Notch (In)Sensitivity of Aluminum Matrix Syntactic Foams

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

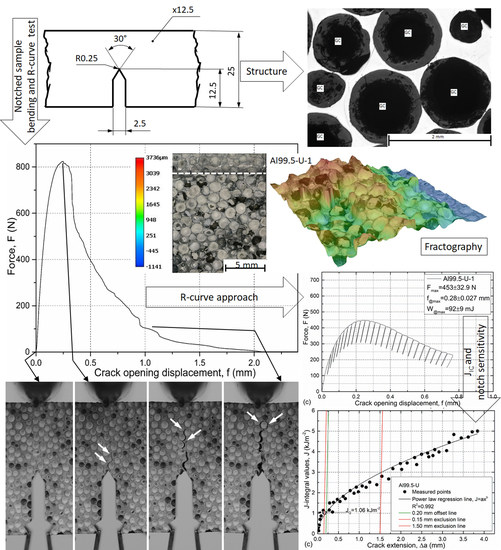

3.1. Toughness

3.2. Fractography

4. Conclusions

- MMSFs showed elastic-plastic fracture behavior; therefore, besides the measurement of the fracture energies, the R-curve approach is suggested for investigating the toughness of MMSFs.

- The fracture energy up to the maximal force values and the critical value of the J-integral are both necessary to judge the toughness of the MMSFs. The W@max values were sensitive to the notch geometry, while the JIC values were affected only by the matrix material.

- In the case of the U notches, the probability of the presence of a critical site at the end of the notch was larger, so U-notched samples broke at lower W@max values.

- The crack initialized at the crack tip propagated differently in the different matrix MMSFs, resulting different failure modes. In the case of the Al99.5 matrix, the cracks went through the hollow spheres, and this fact indicates a high bonding strength between the hollow spheres and the matrix material. In the case of the AlSi12 matrix, almost all of the hollow spheres were bypassed by the crack that propagated along the surfaces of the weakly bonded hollow spheres, resulting in longer propagation distance and higher R-curves.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Zhang, Q.; Lin, Y.; Chi, H.; Chang, J.; Wu, G. Quasi-static and dynamic compression behavior of glass cenospheres/5A03 syntactic foam and its sandwich structure. Compos. Struct. 2018, 183, 499–509. [Google Scholar] [CrossRef]

- Luong, D.D.; Strbik, O.M.; Hammond, V.H.; Gupta, N.; Cho, K. Development of high performance lightweight aluminum alloy/SiC hollow sphere syntactic foams and compressive characterization at quasi-static and high strain rates. J. Alloys Compd. 2013, 550, 412–422. [Google Scholar] [CrossRef]

- Licitra, L.; Luong, D.D.; Strbik, O.M.; Gupta, N. Dynamic properties of alumina hollow particle filled aluminum alloy A356 matrix syntactic foams. Mater. Des. 2015, 66, 504–515. [Google Scholar] [CrossRef]

- Kiser, M.; He, M.Y.; Zok, F.W. The mechanical response of ceramic microballoon reinforced aluminum matrix composites under compressive loading. Acta Mater. 1999, 47, 2685–2694. [Google Scholar] [CrossRef]

- Wu, G.H.; Dou, Z.Y.; Sun, D.L.; Jiang, L.T.; Ding, B.S.; He, B.F. Compression behaviors of cenosphere–pure aluminum syntactic foams. Scr. Mater. 2007, 56, 221–224. [Google Scholar] [CrossRef]

- Zhang, B.; Lin, Y.; Li, S.; Zhai, D.; Wu, G. Quasi-static and high strain rates compressive behavior of aluminum matrix syntactic foams. Compos. Part B Eng. 2016, 98, 288–296. [Google Scholar] [CrossRef]

- Goel, M.D.; Peroni, M.; Solomos, G.; Mondal, D.P.; Matsagar, V.A.; Gupta, A.K.; Larcher, M.; Marburg, S. Dynamic compression behavior of cenosphere aluminum alloy syntactic foam. Mater. Des. 2012, 42, 418–423. [Google Scholar]

- Balch, D.K.; O’Dwyer, J.G.; Davis, G.R.; Cady, C.M.; Gray, G.T.; Dunand, D.C. Plasticity and damage in aluminum syntactic foams deformed under dynamic and quasi-static conditions. Mater. Sci. Eng. A 2005, 391, 408–417. [Google Scholar] [CrossRef]

- Vendra, L.J.; Rabiei, A. A study on aluminum–steel composite metal foam processed by casting. Mater. Sci. Eng. A 2007, 465, 59–67. [Google Scholar] [CrossRef]

- Cox, J.; Luong, D.D.; Shunmugasamy, V.C.; Gupta, N.; Strbik, O.M.; Cho, K. Dynamic and Thermal Properties of Aluminum Alloy A356/Silicon Carbide Hollow Particle Syntactic Foams. Metals 2014, 4, 530–548. [Google Scholar] [CrossRef]

- Anbuchezhiyan, G.; Mohan, B.; Sathianarayanan, D.; Muthuramalingam, T. Synthesis and characterization of hollow glass microspheres reinforced magnesium alloy matrix syntactic foam. J. Alloys Compd. 2017, 719, 125–132. [Google Scholar] [CrossRef]

- Anantharaman, H.; Shunmugasamy, V.C.; Strbik, O.M.; Gupta, N.; Cho, K. Dynamic properties of silicon carbide hollow particle filled magnesium alloy (AZ91D) matrix syntactic foams. Int. J. Impact Eng. 2015, 82, 14–24. [Google Scholar] [CrossRef]

- Xia, X.; Feng, J.; Ding, J.; Song, K.; Chen, X.; Zhao, W.; Liao, B.; Hur, B. Fabrication and characterization of closed-cell magnesium-based composite foams. Mater. Des. 2015, 74, 36–43. [Google Scholar] [CrossRef]

- Braszczyńska-Malik, K.N.; Kamieniak, J. Analysis of interface between components in AZ91 magnesium alloy foam composite with Ni-P coated fly ash cenospheres. J. Alloys Compd. 2017, 720, 352–359. [Google Scholar] [CrossRef]

- Braszczyńska-Malik, K.N.; Kamieniak, J. AZ91 magnesium matrix foam composites with fly ash cenospheres fabricated by negative pressure infiltration technique. Mater. Charact. 2017, 128, 209–216. [Google Scholar] [CrossRef]

- Movahedi, N.; Taherishargh, M.; Belova, I.V; Murch, G.E.; Fiedler, T. Mechanical and Microstructural Characterization of an AZ91—Activated Carbon Syntactic Foam. Materials 2018, 12, 3. [Google Scholar] [CrossRef] [PubMed]

- Xia, X.; Wang, J.; Peng, Y.; Wang, N.; He, X.; Qiu, C.; Ding, J.; Chen, X. Temperature-Time Superposition Effect on Compressive Properties of AZ31B Magnesium Composite Foams. Metals 2018, 8, 434. [Google Scholar] [CrossRef]

- Luong, D.D.; Shunmugasamy, V.C.; Gupta, N.; Weise, J.; Baumeister, J. Quasi-static and high strain rates compressive response of iron and Invar matrix syntactic foams. Mater. Des. 2015, 66, 516–531. [Google Scholar] [CrossRef]

- Peroni, L.; Scapin, M.; Avalle, M.; Weise, J.; Lehmhus, D.; Baumeister, J.; Busse, M. Syntactic Iron Foams—On Deformation Mechanisms and Strain-Rate Dependence of Compressive Properties. Adv. Eng. Mater. 2012, 14, 909–918. [Google Scholar] [CrossRef]

- Peroni, L.; Scapin, M.; Fichera, C.; Lehmhus, D.; Weise, J.; Baumeister, J.; Avalle, M. Investigation of the mechanical behaviour of AISI 316L stainless steel syntactic foams at different strain-rates. Compos. Part B Eng. 2014, 66, 430–442. [Google Scholar] [CrossRef]

- Lehmhus, D.; Weise, J.; Baumeister, J.; Peroni, L.; Scapin, M.; Fichera, C.; Avalle, M.; Busse, M. Quasi-static and Dynamic Mechanical Performance of Glass Microsphere- and Cenosphere-based 316L Syntactic Foams. Procedia Mater. Sci. 2014, 4, 383–387. [Google Scholar] [CrossRef]

- Castro, G.; Nutt, S.R. Synthesis of syntactic steel foam using mechanical pressure infiltration. Mater. Sci. Eng. A 2012, 535, 274–280. [Google Scholar] [CrossRef]

- Castro, G.; Nutt, S.R. Synthesis of syntactic steel foam using gravity-fed infiltration. Mater. Sci. Eng. A 2012, 553, 89–95. [Google Scholar] [CrossRef]

- Hu, L.; Ngai, T.; Peng, H.; Li, L.; Zhou, F.; Peng, Z. Microstructure and Properties of Porous High-N Ni-Free Austenitic Stainless Steel Fabricated by Powder Metallurgical Route. Materials 2018, 11, 1058. [Google Scholar] [CrossRef] [PubMed]

- Szlancsik, A.; Katona, B.; Májlinger, K.; Orbulov, I.N. Compressive Behavior and Microstructural Characteristics of Iron Hollow Sphere Filled Aluminum Matrix Syntactic Foams. Materials 2015, 8, 7926–7937. [Google Scholar] [CrossRef] [PubMed]

- Jha, N.; Mondal, D.P.; Goel, M.D.; Majumdar, J.D.; Das, S.; Modi, O.P. Titanium cenosphere syntactic foam with coarser cenosphere fabricated by powder metallurgy at lower compaction load. Trans. Nonferrous Met. Soc. China 2014, 24, 89–99. [Google Scholar] [CrossRef]

- Xue, X.; Zhao, Y. Ti matrix syntactic foam fabricated by powder metallurgy: Particle breakage and elastic modulus. JOM 2011, 63, 43–47. [Google Scholar] [CrossRef]

- Xue, X.; Wang, L.; Wang, M.; Lü, W.; Zhang, D. Manufacturing, compressive behaviour and elastic modulus of Ti matrix syntactic foam fabricated by powder metallurgy. Trans. Nonferrous Met. Soc. China 2012, 22, s188–s192. [Google Scholar] [CrossRef]

- Mondal, D.P.; Datta Majumder, J.; Jha, N.; Badkul, A.; Das, S.; Patel, A.; Gupta, G. Titanium-cenosphere syntactic foam made through powder metallurgy route. Mater. Des. 2012, 34, 82–89. [Google Scholar] [CrossRef]

- Daoud, A. Synthesis and characterization of novel ZnAl22 syntactic foam composites via casting. Mater. Sci. Eng. A 2008, 488, 281–295. [Google Scholar] [CrossRef]

- Sánchez-Martínez, A.; Cruz, A.; González-Nava, M.; Suárez, M.A. Main process parameters for manufacturing open-cell Zn-22Al-2Cu foams by the centrifugal infiltration route and mechanical properties. Mater. Des. 2016, 108, 494–500. [Google Scholar] [CrossRef]

- Aragon-Lezama, J. A.; Garcia-Borquez, A.; Torres-Villaseñor, G. Foam behavior of solid glass spheres—Zn22Al2Cu composites under compression stresses. Mater. Sci. Eng. A 2015, 638, 165–173. [Google Scholar] [CrossRef]

- Linul, E.; Lell, D.; Movahedi, N.; Codrean, C.; Fiedler, T. Compressive properties of zinc syntactic foams at elevated temperatures. Compos. Part B Eng. 2018, 167, 122–134. [Google Scholar] [CrossRef]

- Rohatgi, P.K.; Kim, J.K.; Gupta, N.; Alaraj, S.; Daoud, A. Compressive characteristics of A356/fly ash cenosphere composites synthesized by pressure infiltration technique. Compos. Part A Appl. Sci. Manuf. 2006, 37, 430–437. [Google Scholar] [CrossRef]

- Rohatgi, P.K.; Guo, R.Q. Mechanism of abrasive wear of Al-Si hypoeutectic alloycontaining 5 vol % fly ash. Tribol. Lett. 1997, 3, 339–347. [Google Scholar] [CrossRef]

- Rohatgi, P.K.; Daoud, A.; Schultz, B.F.; Puri, T. Microstructure and mechanical behavior of die casting AZ91D-Fly ash cenosphere composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 883–896. [Google Scholar] [CrossRef]

- Zhang, Q.; Lee, P.D.; Singh, R.; Wu, G.; Lindley, T.C. Micro-CT characterization of structural features and deformation behavior of fly ash/aluminum syntactic foam. Acta Mater. 2009, 57, 3003–3011. [Google Scholar] [CrossRef]

- Guo, R.Q.; Rohatgi, P.K. Chemical reactions between aluminum and fly ash during synthesis and reheating of Al-fly ash composite. Metall. Mater. Trans. B 1998, 29, 519–525. [Google Scholar] [CrossRef]

- Rohatgi, P.K.; Guo, R.Q.; Iksan, H.; Borchelt, E.J.; Asthana, R. Pressure infiltration technique for synthesis of aluminum–fly ash particulate composite. Mater. Sci. Eng. A 1998, 244, 22–30. [Google Scholar] [CrossRef]

- Rajan, T.P.D.; Pillai, R.M.; Pai, B.C.; Satyanarayana, K.G.; Rohatgi, P.K. Fabrication and characterisation of Al–7Si–0.35Mg/fly ash metal matrix composites processed by different stir casting routes. Compos. Sci. Technol. 2007, 67, 3369–3377. [Google Scholar] [CrossRef]

- Omar, M.Y.; Xiang, C.; Gupta, N.; Strbik, O.M.; Cho, K. Data characterizing flexural properties of Al/Al2O3 syntactic foam core metal matrix sandwich. Data Br. 2015, 5, 564–571. [Google Scholar] [CrossRef] [PubMed]

- Santa Maria, J.A.; Schultz, B.F.; Ferguson, J.B.; Rohatgi, P.K. Al–Al2O3 syntactic foams—Part I: Effect of matrix strength and hollow sphere size on the quasi-static properties of Al-A206/Al2O3 syntactic foams. Mater. Sci. Eng. A 2013, 582, 415–422. [Google Scholar] [CrossRef]

- Ferguson, J.B.; Santa Maria, J.A.; Schultz, B.F.; Rohatgi, P.K. Al–Al2O3 syntactic foams—Part II: Predicting mechanical properties of metal matrix syntactic foams reinforced with ceramic spheres. Mater. Sci. Eng. A 2013, 582, 423–432. [Google Scholar] [CrossRef]

- Santa Maria, J.A.; Schultz, B.F.; Ferguson, J.B.; Gupta, N.; Rohatgi, P.K. Effect of hollow sphere size and size distribution on the quasi-static and high strain rate compressive properties of Al-A380—Al2O3 syntactic foams. J. Mater. Sci. 2014, 49, 1267–1278. [Google Scholar] [CrossRef]

- Taherishargh, M.; Belova, I.V.; Murch, G.E.; Fiedler, T. The effect of particle shape on mechanical properties of perlite/metal syntactic foam. J. Alloys Compd. 2017, 693, 55–60. [Google Scholar] [CrossRef]

- Taherishargh, M.; Vesenjak, M.; Belova, I.V.; Krstulović-Opara, L.; Murch, G.E.; Fiedler, T. In situ manufacturing and mechanical properties of syntactic foam filled tubes. Mater. Des. 2016, 99, 356–368. [Google Scholar] [CrossRef]

- Taherishargh, M.; Belova, I.V.; Murch, G.E.; Fiedler, T. Low-density expanded perlite–aluminium syntactic foam. Mater. Sci. Eng. A 2014, 604, 127–134. [Google Scholar] [CrossRef]

- Borovinšek, M.; Taherishargh, M.; Vesenjak, M.; Ren, Z.; Fiedler, T. Geometrical characterization of perlite-metal syntactic foam. Mater. Charact. 2016, 119, 209–215. [Google Scholar] [CrossRef]

- Sulong, M.A.; Taherishargh, M.; Belova, I.V.; Murch, G.E.; Fiedler, T. On the mechanical anisotropy of the compressive properties of aluminium perlite syntactic foam. Comput. Mater. Sci. 2015, 109, 258–265. [Google Scholar] [CrossRef]

- Taherishargh, M.; Katona, B.; Fiedler, T.; Orbulov, I.N. Fatigue properties of expanded perlite/aluminum syntactic foams. J. Compos. Mater. 2017, 51, 773–781. [Google Scholar] [CrossRef]

- Taherishargh, M.; Belova, I.V.; Murch, G.E.; Fiedler, T. On the mechanical properties of heat-treated expanded perlite–aluminium syntactic foam. Mater. Des. 2014, 63, 375–383. [Google Scholar] [CrossRef]

- Taherishargh, M.; Sulong, M.A.; Belova, I.V.; Murch, G.E.; Fiedler, T. On the particle size effect in expanded perlite aluminium syntactic foam. Mater. Des. 2015, 66, 294–303. [Google Scholar] [CrossRef]

- Broxtermann, S.; Taherishargh, M.; Belova, I.V.; Murch, G.E.; Fiedler, T. On the compressive behaviour of high porosity expanded Perlite-Metal Syntactic Foam (P-MSF). J. Alloys Compd. 2017, 691, 690–697. [Google Scholar] [CrossRef]

- Fiedler, T.; Taherishargh, M.; Krstulović-Opara, L.; Vesenjak, M. Dynamic compressive loading of expanded perlite/aluminum syntactic foam. Mater. Sci. Eng. A 2015, 626, 296–304. [Google Scholar] [CrossRef]

- Fiedler, T.; Belova, I.V.; Murch, G.E. On the thermal properties of expanded perlite—Metallic syntactic foam. Int. J. Heat Mass Transf. 2015, 90, 1009–1014. [Google Scholar] [CrossRef]

- Linul, E.; Marşavina, L.; Linul, P.-A.; Kovacik, J. Cryogenic and high temperature compressive properties of Metal Foam Matrix Composites. Compos. Struct. 2019, 209, 490–498. [Google Scholar] [CrossRef]

- Movahedi, N.; Linul, E.; Marsavina, L. The Temperature Effect on the Compressive Behavior of Closed-Cell Aluminum-Alloy Foams. J. Mater. Eng. Perform. 2018, 27, 99–108. [Google Scholar] [CrossRef]

- Taherishargh, M.; Linul, E.; Broxtermann, S.; Fiedler, T. The mechanical properties of expanded perlite-aluminium syntactic foam at elevated temperatures. J. Alloys Compd. 2018, 737, 590–596. [Google Scholar] [CrossRef]

- Linul, E.; Movahedi, N.; Marsavina, L. The temperature and anisotropy effect on compressive behavior of cylindrical closed-cell aluminum-alloy foams. J. Alloys Compd. 2018, 740, 1172–1179. [Google Scholar] [CrossRef]

- Chernousov, A.A.; Chan, B.Y.B. Optimising in-situ nitridation in piled aluminium flakes for novel closed cell composites with high fracture stress and toughness. Mater. Des. 2018, 150, 113–123. [Google Scholar] [CrossRef]

- ISO13314:2011–Mechanical Testing of Metals—Ductility Testing—Compression Test for Porous and Cellular Metals; International Organization for Standardization: Geneva, Switzerland, 2011.

- ASTM E399-17–Standard Test Method for Linear-Elastic Plane-Strain Fracture Toughness KIc of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM E813-89E01–Test Method for JIC, A Measure of Fracture Toughness (Withdrawn 1997); ASTM International: West Conshohocken, PA, USA, 1989.

- ASTM E1152-95–Test Method for Determining J-R Curves (Withdrawn 1997); ASTM International: West Conshohocken, PA, USA, 1995.

- ASTM E1820-18–Standard Test Method for Measurement of Fracture Toughness; ASTM International: West Conshohocken, PA, USA, 2018.

- McCullough, K.Y.G.; Fleck, N.A.; Ashby, M.F. Toughness of aluminium alloy foams. Acta Mater. 1999, 47, 2331–2343. [Google Scholar] [CrossRef]

- Olurin, O.B.; Fleck, N.A.; Ashby, M.F. Deformation and fracture of aluminium foams. Mater. Sci. Eng. A 2000, 291, 136–146. [Google Scholar] [CrossRef]

- ASTM E647-15e1–Standard Test Method for Measurement of Fatigue Crack Growth Rates; ASTM International: West Conshohocken, PA, USA, 2015.

- Olurin, O.B.; McCullough, K.Y.G.; Fleck, N.A.; Ashby, M.F. Fatigue crack propagation in aluminium alloy foams. Int. J. Fatigue 2001, 23, 375–382. [Google Scholar] [CrossRef]

- Motz, C.; Pippan, R. Fracture behaviour and fracture toughness of ductile closed-cell metallic foams. Acta Mater. 2002, 50, 2013–2033. [Google Scholar] [CrossRef]

- Motz, C.; Friedl, O.; Pippan, R. Fatigue crack propagation in cellular metals. Int. J. Fatigue 2005, 27, 1571–1581. [Google Scholar] [CrossRef]

- Combaz, E.; Mortensen, A. Fracture toughness of Al replicated foam. Acta Mater. 2010, 58, 4590–4603. [Google Scholar] [CrossRef]

- Combaz, E.; Rossoll, A.; Mortensen, A. Hole and notch sensitivity of aluminium replicated foam. Acta Mater. 2011, 59, 572–581. [Google Scholar] [CrossRef]

- Kashef, S.; Asgari, A.; Hilditch, T.B.; Yan, W.; Goel, V.K.; Hodgson, P.D. Fracture toughness of titanium foams for medical applications. Mater. Sci. Eng. A 2010, 527, 7689–7693. [Google Scholar] [CrossRef]

- Kashef, S.; Asgari, A.; Hilditch, T.B.; Yan, W.; Goel, V.K.; Hodgson, P.D. Fatigue crack growth behavior of titanium foams for medical applications. Mater. Sci. Eng. A 2011, 528, 1602–1607. [Google Scholar] [CrossRef]

- Orbulov, I.N. Metal matrix syntactic foams produced by pressure infiltration—The effect of infiltration parameters. Mater. Sci. Eng. A 2013, 583, 11–19. [Google Scholar] [CrossRef]

- Jaeger, H.M.; Nagel, S.R. Physics of the Granular State. Science 1992, 255, 1523–1531. [Google Scholar] [CrossRef]

- Torquato, S.; Truskett, T.M.; Debenedetti, P.G. Is Random Close Packing of Spheres Well Defined? Phys. Rev. Lett. 2000, 84, 2064–2067. [Google Scholar] [CrossRef]

| Alloy | Al | Si | Fe | Cu | Mn | Mg | Zn | V | Ti |

|---|---|---|---|---|---|---|---|---|---|

| Al99.5 | 99.070 | 0.250 | 0.400 | 0.050 | 0.050 | 0.050 | 0.050 | 0.050 | 0.030 |

| AlSi12 | 87.019 | 12.83 | 0.127 | 0.002 | 0.005 | 0.010 | 0.007 | 0.000 | 0.000 |

| MMSF Type | Fracture Energy, W@max (mJ) | Fracture Toughness, JIC (kJm−2) |

|---|---|---|

| Notch-Sensitive | Notch-Insensitive | |

| Al99.5-V | 127 ± 14 | 1.05 |

| AlSi12-V | 128 ± 22 | 2.25 |

| Al99.5-U | 92 ± 9 | 1.06 |

| AlSi12-U | 96 ± 12 | 2.13 |

| MMSF Type | Broken Spheres | All Spheres | Ratio (%) |

|---|---|---|---|

| Al99.5-V | 52 | 87 | 59.8 |

| AlSi12-V | 15 | 98 | 15.3 |

| Al99.5-U | 49 | 89 | 55.1 |

| AlSi12-U | 14 | 96 | 14.6 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szlancsik, A.; Katona, B.; Károly, D.; Orbulov, I.N. Notch (In)Sensitivity of Aluminum Matrix Syntactic Foams. Materials 2019, 12, 574. https://doi.org/10.3390/ma12040574

Szlancsik A, Katona B, Károly D, Orbulov IN. Notch (In)Sensitivity of Aluminum Matrix Syntactic Foams. Materials. 2019; 12(4):574. https://doi.org/10.3390/ma12040574

Chicago/Turabian StyleSzlancsik, Attila, Bálint Katona, Dóra Károly, and Imre Norbert Orbulov. 2019. "Notch (In)Sensitivity of Aluminum Matrix Syntactic Foams" Materials 12, no. 4: 574. https://doi.org/10.3390/ma12040574

APA StyleSzlancsik, A., Katona, B., Károly, D., & Orbulov, I. N. (2019). Notch (In)Sensitivity of Aluminum Matrix Syntactic Foams. Materials, 12(4), 574. https://doi.org/10.3390/ma12040574