Influence of Effective Grain Size on Low Temperature Toughness of High-Strength Pipeline Steel

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Material and Chemical Composition

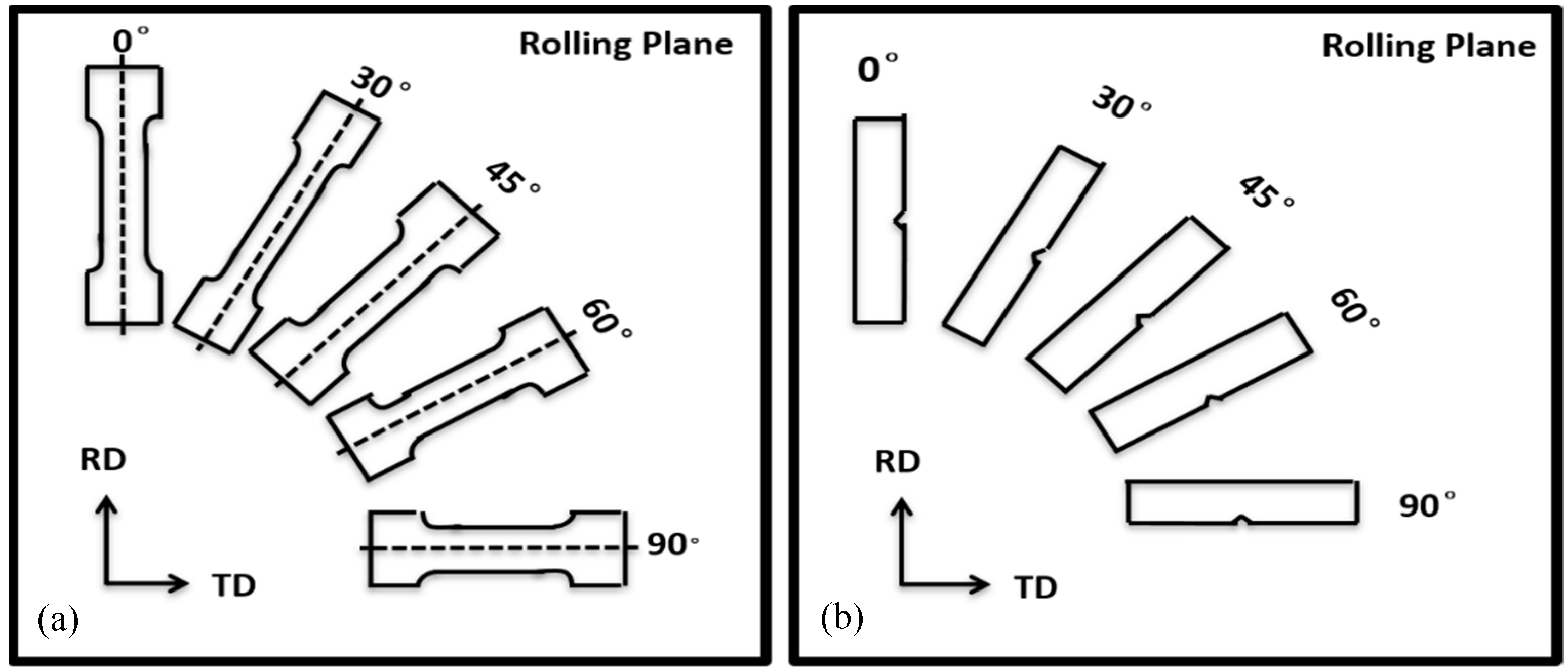

2.2. Mechanical Property Tests

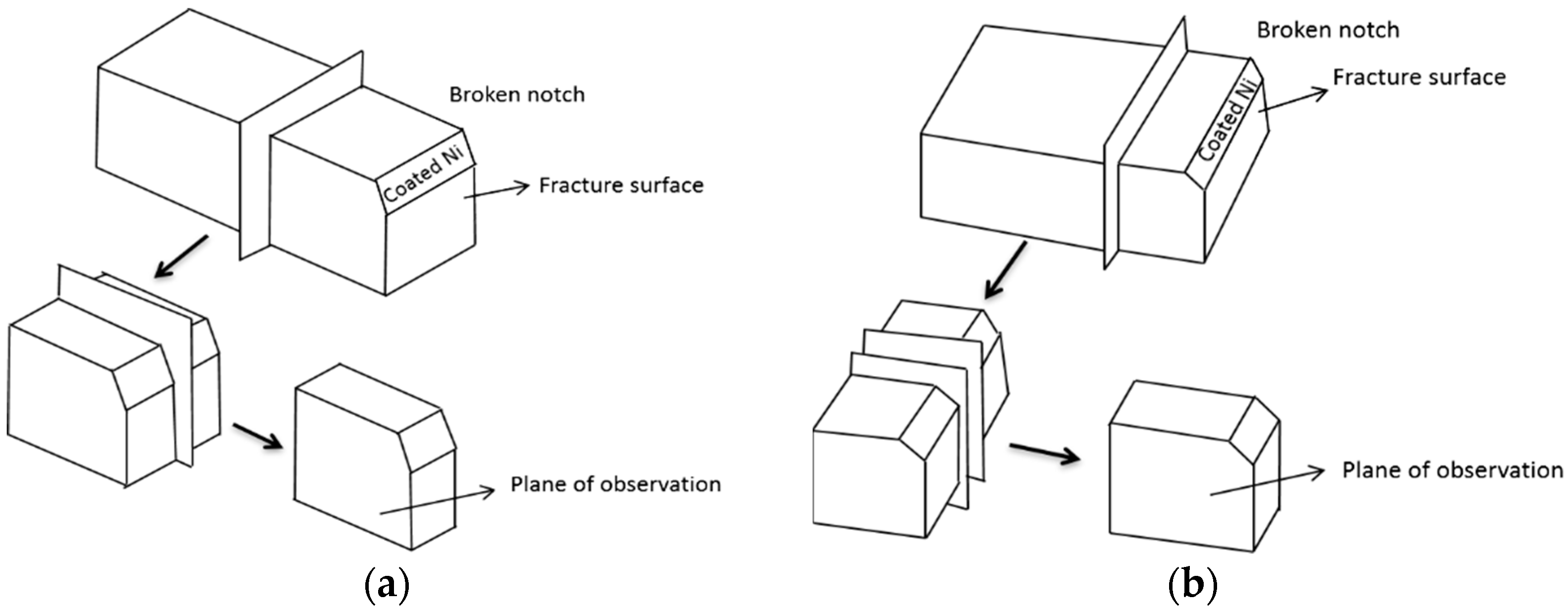

2.3. Microstructural Characterization and Fracture Propagation Observation

3. Results

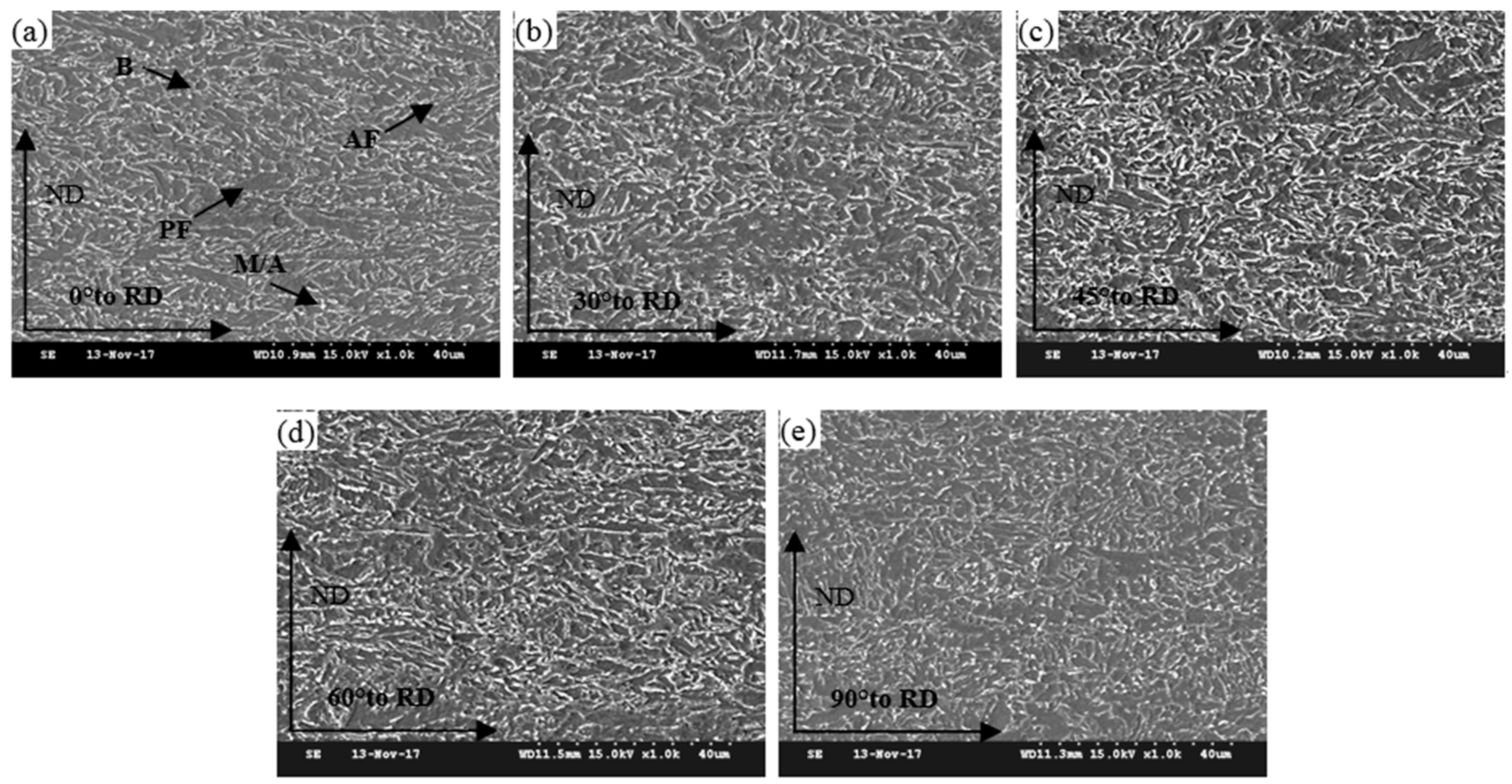

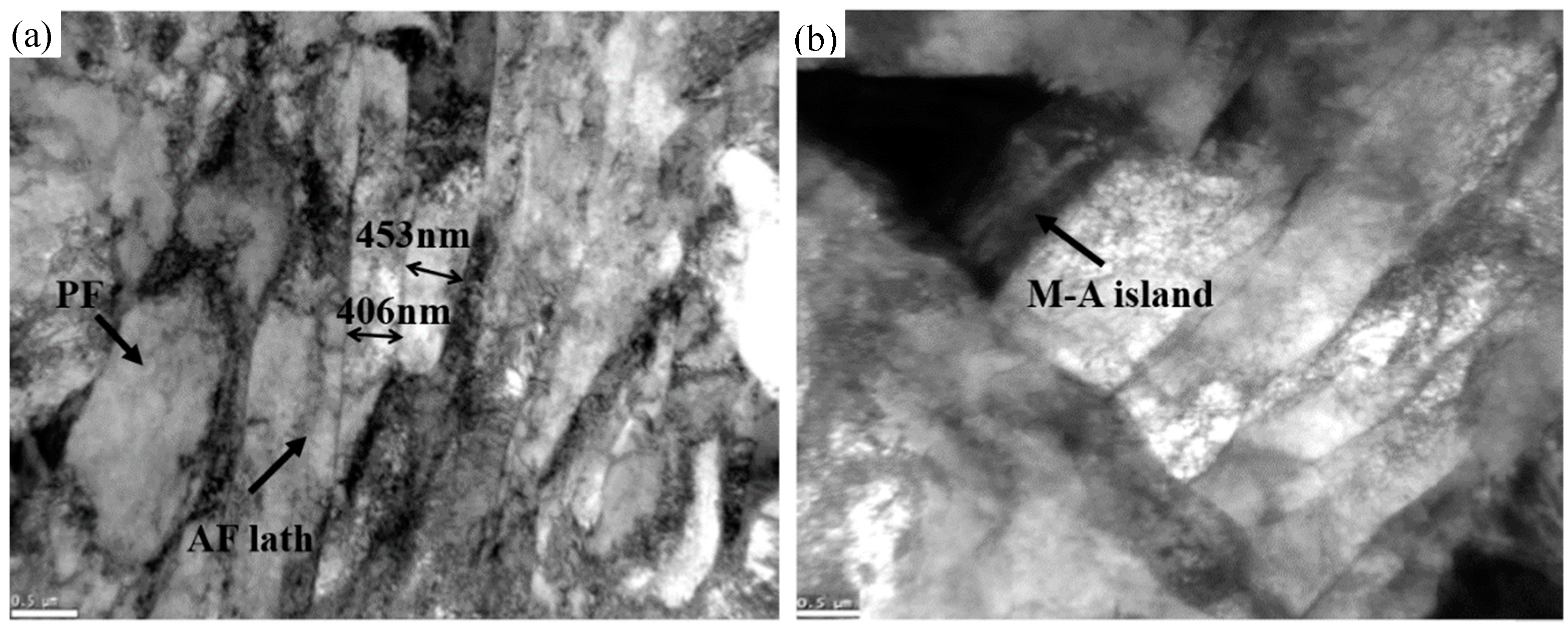

3.1. Microstructures

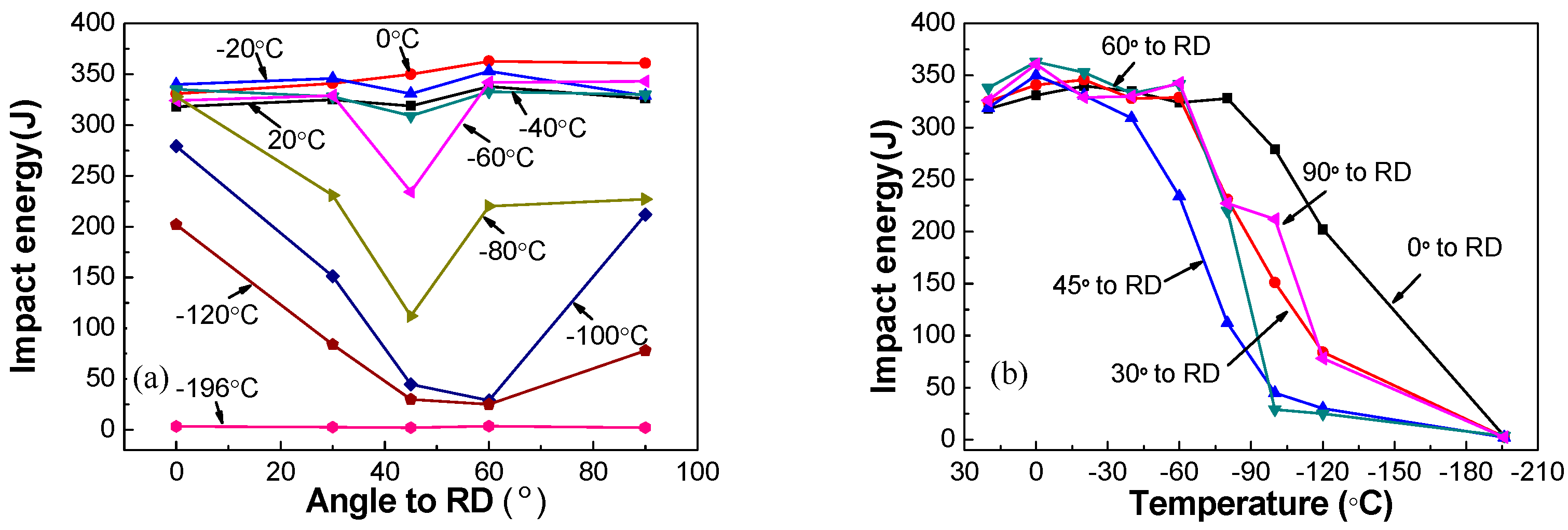

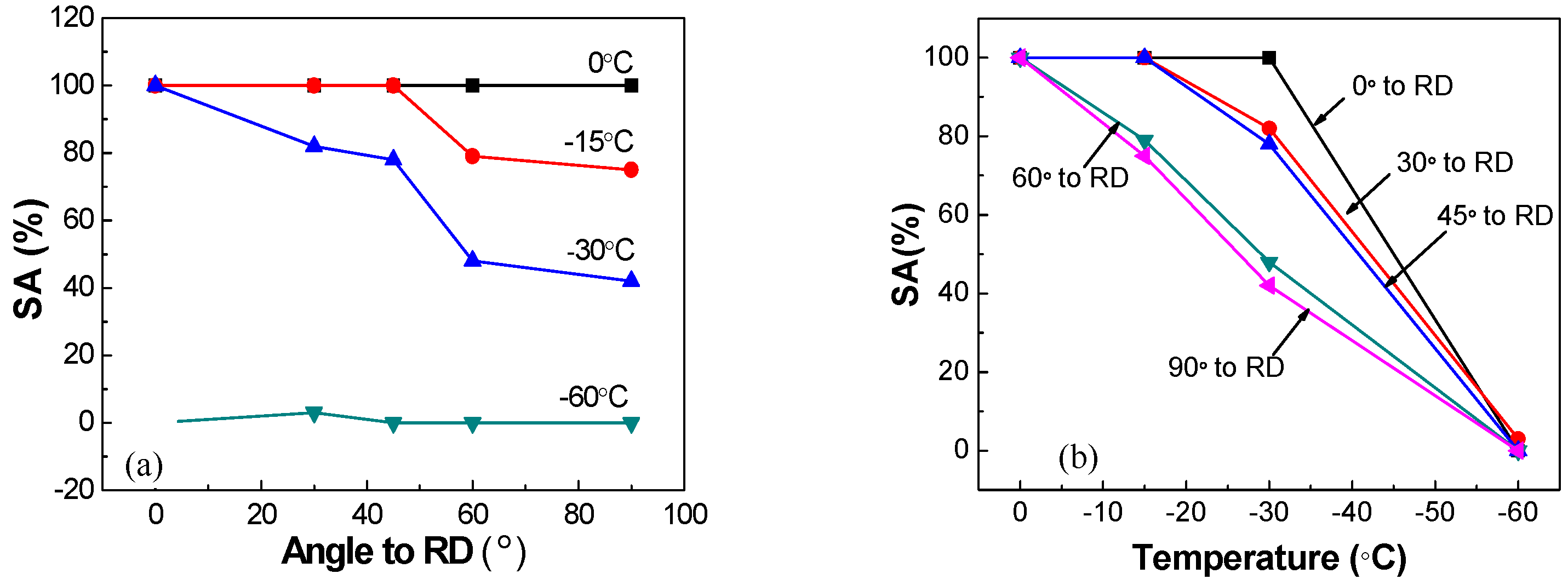

3.2. Mechanical Properties

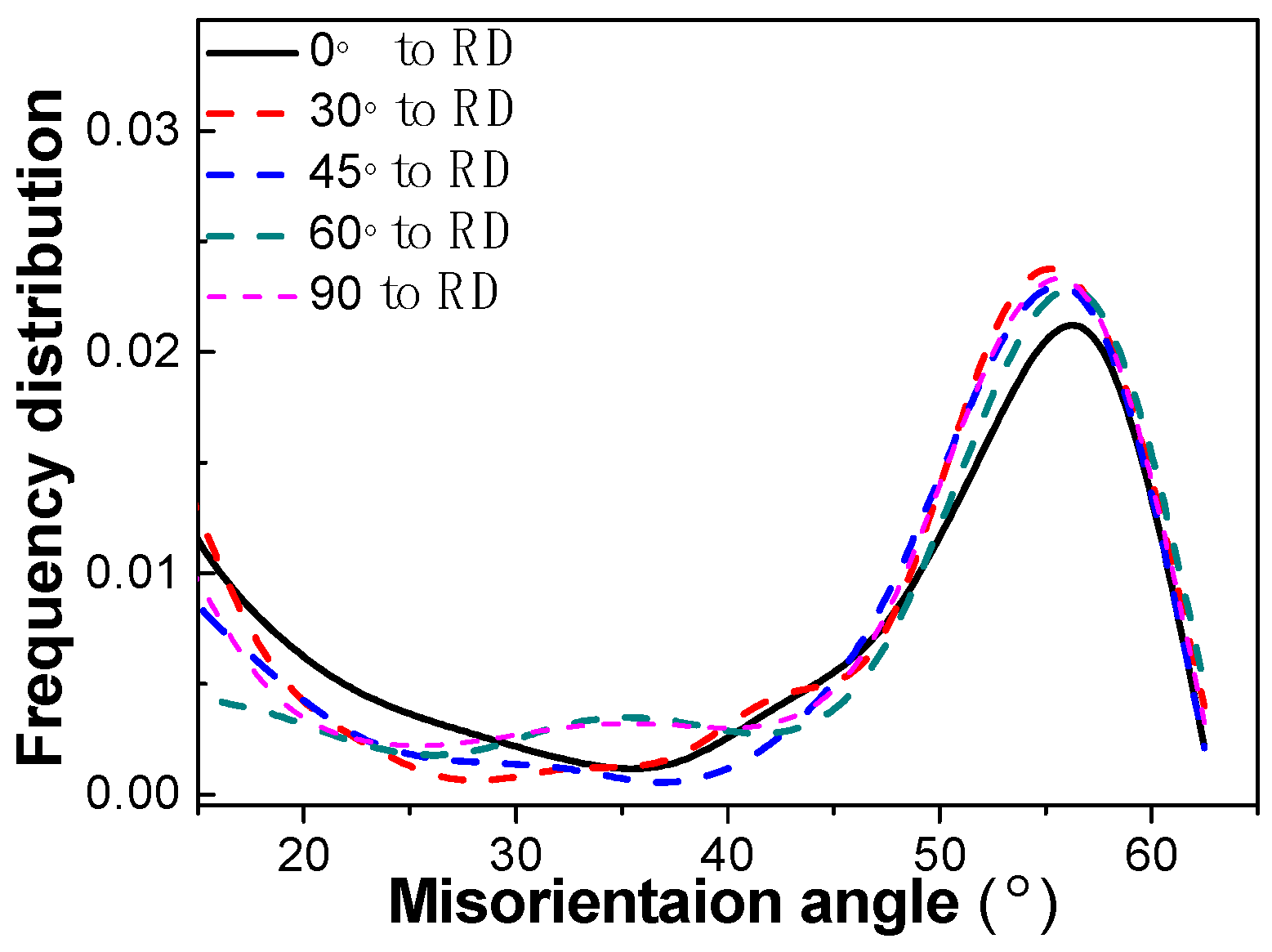

3.3. Crystal Orientation Relation and Effective Grain Size

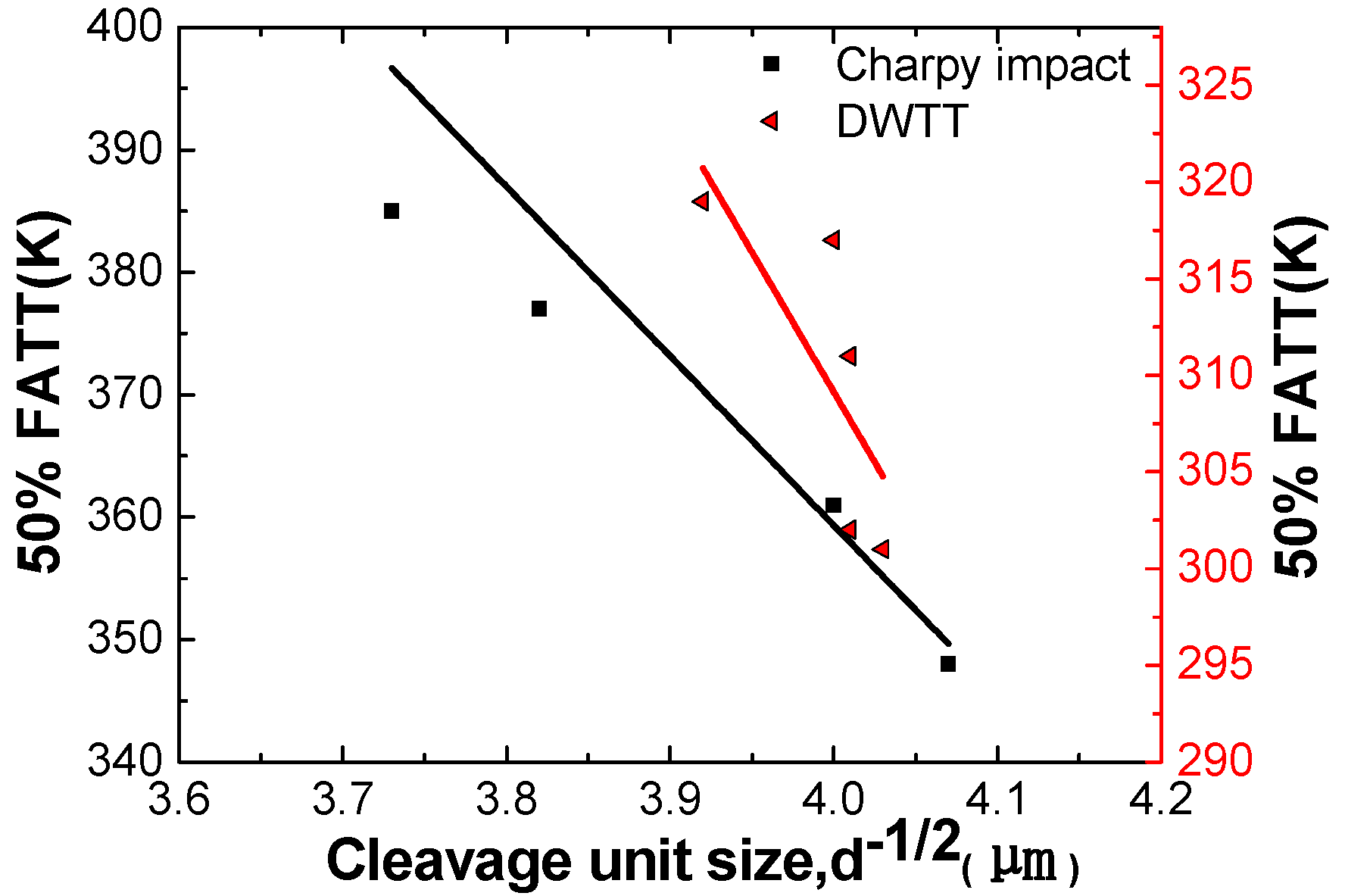

3.4. Quantitative Analysis of Subunit Size and Its Influence on Performance

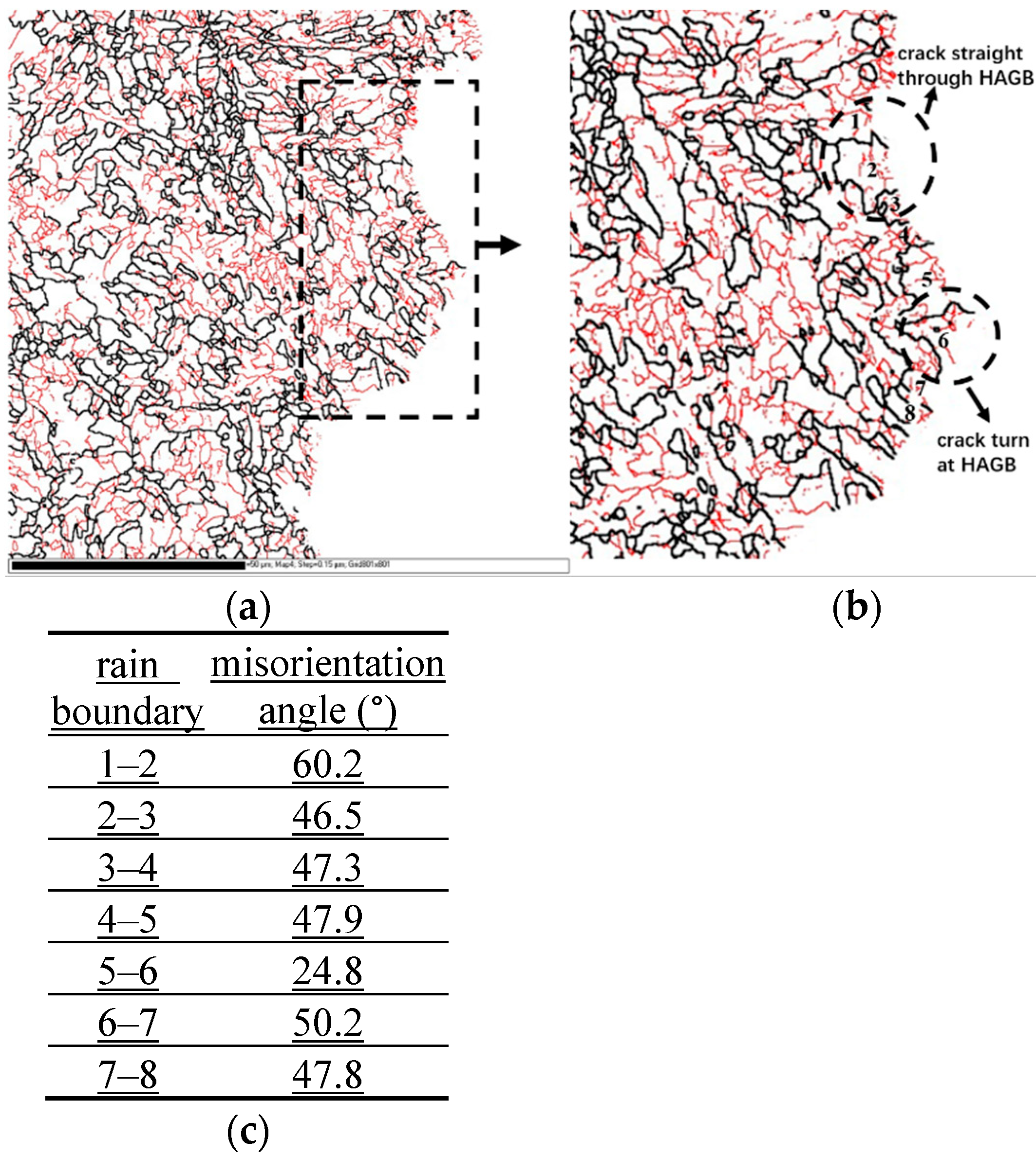

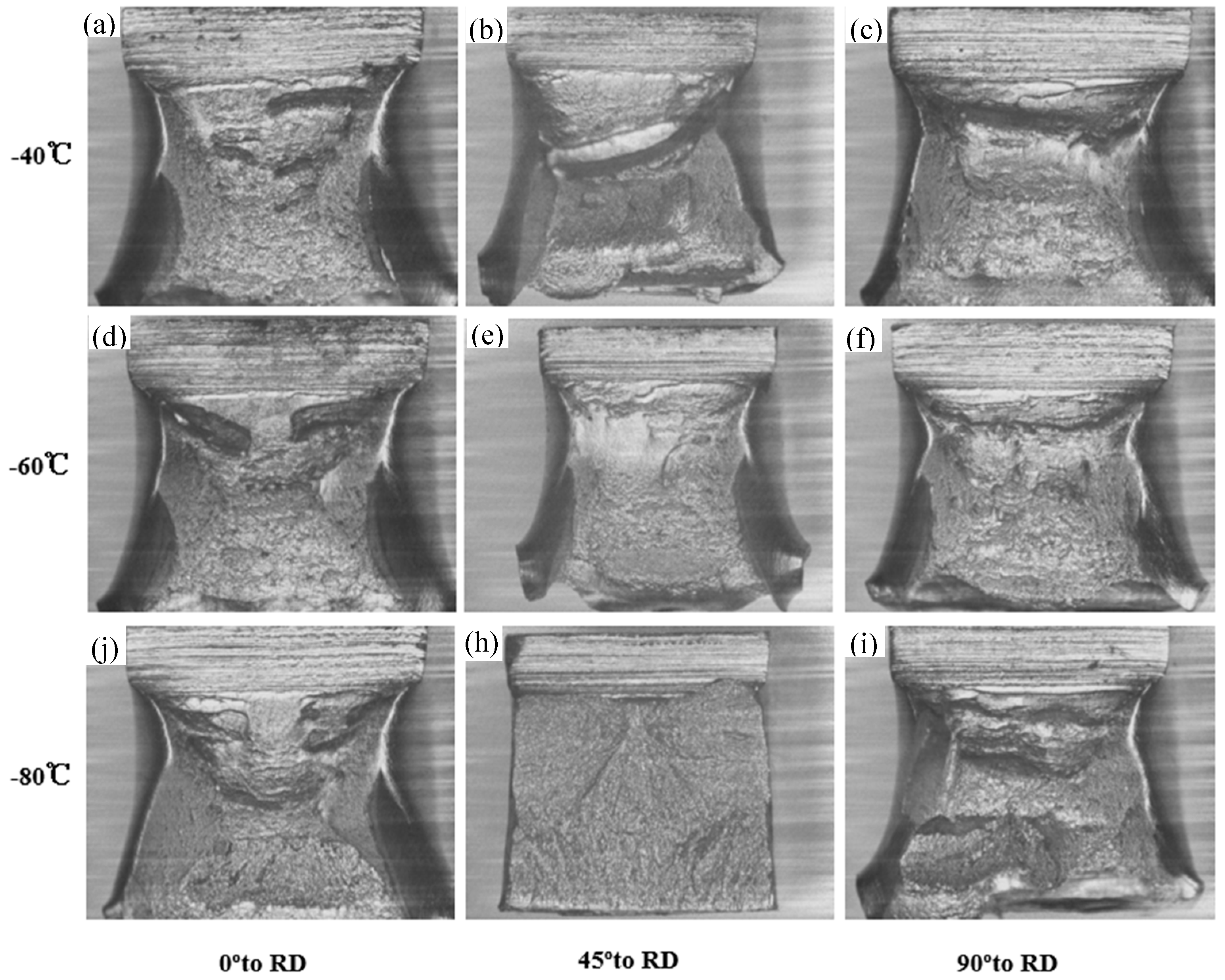

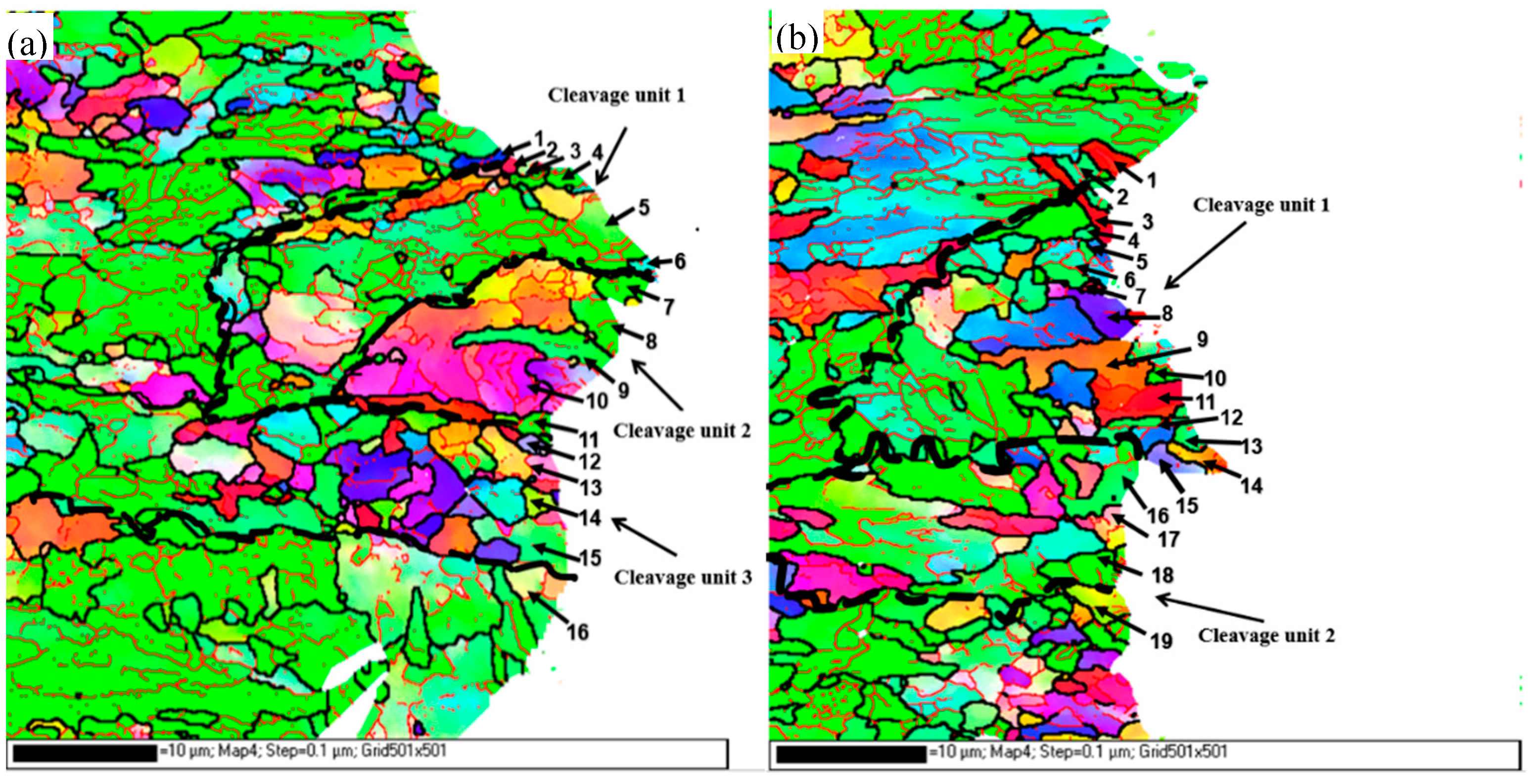

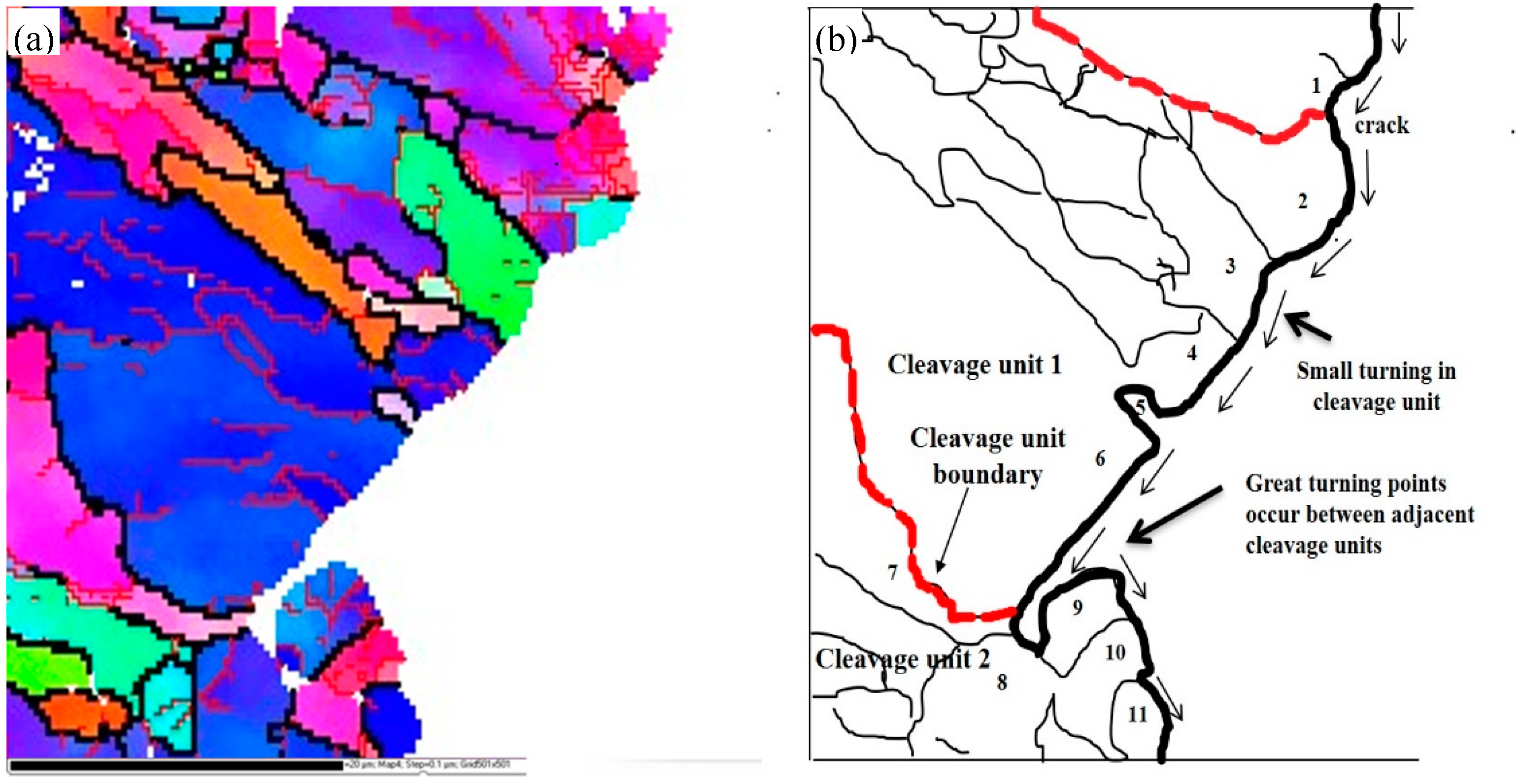

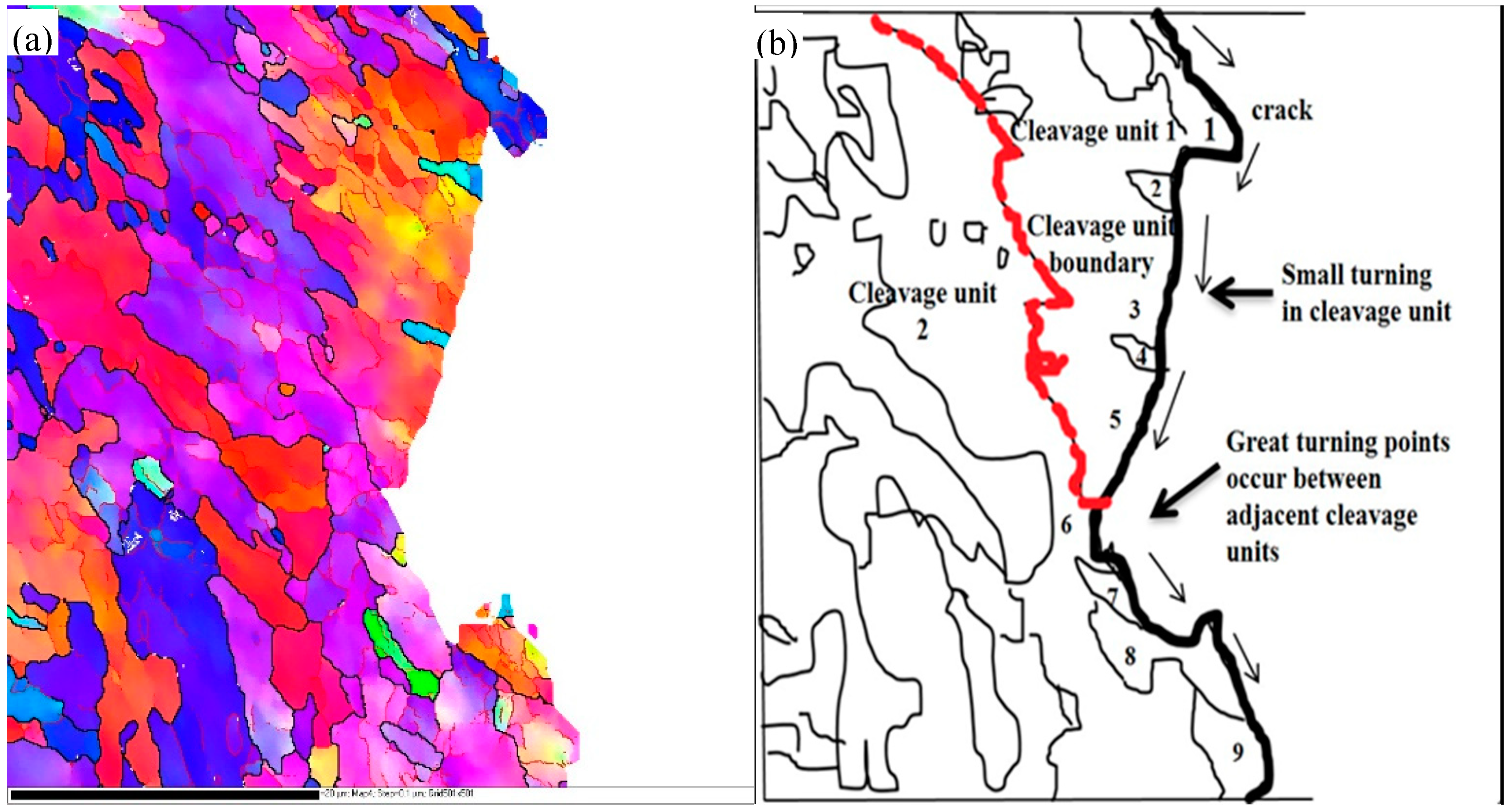

3.5. Cleavage Crack Propagation Path

4. Conclusions

- The microstructure in different directions all consists of refined acicular ferrite (AF) and polygonal ferrite (PF). The distribution of high angle grain boundaries (HAGB) was similar and mainly distributed in the range of 45°–65°, which can ensure acicular ferrite has excellent toughness. However, they have no significant influence on the anisotropy of toughness in acicular pipeline steel.

- The impact energy and SA% to DWTT in the five directions increased when the cleavage unit was composed of grains with a {100} cleavage plane less than 35° between grain boundaries, and the ductile to brittle transition temperature decreased. The cleavage unit composed of grains with a {100} cleavage plane less than 35° between grain boundaries was identified as the effective grain for cleavage fracture.

- In the actual process of crack propagation, when the cleavage crack encounters another cleavage unit (refined redefined effective grain), it will be arrested and then largely change its propagation direction, while when it encounters HAGB, it is possible to cross the HAGB directly. Therefore, it is important to refine the redefined effective grain size to improve the low temperature toughness of materials.

Author Contributions

Funding

Conflicts of Interest

References

- Shukla, R.; Ghosh, S.K.; Chakrabarti, D.; Chatterjee, S. Microstructure, texture, property relationship in thermo-mechanically processed ultra-low carbon micro-alloyed steel for pipeline application. Mater. Sci. Eng. A 2013, 587, 201–208. [Google Scholar] [CrossRef]

- Hwang, B.; Lee, C.G.; Kim, S.J. Low temperature toughening mechanism in thermomechanical processed high strength Low-Alloy Steels. Metal. Mater. Trans. A 2011, 42, 717–728. [Google Scholar] [CrossRef]

- Venkatsurya, P.K.C.; Misra, R.D.K.; Mulholland, M.D.; Manohar, M.; Hartmann, J.E. The impact of microstructure on yield strength anisotropy in pipeline steels. Mater. Sci. Eng. A 2014, 556, 2335–2342. [Google Scholar]

- Zong, C.; Zhu, G.; Mao, W. Effect of crystallographic texture on the anisotropy of Charpy impact behavior in pipeline steel. Mater. Sci. Eng. A 2013, 563, 1–7. [Google Scholar] [CrossRef]

- Zhang, Y.Q.; Guo, A.M.; Shang, C.J.; Liu, Q.Y.; Gray, M.J.; Frank, B. Latest development and application of high strength and heavy gauge pipeline steel in China. J. Mech. Eng. Auto. 2016, 6, 19–24. [Google Scholar] [CrossRef]

- Yang, X.L.; Xu, Y.B.; Tan, X.D.; Wu, D. Influences of crystallography and delamination on anisotropy of Charpy impact toughness in API X100 pipeline steel. Mater. Sci. Eng. A 2014, 607, 53–62. [Google Scholar] [CrossRef]

- Zhao, M.C.; Hanamura, T.; Qiu, H.; Nagai, K. Difference in the role of non-quench aging on mechanical properties between acicular ferrite and ferrite-pearlite pipeline steels. ISIJ Int. 2005, 45, 116–120. [Google Scholar] [CrossRef]

- Xiao, F.R.; Liao, B.; Shan, Y.Y.; Qiao, G.Y.; Zhong, Y.; Zhang, L.C. Challenge of mechanical properties of an acicular ferrite pipeline steel. Mater. Sci. Eng. A 2006, 431, 41–52. [Google Scholar] [CrossRef]

- Zhao, M.C.; Hanamura, T.; Qiu, H.; Yang, K. Lath boundary thin-film martensite in acicular ferrite ultralow carbon pipeline steels. Mater. Sci. Eng. A 2005, 395, 327–332. [Google Scholar] [CrossRef]

- Joo, M.S.; Suh, D.-W.; Bae, J.H.; Bhadeshia, H.K.D.H. Toughness anisotropy in X70 and X80 pipeline steels. Mater. Sci. Eng. A 2012, 556, 601–606. [Google Scholar] [CrossRef]

- Jabr, H.M.A.; Speer, J.G.; Matlock, D.K.; Zhang, P.; Cho, S.H. Anisotropy of mechanical properties of API X70 spiral welded pipe steels. Mater. Sci. Forum 2013, 753, 538–541. [Google Scholar]

- Xiao, F.R.; Liao, B.; Ren, D.L.; Shan, Y.Y.; Yang, K. Acicular ferritic microstructure of a low-carbon Mn-Mo-Nb micro-alloyed pipeline steel. Mater. Charact. 2005, 54, 305–314. [Google Scholar] [CrossRef]

- Sanchez, N.; Petrov, R.; Bae, J.H.; Kim, K. Texture dependent mechanical anisotropy of X80 pipeline steel. Adv. Eng. Mater. 2010, 12, 973–980. [Google Scholar]

- Byun, J.S.; Shim, J.H.; Suh, J.Y.; Oh, Y.J.; Cho, Y.W.; Shim, J.D.; Lee, D.N. Inoculated acicular ferrite microstructure and mechanical properties. Mater. Sci. Eng. A 2001, 319–321, 326–331. [Google Scholar] [CrossRef]

- Massa, F.; Piques, R.; Laurent, A. Rapid crack propagation in polyethylene pipe: Combined effect of strain rate and temperature on fracture toughness. J. Mater. Sci. 1997, 32, 6583–6587. [Google Scholar] [CrossRef]

- Cheng, S.; Zhang, X.; Zhang, J.; Feng, Y.; Ma, J.; Gao, H. Effect of coiling temperature on microstructure and properties of X100 pipeline steel. Mater. Sci. Eng. A 2016, 666, 156–164. [Google Scholar] [CrossRef]

- Duan, Q.; Yan, J.; Zhu, G.H.; Cai, Q.W. Effects of grain size and misorientation on anisotropy of X80 pipeline steel. Hot Working Tech. 2013, 42, 107–109. [Google Scholar]

- Masoumi, M.; Silva, C.C.; Abreu, H.F.G.D. Effect of rolling in the recrystallization temperature region associated with a post-heat treatment on the microstructure, crystal orientation, and mechanical properties of API 5L X70 pipeline steel. J. Mater. Eng. Perfor. 2018, 27, 1694–1705. [Google Scholar] [CrossRef]

- Deng, C.M.; Li, Z.D.; Sun, X.J.; Zhou, Y.; Yong, Q.L. Influence mechanism of high angle boundary on propagation of cleavage cracks in low carbon lath martensite steel. Mater. Mech. Eng. 2014, 38, 20–24. [Google Scholar]

- Shen, J.C.; Luo, Z.J.; Yang, C.F.; Zhang, Y.Q. Effective grain size affecting low temperature toughness in lath structure of HSLA steel. J. Iron Steel Res. Int. 2014, 26, 70–76. [Google Scholar]

- Yang, X.L.; Xu, Y.B.; Tan, X.D.; Wu, D. Relationships among crystallographic texture, fracture behavior and Charpy impact toughness API X100 pipeline steel. Mater. Sci. Eng. A 2015, 641, 96–106. [Google Scholar] [CrossRef]

- Zhao, J.; Hu, W.; Wang, X.; Wang, J.; Yuan, G.; Di, H.; Misra, R.D.K. Effect of microstructure on the crack propagation behavior of micro-alloyed 560MPa(X80) strip during ultra-fast cooling. Mater. Sci. Eng. A 2016, 666, 214–224. [Google Scholar] [CrossRef]

- Cui, G.B.; Ju, X.H.; Peng, G.; Yin, L.X. EBSD characterization on the structure of M-A islands of X80 pipeline steel. J. Elec. Micro. Soc. 2014, 33, 423–428. [Google Scholar]

- Hwang, B.; Lee, S.; Kim, Y.M.; Kim, N.J.; Yoo, J.Y.; Woo, C.S. Analysis of abnormal fracture occurring during drop-weight tear test of high-toughness line-pipe steel. Mater. Sci. Eng. A 2004, 368, 18–27. [Google Scholar] [CrossRef]

- Zhou, M.; Du, L.X.; Yi, H.L.; Liu, X.H. Factors affecting DWTT property of X80 pipeline steel. J. Iron Steel Res. Int. 2009, 21, 33–36. [Google Scholar]

- Zhang, X.L.; Feng, Y.R.; Zhuang, C.J.; Zhao, W.Z.; Huo, C.Y. Study on effective particle size of high-grade pipeline steels and relationship between CVN. Mater. Mech. Eng. 2007, 31, 4–8. [Google Scholar]

- Fuentes, M.D.; Mendia, A.; Gutiérrez, I. Analysis of different acicular ferrite microstructures in low-carbon steels by electron backscattered diffraction. Metal. Mater. Trans. A 2003, 34, 2505–2516. [Google Scholar] [CrossRef]

- Wang, C.F.; Wang, M.Q.; Shi, J.; Hui, W.J.; Dong, H. Effect of microstructural refinement on the toughness of low carbon martensitic steel. Script. Mater. 2008, 58, 492–495. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | S | P | Nb | Mo | V | Ti | Ni | Cr | Cu |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Content | 0.06 | 0.2 | 1.75 | 0.001 | 0.007 | 0.075 | 0.23 | 0.022 | 0.014 | 0.21 | 0.25 | 0.01 |

| Directions | YS (Rp0.2) MPa | TS MPa | YS/TS (%) | A% | Section Shrinkage (%) | |

|---|---|---|---|---|---|---|

| 21.4 mm | 0° | 560 | 675 | 0.83 | 27.5 | 81 |

| 30° | 555 | 640 | 0.87 | 31 | 80 | |

| 45° | 565 | 655 | 0.86 | 27 | 85 | |

| 60° | 560 | 670 | 0.84 | 26.5 | 84 | |

| 90° | 600 | 695 | 0.86 | 23.5 | 80 |

| Charpy Impact | DWTT | ||||||

|---|---|---|---|---|---|---|---|

| Position | Grain | Misorientation Angle | {100} Planes Angle | Position | Grain | Misorientation Angle | {100} Planes Angle |

| cleavage unit 1and adjacent grain | 1–2 | 48.9 | 40.23 | cleavage unit 1 and adjacent grain | 1–2 | 55.26 | 20.12 |

| cleavage unit 1 | 2–3 | 47.5 | 12.25 | cleavage unit 1 | 2–3 | 54.12 | 41.23 |

| 3–4 | 46.3 | 14.62 | 3–4 | 58.31 | 20.43 | ||

| 4–5 | 54.1 | 17.59 | 4–5 | 58.22 | 30.23 | ||

| 5–6 | 48.7 | 12.34 | 5–6 | 52.33 | 25.32 | ||

| cleavage unit2 | 6–7 | 56.3 | 35.62 | 6–7 | 37.22 | 17.24 | |

| 7–8 | 52.1 | 21.68 | 7–8 | 52.56 | 38 | ||

| 8–9 | 51.6 | 22.17 | 8–9 | 49.37 | 10.34 | ||

| 9–10 | 54.1 | 20.96 | 9–10 | 37.45 | 15.24 | ||

| 10–11 | 52.5 | 42.24 | 10–11 | 25.08 | 20.18 | ||

| cleavage unit 3 | 11–12 | 58.4 | 12.11 | 11–12 | 52.12 | 19.15 | |

| 12–13 | 54.1 | 35.24 | 12–13 | 55.15 | 21.55 | ||

| 13–14 | 55.2 | 32.17 | 13–14 | 36.78 | 18.45 | ||

| 14–15 | 54.3 | 32.48 | 14–15 | 60.25 | 40.4 | ||

| cleavage unit 3 and adjacent grain | 15–16 | 52.6 | 45.19 | cleavage unit 2 | 15–16 | 62.12 | 44.87 |

| 16–17 | 55.31 | 25.12 | |||||

| 17–18 | 54.32 | 37.25 | |||||

| cleavage unit 2 and adjacent grain | 18–19 | 49.22 | 40.21 | ||||

| Project | 0° to RD | 30° to RD | 45° to RD | 60° to RD | 90° to RD |

|---|---|---|---|---|---|

| Flatted austenite grain size (μm) | 15.8 | 16.1 | 15.8 | 15.9 | 16.0 |

| Cleavage unit size of impact sample (μm) | 14.1 | 14.5 | 16.7 | 15.1 | 13.9 |

| Cleavage unit size of DWTT sample (μm) | 15 | 15.1 | 16.5 | 16.8 | 16.6 |

| Grain size (μm) | 4.0 | 4.1 | 3.9 | 4.2 | 4.1 |

| 50% FATT (K)- impact sample | 405 | 377 | 348 | 361 | 385 |

| 50% FATT (K)-DWTT sample | 317 | 319 | 311 | 301 | 302 |

| −60 °C impact energy (J) | 324 | 329 | 234 | 342 | 343 |

| −80 °C Charpy energy (J) | 327 | 230 | 112 | 220 | 226 |

| −15 °C SA (%) to DWTT | 100 | 100 | 100 | 78 | 75 |

| −30 °C SA (%) to DWTT | 100 | 77 | 80 | 45 | 42 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niu, Y.; Jia, S.; Liu, Q.; Tong, S.; Li, B.; Ren, Y.; Wang, B. Influence of Effective Grain Size on Low Temperature Toughness of High-Strength Pipeline Steel. Materials 2019, 12, 3672. https://doi.org/10.3390/ma12223672

Niu Y, Jia S, Liu Q, Tong S, Li B, Ren Y, Wang B. Influence of Effective Grain Size on Low Temperature Toughness of High-Strength Pipeline Steel. Materials. 2019; 12(22):3672. https://doi.org/10.3390/ma12223672

Chicago/Turabian StyleNiu, Yanlong, Shujun Jia, Qingyou Liu, Shuai Tong, Ba Li, Yi Ren, and Bing Wang. 2019. "Influence of Effective Grain Size on Low Temperature Toughness of High-Strength Pipeline Steel" Materials 12, no. 22: 3672. https://doi.org/10.3390/ma12223672

APA StyleNiu, Y., Jia, S., Liu, Q., Tong, S., Li, B., Ren, Y., & Wang, B. (2019). Influence of Effective Grain Size on Low Temperature Toughness of High-Strength Pipeline Steel. Materials, 12(22), 3672. https://doi.org/10.3390/ma12223672