The Role of Electric Current-Associated Free Energy and Forced Convection on Grain Refinement in Pure Aluminum under Electropulsing

Abstract

:1. Introduction

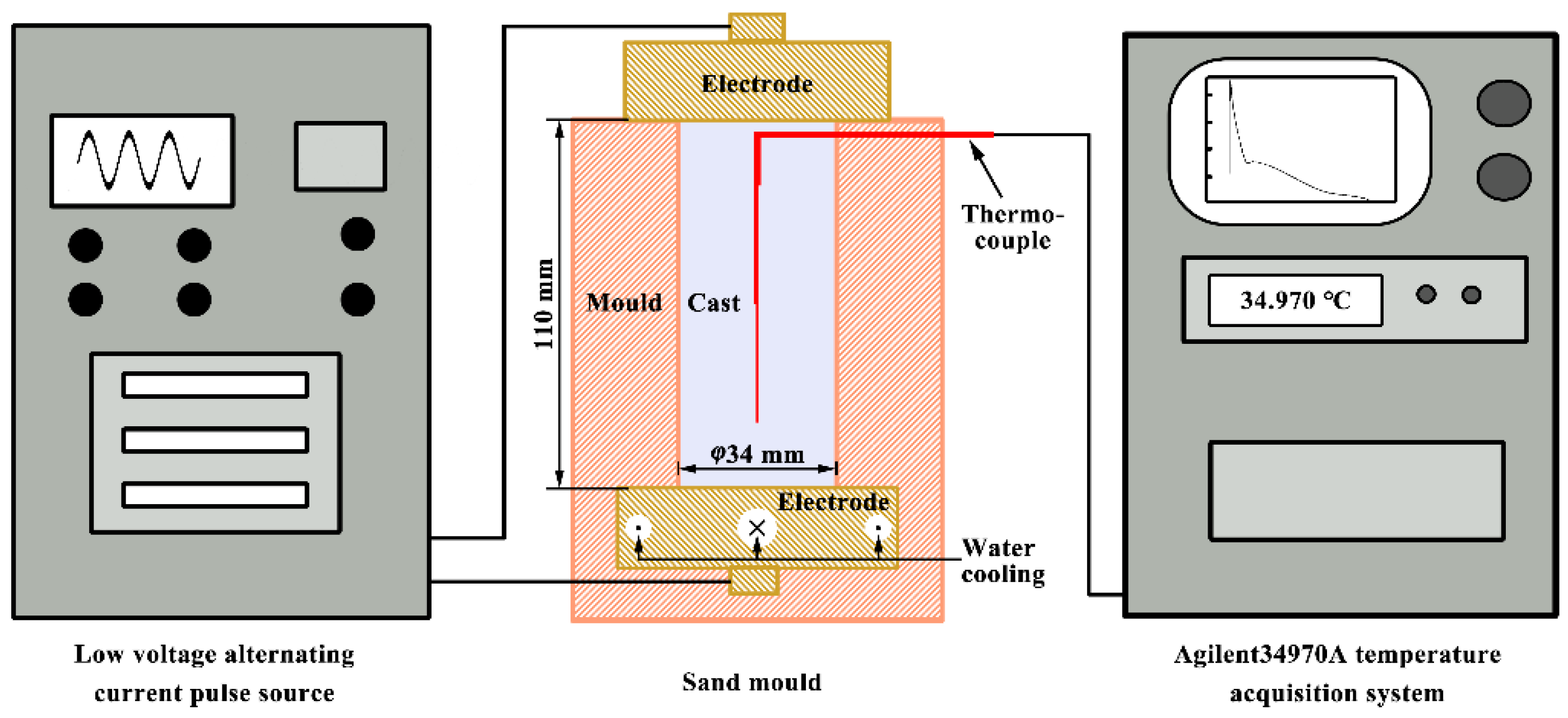

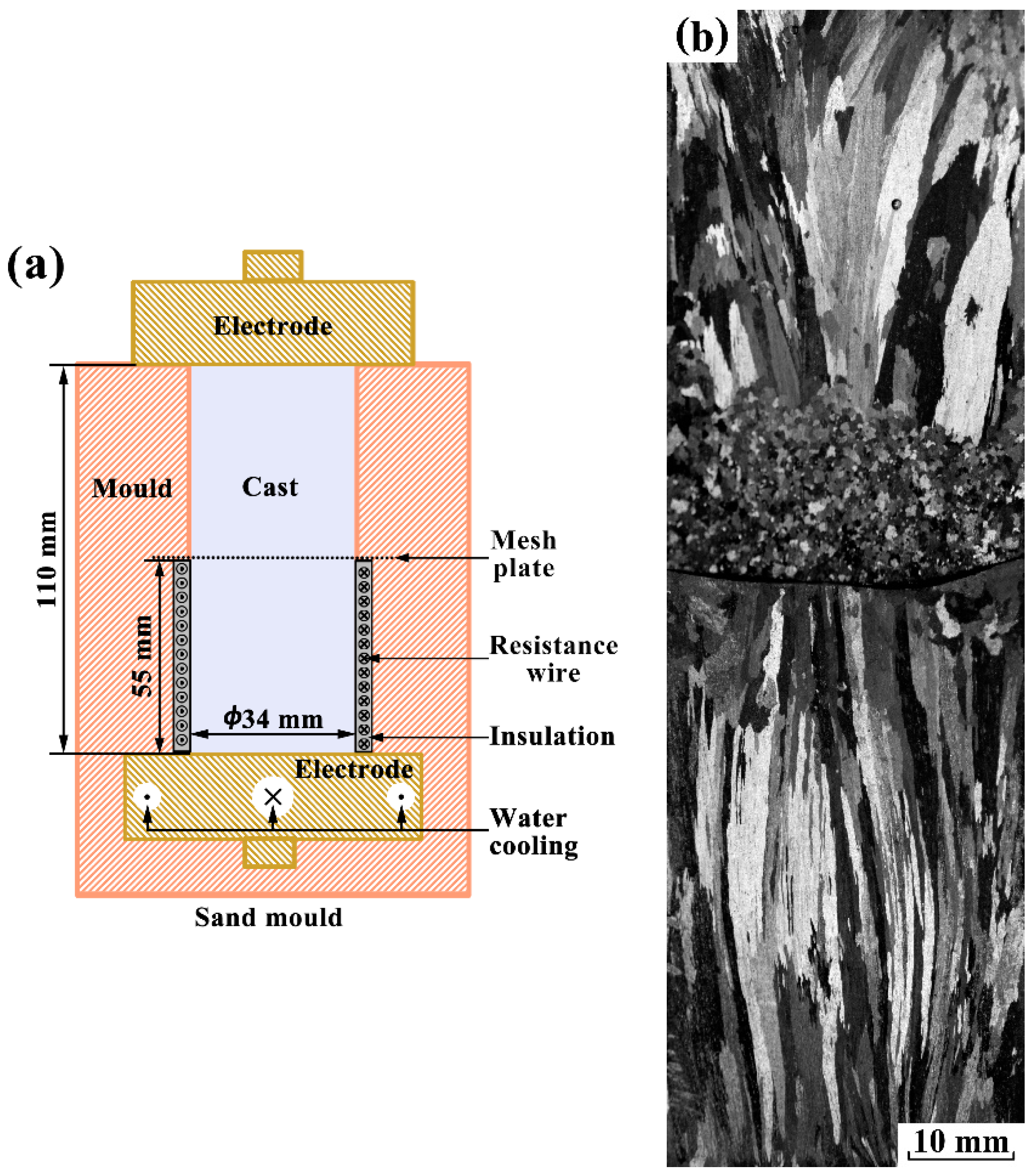

2. Experimental Procedure

3. Results and Discussion

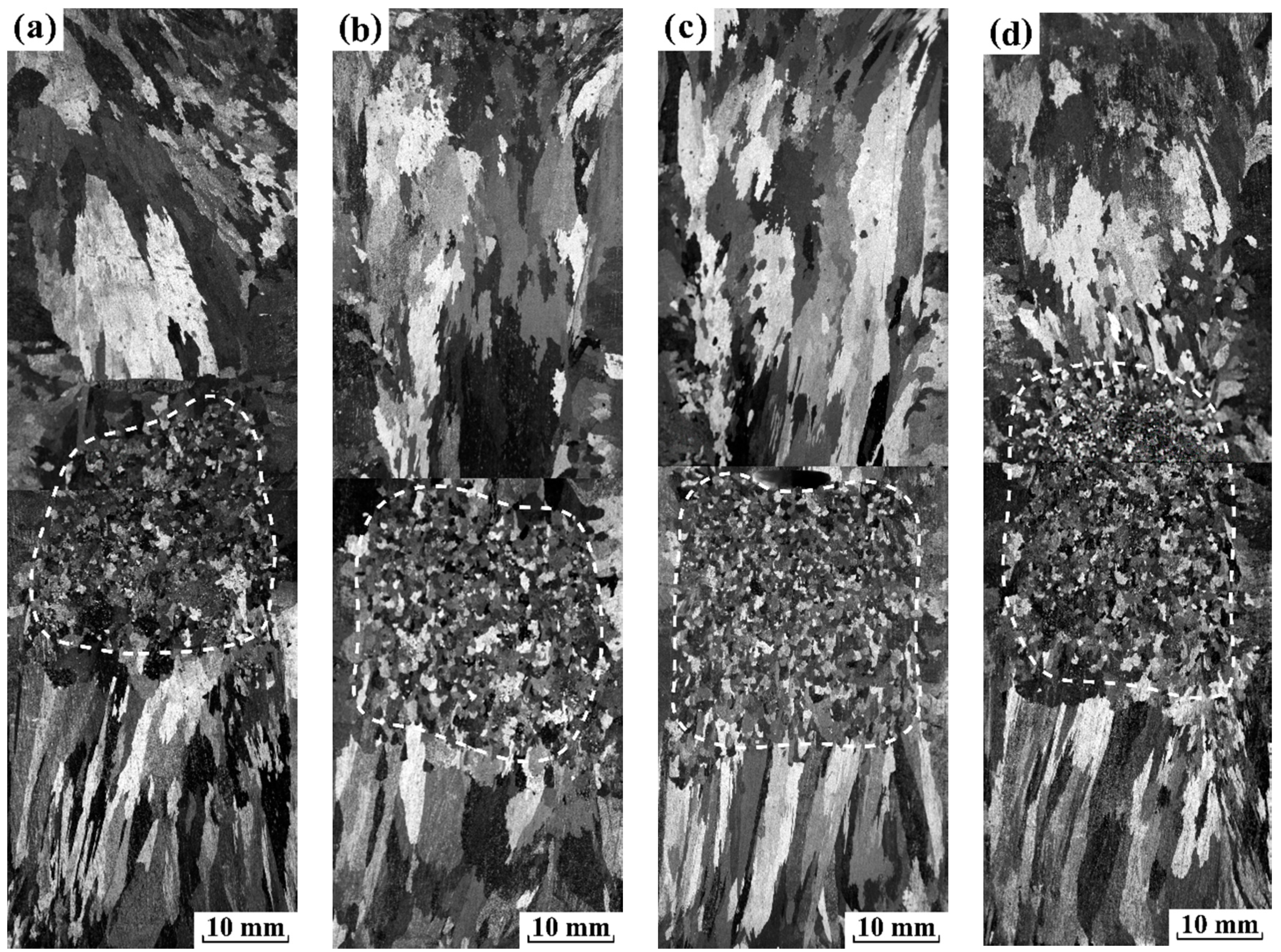

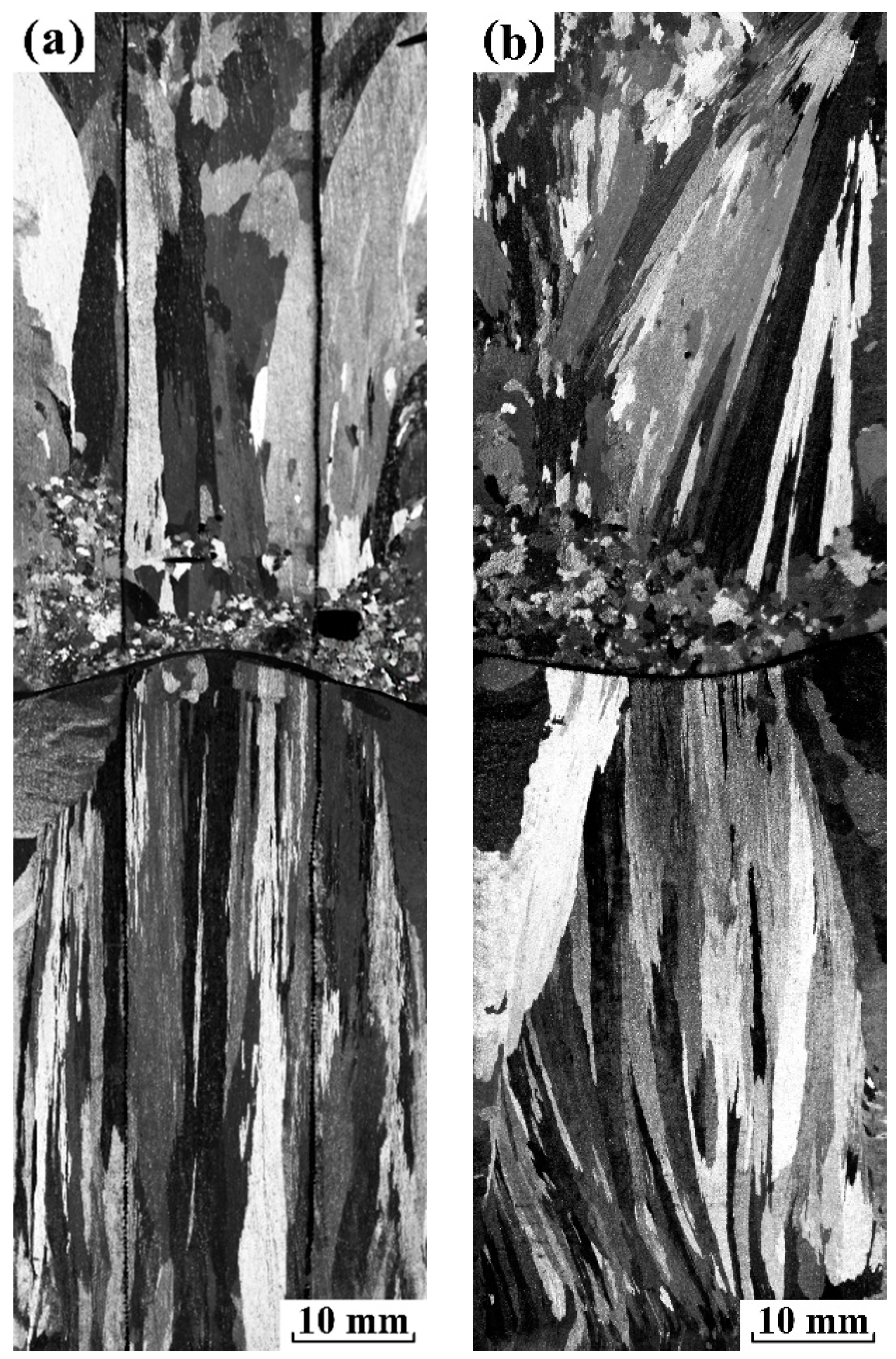

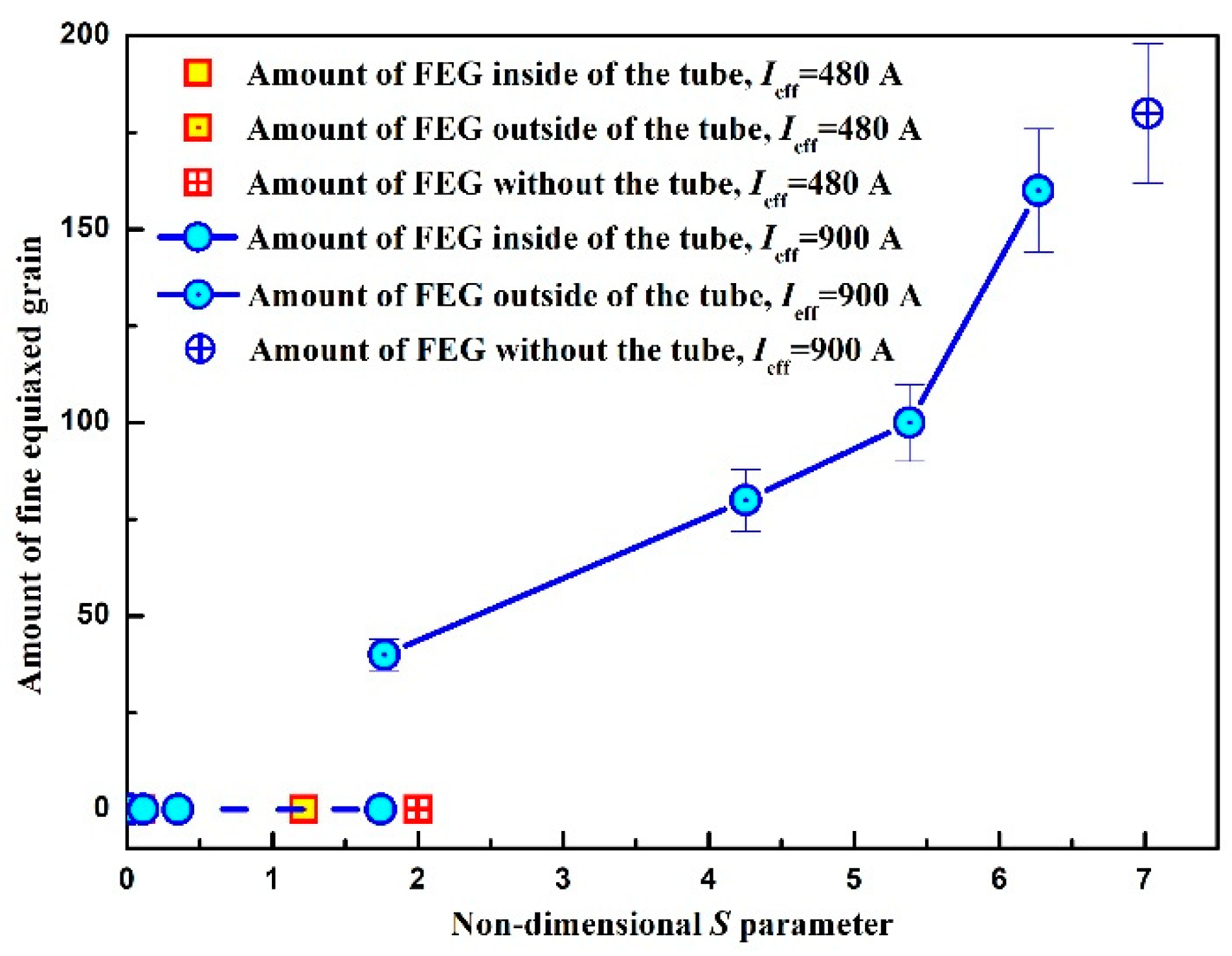

3.1. Effect of Electropulsing on the Grain Macrostructure

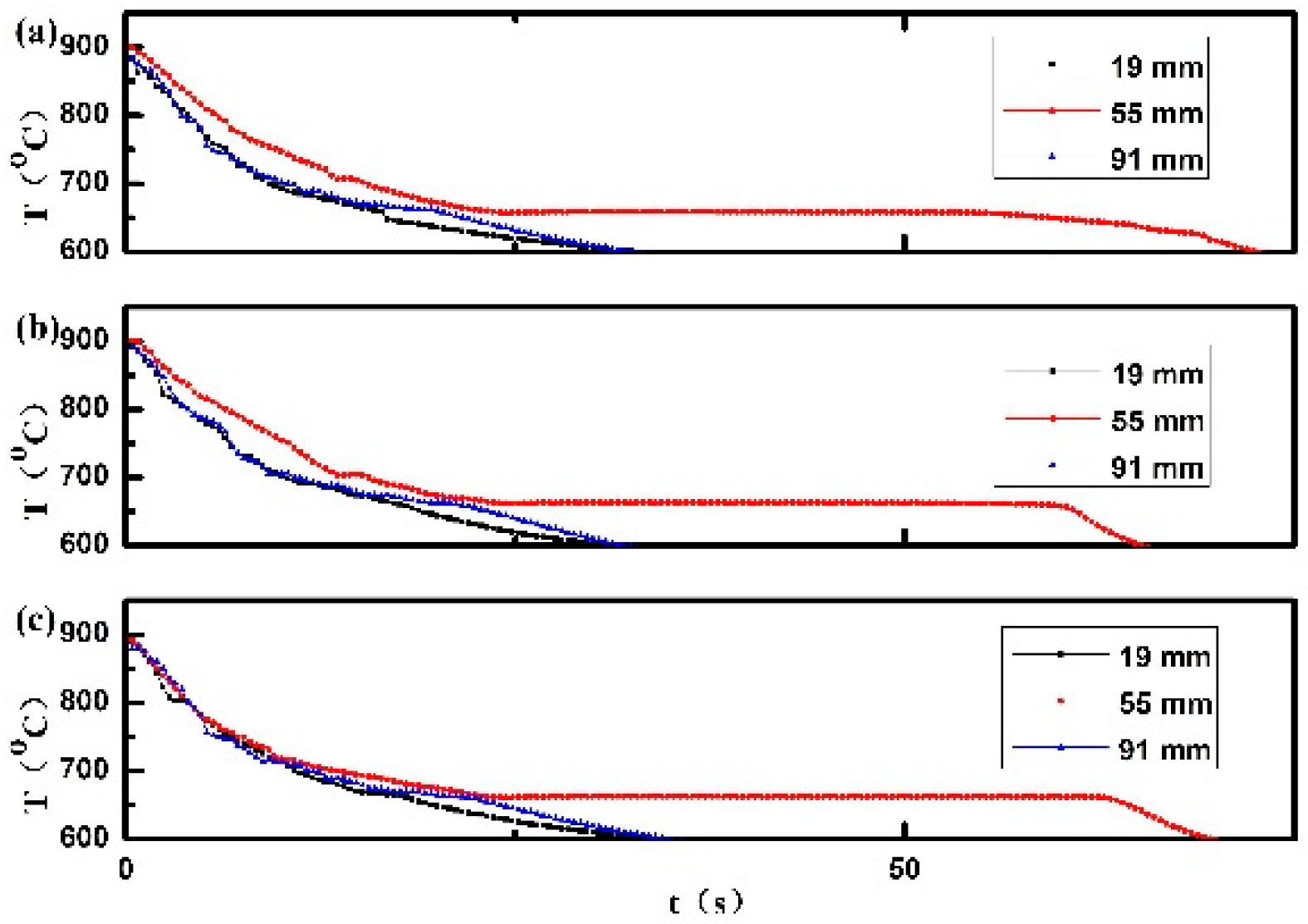

3.2. Forced Flow Field and Relevant Thermal Analysis under Electropulsing

3.3. Refinement Mechanism under Electropulsing

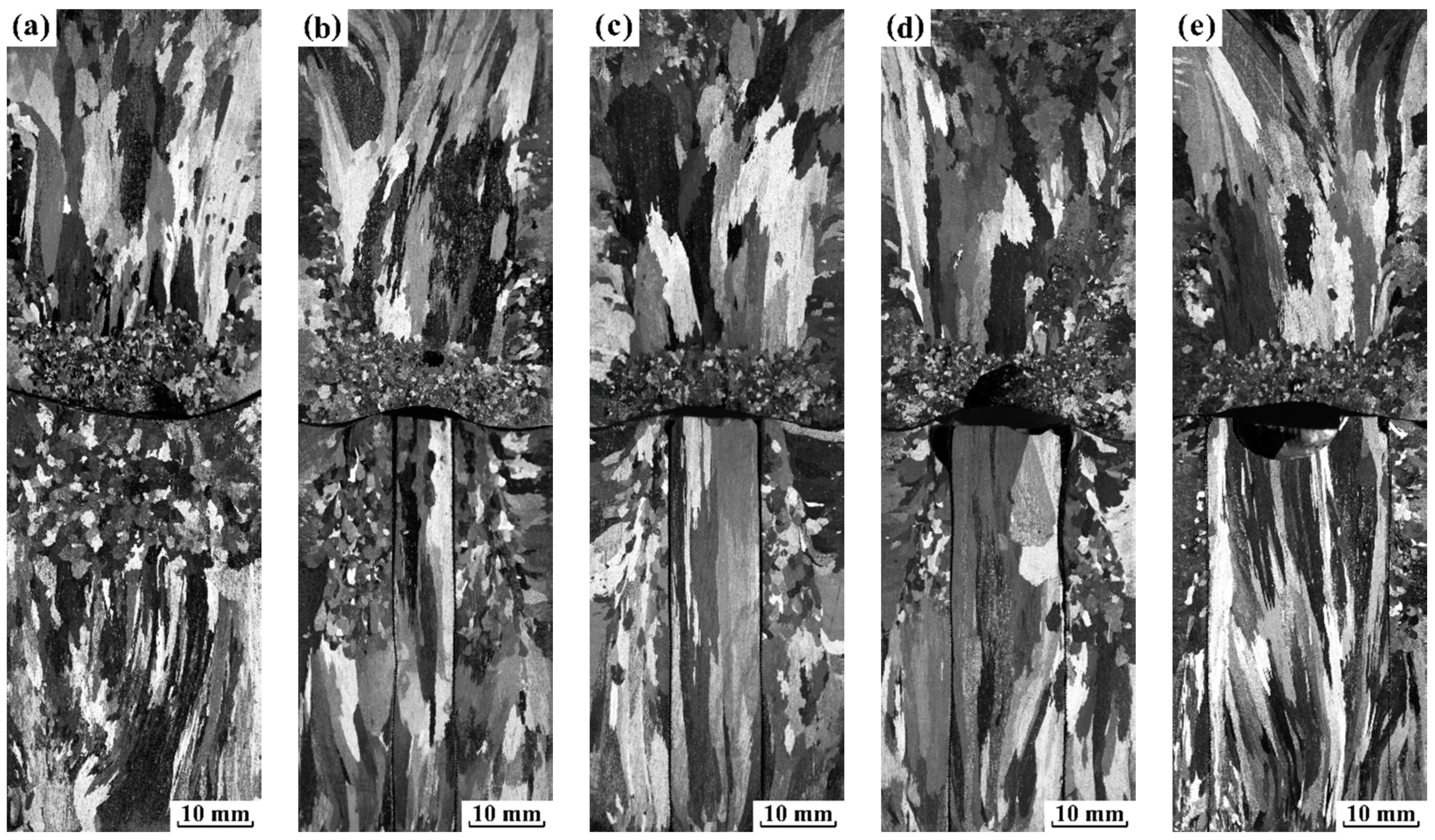

3.3.1. Macrostructure in Sand Mold Embedding the Mesh Tube under Electropulsing

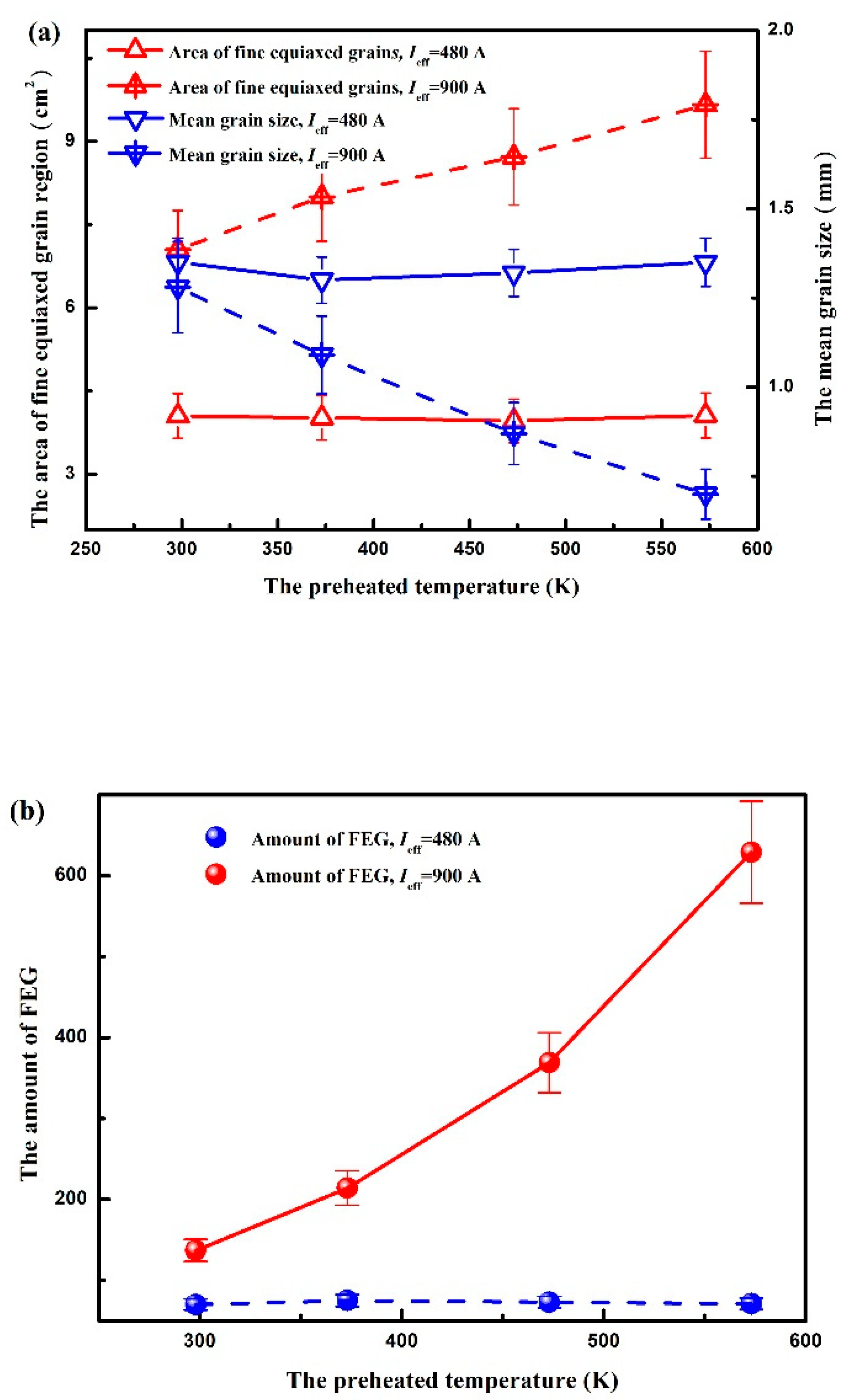

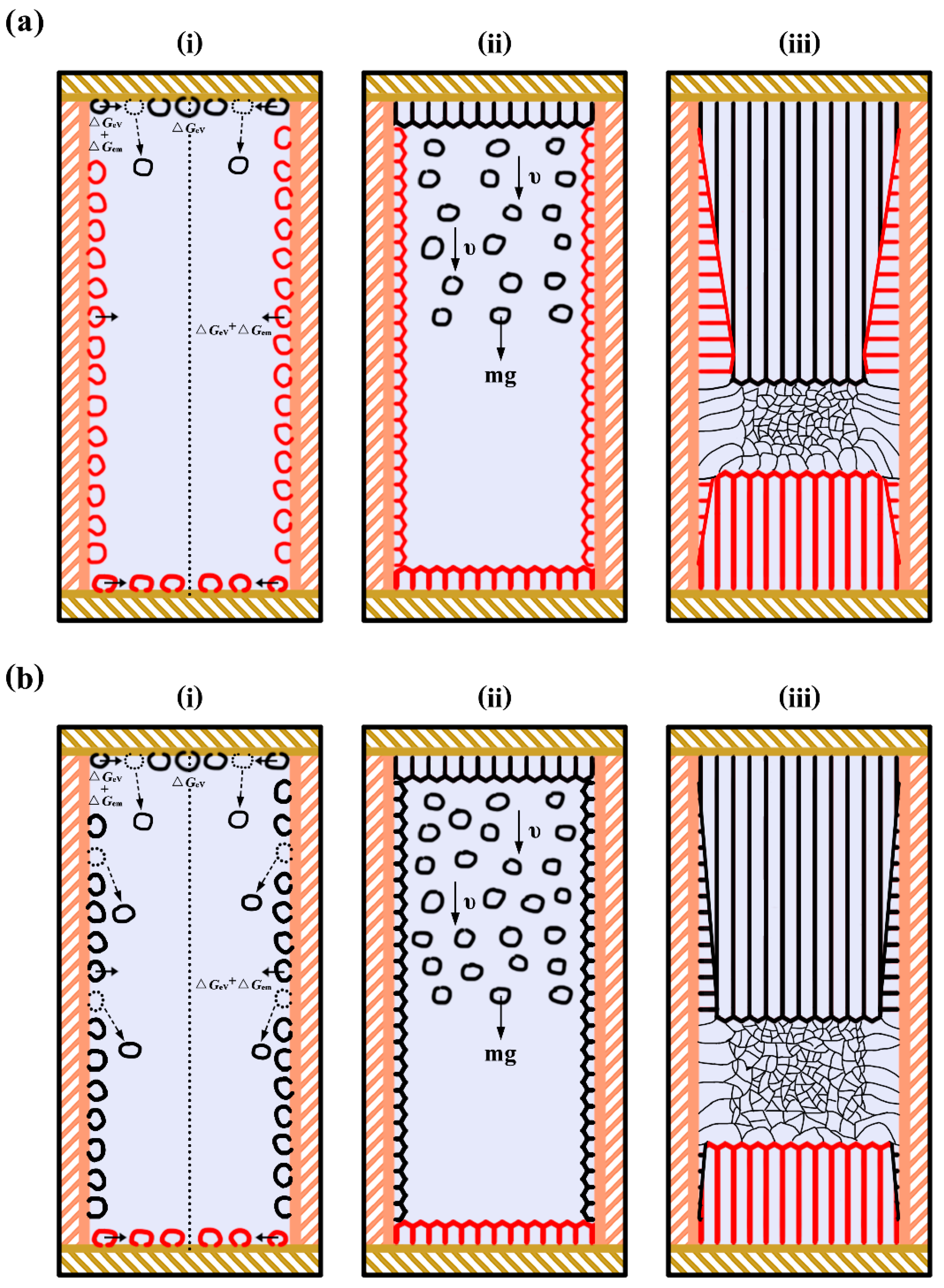

3.3.2. Formation of FEG

- (1)

- The amount of FEG remains almost unchanged as the preheated temperature of mold increased. It confirmed that the dissociation of heterogeneous nuclei formed on the side wall did not occur under electropulsing with 480 A (Figure 3).

- (2)

- A partial FEG result from the dissociation of heterogeneous nuclei formed on the lateral wall when electropulsing with 900 A was applied (Figure 4).

- (3)

- The obvious melt flow did not occur under electropulsing with 480 A. However, the application of electropulsing with 900 A could lead to a laminar melt flow spanning the entire melt volume (Figure 6).

- (4)

- Since the forced melt flow was not taken into account under electropulsing with 480 A, the formation of FEG was attributed to the dissociation of heterogeneous nuclei on the upper interface driven by ΔGem.

- (5)

- The origin of FEG consisted of the dissociation of heterogeneous nuclei on the side wall and the upper interface due to ΔGem and the forced melt flow under electropulsing with 900 A.

3.3.3. The Solidification Macrostructure under Different Conditions

4. Conclusions

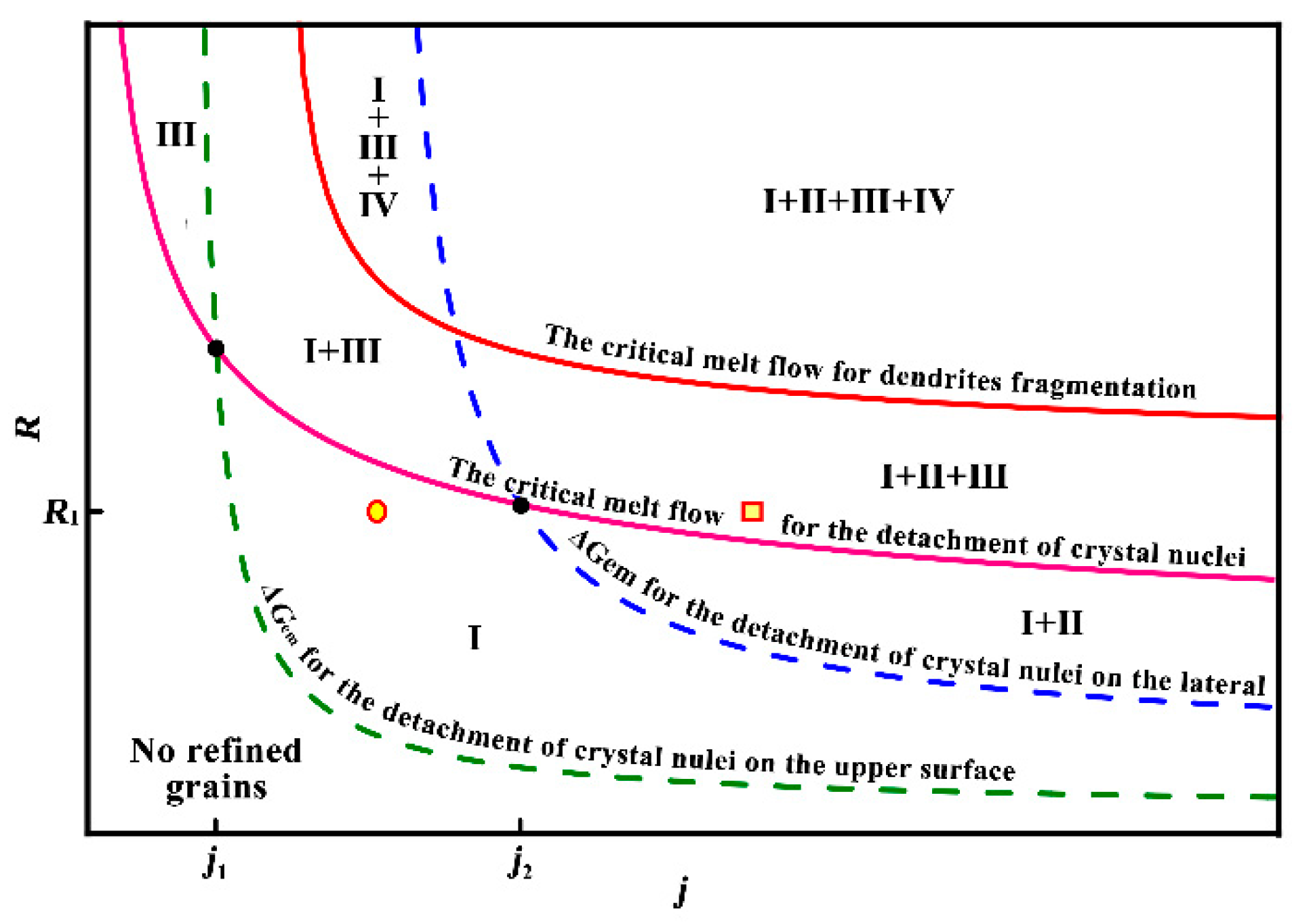

- (1)

- During solidification in the present casting, crystal nuclei firstly generated at the upper interface of the electrodes and the melt and the side wall. The driven force ΔGem was the first to have an effect on grain refinement due to the dissociation of crystal nuclei on the upper interface if j > j1, which ΔGem or the forced convection had a priority to the dissociation of crystal nuclei at the side wall depended on j2 in Figure 12.

- (2)

- There was also a critical value for the forced melt flow, above which the dissociation of crystal nuclei at the upper interface of the electrodes and the melt and the side wall was induced and developed into FEG. With the increase of the forced melt flow, dendrites fragmentation during crystal growth occurred and became a significant factor for grain refinement.

- (3)

- Current density and the size of mold were two main parameters for grain refinement under electropulsing, which determined ΔGem and the forced convection, affected the origin of FEG.

Author Contributions

Funding

Conflicts of Interest

References

- Nakada, M.; Shiohara, Y.; Flemings, M.C. Modification of solidification structures by pulse electric discharging. ISIJ Int. 1990, 30, 27–33. [Google Scholar] [CrossRef]

- Liao, X.; Zhai, Q.; Luo, J.; Chen, W.; Gong, Y. Refining mechanism of the electric current pulse on the solidification structure of pure aluminum. Acta Mater. 2007, 55, 3103–3109. [Google Scholar] [CrossRef]

- Räbiger, D.; Zhang, Y.; Galindo, V.; Franke, S.; Willers, B.; Eckert, S. The relevance of melt convection to grain refinement in Al-Si alloys solidified under the impact of electric currents. Acta Mater. 2014, 79, 327–338. [Google Scholar] [CrossRef]

- Li, N.; Zhang, L.; Zhang, R.; Yin, P.; Xing, H.; Wu, H. Research on grain refinement in hypoeutectic Al-Si alloy during solidification under an alternating electric current pulse. Metals 2019, 9, 571. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Räbiger, D.; Eckert, S. Solidification of pure aluminium affected by a pulsed electrical field and electromagnetic stirring. J. Mater. Sci. 2016, 51, 2153–2159. [Google Scholar] [CrossRef]

- Wang, T.; Zhu, J.; Kang, H.; Chen, Z.; Fu, Y.; Huang, W.; Xiao, T. In situ synchrotron X-ray imaging on morphological evolution of dendrites in Sn-Bi hypoeutectic alloy under electric currents. Appl. Phys. A Mater. 2014, 117, 1059–1066. [Google Scholar] [CrossRef]

- Zhang, L.M.; Li, N.; Zhang, R.; Xing, H.; Song, K.; Wang, J.Y. Effect of medium-density direct current on dendrites of directionally solidified Pb-50Sn alloy. Mater. Sci. Technol. 2016, 32, 1877–1885. [Google Scholar] [CrossRef]

- Atamanenko, T.V.; Eskin, D.G.; Zhang, L.; Katgerman, L. Criteria of grain refinement induced by ultrasonic melt treatment of aluminum alloys containing Zr and Ti. Met. Mater. Trans. A 2010, 41, 2056–2066. [Google Scholar] [CrossRef]

- Zhai, W.; Hong, Z.Y.; Wen, X.L.; Geng, D.L.; Wei, B. Microstructural characteristics and mechanical properties of peritectic Cu-Sn alloy solidified within ultrasonic field. Mater. Des. 2015, 72, 43–50. [Google Scholar] [CrossRef]

- Zheng, D.; Chen, R.; Ma, T.; Ding, H.; Su, Y.; Guo, J.; Fu, H. Coupling effects of melt treatment and ultrasonic treatment on solidifying microstructure and mechanical performance of Ti44Al6Nb1Cr alloy. Met. Mater. Trans. A 2017, 49, 537–549. [Google Scholar]

- Wang, F.; Eskin, D.; Mi, J.; Connolley, T.; Lindsay, J.; Mounib, M. A refining mechanism of primary Al 3 Ti intermetallic particles by ultrasonic treatment in the liquid state. Acta Mater. 2016, 116, 354–363. [Google Scholar] [CrossRef]

- Matsuda, K.; Takehara, T.; Yang, M.; Uno, H.; Kubo, T.; Miyano, G.; Yoshida, M. Verification of the mechanism of grain refinement by ultrasonic treatment of aluminum-4 wt pct silicon molten alloy. Met. Mater. Trans. A 2016, 47, 2509–2516. [Google Scholar] [CrossRef]

- Li, M.; Tamura, T.; Miwa, K. Controlling microstructures of AZ31 magnesium alloys by an electromagnetic vibration technique during solidification: From experimental observation to theoretical understanding. Acta Mater. 2007, 55, 4635–4643. [Google Scholar] [CrossRef]

- Campanella, T.; Charbon, C.; Rappaz, M. Grain refinement induced by electromagnetic stirring: A dendrite fragmentation criterion. Met. Mater. Trans. A 2004, 35, 3201–3210. [Google Scholar] [CrossRef]

- Liu, H.; Xuan, W.; Xie, X.; Li, C.; Wang, J.; Yu, J.; Li, X.; Zhong, Y.; Ren, Z. Columnar-to-equiaxed transition and equiaxed grain alignment in directionally solidified Ni3Al alloy under an axial magnetic field. Met. Mater. Trans. A 2017, 48, 4193–4203. [Google Scholar] [CrossRef]

- Wrobel, T. Structure of pure aluminum after endogenous and exogenous inoculation. Adv. Cryst. Process. 2012, 531–556. [Google Scholar] [CrossRef]

- Conrad, H. Influence of an electric or magnetic field on the liquid-solid transformation in materials and on the microstructure of the solid. Mater. Sci. Eng. A 2000, 287, 205–212. [Google Scholar] [CrossRef]

- Jianming, L.; Shengli, L.; Jin, L.; Hantong, L. Modification of solidification structure by pulse electric discharging. Scr. Met. Mater. 1994, 31, 1691–1694. [Google Scholar] [CrossRef]

- Li, J.; Ma, J.; Gao, Y.; Zhai, Q. Research on solidification structure refinement of pure aluminum by electric current pulse with parallel electrodes. Mater. Sci. Eng. A 2008, 490, 452–456. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, H.; Li, N.; Wang, J.; Zhang, R.; Xing, H.; Song, K. The relevance of forced melt flow to grain refinement in pure aluminum under a low-frequency alternating current pulse. J. Mater. Res. 2016, 31, 396–404. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Xu, Y.Y.; Ye, C.Y.; Sheng, C.; Sun, J.; Wang, G.; Miao, X.C.; Song, C.J.; Zhai, Q.J. Relevance of electrical current distribution to the forced flow and grain refinement in solidified Al-Si hypoeutectic alloy. Sci. Rep. UK 2018, 8, 3242. [Google Scholar] [CrossRef] [PubMed]

- Liotti, E.; Lui, A.; Vincent, R.; Kumar, S.; Guo, Z.; Connolley, T.; Dolbnya, I.P.; Hart, M.; Arnberg, L.; Mathiesen, R.H.; et al. A synchrotron X-ray radiography study of dendrite fragmentation induced by a pulsed electromagnetic field in an Al-15Cu alloy. Acta Mater. 2014, 70, 228–239. [Google Scholar] [CrossRef]

- Jiang, H.; He, J.; Zhao, J. Influence of electric current pulses on the solidification of Cu-Bi-Sn immiscible alloys. Sci. Rep. UK 2015, 5, 12680. [Google Scholar]

- Wang, X.L.; Guo, J.D.; Wang, Y.M.; Wu, X.Y.; Wang, B.Q. Segregation of lead in Cu-Zn alloy under electric current pulses. Appl. Phys. Lett. 2006, 89, 061910. [Google Scholar] [CrossRef]

- Qin, R.S.; Samuel, E.I.; Bhowmik, A. Electropulse-induced cementite nanoparticle formation in deformed pearlitic steels. J. Mater. Sci. 2011, 46, 2838–2842. [Google Scholar] [CrossRef]

- Zhang, X.F.; Qin, R.S. Segregation of copper in An Fe-Cu alloy under pulsed electric current. Phil. Mag. Lett. 2015, 95, 367–375. [Google Scholar] [CrossRef]

- Rahnama, A.; Qin, R.S. Electropulse-induced microstructural evolution in a ferritic-pearlitic 0.14% C steel. Scr. Mater. 2015, 96, 17–20. [Google Scholar] [CrossRef]

- Zhang, X.; Qin, R. Electric current-driven migration of electrically neutral particles in liquids. Appl. Phys. Lett. 2014, 104, 114106. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, R.; Chen, W.; Wu, Y.; Li, N. Effect of a novel low-voltage alternating current pulse on solidification structure of Al-7Si-0.52Mg alloy. Adv. Mater. Res. 2012, 482–484, 1431–1435. [Google Scholar] [CrossRef]

- Du, F.; Zhang, P.; Xu, Z.; Zhao, L. Law of heat transfer and simulation of temperature field for aluminum ingot solidification. Chin. J. Nonferrous Met. 2007, 17, 1750–1754. [Google Scholar]

- Xu, H.; Hou, H.; Zhao, Y.; Chen, Z. Determination of boundary heat-transfer coefficient for casting solidification simulation. Chin. J. Nonferrous Met. 2003, 13, 881–886. [Google Scholar]

- Nikrityuk, P.A.; Eckert, K.; Grundmann, R.; Yang, Y.S. An impact of a low voltage steady electrical current on the solidification of a binary metal alloy: A numerical study. Steel Res. Int. 2007, 78, 402–408. [Google Scholar] [CrossRef]

- Zhang, Y.; Miao, X.; Shen, Z.; Han, Q.; Song, C.; Zhai, Q. Macro segregation formation mechanism of the primary silicon phase in directionally solidified Al-Si hypereutectic alloys under the impact of electric currents. Acta Mater. 2015, 97, 357–366. [Google Scholar] [CrossRef]

- Bojarevičs, V.; Freibergs, J.A.; Shilova, E.I.; Shcherbinin, E.V. Electrically Induced Vortical Flows; Kluwer Academic Piblishers: Dordrecht, The Netherlands, 1989. [Google Scholar]

- Millere, R.P.; Sharamkin, V.I.; Shcherbinin, E.V. Effect of a longitudinal magnetic field on electrically driven rotational flow in a cylindrical vessel. Magnetohydrodynamics 1980, 16, 66–69. [Google Scholar]

- Willers, B.; Eckert, S.; Michel, U.; Haase, I.; Zouhar, G. The columnar-to-equiaxed transition in Pb-Sn alloys affected by electromagnetically driven convection. Mater. Sci. Eng. A 2005, 402, 55–65. [Google Scholar] [CrossRef]

- Dolinsky, Y.; Elperin, T. Thermodynamics of phase transitions in current-carrying conductors. Phys. Rev. B 1993, 47, 14778–14785. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.F.; Lu, W.J.; Qin, R.S. Removal of MnS inclusions in molten steel using electropulsing. Scr. Mater. 2013, 69, 453–456. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.L.; Wang, Y.B.; Wang, Y.M.; Wang, B.Q.; Guo, J.D. Oriented nanotwins induced by electric current pulses in Cu-Zn alloy. Appl. Phys. Lett. 2007, 91, 163112. [Google Scholar] [CrossRef]

- Leenov, D.; Kolin, A. Theory of electromagnetophoresis. I. Magnetohydrodynamic forces experienced by spherical and symmetrically oriented cylindrical particles. J. Chem. Phys. 1954, 22, 683–688. [Google Scholar] [CrossRef]

- Gong, Y.; Luo, J.; Jing, J.; Xia, Z.; Zhai, Q. Structure refinement of pure aluminum by pulse magneto-oscillation. Mater. Sci. Eng. A 2008, 497, 147–152. [Google Scholar] [CrossRef]

- Sun, M.; Geng, H.; Bian, X.; Liu, Y. Abnormal changes in aluminum viscosity and its relationship with the microstructure of melts. Acta Met. Sin. 2000, 36, 1134–1138. [Google Scholar]

- Sklyarchuk, V.; Plevachuk, Y.; Yakymovych, A.; Eckert, S.; Gerbeth, G.; Eigenfeld, K. Structure sensitive properties of liquid Al-Si alloys. Int. J. Thermophys. 2009, 30, 1400–1410. [Google Scholar] [CrossRef]

- Hunt, J.D. Steady state columnar and equiaxed growth of dendrites and eutectic. Mater. Sci. Eng. 1984, 65, 75–83. [Google Scholar] [CrossRef]

- Martorano, M.A.; Beckermann, C.; Gandin, C.A. A solutal interaction mechanism for the columnar-to-equiaxed transition in alloy solidification. Met. Mater. Trans. A 2003, 34, 1657–1674. [Google Scholar] [CrossRef]

- Brandt, R.; Neuer, G. Electrical resistivity and thermal conductivity of pure aluminum and aluminum alloys up to and above the melting temperature. Int. J. Thermophys. 2007, 28, 1429–1446. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, N.; Zhang, L.; Zhang, R.; Yin, P.; Wu, H.; Song, K.; Xing, H. The Role of Electric Current-Associated Free Energy and Forced Convection on Grain Refinement in Pure Aluminum under Electropulsing. Materials 2019, 12, 3846. https://doi.org/10.3390/ma12233846

Li N, Zhang L, Zhang R, Yin P, Wu H, Song K, Xing H. The Role of Electric Current-Associated Free Energy and Forced Convection on Grain Refinement in Pure Aluminum under Electropulsing. Materials. 2019; 12(23):3846. https://doi.org/10.3390/ma12233846

Chicago/Turabian StyleLi, Ning, Limin Zhang, Rong Zhang, Pengfei Yin, Hongjing Wu, Kaikai Song, and Hui Xing. 2019. "The Role of Electric Current-Associated Free Energy and Forced Convection on Grain Refinement in Pure Aluminum under Electropulsing" Materials 12, no. 23: 3846. https://doi.org/10.3390/ma12233846

APA StyleLi, N., Zhang, L., Zhang, R., Yin, P., Wu, H., Song, K., & Xing, H. (2019). The Role of Electric Current-Associated Free Energy and Forced Convection on Grain Refinement in Pure Aluminum under Electropulsing. Materials, 12(23), 3846. https://doi.org/10.3390/ma12233846