High-Performance Nylon-6 Sustainable Filaments for Additive Manufacturing

Abstract

1. Introduction

2. Experimental

2.1. Materials

- AQ34000 R-Nylon-6 filaments with viscosity number 3.4 mL/g (polymer “Aquamid AQ34000”, hereafter referred to as AQ34000 filaments);

- AQ27000 R-Nylon-6–ABS 5% polymer filaments made up of 95% polymer weight AQ27000 and 5% in ABS SM295 (Injection Molding Grade) polymer weight by LG Chemical Ltd. (Seoul, Korea) (AQ27000-B filaments);

- AQ34000 R-Nylon-6–ABS 5% filaments made up of 95% polymer weight AQ34000 and 5% in ABS SM295 polymer weight from LG Chemical Ltd. [31] (AQ34000-B filaments);

- AQ24000 R-Nylon-6–TiO2 30% filaments (top of Figure 1b) consisting of 70% weight polymer “Aquamid AQ24000” (viscosity number 2.4 mL/g) and 30% in weight from titanium dioxide TiO2 made available by Aquafil (AQ24000-T filaments) (Arco, TN, Italy).

2.2. Manufacturing Process

3. Characterization

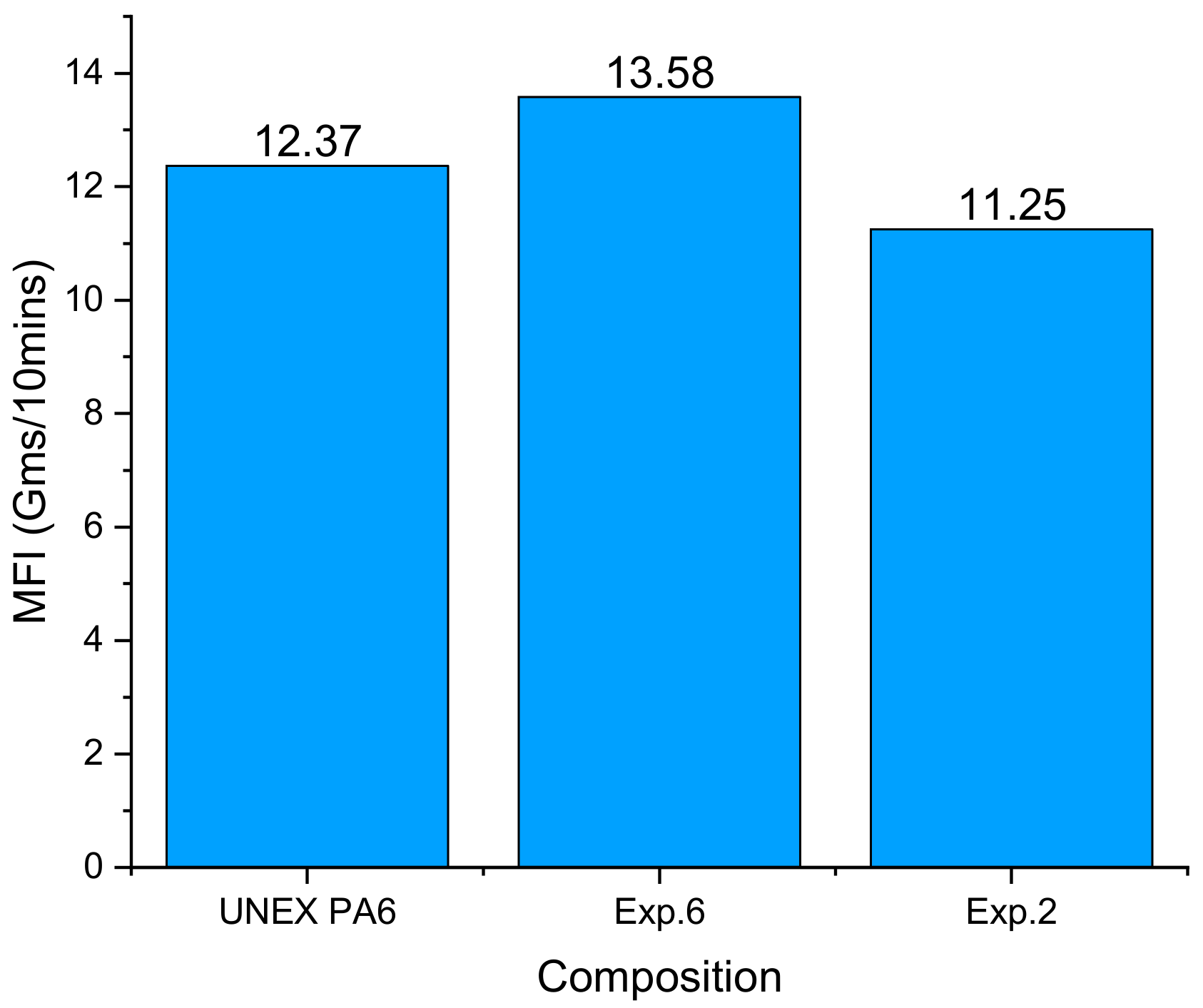

3.1. Melt-Flow-Index Evaluation Tests

3.2. Melt-Flow-Index Evaluation Tests for NR R-Nylon-6

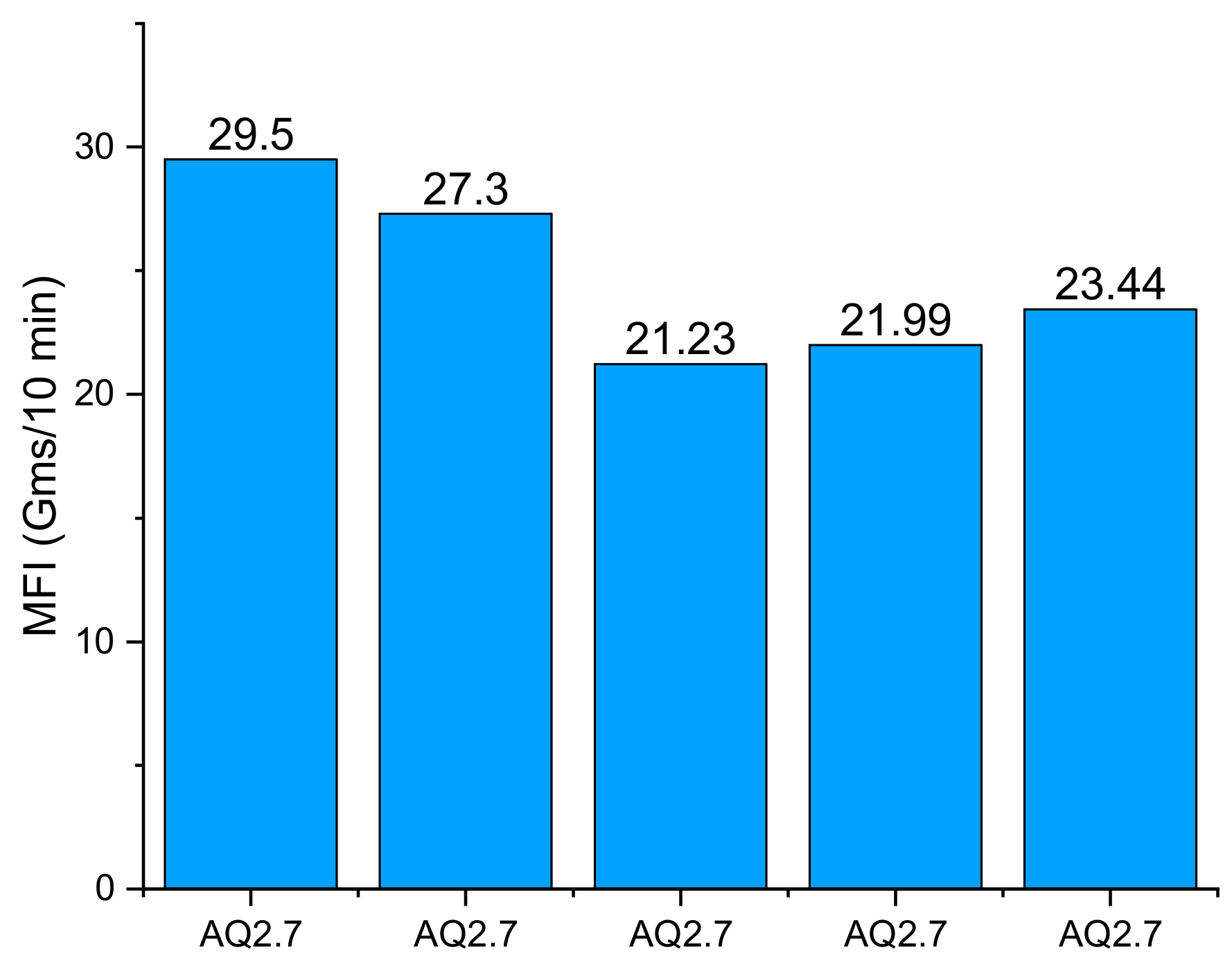

3.3. MFI Tests for AQ R-Nylon-6

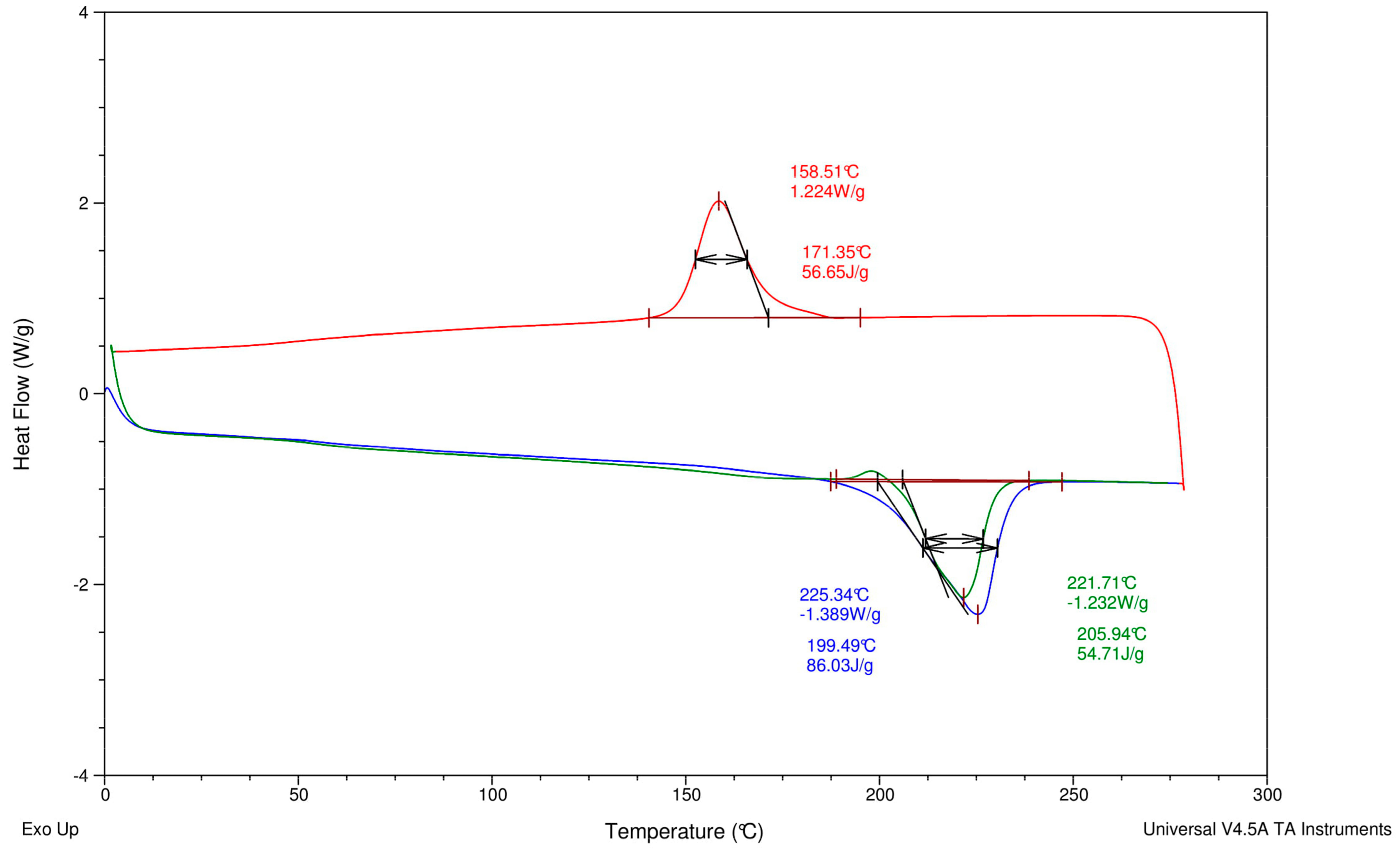

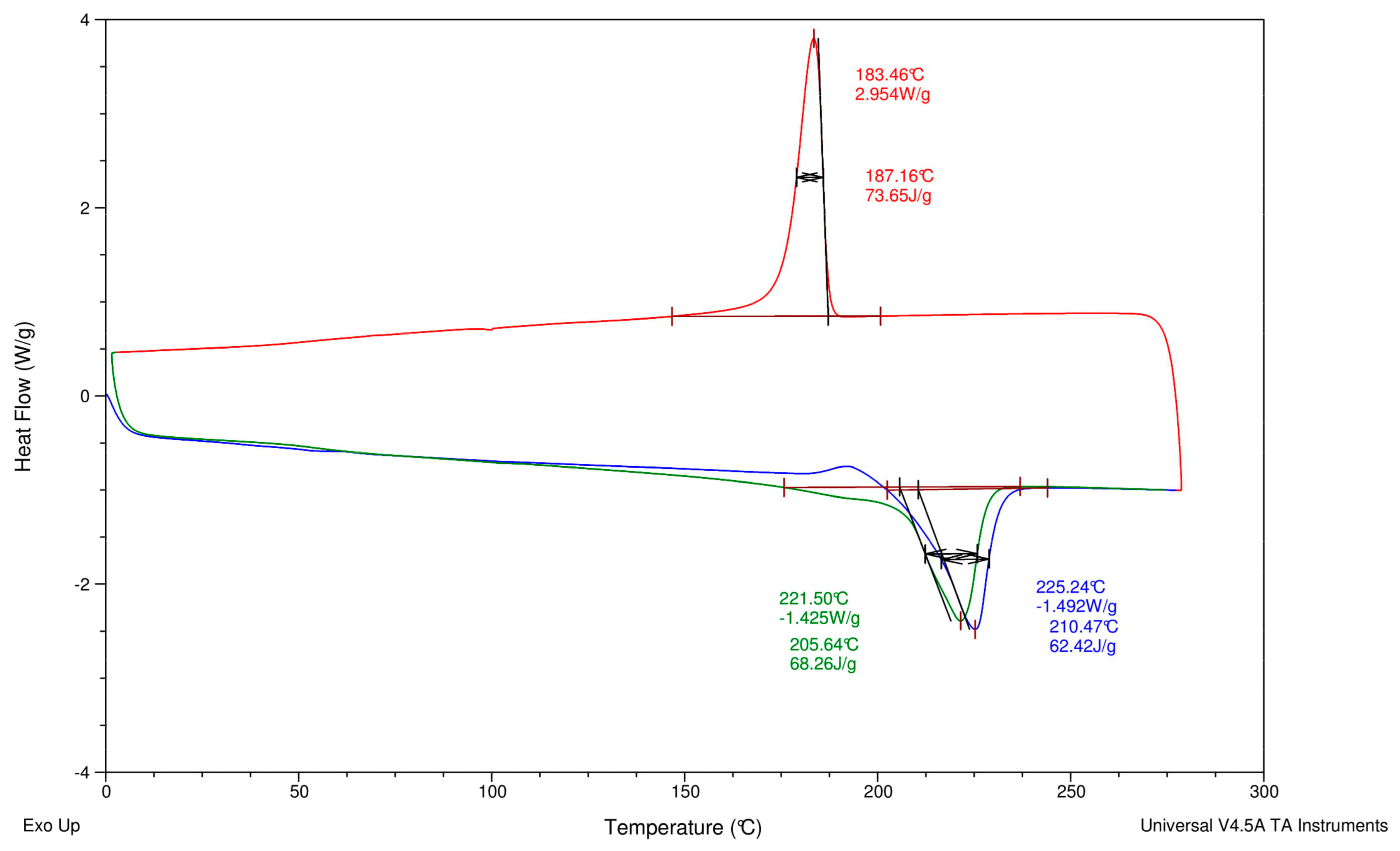

3.4. Thermal Characterization of R-Nylon-6 Granulates (DSC)

3.4.1. Pre- and Post-Extrusion DSC Test for NR R-Nylon-6

3.4.2. Pre- and Post-Extrusion DSC Test for AQ R-Nylon-6

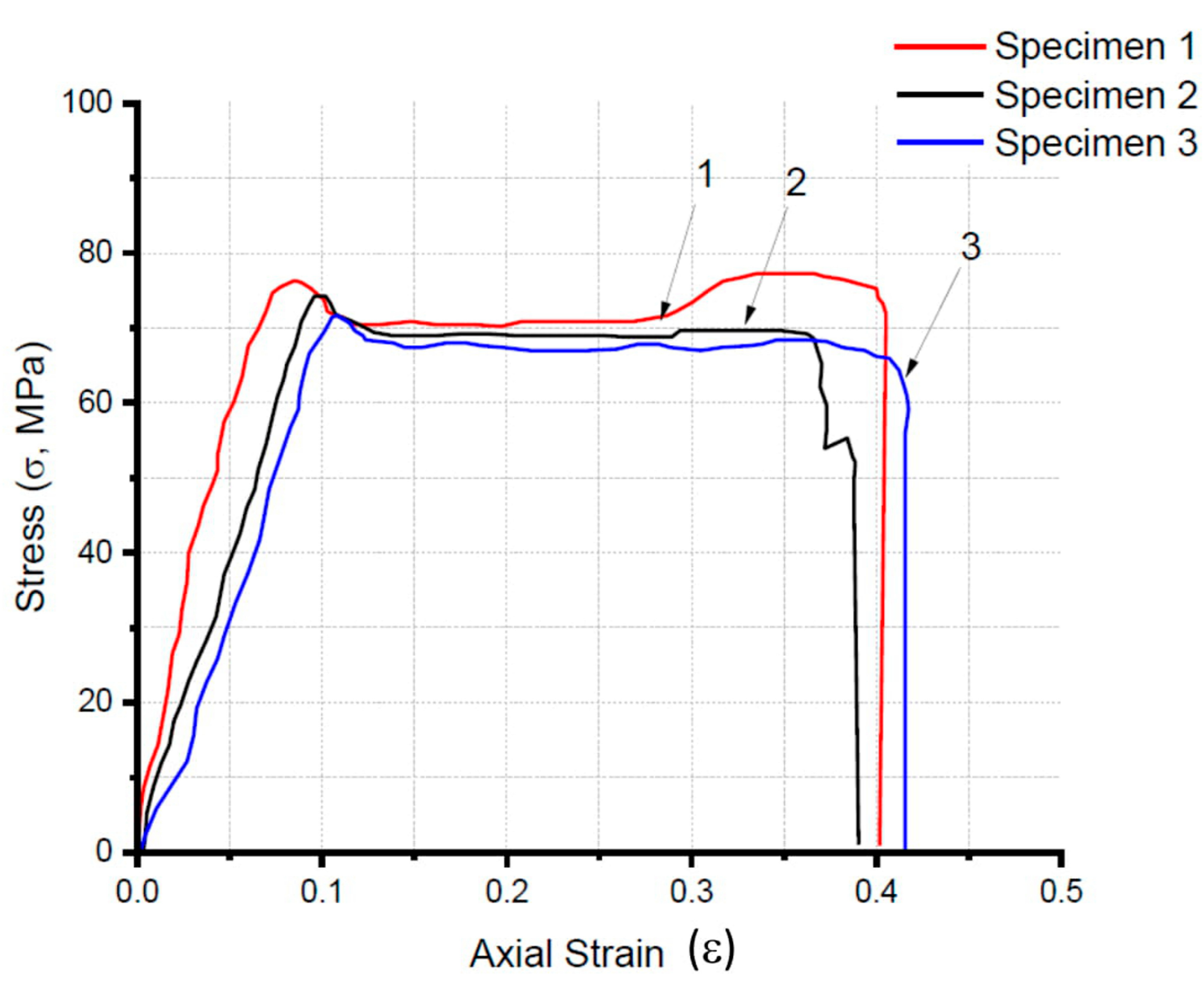

3.5. Tensile Tests

3.5.1. Tensile Tests for NR R-Nylon-6

3.5.2. Tensile Test for AQ R-Nylon-6

3.5.3. Comparison between AQ R-Nylon-6, NR R-Nylon-6, and Commercial Filaments

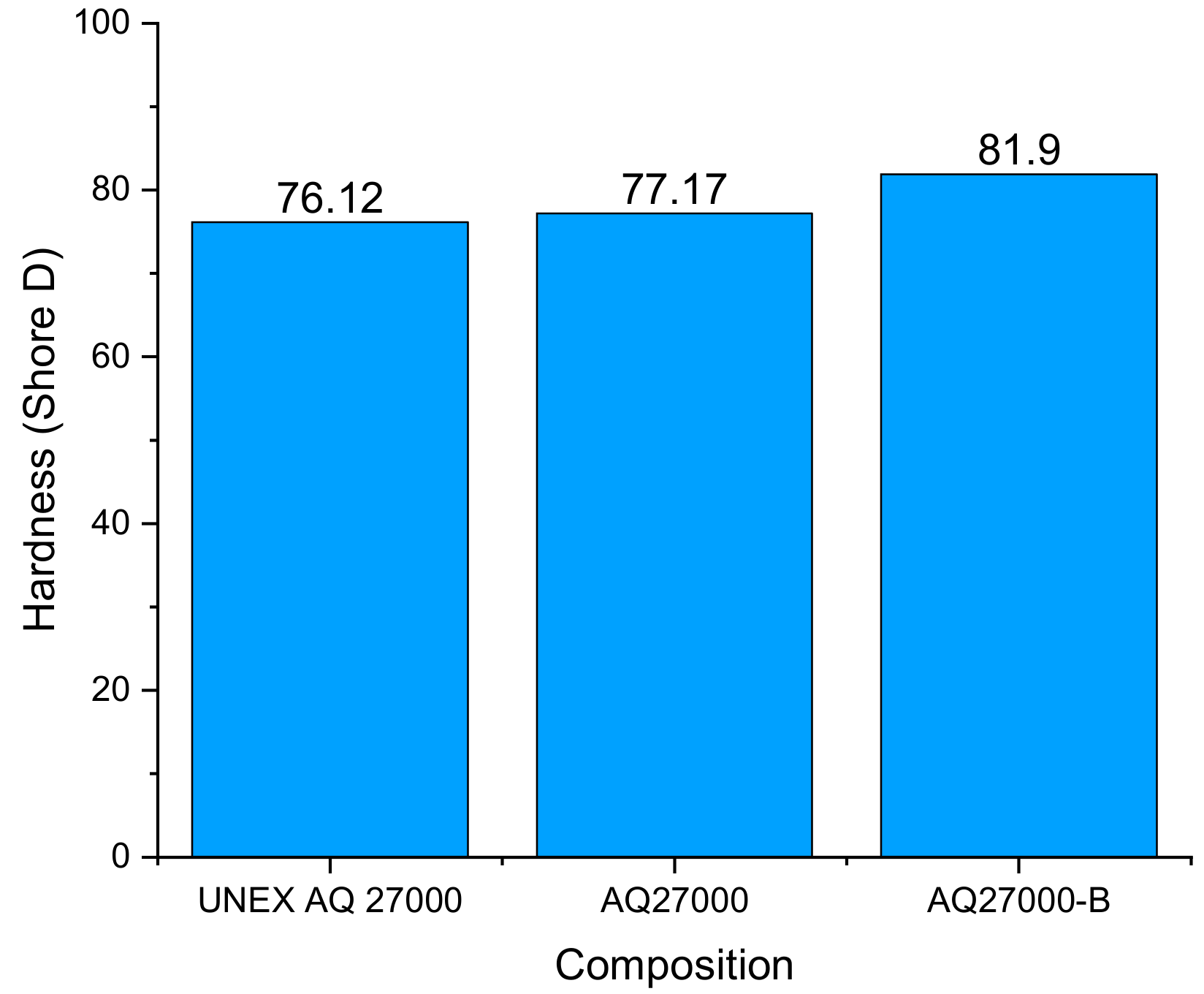

3.6. Wear Resistance

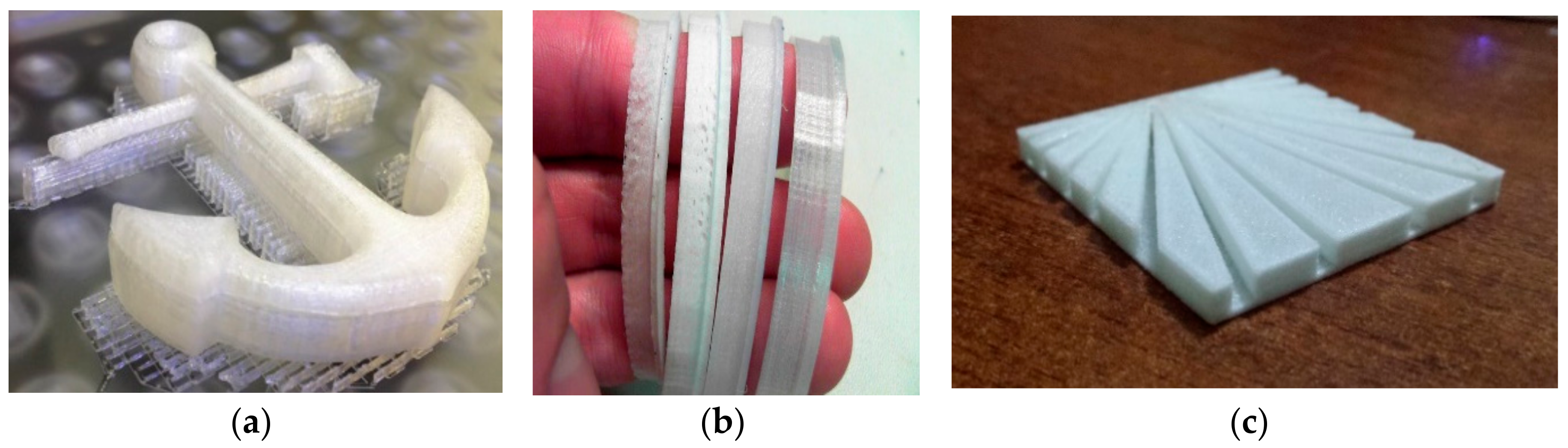

3.7. 3D Printing Feasibility

4. Concluding Remarks

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Van Loon, R.R.; Pujadas-Gispert, E.; Moonen, S.P.; Blok, R. Environmental Optimization of Precast Concrete Beams Using Fibre Reinforced Polymers. Sustainability 2019, 11, 2174. [Google Scholar] [CrossRef]

- Al-Salem, S.M.; Lettieri, P.; Baeyens, J. Recycling and recovery routes of plastic solid waste (PSW): A review. Waste Manag. 2009, 29, 2625–2643. [Google Scholar] [CrossRef]

- USEPA. Municipal Solid Waste in the United States: 2000 Facts and Figures. Executive Summary; EPA530-S−02–001; Office of solid waste management and emergency response (5305W): Washington, DC, USA, June 2002. [Google Scholar]

- Zia, K.M.; Bhatti, H.N.; Bhatti, I.A. Methods for polyurethane and polyurethane composites, recycling and recovery: A review. React. Funct. Polym. 2007, 67, 675–692. [Google Scholar] [CrossRef]

- Scheirs, J. Polymer recycling: Science, technology and applications; Wiley: New York, NY, USA, 1998. [Google Scholar]

- Lei, Y.; Wu, Q.; Yao, F.; Xu, Y. Preparation and properties of recycled HDPE/natural fiber composites. Compos. Part. A: Appl. Sci. Manuf. 2007, 38, 1664–1674. [Google Scholar] [CrossRef]

- Marzouk, O.Y.; Dheilly, R.M.; Queneudec, M. Valorization of post-consumer waste plastic in cementitious concrete composites. Waste Manag. 2007, 27, 310–318. [Google Scholar] [CrossRef]

- James, A.R.; Sbarski, I.; Masood, S.H.; Kosior, E. Thermal and melt rheological behavior of composites produced from waste paper and plastic. J. Polym. Eng. 2007, 27, 55–74. [Google Scholar] [CrossRef]

- Sanchez-Soto, M.; Rossa, A.; Sanchez, A.J.; Gamez-Perez, A.J. Blends of HDPE wastes: Study of the properties. Waste Manag. 2008, 28, 2565–2573. [Google Scholar] [CrossRef]

- Kim, Y.S.; Kim, J.K.; Jeon, E.S. Effect of the Compounding Conditions of Polyamide 6, Carbon Fiber, and Al2O3 on the Mechanical and Thermal Properties of the Composite Polymer. Materials 2019, 12, 3047. [Google Scholar] [CrossRef]

- Cruz, F.; Lanza, S.; Boudaoud, H.; Hoppe, S.; Camargo, M. Polymer Recycling and Additive Manufacturing in an Open Source context: Optimization of processes and methods. In Proceedings of the Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 10–2 August 2015. [Google Scholar]

- Wilcox, C.; Heathcote, G.; Goldberg, J.; Gunn, R.; Peel, D.; Hardesty, B.D. Understanding the sources and effects of abandoned, lost, and discarded fishing gear on marine turtles in northern Australia. Conserv. Biol. 2015, 29, 198–206. [Google Scholar] [CrossRef]

- Afshari, M. Crystalline and amorphous orientation of polypropylene/nylon 6 blend filaments. Iran. Polym. J. 2015, 14, 1042–1049. [Google Scholar]

- Tanikella, N.G.; Wittbrodt, B.; Pearce, J.M. Tensile strength of commercial polymer materials for fused filament fabrication 3D printing. Addit. Manuf. 2017, 15, 40–47. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part. B: Eng 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Singh, N.; Hui, D.; Singh, R.; Ahuja, I.P.S.; Feo, L.; Fraternali, F. Recycling of plastic solid waste: A state of art review and future applications. Compos. Part. B: Eng. 2017, 115, 409–422. [Google Scholar] [CrossRef]

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. Philos. Trans. R. Soc. B: Biol. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef]

- Aquafil. Environmental product declaration for ECONYL® polymer. Available online: https://www.aquafil.com/assets/uploads/EPD_ECONYL%C2%AE-Polymer.pdf (accessed on 25 November 2019).

- Singh, R.; Kumar, R.; Ranjan, N.; Penna, R.; Fraternali, F. On the recyclability of polyamide for sustainable composite structures in civil engineering. Compos. Struct. 2018, 184, 704–713. [Google Scholar] [CrossRef]

- Boparai, K.S.; Singh, R.; Singh, H. Experimental investigations for development of Nylon6-Al-Al2O3 FDM filament alternatives. Rapid Prototyp. J. 2016, 22, 217–224. [Google Scholar] [CrossRef]

- Boparai, K.S.; Singh, R.; Singh, H. Modeling and optimization of extrusion process parameters for the development of Nylon6–Al–Al2O3 alternative FDM filament. Prog. Addit. Manuf. 2016, 1, 1–14. [Google Scholar] [CrossRef]

- Singh, R.; Singh, S.; Fraternali, F. Development of in-house composite wire-based feed stock filaments of fused deposition modelling for wear-resistant materials and structures. Compos. Part. B: Eng. 2016, 98, 244–249. [Google Scholar] [CrossRef]

- Singh, R.; Bedi, O.; Ahuja, I.P.S.; Fraternali, F. Effect of single particle size, double particle size and triple particle size Al2O3 in Nylon-6 matrix on mechanical properties of feed stock filament for FDM filament. Compos. Part. B: Eng. 2016, 106, 20–27. [Google Scholar] [CrossRef]

- Singh, R.; Singh, S.; Amendola, A.; Fraternali, F. On the wear properties of Nylon6-SiC-Al2O3 based fused deposition modelling feed stock filament. Compos. Part. B: Eng. 2017, 119, 125–131. [Google Scholar] [CrossRef]

- Spectrum. Nylon PA6 Low Warp Filament, Technical Data Sheet. Available online: https://cdn-3d.niceshops.com/upload/file/Nylon_PA6_Low_Warp_TDS.pdf (accessed on 25 November 2019).

- Taulman3d. Nylon 645 Specifications. Available online: http://taulman3d.com/nylon-645-spec.html (accessed on 25 November 2019).

- Taulman3d. Nylon 680 Specifications. Available online: https://taulman3d.com/nylon-680-spec.html (accessed on 25 November 2019).

- Commercial Nylon-11 Specifications. Available online: http://www.goodfellow.com/E/Polyamide-Nylon-11.html (accessed on 25 November 2019).

- Commercial Nylon-12 Specifications. Available online: https://www.stratasysdirect.com/materials/thermoplastics/nylon#nylon-12 (accessed on 25 November 2019).

- ISO 307:2017. Plastics — Polyamides — Determination of viscosity number; International Organization for Standardization: Geneva, Switzerland, 2017. [Google Scholar]

- ABS specifications used by Aquafil. Available online: https://www.lgchem.com/global/abs/abs-acrylonitrile-styrene/product-detail-PDBDA00 (accessed on 2 September 2019).

- Commercial Nylon Granules provider, Gujrat fertilizer limited. Available online: https://www.gsfclimited.com/nylon_6.Asp? mnuid=3&fid=3 (accessed on 2 September 2019).

- Wang, J.; Olah, A.; Baer, E. Continuous micro-/nano-fiber composites of polyamide 6/polyethylene oxide with tunable mechanical properties using a novel co-extrusion technique. Polymer 2016, 82, 166–171. [Google Scholar] [CrossRef]

- Shenoy, A.V. Rheology of filled polymer systems, 1st ed.; Springer Science & Business Media: New York, NY, USA, 2013. [Google Scholar]

- Wang, L.; Qiu, J.; Sakai, E.; Wei, X. The relationship between microstructure and mechanical properties of carbon nanotubes/polylactic acid nanocomposites prepared by twin-screw extrusion. Compos. Part. A: Appl. Sci. Manuf. 2016, 89, 18–25. [Google Scholar] [CrossRef]

- John, R.; Wagner, J.; Eldridge, M.M.; Giles, J. Extrusion: The definitive processing guide and handbook, 2nd ed.; William Andrew: New York, NY, USA, 2014. [Google Scholar]

- Crawford, R.J. Plastics Engineering, 2nd ed.; Pergamon Press: Oxford, UK, 1987. [Google Scholar]

- ASTM Committee D-20 on Plastics. Standard Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer. ASTM: West Conshohocken, PA, USA, 2001. [Google Scholar]

- Entov, V.M.; Hinch, E.J. Effect of a spectrum of relaxation times on the capillary thinning of a filament of elastic liquid. J. Non-Newton. Fluid Mech. 1997, 72, 31–53. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, R.; Mascolo, I.; Modano, M. On the applicability of composite PA6-TiO2 filaments for the rapid prototyping of innovative materials and structures. Compos. Part. B: Eng. 2018, 143, 132–140. [Google Scholar] [CrossRef]

- ISO 868:2003. Plastics and Ebonite—Determination of Indentation Hardness by Means of a Durometer (Shore Hardness); International Organization for Standardization: Geneva, Switzerland, 2003. [Google Scholar]

- Typical properties generic, A.B.S. Available online: https://plastics.ulprospector.com/generics/1/c/t/acrylonitrile-butadiene-styrene-abs-properties-processing (accessed on 25 November 2019).

- Anatomy of a 3D Printer. Available online: https://www.matterhackers.com/articles/anatomy-of-a-3d-printer (accessed on 25 November 2019).

- Best practices when printing with Nylon. Available online: https://www.simplify3d.com/support/materials-guide/nylon/ (accessed on 25 November 2019).

- 3D Adidas’ First Mass Market 3D-Printed Shoe. Available online: https://www.youtube.com/watch?v = O2thSsQrZUM (accessed on 25 November 2019).

- Printed Shoes: An Overview. Available online: https://all3dp.com/3d-printed-shoes/ (accessed on 25 November 2019).

- Hoque, M.E.; Chuan, Y.L.; Pashby, I. Extrusion based rapid prototyping technique: An advanced platform for tissue engineering scaffold fabrication. Biopolymers 2012, 97, 83–93. [Google Scholar] [CrossRef]

- Antoniac, I.; Popescu, D.; Zapciu, A.; Antoniac, A.; Miculescu, F.; Moldovan, H. Magnesium Filled Polylactic Acid (PLA) Material for Filament Based 3D printing. Materials 2019, 12, 719. [Google Scholar] [CrossRef]

- Adumitroaie, A.; Antonov, F.; Khaziev, A.; Azarov, A.; Golubev, M.; Vasiliev, V.V. Novel Continuous Fiber Bi-Matrix Composite 3-D Printing Technology. Materials 2019, 12, 3011. [Google Scholar] [CrossRef] [PubMed]

- Trujillo-de Santiago, G.; Flores-Garza, B.G.; Tavares-Negrete, J.A.; Lara-Mayorga, I.M.; González-Gamboa, I.; Zhang, Y.S.; Rojas-Martínez, A.; Ortiz-López, R.; Álvarez, M.M. The Tumor-on-Chip: Recent Advances in the Development of Microfluidic Systems to Recapitulate the Physiology of Solid Tumors. Materials 2019, 12, 2945. [Google Scholar] [CrossRef]

- Reichmann, K.; Feteira, A.; Li, M. Bismuth sodium titanate based materials for piezoelectric actuators. Materials 2015, 8, 8467–8495. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, R.; Hui, D.; Feo, L.; Fraternali, F. Graphene as biomedical sensing element: State of art review and potential engineering applications. Compos. Part. B: Eng. 2018, 134, 193–206. [Google Scholar] [CrossRef]

- Yan, Z.; Zaman, M.; Jiang, L. Electro-mechanical analysis of a curved functionally graded piezoelectric actuator with sandwich structure. Materials 2011, 4, 2151–2170. [Google Scholar] [CrossRef] [PubMed]

- Qi, H.; He, C.; Zhang, P.; Han, W.; Guo, F.; Wu, F.; Du, M. Additive Manufacturing of Silicon Nitride Ceramic Floatation Spheres with Excellent Mechanical Properties. Materials 2019, 12, 2717. [Google Scholar] [CrossRef] [PubMed]

| Composition | NR R-Nylon-6 | Al | Al2O3 | MFI (g/10 min) |

|---|---|---|---|---|

| A | 60 | 26 | 14 | 2.19 |

| B | 60 | 28 | 12 | 2.25 |

| C | 60 | 30 | 10 | 2.31 |

| Specimen | 1st | 2nd | 3rd | 4th | 5th | Avg |

|---|---|---|---|---|---|---|

| MFI (g/10 min) | 29.50 | 27.30 | 21.23 | 21.99 | 23.44 | 24.69 |

| AQ27000-B | AQ34000 | AQ34000-B | AQ24000-T |

|---|---|---|---|

| −22.08% (19.24) | −12.07% (21.71) | −17.92% (20.26) | +58.33% (39.09) |

| Specimen | 1st | 2nd | 3rd | AVG | STD |

|---|---|---|---|---|---|

| Yield strength (MPa) | 77.34 | 76.37 | 74.9 | 76.20 | 1.23 |

| % elongation at Yield | 8.18 | 8.92 | 10.20 | 9.10 | 1.02 |

| Break strength (MPa) | 75 | 69 | 66 | 70 | 4.58 |

| % elongation at break | 39.60 | 38.00 | 41.59 | 39.73 | 1.80 |

| Young modulus (GPa) | 1.66 | 1.64 | 1.63 | 1.64 | 0.01 |

| Speed (mm/min) | 50 | 50 | 50 | 50 | 0 |

| Property | AQ27000 | STD | Pure NR R-Nylon-6 [19] | Blended NR R-Nylon-6 [20,21,22,23,24] | PA6 Spectrum [25] | Ny-lon 645 [26] | Ny-lon 680 [27] | Ny-lon-11 [28] | Ny-lon-12 [29] |

|---|---|---|---|---|---|---|---|---|---|

| Tensile strength at yield [MPa] | 76.20 | 1.23 | 9.02 | 40–83 | 40 | 35.77 | 47.57 | 48 | 32 |

| Young modulus [GPa] | 1.64 | 0.01 | 0.28 | 2.6–3.0 | 1.50 | 0.21 | N/A | 1.50 | 1.30 |

| % Elongation at break | 40 | 1.80 | 14 | 20–60 | 250 | 186 | 34 | 35 | 30 |

| Property | AQ27000-B | AQ34000 | AQ34000-B | AQ24000-T |

|---|---|---|---|---|

| Yield strength (MPa) | +14.06% (86.91) * | +12.85% (85.99) | +6.57% (81.21) | −26.79% (55.79) |

| Young’s modulus (GPa) | +42.78% (2.34) | −1.68% (1.61) | −8.72% (1.50) | −53.75% (0.76) |

| % Elongation at break | −5.89% (37.65) | −0.21% (39.92) | −0.72% (39.71) | −69.32% (12.27) |

| Sample | UNEX AQ27000 | AQ27000 | AQ27000-B |

|---|---|---|---|

| Wear (μm) | 102 | 95 | 92 |

| Parameters | AQ27000 | AQ27000-B | Spectrum PA6 [25] |

|---|---|---|---|

| Print plane tilt | No | No | No |

| Heated printing plane | yes | Yes | Yes |

| First Layer Weight | 0.32 mm | 0.36 mm | 0.36 mm |

| First layer extrusion speed | 65% | 50% | 50% |

| Surrounding temperature | 23 °C | 23 °C | 23 °C |

| Print speed | 50 mm/s | 40 mm/s | 40 mm/s |

| Humidity | Absent | Absent | Absent (Dry) |

| Layer thickness | 0.5 mm | 0.5 mm | 0.5 mm |

| Nozzle diameter | 0.4 mm | 0.4 mm | 0.4 mm |

| Filament diameter | 1.75 mm | 1.75 mm | 1.75 mm |

| Extrusion temperature | 235 °C | 230 °C | 250 °C |

| Activating cooling fan | after 50 s per layer | after 50 s per layer | after 50 s per layer |

| cooling fan slow down | after 10 s per layer | after 10 s per layer | after 10 s per layer |

| Retraction | 0.9 mm | 0.9 mm | 0.9 mm |

| Retraction speed | 15 mm/s | 15 mm/s | 15 mm/s |

| Skirt height | 1 layer | 1 layer | 1 layer |

| Object-skirt Distance | 3 mm | 3 mm | 3 mm |

| Brim | 10 mm | 20 mm | 10 mm |

| % Fill (infill) | 10% | 15% | 10% |

| Infill speed | 80 mm/s | 80 mm/s | 80 mm/s |

| Perimeter printing speed | 60 mm/s | 60 mm/s | 60 mm/s |

| Bridge | 1.2 cm | 1.2 cm | 1.2 cm |

| AQ27000 | |||||||

|---|---|---|---|---|---|---|---|

| Model | Max Size (mm) | T * °C | T ^°C | Raft | Infill Pattern | Result | |

| Trial 1 | anchor | 50 | 235 | 40 | No | Hexagonal | No warping |

| Trial 2 | anchor | 50 | 235 | 60 | No | Hexagonal | No warping |

| Trial 3 | anchor | 50 | 235 | 80 | No | Hexagonal | No warping |

| AQ27000-B | |||||||

|---|---|---|---|---|---|---|---|

| Model | Max Size (mm) | T * °C | T ^°C | Raft | Infill Pattern | Result | |

| Trial 1 | anchor | 50 | 230 | 40 | No | Hexagonal | warping |

| Trial 2 | anchor | 50 | 230 | 60 | No | Hexagonal | warping |

| Trial 3 | anchor | 50 | 230 | 80 | No | Hexagonal | No warping |

| Trial 4 | anchor | 50 | 235 | 80 | No | Hexagonal | No warping |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Farina, I.; Singh, N.; Colangelo, F.; Luciano, R.; Bonazzi, G.; Fraternali, F. High-Performance Nylon-6 Sustainable Filaments for Additive Manufacturing. Materials 2019, 12, 3955. https://doi.org/10.3390/ma12233955

Farina I, Singh N, Colangelo F, Luciano R, Bonazzi G, Fraternali F. High-Performance Nylon-6 Sustainable Filaments for Additive Manufacturing. Materials. 2019; 12(23):3955. https://doi.org/10.3390/ma12233955

Chicago/Turabian StyleFarina, Ilenia, Narinder Singh, Francesco Colangelo, Raimondo Luciano, Giulio Bonazzi, and Fernando Fraternali. 2019. "High-Performance Nylon-6 Sustainable Filaments for Additive Manufacturing" Materials 12, no. 23: 3955. https://doi.org/10.3390/ma12233955

APA StyleFarina, I., Singh, N., Colangelo, F., Luciano, R., Bonazzi, G., & Fraternali, F. (2019). High-Performance Nylon-6 Sustainable Filaments for Additive Manufacturing. Materials, 12(23), 3955. https://doi.org/10.3390/ma12233955