Resistive Switching and Charge Transport in Laser-Fabricated Graphene Oxide Memristors: A Time Series and Quantum Point Contact Modeling Approach

Abstract

1. Introduction

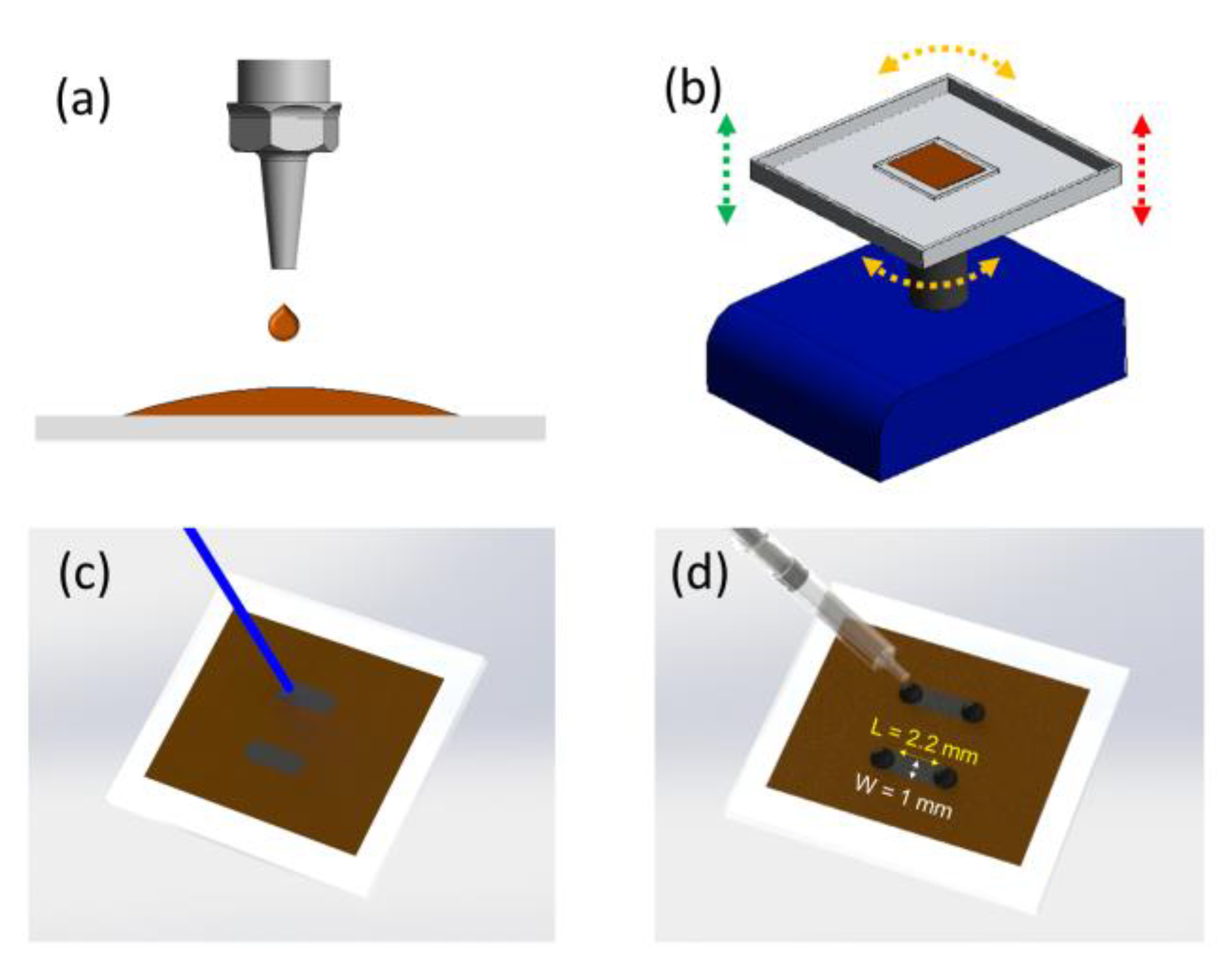

2. Device Fabrication and Measurement

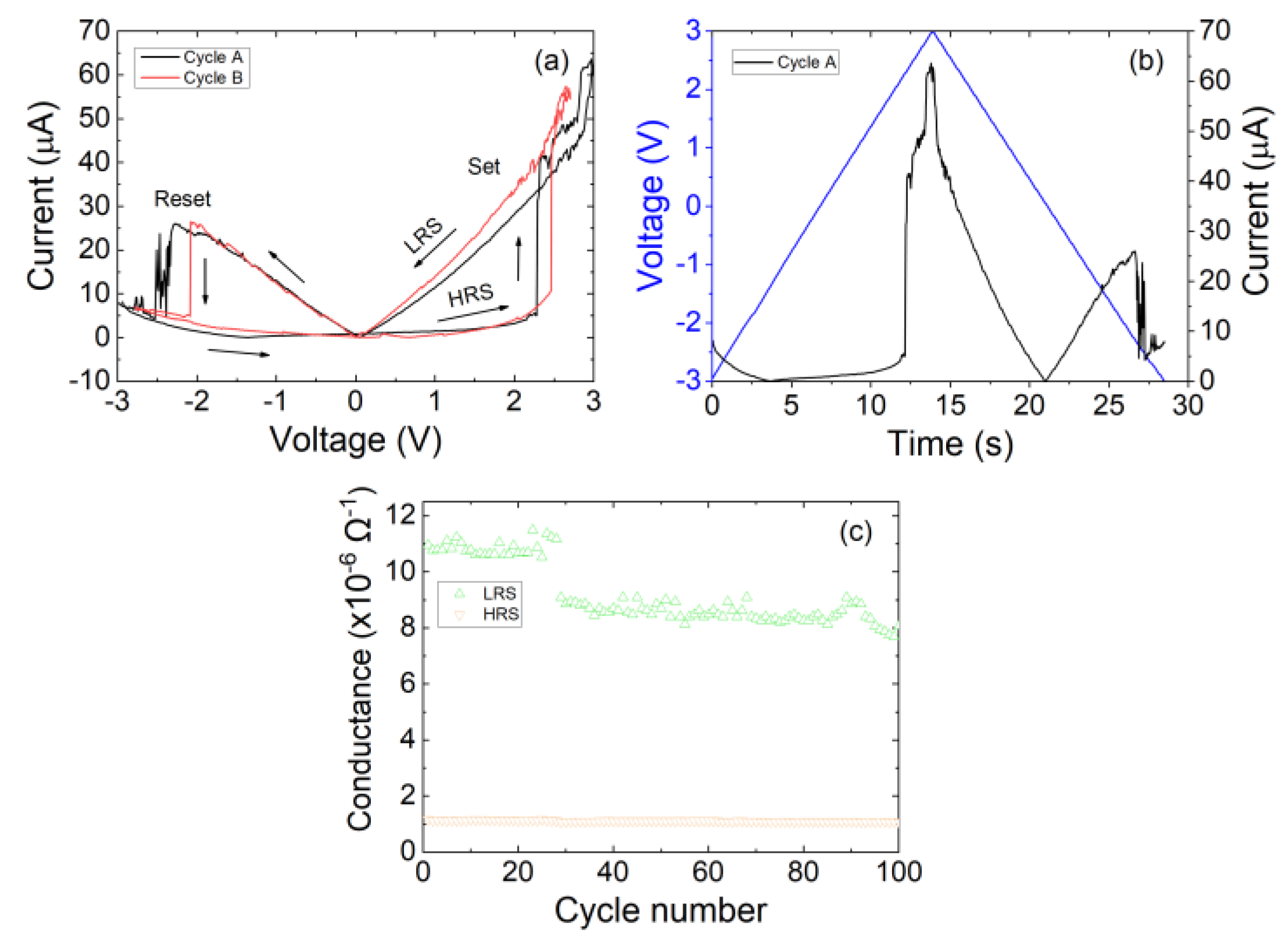

3. Numerical Analysis of Charge Conduction and Resistive Switching Mechanisms, Results and Discussion

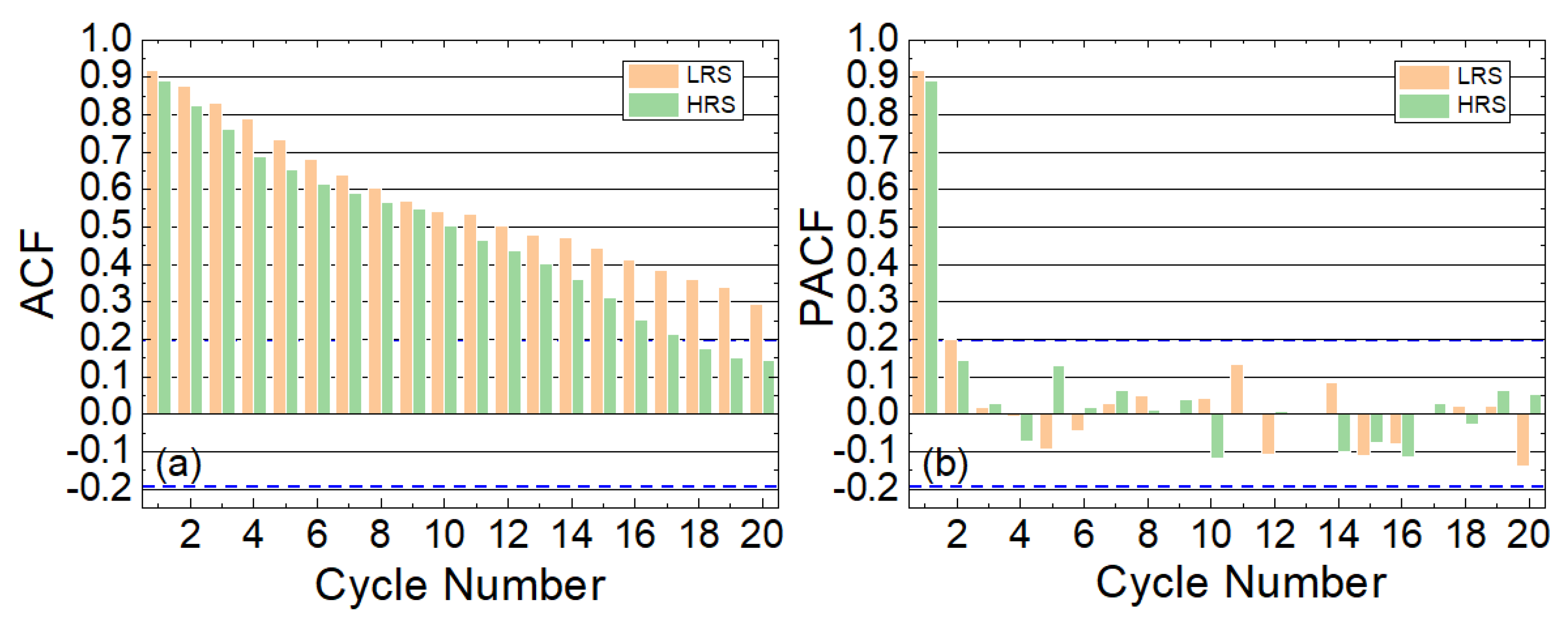

3.1. Time Series Statistical Analysis (TSSA)

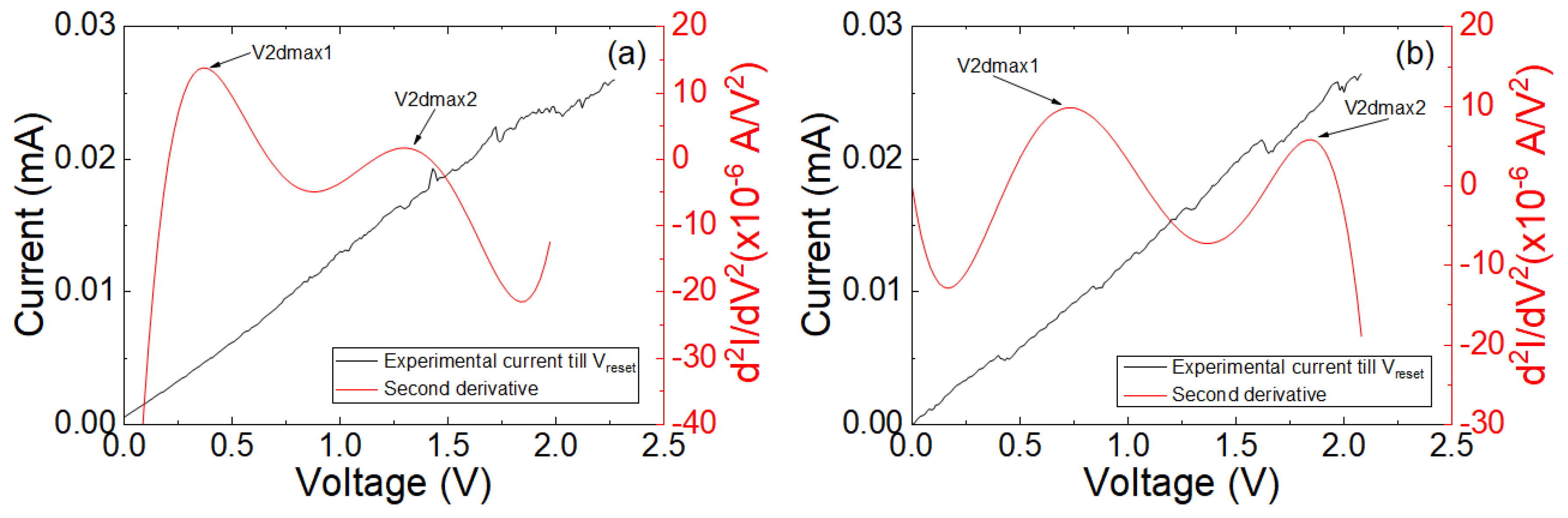

3.2. Quantum Point Contact Modeled Conduction

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Yu, S.; Wu, Y.; Jeyasingh, R.; Kuzum, D.; Wong, H.S. An electronic synapse device based on metal oxide resistive switching memory for neuromorphic computation. IEEE Trans. Electron Devices 2011, 58, 2729–2737. [Google Scholar] [CrossRef]

- Yu, S. Neuro-Inspired Computing Using Resistive Synaptic Devices; Springer: NY, USA, 2017; ISBN 978-3-319-54312-3. [Google Scholar]

- Lanza, M.; Wong, H.-P.P.; Pop, E.; Ielmini, D.; Strukov, D.; Regan, B.C.; Larcher, L.; VillenaJ, M.A.; Yang, J.J.; Goux, L.; et al. Recommended methods to study resistive switching devices. Adv. Electron. Mater. 2019, 5, 1800143. [Google Scholar] [CrossRef]

- Pan, F.; Gao, S.; Chen, C.; Song, C.; Zeng, F. Recent progress in resistive random access memories: Materials, switching mechanisms and performance. Mater. Sci. Eng. 2014, 83, 1–59. [Google Scholar] [CrossRef]

- Ielmini, D.; Waser, R. Resistive Switching: From Fundamentals of Nanoionic Redox Processes to Memristive Device Applications; Wiley-VCH: Weinheim, Germany, 2017; ISBN 978-3-527-33417-9. [Google Scholar]

- Waser, R.; Aono, M. Nanoionics-based resistive switching. Nat. Mater. 2007, 6, 833–840. [Google Scholar] [CrossRef] [PubMed]

- Villena, M.A.; Roldan, J.B.; Jimienez-Molinos, F.; Miranda, E.; Suñe, J.; Lanza, M. SIM2RRAM: A physical model for RRAM devices simulation. J. Comput. Electron. 2017, 16, 1095–1120. [Google Scholar] [CrossRef]

- Long, S.; Cagli, C.; Ielmini, D.; Liu, M.; Suñe, J. Reset statistics of NiO-based resistive switching memories. IEEE Electron Device Lett. 2011, 32, 1570–1572. [Google Scholar] [CrossRef]

- Long, S.; Lian, X.; Ye, T.; Cagli, C.; Perniola, L.; Miranda, E.; Liu, M.; Suñe, J. Cycle-to-cycle intrinsic RESET statistics in HfO2-based unipolar RRAM devices. IEEE Electron Device Lett. 2013, 34, 623–625. [Google Scholar] [CrossRef]

- Gonzalez-Cordero, G.; Roldan, J.B.; Jimenez-Molinos, F.; Suñé, J.; Long, S.; Liu, M. A new model for bipolar RRAMs based on truncated cone conductive filaments, a Verilog-A approach. Semicond. Sci. Technol. 2016, 31, 115013. [Google Scholar] [CrossRef]

- Tsuruoka, T.; Terabe, K.; Hasegawaand, T.; Aono, M. Forming and switching mechanisms of a cation-migration-based oxide resistive memory. Nanotechnology 2010, 21, 425205. [Google Scholar] [CrossRef]

- Padovani, A.; Larcher, L.; Pirrotta, O.; Vandelli, L.; Bersuker, G. Microscopic Modeling of HfO x RRAM Operations: From Forming to Switching. IEEE Trans. Electron Device 2015, 62, 1998–2006. [Google Scholar] [CrossRef]

- Aldana, S.; Garcia-Fernandez, P.; Rodriguez-Fernandez, A.; Romero-Zaliz, R.; Gonzalez, M.B.; Jimenez-Molinos, F.; Campabadal, F.; Gomez-Campos, F.; Roldan, J.B. A 3D Kinetic Monte Carlo simulation study of Resistive Switching processes in Ni/HfO2/Si-n+-based RRAMs. J. Phys. D Appl. Phys. 2017, 50, 335103. [Google Scholar] [CrossRef]

- Guy, J.; Molas, G.; Blaise, P.; Bernard, M.; Roule, A.; Carval, G.L.; Delaye, V.; Toffoli, A.; Ghibaudo, G.; Clermidy, F.; et al. Investigation of Forming, SET, and Data Retention of Conductive-Bridge Random-Access Memory for Stack Optimization. IEEE Trans. Electron Devices 2015, 62, 3482–3489. [Google Scholar] [CrossRef]

- Villena, M.A.; Roldan, J.B.; Gonzalez, M.B.; Gonzalez-Rodalas, P.; Jimenez-Molinos, F.; Campabadal, F.; Barrera, D. A new parameter to characterize the charge transport regime in Ni/HfO2/Si-n+-based RRAMs. Solid State Electron. 2016, 118, 56–60. [Google Scholar] [CrossRef]

- Hui, F.; Villena, M.A.; Fang, W.; Lu, A.-Y.; Kong, J.; Shi, Y.; Jing, X.; Zhu, K.; Lanza, M. Synthesis of large-area multilayer hexagonal boron nitride sheets on iron substrates and its use in resistive switching devices. 2D Mater. 2018, 5, 031011. [Google Scholar] [CrossRef]

- Shi, Y.; Liang, X.; Yuan, B.; Chen, V.; Li, H.; Hui, F.; Yu, Z.; Yuan, F.; Pop, E.; Wong, H.-S.P.; et al. Electronic synapses made of layered two-dimensional materials. Nat. Electron. 2018, 1, 458–465. [Google Scholar] [CrossRef]

- Romero, F.J.; Toral-Lopez, A.; Ohata, A.; Morales, D.P.; Ruiz, F.G.; Godoy, A.; Rodriguez, N. Laser-Fabricated Reduced Graphene Oxide Memristors. Nanomaterials 2019, 9, 897. [Google Scholar] [CrossRef] [PubMed]

- Dimiev, A.M.; Eigler, S. Graphene Oxide: Fundamentals and Applications; Wiley: NJ, USA, 2016; ISBN 978-1-119-06940-9. [Google Scholar]

- Romero, F.J.; Toral-Lopez, A.; Ohata, A.; Morales, D.P.; Ruiz, F.G.; Godoy, A.; Rodriguez, N. Photothermically Lithographed Graphene-Oxide Memristors for Neuromorphic Applications. In Proceedings of the International Conference on Memristive Materials, Devices & Systems (MEMRISYS), Dresden, Germany, 8–11 July 2019. [Google Scholar]

- Porro, S.; Accornero, E.; Pirri, C.F.; Ricciardi, C. Memristive devices based on Graphene oxide. Carbon 2015, 85, 383–395. [Google Scholar] [CrossRef]

- Roldan, J.B.; Miranda, E.; Gonzalez-Cordero, G.; Garcia-Fernandez, P.; Romero-Zaliz, R.; Gonzalez-Rodelas, P.; Aguilera, A.M.; Gonzalez, M.B.; Jimenez-Molinos, F. Multivariate analysis and extraction of parameters in resistive RAMs using the Quantum Point Contact model. J. Appl. Phys. 2018, 123, 014501. [Google Scholar] [CrossRef]

- Villena, M.A.; Gonzalez, M.B.; Roldan, J.B.; Campabadal, F.; Jimenez-Molinos, F.; Gomez-Campos, F.M.; Suñe, J. An in-depth study of thermal effects in reset transitions in HfO2 based RRAMs. Solid State Electron. 2015, 111, 47–51. [Google Scholar] [CrossRef]

- Roldan, J.B.; Alonso, F.J.; Aguilera, A.M.; Maldonado, D.; Lanza, M. Time series statistical analysis: A powerful tool to evaluate the variability of resistive switching memories. J. Appl. Phys. 2019, 125, 174504. [Google Scholar] [CrossRef]

- Yule, G.U. On a method of investigating periodicities in disturbed series, with reference to Wolfer’s Sunspot Numbers. Philos. Trans. R. Soc. Lond. 1927, 226, 267–298. [Google Scholar] [CrossRef]

- Bisgaard, S.; Kulahci, M. Time Series Analysis and Forecasting by Example; Wiley: NJ, USA, 2011; ISBN 978-0-470-54064-0. [Google Scholar]

- Brockwell, P.J.; Davis, R.A. Introduction to Time Series and Forecasting, 2nd ed.; Springer: NY, USA, 2002. [Google Scholar]

- Romero, F.J.; Rivadeneyra, A.; Toral-Lopez, V.; Castillo, E.; Garcia-Ruiz, F.; Morales, D.P.; Rodriguez, N. Design guidelines of laser reduced graphene oxide conformal thermistor for IoT applications. Sens. Actuators A Phys. 2018, 274, 148–154. [Google Scholar] [CrossRef]

- Chua, L. Resistance switching memories are memristors. Appl. Phys. A 2011, 102, 765–783. [Google Scholar] [CrossRef]

- Qi, M.; Bai, L.; Xu, H.; Wang, Z.; Kang, Z.; Zhao, X.; Liu, W.; Ma, J.; Liu, Y. Oxidized carbon quantum dot–graphene oxide nanocomposites for improving data retention of resistive switching memory. J. Mater. Chem. C 2018, 6, 2026–2033. [Google Scholar] [CrossRef]

- Abunahla, H.; Mohammad, B.; Homouz, D.; Okelly, C.J. Modeling Valence Change Memristor Device: Oxide Thickness, Material Type, and Temperature Effects. IEEE Trans. Circuits Syst. I Regul. Pap. 2016, 63, 2139–2148. [Google Scholar] [CrossRef]

- Dai, Y.; Shuang, N.; Li, Z.; Yang, J. Diffusion and desorption of oxygen atoms on graphene. J. Phys. Condens. Matter 2013, 25, 405301. [Google Scholar] [CrossRef]

- Zhou, S.; Bongiorno, A. Origin of the Chemical and Kinetic Stability of Graphene Oxide. Sci. Rep. 2013, 3, 2484. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodriguez, N.; Maldonado, D.; Romero, F.J.; Alonso, F.J.; Aguilera, A.M.; Godoy, A.; Jimenez-Molinos, F.; Ruiz, F.G.; Roldan, J.B. Resistive Switching and Charge Transport in Laser-Fabricated Graphene Oxide Memristors: A Time Series and Quantum Point Contact Modeling Approach. Materials 2019, 12, 3734. https://doi.org/10.3390/ma12223734

Rodriguez N, Maldonado D, Romero FJ, Alonso FJ, Aguilera AM, Godoy A, Jimenez-Molinos F, Ruiz FG, Roldan JB. Resistive Switching and Charge Transport in Laser-Fabricated Graphene Oxide Memristors: A Time Series and Quantum Point Contact Modeling Approach. Materials. 2019; 12(22):3734. https://doi.org/10.3390/ma12223734

Chicago/Turabian StyleRodriguez, N., D. Maldonado, F. J. Romero, F. J. Alonso, A. M. Aguilera, A. Godoy, F. Jimenez-Molinos, F. G. Ruiz, and J. B. Roldan. 2019. "Resistive Switching and Charge Transport in Laser-Fabricated Graphene Oxide Memristors: A Time Series and Quantum Point Contact Modeling Approach" Materials 12, no. 22: 3734. https://doi.org/10.3390/ma12223734

APA StyleRodriguez, N., Maldonado, D., Romero, F. J., Alonso, F. J., Aguilera, A. M., Godoy, A., Jimenez-Molinos, F., Ruiz, F. G., & Roldan, J. B. (2019). Resistive Switching and Charge Transport in Laser-Fabricated Graphene Oxide Memristors: A Time Series and Quantum Point Contact Modeling Approach. Materials, 12(22), 3734. https://doi.org/10.3390/ma12223734