Performance Degradation of Large-Sized Asphalt Mixture Specimen under Heavy Load and Its Affecting Factors Using Multifunctional Pavement Material Tester

Abstract

1. Introduction

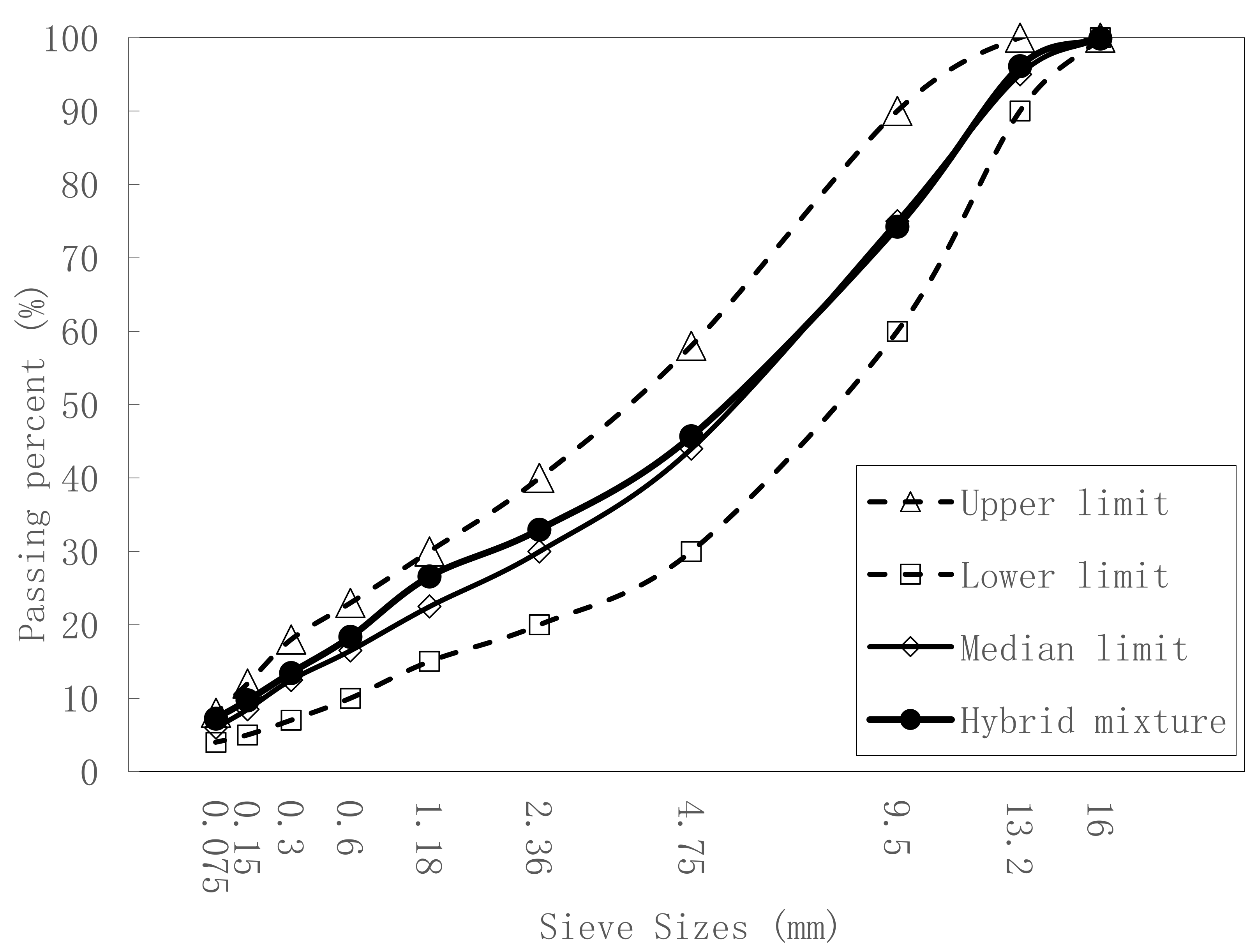

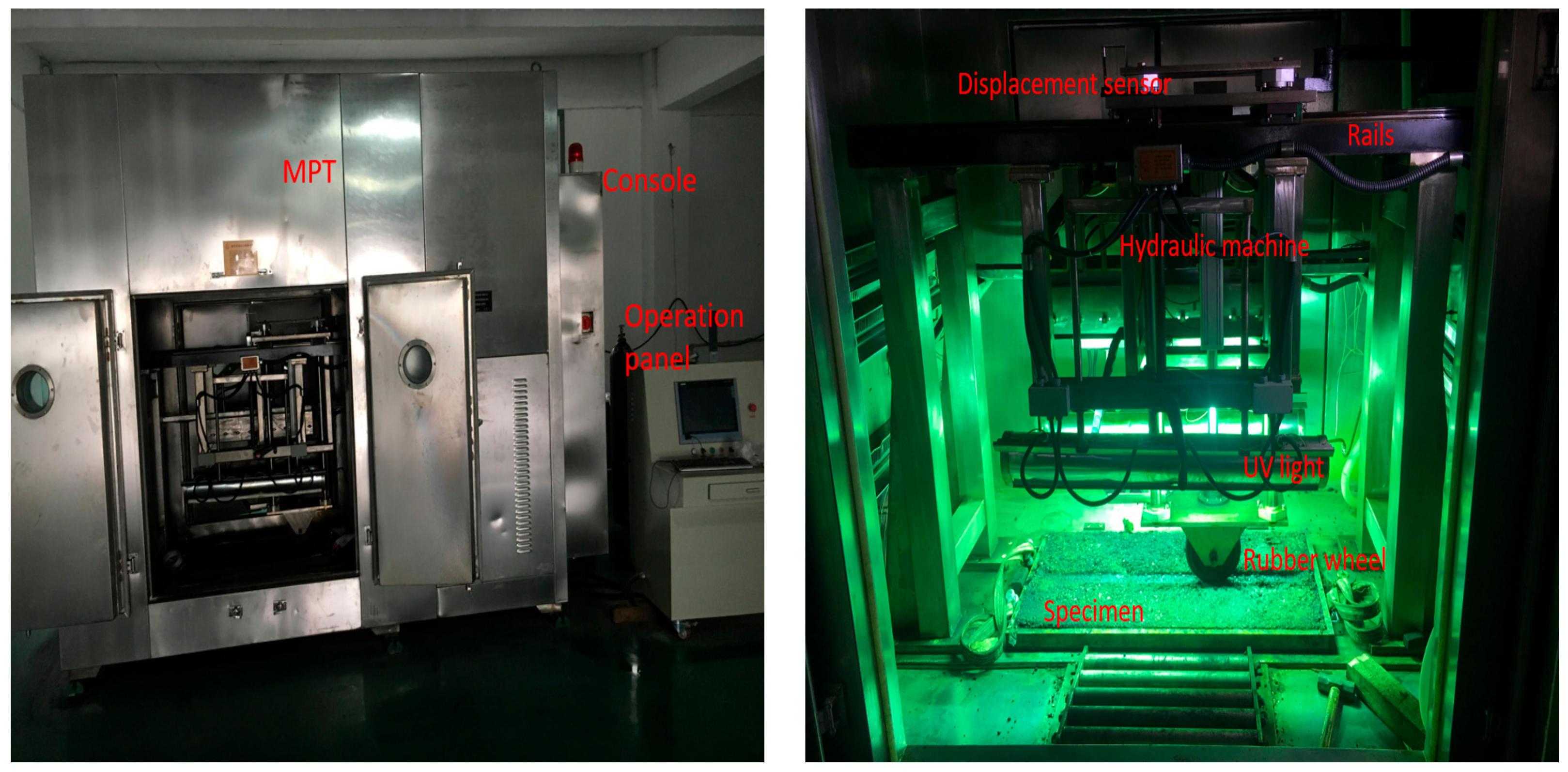

2. Materials and Experimental Program

3. Experimental Results and Discussion

3.1. Permanent Deformation Results

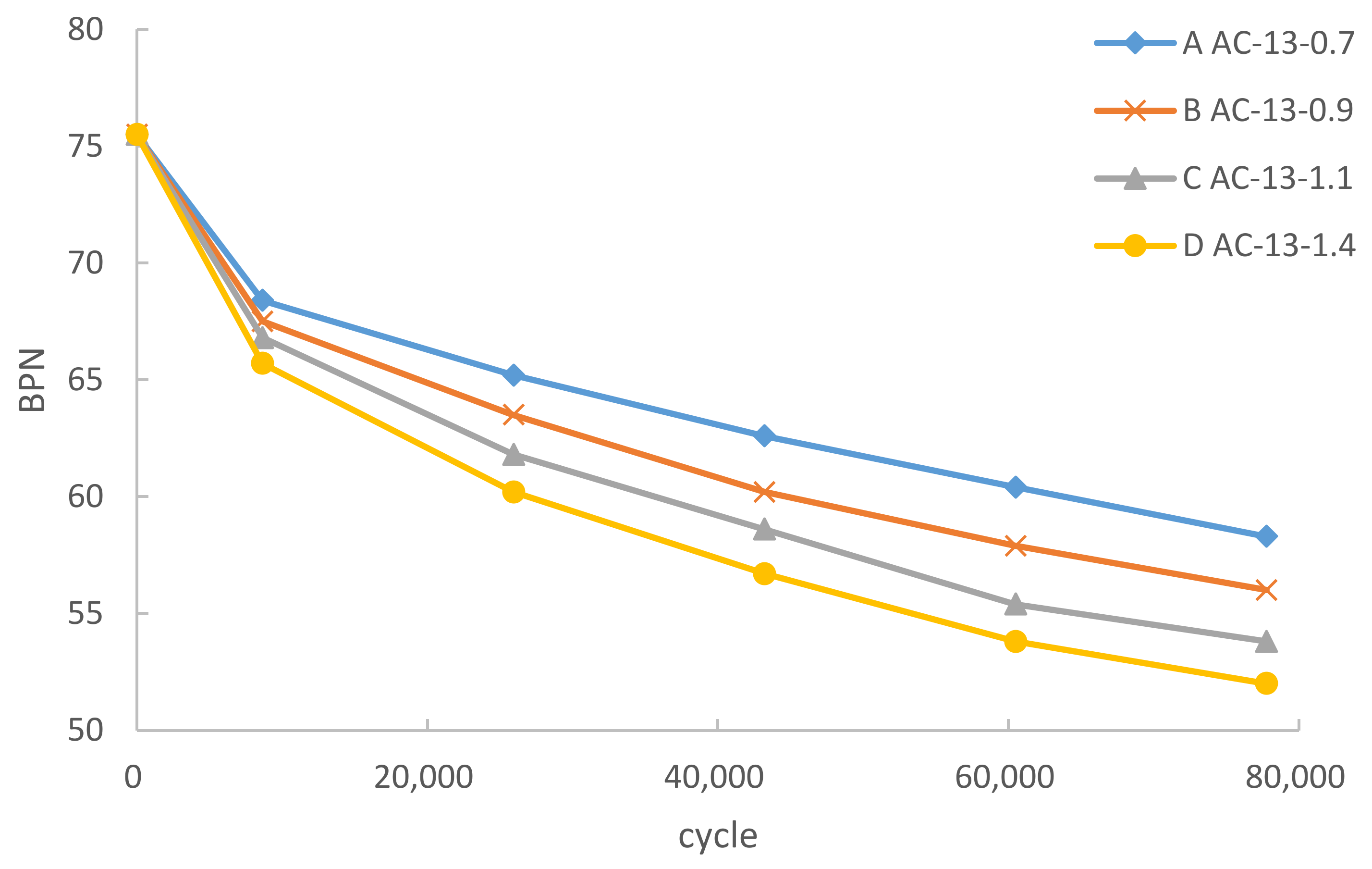

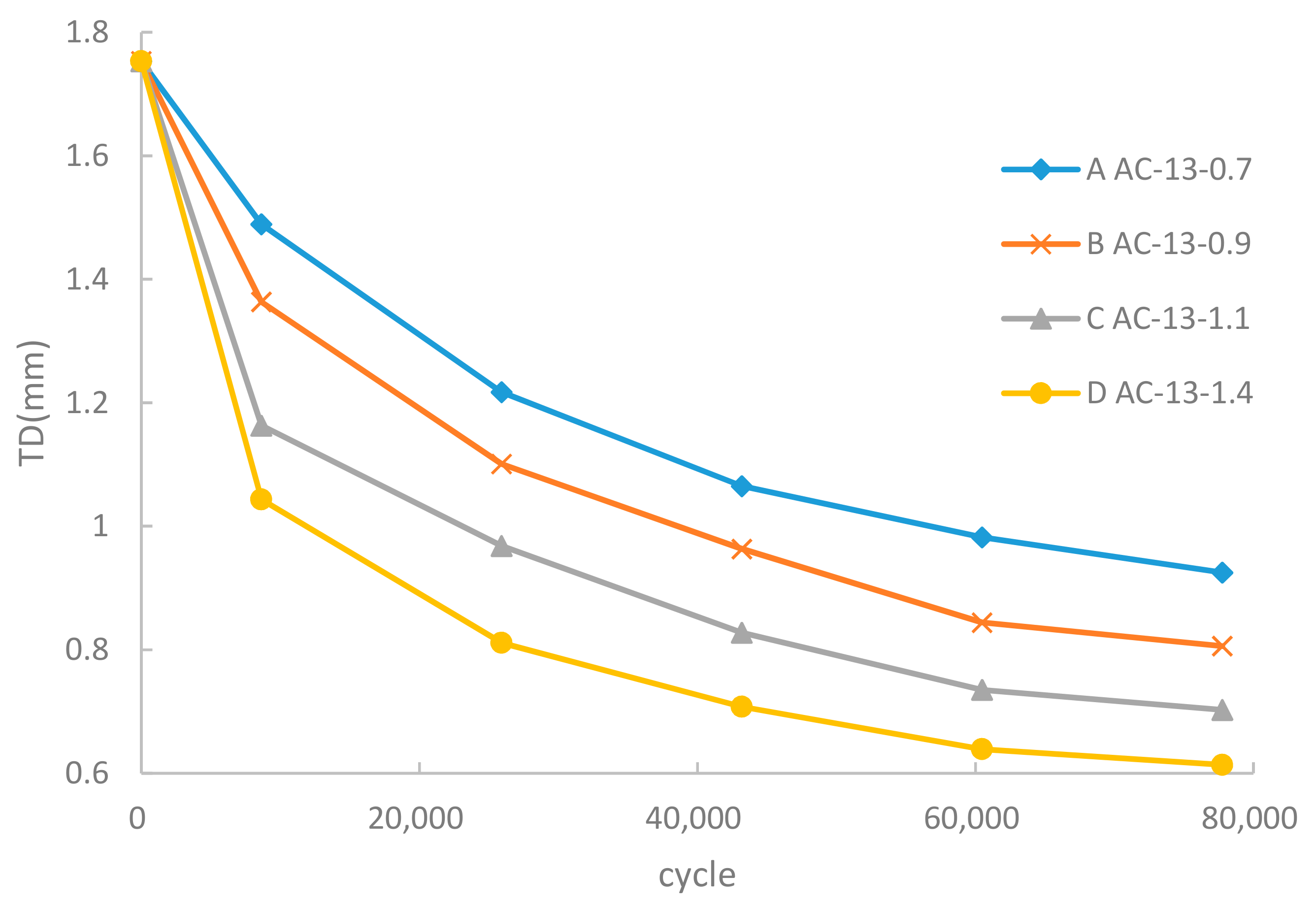

3.2. Skid Resistance Results

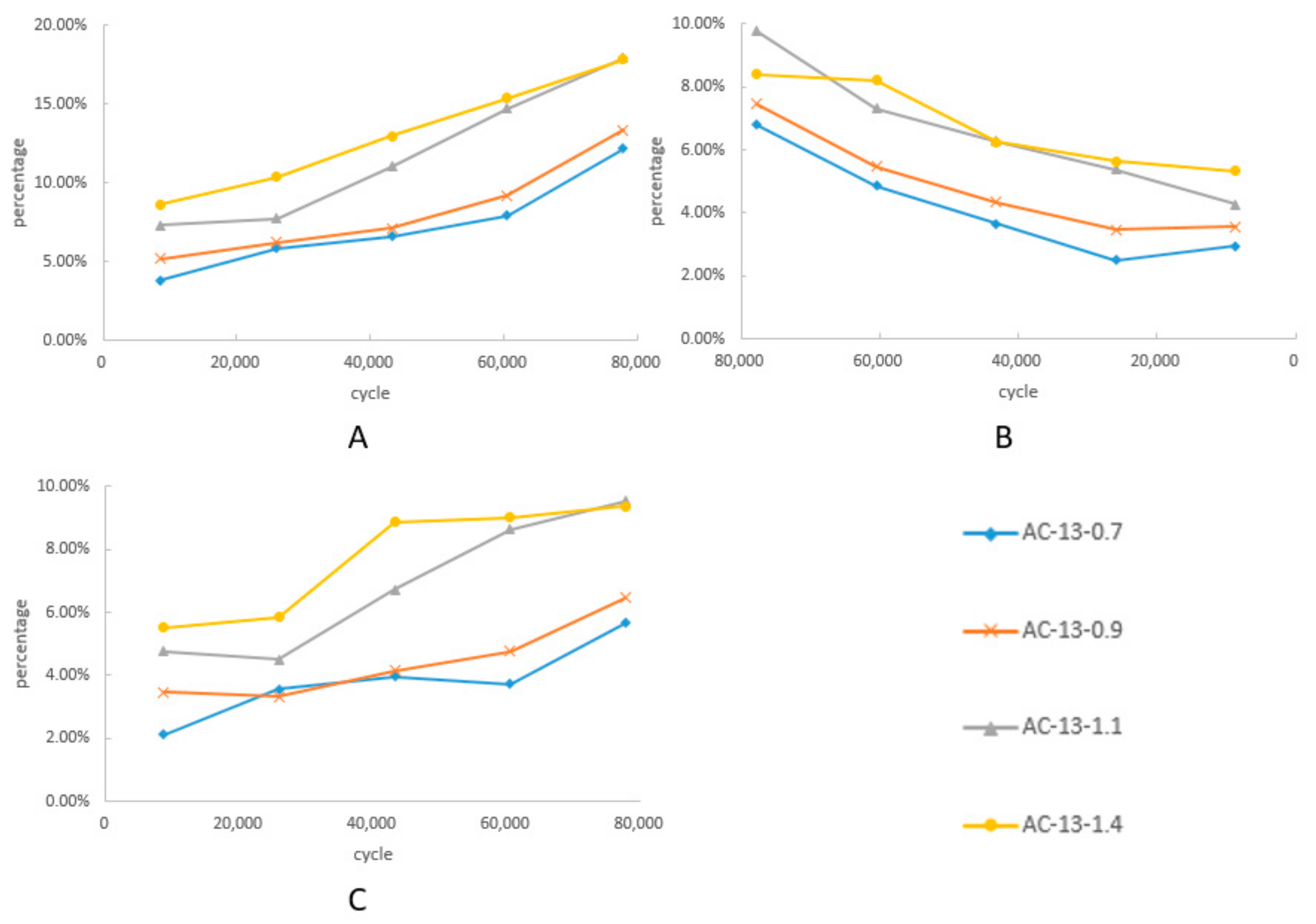

3.3. Sieving Results

3.4. Correlation Analysis

4. Conclusions

- (1)

- In the service of nine years, the permanent deformation of the asphalt mixture increased slowly under low load, while developed by obvious stages under high load: increased rapidly at the initial stage, and then slowed down. The deformation growth speed of the asphalt mixture under high load would decrease due to the formation of a new stable structure after 60,000 cycles. There was a critical load between the two development models, which was related to the performance of the aggregates.

- (2)

- The asphalt mixture on the surface had been compacted, exposing the corners and edges of the aggregates after grinding approximately 5000 times. The skid resistance began to decline rapidly after this point. BPN and TD had a larger degradation range and smaller final value under higher load.

- (3)

- In terms of permanent deformation, the asphalt mixture remained effective for a long time under low load, while it failed after grinding 45,000 times under high load. The failure cumulative cycles of skid resistance under various loads was predicted by the fitting curve. The failure cumulative cycles on BPN under 0.7 MPa, 0.9 MPa, 1.1 MPa, and 1.4 MPa was 4.09 million, 1.26 million, 0.55 million, and 0.34 million, respectively. The failure cumulative cycles on TD under 0.7 MPa, 0.9 MPa, 1.1 MPa, and 1.4 MPa was 0.88 million, 0.39 million, 0.23 million, and 0.12 million, respectively. The failure on TD was faster than BPN.

- (4)

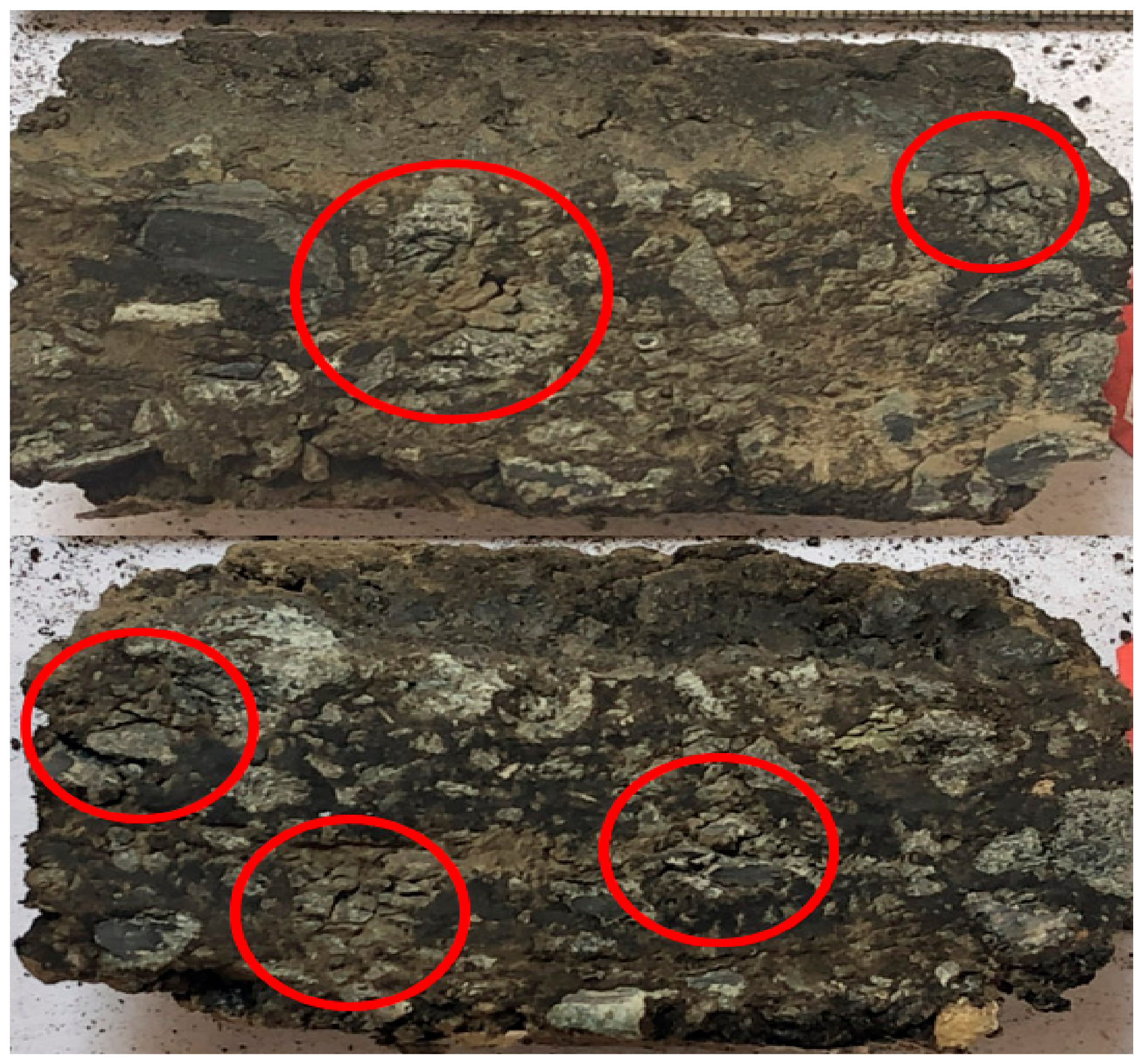

- According to the sieving result of the ground samples under heavy load, it was found that the content of 0–3 mm was almost constant, 10–16 mm decreased, while 5–10 mm and 3–5 mm rose. It could be viewed as some of the 10–16 mm particles were crushed into 5–10 mm and 3–5 mm.

- (5)

- Aggregates were crushed into smaller pieces and reformed a stable structure after high load grinding. The new aggregate gradation of 10–16 mm, 5–10 mm, 3–5 mm, and 0–3 mm was approximately 10%, 37%, 23%, and 30%, respectively.

- (6)

- According to the correlation analysis, the content of 10–16 mm had a significant correlation with the rutting performance of the mixture. There was no significant relationship between the aggregate gradation and skid resistance of the asphalt mixture. With the increase in the load, the correlation between permanent deformation and the aggregates gradually decreased.

Author Contributions

Funding

Conflicts of Interest

References

- Javilla, B.; Mo, L.; Hao, F.; Shu, B.; Wu, S. Multi-stress loading effect on rutting performance of asphalt mixtures based on wheel tracking testing. Constr. Build. Mater. 2017, 148, 1–9. [Google Scholar] [CrossRef]

- Miao, Y.; Li, J.; Zheng, X.; Wang, L. Field investigation of skid resistance degradation of asphalt pavement during early service. Int. J. Pavement Res. Technol. 2016, 9, 313–320. [Google Scholar] [CrossRef][Green Version]

- Karakaş, A.S.; Sayin, B.; Kuloğlu, N. The changes in the mechanical properties of neat and SBS-modified HMA pavements due to traffic loads and environmental effects over a one-year period. Constr. Build. Mater. 2014, 71, 406–415. [Google Scholar] [CrossRef]

- Li, Q.; Yang, H.; Ni, F.; Ma, X.; Luo, L. Cause analysis on permanent deformation for asphalt pavements using field cores. Constr. Build. Mater. 2015, 100, 40–51. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, Y.; Li, X. Rutting in asphalt pavement under heavy load and high temperature. In Proceedings of the Asphalt Material Characterization, Accelerated Testing, and Highway Management, GeoHunan International Conference, Hunan, China, 15 September 2009; pp. 39–48. [Google Scholar]

- Rezaei, A.; Masad, E.; Chowdhury, A.; Harris, P. Predicting asphalt mixture skid resistance by aggregate characteristics and gradation. Transp. Res. Rec. 2009, 2104, 24–33. [Google Scholar] [CrossRef]

- Mataei, B.; Zakeri, H.; Zahedi, M.; Nejad, F.M. Pavement friction and skid resistance measurement methods: A literature review. Open J. Civ. Eng. 2016, 6, 537–565. [Google Scholar] [CrossRef]

- Gao, L.; Liu, M.; Wang, Z.; Xie, J.; Jia, S. Correction of texture depth of porous asphalt pavement based on CT scanning technique. Constr. Build. Mater. 2019, 200, 514–520. [Google Scholar] [CrossRef]

- Ahadi, M.R.; Nasirahmadi, K. The effect of asphalt concrete micro & macro texture on skid resistance. J. Rehabil. Civil Eng. 2013, 1, 15–28. [Google Scholar]

- Luce, A.; Mahmoud, E.; Masad, E.; Chowdhury, A. Relationship of aggregate microtexture to asphalt pavement skid resistance. J. Test. Eval. 2007, 35, 578–588. [Google Scholar]

- Walubita, L.F.; Zhang, J.; Das, G.; Hu, X.; Mushota, C.; Alvarez, A.E.; Scullion, T. Hot-mix asphalt permanent deformation evaluated by Hamburg wheel tracking, dynamic modulus, and repeated load tests. Transp. Res. Rec. 2012, 2296, 46–56. [Google Scholar] [CrossRef]

- Zheng, M.L.; Zhu, H.T. Research progress on testing technology and evaluation model of skid-resistant performance of pavement. Highw. Trans. Res. Dev. 2008, 9, 313–314. [Google Scholar]

- Praticò, F.G.; Vaiana, R. A study on the relationship between mean texture depth and mean profile depth of asphalt pavements. Constr. Build. Mater. 2015, 101, 72–79. [Google Scholar] [CrossRef]

- Zhang, J.X.; Liu, L.H.; Wang, L.L. Influence of speed and texture depth on skid resistance of pavement surface. J. Beijing Univ. Technol. 2009, 35, 48–52. [Google Scholar]

- Lin, C.; Tongjing, W. Effect of fine aggregate angularity on skid-resistance of asphalt pavement using accelerated pavement testing. Constr. Build. Mater. 2018, 168, 41–46. [Google Scholar] [CrossRef]

- JTG E20-2011. Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering; Ministry of Transport: Beijing, China, 2011.

- Korkiala-Tanttu, L.; Dawson, A. Relating full-scale pavement rutting to laboratory permanent deformation testing. Int. J. Pavement Eng. 2007, 8, 19–28. [Google Scholar] [CrossRef]

- Gilchrist, M.D.; Hartman, A.M.; Owende, P.M.O.; Ward, S.M. Full scale accelerated testing of bituminous road pavement mixtures Key Engineering Materials. Trans. Tech. Publ. 2001, 204, 443–452. [Google Scholar]

- Chen, X.; Huang, B.; Xu, Z. Comparison between flat rubber wheeled loaded wheel tester and asphalt pavement analyzer. Road Mater. Pavement Des. 2007, 8, 595–604. [Google Scholar] [CrossRef]

- Iskender, E.; Aksoy, A. Field and laboratory performance comparison for asphalt mixtures with different moisture conditioning systems. Constr. Build. Mater. 2012, 27, 45–53. [Google Scholar] [CrossRef]

- Jaczewski, M.; Judycki, J.; Jaskula, P. Asphalt concrete subjected to long-time loading at low temperatures–Deviations from the time-temperature superposition principle. Constr. Build. Mater. 2019, 202, 426–439. [Google Scholar] [CrossRef]

- Monismith, C.L.; Alexander, R.L.; Secor, K.E. Rheologic behavior of asphalt concrete. Assoc. Asphalt Paving Technol. Proc. 1966, 35, 400–450. [Google Scholar]

- Kim, Y.R. Modeling of Asphalt Concrete. Am. Soc. Civ. Eng. 2009. [Google Scholar]

- Ferry, J.D. Viscoelastic Properties of Polymers; John Wiley and Sons: Hoboken, NJ, USA, 1980. [Google Scholar]

- Yin, Y.; Huang, W.; Lv, J.; Ma, X.; Yan, J. Unified construction of dynamic rheological master curve of asphalts and asphalt mixtures. Int. J. Civ. Eng. 2018, 16, 1057–1067. [Google Scholar] [CrossRef]

- JTG D50-2006. Specifications for Design of Highway Asphalt Pavement; Ministry of Transport: Beijing, China, 2006.

- Witczak, M.W. Simple Performance Test for Superpave Mix Design; Transportation Research Board: Washington, DC, USA, 2002. [Google Scholar]

- JTJ073.2-2001. Technical Specification for Maintenance of Highway Asphalt Pavement; Ministry of Transport: Beijing, China, 2001.

- Morea, F.; Zerbino, R. Wheel tracking test (WTT) conducted under different standards. Study and correlation of test parameters and limits. Mater. Struct. 2015, 48, 4019–4028. [Google Scholar] [CrossRef]

- Sedgwick, P. Pearson’s correlation coefficient. BMJ 2012, 345, e4483. [Google Scholar] [CrossRef]

| Test Items | Results | Requirements | |

|---|---|---|---|

| Penetration 25 °C, 100 g, 5s (0.1 mm) | 76.2 | 60~80 | |

| Softening point (°C) | 63.6 | ≥60 | |

| Ductility 5 cm/min, 5 °C (cm) | 51.2 | ≥30 | |

| Density 15 °C (g/cm3) | 1.031 | / | |

| Solubility (TCE) (%) | 99.8 | ≥99 | |

| Aging 163 °C, 5 h | Mass change (%) | 0.4 | ±1.0 |

| Penetration ratio 25 °C (%) | 83.3 | ≥60 | |

| Residual ductility 5 °C (cm) | 32.3 | ≥20 | |

| Series | Load/MPa | Specimen Label | Duration/h | Cumulative Cycles |

|---|---|---|---|---|

| A | 0.7 | AC-13-0.7-1 | 12 | 8640 |

| AC-13-0.7-2 | 36 | 25,920 | ||

| AC-13-0.7-3 | 60 | 43,200 | ||

| AC-13-0.7-4 | 84 | 60,480 | ||

| AC-13-0.7-5 | 108 | 77,760 | ||

| B | 0.9 | AC-13-0.9-1 | 12 | 8640 |

| AC-13-0.9-2 | 36 | 25,920 | ||

| AC-13-0.9-3 | 60 | 43,200 | ||

| AC-13-0.9-4 | 84 | 60,480 | ||

| AC-13-0.9-5 | 108 | 77,760 | ||

| C | 1.1 | AC-13-1.1-1 | 12 | 8640 |

| AC-13-1.1-2 | 36 | 25,920 | ||

| AC-13-1.1-3 | 60 | 43,200 | ||

| AC-13-1.1-4 | 84 | 60,480 | ||

| AC-13-1.1-5 | 108 | 77,760 | ||

| D | 1.4 | AC-13-1.4-1 | 12 | 8640 |

| AC-13-1.4-2 | 36 | 25,920 | ||

| AC-13-1.4-3 | 60 | 43,200 | ||

| AC-13-1.4-4 | 84 | 60,480 | ||

| AC-13-1.4-5 | 108 | 77,760 |

| Specimen Label | 10–16 mm | 5–10 mm | 3–5 mm | 0–3 mm and Filler |

|---|---|---|---|---|

| AC-13 | 28% | 28% | 14% | 30% |

| AC-13-0.7-1 | 24.18% | 30.95% | 16.11% | 28.75% |

| AC-13-0.7-2 | 22.16% | 30.51% | 17.57% | 29.76% |

| AC-13-0.7-3 | 21.42% | 31.65% | 17.95% | 28.98% |

| AC-13-0.7-4 | 20.09% | 32.86% | 17.71% | 29.34% |

| AC-13-0.7-5 | 15.82% | 34.80% | 19.67% | 29.71% |

| AC-13-0.9-1 | 22.80% | 31.57% | 17.46% | 28.17% |

| AC-13-0.9-2 | 21.77% | 31.46% | 17.32% | 29.45% |

| AC-13-0.9-3 | 20.86% | 32.34% | 18.16% | 28.64% |

| AC-13-0.9-4 | 18.82% | 33.48% | 18.76% | 28.94% |

| AC-13-0.9-5 | 14.66% | 35.46% | 20.45% | 29.43% |

| AC-13-1.1-1 | 20.68% | 32.26% | 18.75% | 28.31% |

| AC-13-1.1-2 | 20.28% | 33.38% | 18.51% | 27.83% |

| AC-13-1.1-3 | 16.97% | 34.27% | 20.73% | 28.03% |

| AC-13-1.1-4 | 13.29% | 35.30% | 22.63% | 28.78% |

| AC-13-1.1-5 | 10.05% | 37.76% | 23.53% | 28.65% |

| AC-13-1.4-1 | 19.38% | 33.34% | 19.51% | 27.77% |

| AC-13-1.4-2 | 17.62% | 33.65% | 19.85% | 28.89% |

| AC-13-1.4-3 | 15.01% | 34.26% | 22.87% | 27.86% |

| AC-13-1.4-4 | 12.61% | 36.22% | 23.02% | 28.16% |

| AC-13-1.4-5 | 10.17% | 36.40% | 23.37% | 30.06% |

| Load/MPa | Aggregate/mm | Permanent Deformation | BPN | TD | |||

|---|---|---|---|---|---|---|---|

| PCC | Sig. | PCC | Sig. | PCC | Sig. | ||

| 0.70 | 10–16 | 0.972 | 0.006 | −0.934 | 0.200 | −0.857 | 0.063 |

| 5–10 | 0.938 | 0.018 | −0.883 | 0.047 | −0.762 | 0.134 | |

| 3–5 | 0.923 | 0.025 | −0.906 | 0.034 | −0.877 | 0.051 | |

| 0.90 | 10–16 | 0.972 | 0.006 | −0.889 | 0.044 | −0.826 | 0.085 |

| 5–10 | 0.957 | 0.011 | −0.868 | 0.056 | −0.794 | 0.109 | |

| 3–5 | 0.950 | 0.013 | −0.861 | 0.061 | −0.783 | 0.117 | |

| 1.10 | 10–16 | 0.926 | 0.024 | −0.929 | 0.023 | −0.896 | 0.040 |

| 5–10 | 0.882 | 0.048 | −0.928 | 0.023 | −0.892 | 0.042 | |

| 3–5 | 0.948 | 0.014 | −0.922 | 0.026 | −0.897 | 0.039 | |

| 1.40 | 10–16 | 0.950 | 0.013 | −0.969 | 0.007 | −0.916 | 0.029 |

| 5–10 | 0.882 | 0.048 | −0.912 | 0.031 | −0.845 | 0.072 | |

| 3–5 | 0.957 | 0.011 | −0.927 | 0.023 | −0.901 | 0.037 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Yu, J.; Xie, J.; Ye, Q. Performance Degradation of Large-Sized Asphalt Mixture Specimen under Heavy Load and Its Affecting Factors Using Multifunctional Pavement Material Tester. Materials 2019, 12, 3814. https://doi.org/10.3390/ma12233814

Li J, Yu J, Xie J, Ye Q. Performance Degradation of Large-Sized Asphalt Mixture Specimen under Heavy Load and Its Affecting Factors Using Multifunctional Pavement Material Tester. Materials. 2019; 12(23):3814. https://doi.org/10.3390/ma12233814

Chicago/Turabian StyleLi, Jiasheng, Jianying Yu, Jun Xie, and Qunshan Ye. 2019. "Performance Degradation of Large-Sized Asphalt Mixture Specimen under Heavy Load and Its Affecting Factors Using Multifunctional Pavement Material Tester" Materials 12, no. 23: 3814. https://doi.org/10.3390/ma12233814

APA StyleLi, J., Yu, J., Xie, J., & Ye, Q. (2019). Performance Degradation of Large-Sized Asphalt Mixture Specimen under Heavy Load and Its Affecting Factors Using Multifunctional Pavement Material Tester. Materials, 12(23), 3814. https://doi.org/10.3390/ma12233814