Maize Straw as a Valuable Energetic Material for Biogas Plant Feeding

Abstract

1. Introduction

1.1. Direct Combustion of Maize Straw

1.2. Bioethanol Production

1.3. Economic and Energy Production Potential

1.4. Biogas Production

2. Materials and Methods

2.1. Physical Analysis

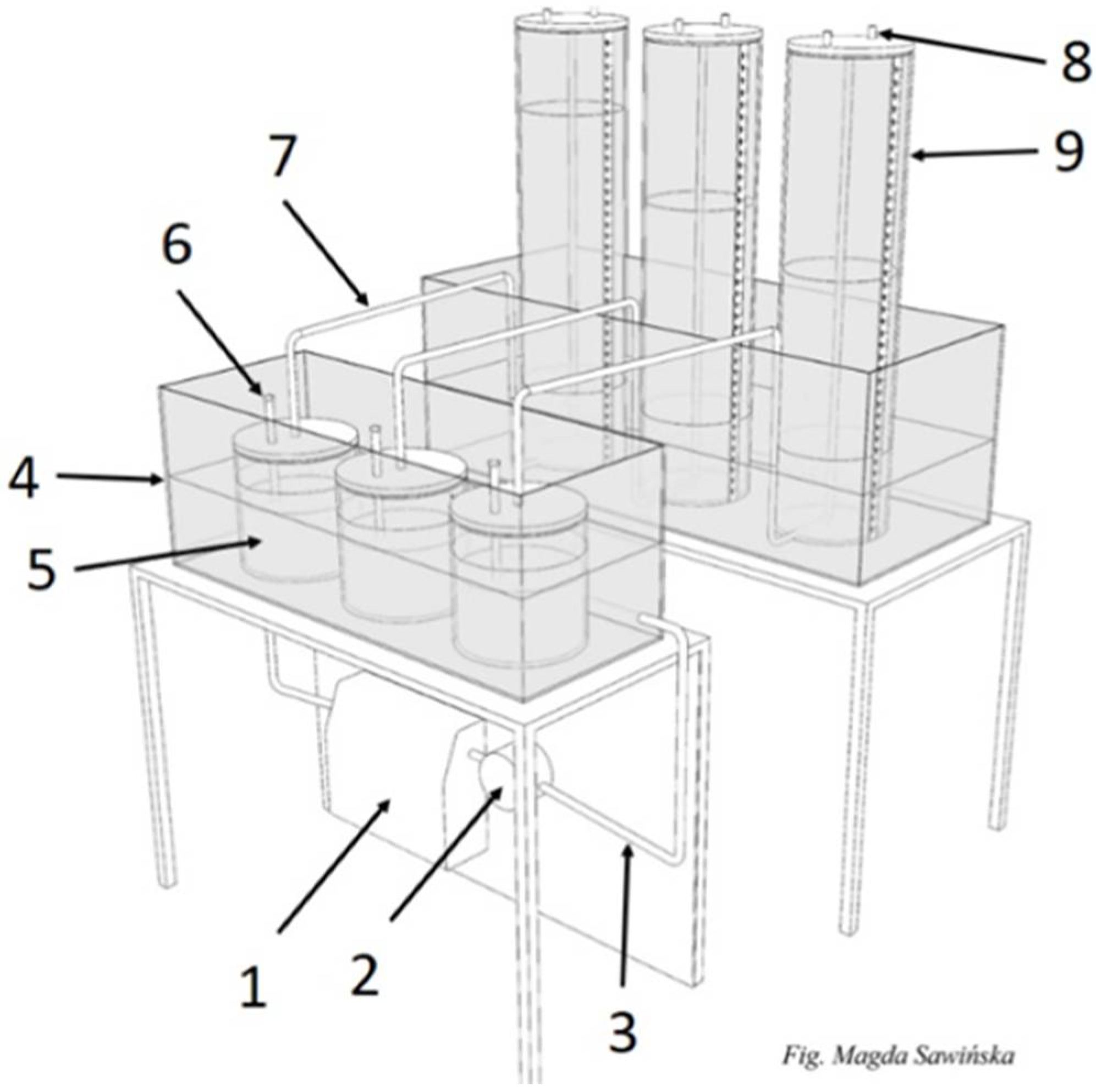

2.2. Methane Fermentation Tests

3. Results

3.1. Physical Analysis

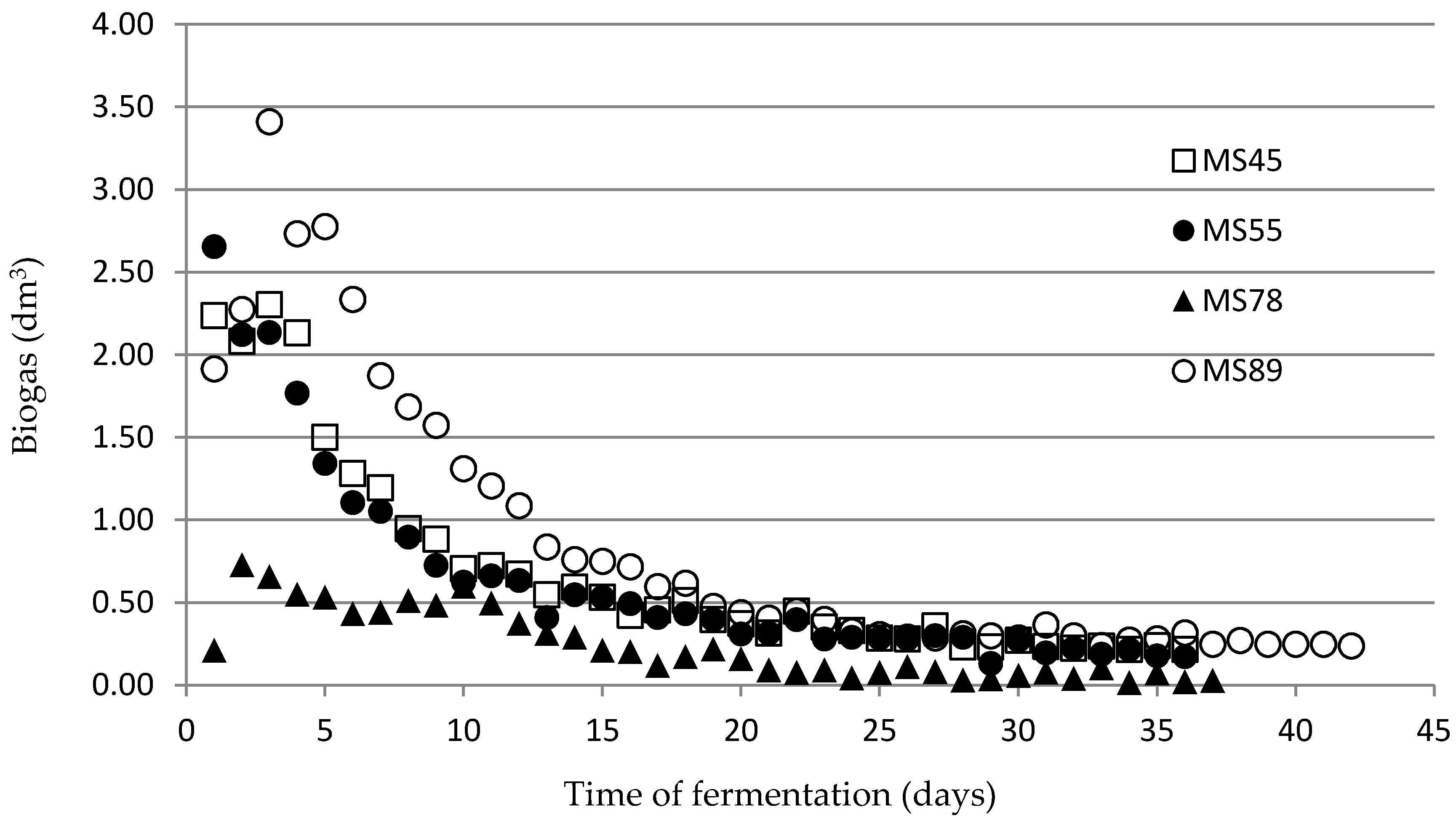

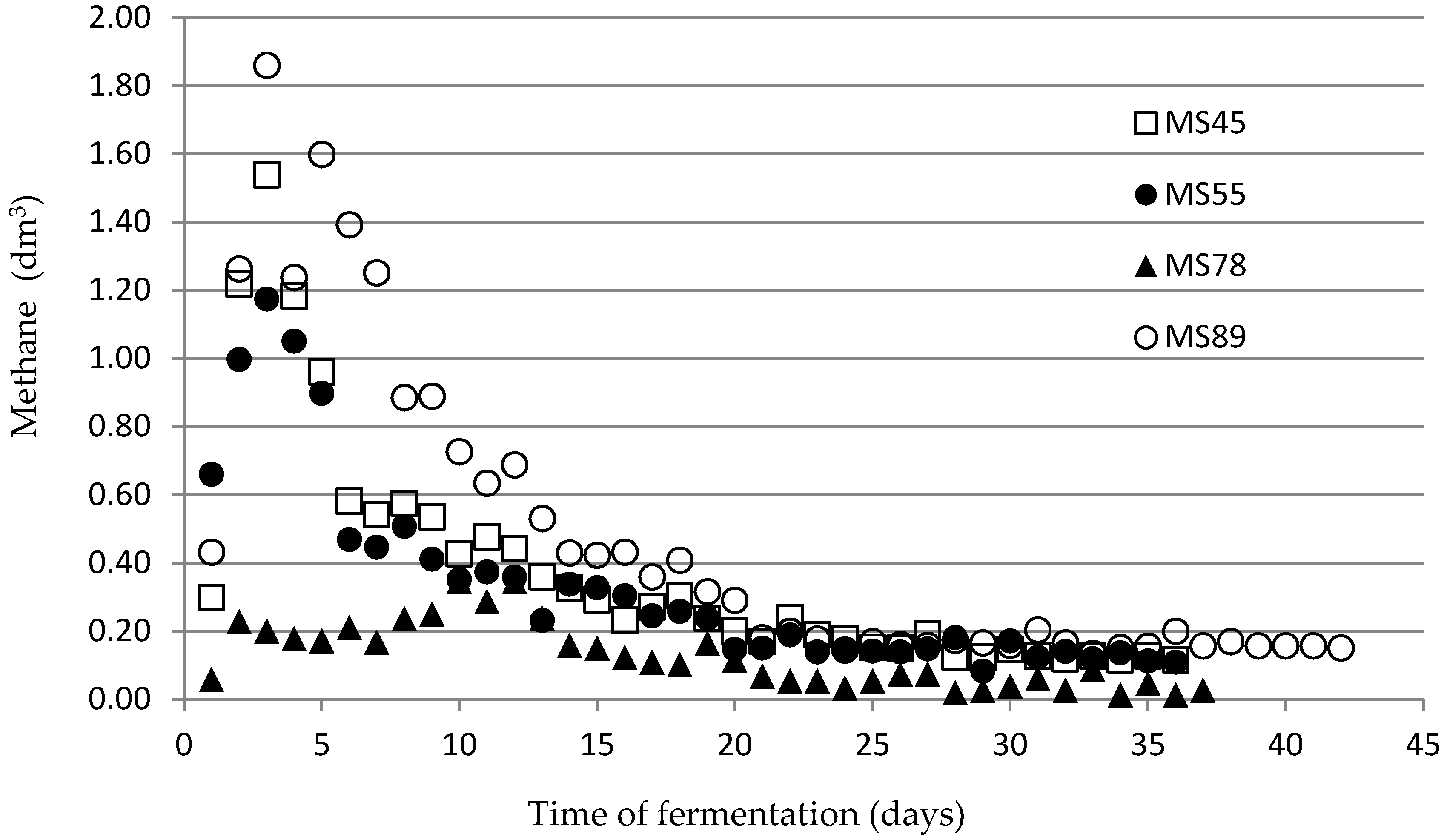

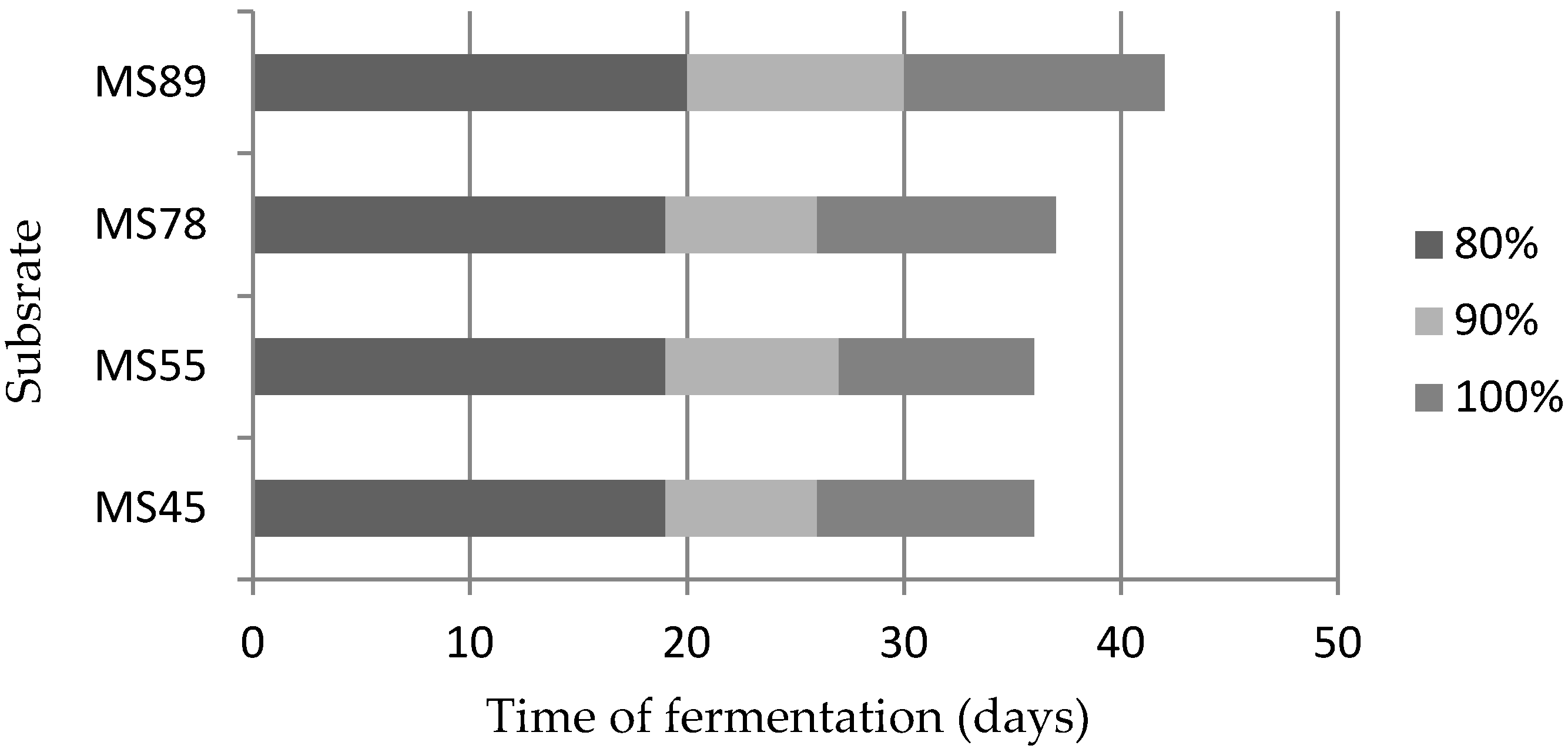

3.2. Fermentation Results

4. Discussion

5. Conclusions

- Maize straw harvested in Central-Eastern Europe can have a broad spectrum of dry mass content, which is related to diverse weather conditions during autumn.

- Independently from moisture content, maize straw can be good (for more wet material) or very good (for more dried straw) substrate for the biogas plant. With the methane productivity reaching 201–207 m3/Mg of fresh mass, this material is significantly better substrate than that typically used in Europe maize silage (approximately 105 m3/Mg FM).

- The retention time for maize straw (36–42 days) is longer than for maize silage (less than 30 days). However, this difference is quite small and can be accommodated by the biogas plant operators.

Author Contributions

Funding

Conflicts of Interest

References

- Dach, J. (Professor at Poznan University of Life Sciences, Poznań, Poland). Personal communication, June 2019.

- Johnson, J.; Reicosky, D.; Sharratt, B.; Lindstrom, M.; Voorhees, W. Corn Stover as a Biofuel. Available online: https://www.researchgate.net/publication/252816491_Corn_stover_as_a_biofuel (accessed on 26 August 2019).

- Richard, T.L. Challenges in Scaling Up Biofuels Infrastructure. Science 2010, 329, 793–796. [Google Scholar] [CrossRef] [PubMed]

- Grain Production Worldwide by Type, 2018/19|Statista. Available online: https://www.statista.com/statistics/263977/world-grain-production-by-type/ (accessed on 26 August 2019).

- Agricultural Production—Crops—Statistics Explained. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php/Agricultural_production_-_crops (accessed on 26 August 2019).

- Wandera, S.M.; Qiao, W.; Algapani, D.E.; Bi, S.; Yin, D.; Qi, X.; Liu, Y.; Dach, J.; Dong, R. Searching for possibilities to improve the performance of full scale agricultural biogas plants. Renew. Energy 2018, 116, 720–727. [Google Scholar] [CrossRef]

- Sun, H.; Cui, X.; Stinner, W.; Mustafa Shah, G.; Cheng, H.; Shan, S.; Guo, J.; Dong, R. Synergetic effect of combined ensiling of freshly harvested and excessively wilted maize stover for efficient biogas production. Bioresour. Technol. 2019, 285, 121338. [Google Scholar] [CrossRef] [PubMed]

- Czajkowski, Ł.; Wojcieszak, D.; Olek, W.; Przybył, J. Thermal properties of fractions of corn stover. Constr. Build. Mater. 2019, 210, 709–712. [Google Scholar] [CrossRef]

- Morissette, R.; Savoie, P.; Villeneuve, J. Combustion of Corn Stover Bales in a Small 146-kW Boiler. Energies 2011, 4, 1102–1111. [Google Scholar] [CrossRef]

- Barten, T.J. Evaluation and Prediction of Corn Stover Biomass and Composition from Commercially Available Corn Hybrids. Ph.D. Thesis, Iowa State University, Ames, IA, USA, 2013. [Google Scholar]

- Wang, J.S.; Steinberger, Y.; Wang, X.Y.; Hu, L.; Chen, X.; Xie, G.H. Variations of Chemical Composition in Corn Stover Used for Biorefining. Available online: https://www.ingentaconnect.com/content/asp/jbmb/2014/00000008/00000006/art00010 (accessed on 26 August 2019).

- Berchem, T.; Roiseux, O.; Vanderghem, C.; Boisdenghien, A.; Foucart, G.; Richel, A. Corn stover as feedstock for the production of ethanol: Chemical composition of different anatomical fractions and varieties. Biofuels Bioprod. Biorefin. 2017, 11, 430–440. [Google Scholar] [CrossRef]

- Garlock, R.J.; Chundawat, S.P.; Balan, V.; Dale, B.E. Optimizing harvest of corn stover fractions based on overall sugar yields following ammonia fiber expansion pretreatment and enzymatic hydrolysis. Biotechnol. Biofuels 2009, 2, 29. [Google Scholar] [CrossRef]

- Dupont, C.; Chiriac, R.; Gauthier, G.; Toche, F. Heat capacity measurements of various biomass types and pyrolysis residues. Fuel 2014, 115, 644–651. [Google Scholar] [CrossRef]

- Wojcieszak, D.; Przybył, J.; Dach, J.; Zaborowicz, M.; Staszak, Ż. Economic Assessment of the Technology Harvesting Maize Straw for Biogas Production. BIO Web Conf. 2018, 10, 01017. [Google Scholar] [CrossRef][Green Version]

- Pordesimo, L.O.; Hames, B.R.; Sokhansanj, S.; Edens, W.C. Variation in corn stover composition and energy content with crop maturity. Biomass Bioenergy 2005, 28, 366–374. [Google Scholar] [CrossRef]

- Kowalczyk-Juśko, A.; Kowalczuk, J.; Szmigielski, M.; Marczuk, A.; Jóźwiakowski, K.; Zarajczyk, K.; Masłowski, A.; Ślaska-Grzywna, B.; Sagan, A.; Zarajczyk, J. Quality of biomass pellets used as fuel or raw material for syngas production. Przemysl Chem. 2015, 94, 1835–1837. [Google Scholar] [CrossRef]

- Wiśniewski, D.; Piechocki, J.; Białowiec, A.; Pulka, J.; Siudak, M.; Jakubowski, B.; Myślak, B. Operational studies of prototype biomass gasification reactor. Rocz. Ochr. Srodowiska 2015, 17, 1094–1112. [Google Scholar]

- Kowalczyk-Juśko, A.; Kościk, B.; Jóźwiakowski, K.; Marczuk, A.; Zarajczyk, J.; Kowalczuk, J.; Szmigielski, M.; Sagan, A. Effects of biochemical and thermochemical conversion of sorghum biomass to usable energy. Przemysl Chem. 2015, 94, 1000–1002. [Google Scholar] [CrossRef]

- Wilhelm, W.W.; Johnson, J.M.F.; Karlen, D.L.; Lightle, D.T. Corn Stover to Sustain Soil Organic Carbon Further Constrains Biomass Supply. Agron. J. 2007, 99, 1665–1667. [Google Scholar] [CrossRef]

- Das, S.; Peterson, B.; Chin, S.-M. Analysis of Fuel Ethanol Transportation Activity and Potential Distribution Constraints. Transp. Res. Rec. 2010, 2168, 136–145. [Google Scholar] [CrossRef]

- Morales, M.; Quintero, J.; Conejeros, R.; Aroca, G. Life cycle assessment of lignocellulosic bioethanol: Environmental impacts and energy balance. Renew. Sustain. Energy Rev. 2015, 42, 1349–1361. [Google Scholar] [CrossRef]

- Zabed, H.; Sahu, J.N.; Boyce, A.N.; Faruq, G. Fuel ethanol production from lignocellulosic biomass: An overview on feedstocks and technological approaches. Renew. Sustain. Energy Rev. 2016, 66, 751–774. [Google Scholar] [CrossRef]

- Zhao, Y.; Damgaard, A.; Christensen, T.H. Bioethanol from corn stover—A review and technical assessment of alternative biotechnologies. Prog. Energy Combust. Sci. 2018, 67, 275–291. [Google Scholar] [CrossRef]

- Zhao, Y.; Damgaard, A.; Xu, Y.; Liu, S.; Christensen, T.H. Bioethanol from corn stover—Global warming footprint of alternative biotechnologies. Appl. Energy 2019, 247, 237–253. [Google Scholar] [CrossRef]

- Kim, S.; Zhang, X.; Dale, B.E.; Reddy, A.D.; Jones, C.D.; Izaurralde, R.C. EISA (Energy Independence and Security Act) compliant ethanol fuel from corn stover in a depot-based decentralized system. Biofuels Bioprod. Biorefin. 2018, 12, 873–881. [Google Scholar] [CrossRef]

- Jazmín Edith, M.-H.; Octavio, L.; Edna Madai, M.-H.; Esperanza, H.; Nicolás Óscar, S.-C. Coupling energy-production processes: The use of residues from bioethanol production to improve the anaerobic digestion of corn stover. Biomass Bioenergy 2019, 128, 105322. [Google Scholar] [CrossRef]

- De Wit, M.; Faaij, A. European biomass resource potential and costs. Biomass Bioenergy 2010, 34, 188–202. [Google Scholar] [CrossRef]

- Xing, X.; Fan, F.; Jiang, W. Characteristics of biochar pellets from corn straw under different pyrolysis temperatures. R. Soc. Open Sci. 2018, 5, 172346. [Google Scholar] [CrossRef] [PubMed]

- Yin, W.; Guo, Y.; Hu, F.; Fan, Z.; Feng, F.; Zhao, C.; Yu, A.; Chai, Q. Wheat-Maize Intercropping with Reduced Tillage and Straw Retention: A Step Towards Enhancing Economic and Environmental Benefits in Arid Areas. Front. Plant Sci. 2018, 9. [Google Scholar] [CrossRef] [PubMed]

- Urbanovičová, O.; Angelovič, M.; Križan, M.; Krištof, K.; Jobbágy, J. Energy potential of densified biomass from maize straw in form of pellets and briquettes. Agron. Res. 2018, 16, 474–482. [Google Scholar] [CrossRef]

- Zbytek, Z.; Dach, J.; Pawłowski, T.; Smurzyńska, A.; Czekała, W.; Janczak, D. Energy and economic potential of maize straw used for biofuels production. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2016; Volume 60. [Google Scholar] [CrossRef]

- Straw Burning Plants Contributing to “Severe Straw Shortages”. Available online: http://www.npa-uk.org.uk/Straw_burning_plants_contributing_to_severe_straw_shortages.html (accessed on 31 October 2019).

- Wojcieszak, D.; Przybył, J.; Mazurkiewicz, J.; Janczak, D.; Zaborowicz, M. Increasing the energy value of corn stover used in biogas plant without pre-processing. In Proceedings of the 18th International Multidisciplinary Scientific GeoConference SGEM2018, Sofia, Bulgaria, 3–6 December 2018; Volume 18, pp. 495–502. [Google Scholar] [CrossRef]

- Haseli, Y. Simplified model of torrefaction-grinding process integrated with a power plant. Fuel Process. Technol. 2019, 188, 118–128. [Google Scholar] [CrossRef]

- Womac, A.R.; Igathinathane, C.; Sokhansanj, S.; Pordesimo, L.O. Biomass moisture relations of an agricultural field residue: Corn stover. Trans. Am. Soc. Agric. Eng. 2005, 48, 2073–2083. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Densification characteristics of corn stover and switchgrass. Trans. ASABE 2009, 52, 907–920. [Google Scholar] [CrossRef]

- Kujawa, S.; Nowakowski, K.; Tomczak, R.J.; Dach, J.; Boniecki, P.; Weres, J.; Mueller, W.; Raba, B.; Piechota, T.; Rodríguez Carmona, P.C. Neural image analysis for maturity classification of sewage sludge composted with maize straw. Comput. Electron. Agric. 2014, 109, 302–310. [Google Scholar] [CrossRef]

- Czekała, W.; Dach, J.; Janczak, D.; Smurzyńska, A.; Kwiatkowska, A.; Kozłowski, K. Influence of maize straw content with sewage sludge on composting process. J. Water Land Dev. 2016, 30, 43–49. [Google Scholar] [CrossRef]

- Dobek, T.; Šařec, P.; Kołosowski, P.; Šařec, O. Effect of chopped maize straw on the quantity and quality of biogas produced. Res. Agric. Eng. 2017, 63, S8–S12. [Google Scholar] [CrossRef]

- Smurzyska, A.; Dach, J.; Kozowski, K.; Mazurkiewicz, J.; Woniak, E.; Boniecki, P.; Kupryaniuk, K.; Janczak, D.; Brzoski, M. Relevant biogas substrate—Maize silage vs slaughterhouse waste. In Proceedings of the International Conference on Information and Communication Technologies in Agriculture, Food and Environment, Chania, Crete Island, Greece, 21–24 September 2017; Volume 2030, pp. 196–204. [Google Scholar]

- Christiansen, K.; Raman, D.R.; Hu, G.; Anex, R. First-order estimates of the costs, input-output energy analysis, and energy returns on investment of conventional and emerging biofuels feedstocks. Biofuel Res. J. 2018, 5, 894–899. [Google Scholar] [CrossRef]

- González-García, S.; Moreira, M.T.; Feijoo, G. Comparative environmental performance of lignocellulosic ethanol from different feedstocks. Renew. Sustain. Energy Rev. 2010, 14, 2077–2085. [Google Scholar] [CrossRef]

- Kim, S.; Dale, B.E. All biomass is local: The cost, volume produced, and global warming impact of cellulosic biofuels depend strongly on logistics and local conditions. Biofuels Bioprod. Biorefin. 2015, 9, 422–434. [Google Scholar] [CrossRef]

- Baral, N.R.; Quiroz-Arita, C.; Bradley, T.H. Uncertainties in corn stover feedstock supply logistics cost and life-cycle greenhouse gas emissions for butanol production. Appl. Energy 2017, 208, 1343–1356. [Google Scholar] [CrossRef]

- Yu, Q.; Liu, R.; Li, K.; Ma, R. A review of crop straw pretreatment methods for biogas production by anaerobic digestion in China. Renew. Sustain. Energy Rev. 2019, 107, 51–58. [Google Scholar] [CrossRef]

- Polish Standard PN-75 C-04616/01. Determination of Dry Matter of Sludge and Organic Substances. Water and Sewage. Special Sludge Tests. Determination of Water Content, Dry Matter, Organic Substances and Mineral Substances in Sewage Sludge; Polish Committee for Standardization: Warsaw, Poland, 1975. [Google Scholar]

- Polish Standard PN-Z-15011-3. Municipal Waste Compost—Determination of pH, Organic Matter Content, Organic Carbon, Nitrogen, Phosphorus and Potassium; Polish Committee for Standardization: Warsaw, Poland, 2001. [Google Scholar]

- Polish Standard PN-90 C-04540/01. Water and Waste Water—Tests for pH, Acidity and Alkalinity. Electrometric pH Determination of Water and Waste Water with Specific Conductivity 10 µS/cm and Higher; Polish Committee for Standardization: Warsaw, Poland, 1990. [Google Scholar]

- Polish Standard PN-EN 27888: 1999. Water Quality—Determination of Specific Electrical Conductivity; Polish Committee for Standardization: Warsaw, Poland, 1999. [Google Scholar]

- DIN 38 414/S8. German Standard Methods for the Examination of Water, Waste Water and Sludge; Sludge and Sediments (Group S); Determination of the Amenability to Anaerobic Digestion (S 8); DIN Deutches Institut für Normung e. V.: Berlin, Germany, 2012. [Google Scholar]

- VDI 4630. Fermentation of Organic Materials. Characterization of the Substrate, Sampling, Collection of Material Data, Fermentation Tests; Verein Deutscher Ingenieure e.V.: Düsseldorf, Germany, 2016. [Google Scholar]

- Cieślik, M.; Dach, J.; Lewicki, A.; Smurzyńska, A.; Janczak, D.; Pawlicka-Kaczorowska, J.; Boniecki, P.; Cyplik, P.; Czekała, W.; Jóźwiakowski, K. Methane fermentation of the maize straw silage under meso- and thermophilic conditions. Energy 2016, 115, 1495–1502. [Google Scholar] [CrossRef]

- Dach, J.; Jóźwiakowski, K.; Kowalczyk-Juśko, A.; Kozłowski, K.; Neugebauer, M. Biogas plant exploitation under the low-subsidies market conditions: Maize silage versus biowaste scenarios. In Proceedings of the 16th International Multidisciplinary Scientific GeoConference SGEM 2016, Sofia, Bulgaria, 2–5 November 2016. [Google Scholar]

- Janczak, D.; Kozłowski, K.; Zbytek, Z.; Cieślik, M.; Bugała, A.; Czekała, W. Energetic efficiency of the vegetable waste used as substrate for biogas production. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2016; Volume 64. [Google Scholar] [CrossRef]

- Kozłowski, K.; Dach, J.; Czekała, W.; Lewicki, A. Influence of Maize Silage Storage Conditions on Biogas Efficiency. Available online: https://www.researchgate.net/publication/308994841_Influence_of_maize_silage_storage_conditions_on_biogas_efficiency (accessed on 11 September 2019).

- Kozłowski, K.; Mazurkiewicz, J.; Chełkowski, D.; Jeżowska, A.; Cieślik, M.; Brzoski, M.; Smurzyńska, A.; Dongmin, Y.; Wei, Q. The effect of mixing during laboratory fermentation of maize straw with thermophilic technology. J. Ecol. Eng. 2018, 19, 93–98. [Google Scholar] [CrossRef]

- Przybył, J.; Wojcieszak, D.; Kowalik, I.; Dach, J. Influence of the Harvesting and Ensilage Technology on the Quality of Maize Straw Silage. BIO Web Conf. 2018, 10, 02027. [Google Scholar] [CrossRef]

| Substrate | TS (% FM) | VS (% TS) |

|---|---|---|

| MS45 | 44.77 | 97.59 |

| MS55 | 54.68 | 93.41 |

| MS78 | 77.80 | 89.78 |

| MS89 | 89.46 | 89.50 |

| Substrate | CH4 Content (%) | CH4 m3/Mg FM | Biogas m3/Mg FM | CH4 m3/Mg TS | Biogas m3/Mg TS | CH4 m3/Mg VS | Biogas m3/Mg VS |

|---|---|---|---|---|---|---|---|

| MS45 | 49.51 | 103.39 | 206.47 | 230.93 | 461.17 | 236.64 | 472.56 |

| MS55 | 48.97 | 98.95 | 199.94 | 180.96 | 366.09 | 193.73 | 391.45 |

| MS78 | 50.17 | 201.12 | 400.90 | 258.52 | 515.29 | 287.94 | 573.95 |

| MS89 | 50.26 | 206.78 | 411.43 | 231.14 | 459.90 | 258.26 | 513.86 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mazurkiewicz, J.; Marczuk, A.; Pochwatka, P.; Kujawa, S. Maize Straw as a Valuable Energetic Material for Biogas Plant Feeding. Materials 2019, 12, 3848. https://doi.org/10.3390/ma12233848

Mazurkiewicz J, Marczuk A, Pochwatka P, Kujawa S. Maize Straw as a Valuable Energetic Material for Biogas Plant Feeding. Materials. 2019; 12(23):3848. https://doi.org/10.3390/ma12233848

Chicago/Turabian StyleMazurkiewicz, Jakub, Andrzej Marczuk, Patrycja Pochwatka, and Sebastian Kujawa. 2019. "Maize Straw as a Valuable Energetic Material for Biogas Plant Feeding" Materials 12, no. 23: 3848. https://doi.org/10.3390/ma12233848

APA StyleMazurkiewicz, J., Marczuk, A., Pochwatka, P., & Kujawa, S. (2019). Maize Straw as a Valuable Energetic Material for Biogas Plant Feeding. Materials, 12(23), 3848. https://doi.org/10.3390/ma12233848