Tribological and Electrochemical Characterization of UHMWPE Hybrid Nanocomposite Coating for Biomedical Applications

Abstract

1. Introduction

2. Experimental Methodology

2.1. Materials

2.2. Hybrid Nanocomposite Powder Preparation

2.3. Coating Procedure

2.4. Thickness Measurements

2.5. Tribological Characterization

2.6. Hardness Measurement

2.7. Scratch Test

2.8. Electrochemical Corrosion Analyses

3. Results and Discussion

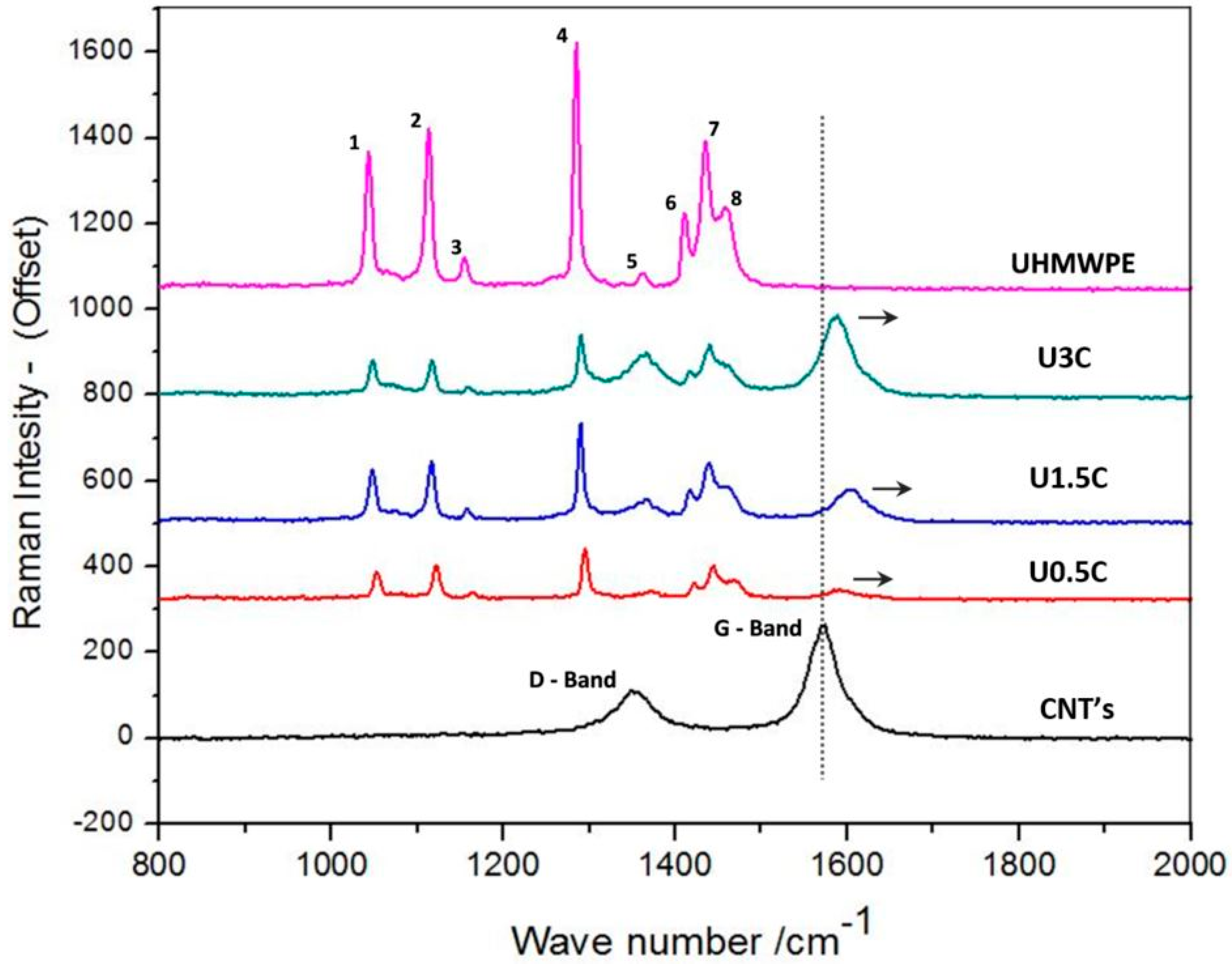

3.1. Evaluation of Interaction of CNT’s with UHMWPE Polymer Matrix Using Raman Spectroscopy

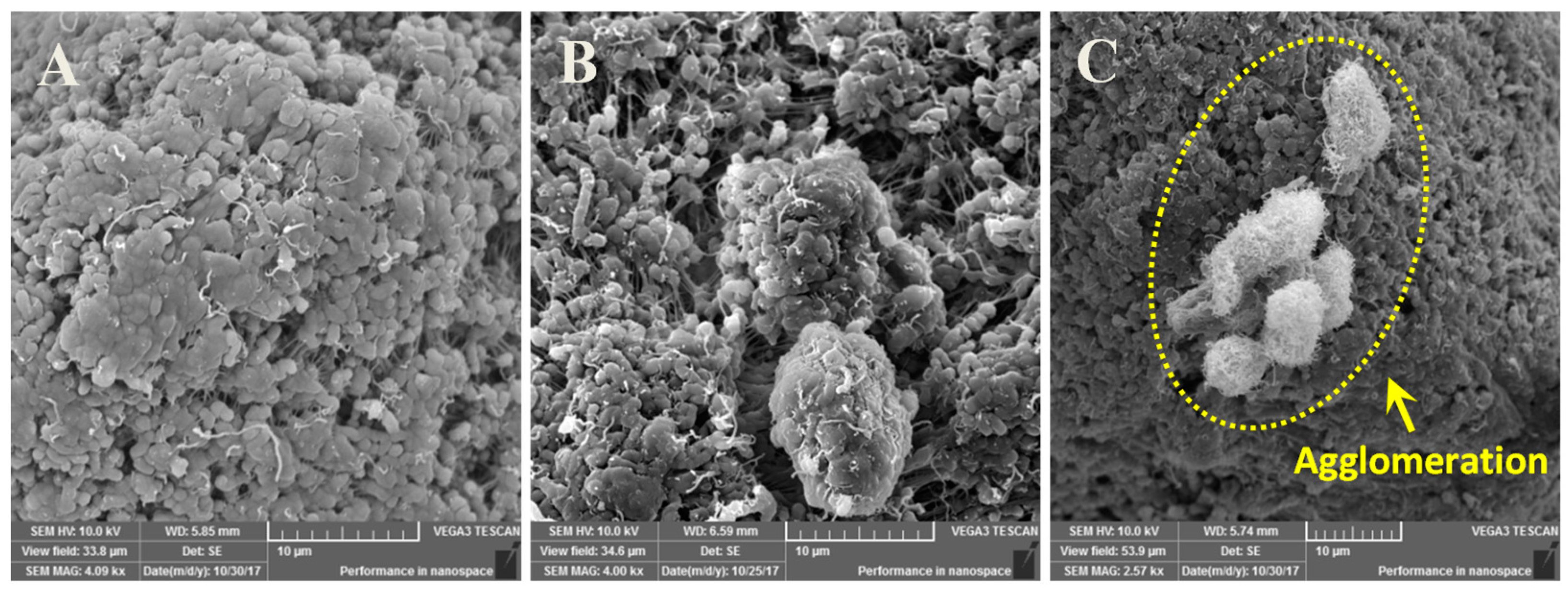

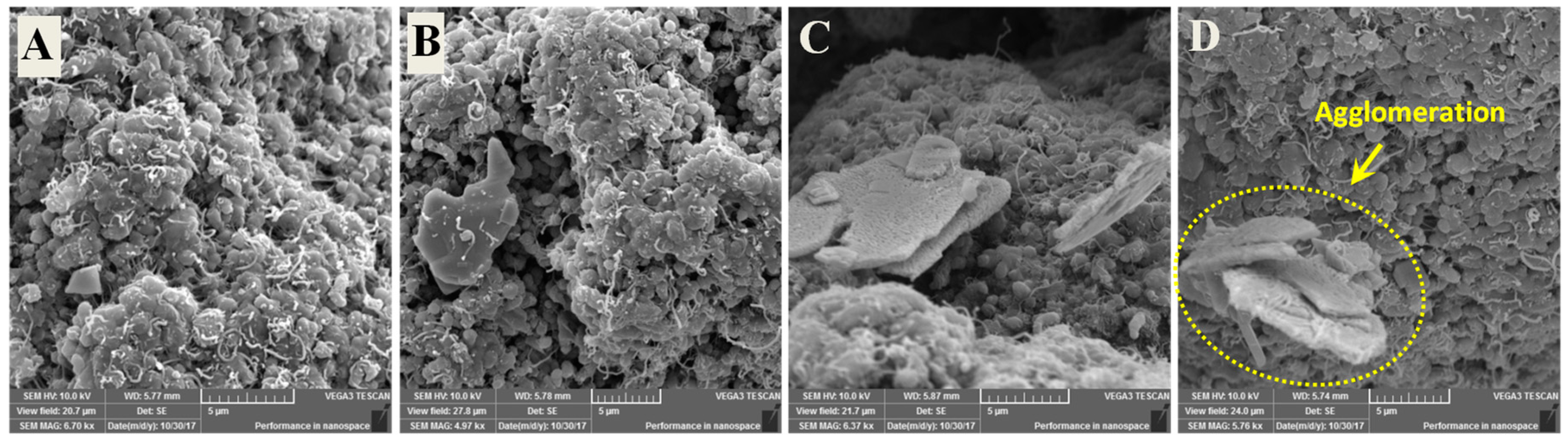

3.2. Dispersion Analysis of CNT’s in UHMWPE Matrix Using SEM

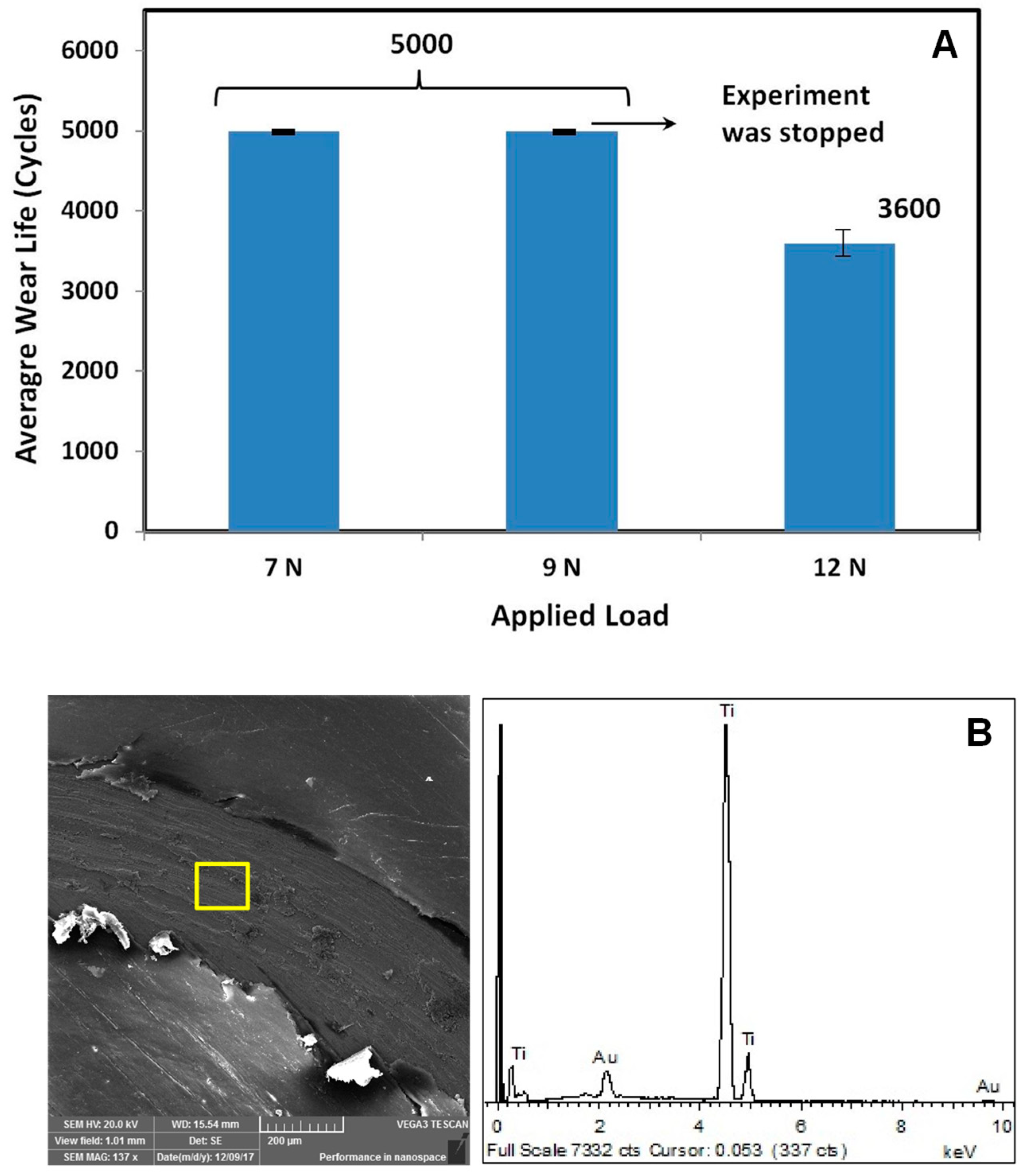

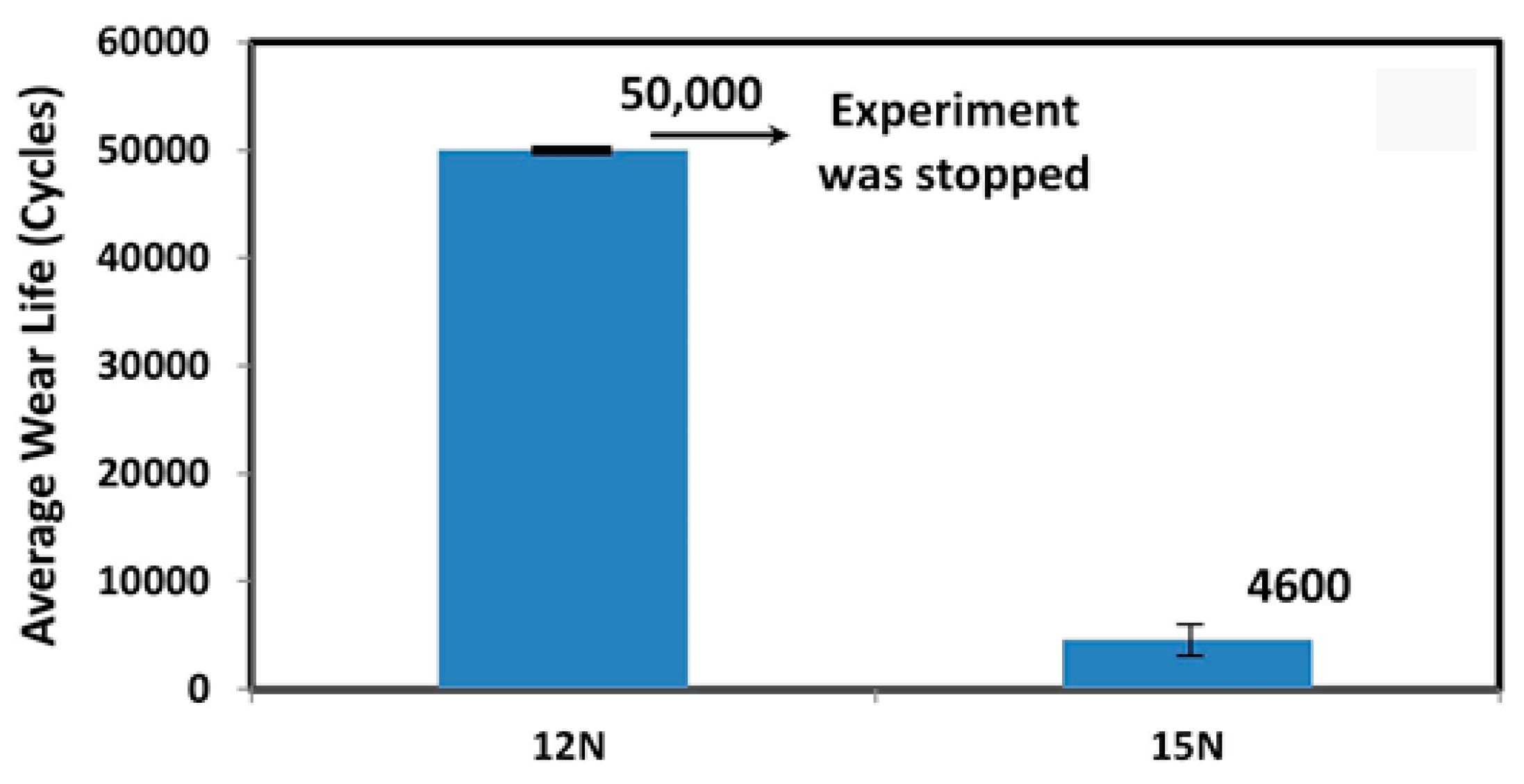

3.3. Tribological Characterization of Pristine UHMWPE Coating

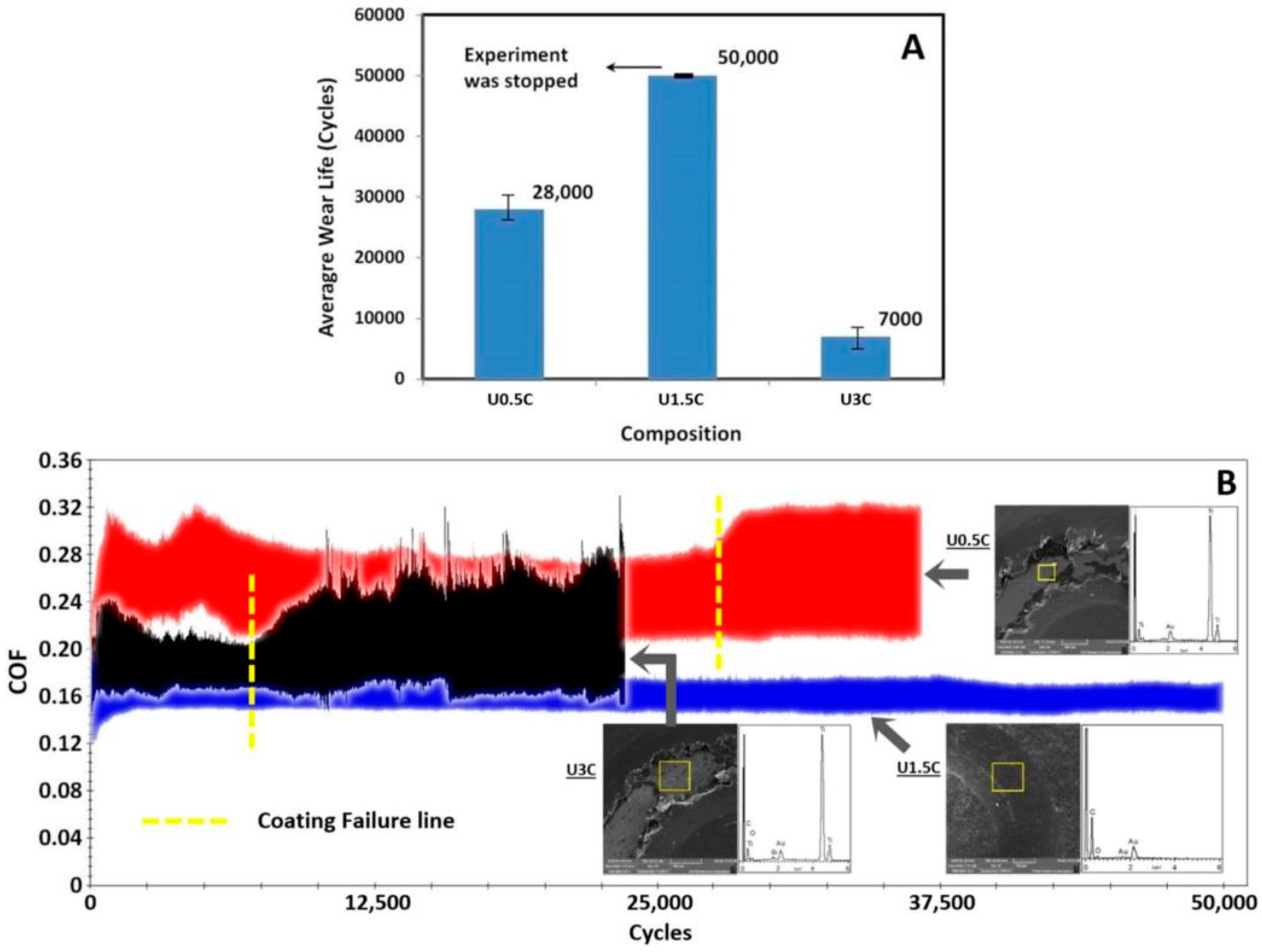

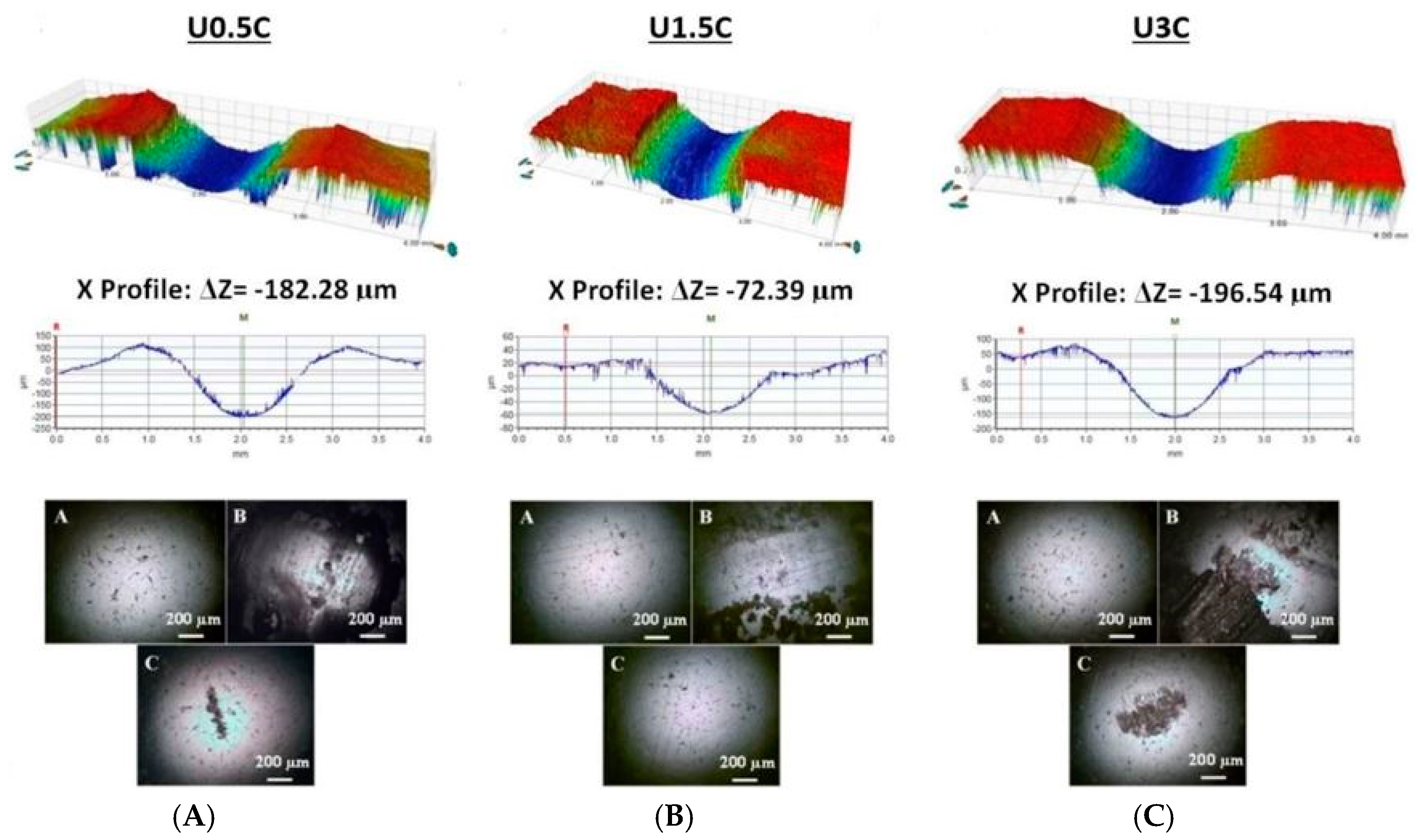

3.4. Tribological Characterization of UHMWPE/CNT’s Nanocomposite Coating

3.5. Development and Characterization of the Hybrid Nanocomposite Coating

3.5.1. Dispersion Analysis of HA in U1.5C Matrix Using SEM

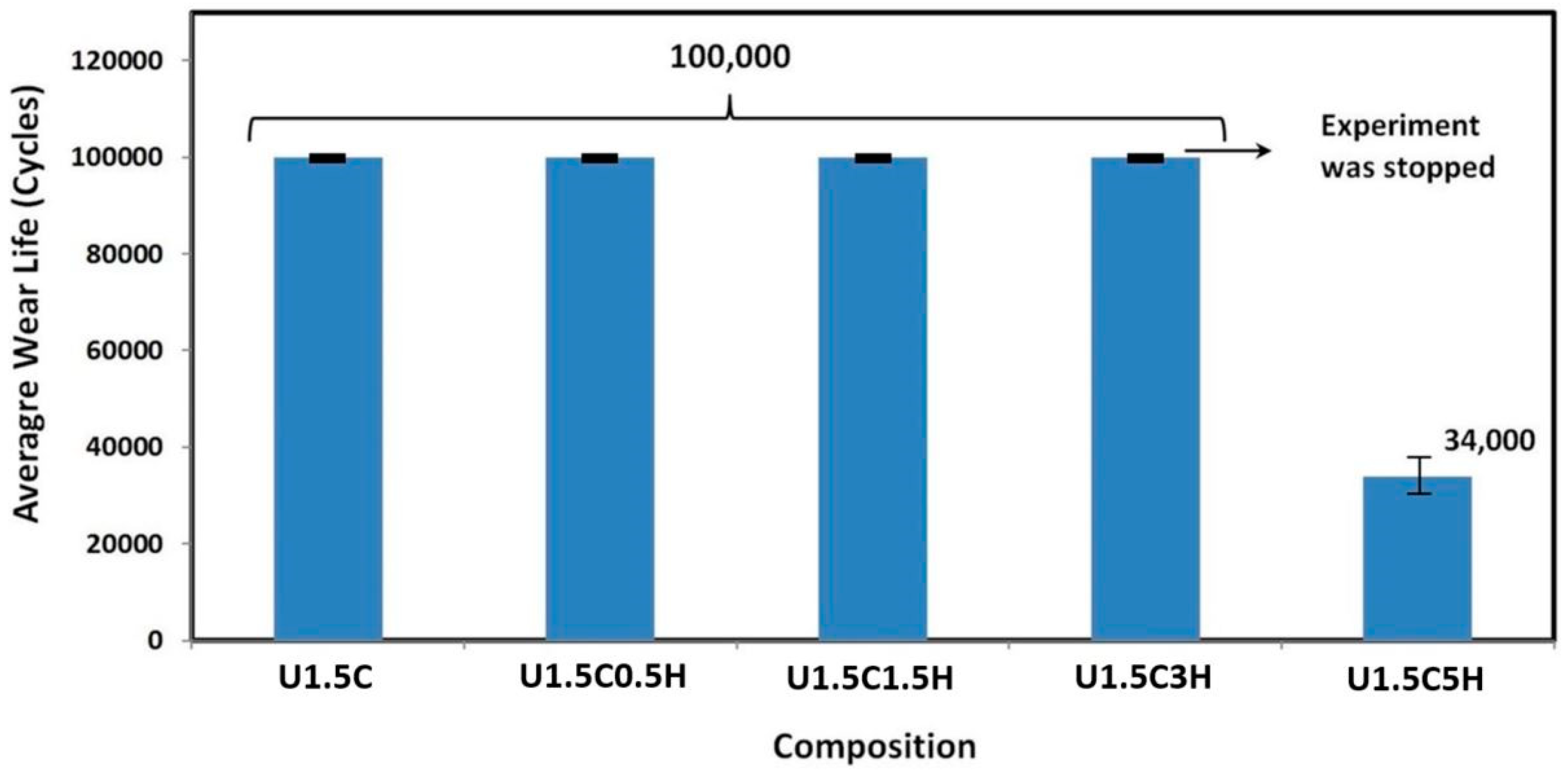

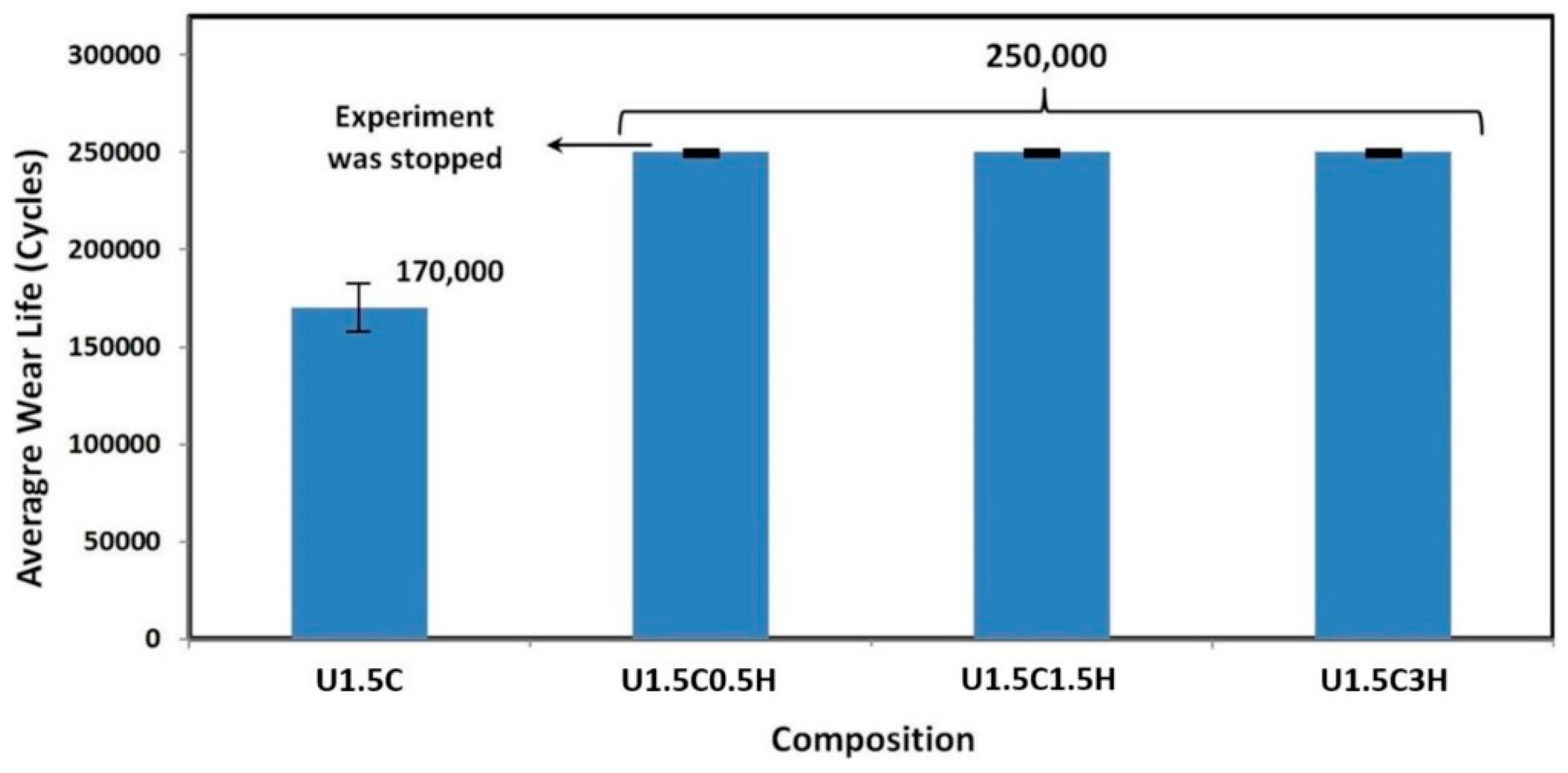

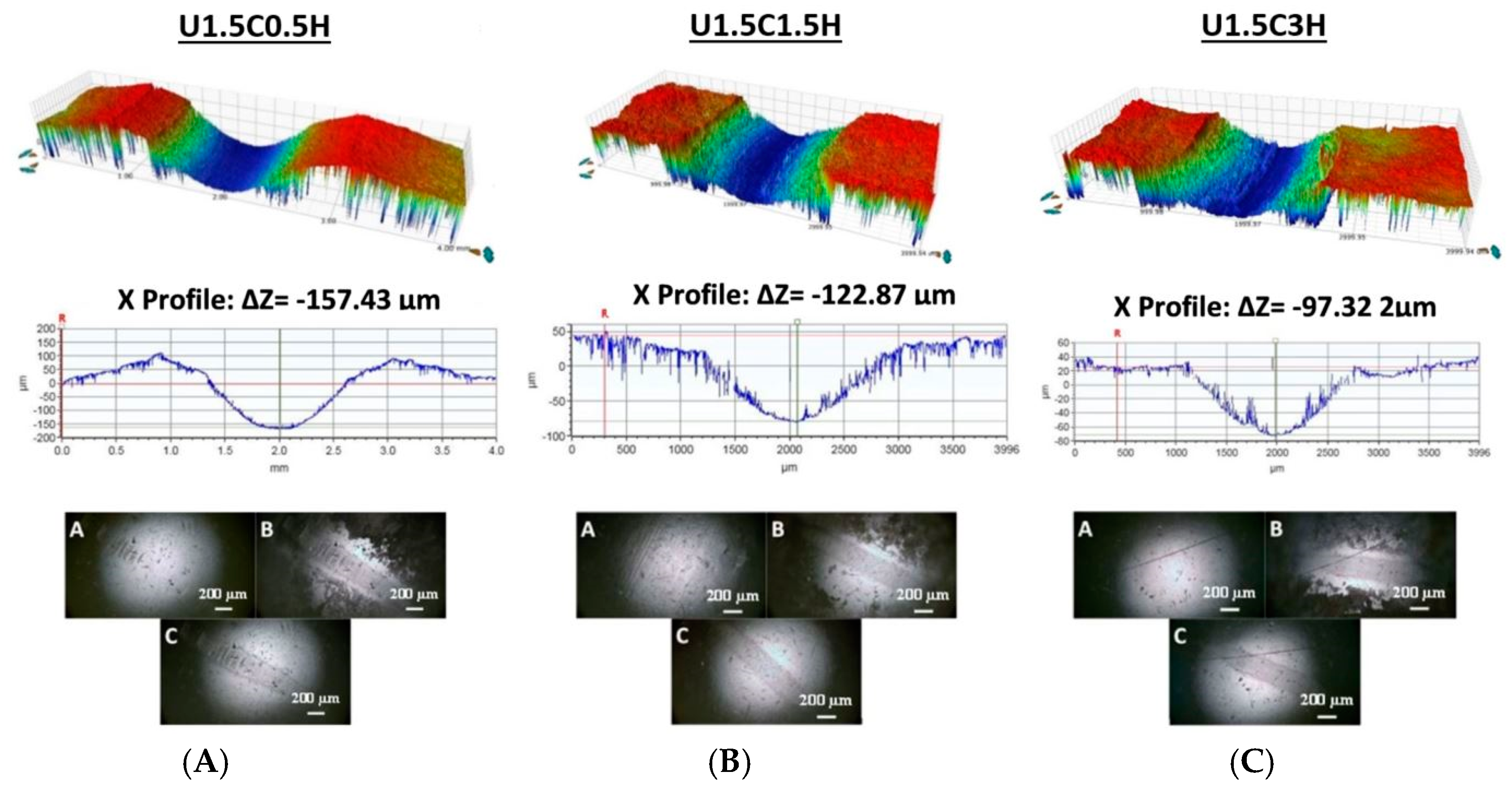

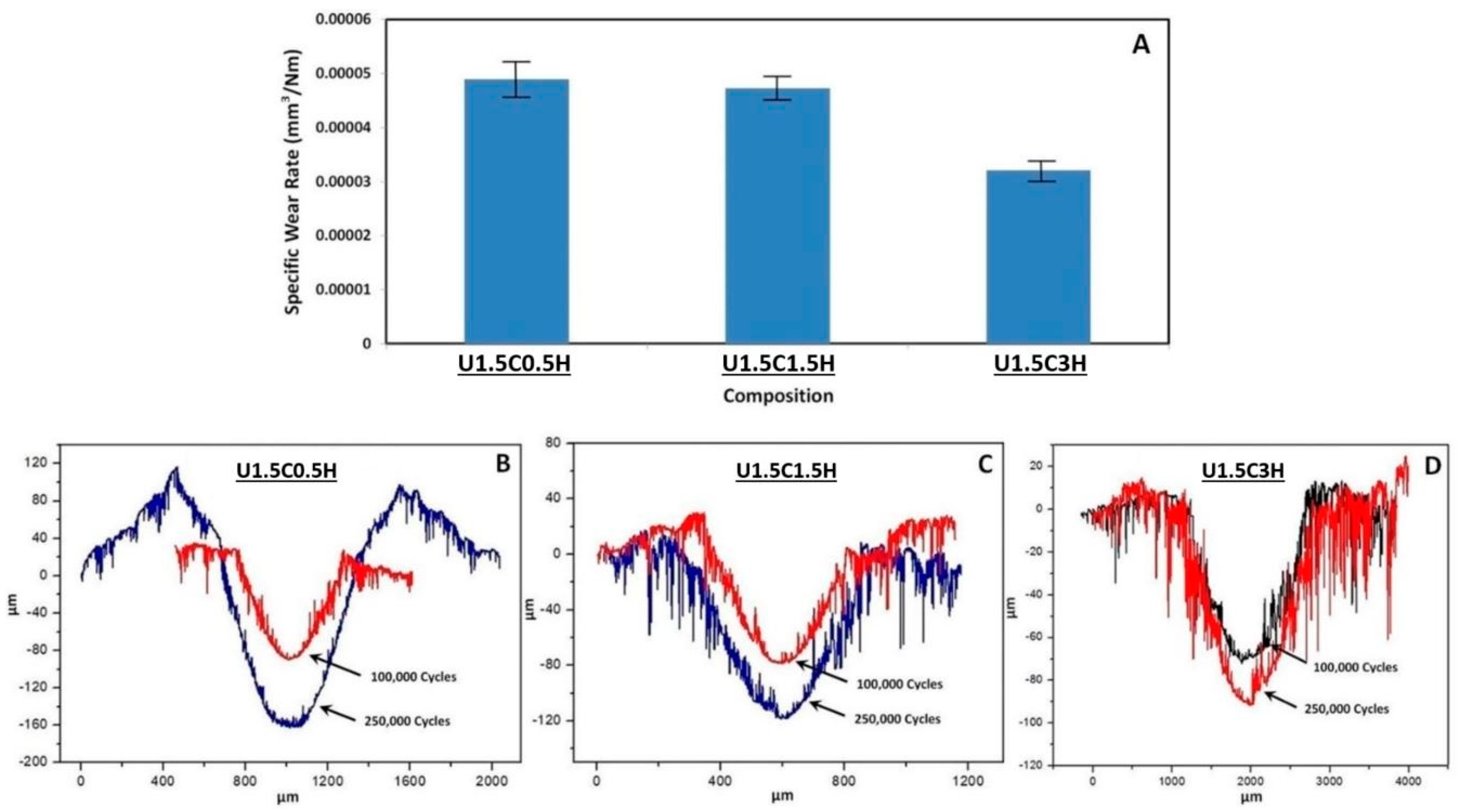

3.5.2. Tribological Characterization of UHMWPE Hybrid Nanocomposite Coating

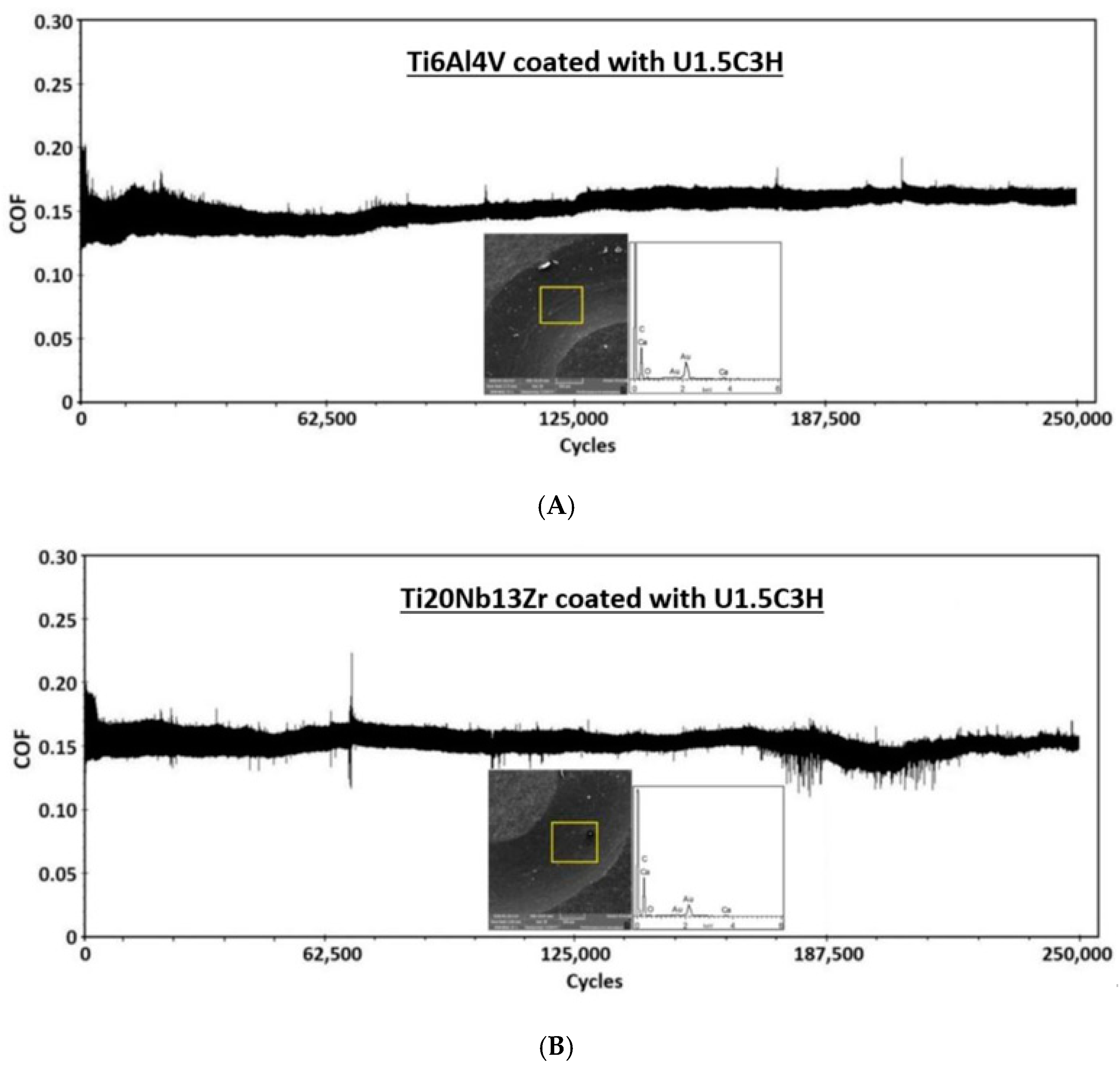

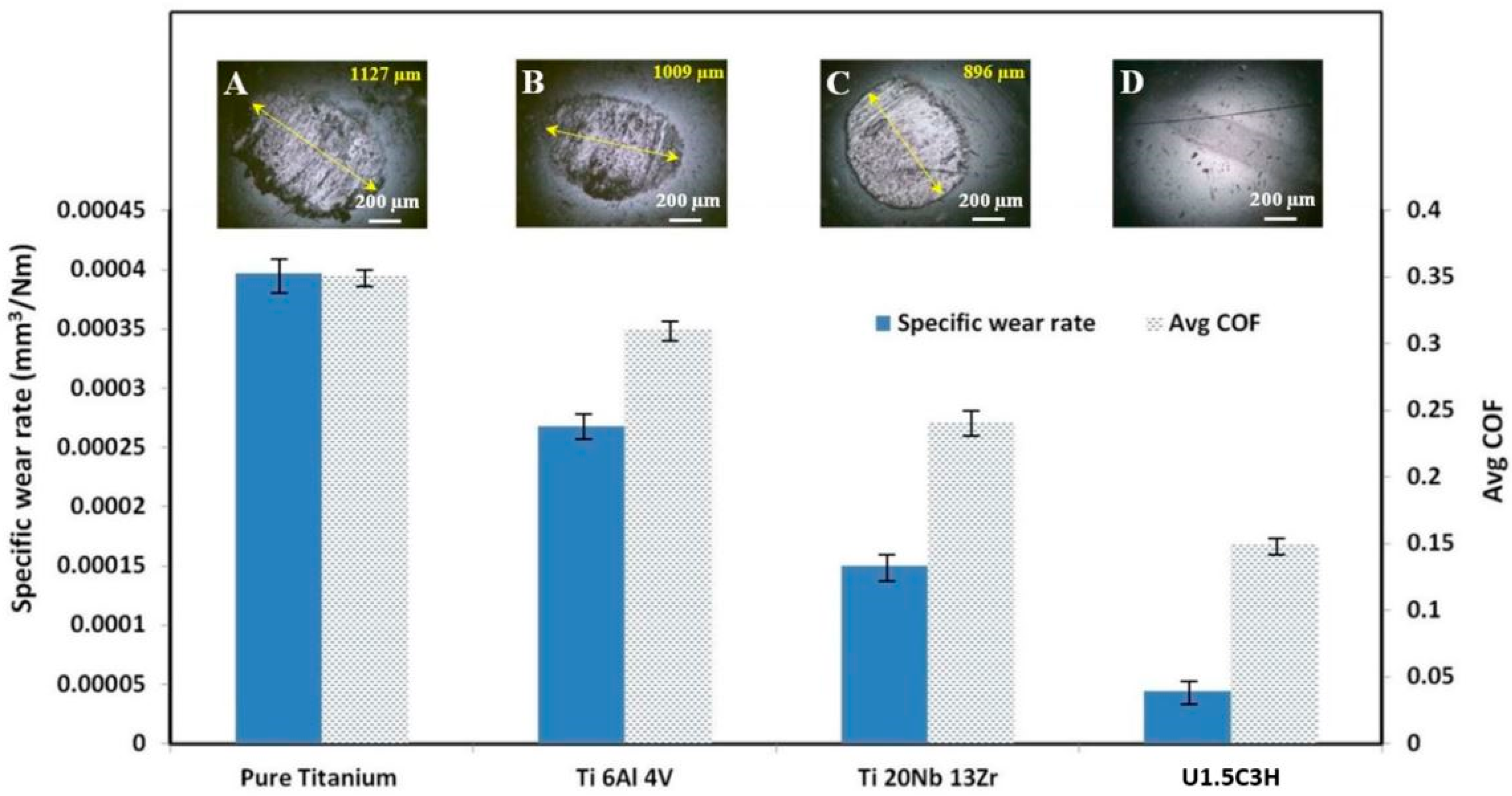

3.5.3. Tribological Characterization of the Optimized Hybrid Nanocomposite Coating Deposited on Titanium Alloys

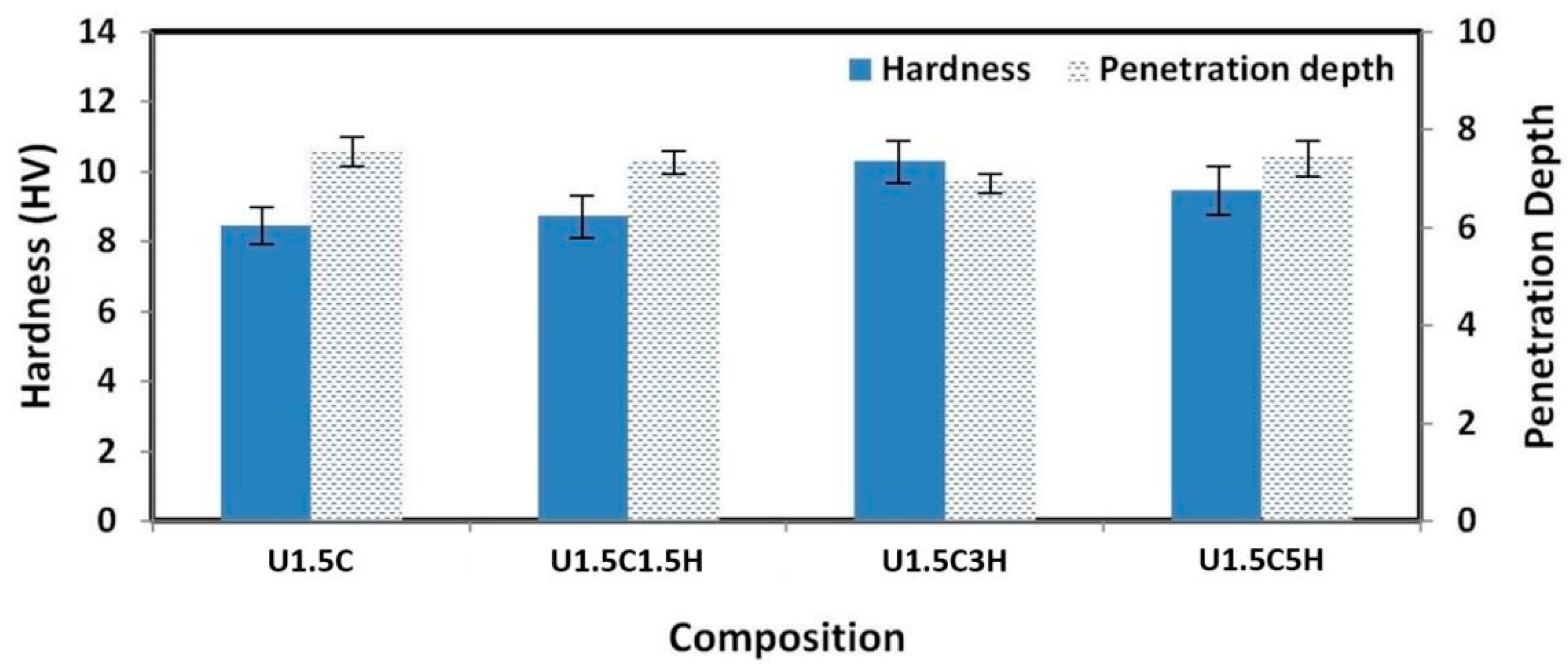

3.6. Hardness Evaluation of the Hybrid Nanocomposite Coatings

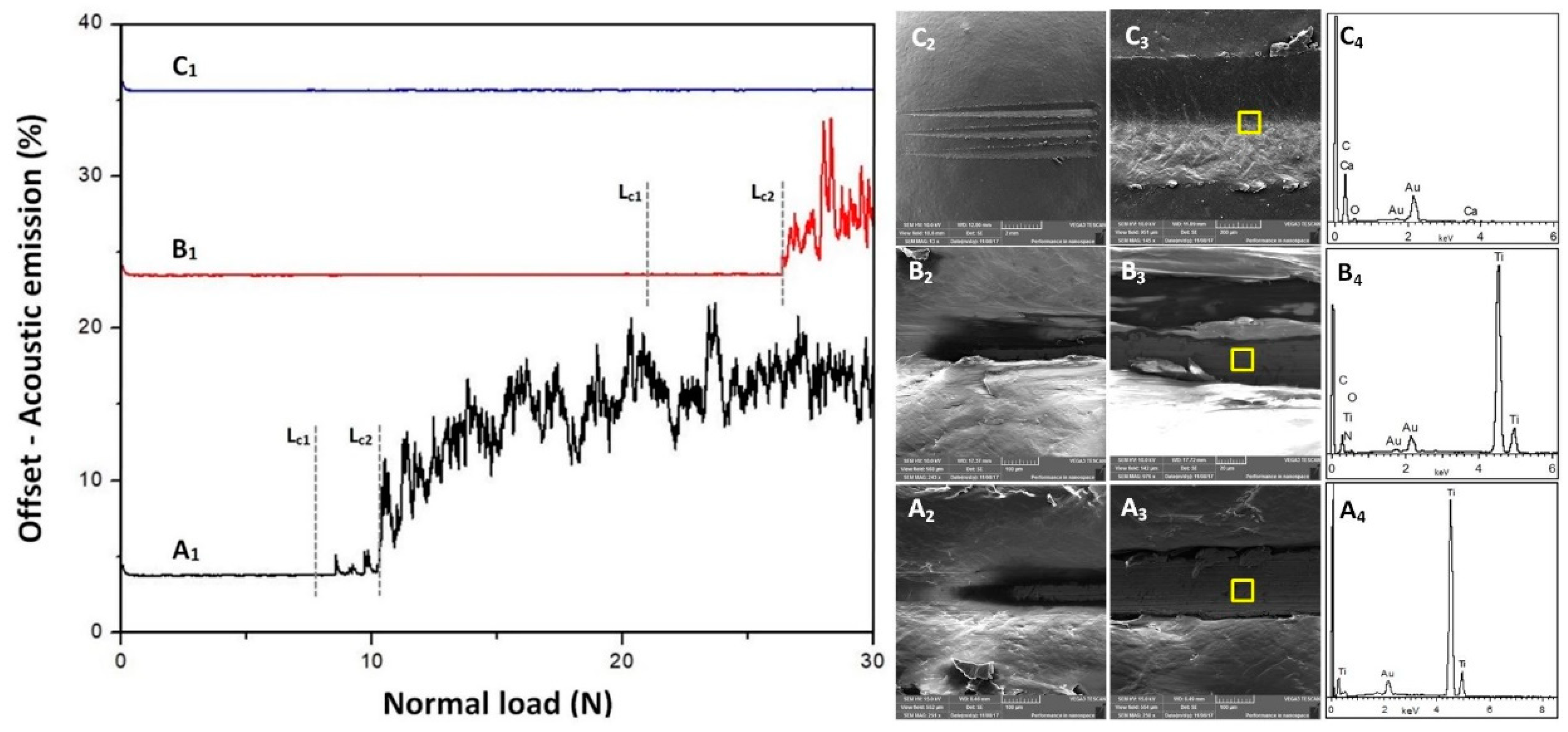

3.7. Evaluation of Scratch Resistance for Pristine UHMWPE, UHMWPE Reinforced with 1.5 wt.% of CNT’s and UHMWPE Reinforced with 1.5 wt.% CNT’s and 3 wt.% HA Coatings

3.8. Comparison of the Tribological Performance of the Bare Substrates with the Substrates Coated with the Developed Optimized Hybrid Nanocomposite Coating

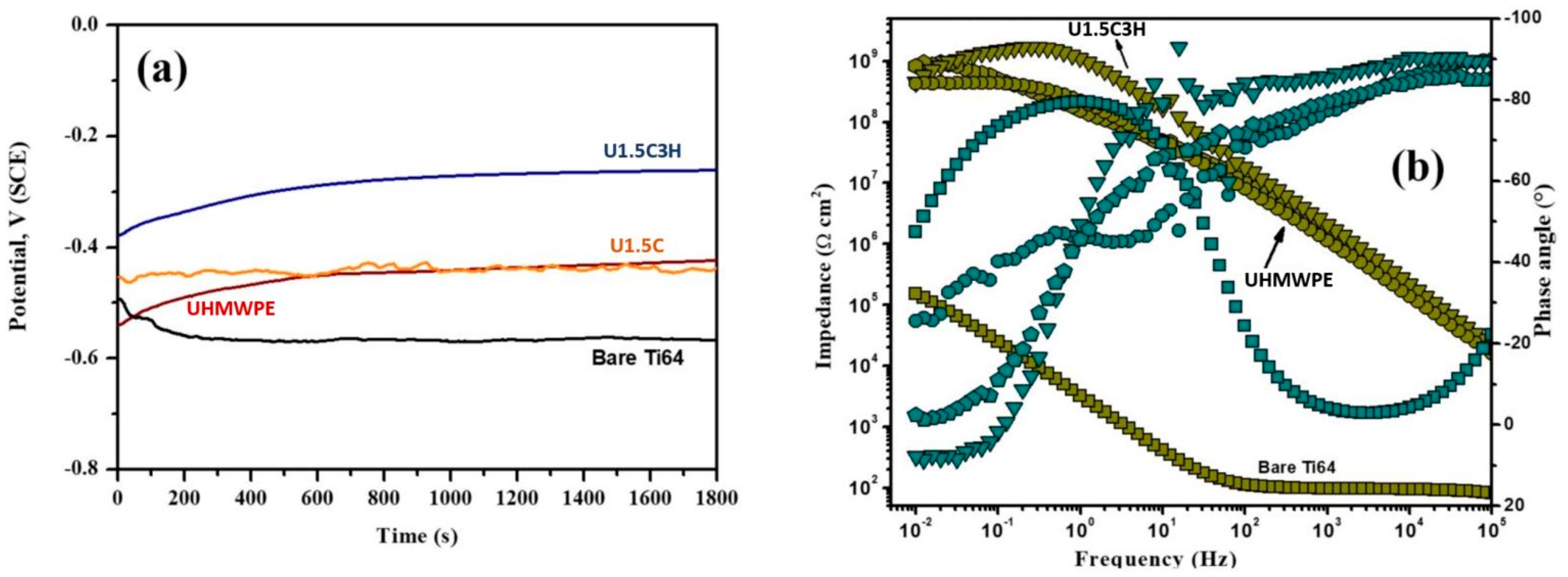

3.9. Corrosion Test of Bare Substrate, Substrates with Nanocomposite and the Hybrid Nanocomposite Coatings

4. Conclusions

- Pristine UHMWPE coating failed at a normal load of 12 N and a sliding velocity of 0.1 m/s, showing a wear life of ~3600 cycles.

- UHMWPE reinforced with 1.5 wt.% CNT’s did not fail the 50,000 cycles wear test, whereas 0.5 wt.% CNT’s and 3 wt.% CNT’s failed at 28,000 cycles and 7000 cycles, respectively, for a normal load of 12 N and sliding velocity of 0.1 m/s.

- Among the three combinations of the developed Hybrid nanocomposite coatings, for a 250,000 cycles wear test and a normal load of 12 N and sliding velocity of 0.1 m/s, UHMWPE reinforced with 1.5 wt.% CNT’s and 3 wt.% HA exhibited excellent tribological performance in terms of lower track depth and protecting the wear and tear of the counterface ball.

- Corrosion test for the optimized hybrid nanocomposite coating revealed a noble shift in potential for the OCP value and the highest impedance value, which confirms the enhanced surface protective performance of the coating against corrosion in SBF medium.

Author Contributions

Funding

Conflicts of Interest

References

- Uwais, Z.A.; Hussein, M.A.; Samad, M.A.; Al-Aqeeli, N. Surface Modification of Metallic B iomaterials for Better Tribological Properties: A Review. Arab. J. Sci. Eng. 2017, 42, 4493–4512. [Google Scholar] [CrossRef]

- Luo, Y.; Ge, S.; Jin, Z.; Fisher, J. Effect of surface modification on surface properties and tribological behaviours of titanium alloys. Proc. Inst. Mech. Eng. Part J 2009, 223, 311–316. [Google Scholar] [CrossRef]

- Minn, M.; Sinha, S.K. DLC and UHMWPE as hard/soft composite film on Si for improved tribological performance. Surf. Coatings Technol. 2008, 202, 3698–3708. [Google Scholar] [CrossRef]

- Bakshi, S.R.; Balani, K.; Laha, T.; Tercero, J.; Agarwal, A. The Nanomechanical and Nanoscratch Properties of MWNT-Reinforced Ultrahigh-Molecular-Weight Polyethylene Coatings. JOM 2007, 57, 50–53. [Google Scholar] [CrossRef]

- Ali, A.B.; Samad, M.A.; Merah, N. UHMWPE Hybrid Nanocomposites for Improved Tribological Performance Under Dry and Water-Lubricated Sliding Conditions. Tribol. Lett. 2017, 65, 1–10. [Google Scholar] [CrossRef]

- Kurtz, S.M.; Oral, E. In Vivo Oxidation of UHMWPE. In UHMWPE Biomaterials Handbook; Elsevier: Amsterdam, The Netherlands, 2016; pp. 488–505. [Google Scholar]

- Suhendra, N.; Stachowiak, G.W. Computational model of asperity contact for the prediction of UHMWPE mechanical and wear behaviour in total hip joint replacements. Tribol. Lett. 2007, 25, 9–22. [Google Scholar] [CrossRef]

- Samad, M.A.; Sinha, S.K. Dry sliding and boundary lubrication performance of a UHMWPE/CNTs nanocomposite coating on steel substrates at elevated temperatures. Wear 2011, 270, 395–402. [Google Scholar] [CrossRef]

- Baena, J.; Wu, J.; Peng, Z. Wear Performance of UHMWPE and Reinforced UHMWPE Composites in Arthroplasty Applications: A Review. Lubricants 2015, 3, 413–436. [Google Scholar] [CrossRef]

- Panjwani, B.; Satyanarayana, N.; Sinha, S.K. Tribological characterization of a biocompatible thin film of UHMWPE on Ti6Al4V and the effects of PFPE as top lubricating layer. J. Mech. Behav. Biomed. Mater. 2011, 4, 953–960. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, Q.; Liu, G.; Guo, W.; Ye, B.; Li, W.; Jiang, H.; Ding, W. Tribological Behavior of Carbon Nanotube-Reinforced AZ91D Composites Processed by Cyclic Extrusion and Compression. Tribol. Lett. 2018, 66, 71. [Google Scholar] [CrossRef]

- Tai, Z.; Chen, Y.; An, Y.; Yan, X.; Xue, Q. Tribological behavior of UHMWPE reinforced with graphene oxide nanosheets. Tribol. Lett. 2012, 46, 55–63. [Google Scholar] [CrossRef]

- Lahiri, D.; Dua, R.; Zhang, C.; de Socarraz-Novoa, I.; Bhat, A.; Ramaswamy, S.; Agarwal, A. Graphene Nanoplatelet-Induced Strengthening of UltraHigh Molecular Weight Polyethylene and Biocompatibility In vitro. ACS Appl. Mater. Interfaces 2012, 4, 2234–2241. [Google Scholar] [CrossRef] [PubMed]

- Plumlee, K.; Schwartz, C.J. Improved wear resistance of orthopaedic UHMWPE by reinforcement with zirconium particles. Wear 2009, 267, 710–717. [Google Scholar] [CrossRef]

- Bakshi, S.R.; Balani, K.; Laha, T.; Tercero, J.; Agarwal, A.; Anderson, R.; Laha, T.; Andara, M.; Tercero, J.; Crumpler, E.; et al. Plasma-sprayed carbon nanotube reinforced hydroxyapatite coatings and their interaction with human osteoblasts in vitro. Biomaterials 2007, 28, 618–624. [Google Scholar] [CrossRef]

- Sreekanth, D.; Rameshbabu, N. Development and characterization of MgO/hydroxyapatite composite coating on AZ31 magnesium alloy by plasma electrolytic oxidation coupled with electrophoretic deposition. Mater. Lett. 2012, 68, 439–442. [Google Scholar] [CrossRef]

- Lu, Y.-P.; Li, M.-S.; Li, S.-T.; Wang, Z.-G.; Zhu, R.-F. Plasma-sprayed hydroxyapatite+titania composite bond coat for hydroxyapatite coating on titanium substrate. Biomaterials 2004, 25, 4393–4403. [Google Scholar] [CrossRef]

- Li, Y.; Li, Q.; Zhu, S.; Luo, E.; Li, J.; Feng, G.; Liao, Y.; Hu, J. The effect of strontium-substituted hydroxyapatite coating on implant fixation in ovariectomized rats. Biomaterials 2010, 31, 9006–9014. [Google Scholar] [CrossRef]

- Kim, H.-W.; Knowles, J.C.; Kim, H.-E. Hydroxyapatite/poly(ε-caprolactone) composite coatings on hydroxyapatite porous bone scaffold for drug delivery. Biomaterials 2004, 25, 1279–1287. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, B.; Gong, Y.; Zhou, P.; Li, H. Mechanical properties of nanodiamond-reinforced hydroxyapatite composite coatings deposited by suspension plasma spraying. Appl. Surf. Sci. 2018, 439, 60–65. [Google Scholar] [CrossRef]

- Balani, K.; Chen, Y.; Harimkar, S.P.; Dahotre, N.B.; Agarwal, A. Tribological behavior of plasma-sprayed carbon nanotube-reinforced hydroxyapatite coating in physiological solution. Acta Biomater. 2007, 3, 944–951. [Google Scholar] [CrossRef]

- Hussein, M.A.; Suryanarayana, C.; Al-Aqeeli, N. Fabrication of nano-grained Ti-Nb-Zr biomaterials using spark plasma sintering. Mater. Des. 2015, 87, 693–700. [Google Scholar] [CrossRef]

- Hussein, M.; Kumar, M.; Drew, R.; Al-Aqeeli, N. Electrochemical Corrosion and In Vitro Bioactivity of Nano-Grained Biomedical Ti-20Nb-13Zr Alloy in a Simulated Body Fluid. Materials 2017, 11, 26. [Google Scholar] [CrossRef] [PubMed]

- Paz, A.; Guadarrama, D.; López, M.; E González, J.; Brizuela, N.; Aragón, J. A comparative study of hydroxyapatite nanoparticles synthesized by different routes. Química Nova 2012, 35, 1724–1727. [Google Scholar] [CrossRef]

- Kwok, C.T.; Wong, P.K.; Cheng, F.T.; Man, H.C. Characterization and corrosion behavior of hydroxyapatite coatings on Ti6Al4V fabricated by electrophoretic deposition. Appl. Surf. Sci. 2009, 255, 6736–6744. [Google Scholar] [CrossRef]

- Azam, M.U.; Samad, M.A. A novel organoclay reinforced UHMWPE nanocomposite coating for tribological applications. Prog. Org. Coat. 2018, 118, 97–107. [Google Scholar] [CrossRef]

- Wang, Y.; Vasileva, D.; Zustiak, S.P.; Kuljanishvili, I. Raman spectroscopy enabled investigation of carbon nanotubes quality upon dispersion in aqueous environments. Biointerphases 2017, 12, 011004. [Google Scholar] [CrossRef]

- Halley, P.; Murphy, M.; Martin, D.; Mcnally, T.; Po, P.; Bell, S.E.J.; Brennan, G.P.; Bein, D.; Lemoine, P.; Paul, J. Polyethylene multiwalled carbon nanotube composites. Polymer 2005, 46, 8222–8232. [Google Scholar] [CrossRef]

- Fang, L.; Leng, Y.; Gao, P. Processing and mechanical properties of HA/UHMWPE nanocomposites. Biomaterials 2006, 27, 3701–3707. [Google Scholar] [CrossRef]

- Williams, G.; McMurray, H.N. Inhibition of filiform corrosion on organic-coated AA2024-T3 by smart-release cation and anion-exchange pigments. Electrochim. Acta 2012, 69, 287–294. [Google Scholar] [CrossRef]

- Yuan, X.; Yue, Z.F.; Chen, X.; Wen, S.F.; Li, L.; Feng, T. EIS study of effective capacitance and water uptake behaviors of silicone-epoxy hybrid coatings on mild steel. Prog. Org. Coat. 2015, 86, 41–48. [Google Scholar] [CrossRef]

| Composition | Code |

|---|---|

| Pristine UHMWPE | UHMWPE |

| UHMWPE/0.5 wt.% CNT’s | U0.5C |

| UHMWPE/1.5 wt.% CNT’s | U1.5C |

| UHMWPE/3 wt.% CNT’s | U3C |

| UHMWPE/1.5 wt.% CNT’s/0.5 wt.% HA | U1.5C0.5H |

| UHMWPE/1.5 wt.% CNT’s/1.5 wt.% HA | U1.5C1.5H |

| UHMWPE/1.5 wt.% CNT’s/3 wt.% HA | U1.5C3H |

| UHMWPE/1.5 wt.% CNT’s/5 wt.% HA | U1.5C5H |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed Baduruthamal, Z.; Mohammed, A.S.; Kumar, A.M.; Hussein, M.A.; Al-Aqeeli, N. Tribological and Electrochemical Characterization of UHMWPE Hybrid Nanocomposite Coating for Biomedical Applications. Materials 2019, 12, 3665. https://doi.org/10.3390/ma12223665

Ahmed Baduruthamal Z, Mohammed AS, Kumar AM, Hussein MA, Al-Aqeeli N. Tribological and Electrochemical Characterization of UHMWPE Hybrid Nanocomposite Coating for Biomedical Applications. Materials. 2019; 12(22):3665. https://doi.org/10.3390/ma12223665

Chicago/Turabian StyleAhmed Baduruthamal, Zahid, Abdul Samad Mohammed, A. Madhan Kumar, Mohamed A. Hussein, and Naser Al-Aqeeli. 2019. "Tribological and Electrochemical Characterization of UHMWPE Hybrid Nanocomposite Coating for Biomedical Applications" Materials 12, no. 22: 3665. https://doi.org/10.3390/ma12223665

APA StyleAhmed Baduruthamal, Z., Mohammed, A. S., Kumar, A. M., Hussein, M. A., & Al-Aqeeli, N. (2019). Tribological and Electrochemical Characterization of UHMWPE Hybrid Nanocomposite Coating for Biomedical Applications. Materials, 12(22), 3665. https://doi.org/10.3390/ma12223665