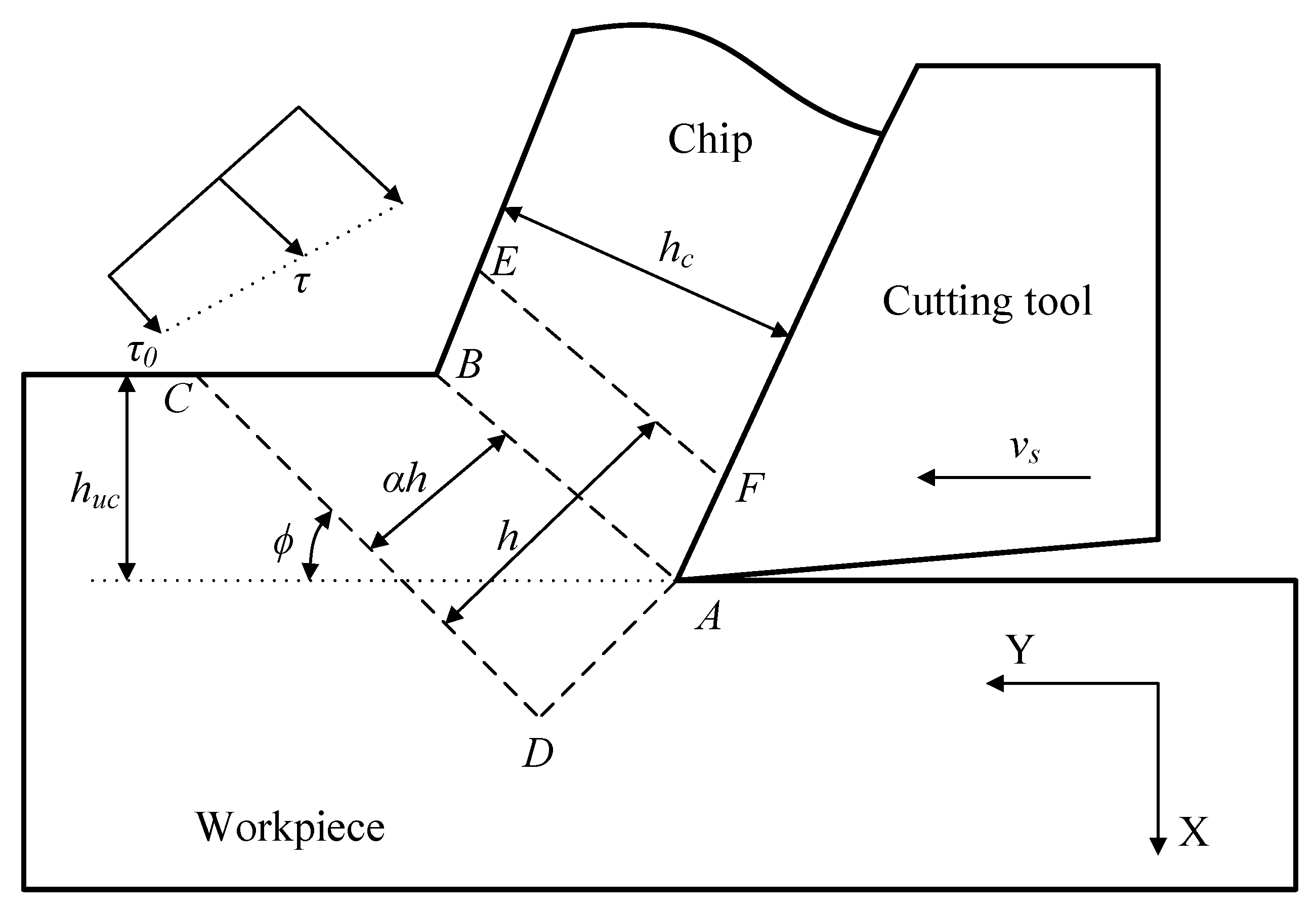

4.2. Johnson–Cook Constitutive Model Obtained from Cutting Experiment

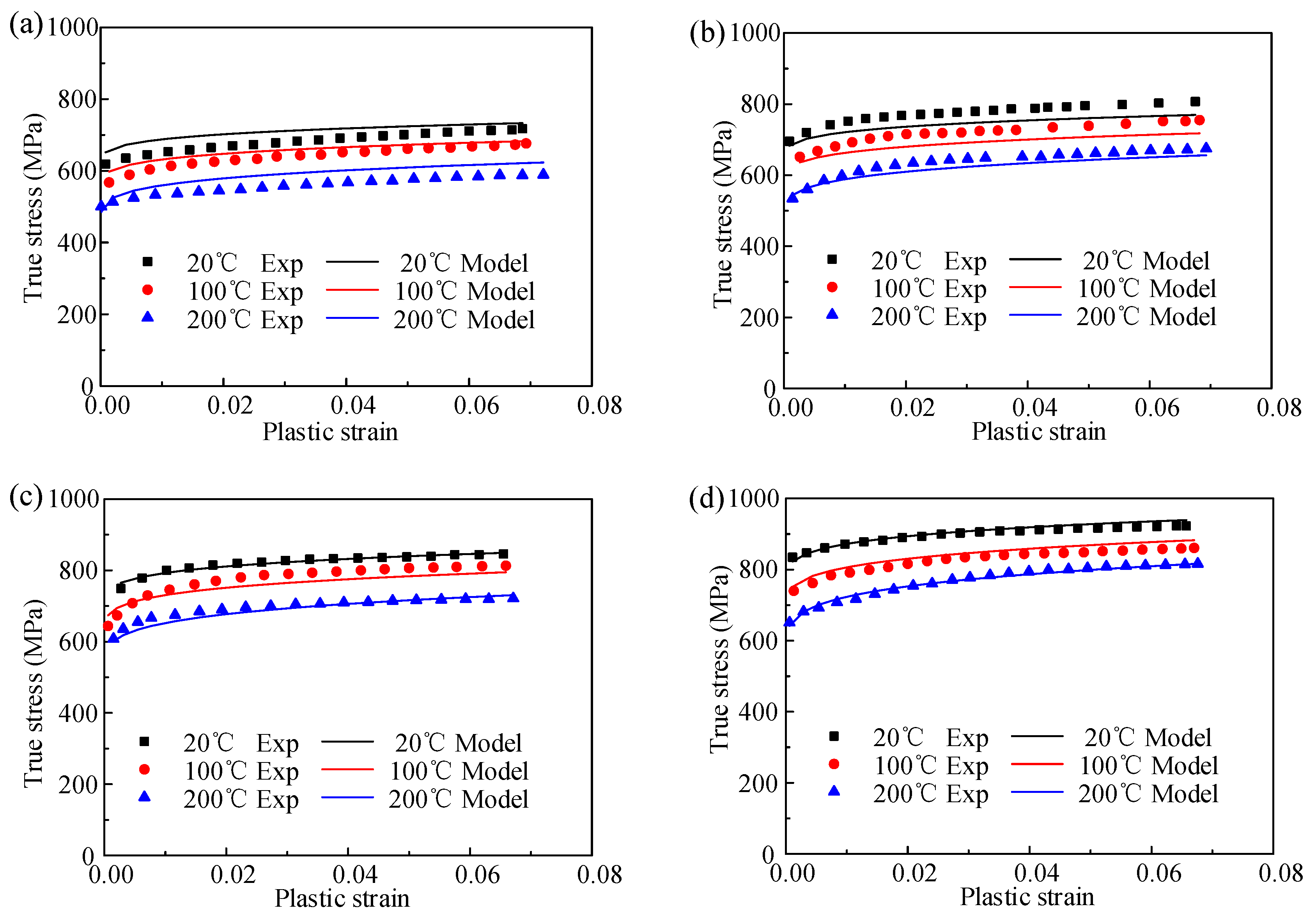

4.3. Khan–Liu Constitutive Model

- (1)

- The material constant A can be determined from the yield stress when the current strain rate = , current temperature T = Tr and plastic strain ε = 0.

- (2)

- By using the experimental result at a reference temperature and ε = 0, the yield stress σY at different conditions can be obtained. Equation (16) reduces to:The material constant C1 can be evaluated from the slope of versus .

- (3)

- By using the yield stress σY of the experiment result when the strain rate = , Equation (16) reduces to:The material constant m2 can be determined from relationship between and using the yield stress at different temperature.

- (4)

- By using the experiment result at reference strain rate and temperature, Equation (16) reduces to:The material constant A can be obtained from the yield stress when plastic strain ε = 0. By the stress data at different plastic strains, B and n can be determined from the intercept and slope of the ln(σA) versus lnε fitting line, respectively.

- (5)

- When strain rate = 1, Equation (16) reduces to:Then the material constant m3 can be determined from the above relationship by the stress–strain data at various temperatures and plastic strains.

- (6)

- When the current temperature T = Tr, Equation (16) reduces to:Then the material constant C3 can be determined from the above relationship by the stress–strain date at different strain rate and plastic strain.

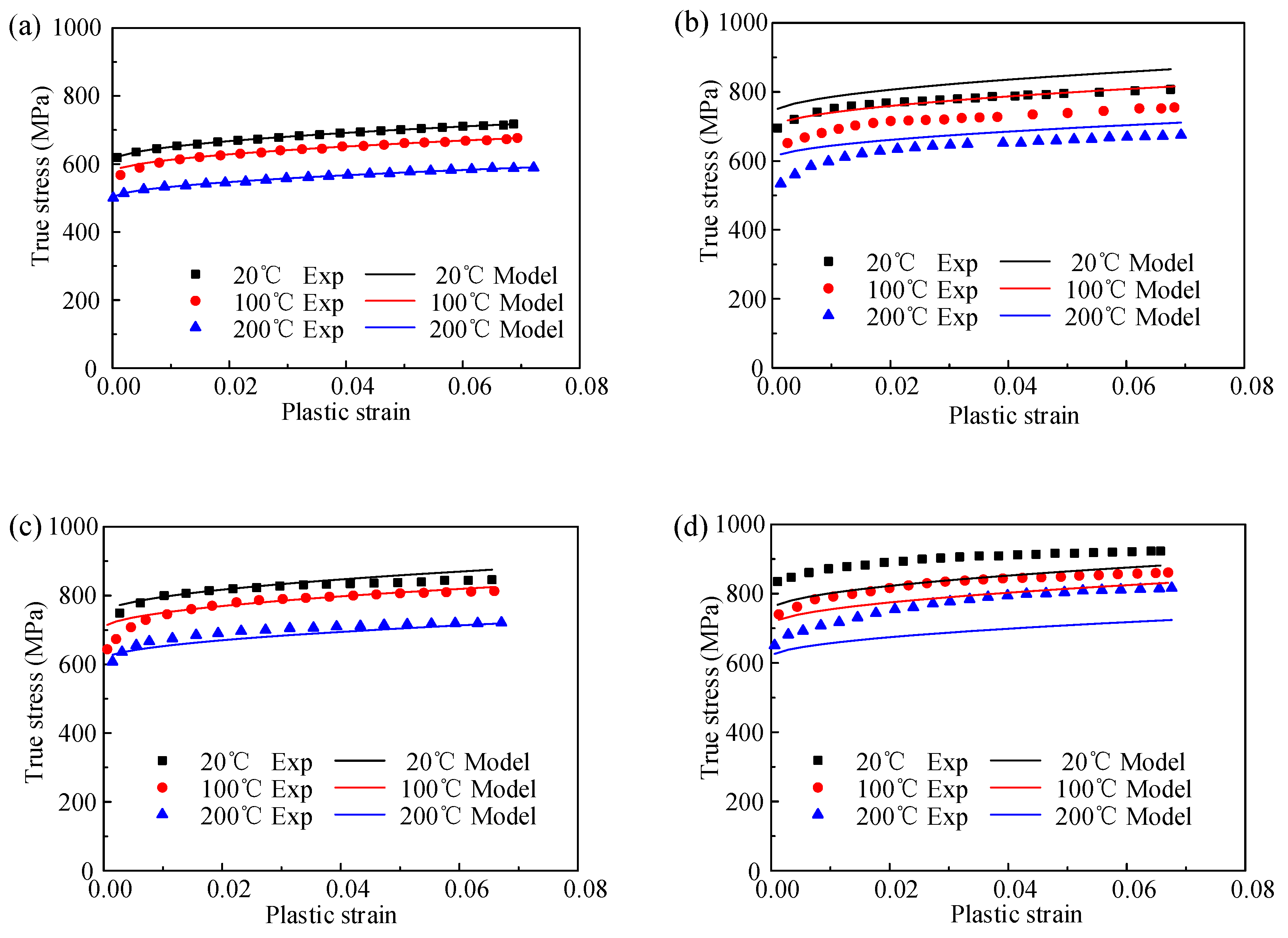

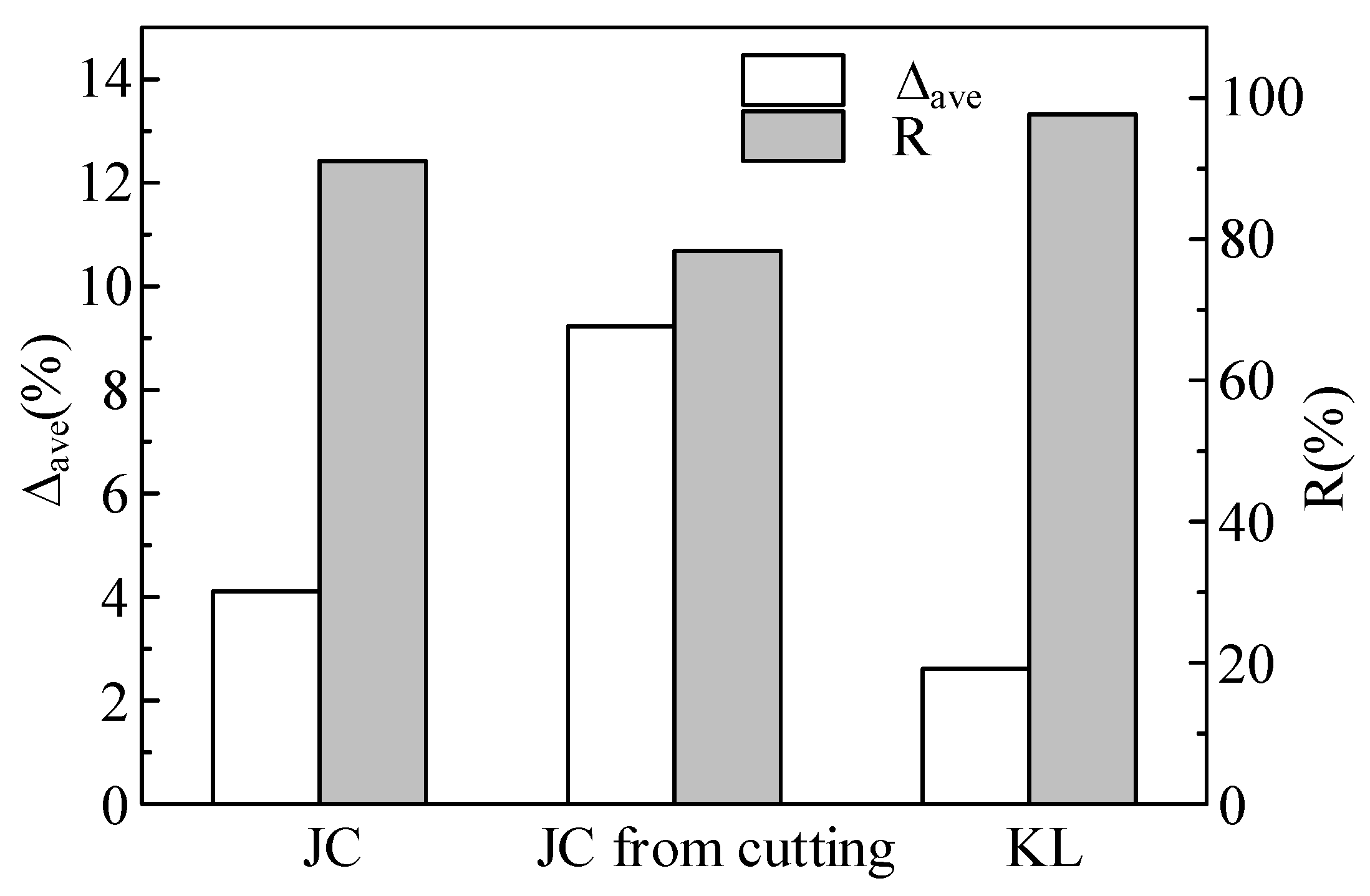

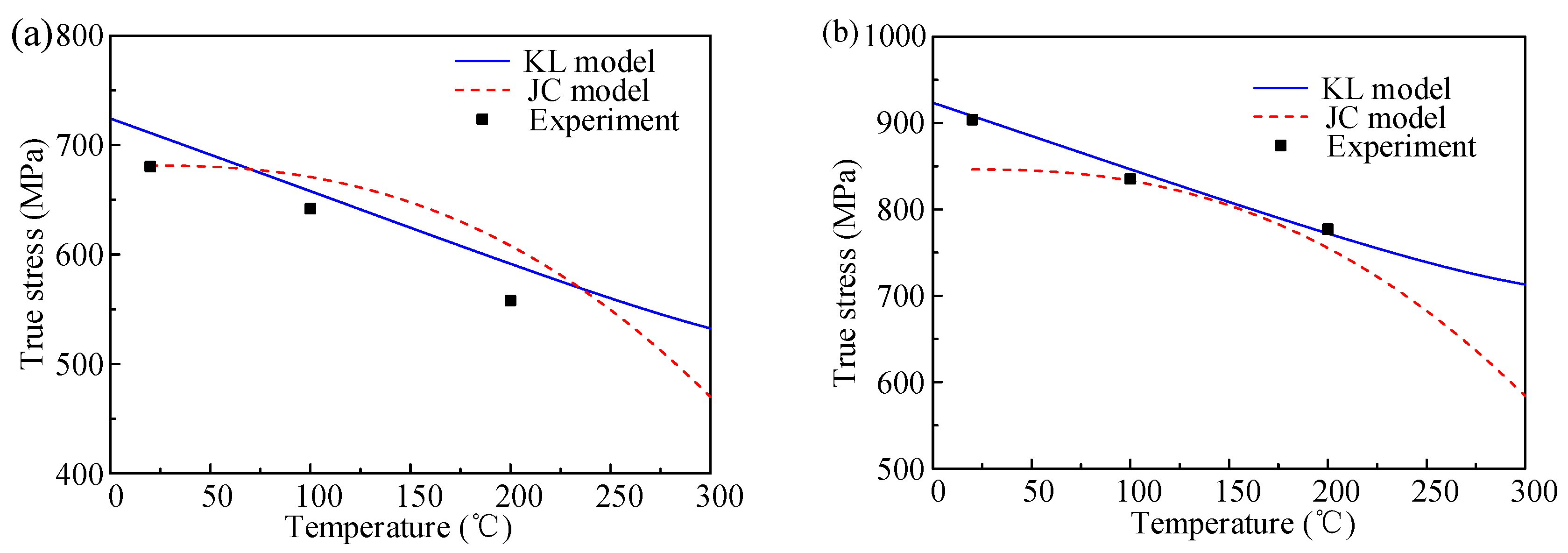

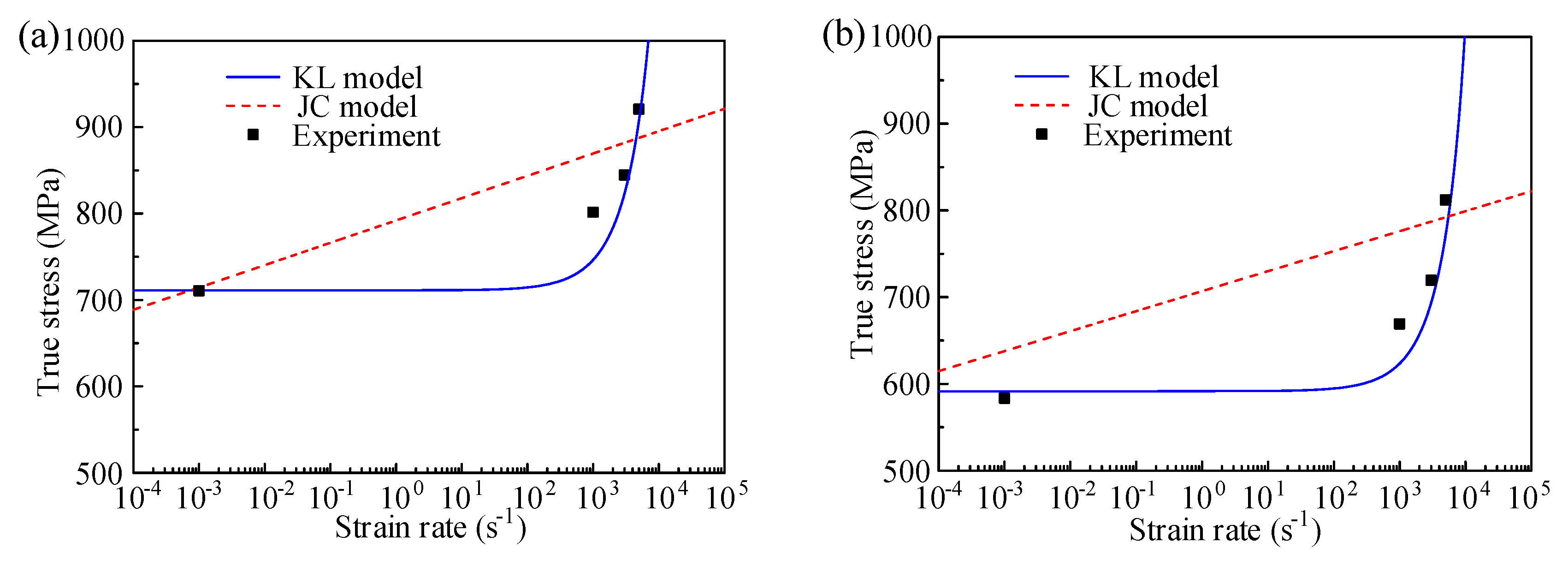

5. Comparison of the Constitutive Models

6. Conclusions

- (1)

- The strain rate and temperature have profound effects on the flow stress behavior of TiB2/7050 Al composites. As the increase of temperature, the flow stress decreases at a specified strain rate due to the soften effect. On the other hand, the flow stress increases with the larger strain rate for a specified temperature.

- (2)

- Due to the mismatch of thermal expansion coefficient and elastic modulus of aluminum matrix and TiB2 reinforcement particle, geometrically dislocation occurs around the particles and contributes to the work hardening effect of TiB2/7050 Al composites. The strength of TiB2/7050 Al composites is much larger than the aluminum matrix.

- (3)

- Compared with the JC constitutive model, the KL constitutive model performs better to predict the stress strain behavior of TiB2/7050 Al composites as it has a lower average absolute error (2.61%) and higher correlation coefficient (97.68%) with the experiment result. In addition, the KL model has shown better performance in characterizing the temperature effect and strain effect than JC model.

- (4)

- Although the JC model from an orthogonal experiment can be used to simulate the cutting process, it cannot describe the flow stress exactly during material deformation. For an accurate constitutive model of a material, the basic tensile or compression test is deemed necessary.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ibrahim, I.; Mohamed, F.; Lavernia, E. Particulate reinforced metal matrix composites—A review. J. Mater. Sci. 1991, 26, 1137–1156. [Google Scholar] [CrossRef]

- Dandekar, C.R.; Shin, Y.C. Modeling of machining of composite materials: A review. Int. J. Mach. Tools Manuf. 2012, 57, 102–121. [Google Scholar] [CrossRef]

- Geng, J.; Liu, G.; Wang, F.; Hong, T.; Dai, J.; Wang, M.; Chen, D.; Ma, N.; Wang, H. Microstructural correlated damage mechanisms of the high-Cycle fatigued in-situ TiB2/Al-Cu-Mg composite. Mater. Des. 2017, 135, 423–438. [Google Scholar] [CrossRef]

- Przestacki, D.; Szymanski, P.; Wojciechowski, S. Formation of surface layer in metal matrix composite A359/20SiCP during laser assisted turning. Compos. Pt. A Appl. Sci. Manuf. 2016, 91, 370–379. [Google Scholar] [CrossRef]

- Wang, T.; Zou, C.; Chen, Z.; Li, M.; Wang, W.; Li, R.; Kang, H. In situ synthesis of TiB2 particulate reinforced copper matrix composite with a rotating magnetic field. Mater. Des. (1980–2015) 2015, 65, 280–288. [Google Scholar] [CrossRef]

- Nemati, N.; Emamy, M.; Penkov, O.V.; Kim, J.; Kim, D.-E. Mechanical and high temperature wear properties of extruded Al composite reinforced with Al13Fe4 CMA nanoparticles. Mater. Des. 2016, 90, 532–544. [Google Scholar] [CrossRef]

- Shen, Y.; Li, X.; Hong, T.; Geng, J.; Wang, H. Effects of TiB2 particles on microstructure and mechanical properties of an in-situ TiB2-Al-Cu-Li matrix composite. Mater. Sci. Eng. A 2016, 655, 265–268. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, X.-M. A critical review of experimental results and constitutive descriptions for metals and alloys in hot working. Mater. Des. 2011, 32, 1733–1759. [Google Scholar] [CrossRef]

- Khan, A.S.; Liu, H. Variable strain rate sensitivity in an aluminum alloy: Response and constitutive modeling. Int. J. Plast. 2012, 36, 1–14. [Google Scholar] [CrossRef]

- Gao, C.; Lu, W.; Chen, L.; Li, X.; Ke, Y. A physically-based plastic constitutive model considering nanoparticle cluster effect for metal matrix nanocomposites. Mater. Sci. Eng. A 2015, 641, 172–180. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures. In Proceedings of the 7th International Symposium on Ballistics, Hague, The Netherlands, 19–21 April 1983; pp. 541–547. [Google Scholar]

- Hoff, N. Approximate analysis of structures in the presence of moderately large creep deformations. Q. Appl. Math. 1954, 12, 49–55. [Google Scholar] [CrossRef]

- Norton, F.H. The Creep of Steel at High Temperatures; McGraw-Hill Book Company: New York, NY, USA, 1929. [Google Scholar]

- Zerilli, F.J.; Armstrong, R.W. Dislocation-mechanics-based constitutive relations for material dynamics calculations. J. Appl. Phys. 1987, 61, 1816–1825. [Google Scholar] [CrossRef]

- Khan, A.S.; Liang, R. Behaviors of three BCC metal over a wide range of strain rates and temperatures: Experiments and modeling. Int. J. Plast. 1999, 15, 1089–1109. [Google Scholar] [CrossRef]

- Pramanik, A.; Zhang, L.C.; Arsecularatne, J.A. An FEM investigation into the behavior of metal matrix composites: Tool-particle interaction during orthogonal cutting. Int. J. Mach. Tools Manuf. 2007, 47, 1497–1506. [Google Scholar] [CrossRef]

- Zhou, L.; Wang, Y.; Ma, Z.Y.; Yu, X.L. Finite element and experimental studies of the formation mechanism of edge defects during machining of SiCp/Al composites. Int. J. Mach. Tools Manuf. 2014, 84, 9–16. [Google Scholar] [CrossRef]

- Song, W.; Ning, J.; Mao, X.; Tang, H. A modified Johnson-Cook model for titanium matrix composites reinforced with titanium carbide particles at elevated temperatures. Mater. Sci. Eng. A 2013, 576, 280–289. [Google Scholar] [CrossRef]

- Rudra, A.; Das, S.; Dasgupta, R. Constitutive Modeling for Hot Deformation Behavior of Al-5083 + SiC Composite. J. Mater. Eng. Perform. 2019, 28, 87–99. [Google Scholar] [CrossRef]

- Huang, S.; Khan, A.S. Modeling the mechanical behaviour of 1100-0 aluminum at different strain rates by the bodner-partom model. Int. J. Plast. 1992, 8, 501–517. [Google Scholar] [CrossRef]

- Liang, R.; Khan, A.S. A critical review of experimental results and constitutive models for BCC and FCC metals over a wide range of strain rates and temperatures. Int. J. Plast. 1999, 15, 963–980. [Google Scholar] [CrossRef]

- Khan, A.S.; Sung Suh, Y.; Kazmi, R. Quasi-static and dynamic loading responses and constitutive modeling of titanium alloys. Int. J. Plast. 2004, 20, 2233–2248. [Google Scholar] [CrossRef]

- Khan, A.S.; Kazmi, R.; Farrokh, B. Multiaxial and non-proportional loading responses, anisotropy and modeling of Ti-6Al-4V titanium alloy over wide ranges of strain rates and temperatures. Int. J. Plast. 2007, 23, 931–950. [Google Scholar] [CrossRef]

- Xu, Z.; Huang, F. Thermomechanical behavior and constitutive modeling of tungsten-based composite over wide temperature and strain rate ranges. Int. J. Plast. 2013, 40, 163–184. [Google Scholar] [CrossRef]

- Tounsi, N.; Vincenti, J.; Otho, A.; Elbestawi, M.A. From the basic mechanics of orthogonal metal cutting toward the identification of the constitutive equation. Int. J. Mach. Tools Manuf. 2002, 42, 1373–1383. [Google Scholar] [CrossRef]

- Umbrello, D.; M’Saoubi, R.; Outeiro, J.C. The influence of Johnson-Cook material constants on finite element simulation of machining of AISI 316L steel. Int. J. Mach. Tools Manuf. 2007, 47, 462–470. [Google Scholar] [CrossRef]

- Ducobu, F.; Rivière-Lorphèvre, E.; Filippi, E. On the importance of the choice of the parameters of the Johnson-Cook constitutive model and their influence on the results of a Ti6Al4V orthogonal cutting model. Int. J. Mech. Sci. 2017, 122, 143–155. [Google Scholar] [CrossRef]

- Daoud, M.; Chatelain, J.F.; Bouzid, A. Effect of rake angle-based Johnson-Cook material constants on the prediction of residual stresses and temperatures induced in Al2024-T3 machining. Int. J. Mech. Sci. 2017, 122, 392–404. [Google Scholar] [CrossRef]

- Xiong, Y.; Wang, W.; Jiang, R.; Lin, K.; Shao, M. Mechanisms and FEM Simulation of Chip Formation in Orthogonal Cutting In-Situ TiB2/7050Al MMC. Materials 2018, 11, 606. [Google Scholar] [CrossRef]

- Geng, J.; Hong, T.; Ma, Y.; Wang, M.; Chen, D.; Ma, N.; Wang, H. The solution treatment of in-situ sub-micron TiB2/2024 Al composite. Mater. Des. 2016, 98, 186–193. [Google Scholar] [CrossRef]

- Tang, Y.; Chen, Z.; Borbély, A.; Ji, G.; Zhong, S.Y.; Schryvers, D.; Ji, V.; Wang, H.W. Quantitative study of particle size distribution in an in-situ grown Al-TiB2 composite by synchrotron X-ray diffraction and electron microscopy. Mater. Charact. 2015, 102, 131–136. [Google Scholar] [CrossRef]

- El Mehtedi, M.; Musharavati, F.; Spigarelli, S. Modelling of the flow behaviour of wrought aluminium alloys at elevated temperatures by a new constitutive equation. Mater. Des. (1980–2015) 2014, 54, 869–873. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, X.-M.; Liu, G. A modified Johnson-Cook model for tensile behaviors of typical high-strength alloy steel. Mater. Sci. Eng. A 2010, 527, 6980–6986. [Google Scholar] [CrossRef]

| Elements | TiB2 | Cu | Mg | Zn | Zr | Al |

|---|---|---|---|---|---|---|

| Content/wt% | 6 | 2.2 | 2.3 | 6.3 | 0.11 | Balance |

| A | B | C | m | n |

|---|---|---|---|---|

| 594 | 446.4538 | 0.0157 | 1.364 | 0.4655 |

| A | B | C | m | n |

|---|---|---|---|---|

| 630 | 1127 | 0.004 | 2.4 | 0.972 |

| A | B | C1 | C3 | n0 | m2 | m3 |

|---|---|---|---|---|---|---|

| 602.6 | 235.5599 | 4.188 × 10−8 | −4.2151 × 10−8 | 0.2211 | 0.6102 | −1.2285 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, K.; Wang, W.; Jiang, R.; Xiong, Y.; Shan, C. Thermo–Mechanical Behavior and Constitutive Modeling of In Situ TiB2/7050 Al Metal Matrix Composites Over Wide Temperature and Strain Rate Ranges. Materials 2019, 12, 1212. https://doi.org/10.3390/ma12081212

Lin K, Wang W, Jiang R, Xiong Y, Shan C. Thermo–Mechanical Behavior and Constitutive Modeling of In Situ TiB2/7050 Al Metal Matrix Composites Over Wide Temperature and Strain Rate Ranges. Materials. 2019; 12(8):1212. https://doi.org/10.3390/ma12081212

Chicago/Turabian StyleLin, Kunyang, Wenhu Wang, Ruisong Jiang, Yifeng Xiong, and Chenwei Shan. 2019. "Thermo–Mechanical Behavior and Constitutive Modeling of In Situ TiB2/7050 Al Metal Matrix Composites Over Wide Temperature and Strain Rate Ranges" Materials 12, no. 8: 1212. https://doi.org/10.3390/ma12081212

APA StyleLin, K., Wang, W., Jiang, R., Xiong, Y., & Shan, C. (2019). Thermo–Mechanical Behavior and Constitutive Modeling of In Situ TiB2/7050 Al Metal Matrix Composites Over Wide Temperature and Strain Rate Ranges. Materials, 12(8), 1212. https://doi.org/10.3390/ma12081212