Does a High Amount of Unhydrated Portland Cement Ensure an Effective Autogenous Self-Healing of Mortar?

Abstract

1. Introduction

2. Materials and Methods

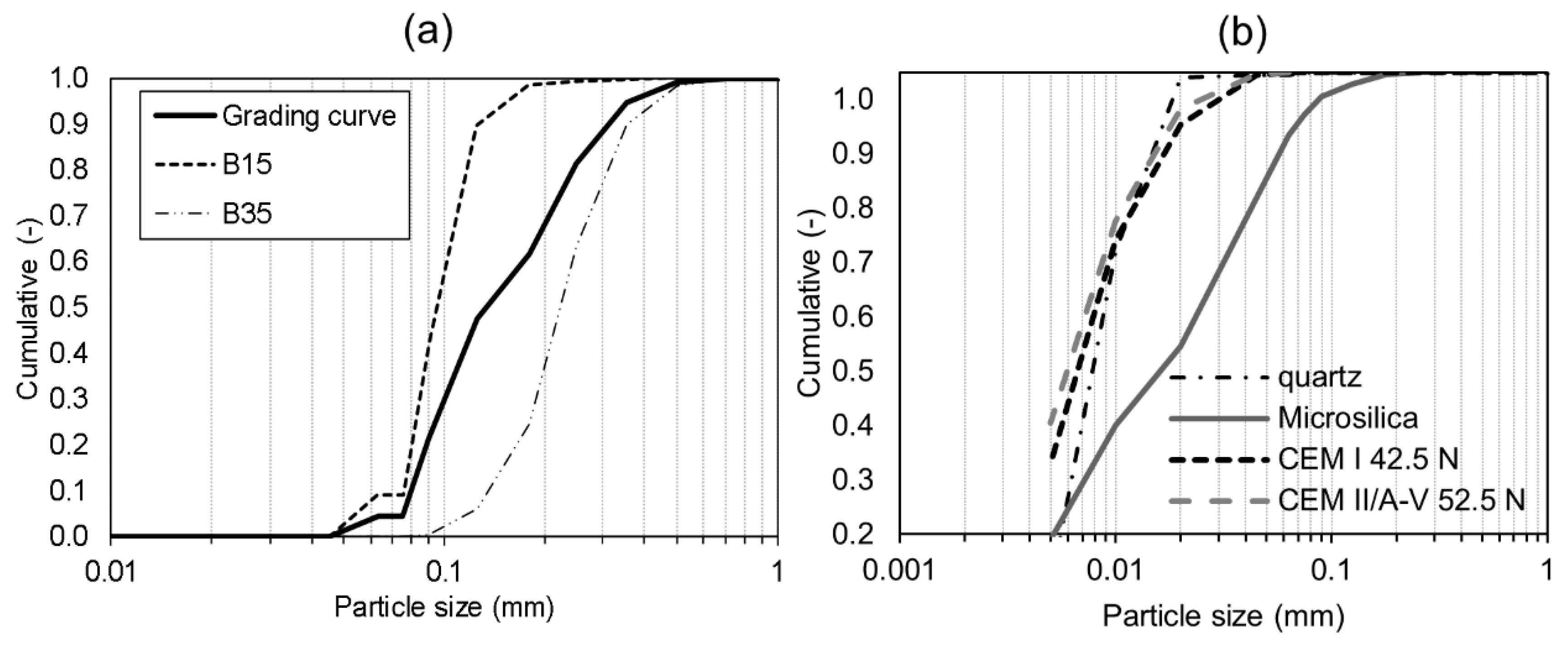

2.1. Materials

2.2. Experimental Setup

2.2.1. Self-Healing Efficiency

2.2.2. Microstructure and Healing Products

3. Results and Discussion

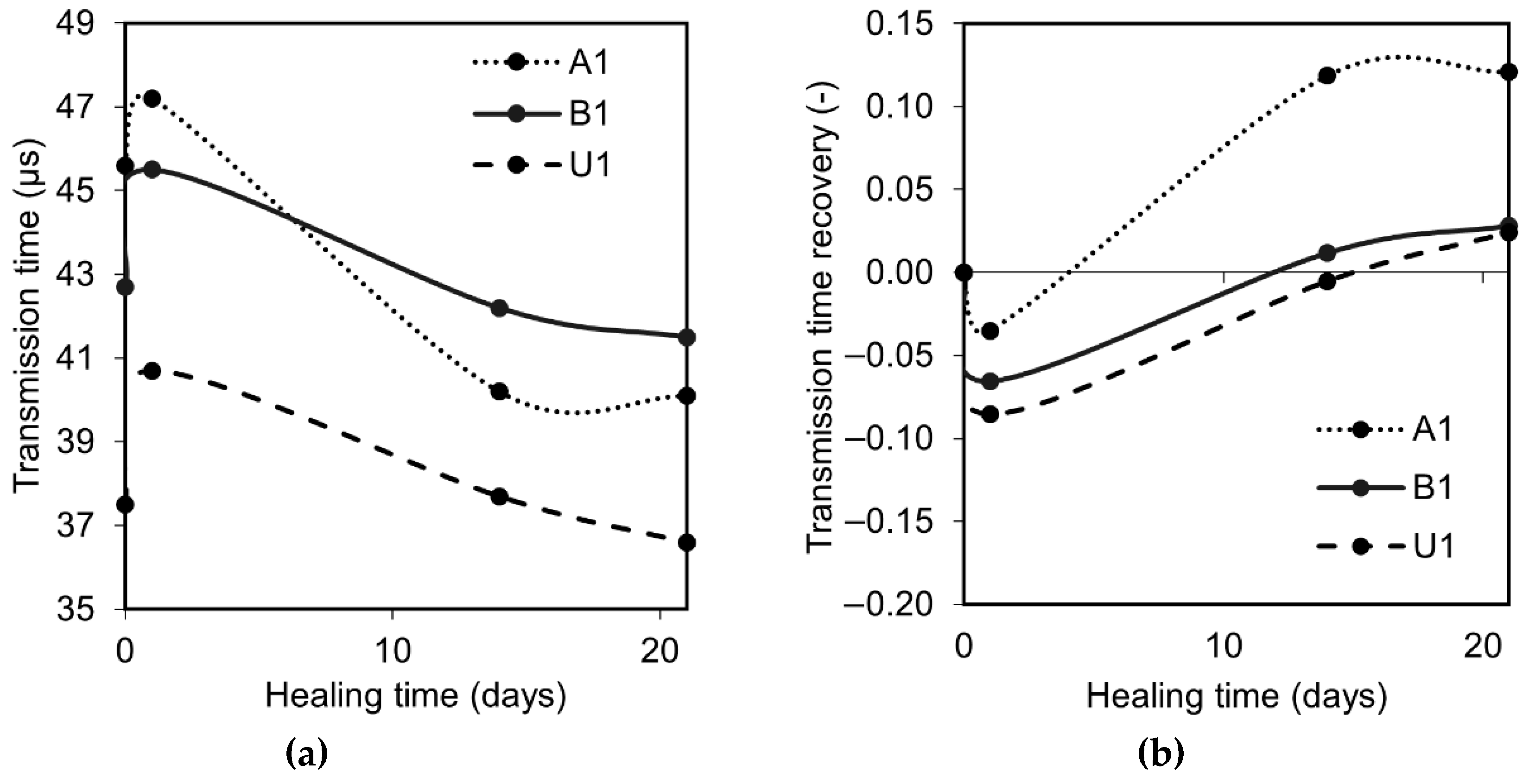

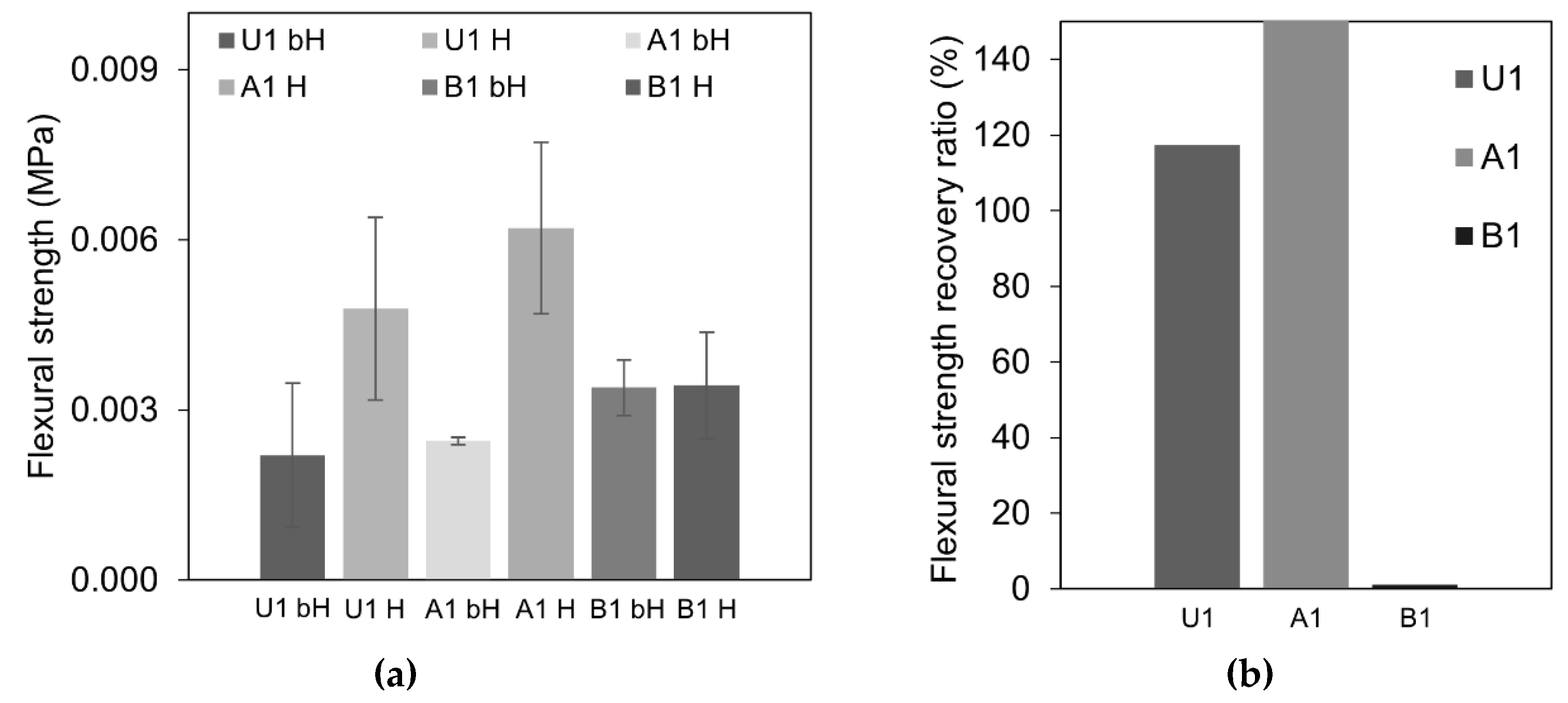

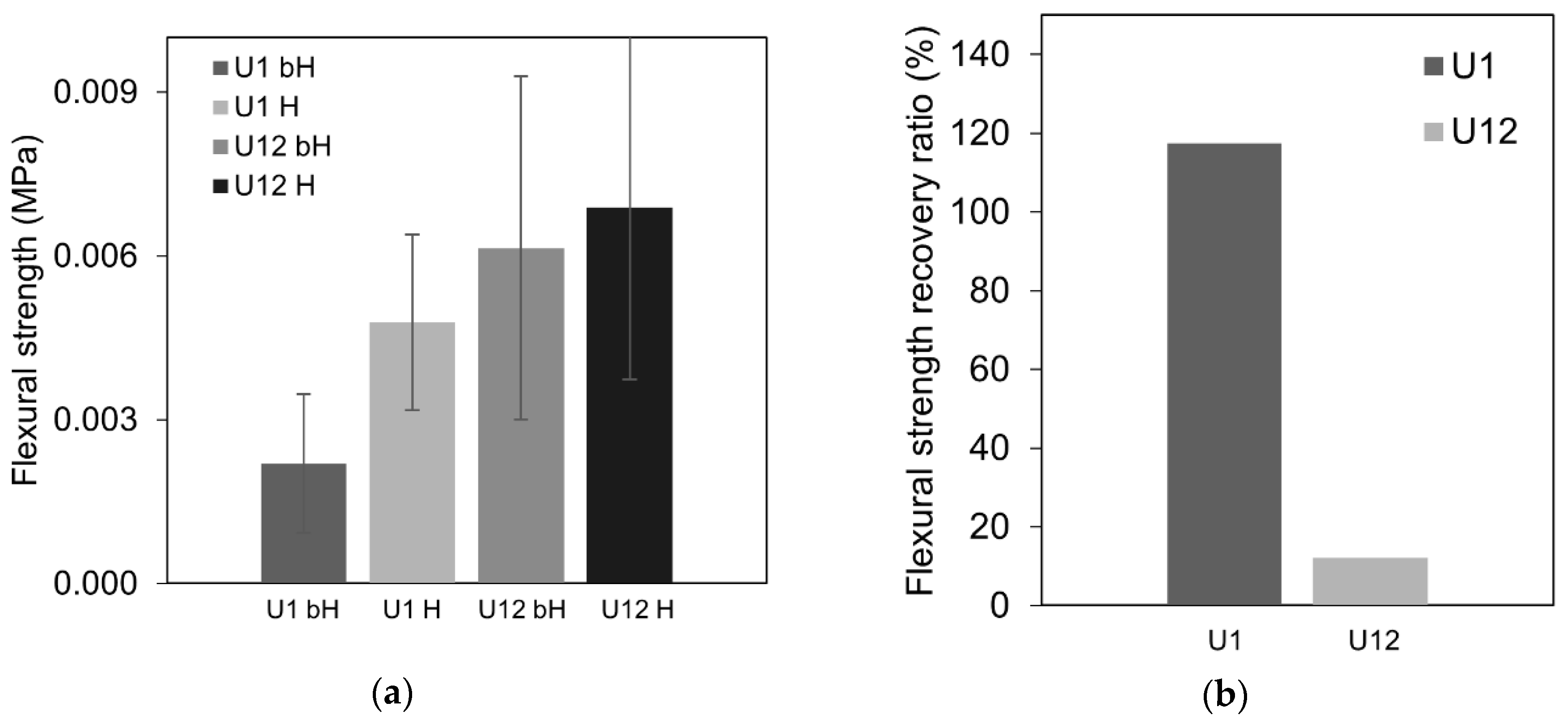

3.1. Ultrasound Transmission Time and Flexural Strength Recovery

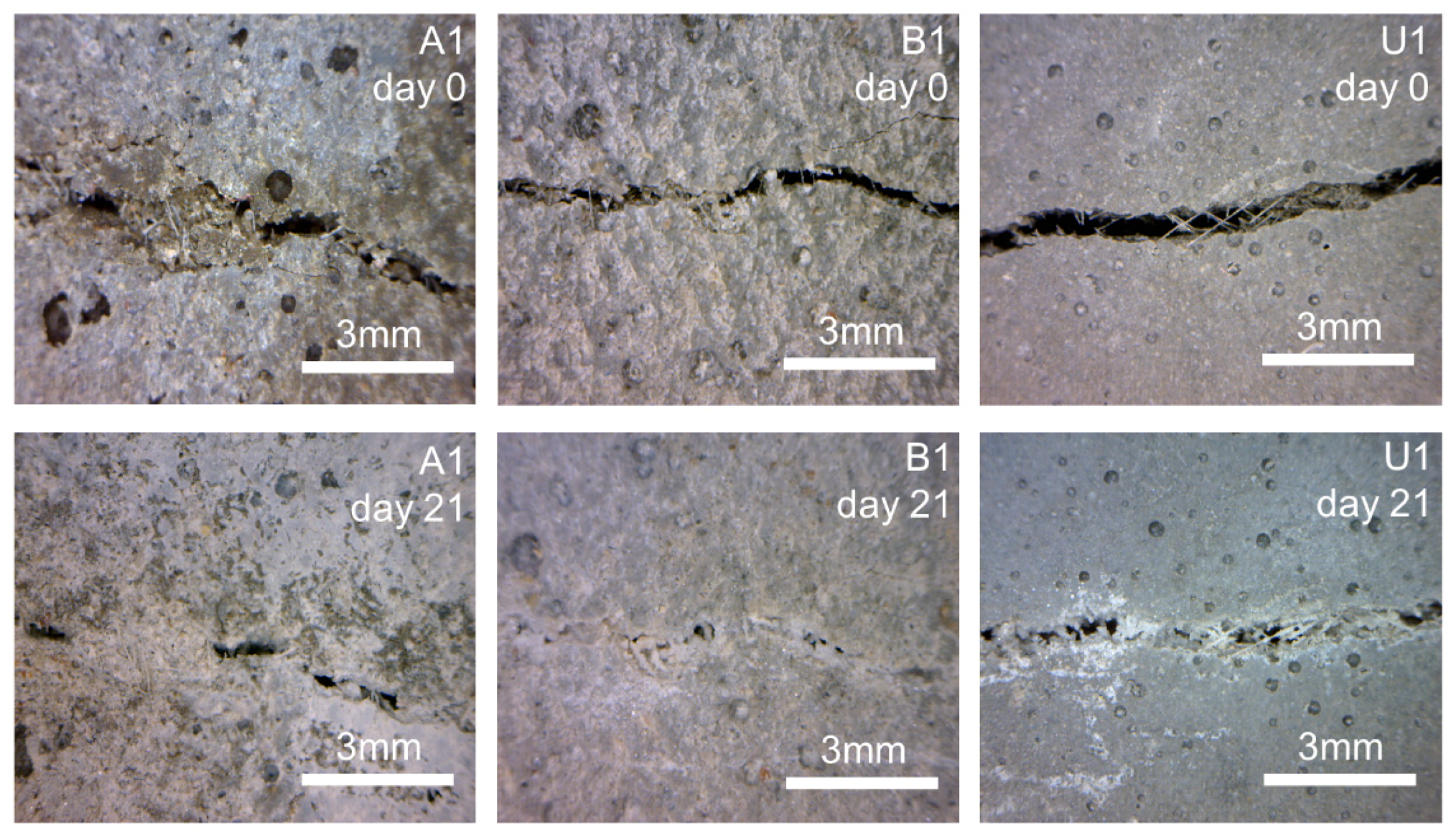

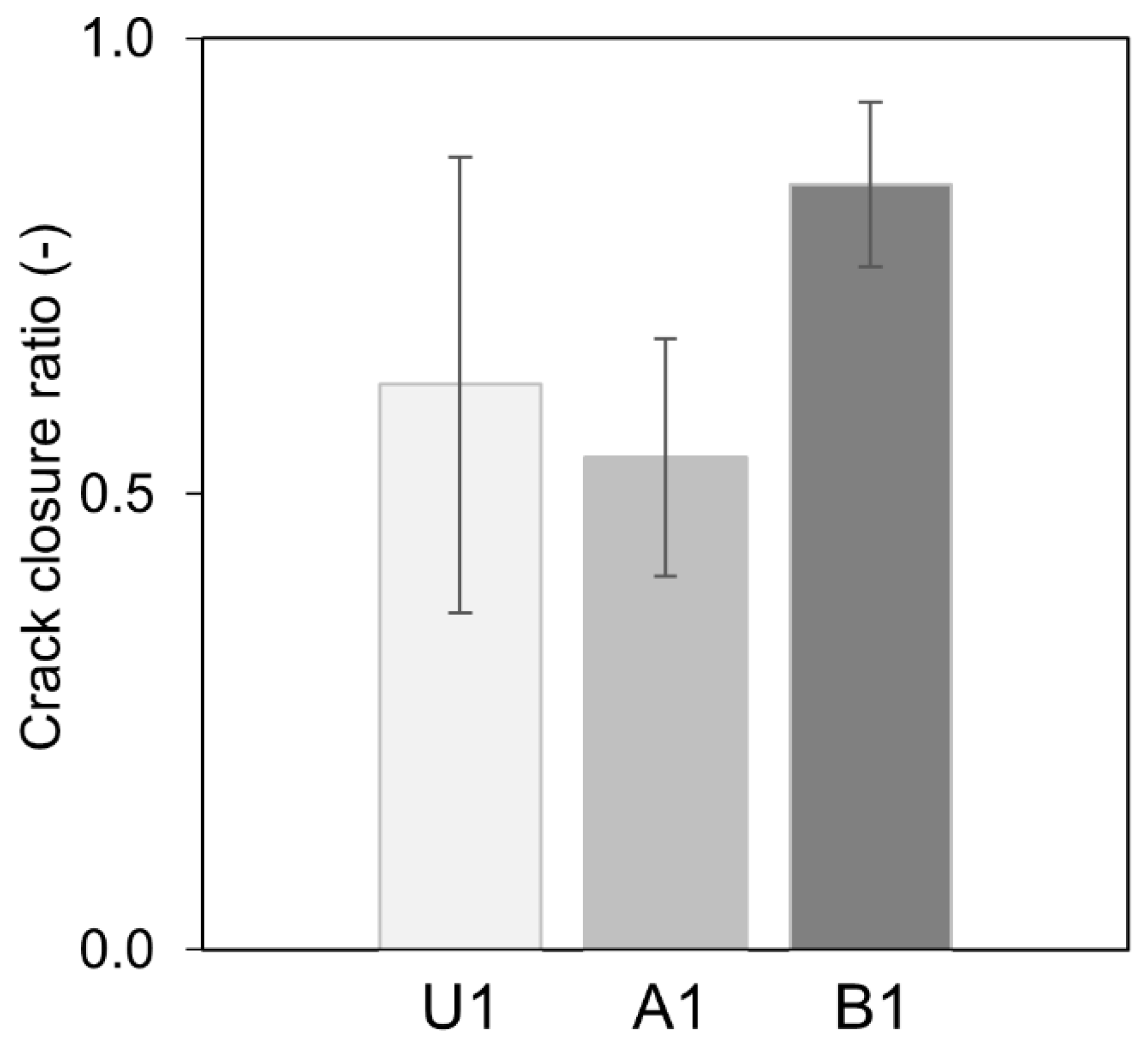

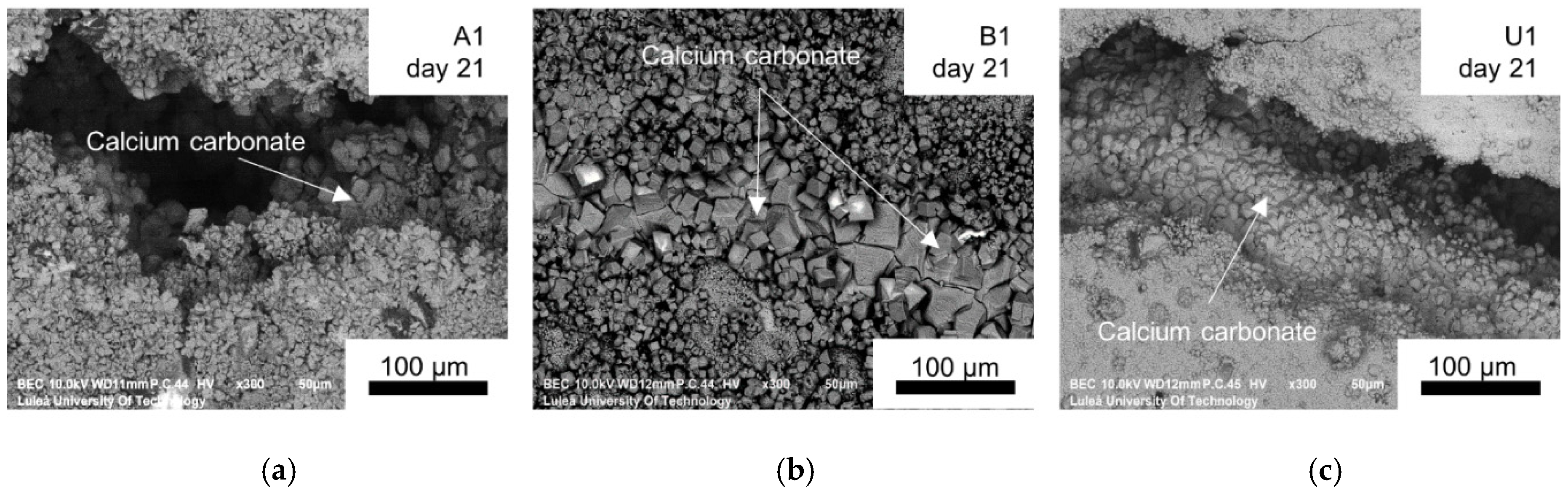

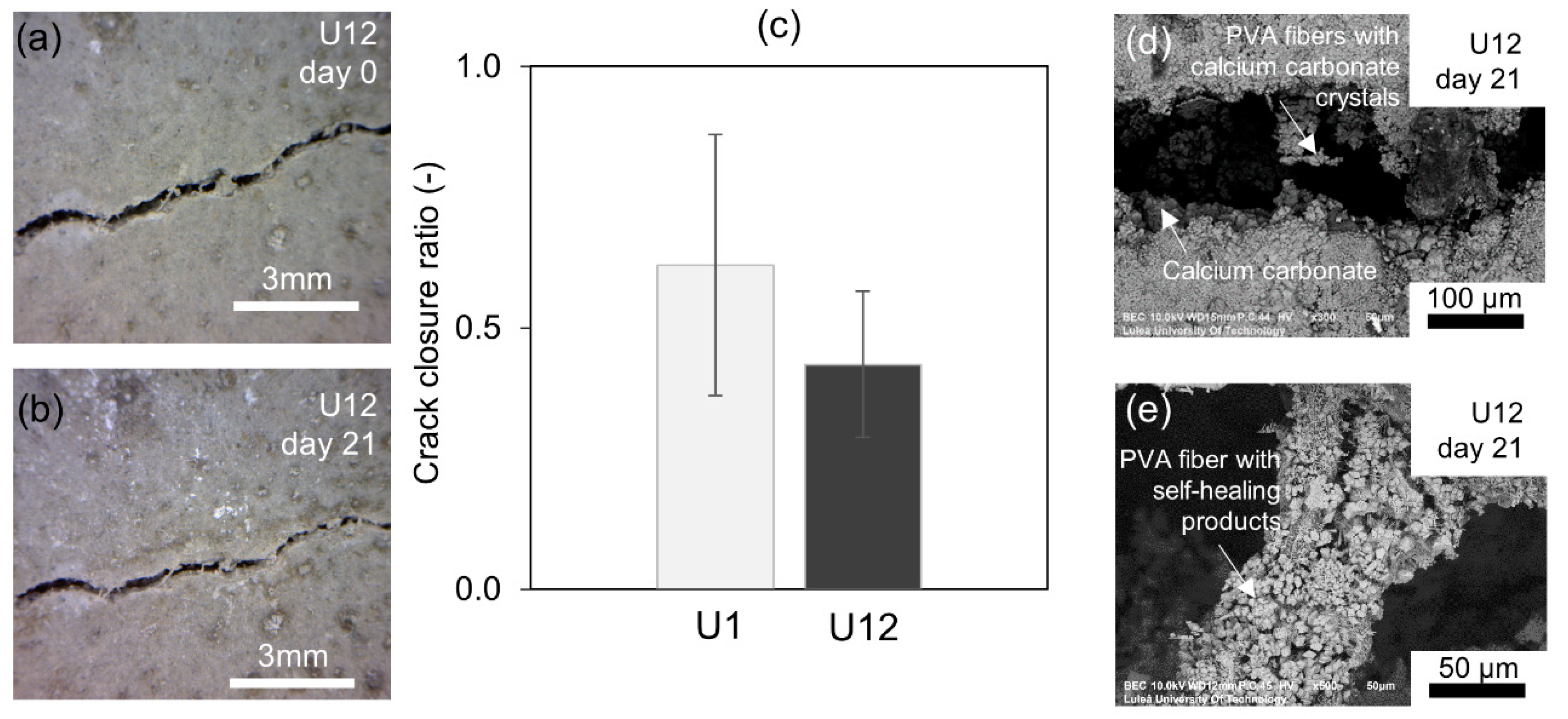

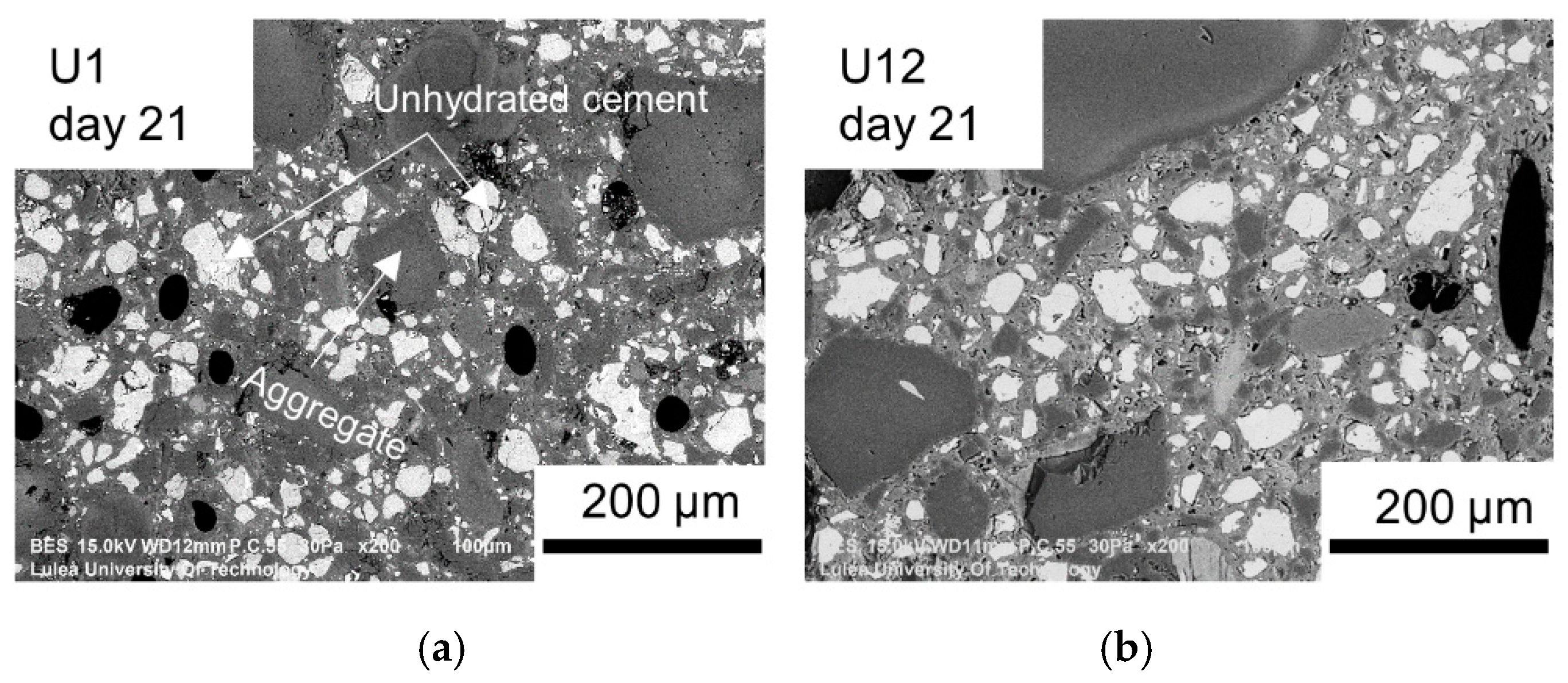

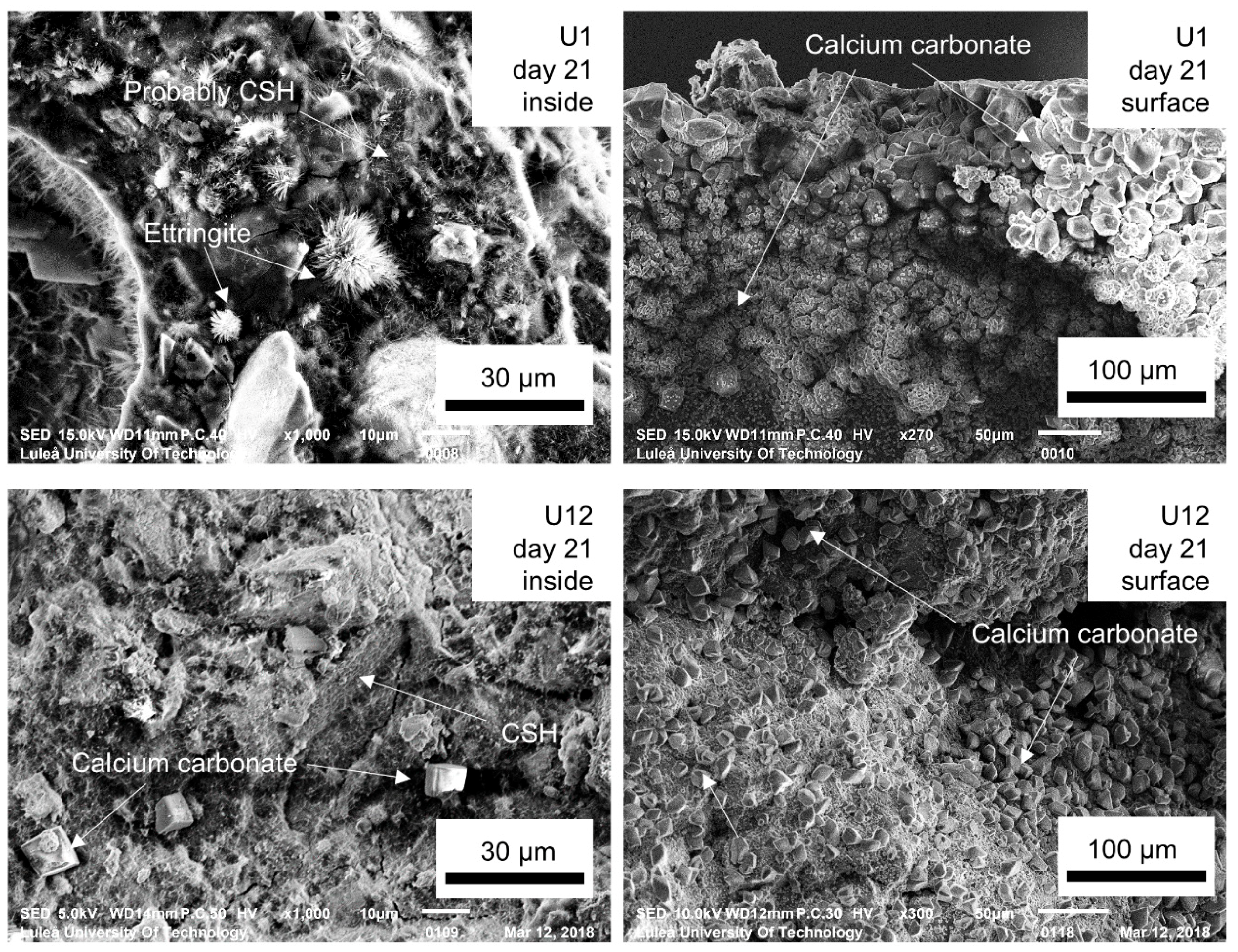

3.2. Crack Closure and Healing Products

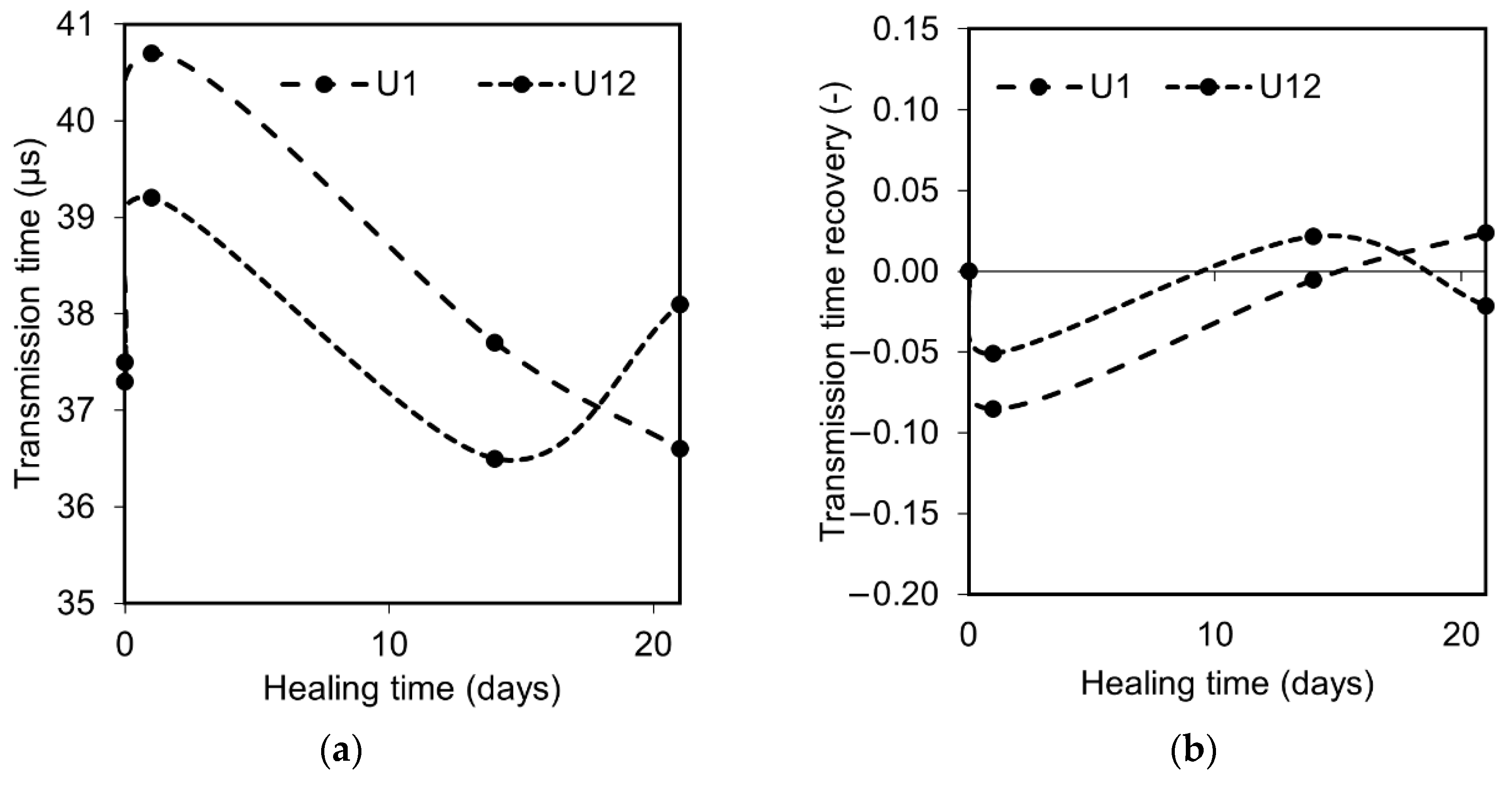

3.3. Age Effect

3.4. Autogenous Self-Healing Mechanism—Hypothesis

4. Conclusions

- The OPC mortar (A1) as well as the mortar containing fly ash (B1) pre-cracked at day 1 demonstrated higher self-healing efficiency in comparison with UHPC.

- The presence of fly ash led to the highest crack closure ratio at the surface due to the calcite formation but showed the lowest flexural strength regain indicating limited or a lack of CSH formation.

- The expected higher self-healing efficiency of the mixes containing large amounts of unhydrated Portland cement was not confirmed in this study.

- A low number of interconnected pores limits transport of Ca and Si ions from the solidified matrix to the healed crack, thus hindering the healing process. The densification of the microstructure caused by, for example, ageing can lower or even hinder the autogenous self-healing process.

- Flexural strength recovery is associated with the formation of the CSH and possibly ettringite. The formation of calcite alone does not affect the flexural strength but instead might control conditions in the crack. A more detailed mineralogical analysis of the self-healing products is necessary in order to confirm the results of the chemical composition.

Author Contributions

Funding

Conflicts of Interest

References

- Azmee, N.M.; Shafiq, N. Ultra-high performance concrete: From fundamental to applications. Case Stud. Constr. Mater. 2018, 9, e00197. [Google Scholar] [CrossRef]

- Richard, P.; Cheyrezy, M. Composition of reactive powder concrete. Cem. Concr. Res. 1995, 25, 1501–1511. [Google Scholar] [CrossRef]

- Andrade, C.; Sanjuán, M.A. Experimental procedure for the calculation of chloride diffusion coefficients in concrete from migration tests. Adv. Cem. Res. 1994, 6, 127–134. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Z.; Xiao, J.; Wang, D.; Huang, Z.; Fang, Z. A review on ultra high performance concrete: Part I. Raw materials and mixture design. Constr. Build. Mater. 2015, 101, 741–751. [Google Scholar] [CrossRef]

- Alkaysi, M.; El-Tawil, S.; Liu, Z.; Hansen, W. Effects of silica powder and cement type on durability of ultra high performance concrete (UHPC). Cem. Concr. Compos. 2016, 66, 47–56. [Google Scholar] [CrossRef]

- Kwon, S.J.; Wang, X.Y. Optimization of the mixture design of low-CO2 high-strength concrete containing silica fume. Adv. Civ. Eng. 2019. [Google Scholar] [CrossRef]

- Lin, R.S.; Wang, X.Y.; Zhang, G.Y. Effects of quartz powder on the microstructure and key properties of cement paste. Sustainability 2018, 10, 3369. [Google Scholar] [CrossRef]

- Randl, N.; Steiner, T.; Ofner, S.; Baumgartner, E.; Mészöly, T. Development of UHPC mixtures from an ecological point of view. Constr. Build. Mater. 2014, 67, 373–378. [Google Scholar] [CrossRef]

- Müller, H.S.; Haist, M.; Vogel, M. Assessment of the sustainability potential of concrete and concrete structures considering their environmental impact, performance and lifetime. Constr. Build. Mater. 2014, 67, 321–337. [Google Scholar] [CrossRef]

- Berodier, E.; Gibson II, L.R.; Burns, E.; Roberts, L.; Cheung, J. Robust production of sustainable concrete through the use of admixtures and in-transit concrete management systems. Cem. Concr. Compos. 2019, 101, 52–66. [Google Scholar] [CrossRef]

- Duxson, P.; Provis, J.L.; Lukey, G.C.; Van Deventer, J.S. The role of inorganic polymer technology in the development of ‘green concrete’. Cem. Concr. Res. 2007, 37, 1590–1597. [Google Scholar] [CrossRef]

- Gursel, A.P.; Maryman, H.; Ostertag, C. A life-cycle approach to environmental, mechanical, and durability properties of “green” concrete mixes with rice husk ash. J. Clean. Prod. 2016, 112, 823–836. [Google Scholar] [CrossRef]

- Lima, C.; Caggiano, A.; Faella, C.; Martinelli, E.; Pepe, M.; Realfonzo, R. Physical properties and mechanical behaviour of concrete made with recycled aggregates and fly ash. Constr. Build. Mater. 2013, 47, 547–559. [Google Scholar] [CrossRef]

- Zhang, M.H.; Malhotra, V.M. High-performance concrete incorporating rice husk ash as a supplementary cementing material. ACI Mater. J. 1996, 93, 629–636. [Google Scholar]

- Yu, J.; Lu, C.; Leung, C.K.; Li, G. Mechanical properties of green structural concrete with ultrahigh-volume fly ash. Constr. Build. Mater. 2017, 147, 510–518. [Google Scholar] [CrossRef]

- Vieira, D.R.; Calmon, J.L.; Coelho, F.Z. Life cycle assessment (LCA) applied to the manufacturing of common and ecological concrete: A review. Constr. Build. Mater. 2016, 124, 656–666. [Google Scholar] [CrossRef]

- Szeląg, M.; Zegardło, B.; Andrzejuk, W. The use of fragmented, worn-out car side windows as an aggregate for cementitious composites. Materials 2019, 12, 1467. [Google Scholar] [CrossRef]

- Ogrodnik, P.; Zegardło, B.; Szeląg, M. The use of heat-resistant concrete made with ceramic sanitary ware waste for a thermal energy storage. Appl. Sci. 2017, 7, 1303. [Google Scholar] [CrossRef]

- Rivera, F.; Martínez, P.; Castro, J.; López, M. Massive volume fly-ash concrete: A more sustainable material with fly ash replacing cement and aggregates. Cem. Concr. Comp. 2015, 63, 104–112. [Google Scholar] [CrossRef]

- Shojaei, M.; Behfarnia, K.; Mohebi, R. Application of alkali-activated slag concrete in railway sleepers. Mater. Des. 2015, 69, 89–95. [Google Scholar] [CrossRef]

- De Rooij, M.; Van Tittelboom, K.; De Belie, N.; Schlangen, E. Self-Healing Phenomena in Cement-Based Materials, State-of-the-Art Report of RILEM Technical Committee 221-SHC.; Springer: Dordrecht, The Netherlands, 2013. [Google Scholar]

- Jacobsen, S.; Sellevold, E.J. Self healing of high strength concrete after deterioration by freeze/thaw. Cem. Concr. Res. 1996, 26, 55–62. [Google Scholar] [CrossRef]

- Reinhardt, H.W.; Jooss, M. Permeability and self-healing of cracked concrete as a function of temperature and crack width. Cem. Concr. Res. 2003, 33, 981–985. [Google Scholar] [CrossRef]

- Zhong, W.; Yao, W. Influence of damage degree on self-healing of concrete. Constr. Build. Mater. 2008, 22, 1137–1142. [Google Scholar] [CrossRef]

- Granger, S.; Pijaudier-Cabot, G.; Loukili, A. Mechanical behavior of self-healed ultra high performance concrete: From experimental evidence to modeling. In Proceedings of the 6th international conference on fracture mechanics of concrete and concrete structures, Catalina, Italy, 17–22 June 2007. [Google Scholar]

- Granger, S.; Loukili, A.; Pijaudier-Cabot, G.; Chanvillard, G. Experimental characterization of the self-healing of cracks in an ultra high performance cementitious material: Mechanical tests and acoustic emission analysis. Cem. Concr. Res. 2007, 37, 519–527. [Google Scholar] [CrossRef]

- Granger, S.; Cabot, G.P.; Loukili, A.; Marlot, D.; Lenain, J.C. Monitoring of cracking and healing in an ultra high performance cementitious material using the time reversal technique. Cem. Concr. Res. 2009, 39, 296–302. [Google Scholar] [CrossRef]

- Escoffres, P.; Desmettre, C.; Charron, J.P. Effect of a crystalline admixture on the self-healing capability of high-performance fiber reinforced concretes in service conditions. Constr. Build. Mater. 2018, 173, 763–774. [Google Scholar] [CrossRef]

- Kim, S.; Yoo, D.Y.; Kim, M.J.; Banthia, N. Self-Healing capability of ultra-high-performance fiber-reinforced concrete after exposure to cryogenic temperature. Cem. Concr. Comp. 2019, 103335. [Google Scholar] [CrossRef]

- Jiang, Z.; Li, W.; Yuan, Z. Influence of mineral additives and environmental conditions on the self-healing capabilities of cementitious materials. Cem. Concr. Comp. 2015, 57, 116–127. [Google Scholar] [CrossRef]

- Ahn, T.H.; Kishi, T. Crack self-healing behavior of cementitious composites incorporating various mineral admixtures. J. Adv. Concr. Technol. 2010, 8, 171–186. [Google Scholar] [CrossRef]

- Kan, L.L.; Shi, H.S.; Sakulich, A.R.; Li, V.C. Self-Healing characterization of engineered cementitious composite materials. ACI Mater. J. 2010, 107, 617–624. [Google Scholar]

- Kan, L.; Shi, H. Investigation of self-healing behavior of engineered cementitious composites (ECC) materials. Constr. Build. Mater. 2012, 29, 348–356. [Google Scholar] [CrossRef]

- Alyousif, A.; Lachemi, M.; Yildirim, G.; Şahmaran, M. Effect of self-healing on the different transport properties of cementitious composites. J. Adv. Concr. Technol. 2015, 13, 112–123. [Google Scholar] [CrossRef]

- Yang, Y.; Lepech, M.D.; Yang, E.; Li, V.C. Autogenous healing of engineered cementitious composites under wet–dry cycles. Cem. Concr. Res. 2009, 39, 382–390. [Google Scholar] [CrossRef]

- Gagné, R.; Argouges, M. A study of the natural self-healing of mortars using air-flow measurements. Mater. Struct. 2012, 45, 1625–1638. [Google Scholar] [CrossRef]

- Ferrara, L.; Krelani, V.; Moretti, F.; Flores, M.R.; Ros, P.S. Effects of autogenous healing on the recovery of mechanical performance of high performance fibre reinforced cementitious composites (HPFRCCs): Part 1. Cem. Concr. Comp. 2017, 83, 76–100. [Google Scholar] [CrossRef]

- Ma, H.; Qian, S.; Zhang, Z. Effect of self-healing on water permeability and mechanical property of medium-early-strength engineered cementitious composites. Constr. Build. Mater. 2014, 68, 92–101. [Google Scholar] [CrossRef]

- Nishiwaki, T.; Sasaki, H.; Sukmin, K. Experimental study on self-healing effect of FRCC with PVA fibers and additives. J. Ceram. Process. Res. 2015, 16, 89–94. [Google Scholar]

- Choi, H.; Inoue, M.; Kwon, S.; Choi, H.; Lim, M. Effective crack control of concrete by self-healing of cementitious composites using synthetic fiber. Materials 2016, 9, 248. [Google Scholar] [CrossRef]

- Snoeck, D. Self-Healing and Microstructure of Cementitious Materials with Microfibres and Superabsorbent Polymers. Ph.D. Thesis, Ghent University, Ghent, The Netherlands, 2015. [Google Scholar]

- British Standards Institution (BSI). British Standard BS EN 12504-4. Testing Concrete. Determination of Ultrasonic Pulse Velocity; BSI: London, UK, 2004. [Google Scholar]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671. [Google Scholar] [CrossRef]

- Igarashi, S.I.; Kawamura, M.; Watanabe, A. Analysis of cement pastes and mortars by a combination of backscatter-based SEM image analysis and calculations based on the powers model. Cem. Concr. Comp. 2004, 26, 977–985. [Google Scholar] [CrossRef]

- Huang, H.; Ye, G.; Damidot, D. Characterization and quantification of self-healing behaviors of microcracks due to further hydration in cement paste. Cem. Concr. Res. 2013, 52, 71–81. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; Gruyaert, E.; Rahier, H.; De Belie, N. Influence of mix composition on the extent of autogenous crack healing by continued hydration or calcium carbonate formation. Constr. Build. Mater. 2012, 37, 349–359. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, E.H.; Li, V.C. Autogenous healing of engineered cementitious composites at early age. Cem. Concr. Res. 2011, 41, 176–183. [Google Scholar] [CrossRef]

- Xu, L.; Wang, P.; Zhang, G. Formation of ettringite in Portland cement/calcium aluminate cement/calcium sulfate ternary system hydrates at lower temperatures. Constr. Build. Mater. 2012, 31, 347–352. [Google Scholar] [CrossRef]

- Gonzalez, M.A.; Irassar, E.F. Ettringite formation in low C3A Portland cement exposed to sodium sulfate solution. Cem. Concr. Res. 1997, 27, 1061–1071. [Google Scholar] [CrossRef]

- Nonat, A. The structure and stoichiometry of CSH. Cem. Concr. Res. 2004, 34, 1521–1528. [Google Scholar] [CrossRef]

- Sisomphon, K.; Copuroglu, O.; Koenders, E.A.B. Self-Healing of surface cracks in mortars with expansive additive and crystalline additive. Cem. Concr. Comp. 2012, 34, 566–574. [Google Scholar] [CrossRef]

| Ingredient | CO2 Emissions | UHPC | Ordinary Concrete | CO2 Emissions | |

|---|---|---|---|---|---|

| UHPC | Ordinary Concrete | ||||

| kg/kg | kg/m3 | kg/m3 | kg/m3 | kg/m3 | |

| Cement | 0.931 [6] | 1000 | 400 | 931 | 372.4 |

| Water | 0.000196 [6] | 220 | 160 | 0.04312 | 0.03136 |

| Quartz | 0.0234 [7] | 300 | 0 | 7.02 | 0 |

| Fine aggregate | 0.0026 [6] | 700 | 1100 | 1.82 | 2.86 |

| Coarse aggregate | 0.0075 [6] | 0 | 730 | 0 | 5.475 |

| Silica | 1.05 [6] | 200 | 0 | 210 | 0 |

| Superplasticizer | 0.25 [6] | 22.5 | 0 | 5.625 | 0 |

| Element thickness reduction [8] | 33% | 0 | |||

| Total CO2 emissions (kg/m3) | 763 | 381 | |||

| Ingredient | U kg/m3 | A kg/m3 | B kg/m3 |

|---|---|---|---|

| Cement type | CEM I 42.5 N | CEM I 42.5 N | CEM II/A-V 52.5 N Portland fly ash 20% |

| w/c | 0.22 | 0.45 | 0.45 |

| Cement | 1000 | 675 | 675 |

| Water | 220 | 303.7 | 303.7 |

| Quartz | 300 | 0 | 0 |

| B15 | 350 | 1196 | 1196 |

| B35 | 350 | 0 | 0 |

| Condensed Micro silica (Elkem 920) | 200 | 0 | 0 |

| Superplasticizer | 22.5 | 0 | 0 |

| PVA fibers | 1.5% vol | 1.5% vol | 1.5% vol |

| 28 day compressive strength (MPa) | 143 ± 11 | 39.5 ± 2.5 | 36.5 ± 2.0 |

| Chemical Analysis | Mean Value (%) | |

|---|---|---|

| CEM I 42.5 N | CEM II/A-V 52.5 N | |

| CaO | 63.30 | 57.1 |

| SiO2 | 21.20 | 22.2 |

| Al2O3 | 3.40 | 6.20 |

| Fe2O3 | 4.10 | 3.40 |

| MgO | 2.20 | 2.90 |

| Na2O | 0.18 | 0.31 |

| K2O | 0.56 | 1.20 |

| SO3 | 2.70 | 3.50 |

| Cl | <0.01 | 0.06 |

| Loss of ignition | 2.50 | - |

| Water soluble Cr6+ | <2 mg/kg | <2 mg/kg |

| Na2O-eq. | 0.55 | 1.10 |

| Specimen | Area of the Crack before Healing Ab (pixel2) | Area of the Crack after 21 Days of Healing Ah (pixel2) | Crack Closure Ratio C | Mean Value Cav | Standard Deviation |

|---|---|---|---|---|---|

| A1 | 21,624.4 | 10,637.7 | 0.51 | 0.54 | 0.13 |

| 31,946.1 | 16,583.8 | 0.48 | |||

| 49,277.3 | 24,413.4 | 0.50 | |||

| 60,618.8 | 20,809.5 | 0.66 | |||

| B1 | 37,418.1 | 2316.9 | 0.94 | 0.84 | 0.09 |

| 30,833.7 | 5387.0 | 0.83 | |||

| 31,099.0 | 7939.7 | 0.74 | |||

| U1 | 67,726.7 | 11,798.8 | 0.83 | 0.62 | 0.25 |

| 68,999.1 | 22,414.1 | 0.68 | |||

| 64,428.9 | 28,099.9 | 0.56 | |||

| 26,838.6 | 15,972.5 | 0.40 |

| Elements | Atomic Norm % | |

|---|---|---|

| Product Type 1 | Product Type 2 | |

| C | 18.48 | 18.45 |

| Ca | 19.08 | 8.39 |

| Si | 0.00 | 7.36 |

| Al | 0.00 | 0.95 |

| O | 62.44 | 63.85 |

| K | 0.00 | 1.00 |

| Ca/Si | 0.00 | 1.14 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rajczakowska, M.; Nilsson, L.; Habermehl-Cwirzen, K.; Hedlund, H.; Cwirzen, A. Does a High Amount of Unhydrated Portland Cement Ensure an Effective Autogenous Self-Healing of Mortar? Materials 2019, 12, 3298. https://doi.org/10.3390/ma12203298

Rajczakowska M, Nilsson L, Habermehl-Cwirzen K, Hedlund H, Cwirzen A. Does a High Amount of Unhydrated Portland Cement Ensure an Effective Autogenous Self-Healing of Mortar? Materials. 2019; 12(20):3298. https://doi.org/10.3390/ma12203298

Chicago/Turabian StyleRajczakowska, Magdalena, Lennart Nilsson, Karin Habermehl-Cwirzen, Hans Hedlund, and Andrzej Cwirzen. 2019. "Does a High Amount of Unhydrated Portland Cement Ensure an Effective Autogenous Self-Healing of Mortar?" Materials 12, no. 20: 3298. https://doi.org/10.3390/ma12203298

APA StyleRajczakowska, M., Nilsson, L., Habermehl-Cwirzen, K., Hedlund, H., & Cwirzen, A. (2019). Does a High Amount of Unhydrated Portland Cement Ensure an Effective Autogenous Self-Healing of Mortar? Materials, 12(20), 3298. https://doi.org/10.3390/ma12203298