The Influence of Selected Local Phenomena in CFRP Laminate on Global Characteristics of Bolted Joints

Abstract

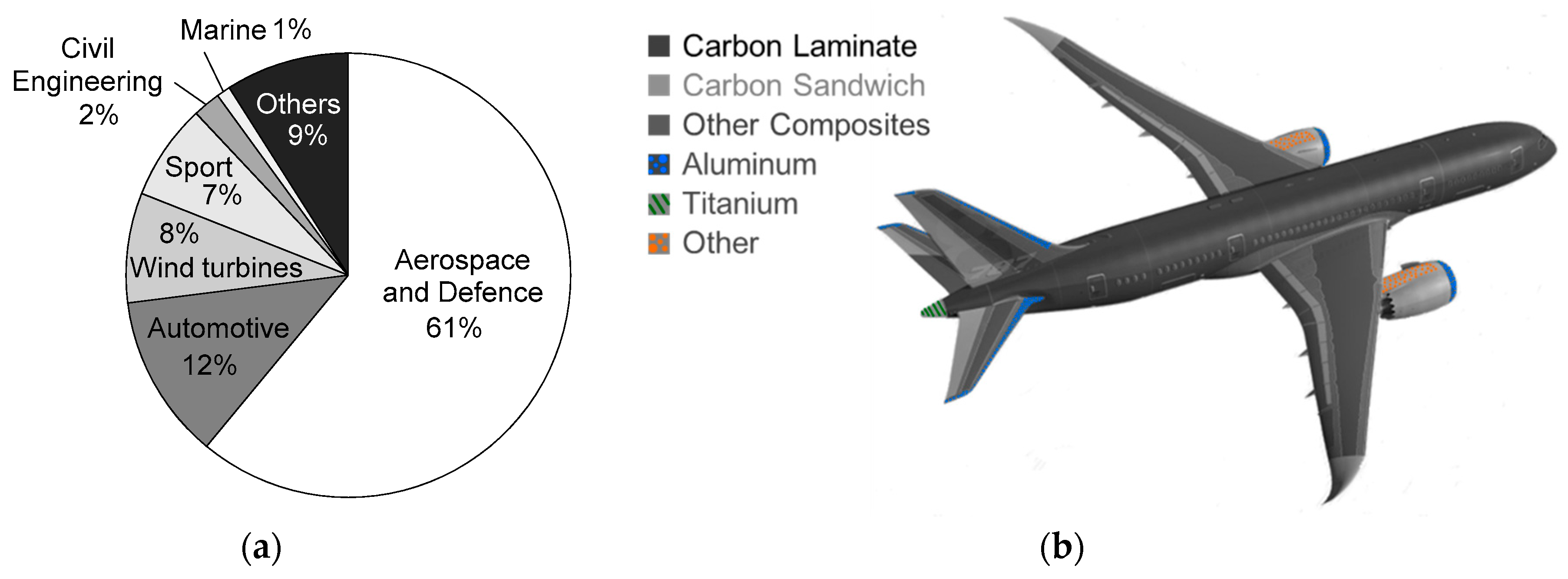

1. Introduction

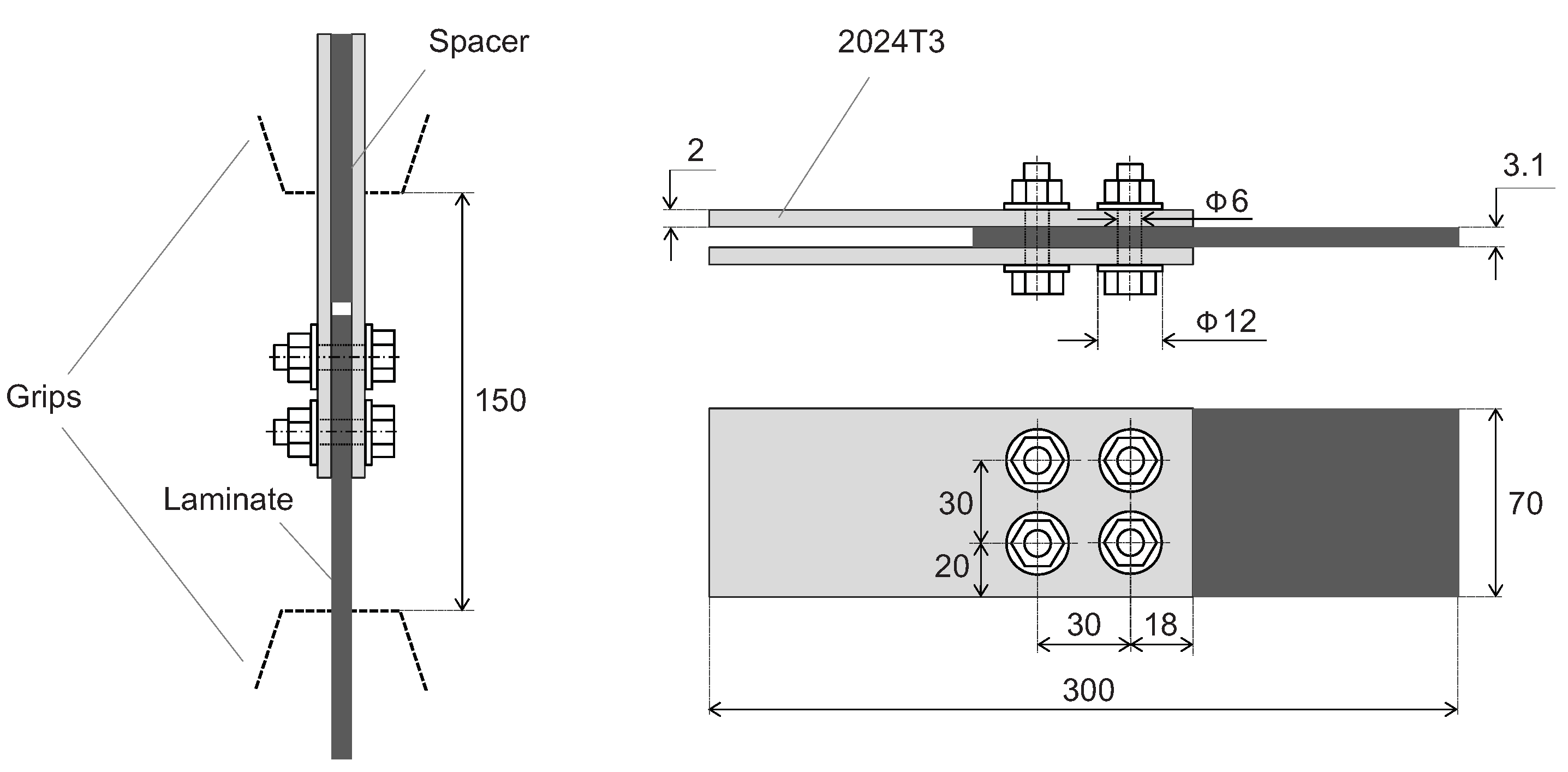

2. Object of Analysis

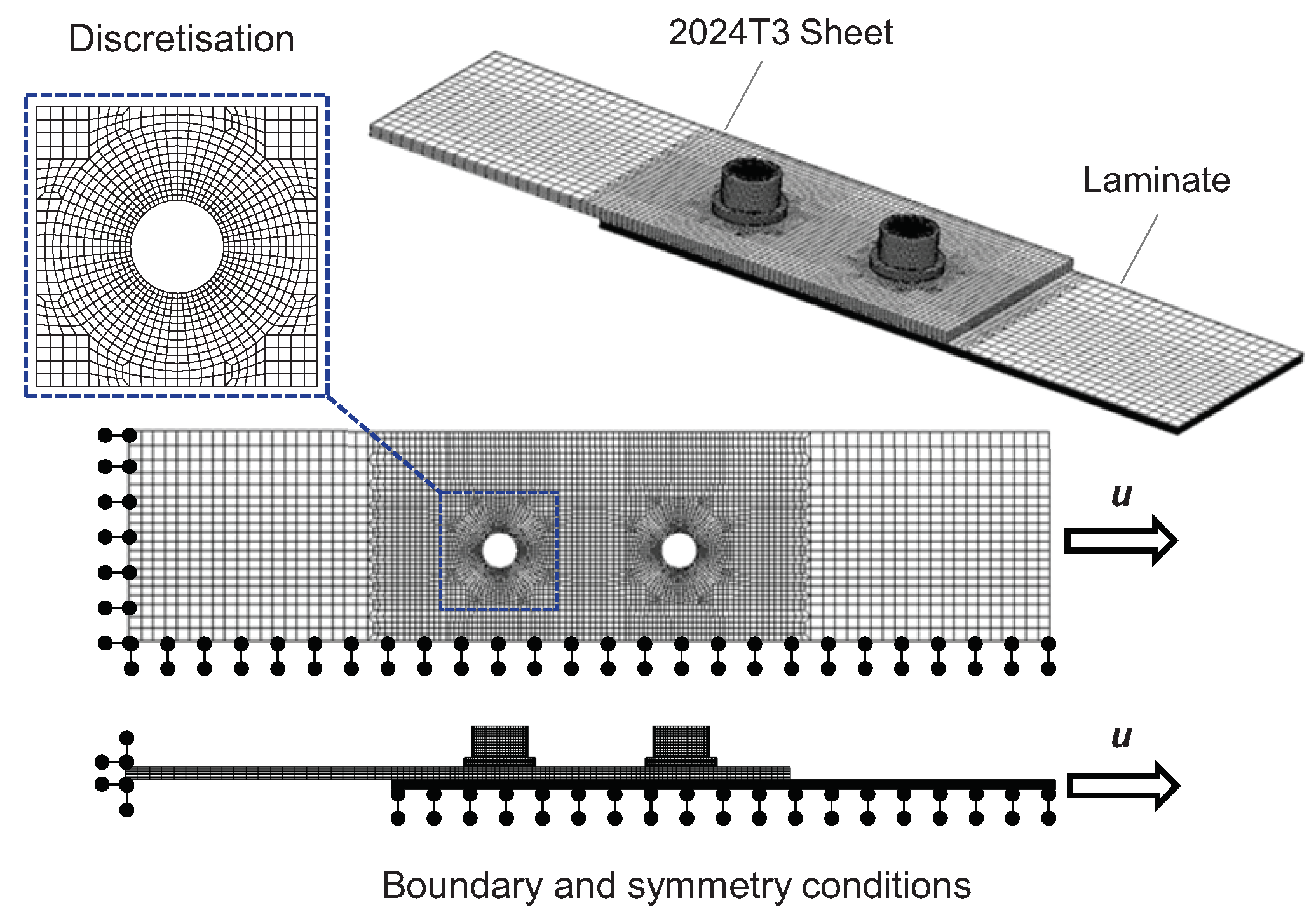

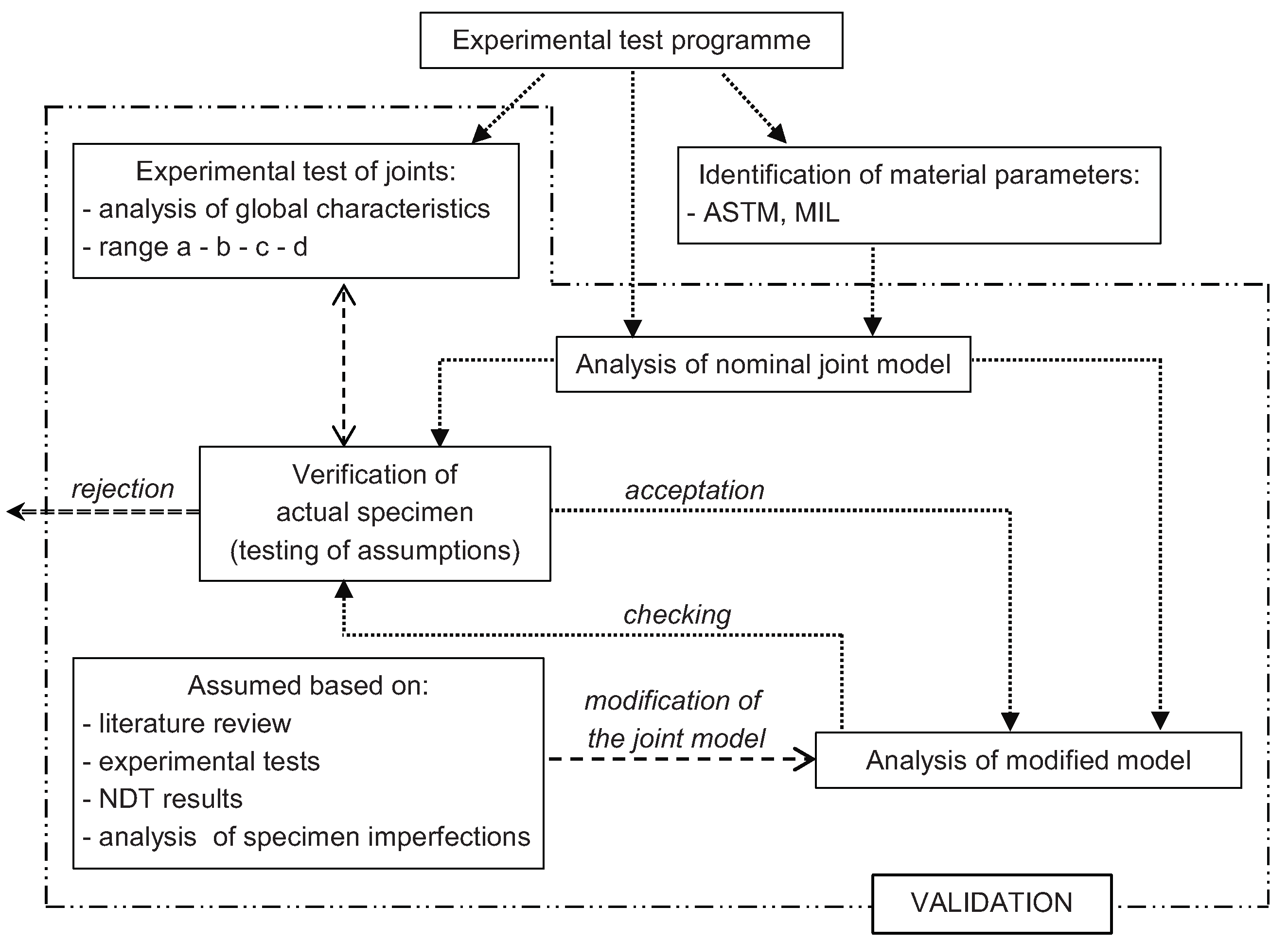

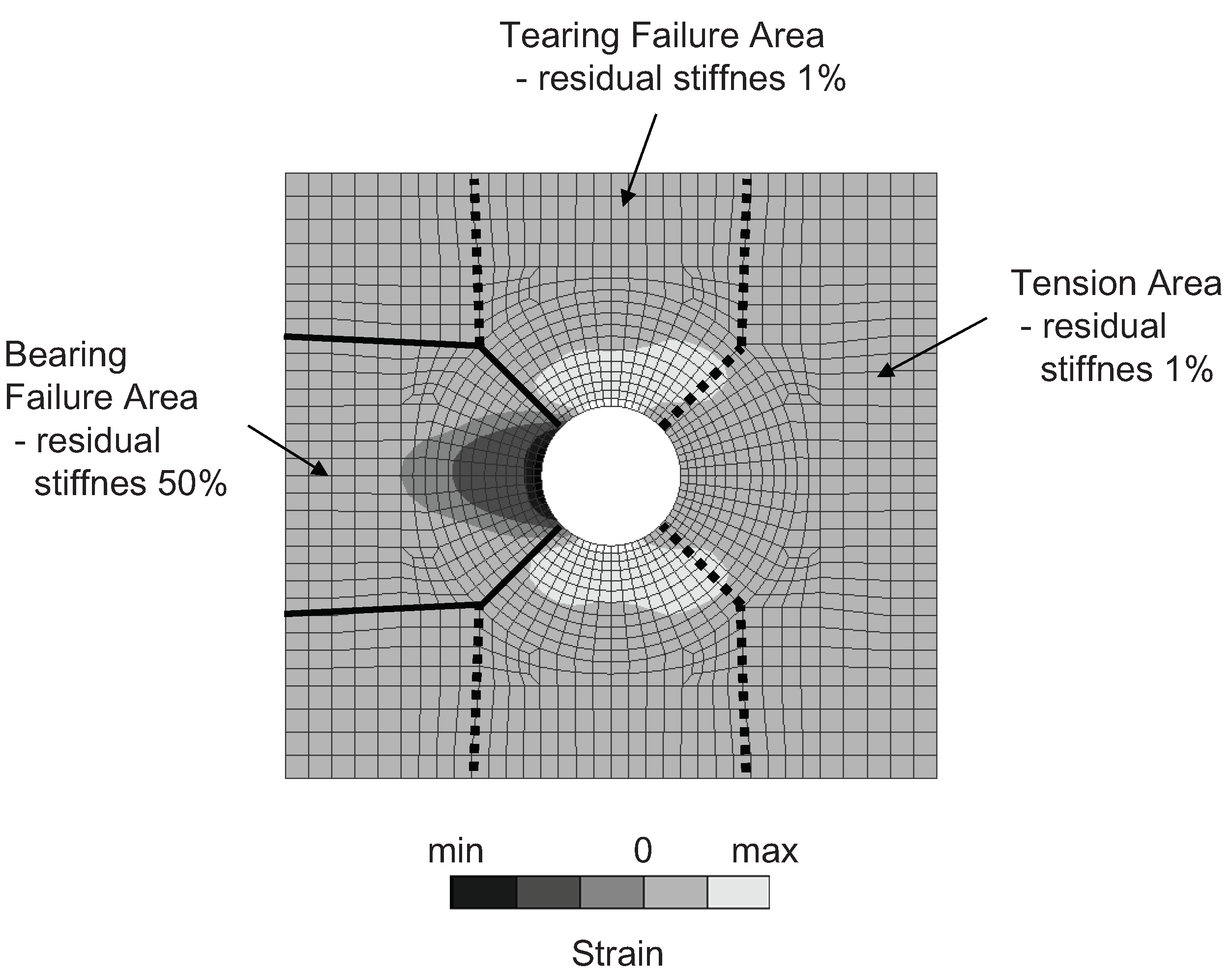

3. Numerical Model of Mechanical Joint

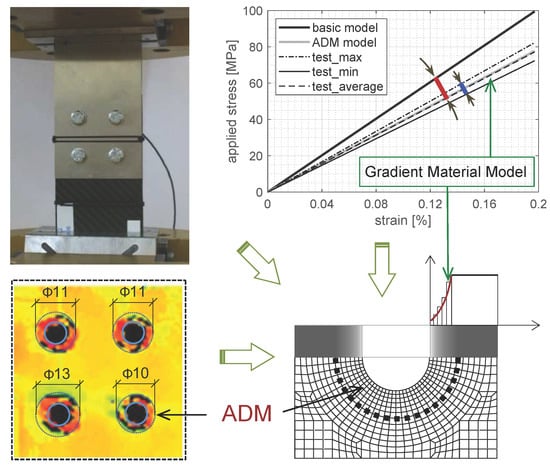

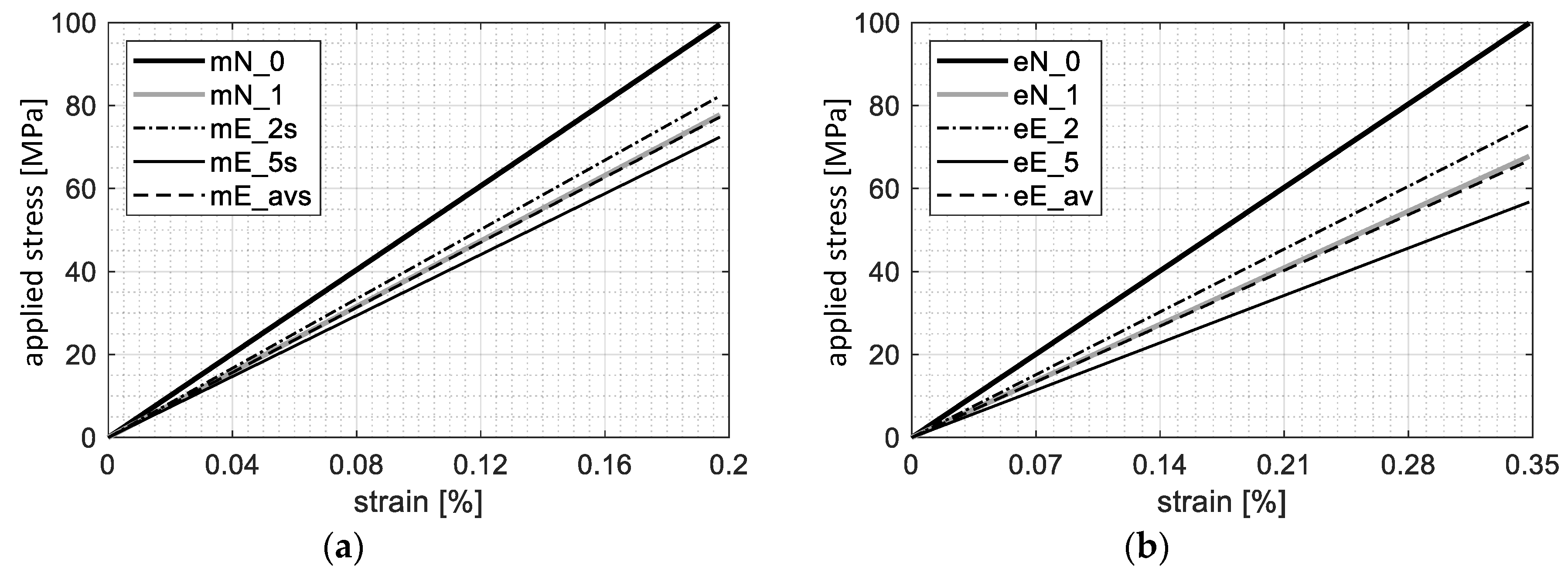

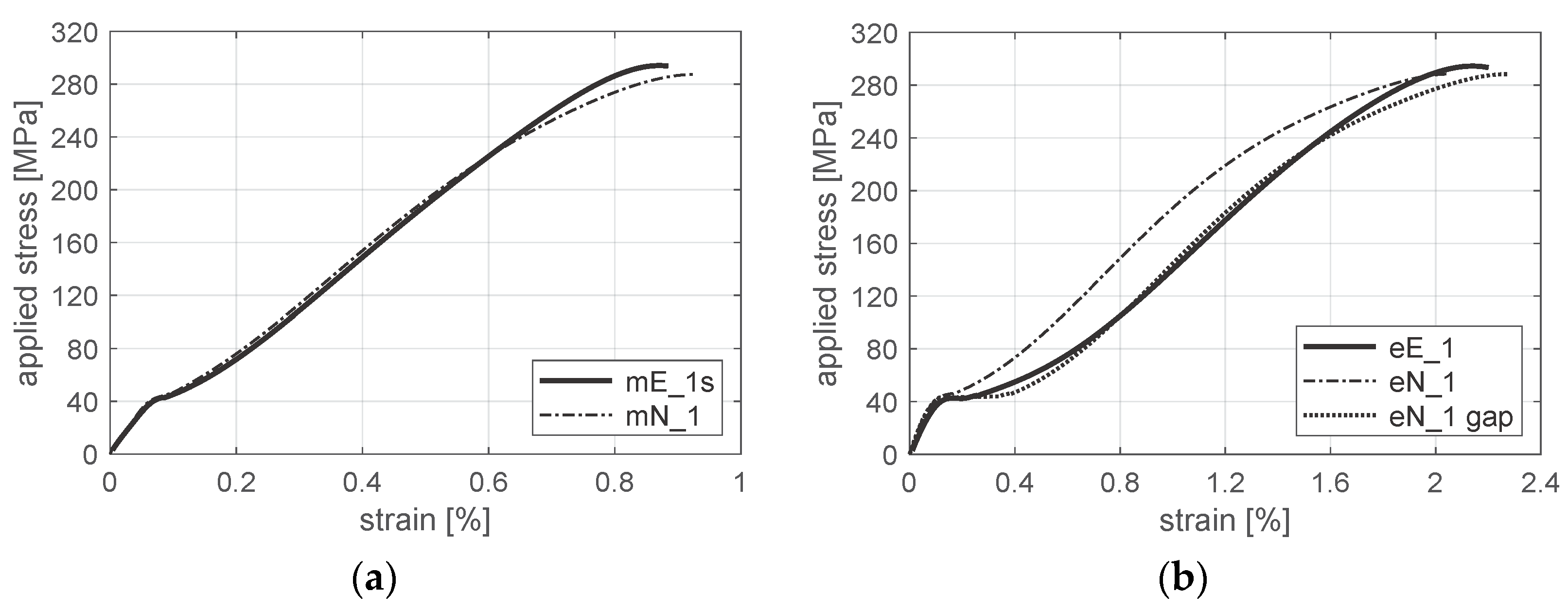

4. Analysis of Joint Behavior in the Aspect of Numerical Model Validation

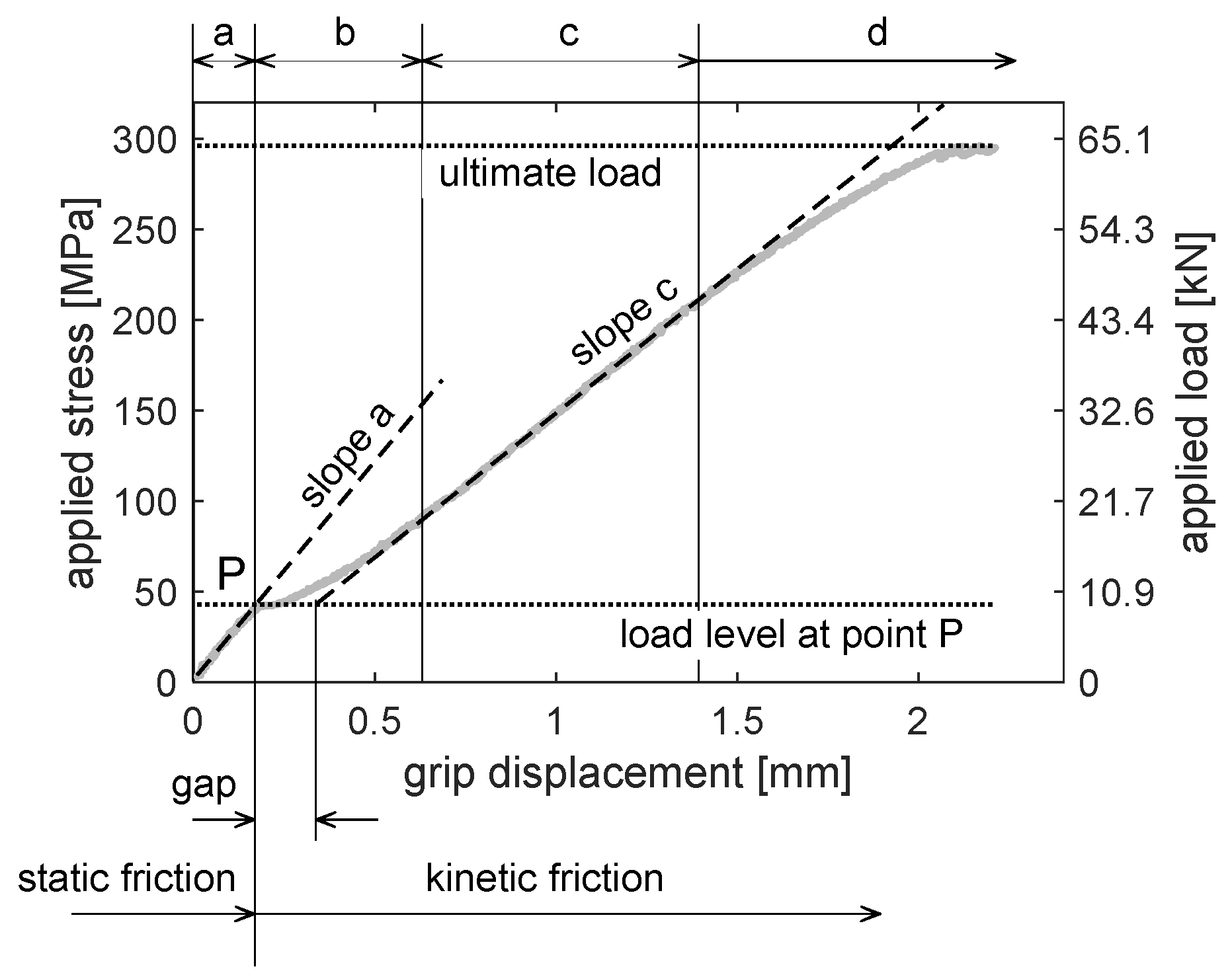

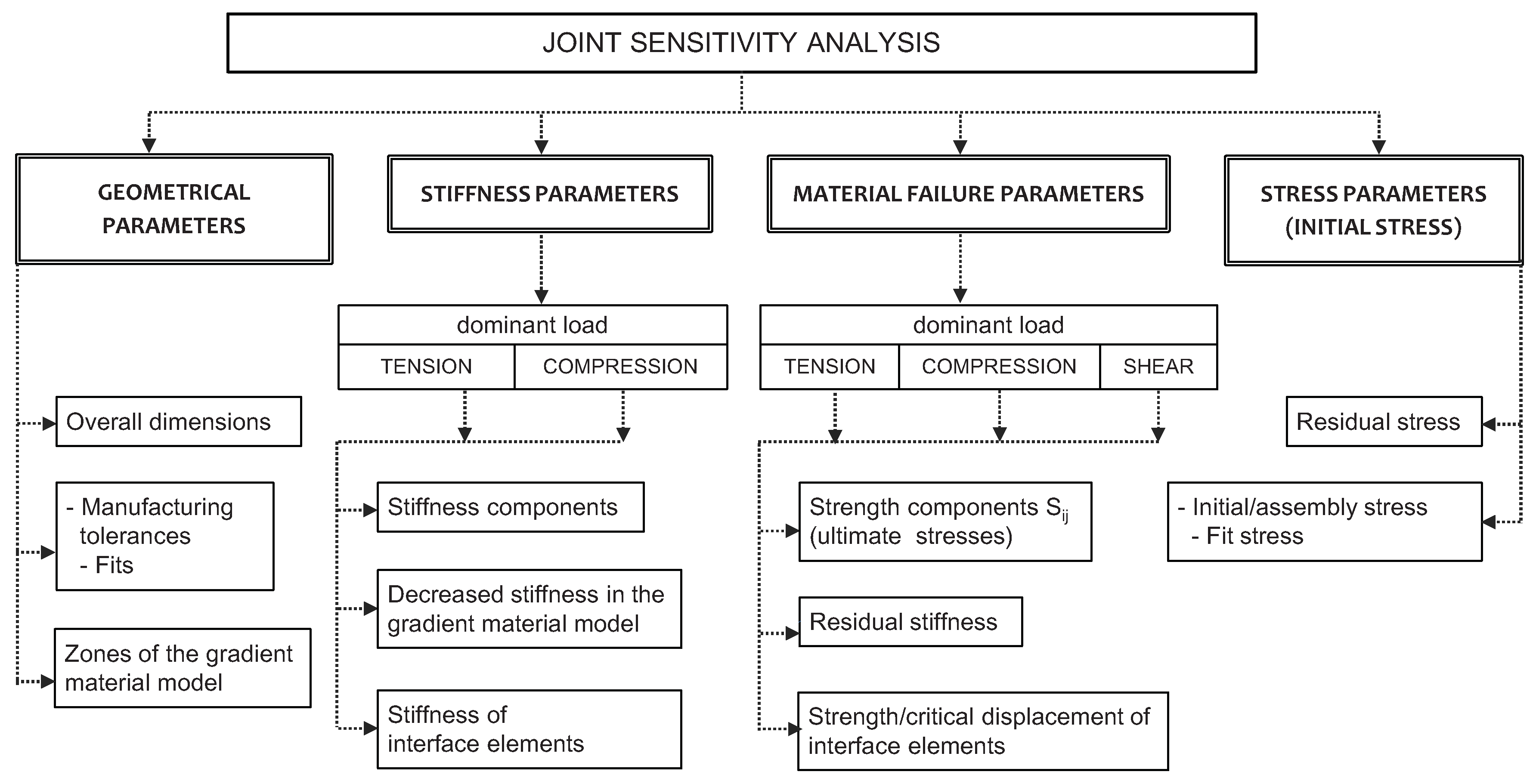

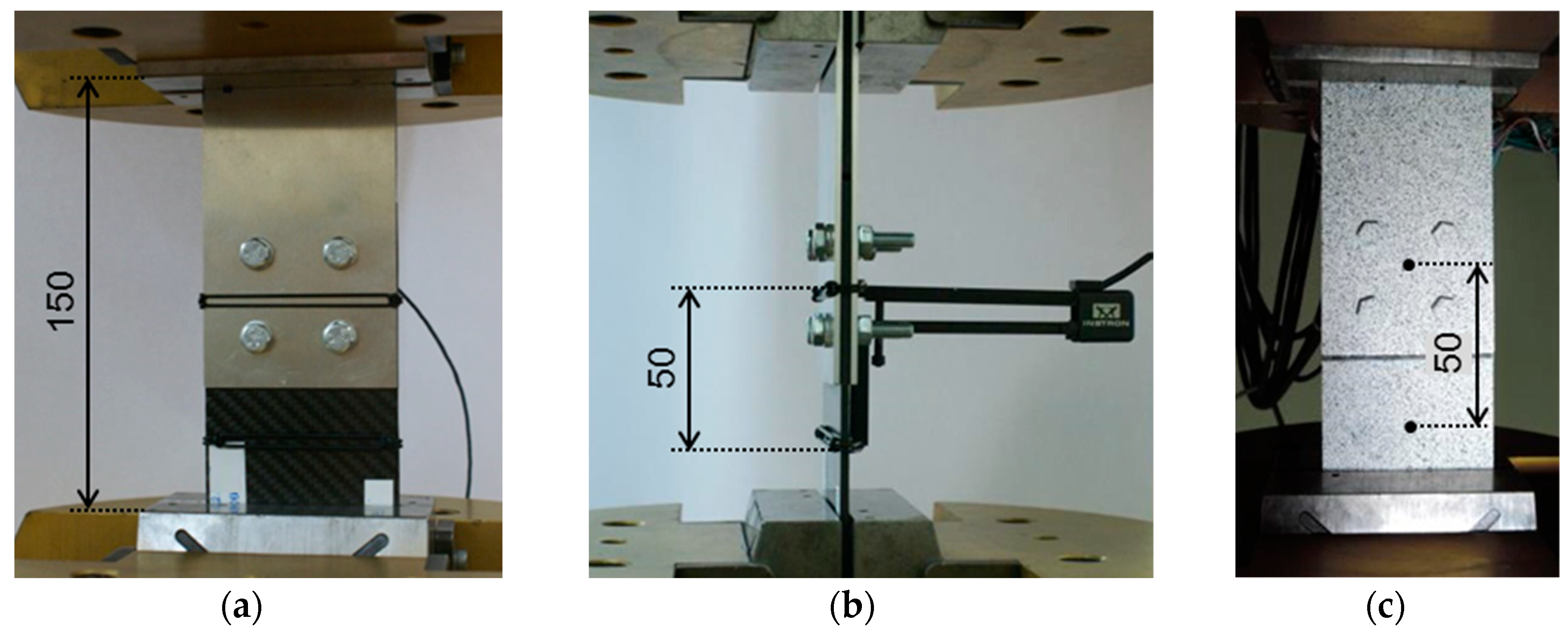

- geometrical parameters,

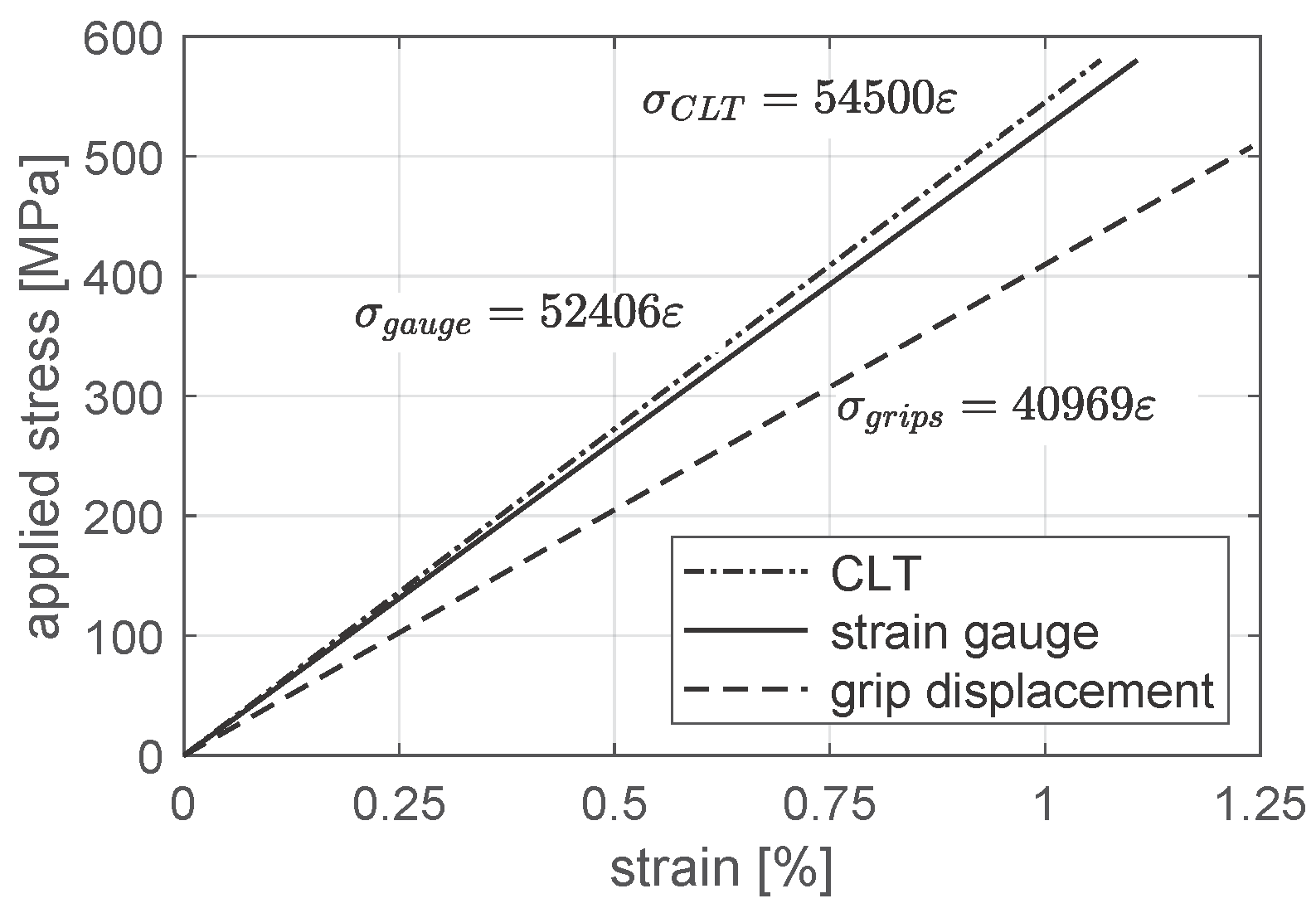

- stiffness parameters,

- material failure parameters,

- stress parameters (initial stress).

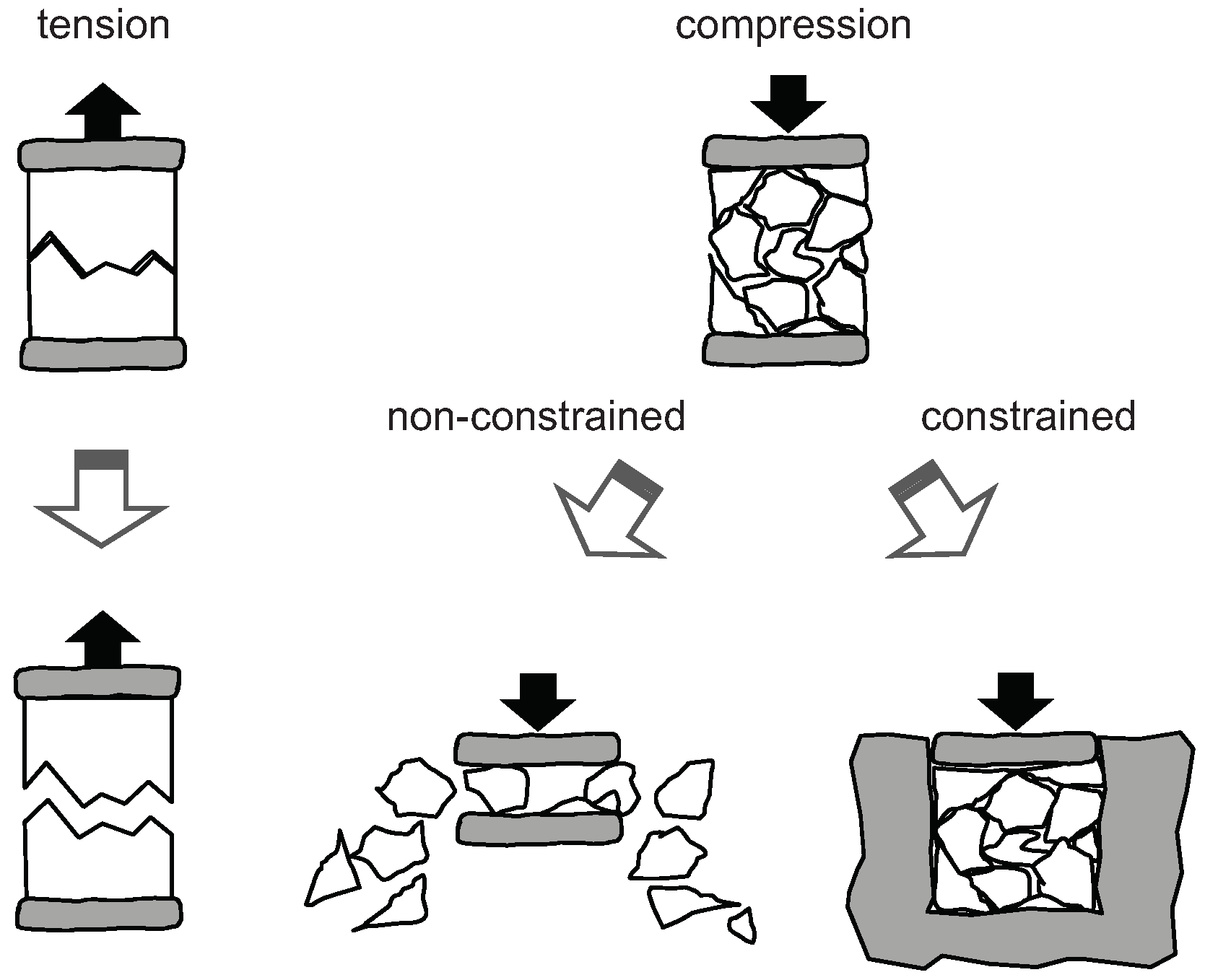

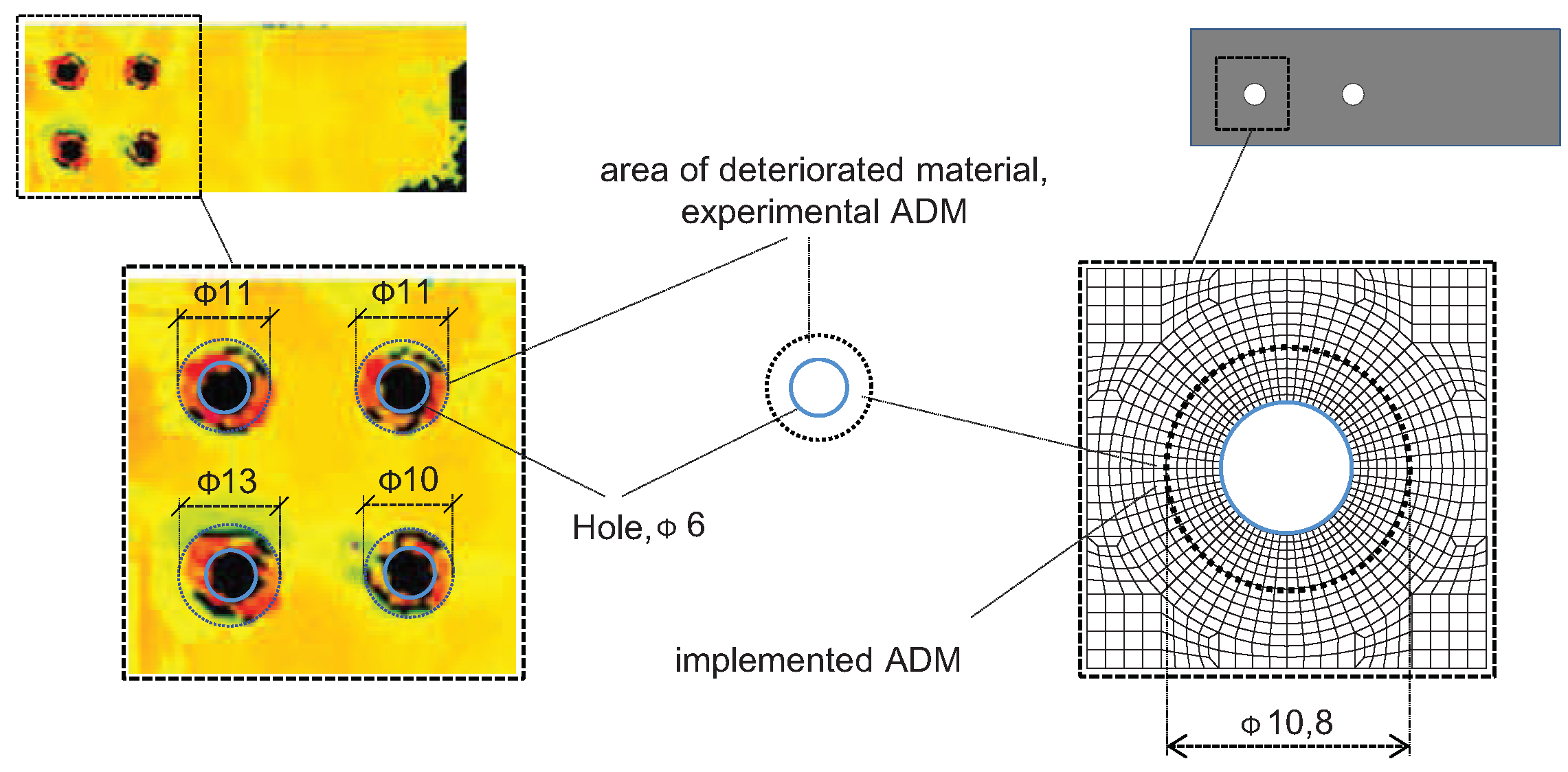

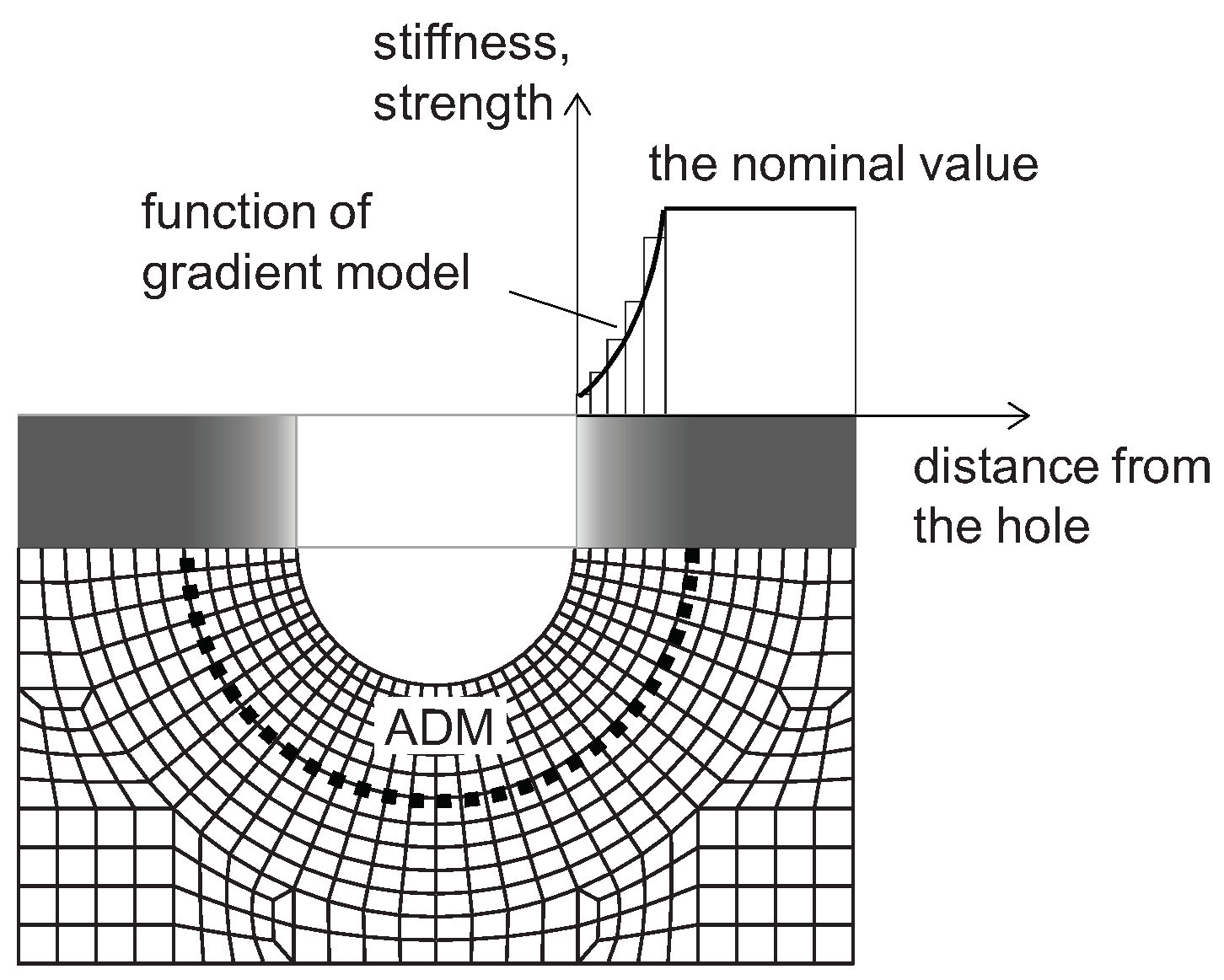

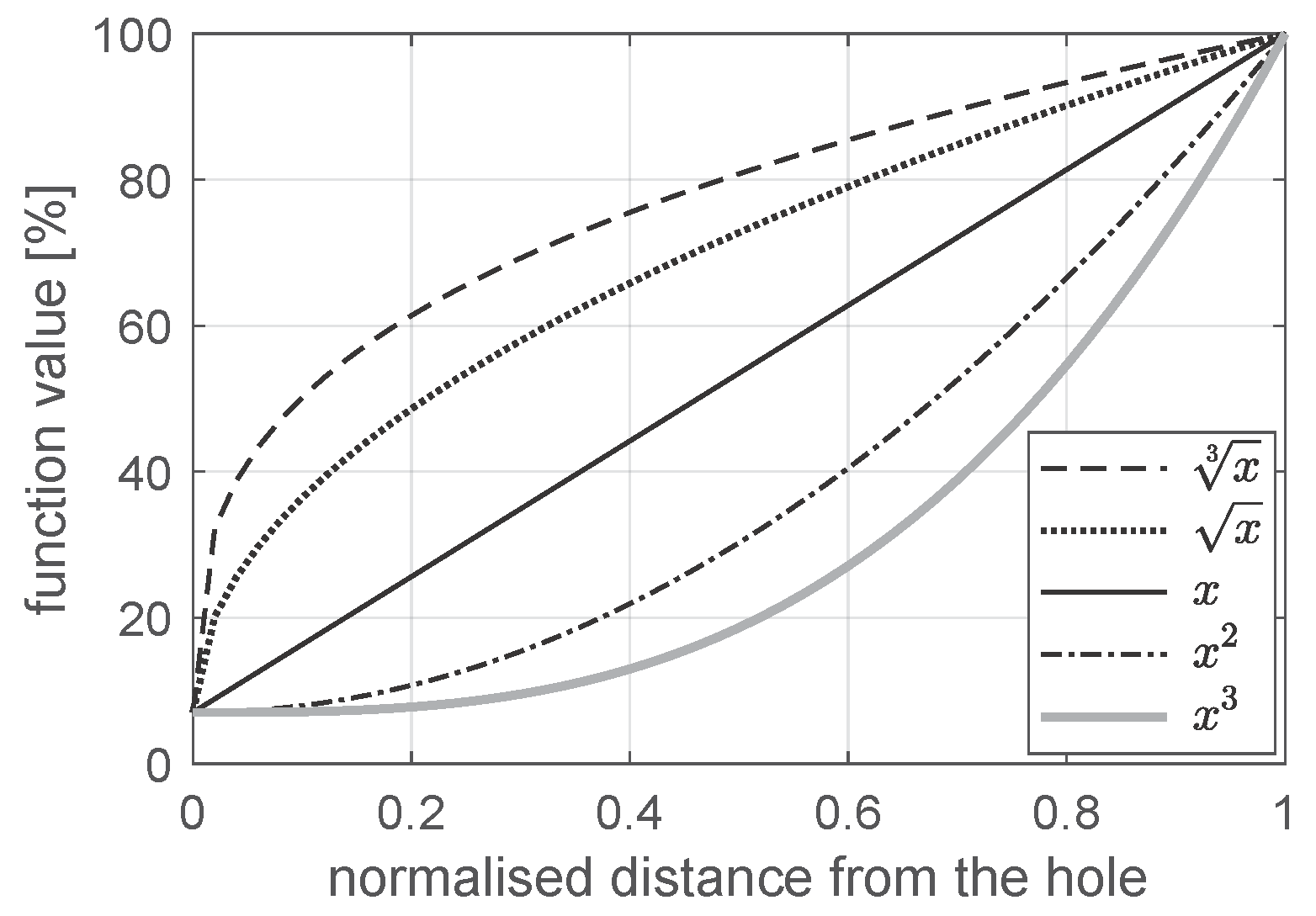

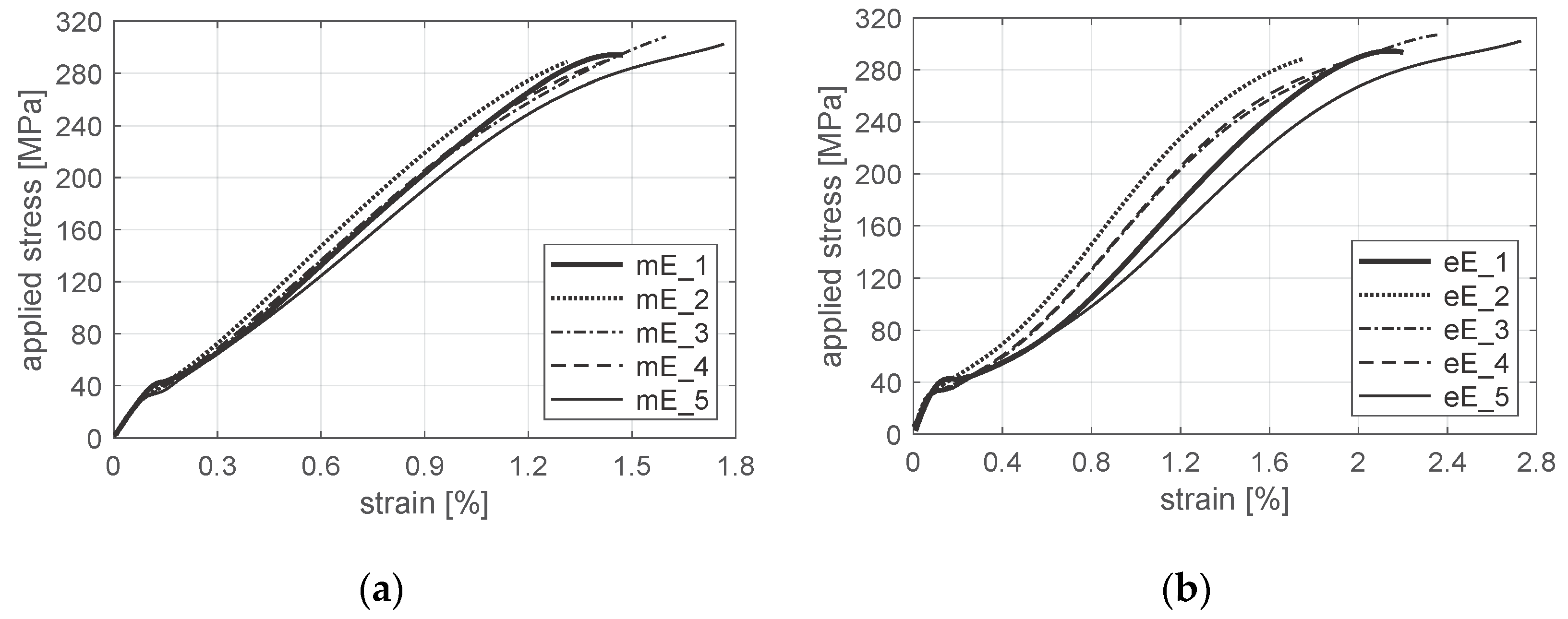

5. Gradient Material Model

6. Results of Experimental Tests

7. Discussion

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Niu Michael, C.Y. Composite Airframe Structures; Conmilit Press Ltd.: Hong Kong, China, 1992. [Google Scholar]

- Ashby, M.F. Materials Selection in Mechanical Design; Butterworth-Heinemann: Oxford, UK, 2010. [Google Scholar]

- Jachimowicz, J.; Szymczyk, E.; Puchała, K. Study of material mass efficiency and numerical analysis of modified CFRP laminate in bearing conditions. Compos. Struct. 2015, 134, 114–123. [Google Scholar] [CrossRef]

- Mazurkiewicz, L.; Tomaszewski, M.; Malachowski, J.; Sybilski, K.; Chebakov, M.; Witek, M.; Yukhymets, P.; Dmitrienko, R. Experimental and numerical study of steel pipe with part-wall defect reinforced with fibre glass sleeve. Int. J. Press. Vessel. Pip. 2017, 149, 108–119. [Google Scholar] [CrossRef]

- Mazurkiewicz, Ł.; Malachowski, J.; Tomaszewski, M.; Baranowski, P.; Yukhymets, P. Performance of steel pipe reinforced with composite sleave. Compos. Struct. 2018, 183. [Google Scholar] [CrossRef]

- U.S. Department of Transportation. Federal Aviation Administration (FAA) Advisory Circular—Composite Aircraft Structure; U S. Department of Transportation: Washington, DC, USA, 2009.

- Schmid Fuertes, T.A.; Kruse, T.; Körwien, T.; Geistbeck, M. Bonding of CFRP primary aerospace structures—Discussion of the certification boundary conditions and related technology fields addressing the needs for development. Compos. Interfaces 2015, 22, 795–808. [Google Scholar] [CrossRef]

- Witten, E.; Kraus, T.; Kühnel, M. Composites Market Report 2016. Market Developments, Trends, Outlook and Challenges; AVK Federation of Reinforced Plastics: Frankfurt, Germany, 2016. [Google Scholar]

- Boeing: 787 by Design. Available online: https://www.boeing.com/commercial/787/by-design/#/advanced-composite-use (accessed on 8 October 2019).

- Nerilli, F.; Vairo, G. Progressive damage in composite bolted joints via a computational micromechanical approach. Compos. Part B Eng. 2017, 111, 357–371. [Google Scholar] [CrossRef]

- Xiang, J.; Zhao, S.; Li, D.; Wu, Y. An improved spring method for calculating the load distribution in multi-bolt composite joints. Compos. Part B Eng. 2017, 117, 1–8. [Google Scholar] [CrossRef]

- Yazdani Nezhad, H.; Egan, B.; Merwick, F.; McCarthy, C.T. Bearing damage characteristics of fibre-reinforced countersunk composite bolted joints subjected to quasi-static shear loading. Compos. Struct. 2017, 166, 184–192. [Google Scholar] [CrossRef]

- Chen, C.; Hu, D.; Liu, Q.; Han, X. Evaluation on the interval values of tolerance fit for the composite bolted joint. Compos. Struct. 2018, 206, 628–636. [Google Scholar] [CrossRef]

- Hu, X.F.; Haris, A.; Ridha, M.; Tan, V.B.C.; Tay, T.E. Progressive failure of bolted single-lap joints of woven fibre-reinforced composites. Compos. Struct. 2018, 189, 443–454. [Google Scholar] [CrossRef]

- Zhuang, F.; Arteiro, A.; Furtado, C.; Chen, P.; Camanho, P.P. Mesoscale modelling of damage in single- and double-shear composite bolted joints. Compos. Struct. 2019, 226. [Google Scholar] [CrossRef]

- Hu, J.; Zhang, K.; Xu, Y.; Cheng, H.; Xu, G.; Li, H. Modeling on bearing behavior and damage evolution of single-lap bolted composite interference-fit joints. Compos. Struct. 2019, 212, 452–464. [Google Scholar] [CrossRef]

- Grzejda, R. Determination of Bolt Forces and Normal Contact Pressure between Elements in the System with Many Bolts for its Assembly Conditions. Adv. Sci. Technol. Res. J. 2019, 13, 116–121. [Google Scholar] [CrossRef]

- Jancelewicz, B.; Mądry, W. Złącze Do Wprowadzania Siły Skupionej W Powłokę Kompozytową; Urząd Patenowy PRL: Warszawa, Polska, 1988. [Google Scholar]

- Camanho, P.P.; Tavares, C.M.L.; de Oliveira, R.; Marques, A.T.; Ferreira, A.J.M. Increasing the efficiency of composite single-shear lap joints using bonded inserts. Compos. Part B Eng. 2005, 36, 372–383. [Google Scholar] [CrossRef]

- Crosky, A.; Kelly, D.; Li, R.; Legrand, X.; Huong, N.; Ujjin, R. Improvement of bearing strength of laminated composites. Compos. Struct. 2006, 76, 260–271. [Google Scholar] [CrossRef]

- Asi, O. An experimental study on the bearing strength behavior of Al2O3 particle filled glass fiber reinforced epoxy composites pinned joints. Compos. Struct. 2010, 92, 354–363. [Google Scholar] [CrossRef]

- Kolesnikov, B.; Herbeck, L.; Fink, A. CFRP/titanium hybrid material for improving composite bolted joints. Compos. Struct. 2008, 83, 368–380. [Google Scholar] [CrossRef]

- Fink, A.; Camanho, P.P. 1—Reinforcement of composite bolted joints by means of local metal hybridization. Woodhead Publishing Series in Composites Science and Engineering. In Composite Joints and Connections; Camanho, P., Tong, L., Eds.; Woodhead Publishing: Cambridge, UK, 2011; pp. 3–34. [Google Scholar]

- Gerendt, C.; Dean, A.; Mahrholz, T.; Rolfes, R. On the progressive failure simulation and experimental validation of fiber metal laminate bolted joints. Compos. Struct. 2019, 229. [Google Scholar] [CrossRef]

- Vasiliev, V.V.; Morozov, E.V. Mechanics and Analysis of Composite Materials; Elsevier Science: Oxford, UK, 2001. [Google Scholar]

- Kwon, Y.; Allen, D.H.; Talreja, R.R. Multiscale Modeling and Simulation of Composite Materials and Structures; Springer: New York, NY, USA, 2008. [Google Scholar]

- Szymczyk, E.; Puchała, K.; Jachimowicz, J. About numerical analysis of pin loaded joints in laminate structure. AIP Conf. Proc. 2019, 2078. [Google Scholar] [CrossRef]

- Jones, R.M. Mechanics of Composite Materials, 2nd ed.; Taylor & Francis, Inc.: Philadelphia, PA, USA, 1998. [Google Scholar]

- Baker, A.A.; Scott, M.L. Composite Materials for Aircraft Structures, 3rd ed.; American Institute of Aeronautics and Astronautics, Inc.: Washington, DC, USA, 2016. [Google Scholar]

- Mikulik, Z.; Haase, P. CODAMEIN—Composite Damage Metrics and Inspection. EASA.2010.C13 Final Report; Bishop GmbH—Aeronautical Engineers: Hamburg, Germany, 2012. [Google Scholar]

- Breuer, U.P. Commercial Aircraft Composite Technology; Springer: Berlin, Germany, 2016. [Google Scholar]

- Seike, S.; Takao, Y.; Wang, W.X.; Matsubara, T. Bearing damage evolution of a pinned joint in CFRP laminates under repeated tensile loading. Int. J. Fatigue 2010, 32, 72–81. [Google Scholar] [CrossRef]

- Persson, E.; Eriksson, I.; Hammersberg, P. Propagation of Hole Machining Defects in Pin-Loaded Composite Laminates. J. Compos. Mater. 1997, 31, 383–408. [Google Scholar] [CrossRef]

- Starikov, R.; Schön, J. Local fatigue behaviour of CFRP bolted joints. Compos. Sci. Technol. 2002, 62, 243–253. [Google Scholar] [CrossRef]

- Persson, E.; Eriksson, I.; Zackrisson, L. Effects of hole machining defects on strength and fatigue life of composite laminates. Compos. Part A Appl. Sci. Manuf. 1997, 28, 141–151. [Google Scholar] [CrossRef]

- Durão, L.M.P.; Tavares, J.M.R.S.; de Albuquerque, V.H.C.; Marques, J.F.S.; Andrade, O.N.G. Drilling Damage in Composite Material. Materials 2014, 7, 3802–3819. [Google Scholar] [CrossRef] [PubMed]

- Bhatnagar, D.N.; Singh, I.; Nayak, D. Damage Investigation in Drilling of Glass Fiber Reinforced Plastic Composite Laminates. Mater. Manuf. Process. 2004, 19, 995–1007. [Google Scholar] [CrossRef]

- Tsao, C.C.; Hochengb, H. Computerized tomography and C-Scan for measuring delamination in the drilling of composite materials using various drills. Int. J. Mach. Tools Manuf. 2005, 45, 1282–1287. [Google Scholar] [CrossRef]

- Davim, J.P.; Rubio, J.C.; Abrao, A.M. A novel approach based on digital image analysis to evaluate the delamination factor after drilling composite laminates. Compos. Sci. Technol. 2007, 67, 1939–1945. [Google Scholar] [CrossRef]

- Grilo, T.J.; Paulo, R.M.F.; Silva, C.R.M.; Davim, J.P. Experimental delamination analyses of CFRPs using different drill geometries. Compos. Part B Eng. 2013, 45, 1344–1350. [Google Scholar] [CrossRef]

- Gemi, L.; Morkavuk, S.; Köklü, U.; Gemi, D.S. An experimental study on the effects of various drill types on drilling performance of GFRP composite pipes and damage formation. Compos. Part B Eng. 2019, 172, 186–194. [Google Scholar] [CrossRef]

- Liu, D.; Tang, Y.; Cong, W.L. A review of mechanical drilling for composite laminates. Compos. Struct. 2012, 94, 1265–1279. [Google Scholar] [CrossRef]

- Kavad, B.V.; Pandey, A.B.; Tadavi, M.V.; Jakharia, H.C. A Review Paper on Effects of Drilling on Glass Fiber Reinforced Plastic. Procedia Technol. 2014, 14, 457–464. [Google Scholar] [CrossRef]

- Panchagnula, K.K.; Palaniyandi, K. Drilling on fiber reinforced polymer/nanopolymer composite laminates: A review. J. Mater. Res. Technol. 2018, 7, 180–189. [Google Scholar] [CrossRef]

- Karataş, A.M.; Gökkaya, H. A review on machinability of carbon fiber reinforced polymer (CFRP) and glass fiber reinforced polymer (GFRP) composite materials. Def. Technol. 2018, 14, 318–326. [Google Scholar] [CrossRef]

- Geng, D.; Liu, Y.; Shao, Z.; Lu, Z.; Cai, J.; Li, X.; Jiang, X.; Zhang, D. Delamination formation, evaluation and suppression during drilling of composite laminates: A review. Compos. Struct. 2019, 216, 168–186. [Google Scholar] [CrossRef]

- Kourra, N.; Warnett, J.M.; Attridge, A.; Kiraci, E.; Gupta, A.; Barnes, S.; WIlliams, M.A. Metrological study of CFRP drilled holes with x-ray computed tomography. Int. J. Adv. Manuf. Technol. 2015, 78, 2025–2035. [Google Scholar] [CrossRef]

- Karimi, Z.N.; Minak, G.; Kianfar, P. Analysis of damage mechanisms in drilling of composite materials by acoustic emission. Compos. Struct. 2015, 131, 107–114. [Google Scholar] [CrossRef]

- Zitoune, R.; Krishnaraj, V.; Collombet, F. Study of drilling of composite material and aluminium stack. Compos. Struct. 2010, 92, 1246–1255. [Google Scholar] [CrossRef]

- Wang, G.D.; Melly, S.K.; Li, N. Experimental studies on a two-step technique to reduce delamination damage during milling of large diameter holes in CFRP/Al stack. Compos. Struct. 2018, 188, 330–339. [Google Scholar] [CrossRef]

- Tagliaferri, V.; Caprino, G.; Diterlizzi, A. Effect of drilling parameters on the finish and mechanical properties of GFRP composites. Int. J. Mach. Tools Manuf. 1990, 30, 77–84. [Google Scholar] [CrossRef]

- Haeger, A.; Schoen, G.; Lissek, F.; Meinhard, D.; Kaufeld, M.; Schneider, G.; Schuhmacher, S.; Knoblauch, V. Non-destructive Detection of Drilling-induced Delamination in CFRP and its Effect on Mechanical Properties. Procedia Eng. 2016, 149, 130–142. [Google Scholar] [CrossRef]

- Puchała, K.; Elżbieta, S.; Jachimowicz, J.; Bogusz, P. Gradient material model in analysis of mechanical joints of CFRP laminate. AIP Conf. Proc. 2018, 1922. [Google Scholar] [CrossRef]

- Rueda, S.H. Curing, Defects and Mechanical Performance of Fiber-Reinforced Composites; Universidad Politécnica de Madrid: Madrid, Spain, 2013. [Google Scholar]

- Awerbuch, J.; Madhukar, M.S. Notched Strength of Composite Laminates: Predictions and Experiments—A Review. J. Reinf. Plast. Compos. 1985, 4, 3–159. [Google Scholar] [CrossRef]

- Xiao, Y.; Ishikawa, T. Bearing strength and failure behavior of bolted composite joints (part I: Experimental investigation). Compos. Sci. Technol. 2005, 65, 1022–1031. [Google Scholar] [CrossRef]

- Shah, P.D.; Melo, J.D.D.; Cimini, C.A.; Ridha, M. Evaluation of Notched Strength of Composite Laminates for Structural Design. J. Compos. Mater. 2010, 44, 2381–2392. [Google Scholar] [CrossRef]

- Camanho, P.P.; Hallett, S. Composite Joints and Connections: Principles, Modelling and Testing; Woodhead Publishing: Oxford, UK, 2011. [Google Scholar]

- McCarthy, M.A.; McCarthy, C.T.; Lawlor, V.P.; Stanley, W.F. Three-dimensional finite element analysis of single-bolt, single-lap composite bolted joints: Part I—model development and validation. Compos. Struct. 2005, 71, 140–158. [Google Scholar] [CrossRef]

- Crews, J.H., Jr.; Naik, R.A. Bearing-Bypass Loading on Bolted Composite Joints; NASA: Washington, DC, USA, 1987.

- Hung, C.L.; Chang, F.K. Strength Envelope of Bolted Composite Joints under Bypass Loads. J. Compos. Mater. 1996, 30, 1402–1435. [Google Scholar] [CrossRef]

- Puchała, K.; Szymczyk, E.; Jachimowicz, J. Sensitivity analysis of numerical model of CFRP mechanical joint. AIP Conf. Proc. 2019, 2078, 020096. [Google Scholar] [CrossRef]

- Puchała, K.; Szymczyk, E.; Jachimowicz, J. FEM design of composite—metal joint for bearing failure analysis. Przegląd Mech. 2015, 2, 33–41. [Google Scholar]

- Dragan, K.; Bieniaś, J.; Sałaciński, M.; Synaszko, P. Inspection methods for quality control of fibre metal laminates in aerospace components. Composites 2011, 11, 130–135. [Google Scholar]

- Wronkowicz-Katunin, A.; Katunin, A.; Dragan, K. Ultrasonic C-Scan Image Processing Using Multilevel Thresholding for Damage Evaluation in Aircraft Vertical Stabilizer. Int. J. Image Graph. Signal Process. 2015, 11, 1–8. [Google Scholar] [CrossRef]

- Sałaciński, M.; Synaszko, P.; Olesiński, D.; Samoraj, P. Approach to evaluation of delamination on the MiG-29′s vertical stabilizers composite skin. In The ICAF 2019—Structural Integrity in the Age of Additive Manufacturing; Niepokolczycki, A., Komorowski, J., Eds.; Springer: Berlin, Germany, 2019; pp. 865–873. [Google Scholar]

- Szymczyk, E. Numeryczna Analiza Zjawisk Lokalnych w Połączeniach Nitowych Konstrukcji Lotniczych; Wojskowa Akademia Techniczna: Warsaw, Poland, 2013. [Google Scholar]

- Kelly, G. Quasi-static strength and fatigue life of hybrid (bonded/bolted) composite single-lap joints. Compos. Struct. 2006, 72, 119–129. [Google Scholar] [CrossRef]

- Dano, M.-L.; Kamal, E.; Gendron, G. Analysis of bolted joints in composite laminates: Strains and bearing stiffness predictions. Compos. Struct. 2007, 79, 562–570. [Google Scholar] [CrossRef]

- Du, A.; Liu, Y.; Xin, H.; Zuo, Y. Progressive damage analysis of PFRP double-lap bolted joints using explicit finite element method. Compos. Struct. 2016, 152, 860–869. [Google Scholar] [CrossRef]

- Stocchi, C.; Robinson, P.; Pinho, S.T. A detailed finite element investigation of composite bolted joints with countersunk fasteners. Compos. Part A Appl. Sci. Manuf. 2013, 52, 143–150. [Google Scholar] [CrossRef]

- Askri, R.; Bois, C.; Wargnier, H.; Gayton, N. Tolerance synthesis of fastened metal-composite joints based on probabilistic and worst-case approaches. Comput.-Aided Des. 2018, 100, 39–51. [Google Scholar] [CrossRef]

- MSC. Marc 2013 Documentation vol. A. In Theory and User Information; MSC Corporation: Newport Beach, CA, USA, 2013. [Google Scholar]

- Kim, K.S.; Hahn, H.T. Residual stress development during processing of graphite/epoxy composites. Compos. Sci. Technol. 1989, 36, 121–132. [Google Scholar] [CrossRef]

- Cho, J.; Sun, C.T. Lowering Thermal Residual Stresses in Composite Patch Repairs in Metallic Aircraft Structure. AIAA J. 2001, 39, 2013–2018. [Google Scholar] [CrossRef]

- Mulle, M.; Collombet, F.; Olivier, P.; Grunevald, Y.-H. Assessment of cure residual strains through the thickness of carbon–epoxy laminates using FBGs, Part I: Elementary specimen. Compos. Part A Appl. Sci. Manuf. 2009, 40, 94–104. [Google Scholar] [CrossRef]

- McCarthy, C.T.; McCarthy, M.A. Three-dimensional finite element analysis of single-bolt, single-lap composite bolted joints: Part II—Effects of bolt-hole clearance. Compos. Struct. 2005, 71, 159–175. [Google Scholar] [CrossRef]

- Khashaba, U.A.; Sebaey, T.A.; Alnefaie, K.A. Failure and reliability analysis of pinned-joints composite laminates: Effects of stacking sequences. Compos. Part B Eng. 2013, 45, 1694–1703. [Google Scholar] [CrossRef]

- Lopez-Cruz, P.; Laliberté, J.; Lessard, L. Investigation of bolted/bonded composite joint behaviour using design of experiments. Compos. Struct. 2017, 170, 192–201. [Google Scholar] [CrossRef]

- Askri, R.; Bois, C.; Wargnier, H. Effect of Hole-location Error on the Strength of Fastened Multi-Material Joints. Procedia CIRP 2016, 43, 292–296. [Google Scholar] [CrossRef][Green Version]

- Lü, X.; Zhao, J.; Hu, L.; Wang, H. Effect of interference fits on the fatigue lives of bolted composite joints. J. Shanghai Jiaotong Univ. Sci. 2016, 21, 648–654. [Google Scholar] [CrossRef]

- Giannopoulos, I.K.; Doroni-Dawes, D.; Kourousis, K.I.; Yasaee, M. Effects of bolt torque tightening on the strength and fatigue life of airframe FRP laminate bolted joints. Compos. Part B Eng. 2017, 125, 19–26. [Google Scholar] [CrossRef]

- Mandal, B.; Chakrabarti, A. Numerical failure assessment of multi-bolt FRP composite joints with varying sizes and preloads of bolts. Compos. Struct. 2018, 187, 169–178. [Google Scholar] [CrossRef]

- Liu, X.; Yang, Y.; Wang, Y.; Bao, Y.; Gao, H. Effects of Hole Perpendicularity Error on Mechanical Performance of Single-Lap Double-Bolt Composite Joints. Int. J. Polym. Sci. 2017, 2017. [Google Scholar] [CrossRef]

- Zhao, L.; Shan, M.; Liu, F.; Zhang, J. A probabilistic model for strength analysis of composite double-lap single-bolt joints. Compos. Struct. 2017, 161, 419–427. [Google Scholar] [CrossRef]

| No. | Sample Function | Deficiency Parameter (%) |

|---|---|---|

| 1 | cubic root | 75.0 |

| 2 | quadratic root | 66.7 |

| 3 | linear | 50.0 |

| 4 | square | 33.3 |

| 5 | cubic | 25.0 |

| Specimen No. | Grip Displacement * | Extensometer Length | |||||

|---|---|---|---|---|---|---|---|

| Stress (MPa) | Stiffness (MPa) | Gap (mm) | Stiffness (MPa) | Gap (mm) | |||

| Point P | Range a | Range c | Point P | Range a | Range c | Point P | |

| No. 1 | 42 | 36100 | 23900 | 0.163 | 39500 | 18500 | 0.181 |

| No. 2 | 31 | 35700 | 25100 | 0.083 | 42300 | 21600 | 0.103 |

| No. 3 | 30 | 36500 | 23200 | 0.096 | 39800 | 19600 | 0.124 |

| No. 4 | 31 | 36900 | 23300 | 0.094 | 35700 | 19800 | 0.122 |

| No. 5 | 31 | 37400 | 22000 | 0.133 | 38300 ** | 16300 ** | 0.170 ** |

| mean | 36500 | 23500 | 0.114 | 39100 | 19200 | 0.140 | |

| std. dev. | 665 | 1130 | 0.033 | 2402 | 1948 | 0.034 | |

| difference | 1700 | 3100 | 0.080 | 6600 | 5300 | 0.078 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Puchała, K.; Szymczyk, E.; Jachimowicz, J.; Bogusz, P.; Sałaciński, M. The Influence of Selected Local Phenomena in CFRP Laminate on Global Characteristics of Bolted Joints. Materials 2019, 12, 4139. https://doi.org/10.3390/ma12244139

Puchała K, Szymczyk E, Jachimowicz J, Bogusz P, Sałaciński M. The Influence of Selected Local Phenomena in CFRP Laminate on Global Characteristics of Bolted Joints. Materials. 2019; 12(24):4139. https://doi.org/10.3390/ma12244139

Chicago/Turabian StylePuchała, Krzysztof, Elżbieta Szymczyk, Jerzy Jachimowicz, Paweł Bogusz, and Michał Sałaciński. 2019. "The Influence of Selected Local Phenomena in CFRP Laminate on Global Characteristics of Bolted Joints" Materials 12, no. 24: 4139. https://doi.org/10.3390/ma12244139

APA StylePuchała, K., Szymczyk, E., Jachimowicz, J., Bogusz, P., & Sałaciński, M. (2019). The Influence of Selected Local Phenomena in CFRP Laminate on Global Characteristics of Bolted Joints. Materials, 12(24), 4139. https://doi.org/10.3390/ma12244139