Comparative Analysis of Static and Dynamic Mechanical Behavior for Dry and Saturated Cement Mortar

Abstract

1. Introduction

2. Materials and Methods

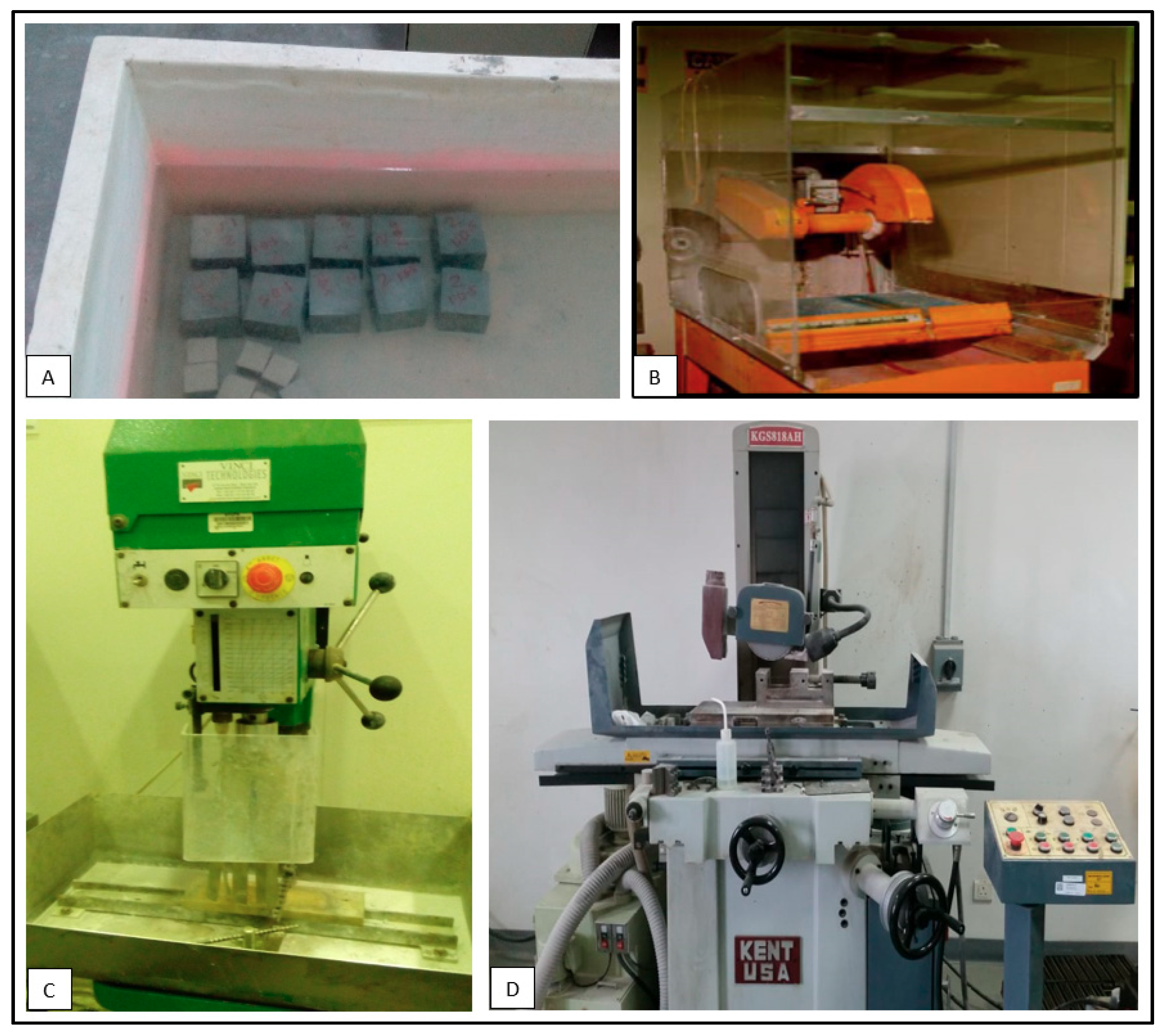

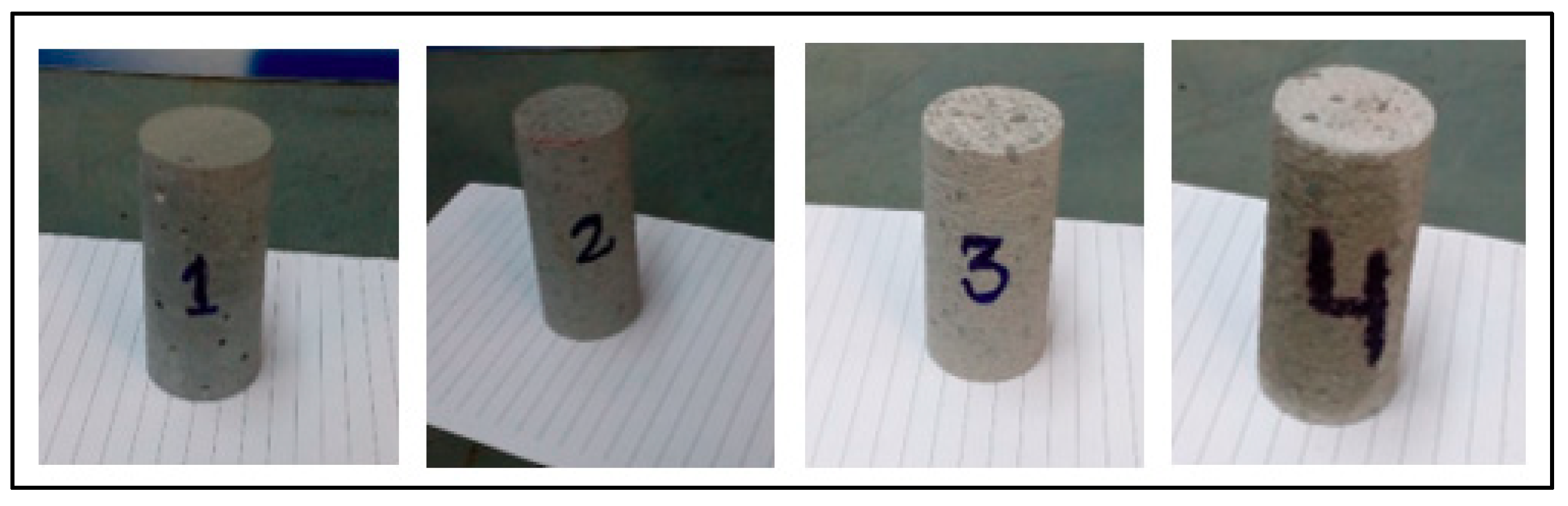

2.1. Sample Preparation

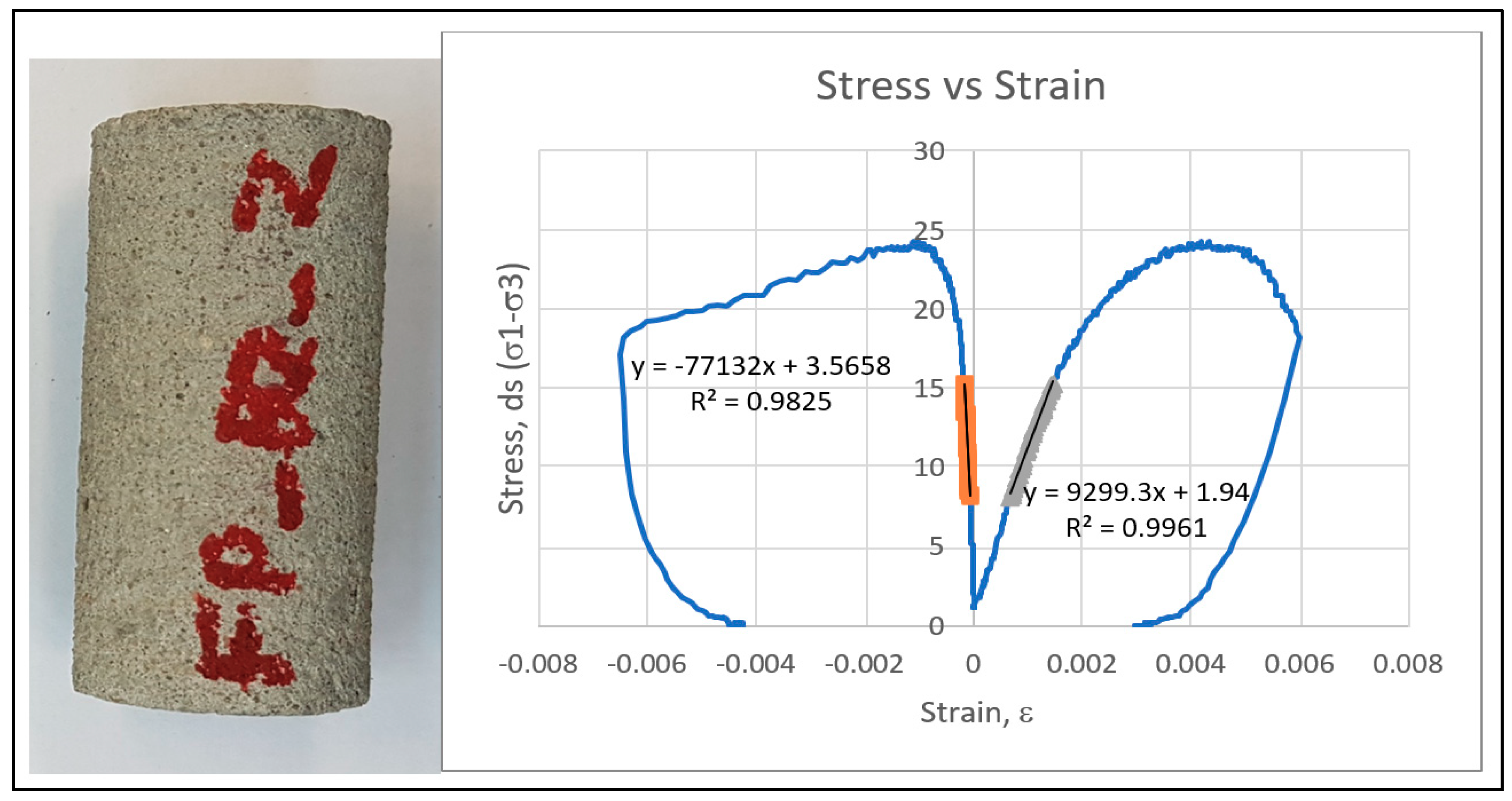

2.2. Uniaxial Compression Test (ASTM C39)

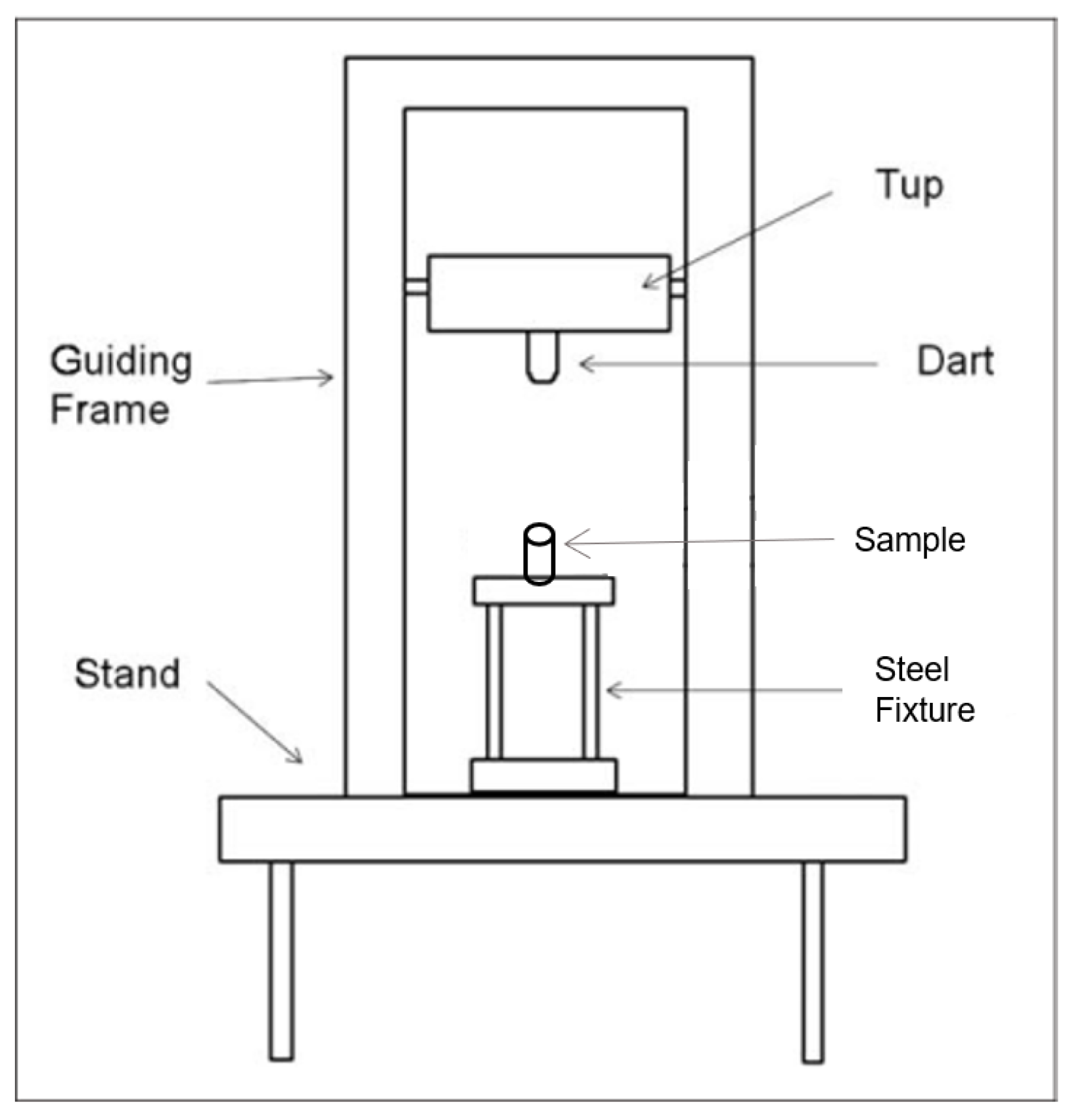

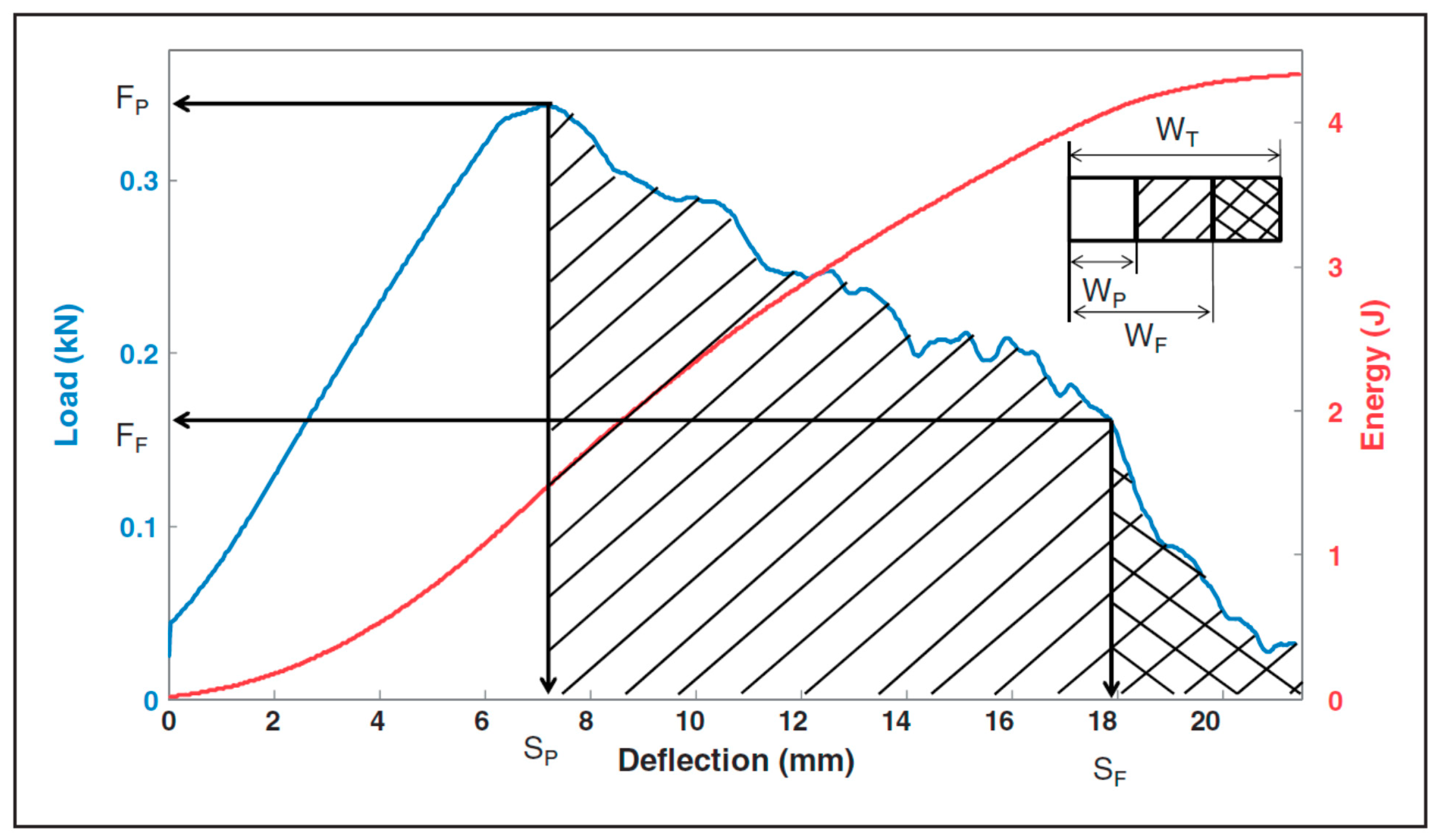

2.3. Impact Test

2.3.1. Impact Velocity

- Wflag= effective flag width = distance from 1st leading edge to 2nd leading edge (1 cm)

- tflag = Time from the moment the 1st leading edge obstructs the beam to the moment the second leading edge obstructs the beam (measured in seconds).

- vflag = Velocity of the flag as it exists in the photo-diode detector

- timp = elapsed time between the 2nd leading edge obstructing the beam to the moment just before impact.

2.3.2. Deflection, Velocity, and Energy

- w(t) = The load applied to the drop weight/pendulum by the specimen at an arbitrary time ‘t’.

- m = The total mass of the drop weight/pendulum.

- g = Gravitational acceleration (9.81 m/s2) or (32.2 ft/s2).

- F(t) = Resultant force acting on the drop weight/pendulum.

- ac(t) = Resultant acceleration of drop weight/pendulum at any time ‘t’.

- V(t) = Velocity of drop weight/pendulum at any time ‘t’.

- D(t) = Deflection (Position) of the drop weight/pendulum at any time ‘t’.

- K(t) = Kinetic energy of drop weight/pendulum at any time ‘t’.

- P(t) = Potential Energy of the drop weight/pendulum at any time ‘t’.

- Ea(t) = Amount of energy absorbed by the specimen up to point in time ‘t’.

- E(t) = Total amount of energy of the drop weight/pendulum and specimen system at any time ‘t’.

3. Results and Discussions

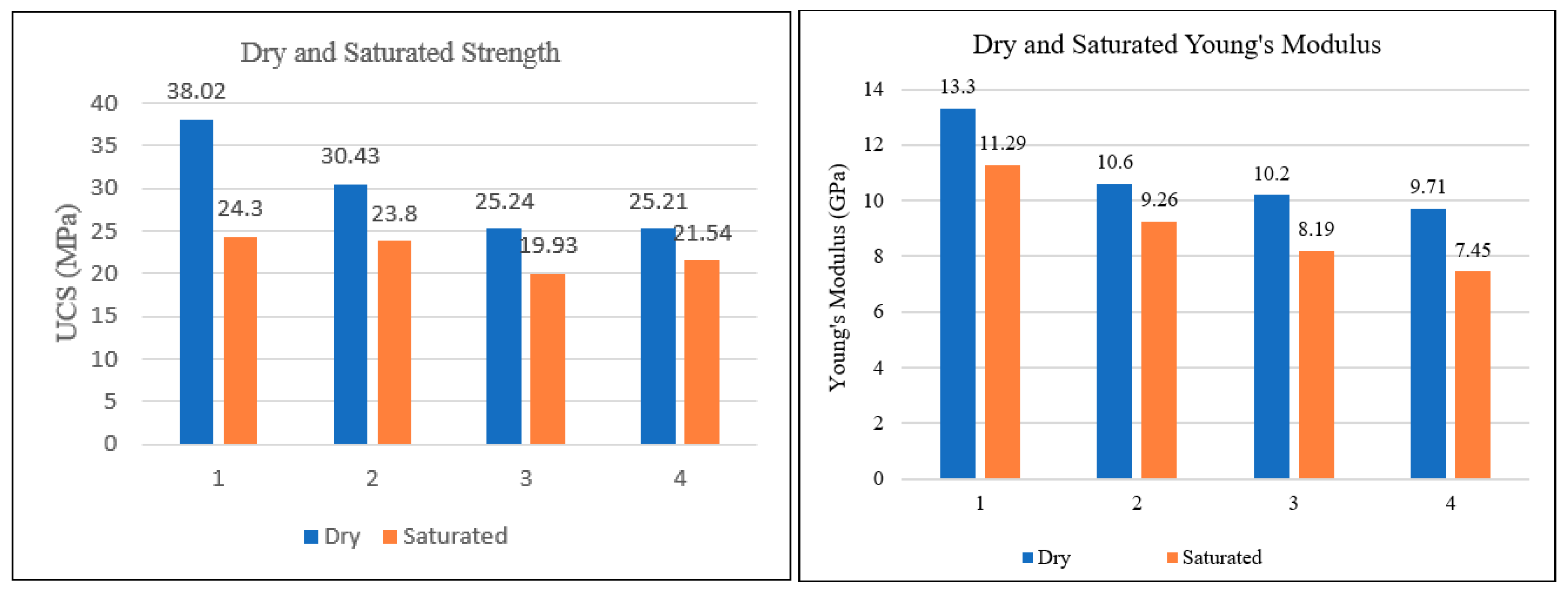

3.1. Static Compression Test Results

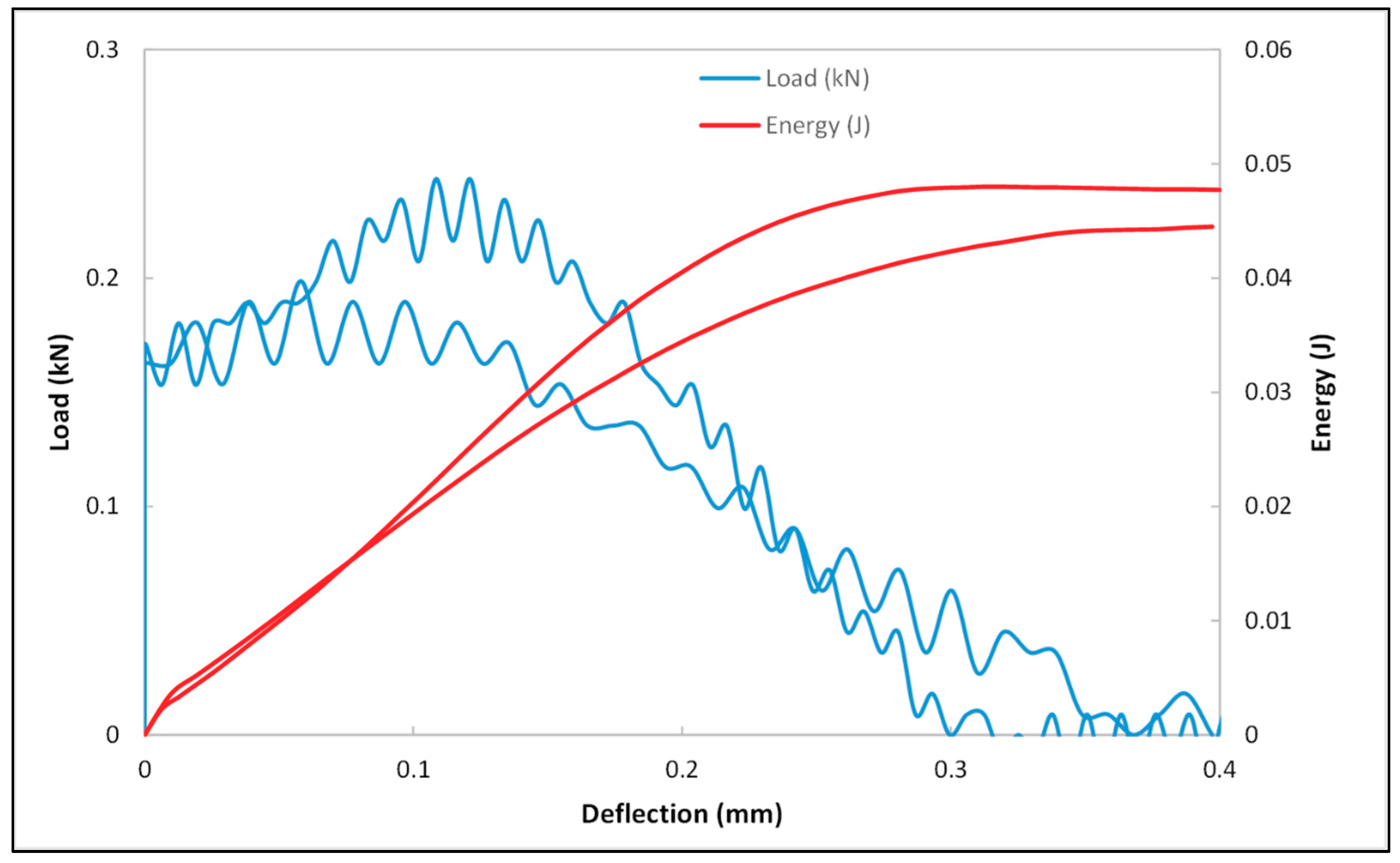

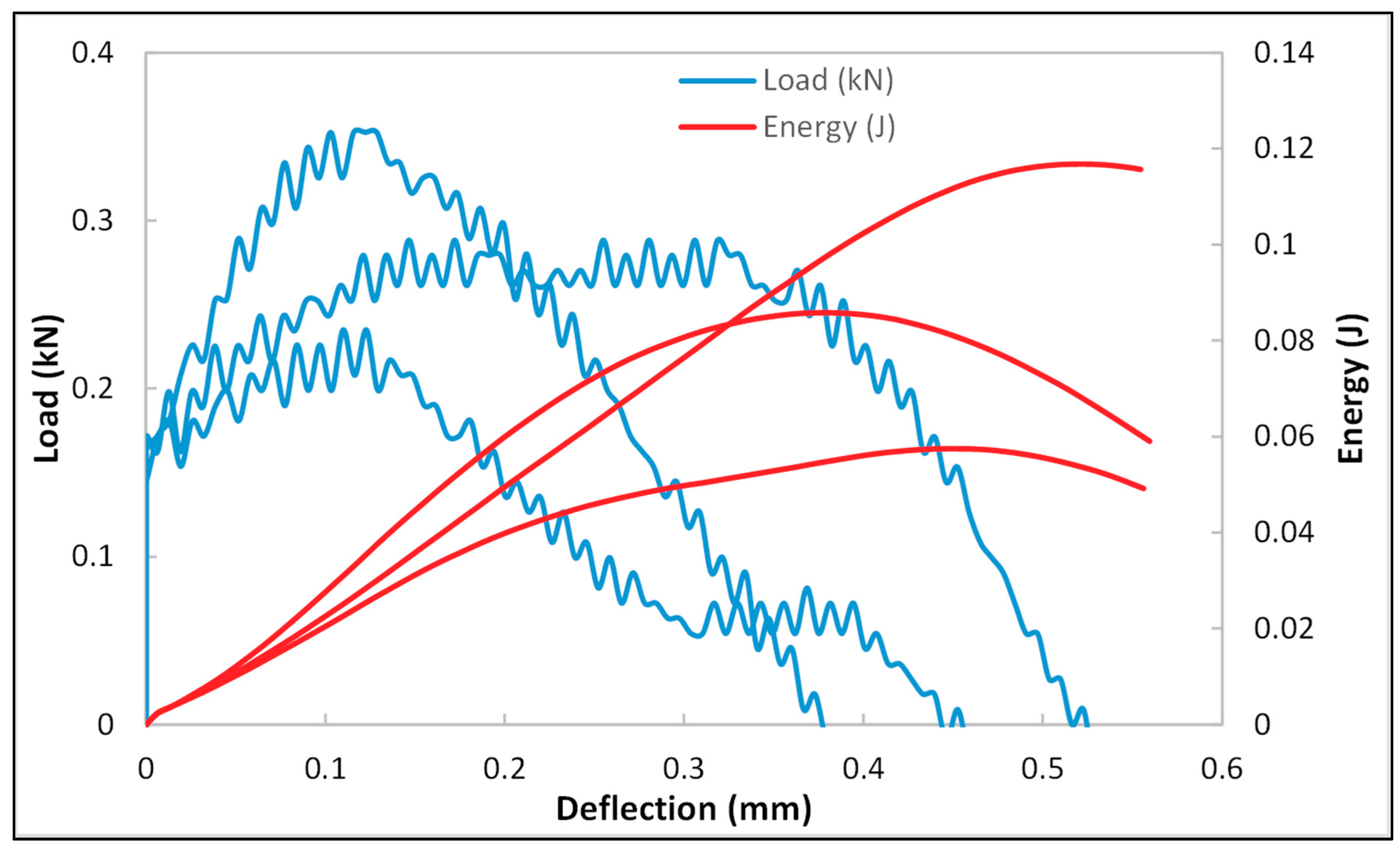

3.2. Impact Load Results

4. Conclusions

- Sustainability of cement mortar structures was strongly influenced by the water exposure in terms of a substantial change in compressive strength characteristics and elastic mechanical parameters (Young’s Modulus and Poisson’s ratio) due to ingress of water into the pores. The water weakening effect deteriorated the compressive strength and stiffness of cement mortar.

- Under static loading, water saturation caused a reduction in the strength of cement mortar of 36% and tended to behave in a more ductile manner as compared to dry samples. On the other side, dry cement mortar exhibited higher strength and deformed in a less ductile or brittle mode. Higher resistance to failure/deformation was noticed for dry cement mortar in terms of higher Young’s modulus in comparison with the saturated case. Saturated cement mortar exhibited a ductile mode of deformation with no evident failure pattern appearing under static load due to saturation effects.

- Under dynamic loading, saturated cement mortar are proved to be stronger in terms of higher impact resistance and fracture toughness as compared to dry mortar. In comparison with dry cement mortar, higher resistance to fracture propagation along the direction of dart impact was offered by saturated samples. A relatively higher amount of impact energy was required to reach the failure/deformation in the saturated case because both solid and fluid parts play an active role in responding to the applied load. The energy of impact load bounced back due to generated pore water pressure. Furthermore, the fracture could propagate to smaller depths along the direction of falling dart before moving outward in the transverse direction as compared to dry mortar.

- Mechanical behaviour for dry and saturated cement mortar has not been completely understood and explained in the literature, particularly under dynamic loads. Hence, this research will effectively contribute to providing a better understanding of the mechanical behavior under static and dynamic loads for two different aspects: dry and saturated states.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Debora, A.A.; Aenlle, A.A.; Tenza-Abril, A.J. Laboratory evaluation of hot asphalt concrete properties with cuban recycled concrete aggregates. Sustainability 2018, 10, 8. [Google Scholar]

- Liu, H.B.; Luo, G.B.; Wei, H.B.; Yu, H. Strength, permeability, and freeze-thaw durability of pervious concrete with different aggregate sizes, porosities, and water-binder ratios. Appl. Sci. 2018, 8, 1217. [Google Scholar] [CrossRef]

- Li, Q.B.; Wang, H.L. Influence of Ambient Water on Properties of Concrete. Sci. Paper Online 2006, 1, 83–94. Available online: http://en.cnki.com.cn/Article_en/CJFDTotal-ZKZX200602003.htm (accessed on 4 October 2019).

- Zheng, D.; Li, X.X. Review of researches on influences of pore water on static properties of concrete. Sci. Technol. Water Res. 2011, 36, 90–94. [Google Scholar]

- Bishchoff, P.H.; Perry, S.H. Compressive behaviour of concrete at high strain rates. Mater. Struct. 1991, 24, 425–450. [Google Scholar] [CrossRef]

- Fu, H.C.; Erki, M.A.; Seckin, M. Review of effects of loading rate on concrete in compression. J. Struct. Eng. 1991, 117, 3645–3659. [Google Scholar] [CrossRef]

- MalvarL, J.; Rossc, A. Review of strain rate effects for concrete in tension. ACI Mater. J. 1998, 95, 435–439. [Google Scholar]

- Yan, D.M.; Xu, P.; Lin, G. Dynamic properties of concrete under severe environmental condition. J. Wuhan Univ. Technol. 2010, 25, 877–882. [Google Scholar] [CrossRef]

- Zhang, W.M.; Sun, W.; Zhang, Y.S.; Chen, H. Degradation of pore structure and microstructures in hardened cement paste subjected to flexural loading and wet-dry cycles in sea water. J. Wuhan Univ. Technol. 2009, 24, 940–944. [Google Scholar] [CrossRef]

- Zhang, G.; Li, X.; Li, Z. Experimental study on static mechanical properties and moisture contents of concrete under water environment. Sustainability 2019, 11, 2962. [Google Scholar] [CrossRef]

- Reinhardt, H.W.; Rossi, P.; van Mier, J.G.M. Joint investigation of concrete at high rates of loading. Mater. Struct. 1990, 23, 213–216. [Google Scholar] [CrossRef]

- Li, G. The Effect of moisture content on the tensile strength properties of concrete; University of Florida: Gainesville, FL, USA, 2004. [Google Scholar]

- Wittmann, F.H.; Sun, Z.; Zhao, T. Surface energy and fracture energy. In Proceedings of the 7th International Conference on Fracture Mechanics of Concrete and Concrete Structures, Jeju, Korea; Korea Concrete Institute: Seoul, Korea, 2010; pp. 13–18. [Google Scholar]

- Rossi, P. Influence of cracking in presence of free water on the mechanical behaviour of concrete. Mag. Concr. Res. 1991, 43, 53–57. [Google Scholar] [CrossRef]

- Cadoni, E.; Labibes, K.; Albertini, C. Strain-rate effect on the tensile behavior of concrete at different relative humidity levels. Mater. Struct. 2001, 34, 21–26. [Google Scholar] [CrossRef]

- Wang, H.L.; Li, Q.B. Experiments of the compressive properties of dry and saturated concrete under different loading rates. J. Hydroelectr. Eng. 2007, 26, 84–89. [Google Scholar]

- Watstein, D. Effect of straining on the compressive strength and elastic properties of concrete. J. Am. Concrete Inst. 1953, 49, 739–744. [Google Scholar]

- Kaplan, S.A. Factors affecting the relationship between rate of loading and measured compressive strength of concrete. Mag. Concr. Res. 1980, 32, 79–88. [Google Scholar] [CrossRef]

- Lohunova, V.A.; Rudenko, V.V.; Radionov, A.K.; Sokolov, I.B. Dynamic strength of concrete. Hydrotech. Constr. 1994, 28, 313–316. [Google Scholar] [CrossRef]

- Tang, S.B.; Yu, C.Y.; Heap, M.J.; Chen, P.Z.; Ren, Y.G. The influence of water saturation on the short- and long-term mechanical behavior of red sandstone. J. Rock Mech. Rock Eng. 2018, 51, 2669–2687. [Google Scholar] [CrossRef]

- Colback, P.S.B.; Wild, B.L. The Influence of Moisture Content on the Compressive Strength of Rocks; Society of Exploration Geophysicists: Tulsa, OK, USA, 1975; pp. 65–83. [Google Scholar]

- Hawkins, A.B.; McConnell, B.J. Sensitivity of sandstone strength and deformability to changes in moisture content. Q. J. Eng. Geol. Hydrogeol. 1992, 25, 115–130. [Google Scholar] [CrossRef]

- Van Eeckhout, E.M. The mechanism of strength reduction due to moisture in coal mine shales. Int. J. Rock Mech. Min. Sci. 1976, 13, 61–67. [Google Scholar] [CrossRef]

- Zhou, Z.; Cai, X.; Ma, D.; Cao, W.; Chen, L.; Zhou, J. Effect of water content on fracture and mechanical behaviour of sandstone with a low clay mineral content. Eng. Fract. Mech. 2018, 193, 47–65. [Google Scholar] [CrossRef]

- Zhou, C.Y.; Deng, Y.M.; Tan, X.S.; Liu, Z.Q.; Shang, W.; Zhan, S. Experimental research on the softening of mechanical properties of saturated soft rocks and application. Chinese J. Rock Mech. Eng. 2005, 24, 33–38. [Google Scholar]

- Wang, Y.; Yang, R. Study of the dynamic fracture characteristics of coal with a bedding structure based int the NSCB impact test. Eng. Fract. Mech. 2017, 184, 319–338. [Google Scholar] [CrossRef]

- Yin, T.; Bai, L.; Li, X.; Li, X.; Zhang, S. Effect of thermal treatment on the mode-I fracture toughness of granite under dynamic and static coupling load. Eng. Fract. Mech. 2018, 199, 143–158. [Google Scholar] [CrossRef]

- Vásárhelyi, B.; Ván, P. Influence of water content on the strength of rock. Eng. Geol. 2006, 84, 70–74. [Google Scholar] [CrossRef]

- Li, X.; Zilong, Z.; Zhao, F.; Zuo, Y.; Ma, C.; Ye, Z.; Hong, L. Mechanical properties of rock under coupled static-dynamic loads. J. Rock Mech. Geotech. Eng. 2009, 1, 41–47. [Google Scholar] [CrossRef]

- Zhang, Q.B.; Zhao, J. Determination of mechanical properties and full-field strain measurements of rock material under dynamic loads. Int. J. Rock Mech. Min. Sci. 2013, 60, 423–439. [Google Scholar] [CrossRef]

- Dehkhoda, S. Experimental and numerical study of rock breakage by pulsed water jets. Ph.D. Thesis, University of Queensland, Brisbane, Australia, December 2011. [Google Scholar]

- Diederichs, M.S. The 2003 Canadian Geotechnical Colloquium: mechanistic interpretation and practical application of damage and spalling prediction criteria for deep tunnelling. Can. Geotech. J. 2007, 44, 1082–1116. [Google Scholar] [CrossRef]

- Kaiser, P.K.; Yazici, S.; Maloney, S. Mining-induced stress change and consequences of stress path on excavation stability–a case study. Int. J. Rock Mech. Min. Sci. 2001, 38, 167–180. [Google Scholar] [CrossRef]

- Li, J.C.; Li, H.B.; Zhao, J. An improved equivalent viscoelastic medium method for wave propagation across layered rock masses. Int. J. Rock Mech. Min. Sci. 2014, 73, 62–69. [Google Scholar] [CrossRef]

- Kishi, N.; Konno, H.; Ikeda, K.; Matsuoka, K.G. Prototype Impact tests on ultimate impact resistance of PC Rock sheds. Int. J. Impact Eng. 2002, 27, 969–985. [Google Scholar] [CrossRef]

- Mindess, S.; Cheng, Y. Perforation Of plain and fibre reinforced concretes subjected to low-velocity impact loading. Cem. Concr. Res. 1993, 23, 83–92. [Google Scholar] [CrossRef]

- Measurement of properties of fibre reinforced concrete. In ACI Manual of Concrete Practice, Part 5: Masonry, Precast Concrete and Special Processes; American Concrete Institute: Farmington Hills, MI, USA, 1996; ACI 544.2R-89.

- Impulse, software for Impact testing system, Instron Dynatup: Norwood, MA, USA.

- Mezghani, K.; Furquan, S. Analysis of dart impact resistance of low-density polyethylene and linear low-density polyethylene blown films via an improved instrumented impact test method. J. Plastic Film Sheeting 2012, 28, 298–313. [Google Scholar] [CrossRef]

| Sample | Strength (Dry Sample) (MPa) | Strength (Saturated) (MPa) | Percentage Decrease (%) | Young’s Modulus (Dry) (GPa) | Young’s Modulus (Saturated) (GPa) | Percentage Decrease (%) |

|---|---|---|---|---|---|---|

| 1 | 38.02 | 24.30 | 36.1 | 13.3 | 11.29 | 15.1 |

| 2 | 30.43 | 23.80 | 21.7 | 10.6 | 9.26 | 12.6 |

| 3 | 25.24 | 19.93 | 21.0 | 10.2 | 8.19 | 19.7 |

| 4 | 25.21 | 21.54 | 14.6 | 9.71 | 7.45 | 23.3 |

| Test No | Maximum Load (kN) | Time to Max Load (ms) | Impact Velocity (m/s) | Total Energy (J) | Total Time (ms) |

|---|---|---|---|---|---|

| 2 | 0.1987 | 0.0153 | 3.1212 | 0.0442 | 0.1129 |

| 5 | 0.2433 | 0.0488 | 2.0096 | 0.0479 | 0.1404 |

| Average | 0.221 | 0.032 | 2.5654 | 0.0461 | 0.1266 |

| Test No | Maximum Load (kN) | Time to Max Load (ms) | Impact Velocity (m/s) | Total Energy (J) | Total Time (ms) |

|---|---|---|---|---|---|

| 1 | 0.2884 | 0.0671 | 2.0057 | 0.1168 | 0.2441 |

| 2 | 0.3525 | 0.0458 | 2.0298 | 0.0858 | 0.177 |

| 3 | 0.235 | 0.0488 | 2.0397 | 0.0575 | 0.2075 |

| Average | 0.292 | 0.0539 | 2.0251 | 0.0867 | 0.2096 |

| Standard Deviation | 0.0588 | 0.0116 | 0.0175 | 0.0297 | 0.0336 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mustafa, A.; Mahmoud, M.A.; Abdulraheem, A.; Furquan, S.A.; Al-Nakhli, A.; BaTaweel, M. Comparative Analysis of Static and Dynamic Mechanical Behavior for Dry and Saturated Cement Mortar. Materials 2019, 12, 3299. https://doi.org/10.3390/ma12203299

Mustafa A, Mahmoud MA, Abdulraheem A, Furquan SA, Al-Nakhli A, BaTaweel M. Comparative Analysis of Static and Dynamic Mechanical Behavior for Dry and Saturated Cement Mortar. Materials. 2019; 12(20):3299. https://doi.org/10.3390/ma12203299

Chicago/Turabian StyleMustafa, Ayyaz, Mohamed A. Mahmoud, Abdulazeez Abdulraheem, Sarfaraz A. Furquan, Ayman Al-Nakhli, and Mohammed BaTaweel. 2019. "Comparative Analysis of Static and Dynamic Mechanical Behavior for Dry and Saturated Cement Mortar" Materials 12, no. 20: 3299. https://doi.org/10.3390/ma12203299

APA StyleMustafa, A., Mahmoud, M. A., Abdulraheem, A., Furquan, S. A., Al-Nakhli, A., & BaTaweel, M. (2019). Comparative Analysis of Static and Dynamic Mechanical Behavior for Dry and Saturated Cement Mortar. Materials, 12(20), 3299. https://doi.org/10.3390/ma12203299