Influence of the Interactions at the Graphene–Substrate Boundary on Graphene Sensitivity to UV Irradiation

Abstract

:1. Introduction

2. Materials and Methods

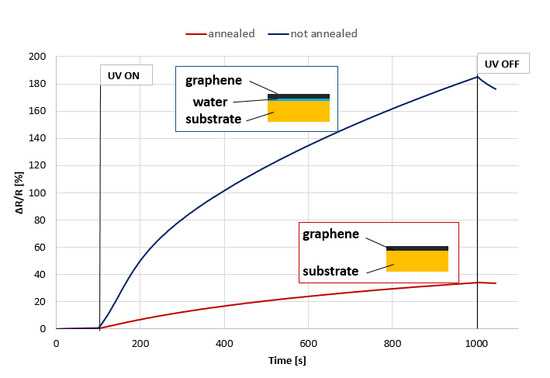

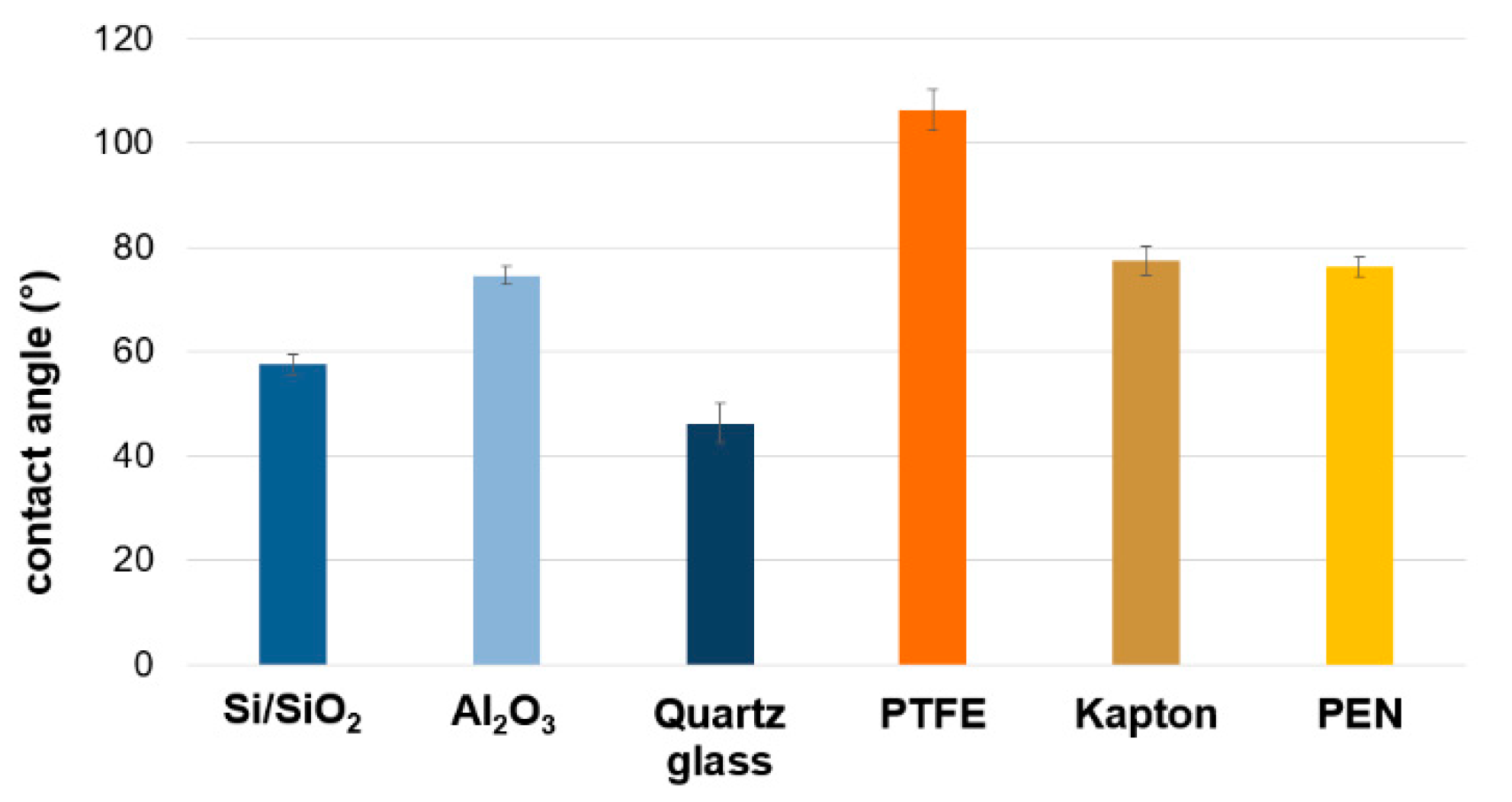

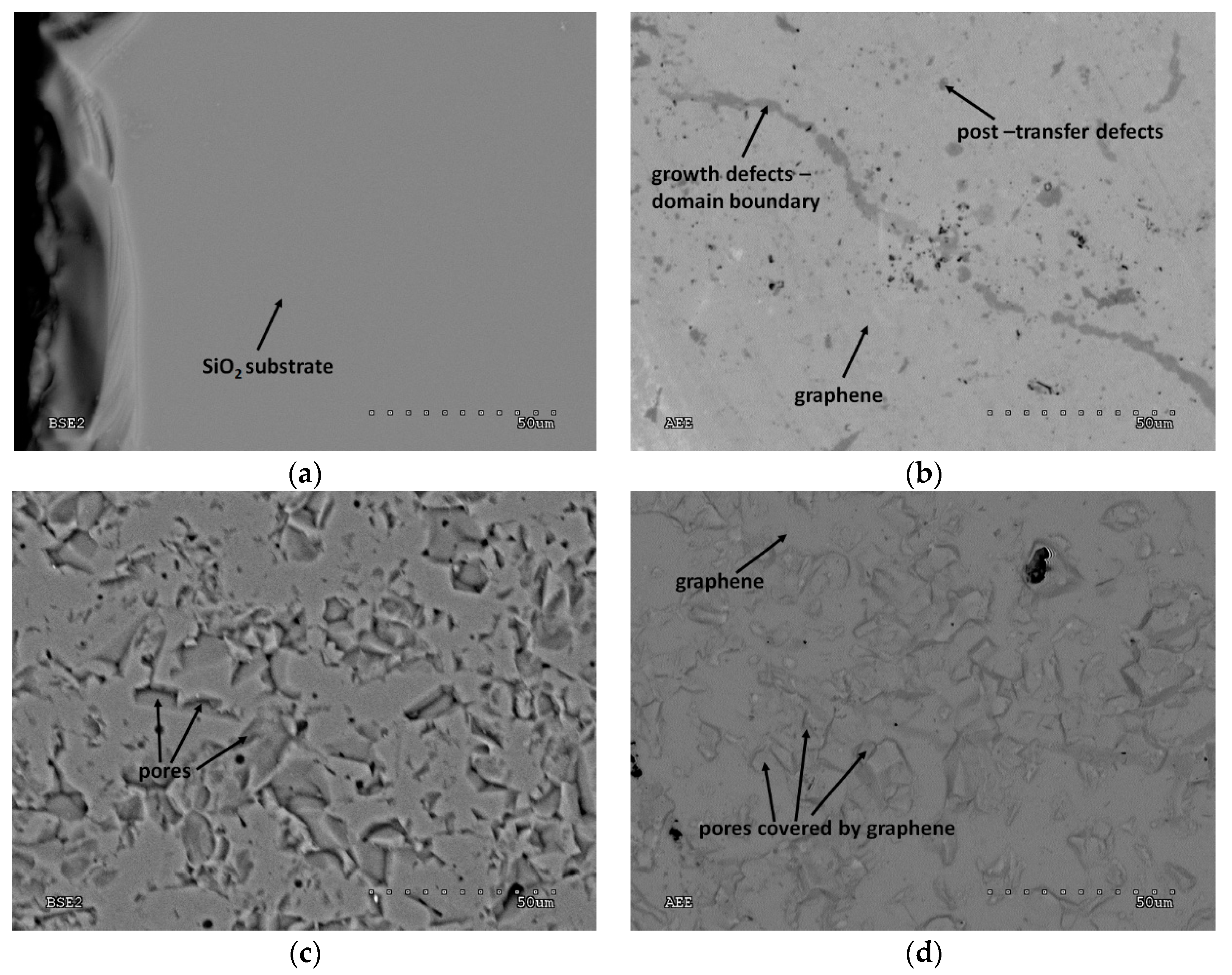

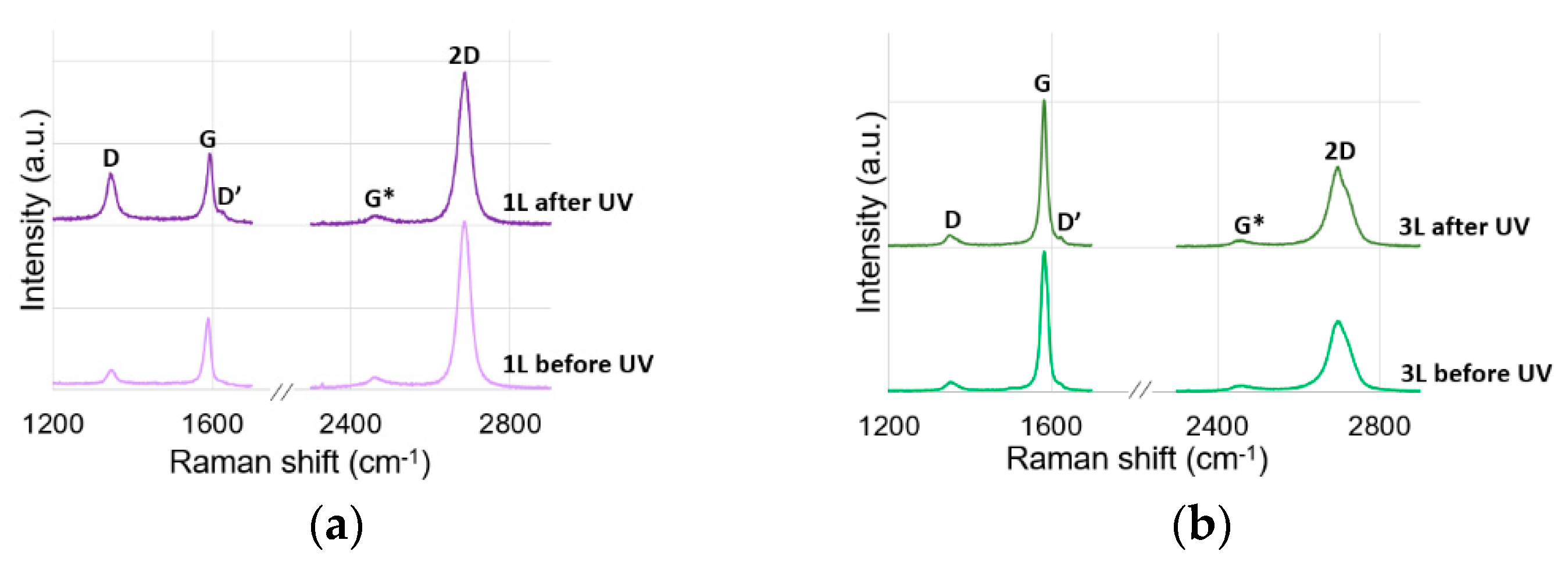

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yang, C.-M.; Chen, T.-C.; Yang, Y.-C.; Hsiao, M.-C.; Meyyappan, M.; Lai, C.-S. Ultraviolet illumination effect on monolayer graphene-based resistive sensor for acetone detection. Vacuum 2017, 140, 89–95. [Google Scholar] [CrossRef]

- Schedin, F.; Geim, A.K.; Morozov, S.V.; Hill, E.W.; Blake, P.; Katsnelson, M.I.; Novoselov, K.S. Detection of individual gas molecules adsorbed on grapheme. Nat. Mater. 2007, 6, 652–655. [Google Scholar] [CrossRef] [PubMed]

- Procházka, P.; Mareček, D.; Lišková, Z.; Čechal, J.; Šikola, T. X-ray induced electrostatic graphene doping via defect charging in gate dielectric. Sci. Rep. 2017, 7, 563. [Google Scholar] [CrossRef] [PubMed]

- Imamura, G.; Saiki, K. Interlayer interaction in the UV irradiated defect formation of grapheme. J. Phys. Chem. C 2014, 118, 11842–11848. [Google Scholar] [CrossRef]

- Imamura, G.; Saiki, K. Modification of Graphene/SiO2 interface by UV-irradiation: Effect on electrical characteristics. ACS Appl. Mater. Interfaces 2015, 7, 2439–2443. [Google Scholar] [CrossRef]

- Sun, P.; Zhu, M.; Wang, K.; Zhong, M.; Wei, J.; Wu, D.; Cheng, Y.; Zhu, H. Photoinduced molecular desorption from graphene films. Appl. Phys. Lett. 2012, 101, 053107. [Google Scholar] [CrossRef]

- Güneş, F.; Han, G.H.; Shin, H.-J.; Lee, S.Y.; Jin, M.; Duong, D.L.; Chae, S.J.; Kim, E.S.; Yao, F.; Benayad, A.; et al. UV-light-assisted oxidative sp3 hybridization of graphene. NANO Brief Rep. Rev. 2011, 6, 409–418. [Google Scholar] [CrossRef]

- Lee, G.; Yang, G.; Cho, A.; Han, J.W.; Kim, J. Defect-engineered graphene chemical sensors with ultrahigh sensitivity. Phys. Chem. Chem. Phys. 2016, 18, 14198–14204. [Google Scholar] [CrossRef]

- Iqbal, M.Z.; Siddique, S.; Iqbal, M.W.; Eom, J. Formation of p–n junction with stable p-doping in graphene field effect transistors using deep UV irradiation. J. Mater. Chem. C 2013, 1, 3078–3083. [Google Scholar] [CrossRef]

- Kula, P.; Rzepkowski, A.; Pietrasik, R.; Atraszkiewicz, R.; Dybowski, K.; Modrzyk, W. Method of producing Graphene from Liquid Metal. U.S. Patent Application No. 9,284,640, 15 March 2016. [Google Scholar]

- Chua, L.; Zaumseil, J.; Chang, J.; Ou, E.C.; Ho, P.K.; Sirringhaus, H.; Friend, R.H. General observation of n-type field-effect behaviour in organic semiconductors. Nature 2005, 434, 194–199. [Google Scholar] [CrossRef]

- Zhuravlev, L.T. The surface chemistry of amorphous silica. Zhuravlev Model. Colloids Surf. A 2000, 173, 1–38. [Google Scholar] [CrossRef]

- Li, X.; Zhu, Y.; Cai, W.; Borysiak, M.; Han, B.; Chen, D.; Piner, R.D.; Colombo, L.; Ruoff, R.S. Transfer of large-area graphene films for high-performance transparent conductive electrodes. Nano Lett. 2009, 9, 4359–4363. [Google Scholar] [CrossRef] [PubMed]

- Kolodziejczyk, L.; Kula, P.; Szymanski, W.; Atraszkiewicz, R.; Dybowski, K.; Pietrasik, R. Frictional behaviour of polycrystalline graphene grown on liquid metallic matrix. Tribol. Int. 2016, 93, 628–639. [Google Scholar] [CrossRef]

- Ferrari, A.C. Raman spectroscopy of Graphene and graphite: Disorder, electron-phonon coupling, doping and nanodiabatic effects. Solid State Commun. 2007, 143, 47–57. [Google Scholar] [CrossRef]

- Pimenta, M.A.; Dresselhaus, G.; Dresselhaus, M.S.; Cançado, L.G.; Jorio, A.; Saito, R. Studying disorder in graphite-based systems by Raman spectroscopy. Phys. Chem. Chem. Phys. 2007, 9, 1276–1291. [Google Scholar] [CrossRef] [PubMed]

- Malard, L.M.; Pimenta, M.A.; Dresselhaus, G.; Dresselhaus, M.S. Raman spectroscopy in grapheme. Phys. Rep. 2009, 473, 51–87. [Google Scholar] [CrossRef]

- Mafra, D.L.; Samsonidze, G.; Malard, L.M.; Elias, D.C.; Brant, J.C.; Plentz, F.; Alves, E.S.; Pimenta, M.A. Determination of LA and TO phonon dispersion relations of graphene near the Dirac point by double resonance Raman scattering. Phys. Rev. B 2007, 76, 233407. [Google Scholar] [CrossRef]

- Nanda, S.S.; Kim, M.J.; Yeom, K.S.; An, S.S.A.; Ju, H.; Yi, D.K. Raman spectrum of graphene with its versatile future perspectives. Trends Anal. Chem. 2016, 80, 125–131. [Google Scholar] [CrossRef]

- Eckmann, A.; Felten, A.; Mishchenko, A.; Britnell, L.; Krupke, R.; Novoselov, K.S.; Casiraghi, C. Probing the nature of defects in graphene by Raman spectroscopy. Nano Lett. 2012, 12, 3925–3930. [Google Scholar] [CrossRef]

- Cancado, L.G.; Jorio, A.; Ferreira, E.H.M.; Stavale, F.; Achete, C.A.; Capaz, R.B.; Moutinho, M.V.O.; Lombardo, A.; Kulmala, T.S.; Ferrari, A.C. Quantifying defects in graphene via Raman spectroscopy at different excitation energies. Nano Lett. 2011, 11, 3190–3196. [Google Scholar] [CrossRef]

- Xu, Z.; Ao, Z.; Chu, D.; Younis, A.; Li, C.M.; Li, S. Reversible hydrophobic to hydrophilic transition in graphene via water splitting induced by UV irradiation. Sci. Rep. 2014, 4, 6450. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.; Ao, Z.; Chu, D.; Li, S. UV irradiation induced reversible Graphene band gap behaviors. J. Mater. Chem. C 2016, 4, 8459–8465. [Google Scholar] [CrossRef]

- Luo, Z.; Pinto, N.J.; Davila, Y.; Johnson, A.T.C. Controlled doping of graphene using ultraviolet irradiation. Appl. Phys. Lett. 2012, 100, 253108. [Google Scholar] [CrossRef]

| Graphene Type | - | I2D/IG | ID/IG | LD (nm) | ID/ID’ |

|---|---|---|---|---|---|

| monolayer | before UV | 2.56 | 0.21 | 29 | 4.52 |

| after UV | 2.32 | 0.69 | 16 | 9.32 | |

| trilayer | before UV | - | 0.06 | 55 | 1.37 |

| after UV | - | 0.07 | 52 | 2.49 |

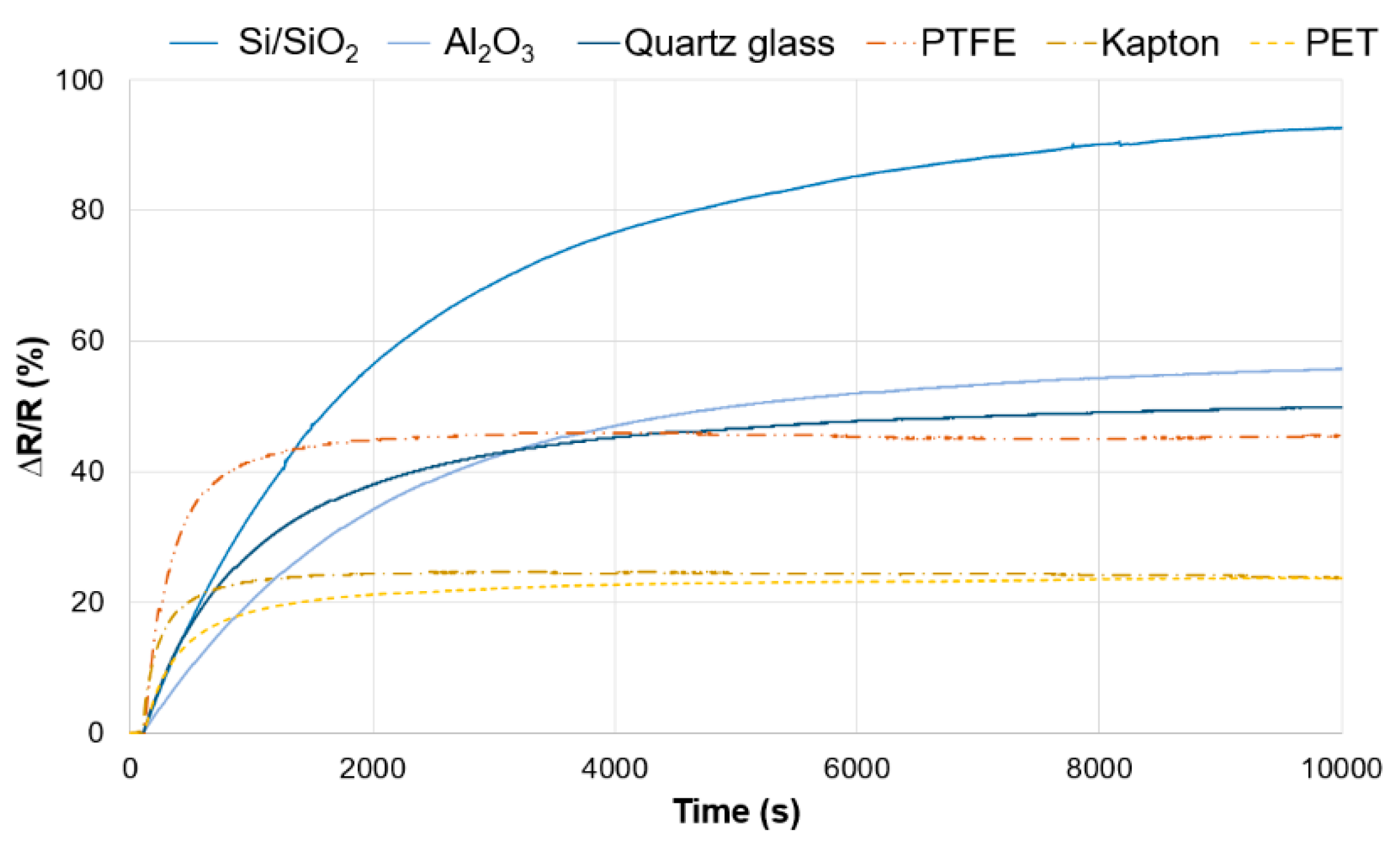

| Resistance | Substratum | |||||

|---|---|---|---|---|---|---|

| Si/SiO2 | Al2O3 | Quartz Glass | PTFE | Kapton | PEN | |

| R0 (Ohm) | 1687 | 5770 | 3990 | 3337 | 3850 | 2300 |

| RF (Ohm) | 3250 | 9370 | 5980 | 4860 | 4760 | 2846 |

| Rmax | 3250 | 9370 | 5980 | 4870 | 4800 | 2847 |

| Rmax Time (s) | 9873 | 9950 | 9501 | 3158 | 2457 | 2843 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nowak, D.; Clapa, M.; Kula, P.; Sochacki, M.; Stonio, B.; Galazka, M.; Pelka, M.; Kuten, D.; Niedzielski, P. Influence of the Interactions at the Graphene–Substrate Boundary on Graphene Sensitivity to UV Irradiation. Materials 2019, 12, 3949. https://doi.org/10.3390/ma12233949

Nowak D, Clapa M, Kula P, Sochacki M, Stonio B, Galazka M, Pelka M, Kuten D, Niedzielski P. Influence of the Interactions at the Graphene–Substrate Boundary on Graphene Sensitivity to UV Irradiation. Materials. 2019; 12(23):3949. https://doi.org/10.3390/ma12233949

Chicago/Turabian StyleNowak, Dorota, Marian Clapa, Piotr Kula, Mariusz Sochacki, Bartlomiej Stonio, Maciej Galazka, Marcin Pelka, Dominika Kuten, and Piotr Niedzielski. 2019. "Influence of the Interactions at the Graphene–Substrate Boundary on Graphene Sensitivity to UV Irradiation" Materials 12, no. 23: 3949. https://doi.org/10.3390/ma12233949

APA StyleNowak, D., Clapa, M., Kula, P., Sochacki, M., Stonio, B., Galazka, M., Pelka, M., Kuten, D., & Niedzielski, P. (2019). Influence of the Interactions at the Graphene–Substrate Boundary on Graphene Sensitivity to UV Irradiation. Materials, 12(23), 3949. https://doi.org/10.3390/ma12233949